Sharpening kitchen knives at home to the point of hair cutting is a technique and necessary tools. Knife sharpening

How to sharpen knives with a bar correctly? To answer this question, you need to understand that this tedious task is necessary so that there is always a well-sharpened knife in the kitchen, which is extremely necessary when preparing food.

Damascus steel has long been considered the best for blades.

Correct sharpening cutting edge this item requires the presence of the knife itself made of high-quality steel and a sharpening tool (bar). Along with this, when carrying out the operation, you should be patient.

How to check the sharpness of a kitchen knife?

Even if this item is of high quality (branded), sooner or later it will become dull and it will have to be sharpened again. But before that you need to check how sharp its blade is. How to do it at home?

There are several methods for this. A hemp rope is taken and folded in four. If you manage to cut this "lace" with a knife in one go, then the blade is still sharp.

If you don't have a rope, you can try to trim a hair on your forearm. If this succeeded the first time, then you can continue to use the knife.

If the above methods show that the cutting edge is worn away, then the tool must be sharpened.

Knife steel that is too hard is brittle.

The blade steel usually has a hardness of 45-60 HRC. Too soft metal will bend, and very hard metal will crumble. The angle of sharpening of the blade directly depends on the hardness index - the harder it is, the more the blade should be inclined during turning.

At home, you can check the hardness of the knife in this way: you need to take a file and hold it along the blade. If the tool slides when pressed lightly, and when pressed hard, it scratches the surface of the blade, then the hardness is normal.

Back to the table of contents

How to sharpen knives at home?

To sharpen the blade, you need to choose a quality sharpening tool, and this is a rather complicated matter. There are many tools on the modern market: a variety of grinding stones, musats, abrasive stones, mechanical and electric sharpeners.

The cost of a professional tool is quite high, but you cannot save on it, since a bad bar can ruin the knife blade. Cheap sharpening tools are not worth buying - they do not provide the required level of sharpening of the blade, but only create the illusion of sharpness.

A good, high-quality bar has a rather high price - it can reach several tens of American dollars. Well-established manufacturers of these products offer the buyer professional stones for sharpening blades with different amounts abrasive grains for every cubic millimeter of the tool. This indicator is usually given on the packaging of the bar, but it must be taken into account that in different countries grain setting systems are different, so you must first understand the standards that exist in a particular state.

The combined bar contains abrasives of different sizes.

To make a high-quality sharpening, you need to purchase a set of two bars. The first is for sharpening the blade, and the second is for grinding it. For professional use, it is best to purchase 3-4 bars with different grain sizes.

Russian manufacturers offer the consumer sharpening stones with undefined markings or even completely without them. Therefore, when choosing (especially when you need to keep within the scanty budget), Russian bars have to rely on luck.

You can also use sharpening tools when sharpening - they are needed for dressing the cutting edge without sharpening. Such a tool looks most like a file and is sold at any hardware store. Most often, musat is used to straighten cutting blades used in the kitchen, which are often dull due to constant work. But this can only be done until the knife loses its sharpness. Then only sharpening with a bar will help.

It must always be remembered that to obtain a high-quality cutting edge with a rectangular sharpening stone, it is necessary to spend at least ½ hour. If you need to sharpen a long forged knife or dagger, craftsmen spend more than 25 hours to obtain the ideal blade shape. So patience is the main thing in this work.

Sharpening machines are only suitable for rough sharpening of knives.

Professional abrasive wheel machines and grinding belts can be used. But this requires special skills. If they are not there, then at any attempt to sharpen a knife on them, a person will simply ruin it. At the same time, on such machines, the cutting edge is very sharp and quickly fails.

Mechanical sharpeners are used in everyday life for quick sharpening kitchen knives and scissors. They have a relatively low cost, and even a child can use them. However, the quality of work on this device leaves much to be desired, so hunting blades or daggers cannot be sharpened with it.

Back to the table of contents

How to sharpen a knife correctly?

At the beginning of the process, a coarser block is used. This continues until a burr forms on the edge of the blade, which runs from the edge over the entire surface. After that, they switch to processing the knife blade using a bar with finer grains.

For the correct production of work, you must put grindstone on a stationary surface (most often a table is used for this). This allows you to constantly monitor the entire sharpening process. It is only necessary to place a flat object under the block before starting the operation in order to prevent scratches on the supporting surface. The whetstone itself should be longer than the blade of the knife. The most optimal option when this ratio is 1.5: 1 or 2: 1.

Manual sharpening is the best option for a knife.

Start the first pass with a knife on the grindstone with the cutting side forward, trying to ensure that the direction of movement approaches the perpendicular with respect to the edge. This is necessary to obtain good cutting properties. The blade should be at an angle of 20-24 ° to the surface of the grindstone. It must be kept within these limits when sharpening. To do this, raise the handle of the knife to the point where its blade begins to bend. The angle itself may have a different value, for example, when sharpening cutting blades, this indicator is higher. The main thing is that in the process of work the value of the angle does not go beyond the required limits.

During the movement of the blade along the bar, it must be moved perpendicular to the direction of movement in such a way that, at the moment of reaching the end of the stone, it must simultaneously reach the edge of the knife. In this case, care must be taken that the cutting edge does not break off, otherwise it will be damaged. side surface blades.

The described movements should be repeated many times for both sides of the knife. We must beware of strong pressure on the whetstone - this will not speed up the work, and the processing accuracy will drop. You need to guide the blade along the bar evenly and accurately, without changing the angle; any inaccurate movement can ruin all work. Learning how to sharpen a knife blade properly takes practice.

To do this, you will have to sharpen a lot of blades.

Sometimes sharpening is not needed, you just need to update the edge a little, removing irregularities and lightly grinding, which makes the knife sharper.

This is called revision.

They do it with musats, fine-grained sandpaper or in the old fashioned way, on a leather belt.

In this case, the angle is not set, but the one that already exists is maintained.

But if you need to change or restore the geometry of the corner of the cutting edge, then this is already sharpening.

And if you do not maintain the correct angle, then it will become simply impossible to cut.

A few words about laser sharpening and self-sharpening steel

Some are afraid to sharpen knives at home, as they believe that now workshops offer almost nanotechnology, as a result of which the blade will stay sharp longer. It's about laser sharpening, as you know.

So here: it's a myth and marketing.

Absolutely nothing is sharpened with a laser, the ray just points to the correct angle (just like laser level to define the plane). And an ordinary stone sharpens, therefore, there is nothing special in such a procedure.

Self-sharpening steel - also from the category of fantasy.

Absolutely everything is dull, but the better the alloy, the longer the knife lasts. Therefore, there is no point in throwing money on such knives, it is better to buy a good sharpener for ordinary ones with them.

Which knives cannot be sharpened by yourself?

Let's start with the most important thing: which knives cannot be sharpened?

If you are doing this for the first time, then you cannot sharpen your favorite and convenient knives.

An incorrect sharpening angle can completely ruin the blade, therefore, it is better to experiment on something simpler, so that you can safely throw it away and not be annoyed.

More do not sharpen your own ceramic knives with ordinary bars... Only a diamond takes ceramics, and if you do not have such a bar, then it is better to give the knife to a professional.

But if there is, then you can try sharpening yourself, since the technology of sharpening a ceramic knife is no different from sharpening steel blades.

Damascus steel and damask steel knives- on the contrary, sharpening on a diamond bar is not recommended categorically, as the blade may crumble.

It is better to give it to the master, since grinding off such steel with an ordinary bar is not a task for the faint of heart: a long process.

Same, do not sharpen knives with a wavy edge at home... Moreover, it makes no sense to carry them to the workshop either, since it is simply impossible to return the saw knife to its original properties.

It is easier to buy a new one or to re-sharpen it for a regular one.

How to sharpen? Considering options

There are many tools available for sharpening knives, ranging from electric to ordinary sticks, which are very inexpensive.

Electric sharpeners

Electric sharpeners two big minuses: an expensive price (within 10,000 rubles) and the ability to strongly remove steel when sharpening, which leads to rapid wear of the knife.

On the other hand, the process is fast, fully automated and there is no need to manually maintain the degree of inclination when sharpening.

How to sharpen a knife on a sharpener, as a rule, is written in the instructions that come with the device.

Musat

Musat is a good thing, but sharpening them with a very dull knife will not work as it is mainly intended for editing. And the effect of such sharpening is a couple of days at most.

How to sharpen a knife with musat is shown schematically here:

Roller knife

Not a bad option for women. Just a couple of movements along the rollers and the knife cuts well (but not for long). They are inexpensive and everyone can afford them.

Sandpaper

Sharpeners are skeptical about using sandpaper for this purpose. But the practice of those who use it convinces us that this is a perfectly acceptable option.

This is not to say that he is the most comfortable, but if there is nothing at hand, but you need to sharpen the knife urgently - then it is quite possible to use sandpaper... Moreover, the article is not for masters, but for amateurs.

Sandpaper strips must be fixed on any wooden base (in the form of a bar) with tape. On the one hand - a coarse-grained fraction, on the other - a fine-grained fraction.

Ceramic bar

It's not worth talking about the price here, since they are very cheap. The main thing is to choose it correctly, so that later it would be comfortable to sharpen.

Two bars are needed... One with a coarser surface (320 grit), for basic sharpening and corner correction, and the second for surface grinding (1000 grit).

The stone should be about the same length as the longest knife in the house.

Width - the wider, the more convenient it is to work with it. And you can read how to sharpen knives with a bar below, in a separate block.

Diamond bar

Diamond bars do not cost five kopecks, but the result cannot be compared with an ordinary stone. Working with him is more comfortable, and even more durable..

It consists of a plastic or aluminum base, on which two metal plates are fixed with a sputtering of diamond grains.

Such bars do not grind, like ceramic ones, and even after repeated sharpening, they remain even, rectangular in shape with sharp corners.

In addition to all these advantages, there are more benefits:

- They are not afraid of impact and will not break if accidentally dropped

- The diamond block is not clogged with steel particles. After sharpening, you only need to lightly rinse it under water and wipe it

- The sharpening process on diamond stones is very fast, which means that the stone will serve you for a very long time, since it almost does not grind

- You do not need to purchase two blocks, as they are made in such a way that one side is coarser, and the other is for grinding.

There is one drawback of diamond stones- price. They are not cheaper than 800 rubles, and if there is, then this is clearly a fake, which will become unusable after five sharpenings.

Japanese water stones

The water stone is also a block. But you need to use it not dry, but wet with water.

In the process of friction, a suspension is formed, which, simultaneously with sharpening, polishes the surface.

They are not cheap, but they wear out quickly enough. So, for simple kitchen knives, this is not the best choice.

Sharpening with an abrasive wheel on a drill or machine

Should not be doing that if this is your first time sharpening a knife.

A couple of seconds will be enough to cause irreparable harm. Moreover, in this case, the steel heats up too much and it is imperative to cool it in the process, and if this is not done, the edge may crumble.

How to sharpen knives correctly on a machine is a topic for a separate and extensive article, therefore, here we will not focus on this.

Also, be sure to check out this video, it is very relevant.

Since, in this case, it is better to see once than hear a hundred times!

About the angles of sharpening and methods of fixing the blade

But whichever stone you choose, there is only one sharpening technology. And this is the main thing to learn.

Practice first on the simplest ceramic bar, and when you see what you get, buy something more expensive.

The most important thing in the sharpening process is to restore the original edge angle. For kitchen, household knives, it is usually standard: from 25 to 45 degrees.

Moreover, the lower the degree, the thinner the cutting edge comes out. Yes, the knife will be sharp, but it will also dull much faster, and also lose the shape of the edge, barely touching something hard.

So if you want to sharpen as little as possible, don't make a 25-degree angle.

Too sharp a knife is a rather traumatic thing in everyday life.

It will cut well not only vegetables with meat, but also kitchen towels along with your hands the moment you wipe it.

And here, pay attention to the fact that the angle in the table is full, that is, it is the sum of the two sides of the edge. And if you want to sharpen the knife at 30 degrees, then you need to remove 15 from each side of the blade.

Accordingly, if an angle of 45 degrees is needed, then we remove 22.5 degrees from each side.

It is necessary to keep this angle during the entire sharpening process, trying not to deviate from set value, since the final result depends on this.

Now the question is different: how to fix and calculate this angle by eye?

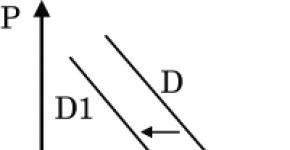

This can be done as shown in the picture:

After you put the paper in, you will roughly know which tilt you need to hold the knife.

Well, now let's move on to the sharpening process itself.

Step-by-step guide to sharpening a knife on a bar

- 1. First thing put the block on the table so that it is convenient for you to sharpen... Can be placed under it kitchen towel to prevent slipping.

It is not necessary to hold the block in your hands, since in this case there can be no question of controlling the angles.

- 2. Moisten it with water... This is necessary for better sliding of steel on stone and further easy cleaning bar from metal particles.

- 3. Place the knife across the bar and start making movements away from you as if you are sharpening a pencil. How exactly it looks, it is best to look at the video that we posted in the last block.

You can't push hard on a stone, this will not speed up the process at all, but it can deform the edge great. Pass 50 times on one side of the bar, trying to maintain the angle all the time.

As soon as you notice that there is a slight roughness on the cutting edge, a so-called burr, turn the knife over and sharpen the other side.

This is what a burr looks like:

Important! If the burr does not form in any way, then continue sharpening. Only this unevenness will show that the steel has been sharpened enough and there is no point in sharpening further.

After you've finished the second side, the burr may go over to it.

In this case, turn the knife the other side again and sharpen. And do this until it completely disappears.

And only after that you can proceed to sanding the edge on a fine stone... It is no longer necessary to move the knife 50 times, 20 times is enough.

And if you want the knife to dull less often, then you can bring the edge to mirror shine using a regular leather belt, which is oiled with GOI paste.

In this case, the movements should not be pointed downwards, but vice versa. That is, you also "plan" the belt, only in the other direction.

We have described the most elementary method that does not require any special costs and accessories. And there is one more, very convenient, but for it you need to build a small machine.

Here is the one as in the photo:

As you can see, there is no need to hold the blade in the process, controlling the degree. The tilted and fixed block does everything for you, and the main task is to keep the knife straight, at 90 degrees.

And this, you see, is much easier than maintaining the level of 22.5 degrees (to be honest, this is an almost impossible task for a beginner, even though everything sounds simple in theory).

Indeed, a deviation by some micron already leads to the fact that the quality of sharpening will not be the best.

How to sharpen a knife in extreme conditions?

And it happens that there is absolutely nothing suitable at hand, and you just need to sharpen the knife urgently.

In this case, the following methods will help you:

- Sharpening a knife on a corner concrete step in the entrance (just wash it thoroughly before that)

- Sharpening a knife on an ordinary stone from the street, which looks more or less even

- Sharpening a knife on a rough edge of a ceramic plate or regular cup

We hope that now you will have an understanding of all the ways how you can sharpen any knife at home without damaging the blade or yourself.

In the kitchen, hunting or in any other business, sharp knives are always needed. With the help of such tools, it is not only easy and pleasant to do something, but also the result is beautiful. There are many mechanical and electrical appliances, with which sharpening knives at home does not present any difficulties. However, all of them, rather, are intended for women.

The real man-owner will definitely use the good old method of manually editing the blade. This process is even more painstaking and longer, but the result will be completely different.

About steel

How high-quality sharpening will turn out will depend not only on skill, grinding materials, but also on steel. Its optimum hardness ranges from 45 to 60 HRC. A knife made of a softer material will have the cutting edge wrinkled easily, and with a harder material it will chip and dull. You can also determine the quality of steel yourself, but this will require a new file. If, with light pressure, it will slide along the edge, and with strong pressure, it will slightly cling, then the hardness of the material is "correct".

Sharpening flat knives

The initial operation is performed with a coarse grain bar. They process the cutting edge of the blade on both sides until a burr appears along its contour - a thin strip of "excess" metal, which is bent in both directions. Then the knife sharpening at home continues with a finer-grained bar. With its help, traces from the impact of the previous donkey are completely removed, not paying attention to the burr. Its removal should be "occupied" by the bar with the finest grain. The burr is grinded from both sides in such a way as to give the cutting edge of the blade an angle of 23 - 45 °. It is this method of sharpening that allows the blade not to dull for quite a long time. Final tweaking the knife is carried out by slate and leather.

As you know, there are no universal knives. Based on this, the sharpening angle of each knife will depend on its purpose. For example, if it is supposed to be used only for slicing cheese, bread, sausages, and the worker - for enough soft materials(leather, paper, etc.), the sharpening angles of these tools can be minimized. If the knife is intended for cutting bony meat or other hard materials, then its sharpening angle should be approximately 30-45 °. It should be noted that the correct sharpening of knives at home for non-professionals can present some difficulties, therefore, it is recommended that novice "sharpeners" use a simple device to form the edge at the desired angle. To make it, you will need from which you need to make a wedge. Its length should be 2.5 times its height. The resulting wedge-shaped device is installed on a touchstone, a knife is pressed against it from above, and then it is necessary to move a wedge with a knife along the blade forward. This method will automatically provide the required edge sharpening angle. In this case, a blade with a wide chamfer will receive a cutting edge at an angle of 25-30 °, and with a narrow one - 30-45 °.

A sharp knife is essential in the kitchen, because it is difficult to imagine cooking without it. Over time, the blade ceases to cope with the task, and then you have to resort to sharpening. There are many ways to sharpen a knife at home. With a competent approach and the choice of a tool for turning, a beginner without special skills can cope with the task.

Knife sharpening angle

Before using a sharpening tool, it is important to determine the sharpening angle. This is the angle of the blade relative to work surface... It depends on the purpose of the knife and on its material. Separation by degrees:

- 10-15 - scalpels, razors;

- 15-20 - a knife for meat, bread and vegetables;

- 20-25 - chef's knives;

- 25-30 - hunting knives.

To choose a sharpening method, it is worth finding out what material the blade is made of. The main blade materials are shown below:

Types of sharpening tools

Manufacturers offer a large selection different instruments to sharpen the blade. However, the choice is not easy, since even the usual grinding stones are available in many versions. In addition to bars, there are machines, sharpeners, musats, and special stones. Each tool requires a different approach. Before dwelling on one of them, it is worth learning how to sharpen knives correctly.

Musat (or simply steel) is often found both in restaurants and in private kitchens. Consists of a handle and a round bar. They use the device either immediately before cooking or immediately after. Suitable for maintaining sharpness, it will not cope with neglected cases.

Musat (or simply steel) is often found both in restaurants and in private kitchens. Consists of a handle and a round bar. They use the device either immediately before cooking or immediately after. Suitable for maintaining sharpness, it will not cope with neglected cases.

It is easy to explain and understand how to sharpen a knife with musat: the device is placed vertically on a hard surface, held by the handle, and the blade is drawn along the steel part. Each side is sharpened 4-5 times with a blade tilt of 20-25 degrees. A special effort do not apply.

We use a whetstone

A sharpening stone is the most common tool, it is made of artificial and natural materials... Most often found in the form of a boat. Sharpening stones vary in grain size. Tool with high degree are used to correct the shape of the cutting edge. A medium tool is used to rebuild the blade. Low grade stones are suitable for sharpening. Whole sets are sold for correct sharpening blades.

A sharpening stone is the most common tool, it is made of artificial and natural materials... Most often found in the form of a boat. Sharpening stones vary in grain size. Tool with high degree are used to correct the shape of the cutting edge. A medium tool is used to rebuild the blade. Low grade stones are suitable for sharpening. Whole sets are sold for correct sharpening blades.

Grinding stone technology:

- Hold the knife in cold water - cold metal more susceptible to handling.

- Drive the blade from the tip to the handle, keeping the required angle. Perform the same number of movements on each side, usually 30-50 is enough.

- Take a fine-grained stone and make 10-15 similar movements.

- Instead of a fine-grained surface, you can use a leather stone with an abrasive paste applied or a well-sharpened object.

We use a bar for sharpening

The bar is similar to a whetstone in terms of properties and sharpening technology. The best option a diamond-coated bar is considered. There are also tools with silicon carbide and electrocorundum spraying. Information about abrasiveness in foreign-made bars is encrypted in the marking. Bars domestic production are selected "by eye", you can assess the degree of abrasiveness by touch or by running your fingernail over them.

The bar is similar to a whetstone in terms of properties and sharpening technology. The best option a diamond-coated bar is considered. There are also tools with silicon carbide and electrocorundum spraying. Information about abrasiveness in foreign-made bars is encrypted in the marking. Bars domestic production are selected "by eye", you can assess the degree of abrasiveness by touch or by running your fingernail over them.

Watch the video on how to sharpen a knife with a bar correctly:

Grinder

The sharpening machine is a fast and efficient tool. It is less common in apartments, often found in private sector residents or in workshops. When sharpening the blades on the machine, they heat up to high temperatures, so it is better to set the minimum speed of the machine.

The sharpening machine is a fast and efficient tool. It is less common in apartments, often found in private sector residents or in workshops. When sharpening the blades on the machine, they heat up to high temperatures, so it is better to set the minimum speed of the machine.

Sharpening takes place with an emery wheel. The blade is pressed against the emery at a certain angle, keeping it constant. The smaller the angle, the thinner the blade will be. If you work carelessly, you can break the knife, so beginners need to learn from inexpensive models.

Mechanical sharpeners

Used in everyday life. Convenient due to the presence of a handle and the absence of requirements for special skills of the grinder. However, the quality of sharpening is poor, suitable for sharpening kitchen knives, it is not recommended to sharpen sports and hunting specimens on them - there is a high risk of damage.

Electric sharpeners

Electric sharpeners used to be found only in restaurants, now they are more available for private use. They set the sharpening program themselves, they are suitable not only for knives, but also for screwdrivers, scissors, etc. Cope with neglected cases.

Electric sharpeners used to be found only in restaurants, now they are more available for private use. They set the sharpening program themselves, they are suitable not only for knives, but also for screwdrivers, scissors, etc. Cope with neglected cases.

The principle of operation is simple: select a mode, bring the blade to the opening of the device, place it inside and press lightly during processing. The electric sharpener will quickly cut the blade with diamond discs.

The advantage of the device is that it can sharpen knives with ceramic blades - it copes well with fragile material.

Knives requiring special sharpening

There are types that you shouldn't even think about, how to sharpen a knife at home. Incorrect machining, there is a high risk of damage to the tool.

- Serrated- knives with a serrated blade, resembling an outwardly saw. Factory sharpening of serreters and semi-serreters is asymmetrical, so processing at home will ruin them. It is worth contacting a professional.

- Unique coated knives... For example, the TwinStar Plus Zwilling J. A. Henckels. The manufacturer has coated the blade with a unique compound that increases the wear resistance of the knife.

- Opinions on the need for sharpening ceramics vary.... Someone says that ceramics does not require sharpening, someone claims that over time, ceramic blades become dull. Manufacturers claim that the hardness of the material is second only to diamond and corundum.

If the knife is under warranty, then you should contact the company workshop and sharpen it for free. You can use diamond-coated wheels. For roughing, wheels with a characteristic of 80 microns are used, for finishing - 40 microns. The machine turns are set to the minimum, each side needs to be processed 2-3 times. The direction of movement is traditional - from the handle to the tip.

After sharpening in any way, be sure to wash the knife with soap under running water, since small particles of chips, grease, oil remain on the blade.

After processing, the sharpness of the blade should be checked. If the result is unsatisfactory, it is worth repeating the procedure or choosing another method:

Cost of basic tools

All sharpening tools are sold at hardware stores. You can purchase them online. German, Japanese and Russian devices are considered to be of the highest quality. The cost depends on the characteristics and the manufacturer. What price can you expect:

- Stones - 80-200 rubles.

- Diamond-coated bars - 450-10,000 rubles.

- Musat - 500-3000 rubles.

- Electric sharpeners - 700-10,000 rubles.

- Grinding machines - 2,000-20,000 rubles.

It is good if there is a planned sharpening, when the tools are at hand. But force majeure circumstances happen when there are no professional devices at hand. Simple items will help out:

- Cobblestone... An ordinary stone will help slightly sharpen the knife in field conditions... Perfect sharpness will not work, but the blade will come into working condition. The technology is similar to the bar sharpening technology.

- Second knife... Two objects can be sharpened at the same time by picking them up and running the blade of one of them over the blade of the other. Processing time 5-10 minutes.

- Glass and ceramics... You can sharpen the blade on the bottom of a plate or the edge of a tile. The main condition is surface roughness.

- Leather belt... Suitable for finishing sharpness. It is necessary to tighten the belt and actively run both sides over the skin several times.

Attention, only TODAY!

Any knife made of the finest steel or ceramic will dull over time when used. This makes it harder for the hostess to prepare food, increasing the time and effort spent, sometimes a blunt knife slips and injures.

To avoid situations like this, you can use simple devices providing instant blade dressing for constant sharpness. Also, sharpening kitchen knives should be repeated periodically - this can be done at home using the simplest tools.

Having mastered the technique, you will not only please the hostess on March 8 and on other days, but you can also greatly surprise the guests (if there is nothing else) by demonstrating a knife at the table that can cut hair. This is the degree of sharpness of a kitchen knife that can be achieved if you know how to properly sharpen a knife using simple inexpensive tools.

Sharpening a knife correctly is not the most difficult thing, the main thing is to listen to the recommendations

What knives can be sharpened

All types of kitchen knives can be sharpened - primarily it depends on the equipment. Professional electric sharpening machines sharpen European, Japanese (one-sided), serrated (wavy surface), cutting, hunting, tourist, ceramic knives with any sharpening angle.

You can effectively sharpen a knife at home if you have simple sharpening stones and follow the technology to the degree of hair cutting, which is more than enough when used in the kitchen.

Unfortunately, not all knives lend themselves well to sharpening.

Some types of knives are made by modern technologies with a coating of the cutting edge with a special wear-resistant compound that provides a self-sharpening effect. Sharpening kitchen knives of this type erases the special coating and the knife loses its advantages - of course, such models cannot be sharpened.

Blade sharpening angle

Knife sharpening angle - the deviation between the line of symmetry of the blade and the plane of its cutting edge.

The sharpness of the blade and its durability depend on this value: the smaller the sharpening angle, the sharper the blade, but it grinds down faster.

A larger knife sharpening angle reduces the sharpness of the cutting edge, but increases the duration of its work.

Kitchen types for everyday cutting of products have sharpening angles from 20 to 30 degrees, ultra-sharp medical scalpels sharpen at an angle of 10 - 17 degrees, hunting knives, kitchen household hatchets for chopping meat with bones and cleavers have a sharpening angle of 25 - 35 degrees.

To know at what angle to sharpen any knife, the blade is inserted into the scissors and the blades are compressed so that their tip is in close contact with the cutting edge of the knife. The angle at which the scissor blades will be pulled apart is the sharpening angle.

Musat

Musat is a device with a handle and a rod 20-25 cm long, reminiscent of a round or oval faceted file made of diamond-coated metal, hard steel or ceramics. The surface of the metal rod along the axis is covered with small grooves, the structure of ceramics is less relief.

Musat is used for regular daily lapping and grinding of the working edge of knives, allows you to maintain the sharpness of their cutting edges in a sharp state.

Musat is not suitable for all types of knives, only for models with a certain steel hardness

The main condition for the use of musat is the competent manufacture of cutting edges and the hardness of the knife steel is less than 60 units. Musat allows you to straighten out smoothing or bending of the cutting edge on hard surfaces.

Work rules

For inexperienced homeowners, sharpening on musat looks like this:

- Musat is taken in left hand and rests with a sharp end on wooden surface at an angle of 25-30 degrees.

- Knife in right hand moves from top to bottom in an arc towards the descent, the movements are repeated with little effort several times on each side of the blade.

- At the final stage of finishing, the effort is reduced, after work, the musat is washed with water and hung for drying on the hook of the handle.

The generally accepted method of checking the quality of sharpening is to cut a sheet of paper - if you can draw curvy lines on it or cut off thin strips, then the sharpness of the blade is very high. The razor sharpness test can be done on the hairline of the hand - the sharpened blade cuts hair easily.

Sharpening stones

When deciding how to sharpen a knife, many primarily consider sharpening stones with varying degrees abrasiveness. Modern bars have two sides - when using abrasive stones, the side with a coarse-grained structure is used at the beginning, at the end of sharpening they go to the fine grain of the other side.

The sharpening stone is classic version for standard kitchen knives

Sharpening rules

Before and during work, the bars are moistened with water or soapy water - this is necessary to clean the pores of the bar from metal dust and its surface from the spent suspension, improving the sliding of the blade (many modern species do not require pretreatment with water). Knowing how to sharpen a kitchen knife will help the rules of work described in the instructions for the bar.

- We moisten the stone with water, add a drop of dishwashing liquid on top.

- We install the block on a flat surface, preferably with a slight relief (not a planed board) for better grip.

- We apply the knife to the surface of the stone at the desired angle.

To set the angle, you can use a regular sheet of paper folded several times, in this case, you can get the final sharpening angle for the blade of 22.5 degrees (obtained by folding the sheet 90 degrees twice). We apply a sheet of paper with the obtained angle and a knife to the bar, we try to remember the resulting slope.

- We install the knife at the beginning and across the bar, while the end of its handle should be at the very edge of the bar, and with a little effort, slide the blade along the bar in an arc in the direction of cutting. For a more stable fixation of the sharpening angle, you can support the blade with your other hand. The movement is repeated 40-50 times, then the side and direction of movement are changed.

- When a burr edge appears along the entire length of the blade, stop sharpening on the coarse-grained side of the bar and switch to the fine-grain side. The sharpening operation is repeated, at the end the pressure on the blade is reduced.

- After processing the knife on a coarse-grained bar, it is possible to fine-tune it on musat.

- At the end of the work, the bars are washed under running water.

If you wish, you can get razor sharpness knife. For this operation are used Genuine Leather(fragment of a leather belt) and abrasive paste (GOI, Dialux). The paste is applied to the belt and a knife is repeatedly passed through it at the desired angle, while the movement is opposite to the cutting direction.

Sandpaper

Sandpaper is the most economical option for keeping the knife sharp

The sharpening process using sandpaper is no different from sharpening stones. You can even make an impromptu bar out of it by gluing or tying sandpaper To wooden beams: coarse-grained sandpaper is fixed on one side, fine sandpaper on the other.

Mechanical sharpener

Similar sharpeners, the most convenient way sharpen a knife at home

Standard design a mechanical type sharpener for kitchen knives is an elongated body consisting of a handle for holding and several slots with sharpening discs for blades of varying degrees of sharpening. The sharpening angle when using it is constant and optimal for frequently used kitchen knives.

Another option for a manual mechanical sharpener is a roller knife sharpener, which has only one groove in the body for sharpening with mechanical rollers.

Sharpening set

The main task when sharpening and dressing knives is setting the exact angle. To accomplish this task, a wide range of mechanical designs of grinding devices have been developed.

Some models consist of a base and a knife blade fastener, the sharpening stone is attached to the guide bar. When working, it moves along the blade at a set angle, then the knife turns over. The set is equipped with uneven-grain bars - this allows you to straighten the geometry of the blade and its polishing.

The sharpening set contains disassembled components for sharpening the knife. This set is quite compact.

Another type of a sharpening machine is a bed with a holder, into which sharpening stones are inserted vertically at a sharpening angle, the knife moves in a strictly vertical plane during operation, sliding along the surface of the bar from top to bottom.

The designs of such devices are quite diverse and simple, everyone can make such a device from improvised means with minimal set necessary tools at home.

Electric sharpener

Most quick way sharpening - electric sharpeners for sharpening and polishing. Structurally, they are made in a closed case with a slot for inserting knives; inside there is an electric motor, on the axis of which conical abrasive wheels with diamond dusting are fixed. This method not very popular in everyday life due to the high cost of devices and is intended for professional work.

The electric sharpener will do all the work for you. You just have to hold the knife correctly at the right angle.

High-quality models of electric sharpeners usually have two types of abrasive wheels - the first for restoring the geometry of the blade, the second for its final polishing, the sharpening angle in such devices can be adjusted or set automatically.

Some models electrical devices allow you to sharpen kitchen knives different types: European, serrated, Japanese, ceramic, and also scissors. In electric machines, each side has its own groove.

Work rules

- With a very blunt working edge with serrations, the knife is processed on coarse-grained emery. It is inserted into the groove and stretches towards itself, the number of repetitions depends on the degree of dullness of the cutting edge.

- After visual or contact checking for sharpness, the knife is inserted into the polishing groove and the process is repeated. To obtain a high sharpness of the blade, 5 to 10 broaches are usually required.

Grinder

The sharpening machine is professional option, with it you can sharpen a dozen knives in a short period of time

Many homeowners have a grinding machine at their disposal - an electric motor with an abrasive grinding wheel mounted on a shaft, sometimes the machine has an adjustable speed.

Abrasive wheels are often used to sharpen knives, but improper use (strong pressure and high speed) can easily overheat the steel and damage the blade. To sharpen on a grinder, you need to know the following rules.