Elements of a brick fence. DIY brick fence posts

Owners of country or city private houses sooner or later are faced with the need to fence their territory. Among the many options for arranging a fence, many choose brickwork as the main material. And there are many reasons for this. If you are thinking about choosing a material for making a fence for a private yard, country house or personal plot, then this publication is for you.

Advantages and disadvantages of building a brick fence

The obvious advantages of using brickwork to create a fence include:

- long service life - a brick fence can easily be left as an inheritance not only to your children, but also to your grandchildren, because the masonry is made of quality material are not afraid of climatic manifestations and temperature changes;

- during operation, a brick fence requires virtually no maintenance; if the material is high-quality and new, then no painting or any other surface coating is needed;

- a brick fence is highly reliable and durable, capable of protecting the area not only from prying eyes, but also from any external manifestations (provided the fence is of sufficient height);

- the ability to independently choose the height of the fence;

- aesthetic appearance - a brick fence can not only become a reliable fence, but also decorate your landscape design, effectively completing the image of your architectural ensemble;

- the ability to create a non-trivial design - simple brick panels can be diversified with decorative inserts, arches, columns (pillars);

- The presence of variations in the design of a brick fence makes it an almost universal option for any stylistic design of the facade of a building.

But the coin always has two sides - brick, which means that a fence made of this material has disadvantages:

- the rather high cost of both the material itself and the work required to install it (therefore, many owners of private houses with land choose the option of combining bricks with other, cheaper materials);

- when using used bricks (in order to save money), the service life of the fence is significantly reduced;

- To build a truly strong and durable brick fence, it is necessary to lay a foundation, which increases the duration of the work and the overall cost.

Classification of brick fences

Fences consisting of brickwork in one modification or another are divided according to the following criteria:

- type of foundation – strip (most often used) or columnar (used only in case of small masonry thickness) foundation;

- the thickness of the brickwork varies from half a brick to three bricks (it is important to understand that its reliability, strength and durability directly depend on the thickness of the fence);

- the height of the brick fence is a relative value, but usually ranges from 50 cm to 3.5 m (the higher the fence, the greater its thickness should be to ensure the necessary stability);

- the presence of pillars (largely depends on the length of the spans and the ideas of the site owners about the beauty of the fence);

- the type of material with which the combination is carried out (if any).

Let's take a closer look at possible options combining bricks with other materials. To make the fence more original, and sometimes to reduce its cost, speed up installation work, you can use combinations with the following materials:

- brick and metal forging;

- wooden picket fence, boards or lattice made of wood;

- metal picket fence or sheet material, metal profile ( a budget option in combination with brick pillars);

- a combination of building bricks with decorative, chipped (“torn”);

- V in rare cases you can find a combination of brick and stone masonry (quite expensive fencing).

Brick and metal forging

In combination with metal forging, brick looks luxurious. Forged elements can be used exclusively as solid decoration brick wall or be an integral part of it, acting as a material for webs or intermediate links.

Metal forging elements can be different shapes and sizes, be located on the fence canvas in different ways, depending on this, there are three types of brick fencing design:

Parapet. Forged rods and decorative elements(the height of metal structures is no more than half a meter, as a rule). The fence turns out to be not only beautiful, but also reliable from the point of view of the possibility of strangers entering the site;

The base is combined with forging elements. The base can have a height from 30 to 150 cm; forged metal structures of various modifications are installed on it. Most often, through such a fence you can see what is happening in the yard or on the site;

Brick pillars plus forged elements. The main part of the fence is made of forging, placed on a base no more than 30 cm high, while brick is present only as part of pillars or columns. Often, when constructing brick pillars, metal reinforcement is inserted into them (to give the structure greater strength and reliability).

Combination of brick and wood

The combination of brick and wood does not always reduce the overall cost of the fence. Only if you already have wood in stock and need it, which is called “attachment” to benefit. Typically, the combination of brickwork and wood elements is due to the need to create a harmonious image of the entire architectural ensemble with local area. If wood is used in the facade of the main building, other buildings or landscape design elements, then it would be logical to use it to create a fence for the site.

If part of the fence itself wooden elements This type of wood is not encountered very often, but the use of wood for making gates and even gates to a brick fence is a very popular phenomenon. Brick in many ways symbolizes the urban and even industrial style, and beautiful wood carvings or intentionally aged boards seem to soften the image and balance the overall picture.

Choosing a brick color palette to create a fence

The modern range of building materials is amazingly diverse. Rich color palette bricks, especially façade cladding bricks, may cause some confusion for owners of private homes who want to fence off their plots. From snow-white and light gray to dark brown and burgundy - brick as a material for creating a fence can support the overall color scheme, and become an accent element in the image of the entire building and the surrounding area.

One of the most popular ways to choose brick for fencing is to replicate the material used for the façade of the main building. Using bricks of the same color for the house and the fence leads to the creation of a harmonious image of the entire ensemble. Most often you can find brick in almost all shades of red, with a predominance of reddish shades. It is not for nothing that the name of the red-orange color appeared - it is often called “brick”.

Brick of all shades of yellow and orange looks no less impressive, but at the same time more restrained...

A wine-colored or marsala-colored brick looks luxurious. As a rule, a fence with this color scheme becomes an accent element of the architectural ensemble.

Gray brick is usually chosen if the building and landscape design of the area are made in modern style and even with an urban slant. If concrete is actively used in the design of a plot or yard, then a brick fence of any shade gray will look more than appropriate.

Brick for fencing a private yard or summer cottage can be chosen to match the color of garden paths and areas (patios), if they are also made of this building material. At the same time, the facade of the main building (house) may differ not only in color, but also in the material itself.

Brick, as a building and facing material, does not require subsequent painting or any other coating. Provided it is used new material. If a used brick is used to prolong its expected service life, protective covering won't hurt. In some cases, painting is necessary to create a balanced image of the entire ensemble - the home and the area around it.

And finally - a few original ideas

The fence “with perforation” looks original. The brick is not laid out in a continuous pattern, but in a checkerboard pattern. As a result, the fence has holes through which you can partially see what is happening on the street and in the yard. The fence turns out to be less durable, in to a greater extent decorative, but still capable of protecting the territory from external influence(except for prying eyes).

A low fence made of brick can serve as a garden bed or flower bed. As a result, the area is decorated original element landscape, and it is easier for plants to provide the care that is necessary for each specific crop.

In some cases, the fence has not so much a fencing function as a decorative one. As a rule, a low fence is present inside large areas to fence off the functional segments of the site. Such zoning not only brings order to the clear demarcation of a yard or personal plot into sectors, but also decorates the landscape. A low brick fence can serve as a border - to delimit areas of garden paths and flower beds or beds.

It’s not difficult to build and line brick fence posts yourself. It is important to carefully study the instructions and strictly follow the laying rules. If the construction scheme is violated, the brick columns will turn out to be unstable and will quickly collapse. For cladding, it is recommended to use decorative bricks of yellow, brown or red color.

Materials and tools

A beautiful fence with brick pillars, forged gates and a wicket will not only decorate your garden plot, but will also serve as a reliable fence. Before you start building a fence, you need to make a work plan and drawing. If you want to build a fence yourself, it is important to carefully study the stages of work and lay bricks without violating the technology. If you decide to hire a team of builders, they will offer ready-made drawings. When all options have been agreed upon and the material has been calculated correctly, it is necessary to prepare the tools that will be needed during construction. It is recommended to stock up on the following “arsenal”:

- shovels - shovel and bayonet;

- container for mixing the solution;

- buckets 2-3 pcs.;

- Master OK;

- spatulas;

- measuring device - level, angle, tape measure, plumb line;

- motor drill or hand drill for making recesses for metal piles;

- scaffolds or trestles, with the help of which you can lay out brick pillars in the upper part;

- rubberized gloves that protect hands from the negative effects of the solution.

How to calculate the dimensions and quantity of materials?

To perform calculations you need to know the parameters of the brick.

To perform calculations you need to know the parameters of the brick. It is not difficult to correctly calculate the material, the main thing is that the dimensions of the fence are accurately determined. The brick pillar is laid out in such a way that one side consists of one and a half blocks. Based on this, it becomes clear that for laying 1 row you will need 4 pieces. bricks. The width of a standard fired block is 120 mm, length - 250 mm. The size of one side of a square column is calculated as follows:

- 250 + 120 + 10 = 380 mm, where the value 10 is the width of the seam.

The thickness of 1 block is 65 mm, so taking into account inter-row seams, to fold a support 2 m high you will need an average of 110 pieces. Next, calculate the thickness of the row with seams:

- 65 + 10 = 75 mm.

To determine the number of rows, you need to divide the height of the column by the thickness of the row:

- 2000 / 75 = 27.

It is important to take into account the fact that the first 3-4 rows from the bottom are laid out from solid blocks. This is required so that the fence supports have great weight and reliable stability. It is recommended to fasten the supports to screw piles, embedded in the foundation. The number of round piles is equal to the number of pillars, while the height of the pipes is taken 500-600 mm larger than the size of the planned brick support, because this difference will be buried in concrete base. Often, instead of piles, round metal reinforcement rods with a diameter of about 15 mm are used. They are also fixed to the foundation. It is important to tie the base with a reinforcing belt. To form 1 pillar you will need a round rod in the amount of 4-6 pieces.

Stages of work

It is better to choose a strip foundation as a basis for pillars.

It is better to choose a strip foundation as a basis for pillars. In order for a fence with brick pillars to be strong and reliable, it is recommended to make a strip foundation as a base, which is additionally reinforced with a reinforcing structure. Reinforcement of the supports is carried out using piles or a round reinforcing bar, around which bricks are laid. Height fence posts can reach up to 3 m, but it is important to consider that the higher the support, the more durable and powerful the foundation should be made. If the fence is combined, for example, a metal profile is installed in the span, the distance between the brick pillars is controlled, on average it is 3000 mm. All these points must be taken into account in the drawings, otherwise the brick fence around the house will be unstable and will quickly collapse.

Forming the Foundation

Before you put brick pillars under the fence with your own hands, you must first lay a strong and reliable one. To do this, a trench with a depth of 50-1000 mm is dug along the intended perimeter, which is well compacted, after which it is filled with a sand and gravel cushion with an average thickness of 20-25 cm. Next, the core of future supports for the brick fence is laid. To strengthen the foundation, it is recommended to perform reinforcement. After finished design is poured with concrete, and until the foundation dries completely, construction is not carried out.

To ensure that the solution is reliable, it is recommended to prepare it by mixing 1:2.8:4.8 shares of cement, sand and crushed stone, respectively.

How is masonry done?

The wide range of brick colors allows you to make the pillars as close as possible in shade to the decoration of the house.

The wide range of brick colors allows you to make the pillars as close as possible in shade to the decoration of the house. Brick for pillars must be durable, frost-resistant, and moisture-proof. Clinker material has these characteristics. Except high performance qualities, the product is available in a wide range of colors. Therefore, you can build a brown, yellow or red fence that will match the facing material laid out on the house.

There are 2 masonry options - 1.5 and 2 bricks. To make the design neat and beautiful, it is important to control the size of the seams in each row. To fasten the picket fence with brick pillars, iron mortgages are formed at the bottom and top of the support. The mortgage will also hold the gate with wickets. To strengthen the pillars, metal mesh reinforcement is used.

The land plot is traditionally surrounded by a fence. The fence is made from different materials. One option is a fence with a base of brick pillars with spans of corrugated sheets, forged elements, wooden picket fence or brickwork. Such a fence looks solid, it reliably protects the territory and is decorative in its decoration.

Brickwork of pillars is quite simple for self-production, if you become familiar with the technology for constructing such supports. Let's consider the details of this type of construction work.

Peculiarities

A fence with brick pillars provides the necessary level of security against unwanted intrusions into the estate. Spans of corrugated sheeting or brickwork, supported on brick pillars, can add impermeability and reliability protective function fencing.

Forged and wooden spans will add external lightness to the structure, while maintaining the required level of insulation from the external environment.

Brick supports are durable and weather resistant. They are sufficiently resistant to increased payload for the installation of massive gates with an automatic sliding or mechanical swing device.

To extend the life of the poles, they need to be covered with caps made of metal or concrete. Here it is worth considering that concrete caps have a greater variety of shapes, but they themselves are destroyed by changes in temperature and humidity.

Metal caps better isolate the brickwork from moisture.

A fence on brick pillars, while providing a sufficient level of protection, is more affordable than a completely brick fence. The types of bricks, masonry patterns and span material provide great scope for decorative creativity when designing such a fence. Brick pillars can be safely equipped electric cable to organize lighting for individual supports, which will be convenient for owners and serve as additional decor.

Types of structures

To build a fence with brick supports, you need to decide on the type and height of the structure. Optimal height the supports are selected about two meters, then the pillar is laid out 1.5 bricks wide, together with the seams this is equal to 38 centimeters.

If necessary, you can increase the height to 3-4 meters, then it is better to lay the bricks in two or more bricks. In this case, the size of the pillar will be about 50 by 50 centimeters. The span width ranges from 2.5 to 6 meters, the dimensions are selected according to the relief or the composition of the fence.

The type of foundation depends on the type of structure: strip or point. For spans made of lighter materials, a point foundation is chosen under brick columns; for heavier ones, a strip foundation is chosen.

Spans made of corrugated sheets are the most common option.

Advantages:

- This fence has a simple appearance and is easy to install.

- You can choose the desired color scheme.

- With such spans, geometric hoods look beautiful.

- It is convenient to install the gate.

A strip foundation is made for this type of fence. You can choose point supports, but wear resistance and decorative qualities will be reduced.

For a fence with forged inserts, you can also use both the first and second options for supports. Of course, forging gives the fence artistic value and emphasizes the well-being of the owners. A strip foundation with several rows of bricks will add solidity to the fence. The airiness of the structure appears when you refuse strip foundation, but the durability features are preserved, reliable protection and decorativeness.

The fence can be made entirely of brick or torn decorative stone; such fences are made on a reinforced foundation; they reliably isolate the territory of land ownership. For decorative effect perform combined fences.

After choosing the type of fence, we begin to select the material.

Selection of materials

The material for the spans is chosen according to the degree of protection required: for better insulation - corrugated sheet or brick, for a decorative effect - metal forging; in rural farmsteads, a wooden or metal picket fence has proven itself well as protection from cold winds and unwanted intrusions.

The fence material should be in harmony with the architecture of the outbuildings and the overall design concept of the site. Classic mansions look harmonious with wrought iron or stone fences. It is better to fence a house in an ethnic style with a fence using a wooden picket fence. In areas where poultry or other livestock are kept, solid fences made of corrugated board will be optimal.

In modern minimalist trends, it is better to use a fence with a minimum of decor. Simple and elegant. Such fences are decorated with spans of special glass or plastic.

Bricks for columns are selected based on general design fence For the first two or three rows you will need an ordinary clay brick, then use a hollow one or the same as in the bottom row. To enhance the decorative effect, the columns are laid out with clinker bricks or facing bricks of the desired color in various combinations.

Relief brick gives greater expressiveness to the architecture of the fence. Decorative finishing can be applied only on the front side of the fence, and the inside can be left in the form of simple brickwork. This will provide significant savings.

According to the number of pillars, steel pipes are purchased, which will become the vertical axis for reinforcing the brickwork. It should be taken into account that the support reinforcement for gate and wicket posts is purchased with a reinforced profile. Reinforcement will be required to strengthen the foundation; its quantity is calculated based on the need for a strip or point arrangement.

You will need construction fillers: cement, sand, crushed stone or expanded clay. You will need to stock up on boards for making formwork. Since brick absorbs moisture very well, and when it freezes it destroys the structure of the material, all brick structures will have to be protected from soil moisture, so waterproofing material will be needed.

Quantity calculation necessary materials produced according to the length of the fence, the pitch of the brick supports and their size.

For a standard column of one and a half bricks, 2 meters high, 110 bricks will be required.

Laying technology

Sequencing:

- The first step is to mark the outline of the fence using twine. Pegs are driven in at the locations of future supports. For pile foundation According to the marks with pegs, using a drill, a hole is made 30-35 centimeters wide and 80 centimeters deep for sandy soil, and for clay soil - up to the freezing layer plus 20 centimeters.

In central Russia, it is best to maintain a depth of 1 meter or 1 meter 20 centimeters. A bucket of crushed stone is poured into this hole and compacted. The formwork is made according to the diameter of the pit; you can roll a tube of the required diameter from roofing felt. A steel pipe is inserted into this formwork and filled with cement mixture.

A mixture of cement and sand is made in a ratio of 1: 5 or 1: 6; for plasticity, you can add a little liquid soap. The solution should be neither liquid nor dry, so add water gradually. The upper part of the foundation is poured into formwork along the width of the column. For a strip foundation, a trench 50 cm deep and 40 cm wide is dug between the pillars. The bottom layer is strengthened with a cushion of crushed stone, formwork made of boards is installed along the trench and filled with mortar.

- After pouring the foundation, brickwork begins no earlier than 2 weeks later. The surface of the foundation is covered waterproofing material so that the brick does not absorb moisture from the soil. Here you can use roofing felt, but more modern material is a bitumen-based waterproofing agent.

- Embedded corners, ears for gate canopy are welded onto a steel pipe, or transverse pipes are welded to secure the span material - picket fence, corrugated sheet or forging.

- The next stage of work is brickwork. Here you need to pay close attention to the quality of the solution and its thickness. To test, place a little mortar on the brick; it should not spread. The bricks are laid according to the masonry pattern with ligation through a row around the steel pipe. The first and second rows are laid with regular full bricks; for the next rows, lightweight hollow bricks can be used.

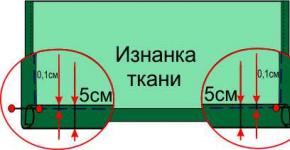

- A layer of cement mortar 1 centimeter thick is applied to the waterproofing, and bricks begin to be laid on this layer; each brick is tapped with a rubber hammer to compact it. To ensure uniform adhesion to the mortar, the brick is first dipped in water. It is better to measure each row with a tape measure, since a shift of even a few millimeters in each row can lead to a skew of the post or an expansion of several centimeters.

Each side should be regularly checked with a level to avoid deviations from the vertical.

- If desired, you can do decorative finishing seams, usually in cement mortar add dye or textured chips and after finishing the masonry, coat the seams separately. This gives neatness and completeness to the entire building.

- After laying the entire column, the middle part around the pipe is filled with a solution; it can be filled with crushed stone and filled with a more liquid solution. The top is again covered with a waterproofing layer.

- A cap made of metal or concrete is attached to the top of the structure. Manufacturers offer a wide variety of shapes, colors and materials for making such caps. A simple rectangular cap can be made from a sheet of metal yourself using a pattern. The color is selected according to the color of the fence design.

- If the project involves combined masonry, then you need to carefully select the dimensions of the main and finishing bricks. If the brick pillar is finished natural stone, then after the masonry has dried, the finishing layer is applied.

- The next stage consists of hanging the span material: corrugated sheets, metal lattice, picket fence or laying out the span with decorative bricks.

- The final type of work is the installation of gates and wickets, installation of lighting.

A few tips on doing masonry will help you do it well even for a novice master:

- To ensure that the seams between the rows of bricks are of the same thickness, a metal rod of the required diameter is laid along the edge. The cement mortar is leveled over it, bricks are laid on top, tapped with a rubber hammer, then the rod is removed and laid on the next row.

Nowadays, very often, in order to isolate themselves from the encroachments of intruders and just prying eyes, owners of suburban areas erect brick fences. Practice shows that building a brick fence with your own hands is not so difficult, compared to the same stone fence.

This is what a red brick fence looks like

Thanks to brick blocks Very affordable, strong and durable, brick fences can be found everywhere. In addition, on the Internet you can find many construction instructions, supported by photographs and videos, which explain in detail how to build a brick fence yourself.

Advantages of brick fences

Disadvantages of brick fences for a home

Let's look at how brick fences are inferior to other types of similar structures:

Differences between brick fences

When considering brick fences, we can identify several criteria by which they will differ:

Various types of fences made of brick blocks

Very often on personal plots you can see fences made not entirely of brick, but combined with other building materials. Such a device for fencing can significantly reduce the cost of the structure. And if you consider that brick goes well with all types of materials, then we can say that such combinations can make the fence more interesting and original.

An example of a combined fence made of decorative brick and forged fencing

Here is an example of the most successful tandems:

- Fencing with brick pillars and wooden canvas;

- Fence with brick pillars and forged canvas;

- Fence with brick pillars and corrugated sheet.

Combined fences can make the site unique, and the fencing design less cluttered. Since combinations of materials significantly reduce the weight of the structure, the foundation for a brick fence can be columnar, which will save cash.

Construction of a brick fence

In order to build a fence, you need to have some construction skills, as well as carefully study the process itself. So as not to lose sight important nuances, let’s break the entire construction process into stages and consider each in detail.

- Preparatory work;

- Foundation construction;

- Decoration of the fence.

Preparatory work

In order not to be distracted by trifles and speed up the construction process, it is best to take care in advance about the availability of all necessary devices and materials.

On preparatory stage often carry out fence projects in order to more clearly imagine what the structure will look like, as well as to more accurately calculate the required materials and find out how many brick blocks are needed.

Foundation structure

As already noted, the foundation for brick fences is usually made of strip or columnar foundations. Which foundation is best depends on the specific case. Let us examine in detail the arrangement of a strip foundation.

Bricklaying

Since this stage of construction is the most important, it is necessary to provide all the conditions for its start, including waiting for the foundation to completely harden. Usually they wait about a day, and in the case of the construction of powerful and high fences - two to three days. Let's discuss some of the subtleties of how to build a brick fence.

The brick fence is laid according to the standard scheme.

- The angles are drawn first. To do this, you need to have a building level at hand.

- Next, the construction of walls begins. The first row is laid directly on the base, or plinth. Its horizontal position must be carefully controlled, because the quality of subsequent rows will depend on this.

- After a certain distance - usually two meters - pillars are erected. Bottom part The fence requires the design of a base.

- After installation, all that remains is to unstitch the seams and treat them with a special compound.

Decorating the fence

When the process of laying the fence is completed, you can begin decorating work, if the projects require this. If facing bricks were used for construction, then any finishing work can be completely excluded. This is because the fence is made of facing bricks red or yellow color looks great on its own.

Fence from white brick can be finished with natural stone or its artificial analogue, similar to torn stone.

In addition, you can experiment with different facing materials, creating an unusual and original drawing.

Fence from sand-lime brick can be combined with corrugated sheets or wooden structures that will fit perfectly together. By trying to combine various building materials for the construction of a fence, you can achieve not only improvements in the appearance of the structure, but also significant savings.

An example of a fence made of decorative bricks

A fence made of brick and corrugated board, for example, is erected much faster than a completely brick fence, and at the same time is not inferior in durability and quality.

The construction of a brick fence can be supplemented with forging elements. can completely replace the fence cloth. Also, forging elements can decorate only the upper part of the canvas. Best with forged products yellow and red brick fences are combined.

Of course, the price of such designs will be much higher, however, its originality will be beyond praise.

Brick has been used in the formation of barriers and permanent fences for a very long time. Its reliability is so great that before the invention of reinforced concrete, only brick structures were a serious alternative natural stone in fortifications. But people’s attention to this solution is caused not only by its undoubted strength, but also by its external attractiveness. What is important is that people can determine for themselves how high the fence they need and what shape it will be. Ready reinforced concrete slabs, mesh and other things do not provide such freedom.

Peculiarities

The key advantages of brick fences compared to others can be considered:

- excellent durability;

- attractive appearance;

- the ability to combine with houses and plots decorated in any style.

The use of facing bricks is recommended when creating decorative masonry. This is a completely ready-made material that does not require additional processing, the variety of its colors and textures allows you to bring to life the most sophisticated design concept.

If you wish, you can complement the brick fence with stone, wood, or stylish artistic forging. The last option is advisable if you want to create an environment that is visually interesting and not too flashy.

A universal fence made of bricks can be easily redone if necessary: if necessary, you can quickly increase its height, lower it, and the structure will look just as attractive. Both from the outside and from the side of a private house from the yard, the appearance will be exactly the same. Depending on the wishes of the customers, it is possible to design the fence additionally; the masonry is plastered or covered with panels that match the design of the home.

However, even the brick that has not undergone additional decoration looks very good.

Material calculation

Calculating the exact need for bricks is very important, and it is not particularly difficult. If the wall is made single-layer, square meter it is created from 100 blocks, and the double type of masonry requires approximately 200 bricks in the same area.

Define the desired height and barrier depth; if it is more of a decorative nature, construction with ½ brick is permissible, in which the elements are laid with the elongated side along the designated line. But if you want to strengthen the defense of your territory, use at least one and a half bricks.

How high the structure should be is determined individually: sizes from 50 to 350 cm are practiced; fences are made higher only occasionally.

Please note that errors in determining the properties of a fence can lead to not only technical, but also legal problems. In some cases, it is better to familiarize yourself with the provisions of regulations, building codes and rules. If you violate them, for example, at your dacha, you can get a fine. Or even an order to demolish an illiterately constructed structure.

It is better to fence all country and garden areas with structures no more than 150 cm in height, and exclusively made of meshes or gratings based on various materials.

An exception can only be made with the general consent of the participants of dacha associations, whose meeting has the right to allow impenetrable barriers of no more than 220 cm. These restrictions are due to concern for good lighting of all public areas and roads. If you don’t want to limit yourself to a lattice, but want to avoid breaking the law, you can make an indentation in depth so that shading does not actually occur.

Such prohibitions do not apply to individual residential construction at all, except in situations where they operate within the framework of regional law.

If the thickness of the structure is the same, but its shape is different, the material consumption can vary widely. So, on a standard 0.06 hectares you can put a square fence (its perimeter is about 98 m), or you can put a triangular one - then the total length of the contours will increase to 112 m. Similar ratios will be for larger territories; the choice of shape is by no means arbitrary, you will have to adapt to the actual configuration of the earth.

The easiest way to make an accurate calculation is to focus on the data cadastral plan, then you won’t have to take independent measurements.

When using sand-lime brick, the dimensions will be the same as when using the standard version.

Important: the concrete must be raised at least 0.1 m above the ground layer.

When intending to build a fence from Slavic brick, be guided by the sizes of the products included in the collection you like. Most often they purchase the so-called “normal” size, single (equal to traditional) or “euro” (0.7).

Approximate consumption of raw materials when receiving 1 cubic meter. m of concrete using the artisanal method is approximately 3 quintals of cement, 10 quintals of washed sand and crushed stone. Up to 0.3 cubic meters are consumed per cubic meter of brickwork. m of mortar - this figure already includes probable losses, inevitable even with very professional work.

If it is decided to create a sectional barrier, calculate the need for building blocks and concrete mortar for individual sections and pillars, after which the resulting indicator is multiplied by the required number.

Types of masonry

Technologists and builders have developed various types of bricklaying; one of the most modern and attractive options is considered lego system. Compared to using classic look blocks, the speed of work increases significantly, and special training is reduced to a minimum. Simply apply the top row to the bottom row in an intuitive way, and then glue it with construction adhesive. Lego bricks are hollow inside, which greatly facilitates their transportation and movement directly during construction, and reduces the labor intensity of the work.

The use of hyper-pressed material is advisable in cases where even the protection provided by the classic type of masonry is insufficient for you. This is a very durable and stable product, and adherence to technology by the manufacturer is critical. If it is violated, cracks and defects will inevitably appear even with the most careful work, and the service life of the fence will be sharply reduced. As for increased thermal conductivity, this indicator does not have any significant significance when constructing fences.

Bavarian masonry brick opens up a number of important opportunities; strictly speaking, this is not so much a special method as a specific material. You can see it in any ancient building, not only on German territory, but also in all other European countries. The essential feature of the Bavarian approach is that outer side The material is painted in a variety of tones and forms unusually attractive patterns. For centuries, no effort by craftsmen could create a good monotonous coloring of bricks. And so they began to turn disadvantage into advantage.

What was considered a problem in the past has now completely turned into characteristic feature country or Provence style, as a way to emphasize the elegance of the old appearance of the fence.

Bavarian brick is made using a specific technology; at the end of its firing, the oxygen concentration in the kiln is increased so that the composition of the clay changes due to chemical reactions. Therefore, the outer layer turns out to be colored differently. The glassy mass is a minimum of 0.2 and a maximum of 0.4 cm in thickness. Bricks produced using the South German method will not be covered with efflorescence even under the most unfavorable circumstances.

The width of the blocks is completely standard, but its appearance has made great strides forward in recent years. Engineers managed to figure out how to make the shape of the streaks very intricate, combining these findings with the creation of smooth or textured surfaces.

Important: the key color covers at least ½ of the entire area, and the remaining two or three tones are distributed randomly, as you see fit.

Construction technology

Most often they use non-original ones. design techniques, but quite traditional ways laying bricks. Variety is introduced through different geometric structures and individual elements designs. The sectional version of the fence differs from the solid one in that the wall is reinforced with supports located at a distance of 250 - 450 cm.

Since the installation of supports depends on the magnitude of the load exerted, the thinner the barrier created, the less often the pillars can be mounted.

Regardless of whether considerations are put first maximum strength or design, the working methodology is approximately similar. First of all, they create markings according to which the foundation needs to be poured.

Others necessary components When working there are ladles and trowels. The first are hemispheres with wooden handles and are designed to make the distribution of the mortar over the masonry more uniform. Trowels ensure leveling of cement, remove its excess at the ends and joints, and help saturate the seams with mortar. Careful blows with the back of the tool's handle allow you to seat the bricks in the precisely designated places.

If the fence is supplemented with columns, the accuracy of their placement and minimal deviation from a straight line is ensured by controlling the angles building level. To break off a piece of the required size from a brick, professionals advise using a pick.

The evenness of the facade of the masonry is verified using smooth slats from 120 to 200 cm in length. Using orders (rulers made of metal or wood, marked in increments equal to the sum of the thickness of the seams and the height of the bricks), you can control the quality of the masonry of an individual tier.

Also, when working, use a standard cone, skeins of twisted cords, a chisel, and a chisel.

When the bricks are laid in the same direction as the entire masonry as a whole, the corresponding strip is called a spoon strip, and when perpendicular to it - a bond strip.

Important: brick fences cannot be made with ¼ bricks, only ½ bricks and higher, otherwise they will not be reliable enough!

Pressure laying requires saturation of vertical seams mortar using a trowel; Most often, a similar technique is needed to make full-seam masonry using a viscous mixture. Initially, a layer of mortar of 15-20 mm is placed 10-15 mm from the border, and then 0.3 to 0.5 cm of the mixture is taken from the bricks of the previous row and transferred to the sidewalls. Pressing the block tightly with a trowel, sharply remove the tool, and use it to adjust the location of the element in the vertical and horizontal planes.

The “end-to-end” laying method implies that the cement mortar is taken not with trowels, but directly with the bricks that need to be laid.

For your information: When working with pillars that will be complemented by a gate or wicket, the reinforcement inside the structure must be brought almost to the very top. If none additional elements there is no need to hold, you can make an indent of 0.4-0.5 m from the top, there is no risk in that.

In some cases, fences are coated with facade paints, whitewash or plaster; Options for installing canopies and awnings are quite common.

In cases where you cannot make a full-fledged brick fence (due to lack of funds), you can resort to its imitation - full or partial. Such structures are made of high-grade polypropylene, resistant to the destructive effects of the external environment and at the same time safe in environmental and sanitary terms. Additionally, the quality of special panels can be improved by applying paint to them, which suppresses peeling and fading and slows down the loss of strength.

Important: optimal choice the type of material requires taking into account weather conditions and soil properties in a particular area.

You can learn more about such structures and methods of attaching them from the following video.

Decor

Brick in combination with forging is perceived as very chic; you can use it either as decorative parts or as a functional part of the structure. You can vary the configuration and size of forged blocks and arrange them in an original way.

With a parapet scheme, forged rods and other decorative elements are placed on a continuous layer of brick.

Important: their height above the top edge of the fence should not exceed 50 cm. Similar solution looks attractive and, in addition, reliably stops most unprepared attackers.

If a base (0.3-1.5 m) is exposed above the main part of the bricks, a wide variety of forged blocks are also mounted on top of it. A characteristic feature of this approach is that the fence is transparent.

You can choose a third method, in which brick pillars are combined with forged structures. It is the forging in this version that accounts for the bulk of the length, and the bricks can only be seen in pillars or columns. And even the pillars themselves, the columns inside, can have reinforcement that increases their mechanical resistance.

Brickwork can complement not only the curly forged element, but also wood; Please note that its presence does not always mean an opportunity to save money. Most often, this step is taken in the desire to use wood that is not needed for other purposes and at the same time create an effective, laconic architectural ensemble.

However, even if you limit yourself to just one brick, you can also achieve a very interesting result. Color solutions are quite diverse, and many novice experimenters are baffled by such a huge choice. Often they try to reproduce the look of the façade covering in a house, for example, using shades of red with orange inclusions. Experiments with brown, yellow, and white bricks are also widespread.

Wine tonality (Marsala) is perceived very attractively, it is especially good to use such fences as accent elements. It makes sense to use a gray palette in areas decorated in a modern or urban style; This color goes well with the abundant use of concrete.

When choosing a combination in a country house, in a country house, focus on the color scheme garden path and sites; in this case, it will be possible to use not just a different color, but also a completely different material to decorate the facade of the home.

From ordinary and clinker bricks you can build a “perforated” fence, built in a checkerboard pattern. Through the gaps you can observe the yard and the street; the strength of the structure decreases somewhat, but this is not so significant.

In addition to the options listed, you can decorate the fence ordinary plants, imitations, stained glass and ceramics.

Returning to the topic of clinker, it is worth emphasizing that it not only looks very elegant, but also absorbs very little water and does not crumble for as long as possible. A fence made from it will last a long time, and the block can be very diverse in appearance - corrugated, rough, completely smooth. Clinker fencing looks optimal both in ultra-modern villas and in imitations of ancient estates; it is even permissible to simultaneously lay out the walls of a house from it.