How to make a metal detector with your own hands: principle of operation, diagrams, step-by-step instructions. How to make a metal detector with your own hands at home Make a device for deep metal search yourself

Have you decided to figure out how to create a metal detector and try to make your own experimental device to get acquainted with the principle of operation and to test your own strength, but you don’t know where to start? Let's figure it out together, because recreating simple electronic circuits, including metal detectors, with your own hands is not so difficult.

Metal detector allows you to find objects that have certain electrical and electromagnetic properties that distinguish them from their environment. Such objects include, for example, various metals in the ground. Metal detectors are used by inspection services, the military, geologists, builders and specialists in a number of other professions to find metal in the soil and more.

Nowadays, a metal detector is often used by ordinary people to search for scrap metal from ferrous metallurgy and find non-ferrous metals that make up various coins, jewelry and military paraphernalia: shell casings, tokens and much more. Also, a metal detector can help in searching for items lost due to negligence that are vital or have material or moral value (parts of mechanisms, keys, rings, jewelry, etc.).

The sensitivity of this device depends on the diameter of the search coil. The larger its diameter (from 30 cm), the less sensitivity to small objects, but increases in sensitivity to large, deep ones. Conversely, the smaller its diameter, the better the reaction to smaller objects. Industrial designs provide detailed instructions on the sensitivity and use of the various coils.

Metal detector signal for large and small coins

Metal detector signal for large and small coins In a homemade device, the dependence of its sensitivity on the diameter of the coil is also preserved. But you need to remember that a homemade device will be far from professional equipment in its qualities due to various nuances of the physical processes occurring. In one phrase, the operating principle of a metal detector can be described as follows: the coil sends electromagnetic waves and simultaneously reacts to inductively induced currents in the metal, which generate their own magnetic field under the influence of the coil winding.

In reality, the physical processes are much more complex, and the search for treasures with professional equipment (with selectivity and separation) is not as simple as it might seem, and the abundance of debris in the soil can completely discourage digging when a high-quality device beeps every time. Therefore, the device given below cannot guarantee lucky finds of unimaginable treasures, but it will help you understand from your own experience the very principle of interaction between metal and the search coil of a metal detector.

Creating a device of this type does not present any great difficulties; you just need to be able to understand circuits and use a soldering iron. In this case, a simple circuit will be described using mainly a 555 chip (universal timer).

To familiarize yourself with the operation of such a timer, it is recommended to read the corresponding sheet with the parameters of this microcircuit (datasheet).

Required materials and tools:

- 555 chip (universal timer);

- 2 capacitors of 2.2 µF;

- resistor=47 kOhm;

- batteries = 9 V, wires for connections, cable for battery, switch;

- circuit board;

- copper wire=100 m (d=0.2 mm);

- buzzer for sound signals (it can be replaced with a speaker with resistance = 8 ohms and capacitor = 10 μF);

- wood glue and electrical tape;

- cardboard;

- pliers with which you can make a hole, tweezers;

- solder in the form of a wire and a soldering iron;

- ruler, sharp knife, compass, pencil;

- glue used for hot gluing;

- wires and breadboard.

Materials for making a simple metal detector

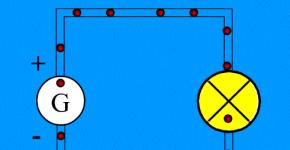

Materials for making a simple metal detector Metal detector circuit

You may come across various homemade metal detectors. They are freely available, you just need to enter “metal detector circuits” in the search bar. This one was taken in the same way from the Internet, but a buzzer was added instead of a speaker and a switch (for the battery).

Making a coil

For ease of calculation, you can use an online air coil calculator. Using it, you can calculate that for a coil with a diameter of 9 cm, 250 turns (turns) of varnished copper wire d = 0.2 mm are needed. The inductance of this coil will be approximately 10 MGn.

The smaller its d (diameter), the more revolutions will be needed (for a coil with a diameter of 7 cm, 290 revolutions are required).

Metal detector screen

Metal detector screen Buying a ready-made one is not difficult. If you still decide to assemble it yourself, then before soldering the two ends of the wire you need to clean them using sandpaper. You must try to make all connections very carefully in order to exclude the influence of poor-quality installation on a homemade device, which will already respond to a lot of interference.

Assembled metal detector screen

Assembled metal detector screen Coil testing and PCB creation

In order not to spoil the working board, it is better to test this circuit on a breadboard.

Checking functionality on a breadboard

Checking functionality on a breadboard The next step is to make the circuit board. If you don’t know how, then it’s better to find a description on the Internet with video lessons.

Circuit board assembled

Circuit board assembled Testing

Basis for construction

The base for your simple metal detector can be made of any materials convenient for you (wood, plastic, etc.). In this case, cardboard served as the basis. It is easier to use.

First you need to make a sketch of the handle (3 parts), you can even do it without calculations. This handle will have to fit the battery, circuit board, switch and coil.

Metal detector handle made of cardboard

Metal detector handle made of cardboard Cut out holes for the switch and battery. Glue the cardboard parts together using wood glue and leave to dry overnight (approximately 12 hours).

Cutting holes for batteries and wires

Cutting holes for batteries and wires  glue these parts together

glue these parts together After the glue has dried, you need to make a hole in the handle next to the switch so that the wires can pass through it freely. Finally, glue the spool to the cardboard handle using hot glue.

We place the battery and other parts on the handle

We place the battery and other parts on the handle Assembly of parts and conclusion

When all the parts have been completed individually, all that remains is to assemble them. First you need to glue the switch to the handle using hot glue, insert the battery and then glue the circuit board.

Now it's time to connect all the components to each other and test the device you created. It will not be easy for a beginner to understand this manual, but if this is not your first time making a metal detector, you will quickly figure it out.

Assembled metal detector

Assembled metal detector This assembled metal detector is quite powerful for finding small objects at close distances and preferably indoors, in order to avoid problems. But it should be remembered that this homemade product will be very inferior in sensitivity, detection quality, separation and selectivity, resistance to interference to industrial equipment, and it is worth repeating it rather for the sake of sporting interest and familiarization with the principle of operation of a metal detector.

What happened eventually:

A metal detector is a device that can be used to find metal objects underground. There are many types and varieties of this device. The main differences are in scanning depth and ease of use. The deeper a metal detector “sees,” the more expensive its cost.

The principle of its operation is based on the magnetic attraction of objects. The device generates a magnetic field that you direct into the ground. As soon as an object is encountered, the field is reflected from it and returns back. In this case, a signal about the find is issued.

Now we will tell you how to make a metal detector with your own hands.

- Timer chip 555 (SE555/NE555);

- Resistor forty-seven kilo-ohms;

- Two 2.2 microfarad capacitors;

- Battery "Krona" nine volts;

- Buzzer;

- Copper wire 0.2 millimeters in diameter;

- Wires;

- Scotch;

- A piece of cardboard;

- Glue.

- Any discs, but double-sided ones are better, so the device will be more sensitive.

- Headphones.

- Calculator without solar panels.

- The battery is 9 volt, you can use the crown.

- Glue.

- Insulating tape.

Show all

How to make a high-frequency metal detector with your own hands?

First, assemble the command block. You can use a laptop or radio for this.

Tune the radio to the AM frequency, as high as possible. Make sure there is no radio station operating on this frequency.

Now you need to make a search head. To do this, cut out two circles using a thin plywood sheet as the material. One should have a diameter of fifteen centimeters, the other approximately ten, so that they can fit into each other.

Now cut out the sticks from wood so that the rings are parallel to each other.

Using enameled copper wire a quarter of a millimeter thick, make fifteen turns from the plates.

Now you can attach the craft to the block itself.

Take a pole and attach a head to the lower end, and a radio detector to the upper end.

Turn on the frequency. If you did everything correctly, a quiet sound will be heard. To hear it better, you can connect headphones.

How to make a metal detector with your own hands? Easy way

You will need:

Electrical diagram

Making a coil

To make a coil with your own hands with a diameter of ninety millimeters, you need to wind two hundred and fifty turns of copper wire, and for a coil with a diameter of seventy millimeters - two hundred and ninety turns. After these manipulations we get 10 mH.

The frames for the coils can be made of cardboard and the wire is wound on them.

Testing the circuit

Assemble the parts on the circuit board and check how it works.

If everything works as it should, you make a printed circuit board on which you assemble all the parts.

Making a handle for the device

You can make it yourself using cardboard for the base. From it you cut out three identical parts in the shape of a boomerang, and make a hole in them for the battery. Then glue all three parts together. Dry and cut out a place for the switch. Attach the circuit, connect the battery, switch and glue the coil.

Checking the resulting metal detector

What you will need:

Cut off the headphone plug and strip off the insulation at the ends. Expose the wires by ten millimeters.

Divide the stripped wires into two parts, you get four wires.

Take one end of the wire from different headphones and glue it to the writing sides of both discs.

Using electrical tape, secure the wires to the drives.

Connect the two bare ends of the wires that remain to the plus and minus of the battery and also secure with electrical tape.

Turn on the calculator and attach it to the top of one of the disks.

Place the second disk on the calculator and fasten the disks with electrical tape.

Again, use electrical tape to attach the battery to the disk.

Ready! You can test it.

Metal detector at home

To get started, stock up on an empty computer disk box.

Take a small radio and attach it with the back wall to one of the doors of the box.

You also attach a working calculator without solar panels to the other door with its back.

Now set up the device. Turn on the radio and switch it to the AM reception range. Make sure there is no broadcast on this frequency. If it is on, adjust the dial until there is complete silence on the air. When you turn the receiver volume up to maximum, you should only hear noise.

The time has come to check the functionality of the device. To do this, slowly and slowly close the box. At some point there will be a loud sound. This means that the radio picked up the magnetic waves emitted by the calculator.

Now open the box so that the sound is not loud. Hold the box in this position, bring it to a metal object, and you will hear the same loud sound. This means that the device is working.

This is such a simple device that it is better to use it to find lost metal products at home. It is possible in nature, but there you need a more advanced device.

Simple and reliable metal detector

Electrical diagram

In order to make such a device, you will first need a vinyl plastic tube, the outer diameter of which is one and a half centimeters, and the inner diameter is one centimeter. It needs to be twisted into a ring twenty-five centimeters in diameter. This will serve as the base of the search coil (indicated in the diagram as L1). Do not forget to provide an exit hole; a stick will be inserted into it for holding.

Wrap the coil a hundred times with PELSHO wire with a diameter of 02.7, wrap aluminum foil in the form of a tape along the top, it will serve as a screen for the device. It is important that you remember to leave a small gap in the screen so that the L1 coil does not become shorted.

The device is powered by a battery or battery. You can control the frequency and sound of the signal using headphones.

A device that allows you to search for metal objects located in a neutral environment, such as soil, due to their conductivity is called a metal detector (metal detector). This device allows you to find metal objects in various environments, including in the human body.

Largely thanks to the development of microelectronics, metal detectors, which are produced by many enterprises around the world, are highly reliable and have small overall and weight characteristics.

Not so long ago, such devices could most often be seen among sappers, but now they are used by rescuers, treasure hunters, and utility workers when searching for pipes, cables, etc. Moreover, many “treasure hunters” use metal detectors, which they assemble with their own hands .

Design and principle of operation of the device

Metal detectors on the market operate on different principles. Many believe that they use the principle of pulse echo or radar. Their difference from locators lies in the fact that the transmitted and received signals act constantly and simultaneously; in addition, they operate at the same frequencies.

Devices operating on the “receive-transmit” principle record the signal reflected (re-emitted) from a metal object. This signal appears due to the exposure of a metal object to an alternating magnetic field generated by the metal detector coils. That is, the design of devices of this type provides for the presence of two coils, the first is transmitting, the second is receiving.

Devices of this class have the following advantages:

- simplicity of design;

- Great potential for detecting metallic materials.

At the same time, metal detectors of this class have certain disadvantages:

- metal detectors can be sensitive to the composition of the soil in which they search for metal objects.

- technological difficulties in the production of the product.

In other words, devices of this type must be configured with your own hands before work.

Other devices are sometimes called beat metal detectors. This name comes from the distant past, more precisely from the times when superheterodyne receivers were widely used. Beating is a phenomenon that becomes noticeable when two signals with similar frequencies and equal amplitudes are summed. The beat consists of pulsating the amplitude of the summed signal.

The signal pulsation frequency is equal to the difference in the frequencies of the summed signals. By passing such a signal through a rectifier, it is also called a detector, and the so-called difference frequency is isolated.

This scheme has been used for a long time, but nowadays it is not used. They were replaced by synchronous detectors, but the term remained in use.

A beat metal detector works using the following principle - it registers the difference in frequencies from two generator coils. One frequency is stable, the second contains an inductor.

The device is configured with your own hands so that the generated frequencies match or at least are close. As soon as metal enters the action zone, the set parameters change and the frequency changes. The frequency difference can be recorded in a variety of ways, from headphones to digital methods.

Devices of this class are characterized by a simple sensor design and low sensitivity to the mineral composition of the soil.

But besides this, when operating them, it is necessary to take into account the fact that they have high energy consumption.

Typical design

The metal detector includes the following components:

- The coil is a box-type structure that houses the signal receiver and transmitter. Most often, the coil has an elliptical shape and polymers are used for its manufacture. A wire is connected to it connecting it to the control unit. This wire transmits the signal from the receiver to the control unit. The transmitter generates a signal when metal is detected, which is transmitted to the receiver. The coil is installed on the lower rod.

- The metal part on which the reel is fixed and its angle of inclination is adjusted is called the lower rod. Thanks to this solution, a more thorough examination of the surface occurs. There are models in which the lower part can adjust the height of the metal detector and provides a telescopic connection to the rod, which is called the middle one.

- The middle rod is the unit located between the lower and upper rods. Devices are attached to it that allow you to adjust the size of the device. On the market you can find models that consist of two rods.

- The top rod usually has a curved appearance. It resembles the letter S. This shape is considered optimal for attaching it to the hand. An armrest, a control unit and a handle are installed on it. The armrest and handle are made of polymer materials.

- The metal detector control unit is necessary to process the data received from the coil. After the signal is converted, it is sent to headphones or other display devices. In addition, the control unit is designed to regulate the operating mode of the device. The wire from the coil is connected using a quick release device.

All devices included in the metal detector are waterproof.

It is this relative simplicity of design that allows you to make metal detectors with your own hands.

Types of metal detectors

There is a wide range of metal detectors on the market, used in many areas. Below is a list that shows some of the varieties of these devices:

Most modern metal detectors can find metal objects at a depth of up to 2.5 m; special deep products can detect a product at a depth of up to 6 meters.

Operating frequency

The second parameter is the operating frequency. The thing is that low frequencies allow the metal detector to see to a fairly large depth, but they are not able to see small details. High frequencies allow you to notice small objects, but do not allow you to view the ground to great depths.

The simplest (budget) models operate at one frequency; models that fall into the middle price range use 2 or more frequencies. There are models that use 28 frequencies when searching.

Modern metal detectors are equipped with a function such as metal discrimination. It allows you to distinguish the type of material located at depth. In this case, when ferrous metal is detected, one sound will sound in the search engine’s headphones, and when non-ferrous metal is detected, another sound will sound.

Such devices are classified as pulse-balanced. They use frequencies from 8 to 15 kHz in their work. Batteries of 9 - 12 V are used as a source.

Devices of this class are capable of detecting a gold object at a depth of several tens of centimeters, and ferrous metal products at a depth of about 1 meter or more.

But, of course, these parameters depend on the device model.

How to assemble a homemade metal detector with your own hands

There are many models of devices on the market for detecting metal in the ground, walls, etc. Despite its external complexity, making a metal detector with your own hands is not that difficult and almost anyone can do it. As noted above, any metal detector consists of the following key components - a coil, a decoder and a power supply signaling device.

To assemble such a metal detector with your own hands, you need the following set of elements:

- controller;

- resonator;

- capacitors of various types, including film ones;

- resistors;

- sound emitter;

- Voltage regulator.

Do-it-yourself simple metal detector

The metal detector circuit is not complicated, and you can find it either on the vast world wide web or in specialized literature. Above is a list of radio elements that are useful for assembling a metal detector with your own hands at home. You can assemble a simple metal detector with your own hands using a soldering iron or other available method. The main thing is that the parts should not touch the body of the device. To ensure the operation of the assembled metal detector, power supplies of 9 - 12 volts are used.

To wind the coil, use a wire with a cross-sectional diameter within 0.3 mm; of course, this will depend on the chosen circuit. By the way, the wound coil must be protected from exposure to extraneous radiation. To do this, shield it with your own hands using ordinary food foil.

To flash the controller firmware, special programs are used, which can also be found on the Internet.

Metal detector without chips

If a novice “treasure hunter” has no desire to get involved with microcircuits, there are circuits without them.

There are simpler circuits based on the use of traditional transistors. Such a device can find metal at a depth of several tens of centimeters.

Deep metal detectors are used to search for metals at great depths. But it is worth noting that they are not cheap and therefore it is quite possible to assemble it yourself. But before you start making it, you need to understand how a typical circuit works.

The circuit of a deep metal detector is not the simplest and there are several options for its implementation. Before assembling it, you need to prepare the following set of parts and elements:

- capacitors of various types - film, ceramic, etc.;

- resistors of different values;

- semiconductors - transistors and diodes.

Nominal parameters and quantity depend on the selected circuit diagram of the device. To assemble the above elements, you will need a soldering iron, a set of tools (screwdriver, pliers, wire cutters, etc.), and material for making the board.

The process of assembling a deep metal detector looks something like this. First, a control unit is assembled, the basis of which is a printed circuit board. It is made from textolite. Then the assembly diagram is transferred directly to the surface of the finished board. After the drawing is transferred, the board must be etched. To do this, use a solution that includes hydrogen peroxide, salt, and electrolyte.

After the board is etched, it is necessary to make holes in it to install the circuit components. After tinning the board. The most important stage is coming. Do-it-yourself installation and soldering of parts onto a prepared board.

To wind the coil with your own hands, use PEV brand wire with a diameter of 0.5 mm. The number of turns and the diameter of the coil depend on the selected circuit of the deep metal detector.

A little about smartphones

There is an opinion that it is quite possible to make a metal detector from a smartphone. This is wrong! Yes, there are applications that install under Android OS.

But in fact, after installing such an application, he will actually be able to find metal objects, but only pre-magnetized ones. It will not be able to search for, much less discriminate against, metals.

Instrumental search is simply enormously popular. Adults and children, amateurs and professionals are looking for it. They are looking for treasures, coins, lost things and buried scrap metal. And the main search tool is metal detector.

There are a great variety of different metal detectors to suit every taste and color. But for many people, buying a ready-made branded metal detector is simply financially expensive. And some people want to assemble a metal detector with their own hands, and some even build their own small business on their assembly.

Homemade metal detectors

In this section of our website about homemade metal detectors, I will be collected: best metal detector circuits, their descriptions, programs and other data for manufacturing DIY metal detector. There are no metal detector circuits from the USSR or circuits with two transistors here. Since such metal detectors are only suitable for visually demonstrating the principles of metal detection, but are not at all suitable for real use.

All metal detectors in this section will be quite technologically advanced. They will have good search characteristics. And a well-assembled homemade metal detector is not much inferior to its factory counterparts. Basically, there are various schemes presented here pulse metal detectors And metal detector circuits with metal discrimination.

But to make these metal detectors, you will need not only desire, but also certain skills and abilities. We tried to break down the diagrams of the given metal detectors by level of complexity.

In addition to the basic data required to assemble a metal detector, there will also be information about the required minimum level of knowledge and equipment for making a metal detector yourself.

To assemble a metal detector with your own hands, you will definitely need:

This list will contain the necessary tools, materials and equipment for self-assembly of all metal detectors without exception. For many schemes you will also need various additional equipment and materials, here are just the basics for all schemes.

- Soldering iron, solder, tin and other soldering supplies.

- Screwdrivers, pliers, wire cutters and other tools.

- Materials and skills for making a printed circuit board.

- Minimum experience and knowledge in electronics and electrical engineering as well.

- And also straight hands will be very useful when assembling a metal detector with your own hands.

Here you can find diagrams for self-assembly of the following models of metal detectors:

|

Principle of operation | I.B. |

| Metal discrimination | There is | |

| Maximum search depth | ||

| There is | ||

| Operating frequency | 4 - 17 kHz | |

| Difficulty level | Average | |

|

Principle of operation | I.B. |

| Metal discrimination | There is | |

| Maximum search depth | 1-1.5 meters (Depends on the size of the coil) | |

| Programmable microcontrollers | There is | |

| Operating frequency | 4 - 16 kHz | |

| Difficulty level | Average | |

|

Principle of operation | I.B. |

| Metal discrimination | There is | |

| Maximum search depth | 1 - 2 meters (Depends on the size of the coil) | |

| Programmable microcontrollers | There is | |

| Operating frequency | 4.5 - 19.5 kHz | |

| Difficulty level | High | |

Now, perhaps, there is no person who does not know what a metal detector or metal detector is. But let us remind you once again that this is a device that allows you to determine the hidden location of metals. The metal detector is very popular among amateur archaeologists and treasure hunters. The device is quite expensive, and some models are even sky-high, which is why most radio amateurs prefer to assemble it themselves. In today's article we will look at how to make a metal detector with your own hands, the operating principle of the device, popular circuits, as well as assembly and configuration features.

Read in the article

How does a metal detector work?

A metal detector, or metal detector, is an electronic device consisting of a primary sensor (coil with winding) and a secondary unit. Metal detection devices are divided into several types:

- "reception and transmission";

- induction;

- pulse;

- generator

Devices in the mid-price category are mainly of the “receive-transmit” type. The operating principle of such metal detectors is based on the transmission and reception of electromagnetic waves. The main elements of a device of this type are two coils: one is transmitting, and the second is receiving. The first coil transmits electromagnetic waves that freely pass through a neutral medium and which, when colliding with metal objects, are reflected and transmitted to the receiving device. After the reflected signal hits the second coil, the operator is informed by a buzzer that the target has been found.

An induction-type metal detector operates on the same principle as transmit-receive devices. The main difference between them is the number of coils with winding. An induction metal detector has one coil that sends and receives a signal simultaneously. Pulse devices are insensitive to the concentration of salts in the soil and include in their design a coil, the electromagnetic field of which creates eddy currents on the metal surface that are captured by the detector. This principle of operation reduces the possibility of discrimination, which can complicate the search.

Generator-type metal detectors come in different types, but they are all built on the basis of an LC generator. They have a low level of sensitivity and are generally designed to find only one type of metal. Metal detectors can also be divided into three categories:

- common use;

- middle class;

- professional equipment.

Functional and technical parameters of metal detectors

Before choosing and buying a good metal detector, you should clearly decide in what environment the search work will be carried out. It is also necessary to take into account the expected size of the objects being sought and the depth of their location. Let's look at the main characteristics that you need to pay special attention to when purchasing a detector:

- operating principle;

- operating frequency of the device;

- sensitivity;

- ground balancing;

- target designation;

- discriminator;

- additional functions.

The operating principle and operating frequency of the detector are the main characteristics that determine the capabilities of the device and show which category it can be classified into (simple ground, middle class or professional). Sensitivity determines the depth of objects with which the device can operate. As a rule, this figure ranges from 100−150 mm to 600−1500 mm. However, there are depth models designed to search for objects at a depth of 5 meters. The discriminator makes it possible to configure the device to search for a specific type of metal. This allows the operator not to be distracted by metallized debris.

What types of metal detectors can you make yourself?

You can purchase a detector at a specialized store or make a metal detector with your own hands at home. There are schemes that even a novice radio amateur can do. Devices that you can assemble yourself include:

- "butterfly";

- device without microcircuits (IC);

- model "Pirate";

- "Terminator 3" etc.

There is information on the Internet that you can supposedly assemble a metal detector from your phone with your own hands. Remember two words - this is fiction. There are some applications that allow you to include a tablet or smartphone in the detector circuit, but it is impossible to make a full-fledged device for searching for metals and recognizing them.

How to assemble a “Pirate” metal detector with your own hands: detailed instructions

Models of the “Pirate” series cost about $100–300. This cost is due to the device’s ability to detect objects at a depth of 200 mm (for small items) and 1500 mm (large items). Let's look at the features of assembling and setting up a device for detecting metals, as well as its components.

Materials needed to assemble a powerful metal detector with your own hands

To make a metal detector you will need the following materials and components:

- IC KR 1006VI1 or NE 555 (foreign equivalent) to create a transmitting unit;

- transistor IRF 740;

- IC K 157UD2 and transistor BC 547 for assembling the receiving unit;

- NPN type transistors;

- PEV 0.5 wire to create a coil;

- materials for the manufacture of the body, rod, etc.;

- a plate covered with copper sheet for making a printed circuit board;

- wires;

- insulating tape;

- side cutters;

- soldering iron;

- scalpel;

- Screwdriver Set;

- pliers;

- various types of fasteners.

Assembling a metal detector with your own hands: diagrams

Currently, there are many circuits for the “Pirate” metal detector, since some radio amateurs have begun to modernize them to suit their needs. All options will not be considered, only the most proven and most popular.

NE555 detector circuit

The classic circuit of a metal detector of the “Pirate” series, built on the NE555 IC timer. The operation of the device depends on a comparator, one output of which is connected to the IC pulse generator, the second to the coil, and the output to the speaker. If metal objects are detected, the signal from the coil is sent to the comparator, and then to the speaker, which notifies the operator of the presence of the desired objects.

DIY metal detector assembly without microcircuits

Unlike the previous circuit, this device uses Soviet-style transistors KT-361 and KT-315 to generate signals (you can use similar radio components).

DIY printed circuit board

The parts have been purchased, the diagram is available, and now you need to assemble it all. To place radio components, a printed circuit is used, which can be easily made independently. To do this, you will need a piece of sheet getinax covered with copper electrical foil. Transfer the selected diagram to the workpiece, mark the tracks connecting the parts, and drill holes in the places where they are attached and soldered. Cover the tracks with protective varnish, and after drying, lower the future board into ferric chloride for etching (removing unprotected areas of copper foil).

After the board is ready, you can install and solder the radio components. The next step is to check the circuit using measuring instruments.

Metal detector coil - how to make it yourself

Due to the fact that the Pirate metal detector is a pulse-type device, accuracy when assembling the coil is not important. For the base you will need a ring with a diameter of about 200 mm, onto which you need to wind 25 turns of 0.5 mm PEV wire. To increase the depth of metal detection, the coil frame should be in the range of 260−270 mm, and the number of turns should be 21−22 vol. Next, the mandrel with the wire must be well wrapped with insulating tape.

Place the finished coil in a housing made of dielectric material. To do this, you can use suitable-sized cases from faulty “throw away” household appliances. By the way, this will protect the coil from mechanical damage while working with the detector. The winding terminals must be soldered to a stranded wire with a diameter in the range of 0.5-0.7 mm. It is best to use twisted pair cable.

Checking and setting up the metal detector

We attach all the components of the device to the metal detector rod: the body with the coil, the receiving and transmitting unit and the handle. If the control circuit is assembled correctly, then adjustment of the device will not be required, since it initially has maximum sensitivity. Fine tuning is performed using variable resistor R13. Normal operation of the detector should be ensured with the regulator in the middle position. If you have an oscilloscope, then use it to measure the frequency at the gate of transistor T2, which should be 120−150 Hz, and the pulse duration should be 130−150 μs.

The video shows how to set up a metal detector.

How to make an underwater metal detector with your own hands

Sometimes search work has to be moved from land to water. What to do in this case, because the electronics will fail? There are, of course, special devices for working underwater, but you can make a deep metal detector with your own hands. To do this, you can take the most ordinary homemade detector and place all the components in hermetically sealed housings. In addition, it is worth slightly modifying the device and installing light indicators instead of an audible alarm.

How to make a Terminator 3 metal detector with your own hands: detailed instructions

The Terminator 3 model has long been popular among radio amateurs, and over the many years of its existence the device has received many improvements. We offer step-by-step instructions on how to make a metal detector yourself at home. The device has low power consumption, can be configured to search for certain types of metal, and has good depth characteristics.

Tools

Before making a homemade metal detector, you need to prepare the following tools:

- soldering iron or soldering station;

- solder, tin, rosin;

- pliers, round nose pliers, side cutters;

- Screwdriver Set;

- hacksaw for metal;

- oscillography and other instrumentation.

Diagram, selection of parts and circuit board

To manufacture the control unit, it is necessary to make a circuit board on which all the necessary radio components will be placed. The circuit presented below must be transferred to a getinax plate coated with copper foil and a circuit board must be made in the same way as described above in the article for the Pirate metal detector. The size of the circuit should be within 104x66 mm, and the board blank should be 10 mm larger on each side.

We will describe in detail how to prepare a printed circuit board for a metal detector in step-by-step instructions:

| Illustration | Process description |

| We take a textolite plate coated with copper foil. Degrease chemically or mechanically (sand). |

| We apply the diagram to the plate, cover the tracks with a protective varnish and subject the workpiece to etching (described above, as for the “Pirate” metal detector). Using a thin drill, drill holes for radio components and fastenings to the body. |

| We place the radio components in accordance with the diagram and carry out the wiring. |

| This is what the finished Terminator 3 metal detector board will look like. |

Metal detector coil

This is, in fact, the most sensitive part of the device. She is responsible for scanning the space underground. Let's look at the steps to create a simple coil for a metal detector:

| Illustration | Process description |

| On a piece of plywood we draw two circles corresponding to the diameters of the coils - internal and external. We drive nails around the perimeter of the circle. The diameter of the outer winding TX should be within 200mm. The coil is made from two folded wires. We wind 30 turns on the nails. |

| We tie the winding around the circumference with threads. We take out the nails, cover the resulting coil with varnish, and after it dries, wrap it with electrical tape and foil. In exactly the same way we make the internal winding RX, which is half the size of TX and contains 48 turns of wire. |

| We place the coils in the housing and wire the wires that will be connected to the control unit. |

| This is what the finished metal detector frame will look like. |

Homemade metal detector: detailed description of assembly diagram and setup

We discussed in detail the stages of assembling the board and the main elements of the metal detector earlier, now we are faced with the very last and most important steps: assembling the case and setting up the device.

| Illustration | Process description |

| We take a suitable box or make the case ourselves. We drill holes for trimming resistors and a connector. We mount the finished board and regulators in the case. |

| We close the case, connect the metal detector frame and attach everything to a plastic pipe with a handle. The metal detector is assembled and ready for use. |

This video will help you set up your metal detector.

Features of a DIY metal detector with a metal discrimination circuit

Metal detectors with a simple circuit allow you to detect hidden objects, but in order to find out which ones you will have to work with a shovel. Instead of a gold coin or a military helmet, you can find just a piece of pipe and spend a lot of time on it. To make the task easier for search engines, detectors began to be equipped with discriminators that make it possible to distinguish the type of metal and allow various types of debris to pass through. The simplest methods for determining the types of metals were implemented in old instruments and entry-level devices and had two modes - “all metals” and “non-ferrous”. The discrimination function allows the operator to respond to a phase shift of a certain magnitude, compared to a configured (reference) level. In this case, the device cannot distinguish between non-ferrous metals.

Professional metal detectors use discriminators with range selection. The microprocessor systems used in such devices make it possible to program the device to respond only to certain groups of metals. Discrimination is useful in littered areas, but reduces detection depth by 10−20%.

Assembly features of a deep metal detector

A deep-type metal detector is a special device capable of detecting objects hidden at a great distance from the surface of the earth. It is at considerable depth that the most interesting and valuable objects can be found. Some models can detect metals at a distance of 4 to 6 m underground.

There are two types of deep metal detectors: frame and transceiver on a rod. The first type of device is capable of covering a large area of land for scanning. Thus, the search speeds up, but has a negative impact on performance. The second version of the detector works in a small area, but better determines the center of the target. With such a device it is good to search in grass, forest or reeds. Therefore, when choosing the type of metal detector, you need to determine under what conditions the scanning will be carried out.

If you have experience assembling a metal detector yourself, tell others about it! If you have questions for the author of the article, ask him in the comments.