Do-it-yourself garden stove made of bricks. Do-it-yourself barbecue grill made of bricks

You have a cottage. You want to make it not only beautiful, but also convenient and comfortable for your family and friends to relax. And not to cost too much. Don't know where to start? Do-it-yourself braziers and barbecue for a summer cottage made of bricks from a photo are an ideal start for arranging suburban area. We assure you that after reading this article and looking at the drawings, you will build an ideal barbecue on your site, on which you will then cook delicious and healthy food.

A step-by-step guide to preparing and building a barbecue with your own hands from brick

Preliminary work (planning and drawings)

Before you build a brick brazier, you need to carefully consider what it will be like. We recommend paying attention to the following points:

When you decide what kind of barbecue you want to make, draw up detailed drawings with exact dimensions. Thanks to them, you will not only be able to correctly build the structure itself, but also calculate the amount of materials needed.

Choosing a place for the barbecue

Brick barbecue grills can be located anywhere in the summer cottage - in the garden, in the gazebo, on the terrace - as long as it is convenient. But we advise you to consider the following recommendations:

- The first and most important point is fire safety! Do not build garden barbecues near wooden buildings, dry trees and bushes.

- There should not be a playground nearby.

- It is convenient if the stove and the brick wall of the summer kitchen are located nearby so as not to run far for groceries and everything else.

If the project provided for a sink, build a water supply nearby.

In order for the future brazier to stand well and firmly for many years, make its base as reliable and stable as possible. The dimensions and strength of the foundation depend on the dimensions of the planned structure. In any case, the foundation area should be approximately 50 cm larger than the barbecue on each side.

After two weeks (if the heat is less), when everything hardens well, you can start building a barbecue with your own hands.

Choosing a barbecue brick

Here again, fire safety should be remembered. If the barbecue is indoors, you should take a special refractory fireclay brick, it has a lot of clay, due to which it withstands high temperatures well and quickly warms up the room.

Types of bricks that are used to build a barbecue

If the future construction is planned to be street, then professionals do not recommend doing everything from fireclay bricks because he doesn't like moisture. It is better to take a full-bodied ceramic brick M200 or facing. The inside of the firebox itself will be laid out from fireclay bricks.

Optionally, at the final stage of building a barbecue, its decorative finish is done.

We prepare the solution

Required for cladding cement-sand mixture, and for the laying of the furnace itself, clay-sand with the addition of a small amount of cement for strength. Can be taken ready mix for ovens and cook it according to the instructions.

To cook on your own clay mortar, will need:

- red clay;

- sand;

- cement;

- water.

Clay is filled with water and left for 5-6 days. Then it is thoroughly mixed, sand and cement are added little by little (a glass of cement 400 per bucket) and mixed again. The mixture is ready to use.

After the foundation has solidified before construction, two layers of roofing material must be laid on it for waterproofing. This is done so that the brick draws less moisture from the base, this will extend its life.

After that, we determine the position of the wall, apply the mortar and begin to build a brick brazier with our own hands.

Be sure to check everything with a level so that the masonry is even, as this will affect the quality of the furnace in the future.

Laying a simple brazier made of bricks (ordering)

To build such a brazier, carefully consider the scheme according to which step-by-step masonry, the so-called order.

The so-called half-brick laying is performed: each odd row (1.3, etc.) begins with a whole, and each even (2, 4, etc.) from a half. This is done for a bunch of bricks.

On top of the 4th row we lay the overlap, on which you can then put the dishes.

On the 8th row, you need to put 4 thick-walled corners, as shown in the figure. The 9th row is laid on the corners.

In the 10th row, all the beauty of this barbecue is “piano keys”. They can be cut with a grinder from white fireclay and red facing bricks.

The last 2 rows - and the brazier is ready. Please note that in the 11th and 12th rows, longitudinal halves of bricks are used.

Skewers and a grill will then lie on them.

View from all sides

This is how our brazier-piano made of bricks looks like from different sides.

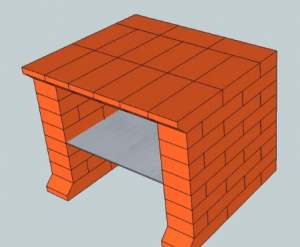

Option 1 - drawing with dimensions (click to enlarge)

Final result with dimensions.

Option 2, improved - drawing with dimensions (click to enlarge)

Another version of the barbecue grill. It is wider and the back wall is built from the bottom. Watch the video for the laying process of this option.

It was the most, which is easy to build on your own, even without experience in this area.

DIY brick barbecue - step by step construction with real photos

Consider another option, more complicated - how to make a brick barbecue with your own hands, which includes two lower compartments for firewood, dishes and other small things, a combustion chamber, a countertop and a chimney at the top.

For the construction of the structure itself, in this case, facing bricks were used, and refractory for the inside of the furnace.

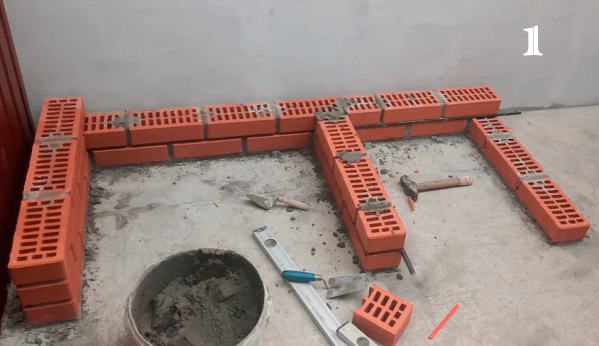

Initial construction stage

We start laying in the same way as described above. The lower part will be in the form of the letter "Ш", only the branches are different in width. What will be wider for firewood, above it there will be a firebox and a chimney. The second is for dishes and other accessories, there will be a countertop at the top.

We make even seams between rows

So that everywhere between the bricks there is the same and even seam, here, when laying, a metal bar is used, in the section of which there is a square with a side of 12 mm. But we advise you to take thinner - 5-10 mm will be enough. You also need to constantly control the level of verticality and horizontal masonry.

Brick laying process

The bar is placed on the edge, as shown in photo 4, then carefully smeared with mortar. On the side where they put the bar, we put the mixture on a par with it, on the other a little more, a slide. We lay a brick, from the side of the plank we hold it with our hand, and on the other, lightly tapping with a hammer, we align it to the level. When the solution dries a little, remove the bar.

In order for the masonry process to progress faster, there should be several planks, as they are needed for each row.

Posting lower part- first 10 rows

According to this principle, 10 rows are laid out.

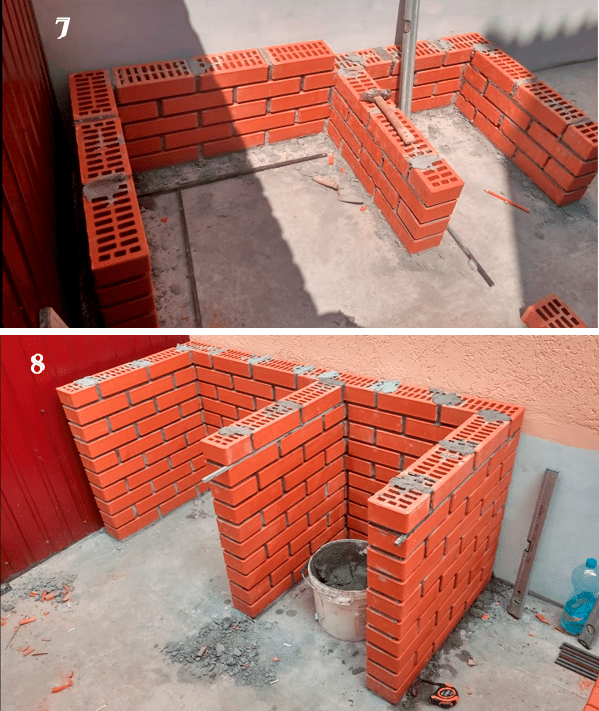

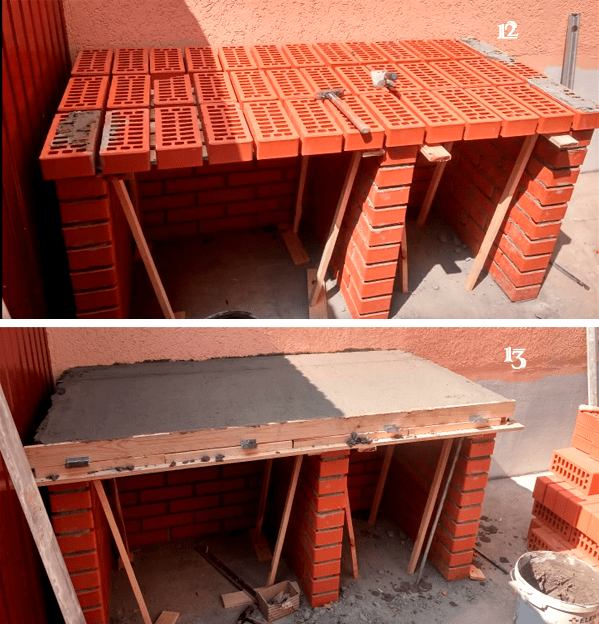

We prepare the basis for the firebox and countertops

Next will be the firebox and countertop. On the 10th row we put reinforcement with a diameter of 12 mm. The distance between the rods is 70 mm. Formwork is placed between the reinforcement so that the mixture does not fall down when the seams between the bricks are filled.

Professional advice: it is better to take metal corners, as there is a possibility that the reinforcement will bend under the weight.

We lay out the brick and fill it with mortar

At the same distance from each other, bricks are laid out over the entire area. Those that fall on previously erected walls are placed on the mortar, the rest are simply on the formwork. Then the gaps between the bricks and the surface are filled with mortar.

We form the combustion chamber and the vault

After drying, a firebox is erected - 8 rows are laid out vertically. Further, the back part, which is located near the wall, is also erected, and the remaining three sides taper up by half a brick. So 9 more rows are laid out.

Building a chimney

The next step is the chimney. In this case, 20 rows are made of bricks, and at the top there is a stainless chimney. A high pipe is needed so that the smoke does not interfere with either you or your neighbors, and the draft is better.

The last stage of construction - we finish the countertop and firebox

AND finishing touches- the tabletop is laid out with tiles, and the inside of the firebox - with refractory bricks.

Final result

After a few days to dry completely, the barbecue is ready to use.

We recommend watching the video, where there is the whole process of laying garden brick oven.

Below in the gallery you can see more photos of barbecues and barbecues for summer cottages made of bricks with your own hands, and choose the one that suits your site in terms of style, functionality and location.

In the gazebo

In the gazebo  On the terrace

On the terrace  WITH hob

WITH hob

On the street

On the street  With built-in smokehouse

With built-in smokehouse

There is no fundamental difference between barbecues and barbecues, except that on the first one, food is cooked on skewers, and the second on the grill. Both can be done on the same structure, the construction of which will be discussed.

Often, a country barbecue is a simple outdoor building in the open. A brick barbecue is a more complex device that can be located in a summer kitchen, gazebo or outdoors, but it already has a chimney and in most cases a cover to protect it from rain and snow.

A temporary brick cooking device is a great summer option

If you do not plan to visit the country house in winter, then a barbecue or barbecue made of bricks without mortar is perfect for this purpose. In the spring it can be easily and quickly folded, and disassembled for the winter.

Masonry scheme without mortar

Here is the diagram and step-by-step instruction, which shows the manufacture of similar barbecues and brick barbecues.

If the barbecue is planned to be small (9-10 rows of bricks), you can simply level and compact the ground well. For a larger structure, it is better to fill the foundation.

We begin to lay out bricks according to the same principle as in previous versions, but in a circle and with gaps of approximately 50 mm.

On top of the 5th row we lay steel sheet, which will serve as a pallet for coal.

We put 2 more rows and install the grate for cooking. Then 2 more rows for protection from the wind.

To build such a round barbecue brick, you need a little more than 100 pieces.

This is one example of a temporary barbecue, you can change it at your own discretion. Or choose for yourself and build one of the options presented below in the photo.

Now gardeners and summer residents are interested in a new product offered in hardware stores - barbecue ovens for the site. You can cook pies and pizza in them, as well as fry shish kebab, which is loved by almost everyone. However, the cost of such a stove stops many, forcing them to dream about it for months. But instead of saving up for one, you can create it yourself.

A self-made brick stove with barbecue will easily replace the stove in your country house.

Many craftsmen have learned how to make a brazier with a brick stove with their own hands. This design is very stable, reliable and perfectly replaces the stove, located in the room. The barbecue oven is usually installed in the garden or in the yard. And it is used most often in the hot season, when there is a desire to stay longer in the fresh air.

The housewives, who got the opportunity to cook on such an oven, are immensely grateful to their men with golden hands for the fact that now they do not languish from the heat in the kitchen when the temperature is very high outside. The advantages of a brazier with stoves are also that you can cook ordinary dishes on it. For example, using a large saucepan, you can easily make jam, which is harvested in the summer for the winter. And if you buy a cauldron, then it becomes possible to cook a very tasty pilaf.

Tools for laying the barbecue and for site equipment

To cut bricks, you need a grinder with sufficient power for this.

The necessary tools with which the craftsmen create their own platform for the stove and build the brazier itself include:

- Master OK;

- grinder for cutting bricks;

- vibrating plate;

- shovel;

- rubber mallet;

- solution container;

- bucket.

Materials for arranging the site and for creating a barbecue

The necessary materials for creating with a stove and equipping a platform for it are:

Refractory fireclay bricks are used for the inner frame of the furnace furnace.

- solid ceramic brick;

- , for framing the firebox;

- dry mixes intended for laying stoves;

- clay;

- sand;

- cement;

- wild stone;

- gravel;

- metal corner 30X40 cm;

- blower door;

- furnace door;

- grate;

- hob;

- ruberoid.

Choosing a place to install the barbecue

The place where the brazier will be built must be open. A large yard is suitable for its installation.

For reasons of fire safety, the place to install the brazier must be chosen away from tall trees.

However, having decided to place it in this way, you should check whether smoke will enter the neighbors' windows. To do this, you need to build a small fire at the place where the brazier will be installed. At the same time, you should ask your neighbors if smoke enters their house or summer kitchen. The stove with barbecue can be built in the garden or in the garden. In this case, you should choose an open area, preferably in the center of the site. If the installation site of such a structure is a garden with many trees, then part of the plantings should be removed from the place where food will be cooked on an open fire. This is necessary so that there are no fires.

Preparing the ground for the barbecue area

Trenches for the foundation of the furnace must be dug to the depth of soil freezing in winter.

If your yard is not concreted, not rolled up with asphalt or paved with stone, then you should prepare a site for the stove. The same recommendations for garden plot or vegetable garden. The oven itself will measure approximately 2.5 m by 1.5. The area for it should be at least 3 square meters. m, but more is better. First, the selected place is cleared of debris and the top layer of soil is removed. Then it is necessary to mark the dimensions of the brazier with a stove on the site and dig trenches to create a foundation. They are made as deep as the soil freezes through. winter time of the year. You can find out these data in design and construction organizations or in the district department of architecture.

Creating a foundation for a brick barbecue

To improve the waterproofing of the finished foundation of the furnace, clay is laid and compacted around it with a layer of about 2 cm.

- The first two rows are usually laid out solid, according to the dimensions provided for in the plan. In this case, you need to make sure that the rows are strictly horizontal, a plumb line will help with this.

- In the third row, you can install the ash door of the stove with your own hands. And the fourth row is created solid.

- In the fifth row, the ash door mentioned above is blocked with a lock and grates are installed. In this case, gaps of 5 mm should be left between the bricks and the grate. The sixth row is laid out without skipping bricks.

- The furnace door is usually installed in the seventh row. Next, lay out several rows all over, while you need to focus on the plan of the brazier.

- From the tenth row, as a rule, they begin to form furnace chimney. And in the eleventh, they block the opening of the furnace door.

- Approximately in the twelfth row, most often they create with their own hands a hearth of a brazier and a stove hob. As a rule, the level of the brazier is from the tenth to the thirteenth row.

- Starting from the fourteenth row, only the back and side walls of the barbecue oven are laid out, as well as the chimney channel of the stove.

- From about 21 rows to 23, a semicircular, arched ceiling of the barbecue hearth is being constructed. At the same time, for correct masonry brick, it is sawn at the right angle with the help of a grinder. Typically, a vault is built using wooden frame with an arcuate line, of the dimensions that are provided in the plan of the furnace. You can make such a frame with your own hands.

- From levels 24 to 31, bricks are most often laid out in continuous rows. At about 26, the smoke channel of the stove is displayed.

- Somewhere from the 32nd row, the smoke-collecting part of the brazier made of brick passes into the pipe. The cap above it is laid out from the same building material as the furnace itself. Some use ready-made - metal.

Arrangement of the site where the barbecue is located

The easiest way would be to put the formwork and fill the entire area with concrete. However, the latter cracks and crumbles over time, from rain and heating. This means that after a very short period of time, such a foundation will require a major overhaul. Therefore, it is recommended to install the stove on a concrete foundation, and pave the site with wild stone. This remains stable for decades, and besides, it always looks well-groomed.

Difficulties with laying stone in the yard, for those who are going with their own hands, cannot arise, because the latter is a rather complicated matter, which most often only an experienced stove-maker can do. Usually, sand is used to paving the site with a stone whose thickness is more than three centimeters. At least 15 cm of sand is poured into a “trough” rammed with a vibrating plate, 30 cm deep. In this case, each five-centimeter layer must be watered and rammed using a vibrating plate.

Between the layers of sand, a layer of gravel should also be poured, which also needs to be compacted. The edge of the barbecue area must be laid out with the same natural stone, however, on a cement mortar. The remaining stones are laid from the middle of the site to the edge and driven into the sand with a special rubber hammer. Between each part of the site, it is necessary to leave gaps of 3 mm, which subsequently need to be filled with sand. When the site is ready, you can relax at your barbecue, made of bricks.

However, this will only be possible if the weather outside is cloudless. If it rains, it will not be possible to fry kebabs. Therefore, it is recommended to create a canopy over a barbecue oven built with your own hands. Usually it is erected from building wood, and the roof is covered with tiles. Slate should not be used, because it does not contribute to fire safety. As can be seen from this publication, you can create a brazier with a stove on your site without resorting to the services of professional stove-makers. All you need is a quality plan, building material, time and the desire to create useful thing for yourself and your family.

Often the concepts of barbecue and barbecue are confused, as they are built for cooking on smoke and coals. But a brazier is needed for cooking barbecue, and a barbecue is a way to cook dishes on an open fire using a grill.

Ordinary brazier can be turned into a barbecue by attaching a grill to it.

barbecue oven are mobile and stationary, the dimensions depend on the functions performed. The simplest furnace is built in dimensions 0.18*0.07*0.9m, resembles an ordinary brazier with a grate.

A slightly improved barbecue is being built with a place for a hob, its dimensions are 1.7*0.4*1.9m. Protozoa furnace complex has dimensions 1.2*2.2*1.9m.

Furnaces are offered for construction with a cauldron, barbecue, stove, and other devices for cooking on charcoal. You just have to choose the project that suits your needs. We will tell you in detail in this article about how to build a brick barbecue with your own hands. Drawings, photos of some projects are attached. Well, the dimensions of a brick barbecue, drawings and photographs of other models of stoves can be found on the adjacent pages of our site.

Why build an outdoor brick barbecue with your own hands?

Contemporary variety of street tiles does not make it possible to choose a single model - I want to take an element from each project. Building a brick garden barbecue oven with your own hands allows you to combine them into one perfect oven on your site.

Photo 1. A small, highly aesthetic garden barbecue oven made of bricks with a barbecue and a work table. Such an uncomplicated do-it-yourself barbecue stove is built from brick and stone easily and quickly, especially if there is a special instruction for laying a barbecue with a barbecue.

TO advantages of a brick oven own construction include the following advantages:

- the possibility of creating your own project;

- the stove constructed in this way will stationary- it will not be stolen, even if the owners of the site will be absent for a long time;

- confidence in the materials and durability of the assembled furnace;

- laying a barbecue is so simple that a person without the experience of a stove-maker can master it;

- giving the site classical style or country style;

- creating a reason for pride in front of friends.

What are the projects of a barbecue oven and a brick barbecue?

The main projects for building a barbecue for a brick cottage are divided into 3 types:

- without pipe- the simplest oven, resembling a barbecue, requiring minimal cost to the building;

- with pipe- an improved oven, when cooking in which the smoke will not be scattered by the wind in different directions;

- with pipe and hob- for the possibility of preparing first courses, for example, soups, borscht, fish soup.

The best option is to create furnaces with a pipe without a plate, because most often the company is going to eat hot kebabs with no less hot drinks.

The pipe in the design of the stove will protect the vacationers from the random dispersion of smoke, flying ash particles.

Brick BBQ Building: Cost Estimate

One of the first stages in the implementation of the project is the calculation of the material that will be needed to build the furnace. Garden barbecues for summer cottages have many diagrams showing how to make this or that structure, and ordering is attached to some of them. Here it is especially convenient to determine in advance the volume of necessary building materials.

Calculation of the amount of ordinary brick for construction stove with chimney(in rows): 38+10.5+10.5+10.5+10.5+33+33.5+13+13+13+13+35+35+9+9+9+9+9 +9+9+9+18+26+22+20+12+10+9+7+5+5 = 474.5 pcs.

- ordinary Red brick 1 grade - 474.5 pcs.;

Calculation of the amount of refractory bricks for laying out firebox(starting from row 14): 7+7+7.5+7.5+7+7.5+7+3 = 53.5 pcs.

- refractory brick to create a firebox - 53.5 pcs.;

- concrete mortar for pouring the foundation or its mixture of water, sand, crushed stone, cement in a ratio of 4:4:4:1;

- metal pipe 15-20 cm in diameter - 1 piece;

- board for the formation of formwork - 1 pc.;

- coarse sand- 17 kg;

- reinforcing mesh - 2 m;

- sheet metal - 1 PC.;

- countertop- 1 PC.;

- oven grate for collecting coal - 1 pc.;

- silicone and heat resistant sealant for sealing cracks in masonry - 1 tube;

- facing material.

Before proceeding to the construction phase, check if there is tools:

- shovel;

- building level;

- rope;

- roulette;

- hammer.

Such tools are so simple that it is difficult to find an alternative to use them.

Attention! When building a furnace, you will need half bricks - they can be made using a grinder.

You will also be interested in:

Choosing and preparing a place for construction

The place where you can build a barbecue oven with your own hands is chosen based on comfort and fire safety. On distance of 3-4 meters from the furnace trees, bushes, grass should not grow. If extensions, a bathhouse, and other buildings are built on the site, the stove must be built in the distance. The prevailing wind direction should not be the direction towards your own and neighboring buildings.

Photo 2. An improvised place to relax with a barbecue in garden thickets. Surely you have such a corner on the site where a brick barbecue fits perfectly. The photo does not allow us to estimate the size of the site, but even a small stove will look better than such a scorched piece of land.

If we discuss the comfort of using future cooking in an outdoor oven, it is most convenient to place the structure next to recreation area- patio, gazebo, terrace. If there are no such places on the site, you can choose any place for a barbecue, and place a table with chairs next to it. Keep in mind that you will need a lot of water and wood for cooking and maintaining the stove. The size of the working area of the furnace is selected depending on the financial capabilities and the size of the site.

- located on the leeward side of a residential building. Otherwise, the smoke will go to the house, penetrating inside and leaving traces of soot outside;

- the undesirable presence of plants next to a barbecue grill made of bricks - their vital activity will be disrupted due to high temperatures.

When a place is chosen, you should prepare platform for the oven zone. The soil is cleared of the fertile layer: grass, bushes, trees. It is allowed to remove trees from your site without the consent of the local authorities, provided there are no environmental restrictions.

Attention! Be aware that roots left in the ground can sprout and damage the floor covering in the oven area.

Usually, during the planning and clearing of the area for future construction, coniferous and fruit trees. After that, you can go to the stage of pouring the foundation according to the shape and size that the barbecue drawing scheme you have chosen suggests.

Brick barbecue construction

Oven on personal plot, no matter what type it belongs to, this structure is quite intricate and requires a certain amount of knowledge. Therefore, for everyone who decides to build a barbecue for a summer residence with their own hands, step-by-step instruction, which is given on this page of the site, is simply necessary. If laying barbecue ovens with your hands is a process unfamiliar to you, you are unlikely to be able to lay out even the first row of brickwork without such instructions.

Prior to construction, it is desirable to carry out an approximate drawing for calculation required amount materials and proper construction.

Stove builders with extensive experience do not use a masonry drawing (they already know by heart how to lay out a brick barbecue with their own hands).

If you are not a specialist, you - in addition to the usual drawing - will also need ordering brick barbecue, masonry drawings or a detailed diagram of barbecue masonry.

Any brick barbecue oven is built in layers - one row of bricks after another. The number of bricks in each row is not the same and they can be stacked in different ways. In order to know exactly how to fold a brick barbecue with your own hands and not confuse anything, you need drawings with order. Even a novice stove-maker, having such drawings in his hands, is sure that the projects for ordering barbecue ovens will help to avoid gross mistakes during the construction.

How barbecue stoves are made for brick cottages: foundation (in stages)

The heavy weight of a brick oven requires a solid foundation. Equally suitable tape And monolithic foundation. We will use the recommendations of furnace specialists and give preference to the monolithic version.

Attention! Best to pave working area around the oven.

So, let's start building a barbecue with our own hands - step by step instructions for pouring the foundation:

- digging a pit 1.5*2 m with depth up to 0.4 m.

- the bottom is leveled with a shovel;

- covered with a layer of sand 10 cm thick, filled with a small amount of water, rammed;

- a wooden formwork fastened with self-tapping screws is installed;

- reinforcing mesh is laid;

- the foundation is poured with concrete mortar;

- leave for a week to freeze.

Attention! When mixing, air accumulates in the solution, due to which the strength of the structure decreases. To eliminate air, you need to make holes in the uncured concrete.

Brick BBQ: base

The base on which the entire structure of the stove will be installed is the first stage from which the laying of a brick barbecue begins. The step-by-step instructions that we provide here should help to avoid mistakes, due to which the entire structure may ultimately be unusable.

Attention! At the stage of laying out a barbecue with your own hands, red burnt bricks of the 1st grade and a cement mortar are used step by step.

After the foundation has hardened, it is carefully studied for presence of cracks. They need to be sealed and wait until they harden.

Next, marked furnace outline. Experts recommend pulling the cord between pieces of reinforcement stuck in the corners. Bricks are laid along the cord, lubricated with cement mortar and 2 layers are laid, starting with half a brick.

You should check the evenness of the masonry with a level.

Attention! Tap with a hammer on the top and side of each laid brick - this strengthens the adhesion of building materials.

A grate for coals is laid on the second row. Apply the mortar to the end of the brick to increase the reliability of the masonry.

Subsequent rows will start with halves of a brick. Further, 5 rows of bricks are laid according to the presented scheme. Starting from the 6th, will be located oven tray- a small protrusion is made here. 3 rows are laid according to the scheme, and a new ledge for oven table basics.

Advice! Choose the height of the oven and table, guided by ease of use. You can freely relate to the number of initial rows - they do not affect the strength and reliability of the structure.

You will also be interested in:

Barbecue oven masonry: firebox

Attention! At this stage, you will need 2 types of bricks - ordinary red and refractory, a solution of clay and sand. The bricks will be laid out in 2 rows - the outer one is made of red brick, the inner one is made of fireclay. The bottom of the firebox should also be lined with refractory bricks.

Basis for firebox And countertops made in the form of a screed. Bars of boards are laid out with a thickness of one brick of bricks, cut into the size of the span. From above it is poured with a solution of concrete, left for 5 days.

The height of this part of the furnace depends on its shape: 9 bricks for a rectangular one, 7 for an arched one. Depth - up to 70 cm. The pipe is displayed after a few rows.

Photo 3. There is a process of building a brick barbecue. The photo was taken at the stage when the laying of the barbecue oven is almost ready and the construction of the woodshed is being completed. Another module is in the process of laying the first row of bricks.

Attention! To remove the chimney, the masonry area is gradually reduced, each row is reduced by half a brick in length and ¼ in width. From the 7th row, the laying of a pipe up to 13 rows high will begin.

Chimney masonry

Attention! At this stage, red brick and cement mortar are used.

A chimney in a brick barbecue located in the gazebo is bought at a hardware store or welded from sheet material . To seal the free space between the pipe and the furnace, apply heat resistant sealant. The gazebo must have a fireproof opening for the chimney.

Important! A cap is put on the upper end of the pipe to create the correct draft and protect the furnace from precipitation, which can impair its functionality.

It is easier to buy a tabletop in a store by attaching it to the created ledge silicone sealant . To make it yourself, you need to plaster with cement and tile or stone the surface after installing the slab.

Decorating a stove with a pipe

After removing the chimney, you can take care of the appearance of the barbecue. To do this, decorating the barbecue and barbecue oven with your own hands is done: the floor covering is laid out with non-slip material, for example, porcelain stoneware. In this case, a special glue is used. Walking along the facade grinder and clean with a brush to remove residual mortar. You can use tiles or wild stone to improve the aesthetic appearance of the structure.

Additional Attributes

To increase the comfort of rest next to the outdoor stove, it is advisable to take care of additional attributes.

To decorate the site and the possibility of a cozy time in the evening, you should supply electricity and perform table lighting, hearth, space under the roof, the boundaries of the recreation area or site.

Photo 4. A detailed diagram of a barbecue made of bricks by English-speaking specialists. In addition to the oven itself, the figure also contains a description of the work table with required dimensions. If you are going to build a brick barbecue with your own hands, drawings of this kind will be necessary.

work table to prepare food for cooking, rack for placement of spices, utensils and accessories are located next to the working area.

It is possible to completely place the furnace with a pipe in glazed gazebo and cook delicious kebabs all year round or mount a canopy for basic protection from rain.

As furniture for relaxation, a table, benches or chairs are purchased or created. Designers do not recommend buying cheap plastic furniture- it will spoil the atmosphere of outdoor cooking and can cause a fire. It is better to give preference to forged, wooden, wicker furniture in natural colors.

Fire safety

Remember to follow the rules fire safety. No one wants to interrupt their vacation to call the fire department and eliminate the consequences of a fire in nearby objects.

Fire Prevention Stove Installation Rules:

- the need to build on solid foundation ;

- metal sheet finishing or other non-flammable floor material in front of the stove;

- accommodation at a reasonable distance from flammable substances, trees, bushes, buildings.

Photo 5. A set of imported fire extinguishers of various sizes. For fire safety purposes, any brick barbecue oven must be equipped with one of these items: the photo shows how rich the choice of the owner of the cottage is.

Operating rules:

- when the oven is idle, it is covered case so that precipitation does not disrupt functionality;

- protect children from a location close to the furnace;

- do not leave a lit stove, especially with food, without supervision.

Various brick barbecue ovens: projects, photos, drawings

When you can’t stop at any one brick barbecue project, photos, diagrams, barbecue masonry drawings can make a choice. Explore the selection of illustrations we have prepared to understand which of the projects you like best. Pay Special attention on the complexity of the proposed design: will you be able to carry out this or that project with my own hands?

Photo 6. A fragment of an instruction showing how a barbecue oven is made of bricks. A barbecue laying order like this makes the job much easier, and especially for those who have never built a brick barbecue with their own hands. Drawings, so try to choose exactly with the order.

Photo 7. Graphic diagram of a brick barbecue. With your own hands, laying down a brick barbecue for a summer residence according to such a project will not be difficult at all.

Photo 8. Computer model of a brick barbecue: order and construction scheme. It will be easier to fold the barbecue with a more detailed diagram, but even such a drawing speeds up the construction of the structure.

Photo 9. A computer-generated approximate diagram of a brick barbecue. Masonry drawings attached to such a scheme will give accurate information about the size of the structure and the order of its construction.

Photo 10. Schematic sketch of a pedestal for a barbecue project. Dimensional drawings are necessary, no matter what type of stove you choose - stone or brick, small or large, complex in design or not.

Photo 11. Computer generated brick barbecue project. Downloading a similar project for free is very useful when there is a desire to lay out garden barbecue from bricks with their own hands.

Photo 12 The photo was taken at the stage when the foundation is ready and several rows of bricks have already been laid.

Photo 13. A small outdoor brick barbecue. The drawings of such a structure are extremely simple, however, if you decide to build a brick barbecue with your own hands, an order that describes in detail the laying of bricks is also desirable in this case.

h

Photo 14. Brick oven with two pipes. On our site you can see the most unusual barbecue projects. A photo of this model, for example, shows that a do-it-yourself barbecue and barbecue stove, folded with your own hands, can resemble a stove from a Russian hut in outline.

Photo 15. There are a wide variety of types of barbecue for brick cottages. The photo shows an elongated model folded in a corner. It is noticeable on the side wall that was used original circuit brick BBQ masonry.

Photo 16 This building consists of three simple sections. It can be seen that a rather unusual brick barbecue layout was used.

Photo 17. Brick structure for cooking various dishes in the open air. To build even such a relatively simple do-it-yourself barbecue oven, brickwork ordering may be necessary.

Photo 18 country house with a barbecue area and a stove with a large chimney. To build such a rather complex brick barbecue with your own hands, diagrams with detailed dimensions and sequence of actions are simply necessary.

Useful video

Watch the video posted here, in which you can see how to make a brick barbecue with your own hands. All other stages of construction are also shown.

average rating: 5 out of 5 .

Rated: 1 reader .

To make delicious meals in the country, good option will use a brick barbecue. Do-it-yourself construction is quite simple.

Our article will acquaint you with the principles of operation of a mini oven, you will find out what it can consist of.

Barbecue is the most popular way of cooking outdoors. A similar design is similar to a barbecue, has a typical device.

The difference between barbecue and barbecue

Barbecue specialists who have remade a lot of outdoor stoves with their own hands know that the brazier fries food from below due to glowing coals.

The food is not fried on top. Therefore, you have to constantly turn the skewer.

Barbecue is different. Meat is placed on the grate, the grate itself becomes slightly lower than the side walls. This is the whole essence of the work of this design. In a barbecue oven, the tray looks like a solid canvas, without grates.

During the smoldering of coal, food is gradually fried due to reflection from the walls of the oven itself.

The walls of the barbecue are high, due to this, a smoke cap is formed above the products, they are slightly smoked in it, this gives them a special aroma. If you put a piece of tough pork in such an oven, it will become soft and juicy during roasting in the oven.

You might think that the height above the walls of 25 cm does not matter, but this is not so. The culinary process is a delicate matter, food lends itself to the slightest change in temperature.

If you pay attention, you will notice that most picnics in nature or in the country are not complete without a barbecue oven, the brazier is not so popular. There are a lot of designs of a brick barbecue oven, you can easily choose a convenient option for yourself.

How to build a barbecue yourself?

At first glance, it seems that not simple cooking in a barbecue oven means that the design is complex. However, this is not so, building a stove with your own hands is quite simple.

It is the lovers of country gatherings who build stoves with their own hands. The materials for its construction are always at hand for each owner. Each man held bricks in his hands, which means that building a furnace for him will not be difficult.

First they put brick walls, then they measure the place where the firewood tray will stand, the last step is to install the grate for groceries.

When building a barbecue oven, it is important to think about its appearance. A beautifully crafted design will the best decoration suburban area.

Design features

If you speak to plain language, the barbecue oven is the most primitive brickwork. Make it in the form of the letter "P". Such a simple structure will be an excellent option for outdoor cooking.

Skillful builders put fasteners for skewers on the ovens, this greatly facilitates the work when frying meat, you don’t need to hold anything with your hands, just turn it over.

Barbecue Oven Materials

The barbecue oven is assembled from standard red brick, which is always available on the site. It is impossible to coat the layers of brick with ordinary clay; here you need a high-quality cement mortar.

At the end of the construction of such a furnace, a pipe is always removed, it serves as an exhaust hood, a canopy from bad weather and strong winds.

If there is an exhaust hood, such a stove can easily be placed in a gazebo, on outdoor terrace, acrid smoke will not come from it directly in the face.

Braziers, barbecues - have recently been very popular with absolutely everyone. Who doesn't love eating delicious food outdoors?

Without exception, everyone loves the taste of juicy, roasted meat. It is for such a pleasure that it is worth using all the strength, experience, building a similar oven. You will be proud of your invention, as well as delight your loved ones with new barbecue recipes.

Brick barbecue photo

Exist different variants brazier designs, most you can buy in the store or order from the masters. If the budget is limited, many structures are built independently. Good example- do-it-yourself brick brazier. Drawings and photos, step-by-step instructions and a detailed description are given in the article. Its design will perfectly fit into the landscape design of any suburban area. Within the framework of the article, we will describe in detail this process, “from A to Z”.

How to make a brick brazier with your own hands? Look for step-by-step instructions, drawings and photos below!

Brick brazier device or what may be included in it

A brick barbecue device can be simple type or more complex. Device simple brazier:

- several rows of bricks;

- brazier.

More complex structures are presented either as one massive building, or as a whole complex of buildings. All of them have a similar building structure and layout:

- foundation;

- plinth;

- lower side walls;

- brazier;

- upper side walls;

- chimney.

As outbuildings may perform:

- smokehouse;

- bake;

- tandoor;

- washing;

- cauldron;

- countertops for food preparation;

- niches for storing dishes.

Methods for determining the quality of a brick

Each type of brick has certain characteristic features. You can learn about them from the marking, which is presented in the form of letters and numbers on the product. Material properties meet the requirements normative documents and determine its scope. This is especially important when building a brick brazier with your own hands. Drawings and photos, step-by-step instructions and ordering are presented in the corresponding section of the article.

It is necessary to be able to independently determine the quality of the building material. There are a few simple ways that will help you with this. In addition, in this way it is easy to check the integrity of the manufacturer.

When choosing a brick, you need to look at:

- appearance. The form must be correct and not have any significant damage. Tolerances from the norm are within two millimeters for one of the sides;

- vibration and sound. Try lightly hitting the brick wall with a hammer. If it is of high quality and there are no internal cracks in it, the hammer will bounce and ringing will appear;

- internal structure. There should be no chips on the product, and the uniform color of the section is welcome. Fireclay should not crumble from bricks.

These measures will help you decide which brick is needed for the barbecue in your case. Remember: quality materials- a guarantee of a strong and durable design. Only in this way will it be able to withstand exposure to high temperatures and serve you for many years.

A brick that makes a dull sound when struck with a hammer indicates the use of low-quality raw materials in its manufacture and a violation of production technology.

Characteristics of refractory bricks

The question of what kind of brick to use for the barbecue worries those who decide to build a structure with their own hands and want to choose the best material for construction. Since the material will be used at high temperatures, it must meet important technical requirements:

- heat resistance. The brick must be designed for use at temperatures over 900 degrees. Such a temperature should not lead to its destruction even with prolonged exposure;

- the lower the thermal conductivity, the better. So you will reliably protect the buildings that are nearby;

- high mechanical strength.

The optimal characteristics of bricks for barbecue are:

Requirements according to GOST

The brick that is used for laying the barbecue must meet certain requirements in accordance with state regulations. We are talking about the following indicators: strength, temperature limit, and so on.

To assess the quality use GOST 8691-73. It determines the exact indicators in production:

- dimensions;

- weight;

- volume.

Density and fullness

The density and fullness of the material depends on the composition of the raw materials used in the manufacture. If it is clay, then the indicator should be in the region of 1800-2000 kg / m3, if quartz sand– 1800-1950 kg/m3.

Also important role plays the extent to which the manufacturing technology is observed. When constructing braziers, it is necessary to use solid brick, as it has a good indicator of strength. This type is resistant to various impact factors (adverse weather conditions, high temperatures).

Strength

For each brand of product, the value of strength is different. It depends on whether the recipe and brick manufacturing technology, as well as GOSTs, are observed.

Fireclay bricks have the best strength indicator. It is equal to 22 N / mm 2. Such products are great for the construction of fireboxes for barbecues and stoves. Strength is a determining parameter when choosing a material.

temperature limit

This indicator depends on the material and technology by which the brick is made.

For fireclay, this indicator is in a large range of 1640-1740 degrees. Such material is suitable for arranging a brazier.

Ordinary ceramic brick freely withstands lower temperature levels - up to 1200 degrees Celsius. Therefore, we recommend using it for laying the lower levels of the barbecue, external walls, as well as a smoke box.

Other sections of the structure can be made of brick with less stringent requirements.

Thermal conductivity

The thermal conductivity index is responsible for the ability of the material to give off heat. Since the brazier is located near other buildings, it is important to provide them reliable protection. This can only be achieved by using bricks with low thermal conductivity.

There is a certain coefficient called the thermal conductivity coefficient. The lower it is, the more refractory the brick is.

For ceramic, this indicator is up to 0.8 units, and for fireclay - up to 0.6.

Resistance to aggressive substances

During the combustion of firewood, coal and other raw materials, products are formed that adversely affect the brick. The most common substances that have a negative effect on brick include:

- acids;

- alkalis;

- salt.

Under their influence over time, the material is destroyed. To prevent this, it is necessary to choose brands resistant to aggressive substances. We recommend using fireclay bricks.

Silicate, hollow and quartz bricks are unlikely to be suitable for use in such conditions, due to their composition. In an acidic environment, they begin to break down.

Water absorption

The main feature of fire-resistant brick is that it has voids inside. This is due to the raw materials from which it is produced and the production technology itself. As a result, such products are able to absorb water, both from the atmosphere and in direct contact with it. Blocks can accumulate up to 25% of liquid. Depending on the quality, this indicator may vary.

The higher the water absorption of a brick, the less frost resistant it is: if, for example, a product has this indicator at the level of 10%, then, as a rule, its frost resistance is very low.

Silicate bricks have a water absorption coefficient of up to 15%. Builders do not recommend building foundations and plinths from it, as it will quickly lose its strength and break.

The optimal water absorption rate for bricks is 8%

Frost resistance

This indicator characterizes the ability of the material to withstand low and high exposure temperatures, subject to the maximum absorption of a large amount of moisture. To calculate the indicator in production, the brick is subjected to freezing and thawing in a special way, and then it is measured whether there have been any significant changes in its structure.

The number of freezing cycles is an indicator of frost resistance. Optimal value this indicator varies by regions. For example, in warm regions of Russia, 15-20 F is considered the norm, and in areas with a more severe climate, 35-50 F.

The frost resistance index is regulated by several GOSTs:

- GOST 530-2012;

- GOST 379-95.

Dimensions and accuracy of geometric shapes

This indicator is one of the most important for any brick, since it directly depends on the quality and size matching whether the final masonry will be even. Refractory is no exception. Its dimensions are regulated by the rules of GOST 8691-73.

According to the requirements, the product must have 11 standard sizes. At the same time, the length, thickness and height are in a certain ratio among themselves (standard brick: 250x120x65). As for deviations, they should not deviate from the norm by 5, 5 and 2 mm, respectively.

Control given parameter is carried out directly at the enterprises that are engaged in the manufacture of bricks. From a batch of products, several are selectively taken and their compliance with the standard is assessed.

Choosing a brick manufacturer

Bricks are produced by domestic and foreign factories. They offer a large selection of products that are distinguished by their characteristics and can be used in the construction of barbecues. We offer three manufacturers for consideration: the Vitebsk brick factory (we will use it in the construction of the brazier), the Borovichi factory and LODE.

| Company name | Characteristic features of a brick |

|---|---|

|

|

|

|

| LODE

|

|

When choosing a brick, there are several factors to consider. The main ones are the requirements of standards and the cost of masonry. The operational properties of the brazier depend on how correctly the brick is chosen. In this matter, it is recommended not to save and give preference to quality material

Advantages and disadvantages of brick barbecue

Before assembling a brick brazier, you need to dig deeper into the topic and understand the types of materials from which braziers are made.

by the most popular materials for the assembly of braziers are:

- heat-resistant steel (for example, grade 09G2S);

- cast iron;

- brick;

- concrete blocks;

Craftsmen make them from improvised materials:

- gas cylinder;

- ordinary large natural stone;

- metal barrel.

Among purchased barbecues have become widespread:

- folding;

- electrical.

These types of braziers differ from each other primarily in price, dimensions, and also weight. If you still can't decide which option is best for you, we invite you to take a look at the comparison table below.

| Type of barbecue | Advantages | Flaws |

|---|---|---|

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

| Folding brazier |

|

|

|

||

|

|

|

|

||

| Electric grills |

|

|

|

||

Which brick is better for building a barbecue

The modern building materials market offers customers a large selection of bricks of different shapes, sizes and colors. They are produced by different factories and differ from each other in a number of key parameters. Below, we will try to figure out which brick for the barbecue is best suited. More detailed information in the table:

| Picture | brick name | Dimensions, mm | Porosity, % | Density, kg/m3 | Thermal conductivity coefficient, W/m*K | colors |

|---|---|---|---|---|---|---|

| 250 by 120 by 65 | 8% | 1800-1950 kg/m3 | 0,7-0,8 | White gray | ||

| 250 by 120 by 88 | 6-8% | 1515 kg/m3 | 0,66 | White gray | |

| 250 by 120 by 88 | 6-8% | 1000-1450 kg/cm3 | 0,4 | grey | |

| 250 by 120 by 65 250 by 120 by 88 | 8% | 2000 kg/m3 | 0,5-0,8 | red, brown, yellow, light brown | |

| 250 by 120 by 88 | 6-8% | 1100–1400 kg/m3 | 0,57 | dark brown | |

| 250 by 120 by 65 250 by 120 by 138 | 6-8% | 1600 kg/m3 | 0,34-0,43 | dark brown | |

| 250 by 120 by 140 250 by 250 by 188 380 by 250 by 219 510 by 250 by 219 | up to 14% | 790-960 kg/m3 | 0,22 | brown, dark brown, yellow | |

| 380 by 250 by 219 | up to 14% | 700-1200 kg/m3 | 0,11 | brown, dark brown, yellow, red | |

| 240 by 115 by 52 240 by 115 by 65 240 by 115 by 71 210 by 100 by 65 240 by 115 by 113 | until 6% | 1900-2100 kg/m3 | 0,8-0,9 | brown, red, yellow | |

| 250 x 124 x 65 | 3-8% | 1700–1900 kg/m3 | 0,6 | brown, red, yellow, beige |

There are special requirements for the material that is used in the construction of a brick brazier with your own hands, since the integrity and service life of the future structure depend on it.

The best option is fire-resistant brick. It allows you to get a safe, durable and robust design. You can build a brazier from the following types of bricks:

- from red;

- from fireclay;

- from white;

- from facing;

- from ceramic;

- from silicate.

We build a brick brazier with our own hands: step-by-step instructions, drawings and photos

Despite the fact that building a brazier out of bricks with your own hands is a simple task, it has a fairly large number of stages. Each of them has its own small construction features, which together lead to a large positive result. Therefore, it is important to draw up a plan for how you will build the future structure and strictly adhere to it. The object of this master class in the photo below.

- Conduct preparatory work. Analyze the topic, learn in more detail the features of barbecues and more about their designs.

- Determine a place for the structure on your site and prepare it.

- Make a blueprint.

- Buy everything necessary tools and materials - everything you need to work on the project.

- Decide on the order. As part of this step, you will prepare a plan for how to properly lay brick for your barbecue.

- Lay the foundation of.

- Prepare masonry mortars.

- Put the grill out to dry.

- Put the brazier on the solution.

- Build a canopy.

Preparatory work

Let's start with preparation. Take enough time to dive into the topic and learn all the details of the project. Look at examples of popular garden barbecues, their features, pros and cons. This will save you from wrong actions in the future. As a result, you will definitely know how to build a brick brazier. After that, you can proceed to the stage of selecting a place on the site.

We determine the place for installation on the site

The choice of a place for building a brazier made of bricks with your own hands, drawings and photos, as well as step-by-step instructions for which are located below, should be carried out taking into account its safe and convenient operation. You should not place the building:

- Near the house or other buildings. The minimum distance from structures is three meters.

- Under hanging tree branches.

- Back to back with a support in the form of a fence, the walls of the house.

- Near objects that are flammable.

Such restrictions are not determined by chance. During cooking, the structure heats up, it is likely that sparks from coals and other raw materials will fly. When choosing a place, you must be guided by the requirements of fire safety.

You can draw a plan of your site to make it easier to imagine where to place the barbecue complex.

- The presence of groundwater. It is better to choose a place where they are not;

- Direction of the wind. It should not lead to ventilation and smoke problems;

Before you build a homemade brick brazier on the site, let's deal with its project and draw the dimensions - more on that later.

Project, drawing and diagram on paper

It is not easy to prepare a project and drawings of a brick brazier with your own hands with dimensions. This work requires certain knowledge and skills.

This stage involves determining the dimensions of the future structure. They will be used in drawing up the project plan. On the drawing you need:

- draw all structural elements;

- designate dimensions;

- indicate the exact location of the elements.

In this case, it is important to observe the accuracy of proportions. Thus, it will be possible to visually assess the appearance and ergonomics of the future structure. We offer a plan and a drawing below. The only blot is that this plan shows a brazier with countertops instead of a stove, but otherwise its design is similar. You can see what the stove looks like in the photo below.

, as well as the explanation and description below

, as well as the explanation and description below Detail drawing designs are shown below.

- The total width of the structure is 8 bricks - 2000 mm;

- Length 3 bricks (not shown in the drawing) - 750 mm;

- The height of the slab in 12 bricks is 780 mm;

- The internal height of the combustion chamber in 12 bricks is 780 mm;

- The total height, together with a smoke chamber of 43 bricks, is 2795 mm;

Tools and materials

When the brick brazier scheme is ready, you can take care of the tools that will be required to complete the plan. You will need:

Tools:

Gloves

Rope and pegs

Cement tank

Bulgarian

materials:

Ordinary brick 180 pcs

Brick Sh-8 - 175 pcs

Brick Sh47 for the arch - 26 pcs

fireclay sand

corner

Cleaning door 140x140

Furnace door 410x410

Cast iron tiles

How many bricks do you need for a barbecue? For this project, 831 pieces will be required, as detailed above. In addition, we need cement, sand, clay, rebar, metal corners, tiles, and more. Only if all the materials are available, you can start the main work.

Installation

It's time to proceed directly to the construction of the barbecue with your own hands. When doing work, it is important to consider each brick row. This will be described in more detail below in the paragraph on ordering, but for now we suggest that you familiarize yourself with the types of solutions that are useful for work.

Masonry mortar

When building a brazier in the open air, 3 types of mortar are used. This is due to the different heating temperatures. different parts designs.

| Solution type | Application | Description |

|---|---|---|

| Cement-sand | The outer verst of masonry is the foundation, the first rows of the brazier (up to fireclay bricks), the head and neck of the chimney. | A cement-based mortar is used in places where there is no strong heat. Not suitable for laying the inside of the oven. |

| clay-sand | Masonry of the inner verst, namely, the thermal storage zone, the source and fluff of the chimney. | More heat-resistant (up to 400 degrees) than the cement analogue, and also environmentally friendly. The shelf life of the solution is not limited! In case of evaporation of moisture, it is treated by diluting water. |

| We use for laying the combustion chamber. | When buying fireclay clay, make sure that it is not spoiled and has not been in a humid room for a long time. During operation, such clay can withstand up to 1800 degrees Celsius. The solution based on it is plastic, but when dried it is extremely durable. |

In the manufacture of fireclay mortar for barbecue from bricks to areas with increased heat load, you will need:

- fireclay sand;

- ordinary clay;

- water.

To do refractory mortar, do the following.

- To get started, take the clay (a full ten-liter bucket), add water to it and stir until a homogeneous slurry. Leave for 3 days until swelling.

- Next, take more water and add to the solution. Gradually mix in the sand. The resulting mass should be in consistency like thick sour cream, for example. The optimal ratio of sand:clay = 2:1.

- In case of water overflow, add a little more clay to the solution.

Clay-sand mortar

Let's make, we need:

- gray or white clay;

- shovel;

- sand;

- water.

- It is necessary to soak fireclay and ordinary clay 1:1. After the latter swells, mix with a spatula so that there are no lumps.

- Add sand in a ratio of 4:2 with clay and water. We do not use cement in such a solution.

- The last point is to check the readiness of the solution. We take two bricks and put them on top of each other with a 5 mm mortar seam, removing its excess. We give 40 minutes to dry and check the quality of the hitch - we lift the structure by the upper brick so that the lower one remains suspended. If it does not come off - the solution is of high quality. This concept is called adhesion.

cement mortar

We prepare a cement mortar, for its manufacture we will use:

- cement brand M400;

- water;

- sand;

- mixing container.

Manufacturing technology cement mortar for brick brazier not so complicated anymore:

- We use the proportions cement:sand = 1:3.

- Sand should be free of any impurities, as the process of weathering the mortar from the masonry will accelerate. The yellower the sand, the lower quality it is.

- We use a container - 1 bucket of cement, for 4 buckets of sand. We get 40 liters of the mixture, because. cement still fills the gap between the sand.

- Adding water room temperature at the rate of 0.75 l per 1 kg of cement, stirring the solution.

- Check for adhesion, as in the previous paragraph.

On average, for laying 100 pieces of brick with a seam of 5 mm, about 30 liters of mortar will be required.

Since this structure has a lot of weight, you can’t do without a strong foundation for a brick brazier.

- Breakdown of the foundation and marking of the site. With the help of a tape measure, the place where the structure will be located is measured. Next, a spatula, pegs and rope are used;

- Digging a pit. Its depth should be 30-35 cm for a monolithic slab. This is quite enough (but it all depends on the soil in your area). Length - 2200 mm, width - 950 mm.

- We fall asleep a layer of sand by 10 cm and do sand cushion pouring water and ramming. Next, we lay a mixture of crushed stone and sand 3: 1, also 10 cm.

- Around the base, you can make a horizontal waterproofing layer, into which we fill the clay and carefully tamp.

- We lay the lining roofing material of the brand RKP-350 (400) for vertical coating waterproofing. This is a fairly durable and affordable material. This stage is mandatory if the groundwater level in your area is at a depth of more than 1 meter from the bottom of the barbecue foundation.

- The construction of formwork from planed timber (or any durable substitute) around the perimeter of the pit. It should rise about 8 cm above the ground. It is reinforced with props from two edges and in the middle of the structure in order to prevent destruction during concrete pouring. Formwork is needed to ensure that the monolithic slab is smooth.

Treat the boards with machine oil before laying to make it easier to remove.

- We lay reinforcement (8mm) at equal intervals of 10 cm in length and width (reinforcement). We knit the reinforcement with wire and primer with cement milk of the dough consistency. It is installed on linings so that when pouring it is approximately in the middle of the plate.

- We use cement brand M400. The solution in this proportion is cement: sand: gravel = 1: 2: 4. Dilute with water to a thick slurry.

- Pour in one go to get monolithic slab no cracks on the inside.

- The surface must be leveled with a spatula.

- The first 3 days we cover the stove plastic wrap to keep it from drying out.

- Formwork can be removed after 6-8 days.

After the foundation for the brick brazier is ready, it is necessary to leave it for a while. 3 weeks will be enough (however, it all depends on the thickness of the structure). During this period, he will sit down and gain the necessary strength, so that it will be possible to start bricklaying.

Do-it-yourself brick brazier ordering

Do-it-yourself brick brazier allows you to:

- Calculate the number of bricks required for construction (831 pcs);

- Calculate the required amount of mortar for masonry (~ 250 liters);

Brick barbecue ordering (masonry drawings)

Brick barbecue ordering (masonry drawings) The order is shown up to 24 rows(smoke chamber). The scheme of its masonry can be viewed on the sections, and the drawing in the corresponding section of the article.

Now let's take a closer look at each of the rows. For convenience, we introduce brick symbols:

- Vitebsk - "B";

- Private - "P";

- Brick Sh-8 - “Sh-8”;

- Brick Sh-47 - "Sh-47".

| Row | Brick |

|---|