How to level asbestos floor. How to level the concrete floor with your own hands? Preparing to pour the concrete base

Whatever coating you look for for the floor in your apartment, you need to level the base under it. Then linoleum, laminate or ceramic tiles will lay down beautifully and last a long time. Different types finishes also have different requirements for surface quality, so do-it-yourself floor leveling can be done in several ways. The main materials are plywood, the same concrete, sometimes GVL. But before laying them in any case, preparation will be needed.

Correction of draft surfaces according to any of the schemes listed below requires evaluation and measurement of irregularities. This will help to accurately calculate the degree of alignment that the concrete floor needs, choose for this best way and determine the amount of building materials.

Irregularities in the apartment are easy to measure with a long rail. A two-meter bar is laid on concrete base in different directions, and the detected vertical gaps are determined by the ruler. In panel-type houses, such difficulties are useless - the floors themselves are quite even. Problems arise only if the plates were initially laid incorrectly.

Before proceeding with leveling, the concrete floor should be thoroughly cleaned. After that, the base must be repaired if its condition is unsatisfactory. All cracks and chips must be puttied or smeared with ordinary tile adhesive. It is better to knock down the bumps with a chisel to reduce the consumption of leveling concrete mixtures or not damage the plywood.

Log system

Leveling the floor with a log is required with a large difference in levels in the neighboring rooms of the apartment - about 8-10 cm. Most often, this work needs to be done when redeveloping the premises and attaching a loggia, the floor of which is located lower than in living rooms. In the role of a lag, bars 50x70 or 50x50 mm are suitable, on which it is convenient to attach sheets of plywood.

Leveling the floor with joists. Instruction:

1. Prepare nests for anchors for transverse logs in increments of 60-70 cm.

2. Wooden crate protect from contact with concrete with a layer of waterproofing.

3. Lay the bars on the floor every 50 cm, press firmly and fix with anchor bolts.

4. At the highest point of the transverse row, lay the first longitudinal beam and align it, referring to the level. If the block needs to be lifted, use mounting wedges.

5. In parallel, the second beam is laid against the opposite wall.

6. Lay the intermediate logs in 50 cm increments, align them, checking them for level.

7. The final stage is laying plywood sheets on the floor. Instead of plywood for laminate, you can take a cheaper chipboard or sew up the base with boards.

If it is cold in the apartment, thermal insulation (mineral wool or polystyrene foam boards) should be laid under the coating between the lags of the lower row.

Dry screed

Fast and easy way level the concrete floor with height differences from 3 to 5 cm. Further technology is simple:

1. Lay glassine or a waterproofing film no thinner than 200 microns on the base. Sheets should be laid overlapping and with a bend on the walls of about 8 cm.

2. Glue the edge tape around the perimeter of the room.

3. Install beacons on the concrete floor for leveling in accordance with the zero mark determined during the measurement. If everything is in order with your eye, you can skip this step.

4. Fill the gaps between the slats with loose mass. Compact and level the sand with any improvised tool.

5. Lay plywood, chipboard or any other sheet material. Floor plywood must be at least 1 cm thick.

Such a budget option leveling, however, is reliable enough under linoleum, carpet or laminate. It is not advisable to use it only for laying tiles. With a relatively small height difference under it, it is easier to make a traditional screed.

Leveling the floor with plywood without a lag can be done without taking the furniture out of the room, but doing everything in parts. But the main thing is that a dry screed has good thermal insulation properties and does not require other floor insulation under the coating.

self-leveling floor

A fairly expensive way to self-level the concrete floor. Due to the high cost of self-leveling compounds and their high consumption for square meter area, it is advisable to use this technology only when small bumps up to 3 cm.

At the same time, cheaper cement-containing compounds (Found T-45, Bepors) after hardening form a perfectly flat surface for any coating - be it hard laminate boards or thin linoleum without a substrate. And polymer self-leveling floors ( liquid linoleum) and are an excellent finish in their own right.

When the concrete floor is ready for leveling, it must be covered with soil and allowed to dry for about a day. While working with the leveling compound in the apartment, it should be warm enough, but not hot. Optimum temperature– +10-30°С.

We level the floor under the linoleum with our own hands:

1. Dilute the leveling mixture with water according to the instructions and mix thoroughly with a drill with a mixer attachment. Leave for a couple of minutes so that the solution is well saturated.

2. While the composition is settling in the first container, start preparing the second portion.

3. Ready solution it is mixed again and poured onto the concrete floor in a narrow strip of about 30-40 cm - so that it is convenient to level each portion with a spatula.

4. Roll the mixture on the floor with a needle roller on a long handle and release air bubbles. Particular care must be taken to roll out the boundaries of neighboring batches.

5. After pouring the entire area, level the fresh composition again with a roller. Everything must be done within half an hour, until the solution has had time to set.

6. A couple of hours after pouring, cover the entire area with a film. In this case, the new concrete floor will not dry out too quickly and the coating will not crack.

In the case when for finishing was chosen tile, its laying can be carried out already 3 days after the concrete floor has hardened. And with the alignment under the laminate or linoleum, you will have to wait about a week.

Tip: if the concrete pavement could not be thoroughly rolled with a spiked roller, and small bumps appeared, they will be leveled with a grindstone.

Concrete screed

In the apartments of the old stock, this leveling method is not applicable, since it significantly increases the load on the dilapidated bearing structures. But in a private house, and even on the ground floor, a concrete floor screed is quite acceptable and inexpensive option. Conventional concrete pouring makes it possible to equalize height differences up to 6 cm. Although this process, of course, is laborious and time consuming.

Before pouring the solution, the base must be covered with two layers of soil with complete drying of each. For this, the traditional Concrete-contact (TM Lakra) is used. Expansion joints are left along the contour of the future screed, so at the junction of the floor and walls, you will need to glue a damper tape.

You can combine the leveling of the floor with its insulation. To do this, heat-insulating material (expanded clay or expanded polystyrene) and waterproofing are laid on the rough base. After carrying out all the preparatory work, the alignment with a cement-sand screed is carried out according to the following scheme:

1. Installation of beacons (metal or cement) in increments of 1 to 3 m.

2. Preparation of a leveling solution. It will require 1 part of cement and 3-4 parts of sand. To facilitate the screed and reduce the thermal conductivity of concrete, sand can be partially replaced with small expanded clay granules.

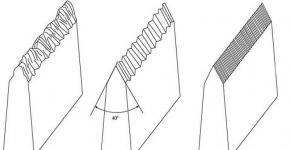

3. Laying the finished composition on the floor between the beacons and leveling it with a wide rule.

4. Reprimer.

5. Applying a thin layer of leveling compound, if the floor needs to be perfectly leveled for finishing. You can refuse to use the finishing pouring of the screed, replacing it with a more time-consuming, but completely free grout.

It will be difficult to perform all the “wet” alignment processes yourself - cement mortar hardens quickly enough, so you should invite a partner or find a way to level the floor under the laminate without a screed.

Choosing an alignment method concrete surfaces, first of all, you need to focus on the thickness of the required layer. Naturally, the smaller it is, the cheaper and faster it is possible to correct the flaws of the builders. In any case, it will be easier to level the concrete floor than to regularly change linoleum that has broken through on the hillocks or cracked laminate later.

raw special formulations the concrete base begins to collapse over time, despite the apparent strength of the stone. The coating begins to dust, chips and potholes appear on its surface. This can happen for several reasons. Quite often, another problem appears, which consists in the fact that the base of the floor is initially bumpy, far from perfectly even, and the floor slabs are laid crookedly. In any case, a reasonable question arises, how to level the concrete floor? Let's try to consider several options that will suit both newcomers and old-timers who decide to repair.

The choice of concrete floor leveling method depends on:

- from the material floor covering;

- on the magnitude of the existing height difference;

- on the number of cracks and chips.

In addition to leveling the concrete base, dry screed performs the functions of insulation and soundproofing. The process of its device is quite simple, even a beginner who is just starting his way in the construction business can handle it.

The concrete base is cleaned, after which a primer is applied to it in order to increase the strength and waterproofing properties of concrete. After the composition dries, a plastic film is laid on the leveled surface with an overlap of 17-20 cm, gluing the edges with adhesive tape. Along the perimeter of the room and in other places where walls and partitions adjoin, allowances for bends of 13-15 cm are left, which are subsequently glued with a damper tape.

The film acts as a waterproofing layer.

A leveling mixture five to seven centimeters thick is poured onto the prepared surface, which may consist of:

- from expanded clay;

- from quartz sand;

- from expanded polystyrene;

- from granulate.

Lay on top:

- plywood;

- moisture resistant gypsum fiber sheets;

- Chipboard or fiberboard.

Leveling concrete floors with a dry screed has several advantages. In particular:

- there is no need to mix the solution;

- there is a possibility self-fulfillment work, without assistants;

- it is allowed to level the surface in separate small areas;

- no additional device for heat and sound insulation is required;

- there is a possibility of laying the necessary communications inside the layer;

- work is carried out quickly, after their completion, you can immediately start laying the flooring.

The classic option for leveling a concrete base is a cement-concrete screed. Professionals tend to this point of view, as the result is a solid, perfectly even base for laying the top coat.

Thickness cement-sand screed must be at least three centimeters, otherwise its strength will not meet the necessary requirements.

Wet screed has proven itself positively when leveling floor slabs and with a large difference in floor levels - up to six centimeters. The technology of its device is quite laborious and has certain difficulties. But with quality work performed, the result remains unchanged - reliability and durability will be guaranteed.

Before starting work, the concrete base is cleared of unstable areas, construction debris, dust and dirt. Oil stains are also recommended to be removed. Next, a waterproofing layer is laid, for which any available material can be used. The main thing is that the joints and overlaps are securely glued to prevent leaks on the ceiling of the neighbors. Do not forget about the allowances of waterproofing material, which must be left near the walls.

At the next stage, beacons are installed when using conventional or laser levels in the work. To install beacons, metal profiles are chosen, which are installed on a thick mortar or a quickly hardening gypsum mixture. For the convenience of pouring and leveling the screed, the distance between the guides is made no more than 0.9-1 meter.

The mixed solution is poured in parts between the profiles, immediately distributing and leveling the mixture with the rule. It is led not only along the guides, but also the tool is moved from side to side. This contributes to the filling of voids, as well as the compaction of the screed layer.

When laying the mortar, long breaks in work should be avoided, otherwise there is a high probability of the formation of so-called cold joints. This process negatively affects the strength of the cement-sand layer.

With a large thickness of the screed, it is additionally reinforced with reinforcement. The material can be any, its choice depends on the height of the leveling layer and the type of flooring.

To prevent the appearance of cracks on the finished screed, experts recommend cutting shrinkage seams in it every three meters.

One day after laying the mortar, the cement-sand surface is moistened. To do this, you can use a paint roller with a long handle or a spray gun. On the third day, the degree of setting of the solution is checked. If, when walking on the screed, no traces remain on it, they begin to remove the metal profiles and fill the resulting voids with a mixture.

The surface of the screed is again moistened and covered with polyethylene so that the solution cannot dry out too quickly and crack. The wetting process is carried out for several days in a row (usually a week), after which the film is removed, and the screed is kept at natural humidity.

Full curing wet screed occurs for at least two weeks, but it would be better not to proceed with further work for a month.

To obtain a perfectly smooth surface, the screed is ground, but only if necessary. In order to eliminate irregularities, the coating is simply rubbed with a special machine in two opposite directions.

Leveling a concrete floor with a self-leveling mixture is convenient and quite affordable. The solution is mixed in a container with construction mixer, is poured onto the base and spread over it with notched trowels, or with special spiked rollers that remove unnecessary air bubbles. The work is done quickly, as the mixture can begin to set in ten minutes. This is its main drawback.

The fluidity period of the material is indicated on the packaging. Based this indicator, the amount of material required for mixing is calculated. It is not allowed to deviate from the manufacturer's instructions!

The advantage of self-leveling mixtures is their spontaneous spreading along concrete floor. This results in an even horizontal surface bases for flooring. The advantages include a small thickness of the leveling layer, which is an undoubted benefit for low rooms.

Before pouring, the concrete base is prepared. To do this, without fail, close up deep and wide cracks and cracks with a solution, after which they allow it to dry.

The use of self-leveling compounds is recommended for height differences of less than three centimeters. Otherwise, the layer may crack in the future.

An interesting fact is that the solution is able to harden within half an hour. But this is not a reason to start further work. It is necessary to allow the base to stand for three days. It should be noted that for a self-leveling mixture, a finishing coating is necessary, since the cured surface does not have sufficient strength. Also, it is not intended for coloring.

Leveling a concrete floor for some types of flooring

To top coat the floor served as long as possible, it is necessary to responsibly approach the leveling of the concrete base under the flooring. For each of the materials, one or another option and the quality of surface leveling are suitable.

For example, laminate does not tolerate differences even in 4mm. In this case, laying a soft substrate will not be able to save from damage to locks or divergence of joints. Under the laminated coating, one of three types of leveling the concrete base is performed. The main thing is to get a flat, horizontal surface.

Linoleum is not as capricious in evenness as in the smoothness of concrete. Any pebble can push through the elastic material. Linoleum will lie softly over irregularities, but it will not be able to hide them. When viewed from the side, all the curves will be noticeable. The concrete floor under the linoleum can be leveled by all available means.

Large differences in the base are eliminated with plywood laid along the logs. This option is also resorted to if it is necessary to raise the level of the floor, regardless of the type of flooring subsequently laid. The main thing is that the material is not heavy.

For ceramic tiles, it is recommended to install a full-fledged cement-sand screed laid on a carefully made waterproofing layer. Moreover, the base additionally levels the layer of tile adhesive. The main condition, in this case, is the absence of differences in height.

Leveling the floor in the garage and basement

In utility rooms, the finish coating is rarely laid. The floor here is usually left concrete. They level it with a screed and strengthen it with special impregnations and hardening compounds called toppings. They do not allow dusting and destruction of the concrete surface.

A flat floor in any room is necessary not only for aesthetic reasons, but also prevents injury to the owner of the property. The unpleasant appearance of a rickety cabinet cannot be compared with the overturning of a rocking TV or a broken limb as a result of a fall on "almost level ground." Whatever the cause: initial errors during construction or the appearance of potholes and cracks during operation, the question “How to level the floor?” sooner or later it gets up before new settlers, and during repairs.

In modern housing construction, the basis of the floor in a house, apartment, garage, office is concrete or concrete plates. Depending on the purpose of the room, linoleum, ceramic or pvc tiles, parquet, laminate, carpet, and the durability of the external, often expensive coating depends on the evenness of the concrete floor base.

To get an even solid foundation under the floor finish, achieving heat, hydro and sound insulation, leveling is carried out either by the screed method, or by applying solutions of special mixtures for leveling the floor.

The choice of leveling method depends on the size of the floor height difference and the finished floor material: with a floor level difference of 3-4 cm, a leveling screed of the concrete floor is performed; if the floor is generally even, but a large number of cracks are found, then leveling is performed with self-spreading mixtures or tile adhesive.

Experts distinguish between several types of screed, based on two main laying methods: dry screed and screed with the addition of various liquids.

Dry screed is easily performed even by a novice builder, it is cheaper and significantly insulates the room. Expanded clay, dry quartz sand, expanded polystyrene are used as a filler. Plywood, gypsum-fiber moisture-resistant sheets (GVL) or wood boards (chipboard, fiberboard) are laid on top, so a dry screed is made more often in living rooms.

The cleaned floor is impregnated with a primer solution that strengthens the concrete and increases its waterproofing properties. You can use "Betonkontakt". After drying, a layer of polyethylene (more than 50 microns) film is laid, joining the panels with an overlap of 18-20 cm and gluing them with adhesive tape. An overlap of 12-15 cm is left along the walls and glued with a damper tape.

In the absence of the necessary experience, it is advisable to lay U-shaped profiles turned upside down on the floor as beacons, setting them in level. Having filled a part of the filler into the formed cells, level it with a rule and lay sheets of the future floor, gluing the joints of the GVL with PVA glue and tightening it with self-tapping screws after 18-20 cm.

At the walls, the edge of the gypsum fiber sheets is cut off. You should not pay attention to the apparent instability of the first sheets; when they are spliced into a single monolith, they get a solid warm floor.

Thinking about the best way to level the floor, the majority tends to the classic version of the cement-sand screed, which gives a solid, even base for the finishing layer of the floor. The thickness of the future screed must be at least 3 cm, otherwise the strength is reduced significantly.

The concrete base is also cleaned, primed and dried. With the help of ordinary, water or laser level install beacons using a laser level, you can install beacons without assistants. Lighthouses are mainly installed with durable metal slats or T-profiles, but you can use pipes, edged board or bar.

The slats are installed on a thick solution, at a distance of no more than a meter from each other. The solution must be allowed to harden, otherwise, when leveling the screed, you can move the beacons and all the work will go down the drain.

Subsequent work does not require experience, but patience: pouring out the solution sequentially from the far corner, the floor is carefully leveled with a rule, moving it not only along the rails, but also making hand movements in a circle. In this case, the solution moves to the right and left, compacting and filling the voids.

To prepare the solution, cement of the M500 brand is most often used, adding three parts of sifted sand and water to one part of it (about 1 liter per 1 kg of cement). You can also use ready-made leveling compounds for the floor, commercially available: M150, M200, M400. How more number in the name of the mixture, the stronger the resulting coating. Prepare solutions in accordance with the instructions on the bag.

On the next day after laying, the screed must be lightly moistened with a roller, on the second day it is re-moistened and the strength of the solution is checked. If it is already possible to walk on it, the beacons are carefully pulled out and all the voids formed are rubbed with a fresh solution.

The screed is covered polyethylene film and, periodically moisturizing over the next week, they are kept until hardened for at least 2 weeks, and preferably a month.

Along with strength and relative cheapness, the leveling floor screed takes a lot of time, which modern self-leveling mixtures, more often called self-leveling floors or equalizing mixtures. Top Coat can be installed after 10-12 hours, and a fully self-leveling floor acquires its characteristics within 12-14 days.

Such mixtures can be used with a height difference of not more than 3 cm, guided by the instructions attached to the bags with mixtures, since further coating strength in more depends on the chemical filler of the mixture. Deep (more than 6 mm) cracks and depressions must first be repaired with mortar and dried.

A leveling mixture diluted according to the instructions is poured onto the cleaned and primed concrete and leveled with a metal spatula. After that, the self-leveling floor is rolled with a spiked roller, removing the smallest air bubbles that reduce the strength of the floor.

It is necessary to do the work together, as the mixture sets in about 10 minutes. If necessary, slow down the curing rate, the floor is slightly moistened beforehand. cold water, which also avoids cracking of self-leveling floors.

The small thickness of the finished floor allows it to be widely used in rooms with low ceilings. Along with the high cost, the negative characteristics of self-leveling compounds include brittleness and poor resistance to low temperatures epoxy mixtures; mixtures based on polyurethanes are not resistant to chemical attack; methyl methacrylic are slightly resistant to abrasives.

Sometimes small cracks or irregularities are found in the floor, in which case it is possible to level the floor with tile adhesive, given that, for example, Ceresit can crack already at a thickness of 3 mm. It is undesirable to use full leveling of the floor with tile adhesive, replacing the self-leveling floor with it, despite the cheapness of the glue.

When deciding for yourself how or with what mixture to level the floor, it is necessary to take into account the temperature and humidity of the room, the level difference and the slope of the concrete base, the expected loads during the operation of the floor, labor and financial costs.

Leveling the concrete floor is necessary for laying the subsequent decorative coating. Therefore, this is an important part of the improvement of the premises, which includes classic and modern ways leveling, such as wet and dry screed, pouring the composition and falling asleep multi-component mixtures.

Peculiarities

In apartments where people live for a long time, the upper part concrete pavement the floor is gradually broken, sometimes coming into disrepair. In this case, it is mandatory to carry out a major overhaul of either the entire floor, or a separately leaky part of it.

In new homes, concrete floor screeds tend to be better prepared and look smoother. But here, too, it is necessary to take into account individual shortcomings that arise in the places where individual plates are joined to each other. And when buying such an apartment, residents most often have to additionally carry out minor repairs. Before the beginning repair work careful measurements, cleaning and other types of floor preparation for leveling are carried out.

The preparatory stage includes the removal of the outer coating and the inspection of all uneven places and crevices found. Some of the defects exist in houses from the moment of construction and then become even more aggravated during operation.

The height of the concrete pavement should ideally be the same over the entire floor area. To determine this indicator, a long tool is used, which is called the level. Often connected to the process and modern appliances– Osepostroiteley laser or water levels.

Preliminary measurements reveal, first of all, two main parameters - the highest point on the surface and the most extensive and deep dent. The gap between them is to be evenly filled with concrete or other material.

It is necessary to raise sagging places up to maximum level, counting from zero - between the horizon and the floor plane. Only after that, linoleum or tile, parquet or laminate is applied to the subfloor. At the same time, we must not forget that all parts of the interior are interconnected: if the coating is excessively raised, it may be difficult to open doors and operate heating batteries. In order not to redo the work twice, these factors must be taken into account in advance.

What is better to equalize?

The ideal material for leveling, according to many experts, has not yet been invented. Putty can eliminate small roughness, putty and cover chips conveniently and with the help of tile adhesive.

A liquid mixture of concrete and water combined with other fibers is an excellent leveling agent for small dents. For preparation as a filler of the sand-concrete composition, cement grade M-400, sand and thinner are used. A building mixer mixes all the components, since it is rather difficult to achieve a high-quality leveler manually.

Significant defects are leveled with cement mortar, achieving results even in case of serious damage to the concrete base during construction. The gypsum composition is used to fix metal guides in the screed process, the so-called lighthouses. At home, when doing do-it-yourself repair work, ready-made dry mixes and polystyrene concrete are preferred, combining synthetic plasticity and fast, durable hardening after application. In the case of using a universal ready-made or mixed mixture of concrete and sand obtained in a mixer, the poured floor is subjected to additional grinding with a special machine.

Work technology

A completely smooth and even floor looks beautiful and elegant, while a curved flooring detracts from the aesthetic perception of the entire room or kitchen. In progress overhaul the floors in the house are the last to be dismantled, and they are the first to be put in order. If a total leveling of surfaces is carried out during the preparatory work, the floor is first leveled, and then they move on to the walls and ceiling.

Among the common defects in the floor screed in both private and multi-storey buildings standard layout, experts call:

- Local minor errors that look like level "swells" that create irregularities on the floor.

- Changes and drops in the form of periodic, especially noticeable on the surface of finding waves from concrete or other material. In private buildings, such waves on the floor can be quite significant, up to several centimeters.

- Small wave drops or "chill". These defects usually remain after application. construction tool- rules.

- Small cracks, lenses and caverns, protruding pieces of rubble, as evidence of the destruction of the floor. In this case, it becomes unsafe to move around the house, it is impossible to securely fix the furniture and household appliances. In addition, the ability of the coating to provide insulation from noise, odors and excess moisture is lost.

The floor needs to be cleaned, putty bumps and chipped parts. In order to reduce the consumption of a concrete-based leveling compound or not to break a plywood sheet, large bumps are knocked down with a chisel.

Leveling methods used by builders: the use of concrete or dry screed on pre-set beacons or without them, as well as the method bulk coating gender. Right choice method depends on the magnitude of the difference between the maximum and minimum levels.

If the irregularities are minor, up to two or three centimeters, a technology such as arranging a self-leveling floor is suitable. This is an expensive method, since a significant amount of leveling mixture is used per square meter of area. Therefore, dry screed or alignment with beacons is most often used.

In order to make a screed based on a sand-concrete mixture with high quality, metal slats are laid on the base, which will indicate guidelines for movement during the screed. The process is labor-intensive, but it allows you to even out potholes and differences of several centimeters, to make the coating perfect in any room.

Step by step, the work is carried out as follows. Necessary:

- Prepare the floor by removing oil stains and dirt.

- Put waterproofing material, gluing the joints. Leave allowances along the walls of the room.

- Using a level, mount metal guides - beacons. The distance between them is allowed no more than one meter, otherwise it will be more difficult to level the surface.

- Prepare a concrete-sand mixture, preferably immediately for the entire area to be poured. Stirring time - from an hour to an hour and a half, so that the composition does not harden. Most often, a building automatic mixer is used, bringing the composition to a semi-liquid state. Ready mix should only spread a little to the sides without spreading.

- Alignment is done from a distant corner, in small parts, using a rule. Applying the mixture, it is immediately leveled. To securely close all dents, the mixture is scattered on the sides, and not just along the guides. In order not to form air gaps, each layer of the screed must be pierced with a metal knitting needle.

- A thick screed is reinforced with other material, and special seams are cut for shrinkage. The distance between them is selected up to three meters. After that, the flooded surface is left for about a day. After this time, the screed must be moistened with water from the sprayer and left for another two days. Then you can check whether the sand concrete mixture has solidified well.

- At the next stage, the surface is moistened again, a polyethylene film is placed on top to protect it from cracks.

- Over the next week, daily moistening of the screed is required, then the film is removed, leaving the floor to dry. naturally. The process of complete drying takes at least a week or even two.

- Dry finished surface has a uniform grey colour. Tapping it with a block of wood causes the layer to sound the same anywhere on the floor.

- If the alignment is done qualitatively, you can proceed with the installation of the coating of laminate, linoleum, and parquet. Tiles can be installed at the same time last layer screeds.

When performing alignment, one should not rush too much, but it is also undesirable to delay the procedure. Cold seams may appear. Therefore, it is recommended, especially in the case of a large room, to invite an assistant and work together.

Material

Whatever the main coating is laid - tiles, parquet boards or linoleum, auxiliary materials are used to level the floor. Most often, plywood, layers of concrete and GVL are placed under the flooring. Only in this case is it possible to achieve required quality flawless surface, ready to serve for many years.

Sand and cement based screed refers to classic options, because it provides a flat surface even in those rooms where the differences reach four or more centimeters. Dry screed is provided with self-leveling mixtures based on quartz sand, granular particles and expanded clay, expanded polystyrene. A flat surface is provided by sheets of plywood, chipboard, fiberboard or gypsum fiber sheets that are resistant to moisture.

room

Leveling the floor, achieving the perfect coverage, is made with polystyrene concrete, wet or dry mix. This method, along with a cement-sand screed, well prepares the floor for laminate and parquet in the living room and bedroom, nursery or dining room. If the apartment is small-sized with a low ceiling, and the differences in the floor are not more than three millimeters, it is better to resort to a flooded floor, which will dry out after 12-14 hours. The entire process of laying the floor, as a rule, does not take more than two weeks.

A polyurethane-based filler floor is not intended for rooms with temperature fluctuations; it is better to use this method starting from the second floor. But it is an excellent option for a rough base for a laminate. Before applying the self-levelling compound, the floor must be thoroughly primed. Then ready liquid composition pour on the floor, leveling with a spatula.

To eliminate air bubbles that cause coating defects, a needle roller is used, piercing the filled layer. The flooded floor dries in just 15 minutes, so you should do all the operations together with an assistant. Slows down hardening cold water with which the coating is wetted.

If you have to lay linoleum, the surface must be absolutely flat. To ensure these goals, a method such as a dry screed for drops of no more than a centimeter and a half is suitable. If repairs need to be done quickly, strengthening the floor with almost no defects, leveling is done with sheets of plywood or chipboard. Strengthen them with self-tapping screws and dowels after gluing to the floor surface.

For kitchens and balconies often used as the main cover beautiful ceramic tiles. There is an easy way to lay it flat at the same time as removing small defects on a concrete base. The method does not give a full leveling of the floor, however, it allows you to lay the tiles evenly. First you need to draw horizontal lines above the floor surface on the walls along the entire perimeter of the room. This will be the level at which the tiles are laid.

With a major overhaul or partial finishing of the premises, it is impossible to do without leveling the concrete floor. This is one of the prerequisites for the installation of linoleum, laminate and other similar materials. If the preparation of the plane is not performed, the final result of the finish is unlikely to please its owner.

Even in new buildings, often the concrete floor is not perfectly even. The most problematic areas are the joints. In old houses, the floor surface is often in a deplorable state. If the concrete has not been exposed special treatment, then over time it begins to dust, crumble, chips and cracks appear on it. Many owners are faced with the question of how to level the concrete floor correctly?

Reasons for leveling a concrete floor:

- the installation technique of many types of flooring requires mandatory surface preparation (linoleum, parquet, laminate, tile);

- elimination of construction defects on concrete slabs: cracks, chips, differences between slabs, unsuccessful joints;

- installation of sound, heat, waterproofing material;

- strengthening the strength and rigidity of load-bearing floors;

- uneven surface complicates the arrangement of furniture and interior.

How to prepare for alignment

Before you level the concrete floor and stop with the choice of technology and materials to eliminate irregularities and defects with your own hands, it is necessary to determine the nature and scope of the work, as well as how strong the deviation from the norm and the angle of inclination. Then the corresponding measurements are taken. To do this, the old coating is first disassembled. After that, an assessment of irregularities is carried out.

The building level checks the entire surface of the floor. First of all, the highest point is determined, which should be noted immediately. Then you need to examine the defects of concrete slabs: worn areas, chips, cracks. The deepest point is also recommended to be noted.

Properly made measurements will prevent errors in the process of further alignment.

If you do the work without determining these points or make incorrect measurements, then there may be consequences that are difficult to fix: the doors will stop closing, the height of the floor may interfere with the heating, linoleum and other coatings will not lie flat. Eliminating such errors is very difficult and will take a lot of time.

Alignment methods

Installation of concrete pavement is the very first thing that is started during the overhaul of the premises. The quality of the rest of the finishing work depends on the evenness of the floor.

There are two main technologies:

- beacon alignment;

- filling surface device.

If the room has small size and the angle of inclination of the plane does not exceed 3.5 cm, then the most appropriate way would be to install a self-leveling floor. If this indicator is exceeded, the technology for leveling concrete slabs will be carried out according to the exposed beacons.

When choosing one of the methods, it is important to understand that each option for eliminating irregularities has both its advantages and disadvantages, so you should carefully study the execution technique and weigh the pros and cons.

The use of this technology allows you to do the work yourself even to someone who is not a professional in the field of decoration. The method is well suited for implementation in large rooms.

First, special beacons, which are metal slats, are laid and fixed on concrete slabs. These are some kind of guidelines for correct execution surface screed work.

The entire alignment process is cost-effective and fast. At minimum investment it allows you to get a quality product. The installation itself is carried out in a short period of time, but it takes an average of 10 to 30 days for the surface to harden. The drying time of the screed depends on the thickness of the applied layer and temperature regime indoors. If you are short on time, we recommend choosing another method.

What do you need to work

Tools for performing concrete floor screed:

- vacuum cleaner or broom for surface preparation;

- Master OK;

- perforated corners;

- rule;

- building level;

- large container for mixing solution.

Surface preparation, installation of beacons

Before performing any construction works important point is preparatory stage. The entire surface is carefully swept or vacuumed. Accumulated debris, dust and dirt must be removed.

After that, beacons are installed, which are perforated metal corners. They are placed along the width of the entire room. The first and final beacons are installed at a distance of 30 cm from the side walls. The remaining elements are placed at the same distance from each other. It should not be more than 1 meter.

Installation is carried out in the following sequence. First, the markup is done. Beacons are installed along the lines, they are attached to cement or plaster. All this is controlled by building level. The design is left to dry.

After the metal slats have seized, all the space remaining under them is filled with cement mortar. At this time, it is possible to correct the position of the beacons, correct them.

The main task is to make the surface as flat as possible. Everything must be left to fix the elements.

After everything dries, work should begin on leveling the resulting plane.

fill

To perform the screed, a cement mortar is prepared. The consistency of the material should resemble outwardly thick sour cream. If you mix a steeper solution, it will be difficult to level it well with your own hands. Too liquid mixture seizes for a long time, such a surface will not have increased strength characteristics.

Leveling work should be carried out from the farthest point towards the exit. Usually filling occurs in rows. The first and second are filled at the same time. After them turn behind the last two rows. Then further work is done one strip from each edge. The end should be on the center path. This row is aligned especially neatly. The material fills the structure in small portions at a distance no further than the outstretched arm.

The resulting solution is poured into the distance between two linear beacons. With the help of a trowel, all hard-to-reach areas are filled. After pouring each strip on the beacons, a rule is established, which is carried out several times to level the floor surface.

In the process of work, do not forget about the periodic mixing of the product, this will ensure uniform distribution material for better drying. Only after complete hardening, you can proceed to the subsequent finishing of the floor. Linoleum will fit perfectly on a flat floor.

The self-leveling floor device is the most modern and easiest way to prepare the floor for linoleum or laminate flooring. To obtain a smooth surface, special building mixtures. They are developed using a special technology that allows the material to self-align. It is enough to pour it on a concrete base, let it dry, and the base for linoleum is ready.

The mixture has specific characteristics. It spreads over the surface of the floor in a thin even layer.

Tools for using leveling mortars:

- vacuum cleaner or other items for cleaning concrete slabs;

- foam roller;

- needle roller.

Work order

The entire surface is pre-cleaned. After that, it is treated with a soil substance. Then, according to the instructions, the finished powder of the self-leveling mixture is diluted, which is simply poured onto the floor.

To help the product spread evenly over the surface and eliminate air bubbles in the product, a spiked roller should be used. They should go in all directions. The work is carried out in special shoes with spikes, which will not allow you to step on the flooded floor.

The material dries in a few hours, after which you can immediately proceed to further finishing premises. The disadvantage of this mixture is that the maximum allowable thickness should not be more than specified by the manufacturer (as a rule, no more than 10 cm, often much less). If the surface has a larger slope, then leveling the concrete floor in this way is not possible.