Private houses made from containers. Container house in “jazz style” or do-it-yourself modular house

When deciding to build their own house from shipping containers, an ordinary person must, first of all, be convinced of the possibility of realizing such an intention and its advantages over other options for constructing a residential building. This article will introduce a potential developer to the classification and structure of sea containers, examples of already built houses, options for their layout, and construction features.

A shipping container is a large metal box. Alloy steel is used for its production. The design of sea containers is highly durable. Fully loaded boxes can be stacked on top of each other in 10-13 rows without experiencing noticeable deformation.

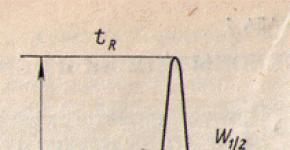

When designing houses from containers, the architect is primarily interested in the dimensions of the structural cells of the house. The international classification of containers and their sizes is based on the English unit of measurement - 1 foot. One foot is equal to 0.3048 meters.

The height of a standard shipping container is 8 feet 6 inches or 2.59 meters. There are also taller tanks of 9 feet 6 inches or 2.9 meters. The height of the module proposed for construction fits perfectly into the standards dictated by Russian building codes and regulations.

Container lengths are 20, 40, 45 feet, which in the SI system corresponds to 6, 12 and 14 meters.

The width of the most common 20 and 40 foot containers is 2.43 meters.

Thus, the house planned for construction will have residential rooms and non-residential premises with an area of 15 m2, 30 m2, 33 m2, and a height of 2.5 m. Analysis of the dimensions of sea containers shows their absolute suitability for arranging residential premises.

But the size of the room is not the main element of living comfort. The walls of the room must ensure heat retention and have sufficient thermal insulation properties.

Container design

Sea cargo containers are reliably protected from any accidents and difficult situations during transportation. Its design is based on a durable thick-walled metal frame made of alloy steel.

The upper and lower base of the block consists of strong longitudinal and transverse steel beams. The side structural elements of the container are welded to them. The walls of the module are sheathed on top and along the side perimeter with corrugated metal with a wall thickness of 1.5 -2 mm.

The use of welding and alloy steel makes the structure as rigid and durable as possible.

The surface of the steel is coated with special compounds that prevent corrosion. The container floors are laid with wooden boards with a thickness of 25 to 40 mm or 3 mm corrugated steel. Wooden floors are treated with antiseptic compounds. The use of lumber ensures a reduction in the weight of the structure, elasticity of the base and the ability to quickly replace failed floor coverings.

Cost of sea containers

Building a house from shipping containers is quite a rare phenomenon for Russia, unlike Europe and the USA, where such houses are being built everywhere and have become a common practice that does not cause surprise. The cost of one typical medium-sized container ranges from 2-2.5 thousand dollars. At the current dollar exchange rate, this is approximately 120-150 thousand rubles.

The cheapest construction option is a country house consisting of one block. A house for permanent residence will require the installation of several containers. The principle of volumetric design from individual cells of a rectangular design allows you to get a dwelling of various heights, original design, in a limited area.

Installing three containers in one plane will require 360-450 thousand rubles to purchase them, while the area of the house will be on average 90 square meters. Adding a second floor using 2 or three additional containers will double the value of the house. If your financial capabilities allow, you can own a durable, spacious house with significant savings in money and labor costs.

The structure of sea containers and the materials used dictate the need for mandatory wall insulation, especially in the harsh Russian climate.

Insulating the walls of a house made from shipping containers somewhat reduces the internal area of the premises. The thickness of the insulation and the method of insulation are calculated during the preparation of the house project and depend on the climatic region of construction. The average thickness of the insulation layer of the inner wall of a house is 0.2 meters and depends on the ability of the insulating materials to retain heat. Even with the increased cost of construction due to the need for insulation, houses made from shipping containers remain an inexpensive housing option compared to conventional houses made of brick or natural wood.

To heat a small country house, you can use a wood stove. For a large house used for permanent residence, the installation of a gas boiler with heating appliances in each room is required.

The options for combining shipping container cubes are truly endless.

Accordingly, house designs made from sea containers are distinguished by their amazing diversity and originality. If the size of the plot allows, you can build a spacious one-story house, in which you don’t have to bother going up to the second floor.

Next to the house you can make a comfortable, spacious garage for a car from the same marine block.

The internal space of rooms can be reduced with the help of light partitions, changing the layout in order to accommodate utility and sanitary rooms and passages. If the site area is insufficient, the rigid, durable structure of the containers will make it possible to add a second floor. At the same time, the floors and ceilings of containers that are joined in height are dismantled, and individual stairs connecting the floors are selected. The original placement of the blocks allows you to get a non-standard building configuration, spacious terraces for relaxation, an individual house layout, and stylish building architecture.

Below you can see ready-made houses made from sea containers; the photos clearly demonstrate the variety of architectural solutions for the layout and location of container modules.

Inexpensive shipping containers can fulfill the dream of many Russian families to build their own home on their own plot of land. A house made of sea containers, projects, prices can be found in the catalogs of design organizations.

Houses made from one block container are simple and unpretentious. One room serving as both a dining room and a bedroom and a small bathroom. There is everything necessary for a comfortable stay for one person or a married couple. More suitable for temporary seasonal residence in the country.

Placing three container modules in one plane provides living space for a family with 2 children: there is a large dining room - 23 square meters, a kitchen of 14 sq.m, several bedrooms 12x3 = 36 sq.m. bathroom 12 sq. m. Total area 85 sq. m. corresponds to the average area of three containers.

The layout of a two-story house made from shipping containers meets the requirements for modern large-area houses for large families. On the ground floor there is a spacious living room for joint meetings of family members or receiving guests, a kitchen - dining room, and bedrooms on the second floor. Both floors have bathrooms and toilets for family and guests, utility rooms: dressing rooms, storage rooms, etc.

A separate container can simultaneously serve as an excellent room for your favorite car and a workshop for a skilled home owner.

The construction of any house begins with obtaining permission from local governments for the construction of a building and developing a project. The project will be carried out by an organization licensed to develop design documentation for residential buildings. When ordering a project, the owner expresses all his wishes and ideas, and the specialists of the design company bring their plans to life.

House made from shipping containers, projects, the price of their attachment is a small fraction of the total cost of building a house.

After the design is completed, the construction process begins in strict accordance with the completed project.

The foundation of the house is laid taking into account the bearing capacity of the soil on the land plot.

The foundation can be monolithic over the entire construction area, strip or columnar, or pile. The foundation is the fundamental element of a building; the stability of the entire structure depends on it. The depth of the foundation is determined by design calculations and must provide strong support and the absence of freezing of the load-bearing soil layer.

The grade of concrete used for the foundation is determined by the project, usually it is grade B15 concrete. The easiest way is to order ready-made concrete from a concrete production plant; you can use a stationary small concrete mixer and prepare the mixture directly at the construction site.

Individual containers are connected to each other using durable metal fasteners and welding. If it is necessary to install additional window or door openings, they are cut out using gas cutting and must be reinforced along the entire perimeter with a metal profile for the entire height of the container. Unnecessary container doors are sealed tightly.

When building a house in the Russian climate with frosty winters and temperature changes, it is very important to properly insulate the walls and ceiling of a house made from shipping containers.

The developer cannot cope with this task on his own. The thickness of the insulation and its fastening on the inside and outside of the house are determined by precise calculations by heating engineers with special knowledge. Thermal insulation must be carried out in strict accordance with the design drawings and ensure dry walls and no condensation.

There are a lot of thermal insulation materials on the modern market for wall insulation.

The best materials for containers are expanded polystyrene foam, as well as mineral wool.

The top of the insulation is covered with a protective material that prevents the penetration of moisture and aggressive elements.

The floors of containers are insulated with similar materials, and a cement screed is placed on top of the insulation. A floor covering made of parquet, laminate or durable linoleum is placed on the leveled base.

The exterior finishing of the house is carried out with siding, decorative plaster, and tiles imitating natural stone.

All work on covering the metal walls of containers is carried out after removing toxic anti-corrosion coatings, removing rust and protecting against corrosion using means that are safe for people.

Houses made from sea containers, photos and design plans proposed for construction in the Russian climate.

If you purchase used shipping containers, their cost can be half the price and amount to two blocks of area 58 sq.m. about 160,000 rubles.

The cost of a strip foundation for two modules will be approximately 90,000 rubles.

Construction of a frame made of lumber and wall cladding with “lining” - 25,000 rubles

Thermal insulation of external walls made of mineral wool boards - 30,000 rubles.

A container block is a rectangular metal or wooden box with a flat roof. It has a door and windows and can be welded or transformable (dismountable). From collapsible blocks, by combining them, buildings of various sizes and complexity are created. More recently, modular buildings were considered exclusively temporary structures that could serve as cabins, warehouses or non-residential buildings - shops, offices, etc. But recently, country houses from block containers are increasingly being built, intended for seasonal recreation or year-round living. What modular houses can be like: photos and descriptions of examples in our article.

Application options for block containers

The container is a metal or wooden frame with a lathing for thermal insulation made of wooden beams around the entire perimeter. Structures made from containers are characterized by a high level of thermal insulation, strength and reliability. Of these they build:

-

houses at tourist bases;

cottages for year-round use;

country houses;

industrial buildings;

warehouses;

modular offices;

workshops;

security posts.

shopping pavilions;

This is not a complete list. In fact, modular technology is suitable for the construction of any low-rise structures. Containers are sold reinforced and insulated, with communications initially installed in them. All this allows you to obtain buildings for any purpose with minimal investment of money and time.

Construction Features

Modular houses are assembled like a children's construction set. Each container block is an element of the overall building structure, which is fully equipped by the manufacturer. At the construction site, the modules prepared according to the project are connected to each other. The process of constructing a modular structure consists of several stages:

foundation construction;

delivery of containers to the site;

installation of containers on the foundation;

connecting containers according to the diagram;

connection of communications.

The building is assembled using proven technology and does not take much time. If you use modules with exterior and interior decoration, after assembling the cottage you can move into it. But developers often use containers without decorative finishing. This allows you to choose facing materials to suit your taste.

A year-round cottage or summer cottage can consist of a different number of modules. There are many options for combining containers. In addition, a building made of modules can be supplemented with a frame extension, or, for example, a traditional attic roof. With the help of cladding, you can “disguise” the structure as a building made of any building material. From the modules you can build a very stylish and respectable cottage, looking at which no one would think that this is a prefabricated transportable building made from containers. The variety of options for modular cottages is ensured by the variability of combining containers.

Advantages and disadvantages

Modular construction represents a new direction in modern low-rise construction. Like any other technology for the construction of architectural structures, it has its advantages and disadvantages.

Advantages

The main advantage of modular cottages is the speed of assembly. In just a few days, the house can be installed and ready for occupancy. The blocks are made airtight, so they can be installed at any time of the year and in any weather. Since containers are delivered immediately with windows and doors and communication lines, the process of preparing for move-in is as short and simplified as possible.

Another important advantage is the ability to complete the house by adding new modules. You can attach it both horizontally and vertically - installing the container on top, on the second level.

Video description

In this video we will look in detail at the cost of each stage of building a small house:

The most attractive plus for private developers is the low cost of modular buildings. Containers can be delivered and installed using simple and inexpensive rental equipment. These processes are often undertaken by container manufacturers.

On our website you can get acquainted with the most popular projects of modular houses from construction companies presented at the exhibition of houses “Low-Rise Country”.

Despite the simple shape of the containers, with their proper combination, architects design very impressive modern cottages. The most original and attractive are modular houses in a modern style. But if the future homeowner loves classical architecture more, he can choose a container home project with a traditional gable roof. In this case, the building takes on the appearance of an ordinary country house, which will harmoniously fit into any environment.

Flaws

The main disadvantage is that factory units do not retain heat well enough. For construction in the southern regions this does not matter much. But when building a modular house in the Moscow region, attention should be paid to additional insulation of containers. The thing is that modular buildings are mostly still temporary or summer. However, some manufacturers are already producing warmer containers that are quite suitable for the construction of permanent housing. How much will such a warm house made from containers cost? Projects and prices for them can be found on the manufacturers’ websites. But on average it will cost 2 million rubles.

Containers made by unscrupulous manufacturers have many disadvantages. They are unreliable, poorly insulated, and the materials used for insulation and interior decoration may be unsafe for human health. Therefore, you need to be very careful when choosing the company from which you will purchase modules for your cottage. It is better to do this together with an experienced specialist; he will at least start by showing and telling what a house made of containers can look like, photos and projects; the specialist’s prices for them always correspond to the present time.

The cost of construction consists of two components - the price of the modules themselves and the cost of their delivery. If the container manufacturing facility is located too far from where the house needs to be built, the total cost will be too high. This is not a minus, but rather a feature of modular construction. If there is no enterprise nearby for the production of high-quality containers, it becomes economically unprofitable.

Loading the module with a manipulator Source alliance-catalog.ru

On our website you can find contacts of construction companies that offer the service of building modular houses. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Finishing

Quite high demands are placed on the appearance and interior of a cottage for permanent residence. Unlike country houses and temporary buildings, it should look solid and attractive. Containers are usually lined with galvanized metal sheets on the outside and clapboard or plywood on the inside. These coatings are covered with more aesthetic decorative materials.

The facades of modular houses can be decorated using conventional painting. But in order to give the building a respectable appearance, panel facing materials are used. If desired, you can even line a modular house with brick or decorative stone, but such a decision must be calculated at the foundation design stage, since facing brick or stone will make the house much heavier.

Decorative panels are also often used for interior decoration. If you need to get smooth surfaces, you can decorate the interior with plaster, paint or wallpaper.

Types of modules

The following can be used as modules for building a house:

module with iron frame;

module with wooden frame;

sea container.

The last option with a sea container is relevant only in regions where you can inexpensively buy and deliver used containers for transporting goods by sea. Such a container has only a frame, and all the filling, including insulating materials and lining, must be installed independently, and this requires qualified specialists.

When choosing between a container with a wooden or a metal frame, you need to take into account the features of their use. Metal modules retain heat well. They make real thermos houses. But in order to create a comfortable microclimate in such a house, it is necessary to think over a good and expensive ventilation system. Houses made of wooden containers do not require extremely effective ventilation, but during their construction more attention needs to be paid to insulation.

Based on size, block containers are divided into standard sizes. Their length can be 3000, 6000, 9000 or 12000 mm. They come in widths of 2500 mm or 3000 mm. The height may vary among different manufacturers, but in any case it should be at least 2400 mm. It is worth noting that not all container production companies strictly adhere to the standards, but the proportions of the modules are approximately the same for all.

Video description

For a clear overview of block containers, watch the video:

Containers 9 and 12 meters long have a fairly high cost, and they are also inconvenient to transport. Therefore, modules with a length of 3 or 6 meters are most often used.

Modular construction in Moscow

Residents of Moscow and the Moscow region have very wide opportunities in the construction of container cottages. There are various companies operating in the capital for the design, manufacture, assembly and installation of modular houses.

In the Moscow suburbs, the number of modular houses made from block containers is increasing every year. More often these are summer cottages that do not require additional insulation. But large cottages are also actively being built. With proper design and high-quality construction, very stylish and comfortable buildings are obtained.

Currently, Muscovites and residents of the Moscow region can purchase modern, beautiful cottages at prices starting from 1,000,000 rubles. For this amount, the customer receives a fully finished cottage with a high-quality layout and stylish design. Houses made from block containers prepared for move-in, the designs and prices of which are immediately indicated by the construction company, are an ideal way to quickly and inexpensively build comfortable housing.

Video description

More about modular houses for permanent residence in the following video:

Project options

The design of a modular house is tied to the parameters of the containers. This makes the architect's task more difficult. However, if an experienced professional gets down to business, he can create such a modular cottage, the layout of which will not have any flaws.

House from one block container

A dwelling consisting of one container block can accommodate everything necessary for living. It cannot be called spacious, but if you need to get a compact and economical house, this is the most acceptable option.

A standard medium-sized container can accommodate a full bathroom, kitchen area and bedroom. This type of housing is ideal for the construction of budget hotels and hostels.

House made of two block containers

By combining two containers, more spacious houses are built, which are quite comparable in size to city apartments. In addition to a bathroom and a bedroom, such housing has a comfortable kitchen-living room. If you install 2 containers parallel to each other at a distance of 3-4 meters, and build up the resulting void as a frame structure, you can get a fairly solid cottage.

Modern architects are designing quite unusual modular houses from two block containers. 2 containers can be combined in an original way. For example, they can be placed one on top of the other. But in this case you need to use large modules. Another option is to combine the modules with a slight vertical offset.

House made of three block containers

Three containers are enough to build a standard-sized cottage. If you make a frame living room in the center, you will get a cottage with a convenient layout and an expressive exterior.

House made of four block containers

The four-block cottage can already be called a solid dwelling of increased comfort. It can be one-story or two-story. You can combine blocks in a variety of ways. Most often they are lined up in one row, resulting in a square building in plan.

Video description

Watch the video to see what a house made from four blocks of containers looks like:

Conclusion

Modular construction technology has recently begun to be used in the construction of low-rise housing. Therefore, many private developers treat it with some caution. However, the most daring experimenters around the world have been building modular houses from containers for many years and proving their reliability, durability and practicality.

If you want to quickly and cost-effectively solve your housing problem, we recommend that you think about building a house from shipping containers. A few decades ago, no one could have imagined that a sea container could be used as temporary or even permanent housing, but technology does not stand still, and today, in light of the lightning-fast rise in housing prices, using a sea container for a house no longer seems unnatural . Despite the fact that in Russia, due to the insufficient distribution of container construction, you are unlikely to be able to find ready-made projects for houses made of containers, the demand for such houses abroad is beyond doubt and is due to the reliability and practicality of the buildings. According to experts, the low popularity of container construction in Russia is due to insufficient awareness of the population about the advantages of buildings built using this technology, as well as insufficient coverage of this issue on the Internet. To correct this, in this article we will, in a sense, try to promote the popularity of houses made from sea containers in Russia and consider the issues of their construction and arrangement.

Residential buildings made from containers: a new era in construction

Despite the fact that the popularity of container construction in Russia has not yet reached its peak, experts rightfully consider it a technology of the future, which will soon gain its loyal fans. This is confirmed by the demand for container construction in European countries, where this technology has contributed to the emergence of a new independent and profitable business sector, the basis of which is the design and production of container “semi-finished houses”. A semi-finished product means a base model made in a factory, the structure of which consists of walls and subfloors. It already has a heating system and electrical wiring installed, windows and doors are installed. Having purchased the required number of blanks provided for by the project, they are delivered to the construction site, where they are combined into a single building. The production of such blanks can significantly reduce the construction time of container houses, which is their most important advantage.

Advantages and disadvantages of houses made from shipping containers

Advantages of houses made from shipping containers:

- Houses made from shipping containers are recognized as one of the most seismically resistant buildings, and therefore they are often built in areas where natural disasters are common - earthquakes, hurricanes and others;

- Container buildings are not much different from permanent houses: the outside can be finished with clapboard, the inside with plasterboard;

- If you live in a home built using shipping containers, you may not be afraid of rodents and insects;

- Houses made from shipping containers can be built in any climatic conditions, but despite this versatility, it is important to remember the need for high-quality thermal insulation;

- The total cost of construction from sea containers is several times lower than the cost of permanent houses;

- If you decide to build a house from shipping containers, remember that they are advantageously combined with various building modules, including brick, reinforced concrete, etc.;

- The construction of a residential building from sea containers takes no more than two to three months, and if you minimize finishing activities and limit yourself to simple finishing, two to three weeks will be enough to complete construction activities;

- Due to the small load that container buildings carry, they do not require the installation of a solid foundation and can even be installed on carefully compacted earth;

- Sea containers can be used not only for the construction of residential buildings, but also commercial facilities. In addition, they can be used to build an outbuilding to an existing building;

- The installation of container buildings on frozen ground is in widespread demand, and therefore, it is often practiced from sea containers, mainly those intended for sea transportation, to build entire housing bases in the far north and Antarctica;

- If your construction project does not involve creating stained glass windows on the entire wall, it will protect you as much as possible from outside intrusion;

- Buildings made from shipping containers can be successfully erected in areas with a large slope.

Disadvantages of houses made from shipping containers:

- Often, special paints and highly toxic compounds are used to treat the walls and floors of shipping containers to protect them from atmospheric influences. In this regard, before using such containers for building a house, take care to remove these compounds;

- In the summer, a shipping container home gets very hot, while in the winter it cools down. Taking this into account, take care of organizing an effective thermal insulation layer;

- To avoid the appearance of rust on the surface of the building, it is necessary to organize careful observation and care of it;

- One of the disadvantages characteristic of container buildings is low ceilings (if the floor and ceiling are insulated, the height of the latter will be about 2.35 m).

Houses made from sea containers: projects, drawings, construction basics

A house made from shipping containers is a design solution that has become popular in Europe and America thanks to the famous architect Adam Culkin. It was he who became the author of the first container house in history, which became his creative experiment. Three shipping containers were used for its construction. As it turned out, purchasing sea containers did not cause any difficulties, and the financial side of the issue only pleased the author of this know-how. Over time, buildings made from sea containers began to be used not only as residential buildings, but also as hotel complexes, restaurants and retail premises, and their high seismic resistance and mobility made them especially popular in areas with frequent natural disasters.

For the construction of a residential building, mainly standard 40-foot cargo containers are used, which are characterized by the following internal dimensions:

- height - about 2.4 m;

- length - 12 m;

- width - 2.35 m.

If from one 40-foot container you can build a spacious extension or utility room, as well as equip a storage room or workshop, then from two or three building blocks you can build a house with an area of 60-120 square meters. meters. For example, two 40-foot containers installed opposite each other can be connected with stained glass windows and subsequently covered with a common roof.

Important! A distinctive feature of sea containers is their high strength. Initially, sea containers are manufactured in such a way that they can subsequently be installed on the sea deck on top of each other in the amount of 8-10 pieces. Considering this feature, it can be assumed that sea containers can be used for the construction of two- and three-story buildings. However, to increase the reliability of the container structure, they must be secured by welding.

Important! For the construction of residential buildings, you can use two, three or more shipping containers. If more than two containers were used to make the house, the space between the separated containers, which remains free, must be equipped as an additional room, using maximum glazing.

The construction of houses from sea containers, the price of which is on average 30% lower than capital buildings, begins with the development of a project and the acquisition of building blocks - cargo containers. You can find a large number of designs for houses made from shipping containers freely available online, amazing in their diversity. The most common designs involve the use of two containers that are placed side by side or at an angle to each other in an "L" or "T" shape. It is also possible to install containers on top of each other.

By moving the containers relative to each other, you will complicate the façade of your home, while at the same time making it more original. On the contrary, by moving the containers apart, you will create additional free space that can be used as a spacious living room with maximum glazing.

The next project is a container house, consisting of two blocks, which are united by a pitched roof. In one of the blocks there are two bedrooms, in the other - a bathroom and a kitchen. A living room is set up in the free space between the blocks, in the area of which the ceiling height will be greater due to the roof slopes.

Craftsmen with experience in building container houses recommend entrusting specialists with the creation of house projects from sea containers; in this case, there will be no problems with the drawing, since they will work out everything down to the smallest detail.

Residential building made from sea containers: stages of construction

If you decide to build a house from shipping containers yourself, without involving a contractor, keep in mind that construction will take longer and will also require the use of special equipment and welding skills. Before you begin construction, you need to purchase containers. To build a full-fledged residential building, experts recommend purchasing at least two containers, which on average (including delivery) will cost about 100 thousand rubles.

Important! Once the containers are delivered to the construction site, they must be tested for radiation. No matter how strange it may sound, it is in such containers that residual radiation often accumulates. As for the norm for background radiation, for our latitudes, it is 35 microroentgens per hour.

Foundation arrangement

The first and one of the most important stages of construction from containers is laying out the foundation. If you place the house directly on the ground, without a foundation, then the soil under the building will sag, and the building itself will freeze. The choice of foundation design for a container house is made taking into account its size and terrain characteristics. If you are planning to build an ordinary shed for spending time in the warm season, you can use several foundation blocks as the foundation. However, if we are talking about a two-story residential building created according to the author’s design, it requires preliminary preparation of the foundation. In most cases, it is recommended to give preference to a reinforced strip foundation.

To do this, a pit is dug, the dimensions and depth of which correspond to the requirements of the project. This will require calling specialized equipment - an excavator and trucks for removing soil. As for the most preferable foundation designs, in most cases experts recommend giving preference to a strip foundation, but sometimes you cannot do without piles. The latter is relevant for regions with weak, marshy soil.

Considering the large weight of a container building (especially if we are talking about a two-story house made of shipping containers), there is often a need to prepare a reliable foundation, the function of which can only be performed by a monolithic foundation. To fill it you will need grade 400 cement, sand and water. To increase its service life, special hardeners and other additives are often added to the solution.

Concrete work, which is an integral stage of foundation construction, can be simplified by ordering ready-mixed concrete. In this case, preparation of the foundation will consist of installing a reinforcement frame in accordance with the drawings, installing formwork and pouring mortar. Be sure to compact the concrete using special deep-well vibrating tools.

Constructive stage - installation of containers

You can start it only after the final maturation of the concrete, which will take at least 22 days from the moment the foundation is poured.

Important! While the concrete is maturing, treat the containers with anti-corrosion treatment. To do this, paint them with iron and then lead. Only then cover them with paint that is resistant to high temperatures.

After the final ripening of the concrete and anti-corrosion treatment of the containers, proceed to the next stage - installing the containers on the foundation. If we are talking about building a house from a 40-foot sea container, you cannot do without using special equipment, namely a truck crane. After you have installed the modules, they need to be tied and welded, fastened to the foundation and to each other. Next, install internal interior partitions. The easiest way to install partitions is from plasterboard sheets, which can be easily installed by yourself. However, in practice, a different technique is more often used. It involves removing and cutting the corrugated sheet from which the walls of the container are made, which will end up inside the building and are not provided for by the project. This is done immediately before their installation on the foundation. At this stage it is also necessary to cut through the doors and windows.

Important! If 20-foot containers are used in addition to 40-foot containers for the construction of a residential building, it is necessary to take into account the difference in their sizes. Combining containers of different sizes allows you to create a building with an unusual, original design.

Roof installation: main stages

Stage 1. To make the attic frame, a beam with a section of 10x10 cm can be used. To attach the beams to the container, use self-tapping screws, and to fasten them together, use plumbing bolts.

Stage 2. Having prepared the attic frame, install the rafters for the roof. The dimensions of the rafter boards are selected in accordance with the project, so that later they do not have to be spliced together. The rafters are connected using self-tapping screws.

Stage 3. Having installed the rafters, proceed with the installation of the sheathing, on top of which you need to lay sheets of galvanized steel. At the same time, it is important not to forget about arranging a vapor barrier, which can be done using two options:

- You can lay a vapor barrier film between the steel sheets and the sheathing;

- On the two sides of the house, under the roof itself, three 40-centimeter pipes with a diameter of 10 cm can be installed, which will ensure effective ventilation of the under-roof space. Holes for installing pipes must be made in advance. Considering the fact that the attic is used mainly in the summer, these pipes will not be closed for the winter.

Obviously, the first method is the simplest.

Important! When giving preference to a steel roof, remember that during strong winds and rain it will make a lot of noise. In this regard, despite the fact that steel roofing is an economical option, experts recommend abandoning it and choosing soft materials, for example, ondulin.

Insulating a house from shipping containers

Thermal insulation is an integral stage in the construction of any residential premises. When building a house from shipping containers, this is especially important, and since the metal from which the containers are made is a good conductor of sounds, it is important to provide not only heat but also sound insulation. The following materials can be used to insulate a house made from sea containers:

- Mineral wool;

- Polyurethane foam;

- Styrofoam.

The service life of mineral wool does not exceed 10 years, after which it loses its original characteristics. Polystyrene foam and polyurethane foam, unlike the previous material, due to their dense structure, are installed very quickly, and their service life is an order of magnitude longer and is about 20 years. They have not only heat but also sound insulation functions, which is not typical for mineral wool. Fastening of any of the listed materials is carried out using special glue or plastic pins. If you prefer pins, they must be screwed into the walls of the container in advance. A plastic film is laid on top of the materials.

Interior and exterior decoration of a house made from shipping containers

After you have completed the insulation, install a sheathing made of wood or metal on the surface of the building, onto which plywood or OSB sheets will subsequently be mounted for subsequent finishing.

The following materials can be used for the exterior decoration of the building:

- Siding;

- Block house;

- Decorative plaster;

- Natural or artificial stone;

- Plastic.

Plastic, block house and siding are attached to a wooden sheathing, previously protected with varnish. Decorative and natural stone - on a primed surface using concrete or special adhesives. The plaster is applied to a flat surface using spatulas of various sizes.

The interior decoration is practically no different from the exterior - insulation is mounted on the sheathing beams, which is covered with sheets of plywood or OSB. In this case, the space between the sheets of plywood should be at least 1.5 cm. Subsequently, they are filled with polyurethane foam, which will prevent dust from entering the house.

When producing interior decoration, plywood and OSB can be replaced with plasterboard, which can subsequently be lined with paint, plaster, wallpaper and other available materials.

When finishing the ceiling, you must remember that its height does not exceed 2.4 meters, and, as a result, abandon multi-level ceiling structures. Experts recommend choosing a regular ceiling, finished with plasterboard, or installing suspended ceilings.

This article discusses the features and specifics of such budget housing as a house made from a sea container: the advantages and disadvantages of buildings, the technical parameters of the building material and the average prices for its purchase. The text contains information that will allow you to independently create a house from containers on your site: interesting ideas, photos and videos, tips for creating a layout and unusual projects, step-by-step construction technology.

If you want to acquire comfortable and practical housing in the shortest possible time, you should pay attention to the projects of houses made from sea containers; the price of such structures in comparison with standard buildings is much lower and more affordable for most owners of suburban areas. This type of construction is only gaining popularity, which is due to low awareness of the population. Housing made from containers has been actively used abroad for several decades.

How container houses are built: photos and features of buildings

Container construction is rightfully considered a technology of the future, which will soon help many people solve their housing problem. In European countries, this approach is widespread, resulting in the emergence of a new business sector. This area includes services for the design and construction of turnkey container houses, the so-called “semi-finished structures”.

A semi-finished product is a model used as a basis for the construction of a building. This structure is manufactured in a factory and has a rough floor and walls. In addition, the standard equipment of the semi-finished product includes additional systems and elements:

- window structures;

- electrical wiring;

- doors;

- heating system.

After selecting a specific project, the owner of the land plot will only have to buy cargo containers in the required quantity. They are delivered to the construction site, where they will subsequently be combined into one structure. The use of such models can significantly reduce the construction time of a house, which is one of the most significant advantages of this technology.

Helpful advice! During the process of building a house, you can advantageously combine shipping containers with other building modules, for example, reinforced concrete or brick.

Why is it profitable to buy a house made from shipping containers: the advantages of buildings

Houses made from sea or cargo containers have many advantages. They have a seismically resistant design, so buildings of this type are often built in regions where various natural disasters are observed, such as hurricanes or earthquakes.

Blanks in the form of containers allow you to get a home that is practically no different from permanent buildings. The outer side of the modules can be finished with clapboard; the inner side is covered with plasterboard sheets. Moreover, the cost of container buildings is much lower than the price of permanent housing. By choosing a shipping container as a material for building a house, the owner can be sure that his home will not be inhabited by harmful insects and rodents.

It takes no more than 2-3 months to construct a container-based building. If you minimize some types of work, for example, simplify the finishing, then 2-3 weeks will be enough to put the house into operation. Since container buildings are light in weight, there is no need to build a massive foundation. The modules can be installed directly onto compacted earth.

Billets can be used not only for the construction of residential buildings. They are ideal for the implementation of projects of houses from shipping containers with extensions and utility facilities.

This technology is not limited to certain climatic conditions. If there is appropriate thermal insulation, a container house can be built in almost any latitude. Since modular blanks are designed for sea transportation, such houses can be safely installed on frozen ground. They are resistant to low temperatures and adverse weather conditions. Container houses can be built on plots with a large slope.

Interesting fact! Shipping containers are widely used for housing construction in Antarctica and regions located in the Far North.

If the design of a house made from shipping containers does not involve the installation of stained glass on the entire wall, such a building will provide residents with maximum protection from intrusion by strangers.

Disadvantages of modular houses made from block containers

Housing made from cargo and sea containers does not have many disadvantages. The amazing durability and longevity of these structures also includes a downside. To ensure that containers can withstand long-term use under aggressive weather conditions, they are pre-treated with special compounds and dyes. These protective coatings contain toxic substances. Therefore, before you start building a container house, you should remove the paint.

The blank modules are made of metal, so in the summer the surface of the structure gets very hot, and in the winter it cools down. To ensure comfortable climatic conditions in your home, you will definitely need to take care of high-quality and effective thermal insulation.

Under the influence of moisture, the metal becomes covered with rust. To prevent premature destruction of the building, it is advisable to regularly inspect the building for corrosion and carefully care for it. Low ceilings are one of the most significant drawbacks. If you insulate the ceiling and floor, the maximum height of the room will be 2.35 m.

Dimensions and photos of containers for building houses

Container dimensions are usually indicated in feet. For the construction of houses, structures intended for the transportation of railway and sea cargo are suitable. Moreover, the dimensions may vary depending on the load capacity. Containers of various capacities are used for transportation by rail, but exclusively large-capacity containers are used for housing construction.

The internal dimensions of a 20 t container are 2.33 x 5.86 x 2.19 m. Having similar dimensions, the structure has 29.5 m³ of usable volume. Minus the space allocated for installation of sheathing and insulation, this will be the approximate size of the interior space of the room.

Typically, standard sized 40 foot long shipping containers are used for building construction. The internal dimensions of this design are 2.4x12x2.35 m. One container will be enough to create:

- utility room;

- spacious extension;

- storage;

- workshop.

Using 2-3 blocks, you can build a house with an area of 120 m². An interesting option would be to install two containers opposite each other, connecting them with stained glass and covering them with one roof.

Interesting fact! In America and Europe, houses made from 40-foot containers are widespread. The first creator of such housing was the architect Adam Kalkin. The house appeared as a result of a creative experiment and consisted of 3 sea containers.

Dimensions of container blocks:

Container size, feet External dimensions of the container, m Container internal dimensions, m Internal volume, m³ Doorway size, m 20 6.05x2.43x2.59 5.75x2.35x2.39 33,1 2.34x2.28 40 12.19x2.43x2.59 12.03x2.35x2.38 67,5 2.34x2.28 45 13.71x2.43x2.89 13.55x2.35x2.7 86,1 2.34x2.58 In most cases, containers are rectangular in shape, although there are also square options with increased height.

How much will it cost to buy building material for a house made from containers: price of blocks

The price of blocks for building a house from containers depends on various factors. It is influenced to a greater extent by the configuration and size of the structure. In addition, the cost depends on whether the container is new or has been previously used. If the product is used, its price will depend on the condition. The cost of shipping containers that are well preserved and have normal geometry will be significantly higher than that of defective products.

Average prices for 40ft containers:

Container type Product Features price, rub. New containers 40 HCDD tall, double doors 305000 40DV standard 330000 40 HC high 360000 Used containers 40DV standard 120000 40 HC high 125000 Building a house based on container blocks will cost about 30% less than the cost of stationary housing made of brick.

Interesting projects and photos of container houses, prices for turnkey construction

Every year the architectural design of residential buildings becomes wider and more diverse. Some people, in an effort to emphasize their status, buy large houses with a modern design, made of steel, concrete and glass, others prefer extravagant solutions, for example, housing made from shipping containers. Moreover, there can be countless variations on this theme. Some people use a container as an extension to a building, while others have their entire house limited to the walls of one container.

Design of container houses: photos, ideas, design options

Despite their simplicity, house designs made from 40-foot containers look quite interesting. Such structures can be used as guest or country houses. The buildings turn out to be small and at the same time very neat. This option is ideal for budget construction if the land area is small.

Of course, the small dimensions and shape of the container significantly limit the owner’s design and decoration of the future home. However, this doesn't stop some people. You can improve the appearance of the building with the help of sliding doors and large stained glass windows, visually expanding the interior space. Homes painted in bright colors, such as blue, green or yellow, look great.

Helpful advice! If you install a small canopy over the front of the building, then during summer rain you can keep the doors open without fear of water getting into the room. Sheets of cellular polycarbonate are suitable for these purposes. To support the overall exterior, you can buy colored polycarbonate for a container house that matches the color of the building.

To create a warm and comfortable environment, it is advisable to use wooden panels as interior cladding. Even the simplest design can be turned into a great place to relax and live by experimenting with colors and materials. Such a house will fit perfectly into the surrounding landscape if you plant flower beds around it. Brave designers can try organizing a flower garden right on the roof, using cacti and other light-loving plants for this purpose.

Houses made from shipping containers: photos and designs of impressive buildings from the best architects

The design of the houses, developed by architect Adam Kalkin, who appreciated the advantages and durability of shipping containers, looks quite impressive in the photo. If you want to acquire housing with a large area, you can use his designs of multi-level buildings.

According to the idea, a kind of “house within a house” is created. To do this, individual smaller components are placed inside the massive structure, which can be used as independent full-fledged buildings. Thanks to large sliding glass doors, you can harmoniously connect your living space with the outside world.

Despite the unusual concept, such a house can accommodate everything you need for a comfortable stay:

- living room;

- kitchen;

- several bedrooms and bathrooms.

From an aesthetic point of view, a multi-level house with many container sections looks attractive and unique, and due to the presence of transparent glass doors, its already large space is filled with lightness and lightness.

Photos of a 2-story house designed by architect Marcio Kogan look no less impressive. This project allows you to create a residential building on the basis of industrial elements combined into one whole in a limited period of time. In order to give the house the required area, the containers are stacked on top of each other, and then the building is expanded. The result is a structure with large internal space. In the widest part you can arrange a comfortable living room.

Helpful advice! By using a clever retractable door system, the living room space can be extended to the outdoors, thereby providing a beautiful view from the room and quick access to the yard.

40 foot shipping containers can be used for construction. Through the use of vibrant colors and modern home ecosystems, simple blocks are transformed into functional homes with a joyful and cheerful design.

Unusual examples of container houses: photos and projects of non-residential buildings

Cargo containers are used not only for the construction of residential buildings, but also for the creation of other projects. An excellent example of this approach is the Starbucks coffee house, which, according to the idea of one businessman, was made of modular elements. This modern cafe made from containers has an original and unusual design, unlike the usual design of these establishments.

Many people associate shipping containers with fast delivery and fresh food, so this concept can be easily used to build your own store or cafe. A compact building made of containers can accommodate everything you need to start your own business. There will be enough space to install equipment and create a small work area for staff.

Taking an idea from designer Stephen Shoup, you can create a temporary office out of containers for a young company. If you are not sure about the stability of business development, modular buildings made from cargo blocks will be an excellent solution to the problem. This method is unusual and does not require large expenses. Stephen Shoup designed the L-shaped office building. However, this does not mean that other container placement options cannot be used.

The shipping container office building is a bit reminiscent of warehouse buildings, but it doesn't lack the appeal of an industrial style. The interior space can be effectively used for arranging office space. In this case, everything necessary for work will always be at hand, and if desired, there will be enough space for holding a small meeting or business meeting. It all depends on how many containers are used to build the office and what its internal layout is.

Interesting container house projects: design options

To create a beautiful modern home, two 40-foot containers will be enough. Such projects are suitable for people who do not strive for excesses. High-quality finishes and modern furniture will help turn a container house into housing that meets the basic requirements.

For people who prefer spacious housing, it is better to give preference to house designs consisting of several blocks. On the Internet you can find photos of houses made from sea containers, which do not always have a presentable appearance, but at the same time they are very practical and comfortable inside. In a building consisting of 4 blocks, you can arrange a large living room and a spacious kitchen, several bedrooms, etc.

Helpful advice! If the second level of the building is pushed forward above the first floor, you can get a kind of canopy. The space underneath is ideal for arranging a terrace, which will be an excellent place to relax outdoors in the summer.

Interesting houses that successfully combine container blocks and open spaces look unusual in the photo. Using modern technologies and design solutions, you can create comfortable living conditions in such a building. Before you start construction, you should think about adding elements such as:

- exploitable roof with landscaping;

- high-tech porous thermal insulation;

- geothermal heating system.

All these innovations will allow you to create a real home suitable for permanent residence of an entire family.

Popular container house projects and construction prices

The cheapest option for housing construction is to purchase and implement a country house project consisting of one container. If you need a place for permanent residence, you should think about building it from several blocks. Thanks to the principle of volumetric design of buildings consisting of individual rectangular cells, it becomes possible to obtain housing with an original design and different number of storeys, and in a limited space.

You can buy a house made of containers with a total area of about 90 m² for about 360-450 thousand rubles. Such a project involves installing three blocks in one plane. If you add a second floor using additional 2-3 containers, the cost of housing will double.

Single container houses are characterized by simplicity and practicality. In one room you can combine a dining room and a bedroom, and also organize a small bathroom behind a partition. This option is suitable for temporary residence of 1-2 people.

If you place 3 blocks in one plane, such housing will be suitable for a comfortable stay for a family with two children. A total area of 85 m² will be enough to equip a kitchen (14 m²), a dining room (23 m²) and several bedrooms (36 m²), as well as a bathroom (12 m²).

Two-story buildings made from cargo blocks have the same conditions as modern buildings with a large area. In this case, it is advisable to divide the layout of a container house into zones according to their intended purpose. On the ground floor it is better to arrange a spacious living room, which can be used for receiving guests and family meetings. It is advisable to organize a dining room and kitchen nearby. The second floor can be used for recreation. It is better to arrange bedrooms here.

It is advisable to locate general purpose premises on each floor:

- toilets;

- bathrooms;

- utility rooms (storage rooms, dressing rooms).

Important! Before construction begins, containers must be checked for radiation. The safe norm is 35 µR/h (micro-roentgen per hour).

Average price of a turnkey container home:

Materials for work price, rub. Used sea containers (2 pcs.) 160000 Arrangement of strip foundation 90000 Flooring installation 40000 Construction and roof insulation (tile or bulk insulation) 36000 Installation of external thermal insulation (mineral wool slabs) 30000 Construction of a wooden frame + clapboard cladding 25000 Ceiling organization (chipboard and timber) 12000 The cost of purchasing materials is 393 thousand rubles. If you hire a contractor to build a modular house from containers, then taking into account the cost of services, the price of housing will approximately double and will be 786 thousand rubles. The figures given are approximate only. Costs will depend on various factors, such as the quality and type of finish, soil characteristics on the site and other conditions.

Features of bathhouses made from sea containers and average construction prices

Cargo containers can be used for more than just residential buildings. Baths made from blocks are in high demand among consumers, who are attracted by the mobility of these structures, affordable price and the ability to adjust parameters to suit individual needs. Most often, 20-foot High Cube blocks are used to build bathhouses from containers. The area of such an element is 13.53 m².

This space is enough to organize the main components:

- shower;

- steam room;

- rest rooms.

Average prices for turnkey baths:

name of the project Equipment price, rub. Standard Cleaning and preparation, foundation installation, flooring, sewerage and water supply, wall and floor finishing 300000 Optimum Standard + glazing, finishing of walls and ceilings, installation of electrical wiring, installation of doors 400000 Maximum Standard + optimum + installation of all elements of the lighting system, plumbing, heating devices, ventilation, heated floors 500000 Note! All projects indicated in the table involve the installation of a steam room, water supply and sewerage systems, supply of electricity and cutting out window openings. The cost of double glazed windows is not included in the total price.

Consumer opinion about container houses: user reviews from forums

Many owners of summer cottages have already taken advantage of the idea of building residential containers and shared their opinions on forums.

“If you adhere to all the requirements and perform full insulation, a house made of container blocks will be a good solution to the housing problem. I like that a minimum of time is spent on erecting the supporting structure. After this, you can select doors and windows, as well as finishing, to your taste. There is no need to build a massive foundation, which greatly simplifies the work. Of course, the size and shape of modular elements are limited by standard frames, but if you have a creative streak, even this problem can be circumvented.”

Evgeniy Dorosh, Moscow

“My neighbor in the country started with one block, gradually adding additional modules to it. Now his country house made of containers looks no worse than a stationary building made of bricks. So I seriously thought about building such housing. The house looks interesting both inside and outside. I’ve never heard any complaints from my neighbor, so I think it’s worth a try.”

Igor Skripach, Ekaterinburg

“A container house can hardly be compared with a brick building. But taking into account the price, which is about 5 times less, such housing can be safely considered if the family’s budgetary capabilities are limited.”

Roman Lubko, Samara

How to build a house from containers: technology and recommendations

Construction of housing on the land plot is carried out in stages. Since the building does not require a complex foundation, all work can be done independently. Main stages of construction:

- project development;

- arrangement of the foundation part of the building;

- installation of containers;

- roofing;

- installation of insulation;

- internal and external finishing works.

Designing a 40ft Container House: Building Layout

The layout is developed taking into account the purpose of the building. Many companies offer standard projects for construction, but to create modern housing from containers it is better to use an individual approach. However, you should not rely solely on your own intuition. Despite the obvious simplicity of the construction process, it is imperative to act within the framework of the design work.

Before you begin constructing a building from cargo containers, it is necessary to perform strength calculations. To do this, weight loads are calculated and, based on the data obtained, the optimal dimensions of the foundation are calculated. In addition to these calculations, the design documentation specifies the type and quantity of building materials, as well as the appearance of the structure.

Note! To find out the cost of container housing, you need to take shipping into account. This service may affect the final price.

Depending on how many containers will be used to build a house, and how they will be placed in relation to each other, you can get rooms with different layouts and areas. Most often, developers resort to an option where several containers are installed in a row under one roof. In this case, the modules are adjacent to each other with the long side. With this arrangement, the rooms are connected by organizing internal openings.

An interesting option is obtained if one of the walls has a folding design. In this case, it can serve as a home space. Panoramic windows can be installed on the inside of the wall. Such a project will not only be successful in terms of ease of use, but also safe.

The layout of a country house made from containers will be more varied if you place the modular blocks in a checkerboard pattern. The designer will have a chance to show his imagination and achieve an interesting result. Options for parallel placement of cargo containers are quite popular. In this case, the modules are installed at a certain distance from each other.

Convenient and comfortable layouts are obtained in those projects where containers are located one above the other. From the outside, this design looks like dresser drawers. If the blocks are placed in a U shape on the site, it will be possible to arrange a patio. This area can be decorated and arranged for family fun.

How to build a container home that meets safety requirements

Bacteria and rodents can cause serious damage to a building, but there are other dangers, such as burglars. There are special design and technological techniques that allow you to avoid invasion from the outside and provide your home with reliable protection.

The front door is one of the most vulnerable areas. To secure this area of the house, it is advisable to install a frame wall immediately behind it, where an opening is cut. During the absence of the owners, the property will be protected by two door structures at once: standard and burglar-resistant.

Another way to make a building more secure against burglary is to install a wall with a lifting structure. This method is convenient and reliable, although it is expensive. A glass wall is installed behind the lifting structure, which will provide the building with additional natural light.

Helpful advice! If the climbing wall will be used as a terrace, it is advisable to use wood for its construction.

The size and shape of door and window structures do not affect the safety level of the building. These elements are selected taking into account the design of the premises or exterior of the house.

Building a foundation for a house from shipping containers with your own hands

The first stage of construction involves carrying out foundation work on the site. The house can be installed on piles, FBS foundation blocks, tapes. The choice of base depends on the relief features of the site and the properties of the soil. It is not recommended to install blocks without a foundation, since the soil will sag under the weight of the building, and in winter the structure will freeze very much.

If you intend to build a country house for temporary residence, foundation blocks are suitable as a basis. The two-story building needs careful preparation. In most cases, experts advise using a reinforced strip foundation. To build it, you will need to dig a pit, so you cannot do without specialized equipment, for example, an excavator, as well as trucks that will remove the soil.

If the site is located on weak, marshy soil, it is better to give preference to a pile foundation. To pour a monolithic foundation for a house made of block containers with several floors, it is advisable to use grade 400 cement, which is mixed with water and sand. By adding special hardeners to the resulting mixture, you can significantly increase the service life of the base.

It is allowed to use the ready-mix for concrete work. In this case, a reinforcement frame and a formwork structure are installed, which is filled with mortar. To get a high-quality result, concrete must be compacted. For this purpose, a deep vibration tool is used.

The structural part of building a house from cargo containers: installing blocks

The installation of cargo containers on the site can only begin after the concrete has completely dried. This requires at least 22 days. If 40-foot-long shipping containers are purchased for construction, then a truck crane will be required for their installation.

Helpful advice! While the concrete is drying, you can perform anti-corrosion treatment on the shipping containers. To do this, the blocks are painted using iron and lead. As a finishing layer, it is better to use a dye that is resistant to high temperatures.

When the concrete pour has completely hardened, the modules can be installed on the foundation. Then they are tied and scalded. This is done in order to secure the structure of the house from two containers to the foundation and connect the modules to each other.

At the next stage, internal interior partitions are formed. For these purposes, it is advisable to use plasterboard sheets. This material is easy to handle and can be processed well. As an alternative, corrugated sheets can be used. To obtain the necessary elements, you need to remove the inner walls of the container, which do not fit into the requirements of the project. This procedure is performed immediately before the blocks are installed on the foundation.

At the same stage, openings for windows and doors are cut out. A grinder can be used for this. After the operation is completed, you should carefully treat the edge of the cut with special means.

Since the design of the cargo container is not designed to have holes, the rigidity of the block will be significantly reduced as a result of installation work. To strengthen the supporting structure in weak places, namely in window and door openings, it is necessary to weld pipes or channels around the entire perimeter. This must be done so that the stiffening ribs extend from the floor to the ceiling.

It is advisable to use a continuous seam to connect all elements of the supporting structure. Fastening the container body to the stiffeners is best done by spot welding. If you do not have the skills to operate a welding machine, it is advisable to use the services of a professional, since it is very important to maintain the necessary inclinations and angles.

How to do roofing work in a container house with your own hands

First, the frame part of the attic floor is formed. For these purposes, it is recommended to use timber with a section size of 10x10 cm. The frame is fixed to the container using self-tapping screws. To fasten the beams together, it is advisable to use plumbing bolts.

When the frame part of the attic is ready, the rafter system is installed. If the size of the boards is specified correctly in the design documentation, then during the work they will not have to be spliced, making the structure more durable and reliable. Self-tapping screws should be used to connect the rafters. Next, a sheathing is formed, on top of which galvanized steel sheets are laid. When performing roofing work, you should not forget about vapor insulation. To do this, a vapor barrier film is placed between the sheathing and the steel sheets.

There is another way to organize vapor insulation. To do this, pipes 40 cm long and 10 cm in diameter (3 pieces on each side) are installed under the roof itself on both sides of the house. They will provide ventilation to the space under the roof. The holes intended for installation of pipes are made in advance.

Important! Steel sheets are affordable, but they make too much noise during heavy rain and wind. Therefore, it is worth giving preference to soft roofing materials, for example, ondulin.

High-quality insulation of a modern container house

Any residential premises need thermal insulation. This is especially true for buildings made from shipping containers, which conduct not only heat well, but also sound. Therefore, it does not hurt to install soundproofing materials along with thermal insulation.

The following types of materials can be used as insulation:

- polyurethane foam;

- mineral wool;

- Styrofoam.

The maximum service life of mineral wool is 10 years. After this, the material loses all its properties. Unlike mineral wool, polyurethane foam and polystyrene foam have a dense structure. Thanks to this, installation of such thermal insulation is quick and easy. The service life of polystyrene foam and polyurethane foam reaches 20 years. These materials have not only heat but also sound insulation properties, which mineral wool cannot boast of.

To fix the insulation, you can use plastic pins or a special adhesive. Plastic elements are screwed into the walls of the cargo container in advance. A polyethylene film is laid over the insulation. Then a decorative layer is installed, for example, chipboard or lining.

Insulation of floors is carried out in a similar way. For this you should use polystyrene foam boards. The use of mineral wool on floors is extremely undesirable, because it can retain moisture. Additionally, you can make a concrete screed.

In the process of insulation, it is very important not only to use high-quality materials, but also to try to eliminate sources of heat loss as much as possible. As a rule, their role is played by design flaws, which include:

- cracks;

- cold bridges;

- areas with high thermal conductivity.

The main source of heat loss is cracks. If the assembly of the structure is performed poorly, all efforts to insulate will be in vain. Therefore, it is very important to carefully treat all joints. Cargo containers are made of metal. This material has high thermal conductivity, so insulation is carried out not only from the inside, but also from the outside of the building.

Window and door openings can serve as a source of heat loss. In order to prevent rapid cooling of the premises, it is necessary to select high-quality materials for thermal insulation of the door structure, as well as double-glazed windows for windows of appropriate thickness.

Note! You shouldn't skimp on insulation. If all the work is done efficiently, in the future you can significantly reduce the heating costs of a container building. Therefore, the choice of materials must be approached very responsibly.

What materials are used for interior and exterior decoration of a house made from modular containers?

After the internal insulation of the house has been completed, the surface of the walls is covered with OSB boards, plasterboard or plywood sheets. These materials are attached to a rigid frame, which is assembled from metal profiles.

Ceiling coverings can be very diverse:

- drywall;

- Armstrong system;

- stretch ceiling;

- painted wood.

To decorate wall surfaces, the same materials are used as in standard houses, for example: wallpaper, plastic panels, decorative plaster, paint. The floors are covered with tiles, parquet, and linoleum. It all depends on the purpose of the room, personal preferences and budgetary capabilities of the owner.

The following materials are used in external finishing works:

- natural stone;

- block house;

- siding;

- decorative plaster;

- fake diamond;

- plastic panels.

Finishing materials for exterior work are selected taking into account the climatic conditions and design of the building.

Connecting a container house to communication systems and heating

Since container buildings do not require a massive foundation, the floors can be cold. The best option for modular houses would be a “warm floor” heating system. If there is high-quality insulation on the walls and roof, it can create comfortable climatic conditions for living. The underfloor heating system cannot be used as the main source of heating, especially if the ceilings in the house are high. Additional heaters will be required.

Helpful advice! If you install solar panels on the roof of a building, you can organize a convenient and efficient heating system.

If the house will be used for permanent residence, care should be taken to ensure that all necessary communications are available. These include:

- sewer system;

- electricity;

- water pipes;

- gas supply.

If electricity and gas supply can be supplied to the house at any time, then the calculation of sewerage and water supply is carried out at the stage of design work. If there is no centralized water supply system, you will have to find alternative sources, for example, build a well and connect pumping equipment. If there are no conditions for creating a sewer system, this issue can be solved using a cesspool or septic tank. It also wouldn’t hurt to install a system that provides natural and forced ventilation.

When all construction and finishing work is completed, you can begin arranging a house from shipping containers. There are no restrictions regarding the style of decoration and furniture. The owner can make his own decisions when creating the design of the premises. The exception is styles such as baroque and classic, which are characterized by the use of massive furniture. In conditions of low ceilings, such a design would be inappropriate.