Original crafts from leftover building materials. Sleight of hand and no fraud: country furniture from nothing Crafts from leftover siding

Installation vinyl siding without the use of accessories is possible. Despite the fact that some builders say the opposite. But not all. Typically, installation of vinyl siding is carried out using fittings (window trims, frames, joints, etc.), which are purchased separately from the siding, having previously selected the color and type.

But is it worth buying it? It's no secret that additional elements for siding they are approximately 1.5-2 times more expensive, although they have the same composition, specific gravity, strength, etc., only the shape is different, although this should not be a reason to increase the price. Many believe that without them, installing siding is almost impossible and, spending their hard earned money, they buy them without complaint. But this is not true at all! You can do without them, and installation of siding will cost you much less and without compromising the aesthetic appearance. Can be used instead of these accessories wooden crafts, which you can do yourself, or siding trims, which will accumulate a lot during the installation process and would be a pity to throw them away. For example, corners can be made from thin boards, and window trims can be made from unnecessary siding remnants using special glue. It will be cheaper and no less effective. Some are confused by the fact that the tree tolerates unfavorable weather conditions very “painfully”, quickly “ages” and requires constant care. This can be easily corrected if you treat the wood with KHMBB antiseptic and apply a special varnish to the surface to protect it from ultraviolet rays, this way the service life will be increased to 20 years. Installation of siding should begin by marking a single horizontal line around the entire perimeter of the house; it is most convenient to use for this purpose laser level. I have more than once installed vinyl siding myself without using fittings. It is best to do this in cloudy weather or in the evening, when the sun has set, so that the laser beam is clearly visible. All walls are reinforced with a frame made of wooden slats, on which the siding will lie, you can, of course, use special metal bars, but this will cost more. Then install the lower starting panel along the line that was previously marked by level. Here it is very important to install it evenly, since all subsequent sheets will exactly copy the horizontal of the starting panel. Taking into account the fact that vinyl siding can expand and contract depending on temperature, during installation it is necessary to leave a gap between the joints: 10 mm if work is carried out in winter, and 5 mm if in summer. When installing walls, it is more advisable to join the panels “overlapping”, since this way the joints will be almost invisible and the house will look more beautiful from the outside than when joining in any other way. The last, top panel must be inserted into the finishing strip, which is attached in advance in the upper inner corner between the cornice and the wall of the house and secured with at least two screws along the entire length, otherwise it may jump out at the first gust of wind. After installing the walls, you can proceed to the windows. Of course, as they say, “there is no friend according to taste,” so there may be different variants: to trim either with wooden planks, or use leftover siding. As you can see, installing vinyl siding without the use of fittings is not that difficult.

Refrigerator repair Automobile plant http://master-nnov.ru.

– an excellent material for cladding a house. At its affordable price, it has many positive operational and technical characteristics.

You are invited detailed instructions By self-installation siding. The guide is universal. Following its provisions, you can complete any finishing that involves installation on the lathing: fiber cement, wood, metal, vinyl, etc.

Installing the sheathing

Siding is best attached to pre-installed sheathing. We work in the following order.

The first stage - choosing the material

The frame can be assembled from wooden beam or metal profile. Metal products are stronger and more durable. In addition, metal lathing is much easier to attach to an uneven base.

Find out and also familiarize yourself with the calculation algorithm with an emphasis on possible nuances.

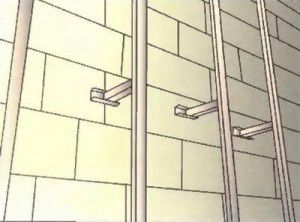

Installation of profiles is carried out in half-meter increments. Hangers are used for wall mounting. This technique will allow you to level out differences in the surface and secure the frame elements at a level.

Wooden sheathing is cheaper. When choosing this option, pay attention to the condition of the wood. It is prohibited to:

- the material has peeled off;

- was deformed;

- had bluish spots and traces of rot, etc.

Elements wooden sheathing need to be impregnated with fire retardant and antiseptic. If the house is built from wooden elements, the walls should also be treated with the listed preparations.

Stage two - preparing the base

The sheathing is easiest to attach to a flat base. First of all, we remove any parts that may interfere. These are all kinds of tiles, bars, platbands, gutters, etc.

The third stage - installing guides

Siding is best mounted horizontally. In this case, we fix the bars or sheathing profiles vertically.

For attaching guides to wooden walls use nails or screws. If the house is built of concrete blocks or bricks, we fasten it with dowels, having previously drilled holes for them in the wall of the house.

We align each rail by level.

Important! If you plan to do exterior work, it is best to install the siding sheathing after all insulation work has been completed. In this case, there will be two lathing: for insulating materials and for cladding. In this case, the slats of the two frames should be placed parallel to each other.

You can, of course, try to lay insulating layers after attaching the siding sheathing, but this is not very convenient.

Mounting J-profiles

The starting guides must be secured perfectly, because... The quality of the entire cladding depends on the correct installation.

First step. Take a level and find the lowest point on the sheathing. We step back 50 mm from it and put a mark. To do this, screw a little self-tapping screw into the rail.

Second step. We consistently move around the building and continue to place marks with self-tapping screws to fix the starting profiles. We also screw screws into the corners of the house.

Third step. We stretch the ropes between the corner marks.

Fourth step. We mark the boundaries of installation of corner profiles on the slats. We take the profile itself and apply it to the corner frame structure and put marks along the edges using a pencil.

Important! We leave a 1-centimeter gap between the profiles to compensate for temperature deformations.

Leave a gap between the starting guides and the nail strips.

To avoid making a 6 mm indentation, you can cut off parts of the nail strips so that they do not rest against the J-profile during temperature changes.

Important! Starting profiles must be mounted strictly horizontally! Correct deviations as long as necessary.

If you install guides that deviate from the level, the siding will also warp. It will be extremely difficult to correct this in the future.

Prices for profile mounts

Profile fastenings

We install external corner profiles

First step. We mark the soffits. We need to see where the edges of these elements will be located in the future.

Second step. We apply the guide to the corner of the frame. We do this with a 3mm gap to the soffit or roof. We fasten the profile with self-tapping screws.

Place the bottom border of the element 0.6 cm below the edge of the starting profile.

Third step. Checking the vertical installation. If there are no deviations, we fix the bottom, and then the remaining places. Experts do not recommend placing fasteners in corner elements too often.

If the house is higher than 300 cm, the profiles will need to be placed one on top of the other. To do this, we trim the top profile. As a result, there should be a 9 mm gap between the planks of the joining elements. When laying the elements, maintain an overlap of 2.5 cm.

Important! We join the profiles at the same level on each side of the house.

If the base has a protruding structure, shorten the profile so that there is a 6 mm gap between it and the base.

Helpful advice! Instead of corner profile It is allowed to install 2 J-elements (starting). This way you can save money. But this solution also has its drawback - the corner will not be as tight as when using a special corner profile. If you decide to use this method, first glue the wall around a similar corner with a strip of rolled waterproofing material.

We install internal corner profiles

The installation procedure for these elements does not differ significantly from the installation technology external corners– between the profile and the soffit we leave a gap of 3 mm, and lower the lower end of the profile below the J-bar by 0.6 cm.

If there is a protruding plinth or other element from below that stands out from the general level, then between it and the profile we also leave a 6-mm indentation - the profile of the internal corner must not rest against it.

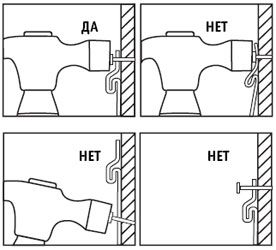

There are 3 methods of arrangement internal corners, see picture.

If the wall height is more than 300 cm, we splice the profiles. The technology is the same as for arranging external corners.

We leave a 9 mm gap between the slats, carefully cutting off excess material. overlap top element on the lower one - 2.5 cm. We install fasteners in 4-centimeter increments, placing them strictly in the center of the holes intended for this. The exception is the highest point. Here the fasteners need to be installed at the top of the hole.

We install frames of openings

For most inexperienced craftsmen, difficulties arise precisely at the stage of framing and doorways. The order of work will vary depending on how the openings are arranged in relation to the plane of the wall.

Openings in the same plane with the facade

In this case, we do the following.

First step. We waterproof openings.

Second step. We attach platbands or J-profiles to the openings. We equip each opening using 4 platbands: a pair of vertical and a pair of horizontal.

Third step. Connecting profiles.

To make the connection of the platbands as neat as possible, we do this:

The platband at the bottom is connected in exactly the same way, only the bridges will need to be cut and bent on the side elements for their further laying on the profile below.

Openings are recessed into the facade

When installing near-window profiles, we follow the same recommendations as when installing platbands, i.e. We create cuts on the profile corresponding to the depth of the opening, and then bend the bridges and insert them into the finishing elements.

Take the time to understand the principles of bending such bridges. We make them so that they cover the joint of the cladding elements. As a result, moisture will not be able to penetrate inside.

Installing the first panel

We start cladding from the least noticeable wall of the building. This way we can practice and work out all sorts of inaccuracies.

First step. We insert the first cladding panel into the corner profile and into the locking connection of the starting strip.

Important! Between the first cladding element and bottom For the corner profile lock, we leave a 6 mm temperature gap.

Second step. Attach the panel to the sheathing.

It is important to maintain the dimensions of technological indents. If the cladding is carried out in warm weather, we maintain a 6 mm gap; if in cold weather, we increase the gap to 9 mm. When installing panel trims, the indents can be reduced.

Extending panels

We build up the cladding elements with an overlap or using an H-profile.

When attaching panels with overlap, you must first shorten the locks cladding panels and mounting frames so that the resulting overlap is 2.5 cm long.

The installation of the H-profile is carried out similarly to the corner elements - at the top we retreat 0.3 cm from the soffit, at the bottom we lower it by 0.6 cm in relation to the starting profile.

Important! We leave a 6mm gap between the H-profile and any obstacles on the house.

Installing the rest of the siding

We continue covering the house with siding. The operating technology is similar to the procedure for attaching the first panel.

Important! Every 2-3 rows we check the horizontality of the cladding using a level.

Having reached the opening, we remove the unnecessary piece of the panel falling on the opening.

We ensure reliable fastening of the panels using “hooks”. For this we need a punch.

We install an additional finishing profile at the bottom of the opening. This will allow the cladding to be leveled.

Installation under the roof

Under roofing structure We attach the J-profile.

We work in the following order.

First step. We measure the distance between the bottom of the lock of the finishing element and the lock of the penultimate facing panel.

Second step. We subtract a 1-2 mm indent from the resulting measurement.

Third step. We mark the whole panel, cut off its upper part with the locking connection.

Fourth step. We create “hooks” in the upper part of the element in 20-centimeter increments. To do this, we make cuts and bend them to the front side.

Fifth step. We insert the trimmed element into the penultimate siding panel. With a slight upward movement, we snap the inserted element into the locking connection of the finishing profile.

We mount the pediment

We sheathe the pediment around the perimeter. All fasteners, except the top one, are installed in the center of the holes. We install the upper fastening element at the top of the hole. It can be sheathed either with profiles for arranging internal corners or with a starting profile.

The installation procedure is similar to fastening wall panels. We trim the edges of the elements and connect them to the locks of the receiving profiles. We remember the 6 mm indentation when installing in warm weather and 9 mm when doing work in winter.

We fasten the last element of the gable cladding directly through the panel material - this can only be done here.

The cladding is complete.

Find out how, and review the calculations and step by step guide, from our new article.

In order for the finishing of the house with panels to be as successful as possible, you need to know certain subtleties performing such work. There is a list general recommendations for any siding, as well as separate tips for panels made from a specific material.

Now you can perform it yourself at the highest level.

| Name (model) | Benefits | Length x width x thickness, mm | Quantity per package, pcs. |

|---|---|---|---|

| Vinyl Siding "Canada Plus" | 1. Coloring in dark colors is performed using the “Cool Color” method (heat absorption), which involves the use of masterbatches. 2. Excellent appearance remains unchanged even when exposed to high and low temperatures, the range of which ranges from -50°C to +60°C. 3. Retains shock resistance even if the temperature environment drops to -20 - 60°C. 4. Not susceptible to microbiological corrosion (fungi, mold). | 3660 x 230 x 1.1 | 20 |

| Acrylic Siding "Canada Plus" | Among the others useful qualities acrylic siding“Canada Plus” is worth highlighting: Increased resistance to direct ultraviolet rays; Excellent tolerance to acidic and alkaline solutions, as well as to various fats; Good tolerance to washing with chemical detergents; High degree deformation resistance (excellently tolerates temperatures up to 75°-80° C). | 3660 x 230 x 1.1 | 20 |

| "Alta-Siding" – Vinyl Siding | "Alta siding" is: one of the safest finishing materials on the Russian market; frost resistance and the ability to maintain strength even at very low temperatures(from -20 to -60°C); resistance to significant temperature changes and exposure external environment; durability: the service life of Alta-siding is up to 30 years; resistance to aggressive substances (can be used to clean siding detergents); non-susceptibility to infection by mold fungi. | 3660 x 230 x 1.1 | 20 |

| Facade metal siding INSI | INSI siding is made of galvanized steel coated with a layer of polymer composition, which means it inherits all the advantages of this material: resistance to temperature changes (-50°C - +80°C) and mechanical damage; long service life with preservation of original properties (about 50 years); environmental friendliness; non-flammability; Possibility of installation both horizontally and vertically; protection of the building from overheating (in a ventilated facade system); and when choosing one of two new colors (alder or rosewood) - a complete imitation of the appearance. | Length up to 6000, width up to 200, thickness 0.5 | - |

Good luck!

Siding prices

Video - Do-it-yourself siding installation

After various construction work There are always scraps, fragments, pieces, even whole sheets left. And, since the materials are quite expensive, it’s not a good idea to throw them away. Everything can be used for crafts both at the dacha and in the apartment.

Vinyl siding

The material is used for finishing facades. Available in the form of lamellas - long finishing boards, and in the form of panels, usually imitating stone or wood chips. Residues always form during lining. The material is produced in a certain size and it is unrealistic to select it so as to completely cover the facade without joining and adjustment.

Even more scraps remain after installing the basement siding - in the form of panels. Since the finish reproduces stone and brick, its edge is always uneven. This does not affect the quality of the joints, however, when facing corners, trimming is inevitable. If the building is finished with two types of panels, the situation gets worse.

What can be made from the remains of siding depends on the needs of the owner and his imagination.

Sale

Finishing is always purchased with a reserve. Damage during transportation, during installation, unsuccessful docking and many other factors lead to the fact that the purchased volume may not be enough. And the shade plinth panels may differ significantly in another batch. Therefore, cladding is purchased with a margin of 10–15%.

However, in the absence of unfavorable factors, this excess remains unclaimed. Basement siding: its remains, if they are large fragments or even entire panels and vinyl slats, can be sold. For this purpose, there are numerous online platforms, like Avito, where free advertisements for the sale of any type of material are posted. Moreover, the cost of what is offered is determined only by the seller. Avito allows for sale both new and used products.

You can offer the trimmings to your neighbors in the country. It is quite possible that just a pair of plinth panels is not enough to cover the foundation.

Large crafts

Crafts made from siding remnants usually find their application on summer cottage or in the garden. The material is designed for external use and is rarely used for decoration inside a building - it looks a bit rough.

- The remains of the cladding are used to finish secondary structures: sheds, utility rooms, garages and even toilets. This option creates a complete ensemble of all dacha buildings and looks quite stylish.

- Cuttings from slats are great for creating borders for flower beds or low fences.

- What can be made from leftover siding is a playground. There is no better entertainment for children at the dacha than their own playhouse. Lamels and panels are perfect for finishing it: it is durable, not afraid of water, does not burn and retains color perfectly. The photo shows a playhouse.

Small crafts

The remains of stone or wood cladding can be used for decorative purposes.

- First of all, this is a handmade wall decoration. The combination of a smoothly plastered wall with separate elements"masonry" or wood cladding It looks fashionable, stylish and original. This option is also suitable for a city apartment.

- From the leftover material you can make small shelves in the kitchen, in the hallway, as well as in utility and utility rooms - a garage or barn. They will not withstand a large load, but they are quite suitable for various small items or kitchen utensils.

- You can include scraps of material in the decor of a veranda or terrace, and use it not only for walls, but also for lining cabinet doors, chests of drawers, and even as a tabletop. Such garden furniture, made with your own hands, looks very unusual.

What can be made from leftover siding is shown in the photo.