Painting pvc and abs plastic. How can you paint plastic panels and how to do it right

Need to repair or repaint decorative coating on the plastic parts and PVC cladding occurs much more often than it might seem at first glance. It could be the surface plastic windows verandas, buildings home appliances, a soft inflatable boat, plastic elements of a body kit on a car and even protective covers made of fabric. It is not difficult to paint PVC plastic, but on one condition, if there is a special paint for PVC.

Difficulties in painting, how to paint PVC correctly

For coloring plastic, acrylic or acrylate paint for PVC profiles is used. As a rule, due to the high gloss or specific “oily”, paraffinic texture of the PVC surface, the usual acrylic paint on plastic lays down very badly, rolls down drops. Even the classic method of increasing paint adhesion by applying artificial roughness does not improve adhesion to the substrate.

Therefore, before attempting to apply paint to the window frame or plastic hinged parts, it will be necessary to thoroughly prepare the PVC surface:

- On the eve of using the paint, the PVC surface is cleaned of dust and dirt with soapy water and washed with clean water so that no traces remain. Ideally, a detergent for PVC parts is best, but you can also use water solution isopropyl alcohol;

- The surface is treated with a special solvent-activator that improves the adhesion or adhesion of the paint to the smooth PVC profile;

- If acrylic paint is used for painting on water based, PVC plastic can be lightly moistened with a hand spray gun, and then applied with a brush or airbrush.

Important! It should be borne in mind that the quality of the painted surface depends primarily on temperature and humidity. The higher the temperature environment, the better the adhesion, and the faster the drying speed.

After about a couple of hours, the paint applied to PVC at a temperature of 20-23 ° C will stop sticking to the hands, and after 26-40 hours the drying process of the painted surface will be completed completely.

Water-soluble acrylic paints allow you to get the painted PVC surface of the most different colors and shades. According to the paint manufacturers, the tinting machine, which is used for tinting and color correction, can produce more than 2,000 color compositions.

Technology for painting household items made of PVC

The high quality of the painted surface can only be obtained by using specially designed products for painting PVC surfaces of any modification. More simple materials, for example, frames and cladding of metal-plastic windows, can even be painted acrylic materials, but to obtain an exemplary glossy surface, a paint containing modifiers and a polyurethane varnish is required.

Therefore, to obtain a high-quality, perfectly smooth PVC texture, the following are most often used:

- Polyurethane paints and varnish compositions from Feyco AG, Switzerland;

- Acrylic-urethane paints "PaliPlast RP Base" used for industrial painting of PVC plastic.

For your information! Painting compositions "PaliPlast" are produced both on a water basis and on a varnish basis.

Despite the fact that, after drying, PaliPlast water-borne compounds are not washed off with water and withstand repeated washing of windows and frames, it is necessary to periodically restore protective layer using varnish, for example, "PaliPlast RP 022 Varnish".

Painting PVC plastic surfaces at home

The most demanded procedure for painting PVC plastics is the painting of frames of metal-plastic windows. Not everyone likes White color standard PVC cladding, or the owners want to make the windows of their shop or showroom more expressive, in any case, the coloring of the windows is not difficult if you use PaliPlast RP Base PVC materials.

It will only be necessary to seal the window, slopes, glass and rubber compressor frames with plastic wrap with masking tape, and you can start painting according to the method described above. The easiest way to apply paint on a PVC profile is with a brush or roller, but best quality obtained when using a spray gun low pressure. The viscosity of the paint is low, but the presence of mineral fillers can sometimes lead to clogging of the nozzle or poor spraying, so the paint solution must be cleaned of films and thoroughly mixed before use.

More difficult is the painting of decorative and protective elements made of PVC plastic on a car. Most often, these are moldings and linings inside the car. The size of the parts is small, so it is best to use spray cans to paint PVC plastic. The composition includes an activator and a solvent, providing good adhesion to plastic and rooted drying of the applied layer.

It is possible to paint small PVC parts both with preliminary dismantling from the car interior, and directly inside the car. In the latter case, you will need to install a fan to carry the aerosol flow out of the passenger compartment and make an apron from polyethylene film, which will close the space around the PVC part to be painted.

Full-sized PVC parts must be dismantled, dusted with alcohol or window cleaner, and then spray-painted in thin layers, 50-70 microns thick.

Difficult options for coloring PVC plastic

Large parts of the body kit or spoilers can be painted with a spray gun or spray gun. Initially, you will need to mat the surface with thick paper and micron-sized abrasive powder. Next, the plastic is thoroughly washed and dried.

Before applying paint, the surface will need to be wiped with a PVC cloth moistened with P646 solvent, and can be painted. If the thing is very thin and soft, then the first layer is best done with Feyco polyurethane varnish, after which the required number of layers of paint can be applied.

PVC pipes, structural frames, even glass and furniture can be painted in a similar way. In order to enhance the adhesion of the paint to a completely smooth and inert glass surface, Feyco proposes to add a special Fey (N) Vetro Zusatz 501 reagent to the paint. Polyurethane and epoxy compounds can be quite easily painted on metal, stone, plastic, wooden surfaces, while the quality of adhesion to the base is much higher than that of acrylic and water-dispersion materials.

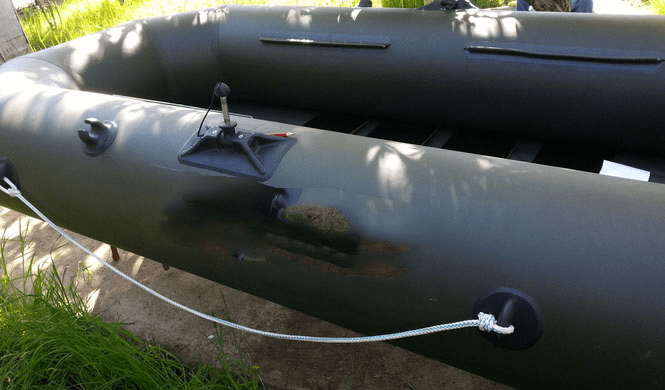

Separately, it is worth mentioning the painting of soft PVC fabrics, for example, covers or cases inflatable boat. Most polyurethane inks can be used on heavy PVC fabrics under one condition. Staining is carried out using a barrier subcoat of a 1:3 solvent-diluted FEYCO Universalprimer 2159 primer, with the addition of Fey (N) Vetro Zusatz 501. The sublayer is applied with a spray gun in a thin layer of 20-25 microns. Subsequent painting is carried out with conventional polyurethane paints.

If there is no particular desire to look for optimal recipes for staining soft tissues, a barrier layer can be made using spray paint for cars.

Conclusion

Staining PVC is not enough challenging task if the right materials are used. Given the high durability of PVC plastic, the demand for special paints for decoration or repair is only increasing, so the technology of painting is improving, and, apparently, in the near future the problem with painting PVC plastic will be finally resolved.

Hello. I know that a similar question has already been asked. But I'll ask anyway. I have wood-effect MDF panels in my kitchen, somewhere in a year or two I'm going to do repairs. In the meantime, I want to paint these panels to freshen up the kitchen. There are several questions. Firstly, since this is a kitchen, is it necessary to degrease the panels and with what? Secondly, since the panels "under the tree" should be primed or painted with white paint before painting (I'm afraid that pseudo-wood can't be painted with colored paint)? Thirdly, all the same, what kind of paint would you advise to paint? And I would like to know your opinion on painting MDF panels with textured paint? I don't know if it will last? Thank you very much in advance for your reply.

Lilia, Krasnoyarsk.

Hello, Lilia from Krasnoyarsk!

American auto giants already at the dawn of their formation were guided by the principle "not to repair, but to change." That is, it was implied that the produced cars exhaust their resources and wear out as much as possible in a certain time. After which, no matter how much the car is repaired, then some nodes, then others will “crumble” in it. What motivated potential customers to buy new cars, and not repair old ones.

MDF panels from the same series. If they are old, cracked somewhere, exfoliated somewhere, rubbed off, their surface is damaged, then it is easier to replace them altogether than to try to renew various paints. No matter how hard you try, it will still be noticeable that they are repainted. You can, of course, try to use trendy super-expensive imported paint, but the cost of preparing the surfaces of MDF panels, buying all the necessary components (degreasers, compressor, paints) and painting itself will exceed the cost of dismantling, buying and installing new panels.

/ By the way, when replacing old panels with new ones, it will be possible to use all the attributes of the old panels, that is, the beacons on which the previous panels were attached. This significantly reduces installation time./

Therefore, think seven times whether it is worth resorting to painting old panels. Moreover, the result may not meet your expectations, since imported paint can be produced in the nearest doorway or on Malaya Arnautskaya by enterprising businessmen who have stuck a branded label on an old container.

But if you absolutely decided to do as they said, then try to do the following.

First of all, you should thoroughly degrease the entire surface of the panels. Since all kinds of solvents can damage the surface layer of the panels, since they are made on the basis of aggressive chemical components, it is better not to risk it and use ordinary detergents, the same ones that you use when washing dishes. With the exception of various compositions based on abrasive materials, that is, with the presence of grains.

Textured paints are generally more intended for coating on plaster or drywall slabs, but you can also experiment with MDF panels, especially since even in the case of a not entirely successful experiment, one or two years before the main repair that you plan to do, you can endure .

Before painting, an acrylic primer can be applied to ensure greater protection against all kinds of translucence of old panel colors.

Application textured paint best for your case structural roller, and not with sponges or a compressor, especially since not all such equipment have in their arsenal.

But I repeat once again, no matter who I ask if they have ever painted MDF panels in their kitchens, everyone unanimously claims that washing is washing, and no one has ever painted. Your right to listen to the opinion of the majority or do it your way.

In any case - good luck!

Ask a question to Semenych (the author of the materials)

Our site is regularly updated with interesting and unique materials and articles on the topic of lumber, building materials and works, the author's opinion and knowledge of a real coven worker with more than 15 years of experience is given. There is a section - funny stories of covenants. If you would like to receive information about this, subscribe to our site's newsletter. We guarantee that your address will not be passed on to third parties.

Today wall and ceiling panels from plastic. Many homeowners use them as a finishing material. But not everyone is satisfied with the proposed color palette, so the question often arises: how to paint PVC panels and is it possible to paint them at all?

Considering the huge range paintwork materials in the sales market, picking up paint for plastic will not be a particular problem for the user. But before you start painting, you need to decide on the color that will most suit the homeowner in the interior of the room. As a rule, acrylic compositions are produced for pastel, medium and saturated colors.

Before you paint plastic panels, it is necessary to prepare the surface for painting, prepare materials and tools, including:

- Cleaner for plastic panels;

- Lint-free cotton fabric;

- Special paint for plastic;

- Protective gloves and respirator.

It is best to treat the surface with a quality and inexpensive cleaner. There may be traces of grease on the plastic, which is coated during manufacture. With the help of a cleaner, the material can be degreased, dust, static electricity removed. This product is applied to a lint-free fabric. It treats the surface of the plastic. After cleaning the surface, you need to wait until it dries, and only then you can paint.

Many people think that the panels can be painted with a roller or brush. This is an erroneous opinion: only an airbrush can be used as a tool for applying paint, and plastic can be painted by spraying.

On the video: types of PVC and MDF panels.

What kind of paint can be used?

Not every paint adheres to plastic panels. Therefore, for such material there are special types formulations. Today, you can easily get the paint of the desired shade. When choosing a paint for plastic, you need to consider the conditions under which the coloring will be carried out. It's one thing when we are talking about internal painting work, and another if they are held outside.

If choose decorative materials, then you should know that they are used for decorative designs, and for their application there are special stencils. Technological compositions are intended for reliable protection surfaces from damage and wear.

To avoid problems when working with paints, you need to strictly choose those materials that are intended for PVC panels. Painting allows you to extend the life of plastic and make it an ornament of interior design.

Often plastic is painted with polyurethane water paint, the durability of which has been tested in practice. In order for the paint layer to be more durable and last longer, varnish is applied on top of the dried composition. Drying can be done naturally or forced.

To date, polyurethane-acrylic water dispersions are also used for painting plastic surfaces. Such coloring materials paint windows, doors, panels, other PVC products. The following advantages of using such dyes can be listed:

- these are environmentally friendly paints and varnishes, which do not contain solvents;

- the coating applied with such paint serves as an excellent decorative decoration;

- the coating is resistant to deformation and pollution;

- such paints are water-repellent.

Acrylic paint for plastic panels dries quickly. So if for some reason the color of the plastic finishing materials the owner is not satisfied, they can be painted with an acrylic compound. A wide range of colors allows you to choose the material for the interior design of any room.

Polyurethane acrylic coatings are resistant to pollution, weathering, elastic and environmentally safe to use. They do not have a pungent odor, are easily cleaned of dirt and dust, and have a water-repellent composition. The service life of such a coating is long. The only drawback of this material is the complexity of application.

When choosing a paint, you need to pay attention to the composition and instructions, because a good product must dry no later than twelve hours later. You should focus on hardness, the degree of repulsion from the surface, find out about the presence of organic compounds in the paint.

You also need to pay attention to the manufacturers of paints and varnishes. Acrylic paints are considered harmless, and after their application, a coating is obtained that looks like the surface of plastic panels. As for water-based analogues, they are not suitable for coloring plastic, because they will simply drain from it.

Staining features

Knowing how to paint plastic panels, how to prepare them for this, what improvised means to use for this, you can start the painting process. Pay attention to these principles:

- Painting work should be started an hour after tinting the paint.

- Before starting staining, it is required to determine the viscosity of the composition and, if necessary, dilute the paint with clean water.

- The paint is applied exclusively with a spray gun.

By following the instructions on how to paint the panels, you can achieve excellent results. In the process of work, it is necessary to cover the surfaces adjacent to the panels with a film so that paint and varnish material is not sprayed on them.

It is necessary to choose the optimal parameters of the spray gun, the diameter of the gun nozzle and operating pressure, as well as monitor the thickness of the applied layer. You need to spray the dye with a layer of 6 mm. The thinner the coating, the faster it dries.

Light plastic can be painted in one layer, and it is better to cover dark plastic with paint twice. To dry the applied paint, the temperature in the room should be at least twenty degrees Celsius. It is necessary to check whether the panels have dried out no earlier than after six hours. If the color of the panels does not suit you, it is better to paint them with an acrylic composition.

can be dyed and oil paints however, they have a strong odour. However, they can be applied with a brush or roller. Just for a while you have to leave the room in which such paint was used. If there are no practical skills in performing such work, then it is better to entrust the painting of plastic panels to experienced specialists in the painting business, who will perform the painting quickly and efficiently. The duration of operation of the painted panels and the interior design of the room in which they are installed depend on the quality of the painting.

What the experts say (2 videos)

PVC panels of different colors (20 photos)

The main reason to change the colors of the plastic is to give it a harmonious look with the interior of the room or the exterior of the building. At the moment there are more than 2000 shades that allow you to do this. One thing remains - to properly apply paint on plastic panels.

In the photo - painting plastic windows

The material during operation also turns yellow due to sunlight, losing its original appearance. In addition, its physical properties are also violated. In this case, coloring will protect the PVC plastic from such influences.

Tip: want to protect metal elements in the apartment from corrosion, for this purpose Zinga electrically conductive paint is used, which can prevent moisture from reaching their surface.

Dyes for PVC in granules

Technology

Painting PVC plastic profiles with a water-based polyurethane acrylic system has several advantages:

- fast and high-quality surface preparation;

- drying takes place a short time at room temperature;

- hardening at a temperature of 20˚С - from 8 hours;

- manual and automatic spray painting;

- large spectrum decorative possibilities- texture "under the tree", mother-of-pearl, metallic.

Acrylic paint for PVC panels

Training

Below we consider the stages of manufacturing colored plastic profiles. And the most important step in this case will be the preparation of products for painting.

You must make sure that there is no dirt, silicone, greasy spots and other substances that will interfere with good adhesion of plastic to paint.

There is a small guide for this:

- remove dust, chips and crumbs with a dry cloth or compressed air;

- impregnate the rags with a special cleaner designed for polystyrene;

- degrease and clean the surface of the product from grease and dirt residues with your own hands, while removing static stress;

- wait 5-10 minutes for the cleaner to evaporate from the plastic surface.

Tip: use special activator cleaners for PVC for this. This liquid also creates micropores on the surface that help materials adhere to each other.

Paint for PVC plastic and interior work

Another way to achieve good adhesion is to sand the PVC and then prime it. but this process more time consuming and requires some skills.

Tip: do not like the price of professional painters, get down to business on your own.

Choosing a paint

Remember that unless you are sanding and priming your plastic, you should only purchase paints that are specifically formulated for painting PVC.

- Choose a shade. To do this, you can use the NCS, RAL or Monicolor catalogs, where there is such a large selection that finding the right color will not be a problem.

- Determine what items, and how much, will need to be painted. This will make it possible to calculate the volume of paint for a certain area.

- Tinted to the desired shade at least 60 minutes before the start of work. The paint will be tinted according to a special recipe with the addition of pigments. The selected shade will be as close as possible to the color in the catalog. If possible, check the viscosity with a VZ-6 viscometer and adjust, if necessary, by adding pretreated water.

Paint for hard PVC products

Coloring

The process should be carried out in one layer at room temperature without prior priming. When using a sprayer, the coating will turn out to be of better quality.

You can also apply paint with a brush or roller. The material dries in about 8 hours, depending on the temperature, but it can only be fully used after 72 hours.

Tip: If necessary, you can apply a second coat, but only when the previous one is completely dry.

If you use a gun for painting, make sure that the temperature of the paint, it and the plastic corresponds to the working room - not lower than 18 ° C, the humidity should not exceed 80%. It must also be dry and clean. It is recommended to apply with a working pressure of 2–2.5 atmospheres, nozzle size - 1.6–1.8 mm.

The desired film thickness is at least 60 microns, otherwise this will affect the adhesion strength to the base. With a layer thickness of more than 120 microns, the drying time will increase and this will affect the decorative effect of the coating.

Tip: there are enough items in the room that can be damaged during a fire. To protect them, use modern fire-retardant paints for metal Polistil, which are diluted with water.

Polyurethane paint PVC

How to dry

Drying of the painted surfaces from ABS plastic occurs at a temperature exceeding 40 °C. They should be placed in a heated dryer no later than 5-10 minutes after staining.

If the wet film thickness is 80-120 µm, the temperature is 50°C, and the relative humidity is 65%, drying will take about 2-3 hours. It is not necessary to immediately check the degree of adhesion, it is better to wait 24 hours, complete polymerization occurs after 5-7 days.

Please note that drying times due to high wet film thickness, lower temperatures, large product dimensions and high humidity dryness can increase significantly.

When storing finished plastic products, they must be protected with film or paper, protected from friction and impact on the painted surface. Also, they should not be exposed to moisture for a long time and negative temperatures until complete polymerization.

Conclusion

From the article it became clear that coloring PVC and ABS plastic is a simple task. It is only necessary to thoroughly clean the surface of any contaminants, determine the color and necessary quantity material (learn also how to paint old parquet on one's own).

You can apply it in a convenient way for yourself - spray or roller with a brush. Drying the first to produce at room temperature, the second at 40 or more degrees.

The video in this article will help you find additional information on this topic.

Before you paint plastic with your own hands, you need to choose based on its structure. After all, this material is quite different.

After choosing a paint, it is important to apply the coating correctly, because it must look and be durable. And this can be done in several ways. Also on the video and photo you can see the most difficult moments of this work.

How to properly paint plastic will depend on its characteristics. But in any case, high-quality surface preparation should be done.

The paint doesn't adhere as well to the PVC surface. So preparation is very important. Painting plastic, like painting any other surface, has its own characteristics.

Attention: Painting is best done with a spray gun. In this case, the coating can be applied most evenly.

For convenience, we will analyze the whole process in steps:

- Before starting work, you need to make sure that there are no contaminants on the surface.. The surface to be treated must be dry and clean.

- Before painting can begin, the plastic must be coated with a special primer for high adhesive plastics. It can be purchased at paint and varnish, construction and auto stores. The primer should be applied by spraying (using a spraying device) or by wiping. After processing, the product must dry completely.

- In order for the staining procedure to be comfortable, and the adhesion between the plastic and the paint to be as strong as possible, a number of conditions must be met:

- The ambient temperature should be more than 18 degrees, and the humidity should not exceed 80%;

- The temperature of the surface to be painted, paint and tooling should be approximately the same.

- Coloring of plastic takes place in one layer, the thickness of which is 60-120 microns. If the layer is thinner, then the wear resistance of such a coating will be very low. And the layer thickness above 120 microns will significantly increase the time for complete drying, which may worsen appearance painted product.

- The recommended drying temperature for plastic surfaces is 18-60 degrees, a more specific temperature range, as well as the drying time itself, directly depend on the thickness of the paint layer. For example, a layer of 80-120 microns at room temperature and a standard humidity of 40-50% will dry in 8-10 hours, and at a temperature of 50 degrees and a relative humidity of 65%, the drying period will be reduced to 3 hours. The surface of polyamides and polypropylenes at an air temperature of 100 degrees will dry in 20 minutes.

- Polymerization (final drying) of the painted surface is completed only for 5-7 days. However, when the layer thickness is more than 120 µm, low ambient temperature and high humidity, the curing time may increase significantly. Until the end of polymerization, it is undesirable to expose the painted plastic to prolonged exposure. low temperatures and high humidity.

Coloring plastic at home

Do-it-yourself coating will be much cheaper than the price of specialists. Consider how to paint plastic at home.

In order to qualitatively paint the plastic surface on our own, we need:

- Aerosol paint-enamel on plastic or enamel on plastic;

- Acrylic spray varnish for final surface treatment (it can be matte and glossy);

- Protective equipment for hands, eyes and respiratory organs (gloves, mask, goggles);

- Polyethylene film (to cover surrounding objects);

- masking tape;

- Plastic cleaners (water, rags, brush, detergent);

- Solvent (for example, white spirit);

- Grinding paper with abrasiveness up to 180 microns.

What paint to use?

What kind of paint can be used to paint plastic, now we will consider in more detail. The choice of paint must be approached with particular scrupulousness, since the type of paint and the features of its interaction with the surface have a direct impact on the final result.

So:

- For products made of soft plastic, it is necessary to use enamels with a high content of elasticity and plasticity. And for products made of hard plastic, universal acrylic paint-enamel is also suitable.

- In our case, acrylic paint on plastic is best suited, which can be purchased at any construction and paint and varnish stores.

Attention: Also, when buying, you should keep in mind that there are two forms of release of such paint: aerosol (in cans) and liquid (in buckets).

- It will be most convenient for us to use spray enamel paint, because. it has good adhesion, is easy to use and dries quickly. If you need the most uniform distribution of enamel over the surface, then you can purchase a specialized tip for aerosol cans that allows you to manually adjust the degree of paint spraying.

Attention: plastic products marked PS (polystyrene), PC (polycarbonate) and PE (polyethylene) are not painted!

- We will finally fix the paint with the help of acrylic aerosol varnish.

If you work with a new surface or use liquid paint, then you will also need a primer for plastic, for example, "Otex" from TM Tikkurila. - If you are going to paint old plastic, then grinding the surface will be enough.

Spray painting process

Conditionally complete staining process plastic product can be divided into 6 steps:

| Product cleaning |

|

| Surface degreasing | Degreasing - milestone pre-treatment of products for painting, since not a single paint and varnish material will adhere to a greasy surface. To delete old paint and degrease the surface of the product to be painted, it must be thoroughly treated with a solvent. After processing, work surface must be thoroughly washed and dried. |

| Surface grinding | Grinding is needed in order to increase the roughness of the painted surface and facilitate its adhesion to the paint.

|

| decoration |

|

| Coloring | Features of painting the surface with spray paint:

The number of layers is directly related to the quality of the paint and the degree of preparation of the surface for painting; when using any aerosol paints and varnishes, do not forget about protective equipment for eyes and respiratory organs. |

| Applying varnish, fixing the result | After the painted product has completely dried, usually after 25-30 minutes, treat it with an aerosol varnish. The principle of processing is the same as when applying paint. Ready product dry. |

Liquid paint process

An alternative method of painting is painting with liquid paint and a brush. Painting with a brush has both pros and cons.

The main disadvantage of this method of staining is the long drying time, during which dust/dirt should not be allowed to settle on the treated surface. Since this cannot be done at home, this staining method is used only in cases where a perfect coating is not needed.

In many ways, this process repeats the above method:

- Product cleaning.

- Surface degreasing.

- Grinding. At this stage, the product is treated with a primer, which will significantly increase the adhesive properties of the plastic surface and improve its adhesion to the paint. After treatment with a primer, the plastic must be dried for several minutes.

- Coloring.

Painting with a brush has a number of special features that you need to consider if you want to get a good result:

- Paint-enamel should be applied in a thin layer, continuously pressing the brush to the surface;

- When picking up paint, do not immerse the brush in it completely;

- During the staining, you should carefully monitor the angle of application of the paint, it should not change;

- First, apply the enamel in wide stripes, and then blend it. This will fill all the surface roughness and achieve the most uniform coverage.

Applying varnish, fixing the result. Keep in mind that the varnish in this case must also be applied after the surface of the product has completely dried, in the case of liquid paint this period is quite long. Keep in mind that spray nail polish dries much faster than regular nail polish. The drying time of conventional varnish is approximately 2-2.5 hours.

You now know how to paint plastic and the instructions will not allow you to make mistakes.