Do-it-yourself folding ladder to the attic: step-by-step instructions for self-manufacturing a folding attic ladder with a hatch. Do-it-yourself attic ladder with a hatch - how to make it easier Do-it-yourself folding attic ladder

This article provides step-by-step instruction to create a folding attic ladder. You will learn how to correctly assemble the main hinge element, what to make sections of the stairs from and how to securely fix the structure in the mounting position. The article contains diagrams and drawings.

The inventory factory ladder to the attic is a fairly common product that can be purchased at many hardware stores. However, budget options are not always reliable, and strong branded products cost accordingly. Making the necessary item or device with your own hands from improvised materials is very popular among home craftsmen. The attic stairs are no exception.

Material for work

To assemble an analogue of a factory product, you will need high-quality materials that may be available, especially during construction:

- Bar 50x50 (pine) grade 1 - 20 linear meters m. The frame of the cover and opening will be made from it.

- Plywood 8-10 mm - 2 sq. m. Needed for covering the lid.

- Board 100x25-30 mm - 15 linear meters. m. Will go to the steps and bowstrings.

- Steel strip 3-4x20 mm - for movable fastening of knees.

- Corner and plate 3-4 mm - for the main mechanical element.

- Bolts, nuts, washers, grovers M12-M14.

- Self-tapping screws.

Tool:

- Carpenter - saw, screwdriver, goniometer.

- Locksmith - welding machine, electrodes 3-4, grinder.

- Workbench and clamps.

Operating procedure

First of all, you need to choose a place for the stairs and make an opening. If necessary, cut and install intermediate beams in the ceiling - 6-7 mm larger than the size of the intended cover. Next, according to the size of the hatch, you need to assemble the lid itself - from a bar and plywood. The design can be arbitrary, but must be reliable (it is better to glue the joints). The bar on one of the short sides should be rounded - so as not to interfere with the lid to open.

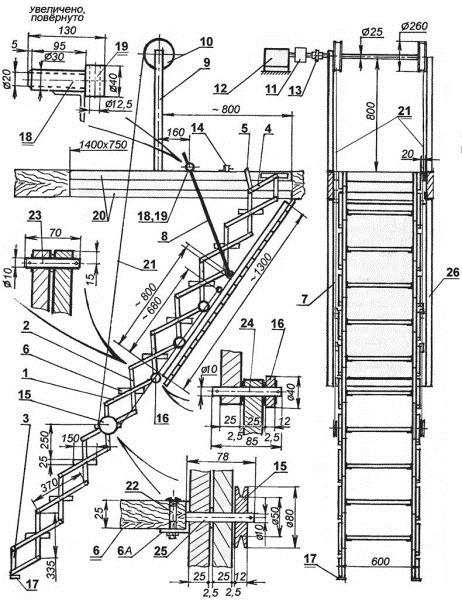

Hinge assembly

This is the most critical element of the design. For its manufacture you will need: a steel corner, a plate and strips with a thickness of at least 3 mm. The shape of the parts is clear from the diagram, but the dimensions of the drilling site should be determined individually, based on the situation at the site. Manufactured parts must be of high quality, they should be cleaned and edged.

1 - thrust plate; 2 - corner, top view; 3 - short wings; 4 - long link

1 - thrust plate; 2 - corner, top view; 3 - short wings; 4 - long link

The key point is to determine the opening angle. This angle is very important and appears in the manufacture of the plate. In order to set it correctly, project the future march on the ground - stretch the thread and empirically (selecting the best position) set the desired angle. Attach it securely to the goniometer - it will be needed in the manufacture of steps.

The resulting angle must be transferred to the part, namely to the plate. To do this, set the mechanism to its original position, attach the goniometer and move until the angles of the angle and goniometer shelf coincide. Then mark the plate along the resulting trajectory and cut out the part travel area.

Holes must be pre-drilled in the plate for mounting to the beam. We assemble the mechanism on the bolts through the washers.

After a rough assembly, you need to try on the knot in place, bait and exactly reproduce the procedure for opening and closing the hatch. If shortcomings are found, correct them.

Then you need to make a response mechanism. It should completely repeat the first one, but in a mirror image. Use clamps and a workbench - by clamping the parts together, you will achieve complete identity in size.

Empirically make the adjustment and final installation. Lid in open position must exactly repeat the angle projected by the cord.

Section manufacturing

Calculation of the length of each section:

- 1st - opening length minus 10%

- 2nd - the length of the first minus 10%

- 3rd - the length of the march minus the sum of the first two

Let's assume that the length of the march is 2500 mm. Based on an opening length of 1200 mm:

- 1st - 1080 mm

- 2nd - 972 mm

- 3rd - 448 mm

We mark the whole boards according to the calculation and transfer the march angle to the bowstrings.

Attention! Bowstrings must be installed mirror! Keep this in mind when marking and drilling.

At the joints of the sections, we drill holes Ø 25 - mirror through one.

All parts need to be processed with a sanding tape with high quality, chamfers are rounded in order to bring the quality as close as possible to the factory one.

Then we cut along the grooves for the steps. We select wood with a chisel.

The design of individual sections is assembled on 65 mm self-tapping screws with a press washer through D-3 carpentry glue.

Knee loops can be made from the same strip as the opening mechanism. To do this, cut 4 strips of 160 mm and 4 of 120 mm, round the ends. To four of them we weld the paws to a length of 160 mm with a hole of 8 mm. You should get 8 parts of the same length, but 4 of them with a step.

Assemble individual plates into hinges using bolts.

Assembly of sections and installation of stairs

Lay out on a flat plane and install the finished sectional hinges so that the mounting bolts fall into the holes in the tree. Install the hinges on the M8-10 bolts.

After assembling the first knee, check the system for operability. Eliminate distortions if necessary.

Then attach the lower short leg and test the system.

Now it remains to mount the ladder in the design position - on the hatch cover. For installation, use bolts (self-tapping screws are not reliable). If, after installation and testing, everything works without distortions, the structure can be dismantled for painting. Use varnishes and spray paint for metal.

Subsequently, the design can be complicated and made more convenient by adding to it:

- Additional hinges to eliminate backlash.

- A spring to support the structure to make opening easier.

- Lock-lock.

- Handrails.

- Use decorative trim and additional insulation.

Finished stairs:

The issue of finishing and insulation is decided locally, based on needs. You can finish the cover with any material that fits into the ceiling. Basically, it is plastic - light, inexpensive and having an additional layer of air. The difference in price between the "home" and "shop" version of the folding ladder is about 90% (80-150 USD). The work required only a few new boards, a coating for them and hardware.

The attic is rarely used, but the stairs leading to this room should be comfortable, compact and safe. Usually, the owners of the house use an attached or stationary ladder installed on the street. To save space in the house, comfortable use and safe lifting, a folding system is installed.

Features and Benefits

Folding ladder in the house is designed to use the attic as needed. It is comfortable to use, since it can be brought into working condition without special efforts and eliminates the need to clear a large area. The main feature of this system is that the principle of its use is similar to the principle of operation of ladders. It is important to take into account not only a large number of advantages, but also some features.

Advantages.

- Safety. The folding ladder is stable and strong. At any time, regardless of weather conditions, there is the possibility of a safe climb to the attic. Some types of folding systems are equipped with steps and railings.

- Compactness. The compact design system allows you to save usable space in the room and in the attic. The unfolded state of the stairs requires little space.

- The convenience of use. This type of product folds quickly and without much effort. There are ready-made electric drive models of the design.

- Ease of installation. The folding ladder installation kit has simple instructions. Following it, even a person without experience will not be difficult to establish a model. The system does not require additional reinforcement of walls, floors and ceilings. The lightness of the design allows you to easily move and install the product in another place.

- Profitability. The finished system is cheaper than a fixed ladder. Folding model can be made at home.

- Aesthetics. The ladder is placed on the hatch cover in the ceiling surface, and quality finish support appearance. The design is completely hidden, so it does not spoil the interior.

- Folding system it is removed to the attic, this is convenient when there are children in the house or the area of \u200b\u200bthe room is small. The design is visible only when used, so there is no need to select a design for the interior.

Peculiarities.

- Some types of models are not always comfortable to use according to the following criteria: the steepness of the climb, the size and number of steps. If the climb is too steep, it is uncomfortable to move with voluminous objects in your hands.

- The presence of a hatch will violate the tightness of the room. The attic needs to be insulated, which leads to additional costs. In some factory models of structures, the hatch is equipped with a seal.

- The need for accurate calculations and skills for self-manufacturing stairs.

Varieties

The principle of operation of the ladder consists of several simple steps: opening the hatch cover, pulling the folded installation towards you. All components will be fixed and become motionless. If you push a little lower part up, then the ladder itself will fold into its original position. At the end, you need to close the hatch.

A simpler way of operation is electric ladders. To bring them into working condition, you must press the button on the remote control.

The stairs leading to the attic have a number of advantages: functionality, compactness and ease of use. The range of designs allows you to choose a specific type that is ideal for the parameters of the house. Folding installations in the attic are different types. They differ in their design.

One of the most common varieties is the "accordion". This type of product has small size, the principle of folding works like accordion furs. The ladder is made of light metal, as its parts are movable, so it is important to take into account its maximum load when used. After a while, it is recommended to lubricate the fasteners. "Accordion" is universal in that it can be stretched to a certain size, depending on the height of the ceiling.

The retractable ladder unfolds according to the telescopic principle. This product is easy to use. When folded, it is the smallest in comparison with other folding ladder systems. The design is assembled from hollow metal (aluminum) tubes, which make up sections with steps, which, when folded, fit into each other and are clamped with clamps. The model can consist of two, three or more sections.

Folding sectional ladder. It is popular among designs performed at home. The model is either folded like a book or booklet, or the sections are stacked on top of each other. Usually the length of the first section is the same as the size of the manhole cover. The design is more overall, but the most reliable and safe.

There is a staircase consisting of two sections. The first short part is fixed on the hatch, and the second - long - unfolds to the floor. This type of system is also called a transformer ladder.

The folding ladder system is the most complex. A folding staircase to the attic consists of steps fixed to the bowstring. The ladder is as large as possible in size and reliable. It is most comfortable during operation, since the angle of inclination is no more than 45 degrees. To create it with your own hands, you need equipment and skills.

It is important to pay attention to the preparation of a room with a hatch. The area potentially occupied by the stairs is released. For safety in the attic, they install a fence around the hatch or frame the folded model with a box.

materials

The choice of material depends on the unfolding technology. Stairs can be crafted from metal (aluminum, stainless steel), wood, or a combination.

Eco-Friendly Wooden Folding Attic Ladder and has an attractive appearance. It will look good in a house where the interior is made "under the tree." The positive qualities of the installation are its good tolerance to temperature changes and exposure to moisture. TO negative qualities the fire hazard of the product can be attributed, insects can also start in the wood.

The folding version of the ladder is made of solid wood. Details are connected using a special technology. At the edges of the steps there are protrusions that are inserted into the gaps of the guides, the connection is fixed with glue. For the manufacture of spans, beams are chosen from an array of coniferous species, beech or ash, for steps - from oak. The load capacity of a wooden folding installation is about 100 kilograms.

The metal folding ladder to the attic is made of metal that does not corrode. For the manufacture of complex design choose aluminum or steel. Main advantage aluminum system- simplicity of construction, such a light and durable metal will last for many years. Steel products are offered with a coating that is protected from corrosion. The load capacity of a metal structure is 200 kilograms, this figure is much more than that of a wooden staircase.

The disadvantages of a metal folding ladder include the complexity of manufacturing at home. To create it, you need to have special skills, experience with welding and equipment.

Strength and lightness are the main characteristics of a folding ladder to the attic. The best option is a combined staircase. This design consists of wooden steps and metal supports. This type of system is cost effective and reliable. Some models use rubber step pads to reduce slip.

How to determine the dimensions?

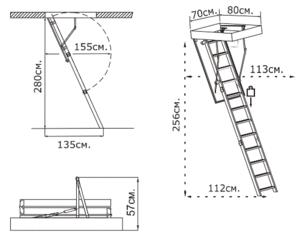

To make the use of the stairs comfortable, it is necessary to determine the main dimensions of the structure and make calculations. It is important to take into account the parameters of the room in which the entrance to the attic will be located: the height of the ceilings, the area where the stairs will be laid out, the stair slope. Usually a model is installed, consisting of 3 or 4 sections for ceilings with a height of 3 meters.

Basic dimensions to be determined.

- Ceiling height and staircase length. The higher the ceiling height, the more reliable and durable the structure should be. When measuring the height of the ceilings, the length, type of folding system and the number of sections are determined. At a height of 3.5 meters, it is recommended to install a stationary version of the stairs.

- Opening and width of the stairs. The size of the opening can be from 0.5-0.6 by 0.7-0.8 meters. The optimal size is 0.8 by 1.20 m. The width of the step depends on the width of the hatch. It will be comfortable to climb stairs with a width of 60-70 cm.

- bias. A safe and comfortable slope angle is 30-55 degrees.

- Step, number and width of steps. Average step and step characteristics that will be safe and comfortable to use: 15-17 steps 20 cm wide and 2 cm thick, step 18-23 cm.

After determining all of the above parameters, you can proceed to the selection of a folding ladder. The safety and reliability of the product is characterized not only by the material and correctly calculated parameters, but also competent installation systems.

Installation

For safety, the following restrictions should be considered:

- do not use the product for plasterboard floors;

- do not disassemble the constituent elements of the structure during installation;

- do not unscrew the fasteners connecting the ladder and the hatch;

- do not operate the folding ladder until the work is completed.

Installation at home of a ready-made folding ladder system begins in the attic, for this, the kit is raised to the attic. First, the structure is placed with the hatch closed, then the ladder is attached to the open hatch cover in the unfolded state. The system must rest against the floor and be stationary at the time of installation. When the “rough” installation is carried out, it is necessary to check how the system works: open the hatch cover from the room several times, disassemble and assemble the ladder. If no problems with the operation of the installation are found, then the installation continues.

Before starting work, you must carefully read the attached instructions and check the design for serviceability.

First you need to place a box on the basis of the opening and attach it with screws, the gap between the box and the opening is filled with foam. Then the top section is installed. Lay out the ladder and make sure it is stable, it forms a straight line. You can correct by cutting the legs of the last section. Both sides of the structure must fit snugly against the surfaces.

In the finished kit there is a fence for the hatch from the side of the attic. It consists of racks and crossbars. To create a more reliable and rigid structure, the racks are fixed with metal struts. They connect the vertical bars to the floor.

Check the tightness of the hatch. The lid must fit snugly into the opening. With poor tightness, heat will leave the room. Then carried out redecorating the bottom side of the manhole cover. When the installation is completed, you can conduct a control check.

Equipping with modern designs and functions of a folding ladder can be varied. This includes handrails, protective covers, electronic system and remote control. by the most simple option is the construction of a folding wooden system. Wood is the most affordable material that is easy to work with.

Before performing work, a drawing of the designed staircase is created. The height from the floor to the place where the hatch is located is measured, calculations are carried out. The easiest way is to create a sectional staircase that opens up like a book.

In most private houses, attics and attics are operated premises. And to get on ground floor Of course you need a ladder.

Types of attic stairs - device and construction types

Attic stairs can be located both outside and inside the building. The advantage of the second option is ease of use. You don't have to go outside to get to the attic, which is in winter time year is very important. In addition, in the absence of access to the street, the attic does not come into contact with cold air, which significantly reduces heat loss.

By type of construction, the following types of attic stairs are distinguished:

- Monolithic:

- screw;

- marching.

- Folding loft ladders:

- scissor;

- folding or lever;

- telescopic or sliding ladders;

- folding.

- Portable:

- ladders;

- attached.

Portable stairs are usually used as a temporary option for connecting floors. They are used during the construction of a house or to access attic spaces that are rarely used. They are not safe.

The most convenient, of course, are the traditional monolithic stairs, with a wide march and railings. But it is not always possible to place massive structure leading to the attic - there may simply not be enough space.

In this case, retractable attic stairs will be the best option. They are quite convenient and safe, easy to use and take up very little space. A wide variety of designs will allow you to choose the option that suits you.

Folding ladder-transformer

Attic folding stairs are made of wood and metal (aluminum). The combination of these materials gives the best results. A flight of stairs is made of wood to reduce the weight of the structure, and springs, mechanisms and fasteners are made of metal to ensure the rigidity of the product. Of course, there are also purely metal models.

For wooden models, hardwoods should be used. The thickness of the beam must be at least 2 cm. The tree should not be used when the folding ladder is used too intensively, because this leads to rapid wear. In this case, the best option is a metal attic ladder.

Also used plastic fittings, which prevents friction of components during transformation and seals the opening when the product is in the folded state. The manhole cover is filled with polystyrene foam and provides good thermal insulation.

Folding attic stairs can be opened both manually and automatically, using an electric drive. Often, with a manual drive, a load is attached to the mechanism, which greatly facilitates the assembly process, as if tightening the ladder into a niche and, on the contrary, smoothly lowers it, compensating for the weight of the product.

The main requirements for such products are compact dimensions and strength. The aesthetics of the model is also important - a good transformer staircase should merge with the ceiling.

Standard dimensions of attic stairs:

- the width of the stairs. The optimal width is about 65 cm;

- ladder height. It is not recommended to use a product with a height of more than three and a half meters, because then the rigidity of the structure suffers, and a fall from such a height can lead to serious injury. The process of lowering or raising it will also be inconvenient. In this case, you still have to opt for a monolithic staircase;

- number of steps. Usually equal to 14 or 15;

- distance between steps. It is believed that the optimal step width is 19.3 cm. With a larger or smaller value, the stairs will be inconvenient to use;

- the thickness of the steps is in the range from 18 to 22 mm;

- the angle of the stairs. The standard value is considered to be a value from 60 to 75 degrees. With a greater slope, it will be dangerous to use the stairs, with a smaller slope, the product will take up too much space;

- folding attic ladder must withstand a weight of at least 150 kg;

- steps should be parallel to the floor and not slip, or anti-slip pads should be glued to the steps.

When buying folding attic stairs, it is necessary to take into account that the product parameters must match the dimensions of the hatch cover, otherwise, the folding parts will touch the opening. The hatch is considered optimal, in which a sliding ladder 70 cm wide and 120 cm long is built in. With a smaller opening, it is inconvenient to climb. If the dimensions of the hatch are too large, then large heat losses are possible. Since the attic is an unheated room, it is necessary to provide good heat and vapor barrier.

When choosing the angle of inclination of the stairs to the attic, it is important to consider that the smaller the angle, the larger the dimensions need to be. attic hatch and the more space the ladder takes up when unfolded.

Sliding attic stairs - retractable marches to the attic

scissor ladder

As a rule, they are made entirely of metal. They also bear the name "accordion staircase", which has taken root due to the fact that the structure is folded in the form of an accordion. And the transformation mechanism resembles a sliding tram current collector and is shaped like a parallelogram or an oval.

A retractable staircase to the attic has one drawback inherent in cheap models. Due to the fact that the structure is completely made of metal, with poor-quality assembly or over time, the flight of stairs begins to creak. This can be avoided by periodically lubricating the retractable ladder.

Telescopic ladders

The telescopic ladder consists of many retractable sections that fold into one another. Made from aluminum for light weight and rigidity. In the domestic market, a sliding attic ladder is quite rare and is not very popular.

Folding stairs to the attic - sectional and articulated

Folding stairs can consist of two, three or four sections, depending on the design. The first knee has a length equal to the dimensions of the hatch cover, and is rigidly fixed to it. The other two segments open up and form an even flight of stairs. Sectional stairs are so mobile thanks to special hinges and hinges.

Reclining ladder

If you love order, you suffer from lack of space, and you have a second floor or attic, a folding staircase can be a great option to meet all your needs at once. The idea is this: most of the time, the structure is folded and fixed to the wall, and only in the evening, when you need to go up to the bedroom, you put it forward.

The steps are attached to the bowstring with card loops. When folded, the structure is fixed on the wall. The reclining design is not very popular because of its complexity, but later in the article we will still tell you how to do it yourself.

Do-it-yourself attic folding stairs

Option number 1 - a simple design of 2 sections

Do-it-yourself attic stairs are made within 2-3 hours. To make an attic ladder we need:

- hacksaw for woodworking;

- measuring tape;

- stairs, the height of which will be about 30 cm more than the distance to the ceiling;

- four card loops as wide as a kosour;

- two bars, the length of which is equal to the width of the hatch and two more bars, longer than the first, by about 20 cm. The thickness of the bars is 2-3 cm;

- self-tapping screws, anchors, hook and eyelet.

We fasten one of the short bars to the upper end of the ladder with the help of loops, the other is rigidly fixed to the bottom. Two slats are attached to the flight of stairs obliquely so that they do not interfere with movement. They will give the whole structure rigidity.

Next, we measure 2/3 of the length of the stairs and make a neat cut. Then we connect both parts with the help of loops. It is important to attach loops right side so that the ladder folds in the correct direction, as shown in the photo.

The upper bar is fixed to the wall immediately under the hatch. So that the folding ladder to the attic does not open, it is fixed to the wall with a hook. The eyelet is screwed into the kosour next to the cut, and the hook is fixed to the wall.

The disadvantage of this model is that it remains in sight. This can be avoided by using a product of a more complex design, in which the sections are attached to the hatch cover. Let's see if it is possible to make such an attic ladder with your own hands.

Option number 2 - a hatch to the attic with a ladder

We will tell you how to make a ladder to the attic, consisting of 3 sections, which is identical in design to those sold in stores. Here is such a folding attic ladder we should succeed.

How to make a hatch to the attic with your own hands - the basis of a folding ladder

You can make a hatch to the attic from improvised means. First, we will determine the location and size of the opening, and then we will make a hatch. Let's say the size of the stairway is 125 by 70 cm. Then, in order to cut out the hatch, you should add 7-8 mm to these dimensions on each side. These gaps will allow the lid to close easily, but will not affect the thermal insulation.

From the material you will need:

- four bars 50 × 50 mm - two short and two long;

- 10mm plywood sheet (in our case, two panels are used - whole sheet unfortunately not available).

At the ends of the bars we make cuts in half the thickness, coat with glue and fix with self-tapping screws, after checking the diagonals. In order for the diagonal not to go away, you should use temporary scarves made of 4 mm plywood. After, we remove them and already fasten a sheet of 10 mm plywood (the photo shows how the sheet is fixed along the perimeter with PSh screws). Next, try on the opening.

In order for the hatch to close well and there are no locks outside, we cut into the lid door latch. Our packaging said "reinforced". To open the latch, we will use an old handle (you can use any device in the form of a cylinder), which is inserted into a special hole. The latch holds the hatch well, very convenient.

Attic ladder mechanism with hatch - articulated without spring

The turn has come to the most difficult - the opening mechanisms. All components, of course, can be bought in the store, but we will go the hard way and do everything ourselves.

To begin with, let's draw on cardboard a drawing of an attic staircase with an approximate angle at which the hatch should open. Cut out the cardboard parts and try on the design. Thus, you can quite accurately choose the length of the hinges.

I think everyone in the garage will find iron corners, trim strips and pieces sheet metal, in general, everything from which you can make a mechanism for stairs. For one mechanism we need:

- one corner;

- piece of sheet metal;

- two strips of different lengths.

Note the holes for the hinges, the distances of which we previously estimated empirically, and drill under the M10 bolt. Assemble together without tightening the bolts too much. With a small one, we measure the desired opening angle of the hatch and push the future mechanism to the selected angle. We mark on the metal the area that, when opened, overlaps the corner and cut it out with a jigsaw.

We bring the strips of metal into the proper form, cutting off the excess length and rounding the ends. So they will not touch the corner and interfere with each other. We assemble the whole mechanism again. After we removed part of the metal, the corner began to abut and stop in the desired position.

So, one mechanism is ready, now we proceed to the manufacture of the second. It is very important that it turns out exactly the same, but in a mirror version. To do this, we fasten each pair of parts with clamps and drill the necessary holes.

After one hole is cut out, insert a bolt into it and drill the second one.

Then, twisting both parts with bolts, we level them in length.

In this way we make all the parts.

The output should be two completely identical mechanisms.

Now we will install the mechanisms on the hatch and try it on in the stairwell. It turned out that even when designing the unit, we made a mistake - we did not take into account the height of the fastening on the floor beam. That is, the part simply got out of the overlap. Because of what we had to install temporary bars.

We adjust the hatch so that it opens well and does not touch the walls of the opening.

Now let's make another simple mechanism to support the whole structure. We need two strips of metal 20 mm wide and a corner. To do this, we weld a piece of metal to the end of one of the strips, into which the second strip will abut. From the corner we make a support platform.

The result should be a hinge, which, when opening the hatch, remains slightly bent and at the same time holds the load. Subsequently, this node will need to be installed in such a way that it is fully expanded when the mechanisms made earlier are opened to the maximum. Then the load that the hinged ladder creates will be equally distributed between them.

Do-it-yourself wooden staircase on bowstrings

Do-it-yourself staircase to the attic is constructed from wooden planks. We will cut the bowstring and steps from an inch board 100 mm wide. The length of the first section is made according to the size of the hatch, the second is the same or slightly less than the first, but taking into account the fact that it should not touch the ceiling during the transformation process. The third section is equal to the distance that is left to the floor.

We measure the angle of inclination of the hatch in the open position with a small one and transfer it to the board, thereby marking the steps. Next, mark the length of the sections.

Pressing the boards tightly against each other and fastening them with molar tape, we transfer all the markings to the second board (the lines should be in mirror image). Using a pen at 25, we drill a hole where the hinge hinge will subsequently be located.

Now attention, we made the mistake of drilling both holes on the same side, because the second recess should be on the outside of the boards, as noted in the photo.

For more aesthetic appearance grind all the edges with a milling cutter.

On the bowstrings of the stairs we make small recesses (5 mm) for the steps. Using glue and PSh screws, we collect all the details together. It should turn out just like in the photo.

Almost all country houses have attics. To organize a comfortable and safe ascent there, it is necessary to equip a ladder.

It can be made from various materials, but the most common and convenient wooden stairs. Let us consider in detail their types, and tell you how it can be made of wood.

Structures for lifting to the attic can be capital and removable. Their type depends on the available space for installation, ceiling height and frequency of use.

Indeed, often the attic is used as a utility room, and there is no need to install a complex architectural structure. However, even among simple designs there are those that will harmoniously fit into the interior, and will not take up much space.

When choosing a type, you do not need to think about the possibility of moving large objects on it or finding two people at the same time, since both of these situations are unlikely to arise.

Stationary types

All structures, according to the type of attachment to the supporting base, are divided into the following types:

Such designs are two supporting bowstrings, straight or curved shape, between which steps are located in the grooves.

- On stringers.

They are a bit like bowstring systems, but the difference lies in the fact that stringers serve as a support beam. The steps are attached to them from above, so that they seem to lie on supports. Usually one or two stringers are used.

- On the pains.

In this case, the steps on one side are fixed with pins to the wall, or to a wall-mounted carrier beam. Such a system of steps looks very stylish.

- On the support post.

This design has found application in the device of screw types. One, tapered end of the step is fixed on a vertical bearing support, and when properly positioned, all steps form a helical march. A big plus in such a system is that it does not take up much space.

- Combined designs.

Such structures can be manufactured using all of the listed types of fasteners.

Stationary types are the most visually attractive, convenient and safe to use. However, for the installation of capital attic systems, it is not always possible to find a suitable free space.

Portable options

They are quite inconvenient to use for interfloor movements:

- Attached. This is the simplest device for ascent and descent. It can be used as a temporary, bring and take away at any time. Attachments are suitable for a rare visit to this room. Such a device can be left in place, but it will not add any aesthetics to the interior. In addition, the shakiness and instability creates problems with the safety of the person using it.

- Ladder. Everything that has been said about the attached variety can be repeated about this type - with the only difference being that stepladders are a little more convenient and safe to use.

Most often, portable options are used when access to the attic is from the street.

Folding types

Manufacturers offer a wide selection. They consist of 3-4 spans and easily adjust to any ceiling height. However, the price of these structures is quite decent.

Manufacturing

If the question arose about manufacturing, wood is the most suitable material for these purposes. There is no need to buy a ready-made structure, as it is quite simple to make it yourself.

The production process of the attic stairs can be viewed on the video in this article:

Manufacture of a stationary ladder on bowstrings

Do-it-yourself capital construction: stages of work. In the manufacture of the structure, you will need bars for the manufacture of bowstrings, boards for steps, a set of screws and anchors for fastening, varnish or paint for finishing.

Tools needed for work:

Manufacturing instructions:

- A design drawing is being prepared.

- Bowstrings and steps are cut in accordance with the drawing.

- In bowstrings, according to a pre-prepared stencil, grooves are cut to install steps to a depth of 15-20 mm. The accuracy of cutting grooves and maintaining geometry are the most important part of the whole process, because, otherwise, the steps will loosen, and the staircase will quickly become unusable.

- All parts are polished with sandpaper.

- Before assembly, the parts are treated with an antiseptic.

- The grooves are coated with glue. Steps are being installed. For greater reliability with outside they are fixed with self-tapping screws. Hats are better to drown and putty.

- If necessary, you can install balusters and railings.

- Finishing treatment with paints and varnishes.

- The structure is anchored to the supports.

The result is a simple but reliable and secure system.

Production

Requirements for folding structures:

- step width - 65-110 mm;

- the number of steps - no more than 15;

- distance between steps - 16-20 cm;

- thickness of steps - 18-22 mm;

- height - no more than 3.5 m;

- load capacity - not less than 150 kg;

- tilt angle - 60-75 degrees.

Consider how to make it yourself:

Important! In the production of the structure, and especially during its installation, you will definitely need an assistant.

- A drawing is created.

- Details are being prepared. All places of cuts are carefully cleaned.

- Manhole frame is being made. The standard size of the hatch is 120x60 or 120x70, however, you can make it in accordance with the existing opening.

- With the help of bolts and metal inserts, the frame is installed in the opening.

- The manhole cover can be made from 2 sheets of plywood 10 mm thick, laying polyethylene between them for vapor barrier. Can be used furniture board. We mount the handle to the lid.

- The cover is hung on the frame.

- On prepared bowstrings (with inside), which will be used as supports, grooves are made (about 5 mm deep) for installing steps.

- The ends of the support beams are sawn off so that they are stably placed on the floor. It is best to install plastic tips.

- For simplicity, you can use the design, sawn into 3 fragments.

- With self-tapping screws, the crossbars are fixed at times between the bowstrings. For strength, we recommend additionally applying glue to the joints.

- The parts are connected to each other with loops.

- The design of the sections, the corners are attached to the cover (as in the photo).

- Gate valve is installed.

- For more convenient opening of the door, we recommend installing a lever-spring mechanism.

- The entire system is treated with a protective compound.

Important! Before attaching the system to the hatch, check that all elements are functioning properly.

The result is a design that will provide safe access to the attic, and will not take up space in the house.

We examined what wooden attic stairs are, their types, options for use. They gave advice on making a comfortable and functional staircase with their own hands. Now it's up to you!

Do-it-yourself attic stairs: standard dimensions and manufacturing process

The attic is a traditional room in almost every country house. Its functionality is extremely wide. For example, this room is used as a storage room or workshop, some homeowners even decorate the attic as a living room or bedroom. In fact, the functional purpose of such a room depends solely on your own imagination, as well as financial capabilities. However, despite the wide variety of attic space design options, it is worth knowing that an attic staircase with a hatch is an integral part of it. If you do not build this structure, then you simply cannot get into this room. Creating an attic staircase is a fairly simple matter, in connection with which you do not even have to turn to professionals in the construction industry.

Attic stairs must be functional

Attic stairs must be functional

Actually, the most time-consuming process in the organization of the attic space is the design of the stair segment. Before creating a project for a specific staircase for your home, you must first determine the design category. There are such options:

- folding;

- stationary;

- portable.

Approximate diagram of a folding ladder with a hatch

Approximate diagram of a folding ladder with a hatch

Features of various designs

Construction industry experts call a wide marching structure the most reliable in the corresponding segment. It should be noted that its durability, reliability and safety cannot be compared with the constructive counterparts on the market. Meanwhile, despite the large number of advantages of this option, the choice in its favor is sometimes impossible due to the banal lack of the necessary free space. Thus, if you do not have a large area for stairs, then stationary model won't suit you. However, you should not despair, because you can always build a folding ladder. Its design has the best performance from stationary and portable analogues. For example, it is as reliable and safe as a stationary marching model, however, to organize such a design, it is necessary to have a very small amount of free space. In addition, folding models are the easiest to implement without the help of experienced professionals.

Simple two piece staircase

Simple two piece staircase

Temporary solution

Portable models will be singled out in a separate category, however, it is quite extensive. The variety of portable products is simply incredible. Meanwhile, do not forget that the daily use of such a product can never become safe or comfortable enough, and the ladder itself is not able to compete with stationary and folding models in terms of operational and technical characteristics.

Stairs should be comfortable and functional

Stairs should be comfortable and functional

Selection of building materials

In the process of creating an attic staircase with your own hands, namely, its preliminary drawing, you should pay attention to what building materials are commonly used in this case. Despite all the variety of products in the building materials segment, any experienced builder will tell you that there are certain types of products that the best way show themselves during operation. As a rule, all the main structural parts are made mainly of wood, while fasteners and fixing elements are made of metals. Thanks to the competent selection of materials, a do-it-yourself attic staircase, the drawing of which was made by a non-professional, will be an order of magnitude stronger and more reliable.

Folding ladder with hinges

Folding ladder with hinges

How to make your choice?

Due to the fact that building materials for folding stairs to the attic are presented in a variety of price segments, source material and characteristics, drowning in a sea of information about them is quite simple. To minimize the time spent on searching and choosing the best options, you should be guided by a number of rules:

- Specify the type functional purpose design, as well as its main parameters, including design features, sectioning, width, etc.

- Choose building materials in strict accordance with how the product will be actively used and in what conditions.

- Identify the negative factors that can reduce the life of the product.

Another typical scheme of the attic stairs

Another typical scheme of the attic stairs

The main thing is to correctly define the function

Any specialist who has the necessary level of qualification and experience in working with such types of objects will tell you that the final result of construction work on erecting stairs to the attic with your own hands largely depends on the competent definition of the functional purpose of the product. This parameter allows you to calculate the allowable load indicator for each step of the product. The standard value of this indicator for a metal product reads about 250 kgf, but wooden models designed only for 150 kGs. In addition, it is worth considering that the above indicators are valid for products made by professionals, while home-made objects have somewhat lower parameters. In general, the indicator of permissible pressure on a step does not mean that it cannot withstand more stress. However, if the structure is overloaded too often, then it will become unusable in a fairly short period of time.

When opening the hatch, you do not have to make great efforts.

When opening the hatch, you do not have to make great efforts.

So, the main criteria by which the choice of the optimal option is carried out are as follows:

- the area of free space in the room;

- functional purpose of the object;

- desired angle of inclination.

The creation of the drawing must be carried out in accordance with the regulations

The creation of the drawing must be carried out in accordance with the regulations

Stages of work and their features

Actually, experts say that there is nothing particularly difficult in creating a staircase with a hatch with your own hands. It is enough to adhere to certain rules, tested over the years. For example, when drawing up design drawings, one should be guided by regulatory and technical documentation, in which, in addition to general conditions, specific parameters of standard products are also given. In addition, on the Internet, a lot of ready-made schemes for every taste are offered in the public domain. Can be taken ready-made version and proceed with the implementation of the project, or slightly modify it in accordance with individual features Houses.

Tools recommended by experts

Tools recommended by experts

What to consider when designing?

The most general requirements of regulatory and technical documentation can be reduced to a number of simple and understandable conditions:

- the ergonomic range of product width is from 60 to 100 centimeters;

- the best height is three and a half meters;

- the maximum number of steps is 15 pieces;

- the distance between adjacent steps should be about 20 centimeters;

- the step height comfortable for a person reaches about 20 centimeters, a deviation of 2 centimeters is allowed;

- if we are talking about a folding structure, then when creating a project, a permissible load of 15 kilograms is taken.

Tools

Having decided on the independent implementation of construction work, it is very important to stock up on a certain set of equipment so that in the process of implementing the product project, you do not stop due to the banal lack of a screwdriver or tape measure. So, the standard set of tools consists of the following items:

- mounting foam;

- bars;

- self-tapping screws;

- electric screwdriver;

- hacksaw;

- yardstick;

- anchors;

- screwdrivers.

Building a staircase is not a difficult task.

Building a staircase is not a difficult task.

Location features

All the nuances of the location of the object in the room will become visible during the construction process. This is especially true if you are engaged in the creation and subsequent implementation of the project yourself. Remember that the product can in no way reduce the comfort of the room. That is why stairs with a hatch are not located in bedrooms, living rooms and kitchens. However, if necessary, you can diversify your staircase project. interesting design. Thanks to this, the product will be able to harmoniously fit into the overall interior of the room.

Project implementation technology

Following a certain technology, you can quickly and efficiently implement even a complex project. So, if you have chosen metal as the main material, then remember that the following steps are carried out:

- the drawing is applied to sheets of cardboard;

- cardboard elements of the future product are cut out;

- hinge marking is applied on metal strips and special holes are prepared;

- prepared parts are fixed to each other;

- the required angle is measured and the structure is moved apart in accordance with the parameters obtained;

- on metal sheets, markings are applied to those places that will subsequently be covered with corners;

- via special tool elements are cut out;

- aesthetic appearance of the object is given;

- existing corners are rounded;

- workpieces are fastened in pairs.

Before starting work, install a temporary ladder

Before starting work, install a temporary ladder

As you can see, the technology for working on the implementation of the staircase project with your own hands is quite simple. It applies not only to metal objects, but also to wooden products.

In order for the appearance of the attic stairs to be as attractive as possible, do not be too lazy to carry out preparatory work on the surface building material. It's about, for example, about applying a special primer before covering the surface with a coloring matter.

Do not be afraid of difficulties, because the technology for the construction of stairs only at first glance may seem problematic and require experience in the construction industry. Applying the optimal amount of effort will help you achieve maximum results.

Ladders to the attic with their own hands. How to make an attic ladder

There is an attic in any country house. Very often this is an unused room, but in some cases some unnecessary things are stored here or even some kind of room is equipped. In any case, there must be access to it, and for this, stairs to the attic are made. They can be created from wood and metal - in this case, you can make them yourself. Or they can be beautiful forged - such designs are usually created to order.

Primary requirements

Before building an attic staircase, you need to consider several of its features. First, it must be convenient and safe to use. Moreover, these two indicators depend on constructive principle the stairs and the attic. Important role plays an account of the type of stairs, the width of its steps, the height of the rise. The height of the stairs is calculated depending on what its design will be. If it is a folding type, then you need to carefully consider its dimensions when folded.

Steps should be of such dimensions that it is convenient and safe for any person to climb them. The correctness of the design also depends on the location of the steps: the distance between them should not be too small or large. If these requirements are not observed, safety regulations will be violated.

The span of the stairs to the attic must be at least 0.8 m. It is important that the angle of inclination is observed: this must be considered at the design stage of the structure.

Types of stairs: folding or stationary?

The choice between these two types of structures depends on how large the attic area is. Of course, a stationary staircase is more reliable and safe, but it is also solid, that is, it requires a lot of space. That is why many people prefer folding attic stairs: they are convenient, take up little space, due to the fact that they can be folded. Most often, such structures consist of several sections that overlap each other, thereby saving space. Moreover, they can always be adjusted depending on the required size.

Or retractable?

These designs are becoming more and more popular, due to their advantages:

- are cheap;

- easy to mount;

- take up little space due to the design in the form of an accordion;

- reliable;

- mask the structure with an attic hatch.

All these advantages make retractable stairs so popular. How to make it yourself?

Self-assembly of a retractable ladder: the main stages

The very first step should be a thorough analysis and verification of the dimensions of the hatch opening. This is necessary so that the parameters you choose match the dimensions of the stairs. Then the location of the bars is thought out - first at the bottom, then at the top. Special spacers are located between the opening and the stairwell - they will help to better fix the structure. When it is laid, the spacers can be removed.

Or outdoor?

If space does not allow mounting retractable stairs, you can replace them with an external structure. It will provide a connection between the outside world and the interior of your home. The main thing is to remember the safety rules, since the operation of such a design has its own characteristics. During installation outdoor stairs it is important to choose the right material: it must be resistant to sunlight, have increased abrasive wear, reliable and wear-resistant.

Wooden ladder

Wooden stairs to the attic - the easiest option, which you can create with your own hands. This can be done in several ways. Consider the most simple and implemented in practice.

To make an attic staircase, you first need to take measurements: we need parameters for the height of the room, the estimated angle of inclination, which most often reaches 30 degrees, while the height is about 2.5 m. To make the staircase reliable and correct in terms of design, you need to think over and draw up the drawings correctly. The simplest wooden stairs are created on the basis of bars for stringers, bars corresponding to the width of the stairs for fastening, overhead hinges and boards from which we will make steps. Yes, and do not forget about folding suspensions - the hatch cover will be fixed on them. The installation process itself is as follows:

- Steps are installed and securely fastened between the stringers. This is done either with a tenon-groove fastening, or with self-tapping screws, or with glue. It is better to treat the steps with anti-slip pads - they will increase the safety of operation of the structure.

- The ladder is first fastened under the ceiling opening on two bars, which are equal to the width of the ladder. Their connection is carried out by loops.

- We check how efficient the hinges are, after which we finally tighten the fasteners.

This is the easiest way to create stairs to the attic.

This is a more time-consuming way of making stairs, which can be mounted even in a country house. It looks more aesthetically pleasing and has more robust design, which is important in conditions of high load on it. The structure itself will be movable on one side, and the other half will be attached to the wall. To create such a staircase to the attic, we need:

- two boards with a length corresponding to the height of the ceiling and the angle of inclination;

- boards for creating steps with a width of at least 0.5 m and a thickness of about 3 cm;

- bolts, self-tapping screws as fasteners;

- card loops with which the steps will be attached.

It is important to arm yourself with a drawing - it will allow you to perform all the work efficiently and accurately. After determining the angle of inclination, you need to saw off the bars from above and below so that they firmly rest on the floor. The boards along the entire length are divided into equal segments - steps will be located here at a distance that you need. The steps are fastened with card loops, and after the construction is completed, you can make it exquisite by varnishing or painting it.

Metal stairs

Attic stairs made of aluminum look very nice, especially if your country house is decorated in the style of “minimalism” or “hi-tech”. Why is metal good? First, it is more reliable. Secondly, such constructions are processed special formulations which protect the surface from mechanical impact or corrosion. Thirdly, metal structures are able to withstand heavy loads.

Metal stairs are considered the most popular among buyers. retractable type which take up little space. They are relevant for rooms that have small size, that is, where rational use of space is required.

How to do it yourself?

Despite all the complexity technological process, you can make a metal staircase yourself. Moreover, it can be made both from metal and from a combination of materials. To make the simplest metal staircase, we need to prepare:

- welding machine;

- mechanical saw;

- emery wheel, which will remove burrs on the metal;

- a circular saw and a clamp for joining parts if the stairs will have wooden parts;

- metallic profile;

- pipes;

- steel sheets.

Note that the quantity of materials is calculated based on the drawing. We will make strong seams with a welding machine, so the staircase will be a monolithic and durable structure.

Such an aluminum or steel staircase will be built on the basis of a channel (size 8-10). The steps are made of sheet steel, if they are without additional finishing, grating on the steps will be required, which will protect against falling. The railings are made of angle steel, and the tread supports are made of rebar. First, support devices are installed and welded on the beam, then brackets for fastening are welded.

Metal attic stairs can have wooden tread plates, but first you need to consider where the additional fasteners will be located. On metal steps, holes for self-tapping screws should be located at a distance of 15 cm from each other. A plywood substrate is mounted to the metal treads - it is attached to a mounting adhesive, which retains its shape after hardening.

Finished aluminum ladder

Very often, many people prefer to buy ready-made structures, rather than mount them on their own. But even in this case, you will have to work hard, since they are delivered unassembled. How to assemble? The general scheme of work is approximately the following:

- First, a sketch of the future staircase is created.

- 4 identical segments are cut from a metal profile or pipe.

- The pipe is fastened in a vice and carefully cleaned of rust.

- Steps are cut out of a metal sheet - they must be the same length.

- Steps are tried on on a flat surface and adjusted to size.

- The steps are attached to the supports by welding - this is a more reliable option than corners and bolts.

- From below the ladder is finished with rubber heels.

Forged designs: beautiful and modern

Very often, in country houses, rooms with an attic or attic are connected with forged stairs. Moreover, they can be simple screw, or they can have ornate patterns, which allows you to fit them into any room in terms of stylistic orientation. All spiral staircases can be divided into several types:

- in the first version, the staircase is carried out with support on the central pillar and walls;

- in the second - a spiral staircase is removed from the walls and is mounted on a support column with steps;

- in the third case, a staircase with a turn does not have a central pillar, but rests on spirally curved bowstrings;

- the fourth option is a reliable metal staircase, which rests on a pillar made of a monolith based on a steel pipe.

The most convenient are stairs, the span width of which is up to 900 mm with a diameter of the entire ladder construction up to 2200 mm.

What if you buy?

If you don’t feel like doing the installation yourself, you can always buy the same forged stairs, which are quite difficult to mount on your own, and even more so to come up with and make. A large selection of attic stairs is offered by many brands, not only in Russia, but also in other countries of the world. Consider the most popular:

- STANDART ISO PLUS (MINKA, Austria). This folding wooden ladder is made of quality MDF and is designed for a maximum load of 150 kg. There are special protective nozzles on the legs, and with the help of a metal handrail, maximum safety is ensured. This is a compact ladder, the price of which is an average of 8200 rubles.

- The Danish company VELTA offers economy class structures that can be mounted in the attic or in the attic. For 6000 rubles you get a simple staircase, which is compact: it consists of three sections that are conveniently assembled and removed into the ceiling.

- FAKRO stairs are made from winter harvested pine, therefore they are reliable and durable in operation. This company offers a wide range of products that are compact and have a wide price range. The insulated manhole cover is the most important advantage that this ladder has. The price of models starts from 8000 rubles. It is also important that all connections of the structure are reliable and durable, the steps are supplemented with anti-slip grooves, making operation safe and comfortable.

conclusions

Now you know how to make a staircase to the attic with your own hands. Having at hand the most simple materials, you will create a concise but comfortable wooden or aluminum structure.

Do-it-yourself attic stairs with a hatch: drawings and step-by-step master classes with instructions

The staircase to the attic is a simple design that you can easily create yourself. It can be solid - made of wood or metal, or it can have a light and convenient folding shape. What options are suitable for your attic and how to make and install an attic staircase with a hatch with your own hands, read in our material.

Attic ladders? It's in the past!

Access to the attic is almost always located in one of living rooms top floor of the house. Therefore, you either have to sacrifice space and spoil the interior, or use a portable stepladder. The last option is not only troublesome, but also quite risky, since unstable steps can break off, and in order to hold the ladder itself, you often need to invite home help.

We suggest you make a choice in favor of a more reliable option - the design and implementation of a new modern attic staircase. The types and recommendations for creating a solid staircase to the attic with your own hands, which we give below, will help you make your choice.

Attic stairs: overview of options

The main elements of the stairs are the bowstring and kosour (side parts); tread (steps) and riser (for fixed stairs).

I. Capital Steps

If there is enough space in your house, then we advise you to build a stationary staircase to access the attic or attic. This option is reliable, practical and durable. Capital stages can be made on the basis of metal frame or quality wood.

Monolithic stairs can be marching, with one or more bends, and spiral (spiral). Marching options have steps in the form of rectangular plates (boards), which evenly tend upward with the same distance. The spiral staircase is folded around the central base, has steps narrowed to the inner edge and is arranged in a spiral. The latter option is more compact and can be built even in small spaces without sacrificing space.

The "pluses" of the capital option include durability, reliability and comfort in use.

The capital staircase, in most cases, does not provide a hatch for access to the attic, so it is more suitable for houses with a warm roof. For a cold roof, the exit to the attic must be closed with an airtight hatch. The standard dimensions of the hatch are 120x70 cm. It does not make sense to make a smaller passage, as this will make it difficult to get into the attic and install the steps.

The material for the hatch is wood, metal or plastic. You can order a blank for the hatch at the factory of metal-plastic structures with installation or self-assembly. The hatch can be automatic and manual opening. The latter option uses a special pole that opens the latch (lock) and lowers the door with a ladder.

II. Portable ladders

Portable steps - the closest analogue of the "good old" stepladders. Such a ladder will be reliable only if you make a folding version with a platform. However, it is difficult to call such a construction convenient. You will have to make extra efforts to get into the attic hole, and the issue of storing such a ladder will cause a lot of trouble.

III. Folding attic stairs with hatch

A very convenient and easy-to-implement type of attic staircase is folding steps connected to a hatch. Due to the convenience of the design, this type of steps has become the most popular among professional craftsmen.

Today, there are many varieties of folding ladders, among which you can choose the most suitable option (telescopic, scissor, folding, etc.).

The folding mechanism is suitable for any attic with a hatch, on which the ladder structure can be fixed.

- Scissor steps. This type is made of metal. The steps themselves can be wooden. The ladder is a compressible mechanism. When folded, the design takes on a very compact shape and size, so it is perfect for a small attic hatch;

- Telescopic steps. They represent a system drawers(similar to a folding telescope). This option is made of aluminum and also looks very compact on a small attic door;

- Folding (folding) ladders. This type is the most popular, as it is characterized by practicality, durability, economy and ease of installation. Next, we will describe it in more detail.

In general, most stairs schematically look like this:

Before proceeding with the design of the attic stairs, consider some of the standard design features:

- The width of the march for attic steps should not exceed 60-65 cm;

- The height of the entire structure (taking into account the slope) is allowed up to 300 cm. Anything that exceeds this length becomes less stable and less strong. The higher the ladder, the less load it can withstand;

- Based on the recommended length of the stairs, the number of steps is selected - 13-15 pieces, with a distance between them of up to 20 cm;

- The most convenient and safe angle of inclination of the stairs is 60-700 degrees;

- Steps are the direct recipient of the load when lifting, so they must have a dense structure and a thickness of 18 mm or more, and be located strictly parallel to the floor.

The choice of material for the flight of stairs should be determined by the frequency of operation of the structure. Wood wears out faster than metal. So, if you go up to the attic every day, it is better to design stairs made of metal. In other cases, the tree material is light, eco-friendly and easy to install, is very popular.

So, let's get started and create a modern attic staircase with a do-it-yourself hatch according to the drawings that our experts have prepared for you.

Stages of design and installation of a ladder of three sections with a hatch

I. Drawing preparation

At this stage, the design is calculated. The length of the stairs is easy to calculate. We use a simple mathematical formula: D \u003d B /, where α is the selected angle of inclination, B is the height of the ceiling. So, with a ceiling height of 3 m and an angle of inclination of 60 degrees, the length of the stairs will be 3 / 0.867 = 3.46 m. Masters advise adding a few centimeters to the resulting figure, so that later you can more accurately measure and cut off the desired length:

The dimensions of the hatch should be slightly smaller than the opening itself. For calculation, 6-7 mm are left on each side of the door.

We calculate the length of the sections according to the following scheme: the first section is the length of the hatch minus 10%; the second section is the length of the first section minus 10%; third section - the sum of the lengths of the first two sections is subtracted from the total length of the stairs.

Now the calculations need to be transferred to paper and proceed to the preparation of the necessary materials and tools.

II. Choice of materials and tools

To implement the project, you need to prepare carpentry tools: a tape measure, a chisel, a hacksaw, a screwdriver, a welding machine (or capital connections for a metal frame), a square, a hacksaw, clamps, carpentry glue, masking tape, electrodes, carpentry glue.

The main materials that we need: 50x50 mm bars for finishing the hatch (about 4-5 pieces); two boards for a bowstring 100x25 mm long, equal to the chosen length of the stairs; board for steps 100x20 or 100x25 mm; plywood or material with similar characteristics (one standard sheet is enough for the hatch door); plates and corners for opening and loops; nuts, bolts, screws, washers, etc.

III. Hatch door manufacturing

Step I. Prepare the bars for the hatch. At the ends of the bars, make notches-grooves to tightly connect the structure into right triangle using mounting adhesive and fasteners. Protect the corners of the frame with temporary plywood plates so that the rectangle does not lead.

Step II. Attach a sheet of plywood of the appropriate size to the base of the bars. Now you need to try on the hatch to the passage to the attic. It should be 6-7 mm smaller on all sides.

Step III. Provide a lock for the attic door. It can be an automatic mechanism, or the most ordinary latch that can be opened with a pole with a tip.

Step IV. We mount the mechanisms for opening / closing the hatch. If you do not want to buy ready-made mechanisms, you can make them yourself. There should be two fasteners - left and right. For work, purchase a 4x20 mm steel plate and a corner. The photo shows a drawing of the left mounting detail. The right one is mirrored. The sizes are given conditionally. For more accurate calculations, consider your parameters. Before fixing, be sure to check the mechanisms in operation:

IV. We assemble the stairs

You can always order a ready-made sectional ladder from the masters, which you can fix yourself according to the finished scheme. But if you decide to do the work with your own hands to the end, you can assemble a ladder from prepared materials.

Step 1. We mark the places for mounting the steps on the bowstrings. To do this, mark each part with a pencil, according to the selected angle of inclination of the stairs and the calculations made earlier. Now press the ends of the boards tightly together and fasten them with masking tape. It is necessary to drill through holes at the junctions of the sections. Drill a hole for a hinge with a diameter of about 25 mm at the junction of the first and second sections. Next, you need to remove the tape and turn the boards over, fastening them again. Now we drill a similar hole at the junction of the second and third sections:

Step 2. Cut the bowstrings along the marked lines. Next, grooves are made for steps on the inside of the bowstrings using a chisel. The depth of the grooves must be at least 5 mm (this should also be taken into account at the first design stage). The lower section of the bowstring should be beveled according to the angle of the stairs.

Step 3. We cut the steps according to the markup and attach them to the left bowstring. We put the steps on glue and fix them with self-tapping screws. We attach the right bowstring and also fasten it with self-tapping screws.

Step 4. We fasten the loops for sliding mechanism stairs. Hinges, like hinge mechanisms, can be bought at the store, or made independently from metal tape. We need eight strips of metal (you can use the remains of the door mechanisms). Weld small pieces of the same strip to four strips. We drill two holes in each part (for fastening and hinge). We connect the hinge with the hinges. Now we join the cut sections and apply the hinges so that each hinge falls into the groove (25 mm holes drilled before cutting the sections). We fix the loops on the bowstrings:

V. Final Assembly

Now the top of the finished ladder needs to be fixed to the hatch, after checking the operation of the hinge mechanisms. The ladder should also be checked after installation. After making sure that all the details are in good condition and functional, open the steps with varnish:

One more thing step by step guide for installation:

You can insulate and seal the hatch with foam rubber or construction wool. The edges of the hatch should be sheathed with a rubber sealant tape.

That's all, your staircase with a hatch is ready! This is exactly the option that is quite feasible "in one helmet." We wish you fast and easy work.

Ladder to the attic with your own hands

For country cottages, private houses and simple country houses equipped with an attic, the presence of a convenient and reliable staircase leading to the said room is a common vital necessity.

Ladder to the attic with your own hands

At the same time, the staircase should not be capital and bulky at all - you can assemble and install an excellent folding structure that will not be inferior to stationary stairs in any way.

Ladder to the attic with your own hands

You can handle all the related tasks with your own hands, saving money and testing your own strength.

Selecting the type of stairs

There are several types of ladders that can be installed to access the attic.

Stationary

A staircase with wide flights and railings is the most reliable, durable and easy-to-use design. However, the possibility of arranging such a staircase is far from being everywhere - it is definitely not possible to equip it in small areas.

portable

They are mainly used as a temporary option, as well as for access to rarely used rooms. The main disadvantages of such a ladder are low safety and ease of use. Therefore, if possible, the use of such a design should be abandoned.

folding

They are something between portable and stationary ladders. In terms of ease of use and safety, they are almost in no way inferior to full-fledged stationary structures and have, at the same time, a significant advantage - for their arrangement you need very little space. Therefore, when making stairs yourself, it is recommended to give preference to a folding structure.

Material selection

Not less than important point is the choice of materials from which the staircase to the attic will be assembled. For the manufacture of the main elements of folding sectional stairs, wood is usually used, and fasteners are traditionally made of metal.

Nowadays, there are many different materials, types of controls and fasteners, which makes it easy to assemble a folding ladder that will best suit your particular room.

When choosing materials for the manufacture of attic stairs, you need to consider a number of important factors. First of all, decide on the functional purpose of the structure, its type, width, as well as the optimal number of sections.

The functional purpose of the stairs to the attic is very important in terms of determining the maximum allowable load on the steps. So, for example, factory-made wooden stairs are able to withstand an average load of 150 kgf, metal - 250 kgf. For homemade stairs, these figures are slightly reduced.

This does not mean that the steps will not be able to withstand a higher load, but it is definitely not worth loading them regularly, otherwise the structure will break very quickly.

Attic stairs, blueprint

The width of the stairs, at the same time, should not be more than the width of the attic opening.

When choosing the size of the attic stairs, be guided by proven and approved standards.

- march width - at the level of 650-1100 mm;

- height - no more than 350 cm. At more significant values, the ladder noticeably loses in terms of rigidity and overall safety;

- the number of steps is up to 15. In some situations, the number of steps can be increased with the obligatory additional strengthening of the structure;

- the distance between the steps is 15-20 cm, they are usually placed at a distance of about 18-19 cm;

- the thickness of the steps is about 2 cm, it may deviate slightly in both directions;

- the angle of inclination is about 60-80 degrees. To install stairs at a small angle, you need a lot free space, while a large angle reduces the safety of the structure.

- When designing stairs, be sure to consider the expected level of load on the structure.

Remember: the steps must be installed strictly parallel to the floor surface. In addition, the stairs must be non-slip. To do this, you can fill over the base material lining of any non-slip material.

Interfloor opening size

Attic stairs guide

In the independent manufacture of stairs to the attic there is nothing super complicated. Of course, an inexperienced craftsman is unlikely to be able to assemble a structure with the same attractive appearance as factory-made models, but it’s definitely worth a try.

Do-it-yourself attic folding ladder

Before starting work, create a drawing of the future stairs. In the absence of the necessary skills, order the creation of a drawing by a specialist, or select the appropriate scheme from the options presented in open sources.

One of the drawings

Tools

Prepare everything at once necessary fixtures, so as not to be distracted by the search for missing tools in the future.

- hacksaw;

- mounting foam;

- electric screwdriver;

- screwdrivers;

- anchor;

- self-tapping screws;

- bars;

- fastening loops;

- yardstick.

Almost complete set

Markup tools

Also, before starting work, you need to buy or assemble an ordinary ladder. For self-assembly of this design, you only need to fix the transverse steps between two long uprights and further strengthen the structure.

The finished staircase should be about 30 cm longer than the distance from the level of the opening to the attic to the floor.

With the manufacture of the hatch, you can also easily do it yourself. From the materials you will need only sheets of plywood and a wooden beam 5x5 cm.