Chain-link on wooden posts. Do-it-yourself chain-link fence

In order to fence off their property in a summer cottage or in the private sector, they use a fence. The construction of such a structure requires additional investment of money and time. To save money, you can make your own fencing. A chain-link fence is perfect for this.

What is a chain-link mesh

This grid was invented in the 19th century by the German mason Karl Rabitz. Initially it was used to facilitate plastering of walls. Over time, it has found application in many industries, ranging from the construction of barriers or cages for animals and birds, and ending with the construction of supports for mining openings in mines.

In production, low-carbon steel wire and other types are used: stainless, aluminum, galvanized or coated with polymers. To obtain a chain-link mesh, a special simple machine is used that screws the wire spiral into each other, and the finished product is wound into rolls.

Advantages and disadvantages of chain-link mesh for building a fence

Advantages:

- It allows air and sunlight to pass through, so it does not interfere with the cultivation of cultivated plants.

- Quick and uncomplicated installation, accessible to every person who is more or less familiar with hand-held construction tools.

- Since the fence structure is lightweight, a reinforced foundation is not required.

- A chain-link fence does not require special care.

- Strong, reliable, inexpensive and durable material.

Flaws:

- A chain-link fence will not hide your site or house from prying eyes, but this problem can also be solved by decorating the fence with plants.

- Does not provide sound insulation.

- Fencing made of non-galvanized mesh quickly rusts.

Types of fence mesh

Non-galvanized

This mesh is made from “black” wire that is not protected from corrosion. It is the cheapest option among all other types and requires additional processing to ensure the durability of the structure. It is used as a temporary barrier and needs painting to increase its service life. The service life of unpainted fabric is 2–3 years, but if the ungalvanized mesh is coated with paint, this will increase the service life to 10 years.

Galvanized

This type of mesh is also made of low-carbon steel, but has a protective layer in the form of a zinc coating. Thanks to this, galvanized mesh is protected from rust and will last for many years without additional treatment or maintenance.

Plasticized

If a polymer is used as a protective layer, then such a mesh is called plasticized. Since dyes are used in its production, it exists in different color shades and looks much more attractive than its relatives. This type of material does not require additional processing and is not afraid of various weather conditions, and a wide color spectrum will provide design solutions when building a fence.

Preparing for the construction of a fence, calculating the area

In order to calculate the area for the fence, you first need to know the perimeter of the site. For example, let’s take a square-shaped plot of 10 acres. Since the length of the square is equal to the width (a) and has right angles, we calculate the perimeter using the formula P = 4 x a. Since the area of the site is known (1000 m2), and the formula for the area of a square is S = a2, then a = 31.63 m, so the perimeter P = 126.52 m. Now you can easily calculate how much materials will be needed. For example, chain-link mesh is sold in rolls of 10 m, so you will need 12 whole rolls plus a 6.5 m section.

The chain-link mesh also differs in the size and shape of the cells, which can be in the form of a rectangle, rhombus, square or other geometric figure. When building a fence, the shape of the cells does not affect the result of the work in any way, and its dimensions have some meaning. It is important to remember that the smaller the cell size, the stronger the fabric, but such a mesh does not transmit light well. Big size segment also has disadvantages, since it will not provide the necessary protection from small animals and poultry. To build a fence, use a mesh with cell sizes from 40 to 50 mm. This version of the canvas will protect the area from unwanted penetration and let in enough light for plants.

Also of considerable importance is the height of the canvas and the thickness of the wire from which it is made. As for the height, it starts from 1.5 m and reaches 3 m. Optimal height the fence fabric is 1.5 m, and a mesh with a wire thickness of 2–2.5 mm is best suited.

If the thickness is greater, this will lead to some difficulties. Firstly, the canvas will cost more, and secondly, this will affect the choice of material for support pillars, since the weight of the mesh will increase and installation will become more difficult.

Calculation of the required quantity

Chain-link mesh is sold in rolls, the standard length of which is 10 m. To prevent it from sagging, supports are installed along the fence line every 2–2.5 m. Therefore, for one roll you will need 5 posts. The part of the support that is above the ground after installation should be 10 cm higher than the width of the mesh. The posts themselves need to be buried in the ground to one third of their height.

Based on this, we can calculate how many pillars and how long the mesh we will need. For example, we are building a fence 30 m long, the height of which should be 1.5 m. This will require 3 rolls of mesh and 16 supports, the length of which will be in the range of 2.3–2.5 m. In addition, each support is equipped with three hooks for fastening (top, bottom and middle) 48 pcs. You will also need a steel rod or reinforcement 5 mm thick in order to tension the mesh. Since it will pass above and below the grid, a total of 60 m will be required.

To calculate required amount concrete to fill one hole with a support column, you need to find out its volume and subtract the volume of that part of the column that is buried in the ground. Since the holes and columns have the shape of a cylinder, we make calculations using the formula:

- Number ∏ = 3.14.

- R is the radius of the cylinder (hole) in meters.

- H is the height of the cylinder (depth of the hole) in meters.

The diameter of the hole is 12 cm (0.12 m), and the radius is 0.12 /2 = 0.06 m. Depth (H) is 80 cm or 0.8 m.

Substitute the data into the formula:

V = 3.14*0.06*2*0.8 = 0.30144 m3 (hole volume)

For the posts we will use metal pipes with a diameter of 80 mm. The radius (R) of such a column is 40 mm or 0.04 m. The height (H) is the same as the depth of the hole - 0.8 m.

We use the same formula:

V = 3.14*0.04*2*0.8 = 0.20096 m3 (volume of the poured part of the support)

Now let’s find out how much solution is needed to install one column in the hole:

0.30144–0.20096 = 0.10048 m3

Accordingly, for 16 holes you will need: 0.10048*16 = 1.60768 m 3 of concrete.

We prepare the batch based on the proportions: 1 part cement (M 400), 2 parts sand, 4 parts crushed stone. Water is added until the mixture reaches the state of sour cream.

To get 1.6 m 3 of concrete you will need:

- Cement (M 400) – 480 kg.

- Crushed stone - 1920 kg.

- Sand - 960 kg.

Calculation of materials for fencing from sections

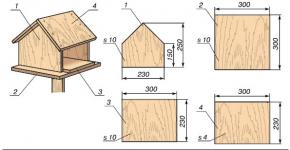

If the fence is built in sections, then you also need to calculate the number of metal corners for each frame in which the mesh is attached. It is better to use a metal corner 40 by 40 mm, with a wall thickness of 5 mm. We calculate its quantity per section: the height of the frame is the same as the height of the mesh (1.5 m), and the distance between the posts is 2–2.5 m.

Having made simple calculations, we see that each section will require 8 m of metal corner. There are 16 sections in total, so the total length of the corner is 128 m. The mesh is attached to a frame of corners using 5–7 mm reinforcement; for such a fence you will need 128 m. To install the finished sections, use metal plates measuring 5 x 15 cm and a thickness of 5 mm, 4 pcs. for internal pillars and 2 pcs. for the extreme ones, total - 60 pcs.

Tools and materials for work

- hand drill or shovel;

- tape measure, building level;

- primer for metal;

- dye;

- metal hooks;

- Rabitz;

- metal pipe with a diameter of 60 to 80 mm;

- sandpaper;

- Bulgarian;

- welding machine;

- metal corner 40×40 mm;

- sand, crushed stone and cement for mortar;

- metal plates (5×15 cm, thickness - 5 mm).

Step-by-step instructions for making a fence with your own hands

Marking the area

We clear the area for erecting the fence from debris, plants and other possible obstacles. We determine the points where the pillars will be located and begin marking the territory. To do this, you need to hammer pegs into the extreme places of the fence and stretch a nylon cord between them.

You need to tighten the cord so that it does not sag or dangle from the wind. Make sure that the tensioned thread does not catch on possible obstacles. Take into account the cross-section of the support pillars, taking into account the fact that they will be located inside the site, and the grid will be located on the side of the street or neighboring territory.

A stretched nylon cord acts as a beacon not only during marking of the area, but throughout the entire construction site. It will ensure linearity and control of the height of the fence along the entire perimeter. After this, we mark the places for the intermediate posts; the distance between them should be within 2.5–3 m.

Installation of posts

After all the materials, tools have been prepared and the area has been marked, they begin to install the pillars. Using pre-made marks, holes with a depth of 80 to 120 cm are made using a shovel or drill. The softer the soil, the deeper the holes should be and vice versa.

Since we will use metal pipes as pillars, before installation they need to be cleaned of rust and oil deposits, and then sanded using sandpaper. Using a welding machine, weld the hooks for attaching the mesh, clean the welded areas with a grinder and prime the entire surface of the post with an anti-corrosion primer.

Next, we install the supports in the holes, level them and secure them in this position with spacers. Make sure all posts are at the same height and in a straight line. If this is not the case, then by adjusting the depth and width of the holes, achieve the desired result. After this, you can safely pour concrete mortar into the holes. It is recommended to start installing the mesh no earlier than 48 hours after the concrete mixture has completely hardened.

Mesh installation

For installation, do not unwind the mesh completely; it will be much more convenient to place a whole roll in a vertical position on the corner post and hook the edges of the mesh onto the prepared hooks.

When attaching the canvas, lift it above the ground by 10–15 cm. This is necessary in order to avoid grass, branches and other debris getting tangled in the mesh in the future.

Next, we unwind the roll, stretch the mesh well and fasten it in the same way to the adjacent post. The work is best done with a partner: one can stretch the fabric, and the other can fasten it with hooks. Carry out this procedure along the entire perimeter of the fence. To prevent the mesh from sagging over time, insert a steel rod or reinforcement into the upper cells at a distance of 5–7 cm from the edge along the entire length of the fence and weld it to each post. From below, do the same, only step back 20 cm from the bottom edge of the mesh.

Manufacturing a sectional fence

Mark the area and install the pillars in the same way as in the previous case, only instead of hooks, metal plates are welded onto the pillars, departing 20 cm from the upper and lower edges. To make a section, you need to measure the distance between adjacent supports and subtract 15–20 from it cm, so we find out the width of the frame. The height will be the same as the width of the mesh minus 20 cm. Next, cut the blanks from the corner of the required length and weld them into a rectangle. Using a grinder, clean the weld areas and grind the internal and outside frames with sandpaper.

After this, the roll is unwound and the required length of the mesh is cut off with a grinder (the distance between the supports is minus 15 cm). Next, along the entire perimeter of the cut fabric, reinforcement 5–7 mm thick is threaded into the outer cells.

The welded frame is placed on a flat surface inside up and place the prepared mesh with reinforcement in it, then weld the upper rod to the upper corner of the frame. Next, tighten the lower side and attach the reinforcement to the corner using welding. The sides are installed in the same way.

After this, the finished section is placed between the supports and attached to pre-prepared metal plates by welding.

When further installing the remaining sections, pay attention to the edges of adjacent frames; they should be at the same level. For convenience, use a level or a tight cord. After installation is complete, all frames must be primed and painted.

Finishing and decoration

In most cases, a chain-link fence is not decorated, but left as is. If you decide to build an original structure, then there is no limit to your imagination in this matter. Here are some options on how you can decorate your fence.

- You can use CDs for decoration. First they are painted, and then attached to the mesh with thin wire.

- If the cells are small, then bottle caps are used for decoration. The mounting method remains the same as in the previous version.

- What is not a decorative material: masking tape.

- If you decorate the fence with colored squares made of glass or plastic, it will look very beautiful and original.

- You can also decorate your fence with embroidery on the mesh cells using colored threads.

- Colored patches or bags for cross stitch will help add originality. To do this, find a suitable picture in a magazine or on the Internet with a ready-made scheme of work, place it in front of you and repeat the drawing in cells in accordance with the original.

Closing ourselves from our neighbors' eyes

The disadvantage of a chain-link fence is that it does not protect the area from prying eyes. In order to correct these omissions, some more effort needs to be made.

One way to close the fence is hedge. Climbing plants are most often used, but it may take several years for them to fill all sections. The way out may be to drop off annual plants, for example, morning glory. Over the course of a season, it will cover not only the fence mesh, but also nearby standing trees and bushes. The disadvantage of such a barrier is that it will only serve until autumn.

Another way to make your fence opaque is to use artificial pine needles. Since it is sold in the form of coils of wire, it will be enough to simply thread it between the cells.

A very original method of closing a fence is reeds. Just like in the previous case, it must be threaded vertically through the meshes of the chain-link.

To make the fence closed and look more modern, polycarbonate is often used. It comes in different transparency and many color shades. Attaches directly to fence posts using self-tapping screws.

If the distances between the supports are greater than the width of the polycarbonate sheet, then you need to install additional metal profiles between them and attach the sheet to them, otherwise the sheets may crack under gusts of wind.

Video: Installing a chain-link mesh on a summer cottage

As you can see, making a chain-link fence is not so difficult. Like other similar structures, it has advantages and disadvantages. It's important to remember that this a budget option, which is often erected as a temporary fencing option. Although, as practice shows, if the installation is done correctly, it will last for many years. In addition, if you show imagination and creativity, such a fence will delight its owner not only with its practicality, but also with its aesthetic, original appearance.

Fence - required element any private property. If country houses Experts recommend fencing with more reliable protective structures, then summer cottages - with practical and inexpensive options. Most suitable material for a country fence - chain-link mesh. With its help, you can not only make a durable one, but also increase the productivity of the beds, since the design does not interfere natural ventilation on plot of land, and also does not block the sun's access to it. To build a chain-link fence with your own hands, you don’t need to be a professional. This article will reveal all the secrets of craftsmen in installing a practical fence without welding, and will also tell you what tools and materials you need to have to perform such work.

Features of chain-link mesh, its advantages

Rabitz - universal material, which is indispensable in summer cottages. It has many advantages that make it even more popular among buyers. These include:

- affordable price. Chain-link mesh is a budget option for building a fence, because not every homeowner is able to allocate a decent amount of money to install a more expensive structure at their dacha;

- long service life. High-quality galvanized mesh is capable of maintaining its original appearance for several decades (up to 40-50 years). It does not rust when correct operation not deformed.

- the need to use a minimum number of tools and fastening materials during the installation of the fence;

Important! You can install a chain-link fence using either welding or without it. Installation without welding is ideal for people who do not know how to work with such equipment.

- ease of care of the material;

- the mesh does not interfere natural circulation air, does not shade the area.

Important! A chain-link fence serves as an ideal fencing not only for beds, flower beds or vegetable gardens, it is also indispensable in the process of arranging children's rooms. playgrounds, enclosures for pets, etc.

Material classification

Depending on the material of manufacture, chain-link mesh comes in three types:

- Non-galvanized.

- Galvanized.

- Plasticized.

Non-galvanized mesh is enough cheap material. Of course, it is more affordable, but its long service life can be doubted, since under the influence of moisture the surface very quickly becomes covered with rust.

Galvanized mesh is the most popular among customers. It is a little more expensive than its non-galvanized counterpart and does not rust, which is really very valuable.

Plasticized material is a modern option, but more expensive. In the manufacturing process, polymers are used that properly protect the metal mesh from moisture. Plasticized mesh has different color scheme. Each homeowner is able to choose a material that will ideally suit the interior of the house, as well as complement it.

Instructions for craftsmen: how to make a simple chain-link fence without welding with your own hands

Making a durable and reliable fence from a chain-link mesh is a fairly simple and interesting task. Its implementation does not require a large amount of professional knowledge and skills. To work, you only need tools and materials, as well as the desire of the master.

There are two ways to make a galvanized fence from chain-link mesh:

- Using a welding machine.

- No welding.

Since not every homeowner has a welding machine at his disposal (or does not know how to use it), we will consider the option of installing a fence without using it.

Important! Installing a fence without welding will allow you to build a structure that will be less practical than its welded counterpart.

Tools and materials

To ensure that the construction of the fence does not cause difficulties, you must first stock up on all necessary tools and materials. During the work you will need:

- chain-link mesh (non-galvanized, galvanized or plasticized);

- support pillars (wooden, metal or reinforced concrete);

- special fastening hooks;

- sand, screenings, crushed stone and cement;

- shovel;

- building level;

- mounting tape;

- hammer or drill;

- bolts, nails or screws.

Step-by-step instructions for installing a galvanized mesh fence

The simplest option for a mesh fence for a summer house is a tension fence. Its installation will not take as much time as it might seem at first glance. For correct execution work, it is necessary to know and follow a clear sequence of the entire technological process.

Advice! For installation tension fence From the chain-link mesh, it is best to attract an assistant who will help you get the job done faster.

A chain-link fence is the best budget option for summer cottage. Install such a fence with your own hands; you will appreciate its advantages not only personal experience, but you will also see by the increased amount of harvest received from the beds.

Video instruction: how to build a chain-link fence without welding with your own hands

Chain-link fence: photo

Mesh is widely used for fencing summer cottages. Anyone can install a chain-link fence with a minimum of tools on hand. Subject to installation technology and selection quality materials, such a fence will last 15-20 years. Before starting work, you need to study the types and characteristics of the mesh, as well as study the instructions in detail to avoid mistakes.

The mesh is made from black and galvanized wire, so the quality of the chain-link varies. Black wire mesh is the cheapest and most short-lived. It becomes covered with rust after the first fog or rain, and after 3-4 years it becomes completely unusable. You can extend the service life of non-galvanized chain-link by using paint or liquid rubber, which should be applied to the mesh before its installation, and then periodically update the protective layer.

A mesh made of galvanized wire is not afraid of corrosion, and therefore lasts longer. It costs a little more than black, but does not need any protective treatment. made from galvanized chain-link, they look neat and attractive.

Plasticized chain-link is becoming increasingly popular. This metal mesh is coated with a dense layer of anti-corrosion polymer, due to which it has increased resistance to atmospheric influences. In addition, the polymer is colored, the mesh looks very attractive and aesthetically pleasing. And although such chain-link is quite expensive, the demand for it is constantly growing.

In addition to quality, chain-link mesh differs in mesh size, wire thickness and roll height. Cells can have sizes from 10 to 65 mm, wire diameter 1-5 mm. The roll height is from 0.8 to 2 m, but the most popular is 1.5 m. Standard length mesh in a roll is 10 m, rolls of 20 m are made to order. The smaller the cells, the more expensive the cost of the mesh, because this increases the consumption of material.

| Type of mesh | Wire diameter, mm | Mesh width, mm | Live mesh cross-section, % | Estimated weight of 1m2 mesh, kg |

|---|---|---|---|---|

| 1,20 | 1000 | 55,0 | 4,52 | |

| woven mesh with rhombic mesh | 1,20 | 1000 | 61,0 | 33,73 |

| woven mesh with rhombic mesh | 1,20 | 1000 | 69,8 | 2,78 |

| woven mesh with rhombic mesh | 1,40 | 1000 | 65,5 | 3,8 |

| 1,20 | 1000,1500 | 75,3 (78,9) | 2,20 (1,94) | |

| woven mesh with rhombic or square mesh | 1,40 | 1000,1500 | 71,5 (76,2) | 3,00 (2,57) |

| woven mesh with rhombic or square mesh | 1,40 | 1000,1500 | 76,3 (77,0) | 3,24 (2,74) |

| woven mesh with rhombic or square mesh | 1,60 | 1000,1500 | 73,3 (77,0) | 3,24 (2,74) |

| woven mesh with rhombic or square mesh | 1,80 | 1000,1500 | 76,0 (78,9) | 3,25 (2,75) |

| woven mesh with rhombic or square mesh | 1,60 | 1000,1500 | 77,5 (80,9) | 2,57 (2,17) |

| 1,4 | 1000-2000 | 83,6 | 1,77 | |

| woven mesh for fencing | 1,4 | 1000-2000 | 87,0 | 1,33 |

| woven mesh for fencing | 1,6 | 1000-2000 | 85,7 | 1,74 |

| woven mesh for fencing | 1,6 | 1000-2000 | 88,0 | 1,39 |

| woven mesh for fencing | 1,8 | 1000-2000 | 87,0 | 1,76 |

| woven mesh for fencing | 1,8 | 1000-2000 | 89 | 1,46 |

| woven mesh for fencing | 2,0 | 1000-2000 | 87,9 | 1,81 |

| woven mesh for fencing | 1,8 | 1000-2000 | 91 | 1,1 |

| woven mesh for fencing | 2,0 | 1000-2000 | 90,7 | 1,36 |

| woven mesh for fencing | 2,0 | 1000-2000 | 91,7 | 1,23 |

| woven mesh for fencing | 2,5 | 1000-2000 | 90,7 | 1,70 |

| woven mesh for fencing | 3,0 | 1000-2000 | 89 | 2,44 |

| woven mesh for fencing | 2,5 | 1000-2000 | 92 | 1,41 |

| woven mesh for fencing | 3,0 | 1000-2000 | 92 | 1,74 |

| woven mesh for fencing | 2,5 | 1000-2000 | 94 | 1,10 |

| woven mesh for fencing | 3,0 | 1000-2000 | 93 | 1,53 |

Prices for mesh netting

Rabitz

Types of mesh fences

Chain-link fencing can be sectional or tensioned. The first option involves the production of rectangular metal sections, inside of which a mesh is fixed. For sections, metal corners, profiles and round pipes small diameter. They are connected by welding or bolts, if not. Such a fence looks more aesthetically pleasing and attractive, metal carcass prevents the mesh from sagging.

A tension fence is quicker and easier to install; its design consists only of support pillars and the mesh itself. Attach the mesh using steel wire, clamps or hung on hooks welded to the posts. Pipes are suitable for poles different diameters, concrete pillars, wooden beams.

Installation of fence posts

For both sectional and tension fences, the marking, preparation and installation of pillars is carried out using the same technology, only in the first case the pillars must be stronger. This is due to the additional load from the metal sections; if the supports are too thin, the fence will definitely warp.

To work you will need:

- roulette;

- wooden pegs;

- a skein of thin rope;

- building level;

- hand drill;

- crushed stone and sand;

- solution;

- profile pipes 60x40 mm;

- Bulgarian;

- primer.

Step 1: Installing Corner Posts

The area allocated for the site is cleared of vegetation, leveled if necessary, and the location of the outer pillars is determined. Experienced builders It is recommended to make corner posts from pipes with a larger cross-section than intermediate ones, and dig them deeper. For example, if for intermediate supports they take a 40x40 mm profile pipe, then for corner supports it is better to take 60x40 mm and 15-20 cm longer.

Start installing the pillars:

When the solution has hardened a little, you can remove the spacers and begin marking for the intermediate posts.

Step 2. Marking

A rope is pulled tightly between the corner supports at a height of 15 cm from the ground - this will be the fence line. The line must be divided into equal segments corresponding to the width of the span. The optimal span width for a chain-link fence is 2-2.5 m; if you increase it, the mesh will definitely sag. They step back from the outermost post to the required distance and drive a peg into the ground, and so on until the opposite corner. All pegs must be in contact with taut rope and be at an equal distance from each other.

Video - New way to install support poles

Step 3. Installation of intermediate supports

In place of the pegs, holes are drilled for the posts and the bottom is filled with sand. To make it more convenient to control the height of the supports, another rope is pulled along the upper edge of the corner posts. Now the pipes are inserted into the pits, leveled in height and vertically, covered with crushed stone and soil and compacted tightly with a crowbar. Concrete is poured on top and the surface is leveled.

If you plan to install a tension fence, and the soil on the site is quite dense, intermediate supports can simply be driven into the ground and not concreted. To do this, drill holes to half the required depth, insert pipes there and hammer them in with a sledgehammer. To protect the upper edge of the posts from deformation, take a larger piece of pipe, weld a steel plate on one side and place it on top of the post. After driving in the supports, the pits are filled with crushed stone and sand, spilled with water for better compaction and compacted thoroughly.

Step 4. Welding the hooks

After about a week, when the concrete has sufficiently hardened, installation can continue. You can secure the mesh to the poles with wire or clamps, but it is more convenient to hang it on hooks. There are profile pipes on sale with already welded hooks, but if you have a welding machine, it is cheaper to make them yourself. For this purpose, pieces of steel rod, screws, nails, even thick wire are suitable - anything that can be welded to the pipe and bent. On a pole 2 m high, it is enough to make 3 hooks: at a distance of 15 cm from the ground, 10 cm from the top of the pipe and in the middle.

Video - DIY chain-link fence

Step 1. Attaching the mesh

A roll of chain-link is placed near a corner post, unwinded a little and the cells are put on the hooks. To securely fix the edge of the mesh, you need to take a piece of reinforcement with a cross-section of 8 mm and a length of 1.5 m and thread it into the cells of the first row. After this, the fittings are attached to the pipe and welded. Now, when tensioning the roll, the mesh will not sag. Having secured the end of the mesh, the roll is transferred to the next support, carefully unwinding it.

Having retreated 10-15 cm from the junction of the chain-link with the pipe, a steel rod is again threaded into the cells. This time there is no need to weld it, it will simply help to tension the mesh evenly. When the mesh is put on the hooks, the rod is removed, the roll is unwound another span, the reinforcement is inserted again, and so on until the very end of the fence. To connect two sheets, use wire from the outermost vertical row of one of the rolls.

Step 2. Fixing the canvas from sagging

Even a well-stretched canvas sags a little over time, so at the installation stage you need to take care of additional fixation of the chain-link between the posts. You will need 6 mm wire and a welding machine. The wire is threaded into the second or third row of cells horizontally along the entire fence. Where the mesh adjoins the posts, the wire is welded. Then the lower edge of the mesh is strengthened in the same way, and finally the hooks are bent. Now the fence canvas is securely fixed on the supports and will not sag or sag.

Step 3. Final stage

Once the fence is installed, the finishing touches need to be completed:

- place plastic plugs on top of the pipes;

- paint the posts;

- Twist the upper tendrils of the chain-link in pairs into 2 turns and bend down.

At this point, the installation of the tension fence is considered completed.

Video - Connecting a chain-link into one roll

Installation of a sectional fence

Manufacturing of sections

Step 2. Preparing the racks

Rectangular plates 20x5 cm and 4-5 mm thick are cut from sheet steel. Take one plate, apply it perpendicular to the pole at a height of 20 cm from the ground and weld it. The second plate is welded at the top, 15-20 cm away from the edge. The plates are attached to the remaining supports in the same way.

Step 3. Installation of sections

The first section is placed between the pillars, raised and leveled. Then they weld the sides to the plates and move on to the next span. It is very important to correctly align the sections in height so that the top crossbars of the frame form a single line. After installing all sections, the welding areas are cleaned, the fence frame is primed and painted.

Read step by step instructions How to do it in our new article.

Video - How to make a chain-link fence

Each owner of a home or a plot of land strives to designate the perimeter of his territory. For this purpose, various fences are built from brick, stone, wood or metal, but their construction is very expensive. The way out of this situation is to build a fence using a chain-link mesh. This material is so easy to install that it is quite possible to handle it with just one pair of hands. The result is a reliable and, at the same time, lightweight fence. So what is chain-link mesh?

Chain-link mesh - what kind of material is it? Advantages and disadvantages of using it for a fence

The history of the creation of this material takes us to late XIX century. In 1878, Czech engineer Karl Rabitz patented his invention. He used this mesh as a reinforcing agent when plastering walls.

This material is a metal wire woven using a machine by twisting flat spirals. Currently, chain-link mesh is widely used:

The use of chain-link mesh in the construction of a fence has both positive and negative criteria. The advantages of using it for these purposes include:

- One person is enough to install this material on the poles. This does not require any special knowledge or skills. It is enough to secure the structure by simply twisting the wire.

- The material does not require large financial costs, so the constructed fence will have a minor impact on the construction budget.

- The design of the material is such that it will not interfere with air circulation and the formation of a continuous shadow. This quality of chain-link mesh is especially valuable when used in fencing for gardens, vegetable gardens and summer cottages.

- IN winter period a fence made of such material will not create snow drifts.

- Chain-link mesh fits perfectly into any environment. Thanks to its visual transparency, this fence does not disturb the landscape, which indicates its versatility.

- With appropriate processing and proper use, the metal mesh will not lose its original appearance for several decades.

The disadvantages of chain-link mesh as a fence include:

- It must be properly secured to the posts, using not just pieces of wire, but also bolts and nuts or a welding machine. Otherwise, there may be people who want to kidnap her.

- Not everyone will like visibility through the mesh, so you will need to additionally cover this space.

- Since the material is made of metal, it is susceptible to corrosion.

Types of fence mesh

To make mesh, chain-links are used various materials or combinations thereof. This significantly affects its service life, specifications and, of course, the price. Therefore, this material is divided into types:

- Non-galvanized mesh has the lowest cost due to its short service life. When wet, this mesh will rust, so it must be treated with a special solution or painted. After several months, these procedures should be repeated, the cost of which will ultimately exceed the purchase price of the mesh itself.

- Galvanized mesh. If you purchase this option, the price is quite high, which not everyone can afford. However, such a mesh does not require additional processing and will last a long time.

- Plasticized mesh is distinguished by the fact that its entire fabric has a polymer coating. This innovation appeared not so long ago, but has already become popular. Prices for mesh with this coating are significantly higher than for previous types. Having installed a fence with it, you can forget about the service life, since with high-quality plastic the wire is well protected from moisture and other weather influences.

- Plastic or polymer mesh differs from the previous ones in that it does not contain metal wire. In the manufacture of this material, special additives are used that make it resistant to ultraviolet exposure. This type of mesh is made with cells various shapes, sizes and shades. Unlike the first three types, it is much softer, so it is not advisable to use it to fence the perimeter of a household.

Galvanized, on the contrary, does not require additional processing

Galvanized, on the contrary, does not require additional processing  Non-galvanized mesh requires protection from moisture

Non-galvanized mesh requires protection from moisture  The polymer coating of the plasticized mesh will reliably protect against natural precipitation and temperature changes

The polymer coating of the plasticized mesh will reliably protect against natural precipitation and temperature changes  The plastic is UV resistant, which is its undeniable advantage.

The plastic is UV resistant, which is its undeniable advantage.

Preparatory actions for construction work: calculating the area of the future fence

Before you begin calculating the area of the future fence, you need to establish what type of foundation will be used. Since the mesh has a relatively light weight, the load on the supports will be insignificant. Therefore, heavy concrete bases are usually not used for chain-link fences, but this also depends on the preferences of the owner.

An important point will be to study the soil in which the pillars are dug or the foundation is laid:

- If it is rocky ground, then spend cash on concrete base there's no point because installed pole does not deform over time.

- If clay soils predominate at the building site, then the gap between the pillar and the hole must be reinforced with gravel or filled with concrete.

- If the fence will be installed in an area whose soil contains a large amount of sand, then it is necessary to use a strip base.

- If the fence is erected on peat bogs, then they use screw piles, on which the chain-link mesh is attached.

When studying the soil, it is necessary to determine the freezing point, since installing a post above it will lead to deformation of the fence at low temperatures.

The width of the strip-column base should be at least 25 - 30 cm, and the length, for example, 30 m. We make the calculation: 0.4·30 = 12 m 2 - this is the total area of the strip base of the chain-link fence.

When pouring strip base, for the purpose of strengthening, the size of the foundation for each support is made wider than the gap between them. For more accurate measurements, it is necessary to add up the areas of the base of all the pillars and the areas of the spaces between them. For example, the size of the base of the pillar is 40x40 cm, and the gap is 30x215 cm.

To calculate the total area of this foundation, you need to find out the values first for the bases of each support, and then for all the intervals. There are 12 supports (pillars) for this fence. Therefore, the length of the base for the pillar must be multiplied by the width, and the resulting result multiplied by the number of supports: 0.4·0.4·12=1.92 m2 - this is the total area of the base for the pillars (supports). The area for the gaps is also calculated, only you need to multiply by one less: 0.3·2.15·11=7.09 m2. Now we need to add up the results obtained, and we get the total area for the entire tape: 1.92 + 7.09 = 9.01 m 2.

What material is suitable, the dimensions of the fence mesh. Tips for choosing

The chain-link mesh is manufactured in different sizes, which are standard. Chain-link mesh with mesh sizes: 0.4x0.4 cm, 0.5x0.5 cm, 0.6x0.6 cm, as well as options with intermediate sizes: 0.45x0.45 cm, 0.55x0.55 cm has found widespread use. According to the roll height (mesh width), this material has dimensions: 120 cm, 150 cm, 180 cm and 200 cm. The length of the mesh web also has established standards. A mesh of 10 or 15 meters in length is rolled up in a roll.

Some manufacturers produce chain-link mesh non-standard sizes. In this case, the material can be up to 4 m high, with cell sizes from 30 mm to 150 mm.

When purchasing a chain-link mesh, you need to pay attention to the thickness of the wire and the quality of the metal. It shouldn't bend easily. The mesh cells must be identical, since any deformation is a sign of low quality metal. Spirals should not be twisted. If you do not take this defect into account, then after a few months the wire in this place may burst.

When purchasing this material, you need to look at both edges of the roll. Each end of the wire must be connected to the adjacent element and bent. The length of the bent “tail” of the wire should be more than half the cell. Otherwise the edges stretched mesh after some time they may bloom, which will lead to its deformation.

If the choice is made on a plastic-coated mesh, then cheap option it will bend easily. Inexpensive mesh options are coated with low-quality polymer, which can crumble after a few seasons. In this regard, it is necessary to clarify the warranty periods established by the manufacturer.

The most inexpensive option is a non-galvanized mesh. The main enemy of this type of mesh is moisture. In this regard, after installing the fence, you need to take care of painting it.

All this suggests that when buying this material you should not choose cheap options.

Carrying out calculations of the required material. Calculation examples

To build a fence using chain-link mesh, you need to determine:

- type of mesh used;

- the width and length of its canvas;

- number of supports;

- type of foundation and required volume of concrete mixture, if a permanent foundation is selected;

To construct a fence from this mesh, you need the following materials:

- Rabitz.

- Metal channel.

- Concrete mixture marked M200.

- Wide wooden boards or sheets of plywood for making formwork.

- Bolts, nuts.

- Wire, metal fastenings and clamps.

- Reinforcing bars.

- Sand.

- Crushed stone.

- Anti-corrosion primer.

- Dye.

To build the fence, a chain-link mesh with polymer coating, with a cell width of 40x40 mm and a wire thickness of 3 mm. The width of the fabric in a roll is 150 cm, length is 15 m. Channels with parameters 50x50x2400 mm are used for the pillars. To install this type of fence, a strip foundation will be poured. The length of the fencing section is 30 m.

Having established what materials will be needed when building a fence with chain-link mesh, you should proceed to calculations. First you need to calculate the total amount of concrete for the permanent foundation. To do this, you need precise parameters for the length, height and width of the base. Since the foundation under the pillars is wider than under the fence span, each of them will be calculated separately.

The calculation of the concrete base for a chain-link fence will look like this:

- To determine the volume of concrete for the base of one pillar, you need to multiply its length, width and height: 0.4·0.4·0.4=0.064 m3.

- To calculate the volume of concrete for one pile, you need: 0.15·0.15·0.5=0.011 m3.

- Now you need to add these values: 0.064·0.011=0.075 m3 - this is the volume of concrete required for the foundation of one pillar.

- In 30 meters of the future fence there will be 12 bases for pillars and 11 for spans. Therefore: 0.075·12=0.9 m3 is overall volume foundation for all pillars.

- In the same way, it is necessary to make a calculation for 11 spans between the pillars. According to the diagram, the distance between the bases of the pillars is 2.15 m, therefore: 0.3 2.15 0.4 = 0.258 m 3 - this is the volume of concrete for one span. For all spans: 0.258·11=2.838 m3.

- Next, you need to find the total value for the concrete required to lay the entire foundation. To do this you need to fold general values for pillars and spans: 0.9+2.838=3.738 m3.

- To calculate total length mesh netting, you need to multiply the distance between the metal channels by the number of spans: 2.5·11=27.5 m.

Required Tools

When building a fence using chain-link mesh, the following materials will be required:

- Hand drill or screw shovel.

- Shovel and bayonet shovel.

- Cord and stakes.

- Concrete mixer.

- Pliers.

- Metal scissors.

- Welding machine.

- Building level.

- Plumb.

- Yardstick.

- Metal brush.

- Molar brushes and roller.

- Hammer.

- Nails.

- Buckets and tanks for water and concrete mixture.

A step-by-step guide to making a chain-link fence on your property with your own hands

When all necessary materials purchased, diagrams and drawings have been drawn up, all calculations have been made, you can begin construction work:

- First of all, you need to make markings for digging a trench. This can be done conveniently using a cord and wooden stakes. If the stretched cord gets in the way during excavation work, it can be loosened. eventually it will reveal all the irregularities.

- Then, using a bayonet and shovel dig a trench 30 cm deep and 40 cm wide.

- Inside the trench, at a distance of 2.5 m from each other, dig holes with a diameter of 35 to 40 cm. These holes are intended for pouring concrete mixture for piles (foundation pillars). To do this, you need to use a hand drill or a screw shovel.

- When all the holes have been dug, you need to carefully compact the bottom of each of them, as well as the trench. Place a layer of sand at the bottom of each hole and trench, which must be compressed to a thickness of 10 cm. In order for the sand cushion to compact well, it must be moistened. In this case, the sand particles will fit closer to each other.

- For a more reliable base for the foundation, you can use it from above sand cushion Apply an even layer of gravel 5 cm thick.

- Now you need to prepare the holes for installing channels and pouring concrete. To do this, it is necessary to install formwork in each of them. As such, you can use roofing felt rolled into a pipe or other elastic waterproofing material. The best option in this case, asbestos-cement pipes of the appropriate diameter will be used.

- To strengthen a concrete pile, it is necessary to make a metal frame from reinforcing bars. The diameter of each rod should be 12 mm. Metal structure must have view of four elements connected to each other. As connecting parts wire must be used. The specified structure must be placed inside the asbestos-cement pipe in the hole. The length of the metal frame should be 20 cm higher than the bottom of the trench.

- Then, in the middle of the metal frame, at the bottom of each hole, install channels measuring 5x5x240 cm. These metal posts must be leveled using building level and plumb line. To prevent the pole from leaning during the concrete hardening, it must be strengthened with temporary braces. Metal struts must be attached to the first and last pillar using electric welding. It should be noted that each channel must first be treated with a metal primer. This will protect it from corrosion.

- Now you need to pour concrete inside the asbestos-cement pipe. After pouring, it takes time for the concrete mixture to harden, usually 3 to 6 days. Freshly poured concrete must be free of air bubbles. To do this, for the first 1.5–2 hours it is necessary to lower the metal rod into concrete and remove it, thereby allowing the air to escape.

- When concrete piles, into which the channels are fixed have frozen, it is necessary to proceed to installation work strip foundation. First you need to make a metal frame from reinforcing bars with a diameter of 12 mm. The principle of fastening and its shape are similar to that installed in piles. The distance between each reinforcing bar should be 30 cm. This structure should be placed horizontally along the entire length of the trench, but not touch its bottom. To do this, you need to put it on the bottom of the trench in advance. wooden beams cross section 5x5 cm, length 40 cm.

- After the metal structure is laid in the trench, it is necessary to make formwork for the strip foundation. To do this, you need to build shields 20 cm high from boards or thick plywood, securing them with self-tapping screws. Install the formwork as shown in the image.

- Now you can pour the concrete. Its level should completely cover the metal frame and be 10 cm above ground level. The result should be strip-column foundation, the total depth of which will be 90 cm.

- The concrete in the strip foundation must harden, which will take 2 to 3 weeks. It should be covered from direct sunlight, as it negatively affects the hardening process. If you ignore this, the base will crack. Please note that in the first two days, every 10–12 hours, you need to water the concrete base with water. These steps will help the mixture harden evenly.

- When the concrete has hardened, you can begin installing the chain-link mesh on the posts.

Fences of this type are made:

- tension;

- sectional.

Tension option

To secure the chain-link mesh by tension method, you need to place the roll vertically and stretch a metal rod through each cell. Then, using electric welding, attach this metal rod threaded through the mesh to the post. Repeat the same actions with the canvas when attaching to each post.

The easiest way to secure the mesh is using wire. This option is faster and cheaper, but in this case the fence can be easily stolen.

If you do not have the skills to operate a welding machine, then you can use bolts, nuts, metal plates or staples as fasteners. This option is much more reliable, since the fastening is rigid and resembles tightening a clamp.

Then the roll is unwound to the next post and secured by tensioning the web. For high-quality stretching, the help of one more person is required.

To prevent the upper edge of the chain-link mesh from sagging over time, you need to reinforce it with wire. To do this, using special fastenings and tensioners, the canvas is strengthened. The wire can be threaded through the last cells of the upper edge or 10–15 cm below. Sometimes the wire is threaded through the bottom of the mesh.

There is another option for securing the mesh, which will eliminate the possibility of its theft. In this case, the chain-link mesh is pulled over the pillars before the strip foundation is poured. Its above-ground edge should be installed slightly below the intended level of the strip base. When pouring the mixture, the bottom strip of the mesh will be concreted.

Sectional fence

To create this option, it is necessary to attach 2 metal plates measuring 20x5 cm to the posts using electric welding. They should be located at a distance of 30 cm from the top and bottom edges.

Sections for the fence are made of metal corners with a side width of 40x40, metal thickness - 5 mm. Then you need to measure the distance between the posts and subtract from this value from 5 to 10 cm. This will be the width for the frame of one section of the fence, and its height will be 150 cm. The result will be four corners, from which, using electric welding, you need to make a rectangular frame measuring 250x150 cm. The resulting scale must be carefully removed using a grinder.

Then, using metal scissors, you need to cut the mesh to size metal frame. The protruding ends of the mesh must be carefully bent to form cells along the edge of the canvas. Now you need to thread metal rods along all edges of the specified segment. After this, it is necessary to weld the rod with the mesh to the inside of the frame. Carry out the same actions with the other parties.

Weld the finished section to the metal plates. During installation, it is necessary to ensure that the sections are at the same level, since the slightest distortion will give an untidy appearance to the entire fence.

Final finishing - decoration, photo

A fence built with your own hands using chain-link mesh has a neat appearance, but nothing more. Over time, the desire arises to somehow decorate it. You don't have to be an artist or designer to do this. It is enough to show your imagination, and your fence will become a piece of art.

The most in a simple way To transform the fence is to plant climbing plants next to it. In a few months, your fence will turn into a flowering wall. The pillars can be decorated with clay pots, this will give the fence ethnic beauty.

Fence cells can be turned into canvas for embroidery. Like a drawing on a canvas, you can weave it with your own hands beautiful patterns. For this you will need wire. If you use colored twine, then with its variety of colors and shades you can create three-dimensional images.

IN Lately It has become popular to decorate the fence with a photo grid. The drawing can be absolutely anything. The peculiarity of this material is that from afar a continuous pattern is visible, but in fact it consists of small polymer mesh which is perfectly ventilated.

Wire resembling lace - interesting option for those who have nothing to hide

Wire resembling lace - interesting option for those who have nothing to hide  Painted roses look elegant. The main thing is that the drawing on the photo grid matches the landscape

Painted roses look elegant. The main thing is that the drawing on the photo grid matches the landscape  Wide grape leaves will decorate and hide the area from prying eyes

Wide grape leaves will decorate and hide the area from prying eyes

How and with what to close the fence from neighbors: options with photographs

Since a chain-link fence is completely transparent, any home owner will want to hide it from prying eyes. It is not advisable to cover it with any shields or boards.

The easiest way is to cover the fence with camouflage netting. Visibility through the fence will be much less, but the appearance will also be unattractive.

You can cover the fence with reed mats. This method is more expensive than the previous one. Attaching them is not difficult; you just need to unwind the roll and secure it in several places with wire.

A similar option is to use artificial pine needles. This material is sold in rolls. It is used in making wreaths and baskets, but it can also be used for fencing.

A fence that is covered with a camouflage net looks aesthetically pleasing only if you are in a paintball zone

A fence that is covered with a camouflage net looks aesthetically pleasing only if you are in a paintball zone  Rolls of reeds are a more expensive option

Rolls of reeds are a more expensive option  The use of artificial needles looks original

The use of artificial needles looks original

Video: how to stretch a chain-link mesh

Using chain-link mesh during construction, you will not only create a permanent fencing of the territory, but will also have the opportunity to realize your design idea by decorating the perimeter to your own taste.