Do-it-yourself smoke generator for a hot-smoked smokehouse. Smoke generator for cold smoking of products: assembly from improvised means

The device responsible for the formation of smoke in the smoking chamber is usually called a smoke generator. Its operating principle is simple: electric heaters inside the device cause the sawdust there to smolder, producing thick smoke. Special thermostats allow you to control the smoke formation process,, if necessary, reduce smoke flows and perform high-quality smoking of products.

Today there are a lot of devices for smoking products. People have learned to produce products with smoke using many homemade devices, including smokehouses with smoke generators. This is the most environmentally friendly method of food processing. During the smoking process, natural thick smoke removes all harmful microorganisms and bacteria from meat or fish. The shelf life of such food is increased, and the taste is enhanced.

Valuable smoking smoke can be obtained thanks to a good smoke generator, which forms the basis of cold smoking. During the process of heating sawdust and its oxygen-free smoldering, the device creates smoke that enters the smoking chamber. Working in automatic mode, the device greatly simplifies the smoking process. The result of his work is very aromatic and no less tasty smoked products, which you can always enjoy if you only have a smoke generator for a cold smoked smokehouse in your household.

Cold smoking is the processing of products with smoke at a temperature of 19 to 25°C. This process can last many hours, or even several days. Immediately before smoking, the products are salted and treated with seasonings.

You can delight yourself and your friends more often with delicacies from the smokehouse by making a smoke generator with your own hands for your home smokehouse.

Externally, the device is a small vacuum box with switches, a receiving hole for sawdust and a small pipe at the top for removing smoke. Inside the box there is a limiter that dispenses sawdust entering the heating element. There is also a container for ash and a control device that is responsible for the temperature of the smoke and the supply of sawdust. This device is initially programmed for an acceptable mode in which the heating element provides a stable temperature necessary for sawdust smoldering, in order to avoid their ignition.

Characteristics of the smoke generator

Considering that a smoke generator is a device that requires quite a long time of operation, it is logical if it consumes a little electrical energy. As a rule, a smoke generator for a smokehouse consumes up to 4 kW per day after the heating element reaches the required smoking temperature and turns off. At the same time, the power heating element is 1 kW. The device is powered from a 220 V outlet.

The sawdust hopper has a standard volume of 1.5 kg. This amount is enough to carry out continuous smoking for 1.5 days. Provided that the chamber volume is 1 m 3, the smoke generator will provide the products with thick smoke and high-quality smoking.

DIY smoke generator

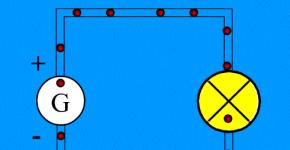

The main function that a smoke generator performs in a smokehouse can be explained this way: imagine a person smoking in a car with an open window. As you remember, all the smoke is pulled out thanks to fast air currents that discharge the air and pull the smoke out of the cabin. Smoke generators work on the same principle.

Moreover, such a device has one undeniable advantage: You no longer need to constantly be near the smokehouse in order to add sawdust. The volume of the smoke generator receiving chamber is sufficient for 24-hour continuous operation of the device. That is, once you add sawdust, you can forget about the smokehouse for a day.

It is not at all difficult to assemble a simple device for smoking food with your own hands; it all depends on the technical capabilities of the manufacturer and the assembly options for the main container, ejector and air pump.

Assembling the parts of a homemade smoke generator:

- Main container. It's about about the combustion chamber, where the sawdust will directly smolder. The smaller the volume of this container, the faster the sawdust will burn in it, and you will need to add raw materials again.

- Therefore, in order to make a container, use any fireproof container: be it a thermos or an unnecessary used fire extinguisher. The most suitable container sizes: pipe diameter – 8-10 cm, length – 40-50 cm;

- Make a hole with a diameter of 10 mm at the bottom of the future reception area. It is necessary to connect the compressor with oxygen and maintain the combustion process;

- make the upper part vacuum so that there is no air leakage.

- Ejector.

- assembly of this main part of the generator can be done using various metal tubes and any of their connections: by welding, soldering, or ordinary thread;

- Place the ejector at the top or bottom of the main container. The pictures show the upper and lower location of the ejector.

Ejector at the bottom of the smoke generator.

- Suitable for small smokehouse chamber. In view of their design features the lower ejector often fades; for this it is necessary to limit the height of the combustion chamber. Thus, the operating time of the smoke generator in continuous mode is reduced. The lower location of the tube does not provide natural draft in the smokehouse due to the fact that the smokehouse and the receiving container are at the same level. As a result, when the pump is turned off, smoke stops flowing into the smokehouse. Such inconveniences can be avoided by installing the ejector at the top of the loading chamber, as shown in the following figure.

- Pump (compressor).

- Raw materials for smoking.

- Wood can be used to create dense smoke different varieties, except pine, spruce, and other evergreens. Such sawdust will cause bitterness in products;

- if your sawdust is too small, then supplement the design of the smoke generator with one small part in the receiving container - a spring for moving smoke through the poured sawdust. If the sawdust is large, then there is no need for an additional part, since smoke smoke will easily seep through the wood.

- In our smoke generator, the temperature of the smoke that is supplied to the smokehouse can be adjusted by reducing or increasing the connecting pipe between the smoking chamber and the smoke generator.

- Before making a smoke generator for a smokehouse, decide on the smoking container. Alternatively, you can use metal barrel, a wooden box and even a cardboard box. A smoking cabinet can be made from an old refrigerator. The door closes tightly, which means that a constant temperature will be maintained inside at any time of the year. The refrigerator is not suitable only for hot smoking, since its plastic walls will not withstand too high temperatures.

- When the smoke generator is assembled, you can put food, previously salted and dried, into the smoking chamber. Wet raw materials are not allowed to be used, as smoke dissolves in moisture and smoking will last much longer.

- Place the device on the fire and the process of cold smoking of fish will begin.

DIY fish smokehouse

In order not to deprive yourself of the pleasure of feasting on fish with “smoke” more often, make home smokehouse with a smoke generator for cold smoking.

There are no striking differences between a factory device and a homemade one; the principle of operation is still based on the same thing.

- First, decide on the amount of food you plan to smoke periodically. A miniature device will be just in case the smokehouse is used once a year, for example. Take a regular metal bucket with a lid.

- Drill a hole at the bottom that matches the diameter of the smoke generator tube to supply smoke, and make a hole in the lid to remove the smoke.

- To make a smoke generator itself, you will need the following parts: frame, drum, fan, electric drive, heat chamber and remote control for the electric model.

- Manufacturing technology of a smoke generator for a fish smokehouse:

- The oil seal mandrel is best suited for the main generator tank. Cover it with a lid and connect a timer to the device, for example from washing machine or microwave;

- for supporting normal pressure at 1 atm, install any compressor as long as it performs its main function of pumping air;

- if the distance between the smoke generator and the smoking chamber is less than 100 cm, then come up with an additional smoke cooling device;

- At the bottom of the device, install a heater for heating sawdust;

- Place large sawdust in the main container of the generator, turn on the heater and compressor;

- Insert the outlet tube of the device into the smoking chamber, where you need to hang the fish in advance.

- The cold smoking process has started. After about a day of continuous operation, check the fish for readiness and the amount of sawdust in the smoke generator.

- Maintain smoking temperature between 30 and 35°C.

- For best work The device is suitable for dry weather.

- Add a little to the sawdust in the smoke generator grapevine or cherries. This way your products will have a richer taste.

- The taste of smoked fish or meat depends on the type of wood chosen.

- To make the smoking process faster, you need to install an electric heater inside the smoke generator to heat the sawdust.

Safety rules for the manufacture of a smoke generator

- The smoke generator must meet fire and electrical safety requirements.

- In the event of unexpected operational problems, the control unit must be equipped with an automatic shutdown device.

- Electrical wiring and other parts should be kept away from the heating element and away from high temperatures.

- The most durable housing for a smoke generator is metal, with a layer of heat-resistant paint.

- It is recommended to install the device on a fire-resistant surface.

Rules for using a smoke generator:

- First of all, install the device on a flat surface.

- Connect the cord to the network.

- Fill the container for shavings with sawdust for smoking.

- Connect the outlet pipe of the smoke generator to the smoking chamber, which you fill in advance with products.

- Turn on the start button and the device will then perform its work automatically. It is necessary to monitor the level of sawdust in the chamber and add it as it burns. Thus, the cold smoking process can last several days. The device cannot be turned off.

You can see the principle of creating a smoke generator for a smokehouse with your own hands in the video master class:

Almost everyone loves smoked products; home-smoked fish or meat is especially tasty when you know for sure that no preservatives were added during the cooking process, especially smoke smoke (various meat processing plants are very fond of it to reduce the cost of production). The smoking process itself takes a lot of time, so the equipment should not fail. If you decide to make a smoke generator for cold smoking with your own hands, the drawings and some features of assembling the device given below will come in handy for you.

Homemade smoke generator option

One of the main elements for high-quality smoking is the source of smoke. Typically, shavings or sawdust are used, which burn slowly inside the generator. At the same time, you can assemble your home smoke generator in such a way that one load of firewood will be enough to operate autonomously for 24 hours. To do this, it is enough to reduce the air flow and increase the volume of chips in the loading chamber.

There are also a lot of assembly options, it all depends on technical capabilities and purposes of creation. There are three main elements, without which no device will function correctly:

- Container (combustion chamber);

- Ejector;

- Air pump.

At the same time, the process of smoking products has its own subtleties that must be observed:

- Minimum temperature of smoke entry;

- Duration of the process;

- Do not use pine sawdust;

- All products are pre-cleaned before smoking.

To comply with all these features of the process, you need to collect the main elements correctly and carefully. And so that the products in your homemade smokehouse turned out to be especially tasty, it is recommended to use slivers of alder, cherry, apple, pear or willow.

Helpful information! Once your smoker is ready, try different wood chips to find the one that works best for you. the best option, because each of them gives its own special taste.

Let's move on to the features of the main elements of the smoke generator and their assembly.

Making a smoke generator for cold smoking with your own hands: drawings of the main elements and assembly procedure

First you need to prepare the elements that will be required to assemble the equipment. You can use the following drawing in your work:

So, to install a smoke generator for a cold smoked smokehouse with your own hands, you will need:

- Pipe, usually stainless steel is used. Cross section - 100 by 100 mm (it is recommended to take a diameter of 10–12 cm for a round pipe).

- Parts metal pipe up to 400 mm, diameter 2.5-4.0 cm (usually used for hot smoking).

- A corrugated plastic pipe 2-3 mm or a metal sleeve, the diameter of which will correspond to the chimney pipe.

- Compressor (you can take an aquarium version).

- Tee with a cross-section corresponding to the diameter of the smoke channel.

- Wires for connecting elements and.

- Thermometer.

All components are in open sale, and often are even at your fingertips, so getting them out won’t be difficult. There are also a lot of drawings, you can find them on the Internet and choose the one that suits your idea.

To connect the elements, also prepare welding machine and Bulgarian. If you have never worked with them, then it is better to invite someone more experienced to help. The main difficulty lies in welding the fitting, making a door for the firebox and removable covers at the bottom and top.

Related article:

In a separate publication we will talk about making the right choice of this device according to your goals and budget.

We assemble a smoke generator with our own hands for cold smoking: video of the process

When you have prepared the drawings of the smoke generator for cold smoking, we begin to assemble the parts. Here are the main elements and sequence of equipment assembly:

- First, we cut off a piece of pipe for the body (0.5 - 0.8 m).

- We make the upper and lower covers to fit the outer diameter of this segment. In this case, the bottom should have sides on the sides so that the ashes do not fly out.

- On the sides of the base, slightly above the sides, drill several holes that will serve for ignition and oxygen supply (diameter 0.6 - 0.8 cm)

- To make it convenient to use the smoke generator, weld the legs, which should be about 15 - 20 cm in height.

Note! If you use a removable bottom, you will not need side doors in the firebox. For a deaf person, make a door and place it on several hinges; in this case, you need to make slits for air to flow in, just like in conventional ovens.

- The top cover must fit tightly onto the pipe, and it is also necessary to make a piece so that the unit can be opened.

- Now we weld the chimney on top of the base, retreating 50 - 80 mm from the cut.

- Weld the fitting perpendicular to the wall, it is necessary to maintain a protrusion 60 - 80 mm long. Before welding, the ends of the part should be equipped with threads for the tee.

- After welding, attach a tee, and 2 pipes to it - one down, the second to the smokehouse.

For the correct process of preparing cold smoked products, we collect all the elements into one system:

- Place the generator on a base that is made of fireproof materials, such as a concrete slab.

- Place about 0.5 - 1 liter of dry wood chips.

- Connect the pipe and chimney to the smoking chamber.

- Light the wood chips using the special drilled holes.

- Start the fan.

The process has begun, the tee acts as an injector. If you have assembled everything correctly, the combustion process will occur independently and your additional participation in the operation of the device will not be required.

Note! You can change the temperature yourself by changing the length of the chimney.

When assembling a smoke generator for cold smoking with your own hands according to the drawings, it is quite possible to use a pan, a can, or other containers in the form of a cylinder as a body. You can assemble the model without a fan, but it will function worse, since most often the natural draft is not enough for the effective process of preparing delicacies.

- If you do not want to assemble such a unit yourself, you can buy a smoke generator for cold smoking, the price of which will vary depending on the performance, chamber volume and company.

- When assembling a smoke generator for cold or hot smoking, do not forget to use the drawings and prepare all elements for assembly in advance.

- The correct assembly sequence and good welding determine how well the unit will perform. You can also try sawdust and wood chips different breeds trees to understand which shade of taste you like best.

You might also be interested in:

How to use a multimeter correctly: simple instructions

How to use a multimeter correctly: simple instructions

Corrugation for wires and cables: device and correct installation

Corrugation for wires and cables: device and correct installation

Self-installation and adjusting the water pressure switch for the pump

Self-installation and adjusting the water pressure switch for the pump

Connection diagram LED strip 220v to the network - do it correctly

Connection diagram LED strip 220v to the network - do it correctly

Smoking meat and fish products, as a way to give them a unique taste and aroma, as well as to preserve them to increase shelf life, has been known for a very long time. Smoked fish- an expensive, and at the same time very healthy delicacy. Smoked chicken or lard are rich sources of protein for the body. Many fellow citizens, buying these delicacy products in the store, wonder whether it is possible to prepare aromatic smoked fish or chicken on their own.

With the spread of the Internet, information about smoking methods, devices for this and ways to make these devices from scrap materials with your own hands has become publicly available. Fashion also played an important role in the spread of home smoking. The trend of eating environmentally friendly products is pushing people to invent. As Lenin would say, “the creative energy of the masses” gives birth to more and more new designs for home smokehouses.

Actually, the definition contains meaning.

Cold smoking is a process of processing products with smoke, the temperature of which does not exceed 25 degrees Celsius. This type of smoking takes from 3 hours to several days, depending on the mass and type of product, and smoke temperature.

Hot smoking is a similar procedure, the only difference being that the processing is also accompanied by thermal effects. The smoke temperature during this preparation ranges from 45 to 120 degrees Celsius. The time spent on hot smoking is much less, 2-4 hours is enough, but cold smoked products will last longer.

Both methods of smoking meat, fish or chicken can be accelerated using a high-voltage electrostatic field and smoke ionization.

Delicacies prepared using the cold smoking method have the following advantages: excellent taste and long shelf life. But in this case you cannot do without a smoke generator for the smokehouse. The installation supplies a smoky gas mixture under low pressure and uniform concentration, which simplifies the process of preparing food.

DIY smoke generator

From a homemade smoke generator for a smokehouse, due to the dispersion and direction of air from the compressor and the resulting vacuum in the chimney, smoke is drawn into the chamber where the products are previously placed. In order to properly establish the process of producing a gaseous mass (air, smoke), you must adhere to the following recommendations indicating how to make a smoke generator for a smoking apparatus.

Preparing the combustion chamber

To prepare the smoke generator body, a pipe with an internal diameter of 90 mm and a length of 50 cm is suitable. This optimal sizes, allowing you to avoid frequent loading of wood chips.

Next, drill holes for the chimney and ejector bosses. They retreat 5-7 cm from the top of the pipe and make holes based on the selected outer diameters of the chimney and boss. They also drill a hole in the lower part of the body (3-5 cm from the bottom) with a diameter of 10 mm to ignite wood chips.

A hinged bottom, made according to the diameter of the pipe, is screwed to the bottom with a wing nut in order to remove ash.

To remove ash, a grate is installed inside the housing at a distance of 2–3 cm, which is welded to the housing. You can fix the grille with an old stretched spring, hooking the other end of the spring onto the ejector tube.

The lid is made in the form of a cork. You can take a plate ∅100 mm and cut a ring 20 mm high from a DN 100 pipe and weld along the contour.

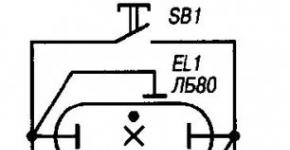

Schematic drawing

Schematic drawing Ejector

A do-it-yourself smoke generator for a cold-smoked smokehouse must be equipped with an ejector. During installation, any metal tubes that are connected to each other are used different ways: soldering, welding, threaded connection. There are several types of smoke generators for smokehouses depending on the location of the ejector:

In our case, consider the location of the ejector in the upper part of the smoke generator.

So, a transmission for a cold-smoked smokehouse with a home-made smoke generator involves the use of a ¾-inch diameter tube, which serves as a chimney, a boss and an air supply fitting. The chimney and boss are welded to the holes made using a welding machine,

The fitting with the ejector tube is screwed into the boss. The length of the tube is selected based on the condition that it extends 1 cm into the chimney (more clearly shown in the schematic drawing). Next, a flexible hose from the compressor is connected to the fitting.

Compressor

A pump for supplying air to the fitting can be purchased at a pet store. These are units that are used for aquariums. The main selection criterion is productivity (liters per hour). This do-it-yourself smoke generator involves using a small compressor - up to 60 l/hour.

Experienced home craftsmen manage to build a compressor from plastic bottle and cooler external unit computer.

Smoking chamber

Before installing a generator with your own hands to produce smoke, you need to decide on the volume of the smoking chamber. It should not be large and can be a barrel, wooden or cardboard box. The main condition is the tightness of the joints, the presence of a smoker (for smoke circulation and condensate removal) and maintaining a constant temperature regime.

The smoke generator is inserted into the hole and attached with a cantilever chimney to the side wall of the smoking chamber. Additionally, chimney clamps are installed or, as an option, a flange connection is made.

wood chips

Making a smoke generator for cold smoking on your own is not difficult, but for the cooking process itself you need to use the right raw materials. For this purpose, chips of fruit trees and alder are used.

Conclusion

The video below was used as a source for the article.

How to make a smoke generator for home use? To do this, it is allowed to use any available materials, fittings and connecting elements. According to the principle given in the article, most smoke generators for cold smoking are made with their own hands, and the design is also modified to allow the unit to be used for portable and stationary smokehouses.

Article rating:(5 ratings, average: 4,40 out of 5)

Briefly about the design of a smoke generator for cold smoking

The difficulty is that smoking is a lengthy process and requires not only the proper equipment, but also a substantial supply of firewood if you are using a traditionally designed smokehouse that burns wood. This smoking lasts up to several days with constant combustion in the firebox.

But inventive thought also found a way out of this situation - a smoke generator for a smokehouse. The main and only purpose of the smoke generator is to produce a significant amount of smoke and supply it to the smoking cabinet, where the preparations for smoking are located. As a result of interaction with smoke of specially marinated meat, fish or poultry, a number of chemical reactions, turning them into highly digestible and very tasty products.

A smoke generator for a smokehouse is a fairly simple, but extremely effective device that can be made with your own hands from scrap materials. The whole attractiveness of the smoke generator is that it can operate in automatic mode. The temperature in the smoking cabinet is not too high, so there is no need to worry about the food burning.

Smoke generator design

Conventional drawing of a smoke generator

The source of smoke is sawdust, shavings or wood chips that slowly smolder inside the generator. The secret to installation is how to ensure consistent, even combustion and how to feed smoke into the smoking cabinet. To assemble a smoke generator for a smokehouse in a home workshop you will need:

Components are readily available and inexpensive

As you can see, the list is not very long, and all the components can be easily bought in a store or, after a good search, found in your own garage or home workshop. Drawings and instructions for assembling a smoke generator for a smokehouse are abundant on the Internet.

To build a smoke generator with your own hands, you will also need a welding machine, an angle grinder and some skills in working with them. The main difficulty is welding the chimney fitting to the pipe, making doors for the firebox and removable bottom and top covers. But first things first.

Smoke generator assembly steps

The first step is to cut a piece 0.5 - 0.8 m long from the pipe intended for the housing. Under it external dimensions from sheet metal The bottom and cover are made. The bottom should have side sides so that the body fits tightly inside and the ashes from burnt sawdust do not spill out. In the side of the body, just above the bottom flange, several holes are drilled, which serve to ignite the fuel and provide oxygen for combustion. Their diameter is 0.6 - 0.8 cm.

It is necessary to make a hole in the smoke generator housing for ignition and oxygen access

For ease of use and stability of the smoke generator, legs 15–20 cm high or a flat platform are welded to the base.

If there is a removable bottom, doors for the firebox in the side wall are not needed. If the bottom is solid, then you need to make side doors on hinges, with slots for air flow, like stove doors. This is a little more complicated, but it is quite possible to do it yourself. The top cover is blank, without a chimney and ventilation holes. It should also fit tightly onto the pipe and be equipped with a handle - a bracket for opening the smoke generator.

A chimney outlet is welded into the upper part of the body, at a distance of 5–8 cm from the pipe cut. The fitting is welded perpendicular to the wall and should protrude from the wall by 6 - 8 cm. In front welding work at its outer end it is necessary to cut a thread for a fitting (tee). After connecting the chimney, a tee and two tubes are connected to it - one goes down, the other to the smokehouse.

One of the options for a smoke generator for a smokehouse with a tee

The tube from the compressor is connected to the fitting going down, and the connecting pipe leading to the smoking cabinet is connected to the side one. As a fan, you can use a compressor from an aquarium, a cooler from a computer, or something similar - it is important to create a not too powerful, but constant flow of air directed towards the container in which smoking occurs.

A compressor can be made from a cooler and a bottle

As an option, the tee can be connected to the smoke generator cover without affecting the integrity of the side wall. In this case, the lower fitting is connected to the lid, the rear one to the air duct from the compressor, and the front one to the smokehouse.

Smoke generator for smokehouse with top tee

That's all - the smoke generator for the smokehouse is ready.

How it works

A smokehouse with a smoke generator, built with your own hands, is very mobile and compact. When not in use, it can be stored in a garage, basement, or even a closet. This depends on what is used as a smokehouse. You can use any metal box for the camera suitable size. If there is no ready-made one, then you can make it yourself without any problems. The box sizes vary, depending on the volume of product you will be smoking.

For home smoking, the optimal dimensions are 1.0 / 0.6 / 0.6 m (H / W / D). The top of the box is closed with a lid with a built-in thermometer and several small (0.3 -0.5 mm) holes to create traction. The upper part of the smokehouse in working condition should be above the smoke generator - this creates additional natural draft, and even when the fan stops, smoke will enter the chamber without delay.

Now you need to assemble everything:

- We install the generator on a fireproof base - metal table, concrete slab or gender, ceramic tiles. This must be done for reasons fire safety. In addition to the fact that the smoke generator gets quite hot, pieces of burning wood chips may fall out of it.

- We load approximately 0.5 - 1 liter of dry wood chips, sawdust, shavings into the smoke generator deciduous trees(conifers are not used for smoking) and close it tightly with a lid.

- We connect the compressor pipe and connect the chimney to the smoking chamber.

- We ignite the fuel through the side hole.

- Turn on the fan.

The smoking process has begun. The tee with the fan acts as an injector. A vacuum is created in the chimney pipe, which causes smoke to be drawn in from the generator, and a rather noticeable air-smoke flow is directed towards smoking cabinet. At the same time, an influx of air into the furnace is formed from the outside, through side holes in the smoke generator. The combustion is self-sustaining and no human intervention is required.

The temperature inside the cabinet is controlled by means of a thermometer inserted into the smokehouse.

By increasing or decreasing the length of the chimney, you can regulate the smoking temperature, therefore, use hot or cold smoking. For hot smoking, the smoke generator fitting is directly connected to the smoking chamber.

The dimensions of the smoke generator are average. When building it with your own hands, you can start from available materials and components. For example, cans, pans, and any cylindrical metal containers can be used as a body. Any pipe that is resistant to high temperature(but a metal hose is best). Without a fan, the smoke generator also works, but not as efficiently - the natural draft is too weak and the smoking process takes longer.