Bath do it yourself: projects, photos, description of construction stages. What to build a bath is better: general information, features and recommendations, which bathing is better to build a bath with scratch

Almost every gift I want to have a bath on my plot. The question arises where to start the construction of the bath and can actually cope with it independently, without hiring a huge brigade of workers. For such a case, quite a slight experience in a carpentry business. There will be no one to carry out the intended, but 2-3 people will ideally cope with the construction of a bath.

How to start building a bath? There are several important points for which attention should be paid before proceeding. It is significantly easy to simplify the task, because all the nuances are better to provide in advance.

First of all, you need to consider that any building begins with. Therefore, if there is no many years of experience in construction, it is necessary to choose the most simple form of the foundation. In this case, the bridal foundation is suitable. He has a low price, but there is one feature - such a basis can be installed only on weakly soils.

Secondly, it is necessary to determine the materials from which the bath will be built. It is very important to calculate the cost in advance so that there are no unpleasant surprises in the form of additional financial costs.

Thirdly, decide which specifically the construction is needed. After all, the baths can be completely different. Of course, it is easiest to build the most simple, small size. But it is possible not to be limited to small and make a huge room for a bath - with a spacious pre-banner and mandatory shower installation. The area of \u200b\u200bsuch a structure can reach up to 20 m 2. It is necessary to determine with the size of the bath, based on the number of people in the family, as well as personal preferences in terms of comfort.

When building a large premises of simple builder skills will be not enough. Be sure to be a good carpenter, which has various skills of wall cutting. It is advisable to the usual builder not to be independently for the complex project, and start building a simple wooden bath from a bar.

When building a large premises of simple builder skills will be not enough. Be sure to be a good carpenter, which has various skills of wall cutting. It is advisable to the usual builder not to be independently for the complex project, and start building a simple wooden bath from a bar.

How to start building a bath? The very first question that arises from the master is where to start the construction of a bath on the site primarily you need to be located where the construction will be located.

By choosing an estimated place on the site, you can move to the next step - the preparation of the estimate. This is a very important point that should not be neglected. After all, thanks to the estimate, you can easily figure out how to save money when building a bath . Usually the estimate consists of such items: the foundation, walls, roof, communications, installation of the furnace, finishing works. Also, this list is worth adding payment for the service of the architect to create a Bani project.

The next step is the purchase of materials necessary for the construction. Most often, the baths are built from a profiled bar, which has a low thermal conductivity. But he has a minus: it's necessary time for a shrink shrink. Also often builders use glued bar. It is expensive, but this material has many advantages. The glued bar has a flat surface, perfectly retains heat, does not rot, perfectly resisting rodents, does not require shrinkage after construction.

The next step is the purchase of materials necessary for the construction. Most often, the baths are built from a profiled bar, which has a low thermal conductivity. But he has a minus: it's necessary time for a shrink shrink. Also often builders use glued bar. It is expensive, but this material has many advantages. The glued bar has a flat surface, perfectly retains heat, does not rot, perfectly resisting rodents, does not require shrinkage after construction.

In some cases, the bath is built from a planed timber, logs, bricks, slag blocks or. All these materials have their advantages and cons. For example, during construction from the logs it is very important to take into account the directness of woody fibers and be sure to cross all the cracks after the construction of a cut, otherwise the construction will not serve the owners for a long time. But the brick is good in that durable and fireproof.

After purchasing the necessary materials, you can proceed directly to the construction itself. How to start building a bath? Just as when building any house - the foundation is first poured, the size of which depends on the alleged weight of the structure.

This can be done independently, observing step-by-step all items:

- Preparation of the construction site.

- The device is pitched.

- Formwork made of edged board.

- Reinforcement of the base.

- Ventilation.

- Fill basics.

After filling the foundation, you can move to the construction of walls, flooring and roof flooring. Installation of walls is most often carried out using wooden brazing. When flooring on the foundation laid lags from the edged board. Next, another layer of boards are placed, which are mounted with metal screws. At the end of the floor grind.

The installation of the roof is a rather complicated process. Initially, you need to install rafted bats on the logboard. There is one important nuance here: the rafters should not have the length of more walls, otherwise the likelihood of the need to install an additional support. Next, it is necessary to install rafters on the upper crown and secure with metal brackets. Staying slate and the creation of thermal insulation. It is also worth noting that the roof covering can be not only from slate. For this purpose, it is quite possible to use a tree or tile.

When all these three steps are complied with, it is necessary to determine which ceiling needed. It can be additionally late to boards from below or installed by the floor. Now the most difficult behind, it remains to perform the inner decoration of the room and external, outside, as well as to carry out water and electricity.

When all these three steps are complied with, it is necessary to determine which ceiling needed. It can be additionally late to boards from below or installed by the floor. Now the most difficult behind, it remains to perform the inner decoration of the room and external, outside, as well as to carry out water and electricity.

Separately, it should be noted that it is imperative that it is imperative to take the furnace mount. There are certain fireproof norms that need to be observed. Place the furnace should be away from combustible structures. If the walls of the tree are made of wood, then they need to secure, for example, lay out bricks. Also, the bath must be equipped with extensive fire extinguishing.

Observing all these items, you can independently, without hiring the team of professionals, build a small bath, which will delight the family at any time of the year.

Build a bath from a log of a difficult task, however, the technology of construction, the choice of materials and even the exact sequence of actions have long been known and worked with many masters. In this material, all key points will be explained in the construction of a bathroom from a log cabin: from bookmarking the foundation to interior decoration.

The steam bath is known since the times of Scythians who have grown with them special bath tents and hiking chambers. And in the XXI century, the Russian bath did not become a certain archaism, successfully withstanding age-old competition with bathrooms and shower. Get rid of a variety of pigeons, remove harmful substances from the body accumulated in urban weekdays, give a full-fledged holiday - all this is achieved when visiting the bath for more than one and a half thousand years.

What a design is preferable how to choose a place to accommodate it, as it works in general - answers to many "bath" questions you will find in this article.

Bath Place and Planning

One of the important additions to the bath itself at all times was fresh water water, located nearby - in the absence of another source of water, the water was taken from it. A special charm in the proximity of such a reservoir lies in the possibility of contrasting ablution - rushing in a Russian bathhouse, to run out of it and plunge into the cool water of the reservoir. In addition, the natural reservoir allowed to quickly cope with the fire of the bath, which arose quite often due to disorders during the furnace device.

Today, in the binding of the country bath, there is no particular need, but still it is convenient if it is located near, say, artificial reservoir - the final decision always remains for the owner of the cottage.

The main criteria for choosing a place for a bath: removal from the road, the presence of natural or artificial fence from foreign spectators (thick bushes, crowns of trees, fence, economic buildings), fire-fighting distance from the main residential building at least 15 meters.

Basic bathrooms - pre-banker, washing and steam room (the last two rooms can be combined into one). The size of the pre-banker is determined by the calculation of 1.4 m 2 per bathing, the size of the washer is 1.2 m 2 per person. In addition, there should be a place for furniture (locker for clothing, benches for seating) and for storing fuel (coal or firebox). It will take a place for containers with hot and cold water, a furnace and a place for sun beds.

For example, for a small family (no more than 4 people) the bath of the following sizes will suit: external size - 4x4 m; Pregnant - 1.5x2.4 m; washing - 2x2 m; The steam room is 2x1.5 m. True, in the bath of such sizes it will not be particularly unfolded - but the places it takes a little.

In general, the sizes of the bath are directly related to the size of the site, which can be allocated under it. If the site is significant, then the bath can be expanded by adding a shower cabin, restrooms, etc.

In moderate and cold climatic zones, it will be right if the entrance to the bath is located in the south, and the window processes are on the Western (south-western) side. Such an entry arrangement will greatly simplify the use of bath in the winter season, since the southern side drifts are faster, and the direction of windows will allow longer to cover its premises with sunlight.

Building Baths - Stages

There are several of them:

- Blanks of basic materials.

- Select and bookmark the foundation.

- Creating a foundation for a stove-heater (if necessary).

- Creating a floor and sewer system bath.

- Build a shruck bath.

- Roof construction.

- Formation of the scene around the perimeter.

- Canopate wall baths.

- Laying or installation of the furnace, chimney mounting.

- Electrician and water supply bath.

- Installation of doors and installation of shelves.

Preparation of basic materials for the bath

The classic and most successful structural material for the Russian bath was and there will be a tree - wood easily copes with the revenge of the bathrooms, pulling out an extra moisture outward.

What wood is suitable for building a bath? As a rule, the baths are built from the roundabout of pine or ate with a diameter of no more than 250 mm - only the tree will create an indescribable inner atmosphere in the steam room. However, in the design of the bath, it is better to turn on the wood of other breeds - oak, larch and lip. For example, the lower crowns and lags for flooring, made of oak, will allow you to get a truly durable bath. Nuance - Oak should be a spile "in the juice" (i.e., not a dry) and dried under the canopy. The lower crowns (no more than 4), following the first oak, it is better to perform from larch. The final crowns, the elements of the interior decoration and the trim should be made from the linden or white ate - their wood is better than the wicking.

When should I store wood for building a bath? Rounded, wood for interior decorations must be cut down in winter, in the period when trees trunks contain the smallest amount of moisture - dry easier. In addition, not the entire trunk of the tree is suitable for the construction of the bath - only the middle part of the trunk will suit, that is, the top and kolly are not suitable.

An important criterion in the selection of wood will be the absence of cavities and sweats of resin on rounding coniferous rocks, dryness, a siny surface, the absence of stunned sites and places of defeat by the beetle-tree.

Foundation for baths

The main types of foundation for building a bath are ribbon and column, depending on local soils. Regardless of the chosen type of foundation, it is necessary to lay them with maximum accuracy - better if the ground freezing depth. Preliminary works before booking by the foundation of any type: cleaning the platform from the garbage, the complete removal of the upper layer of the soil to the depth of 200 mm (we remove the fertile layer).

To choose the right foundation, you need to determine the type of local soil, which may refer to one of the three main groups:

- Weak soil consists of peat, sludge, dust sand (contains plenty of water), clay fluid or teecolastic.

- Punching soil (susceptible to seasonal swelling) consists of sand (dustless or small), clay components (clay, loam and sandy).

- The weakly soil is formed by rocky rocks, medium and large sand grains.

Stamp (pile) Foundation for a bath

It is suitable on weakly soils: consists of pillars embedded in the corners of the bath, as well as in places of connecting internal and external walls. If the distance between two adjacent foundation columns is more than 2 m, another pillar is laid between them. The depth of laying a column foundation is at least 1.5 m.

The pillars for such a foundation are easy to make directly on the site of the construction of the bath, the material for them can be red brick, buttone bound by concrete solution. The main (angular) brick poles for a column foundation are usually a square shape, with a side of 380 mm, auxiliary - rectangular, cross section 380x250 mm. If necessary, the main pillars are performed in two bricks - cross section 510x510 mm. The savings of the boob stone and the brick during the construction of a column foundation is achieved by filling the foundation yam sand - half of their depth, the large-phrase sand is laid in layers (each layer - 100-150 mm), poured with water and tram.

The foundation pillars when building a bath with their own hands can also be made independently. This will require a collapsible formwork from boards, missed from the inside with unscrewing lubricant type "Emulsol". Inside the collected formwork, you need to put iron fittings, then pour a concrete mixture.

For casting the foundation pillars inside the holes open to them, a sliding formwork is used, made of roofing iron, plastic, roofing or thick cardboard. From the material selected for the sliding formwork, a pipe with a diameter of 200 mm is created, placed in the foundation pit of a larger diameter - from 300 mm. The free space around the formwork is falling asleep - it will perform the role of lubrication and prevents the approach of the concrete pillar when the soil is frozen. Armature tied up with a thick wire is inserted into the formwork, then a concrete mixture is poured, which must be carefully sealing. For wire handles, pre-mounted on a sliding formwork, it is lifted by squeaking at 400 mm, sweep the sand outside and pour a new portion of concrete.

Asbestos-cement pipes can be used as a bar foundation, they are durable, non-rotting, and their outer surface is smooth enough, which allows them not to change their position when the soil is frozen. Asbestos-cement pipes are also filled with concrete, their underground part must be covered with a mineral-based construction lubricant, to reduce the threat of facepits to the soil.

In the intervals between the foundation pillars of the outer walls of the bath and the inner walls of the pair of steam room, the walls of brick are laid out, sufficient thickness of their brick and even the pollockich. Such brick walls must be opened in a soil by 250 mm.

The foundation pillars and brick walls between them are displayed at a height of 300-400 mm on the level of the soil, they need to be aligned with the cement mortar and clamping the rubberoid for waterproofing. In the ends of the pillars, when casting, the mortgages of the required form of metal are installed - they are designed to fasten the shrue bath to the foundation.

When building a bath on bunched soils, the creation of a ribbon monolithic foundation will be required.

Sequence of work:

- Marking of the construction site of the beeps, stretched between the pegs.

- Digging the trench of the required depth (its size is associated with the characteristics of local soils, not less than 400 mm) and 300 mm width.

- Running on the bottom of the trench of the sand layer, then gravel (each 70-100 mm).

- Installing formwork.

- Bookmark fittings.

- Pouring a concrete mix.

The fittings stacked on the bottom of the foundation trenches must have a cross section of at least 12 mm, it is placed along each of the two sides of the trench and knit into the frame, lifting it up to its middle with brick debris.

The composition of the concrete mix is \u200b\u200bcalculated by the proportion of 5: 3: 1 (crushed stone: sand: cement), the sand used should be dry and clean (washed). Calculate the volume of concrete needed to fill the tape base, it is enough simple, you only need to measure the width, depth, and the total length of the foundation. For example, with a width of 0.3 m, a depth of 0.4 m and a total length of 22 m is required by such a volume of concrete mix:

- 0.3 x 0.4 x 22 \u003d 2.64 m 3

One of the difficulties in the preparation of a dry mixture of concrete is the lack of weights on construction sites. Therefore, it is useful for you to calculate the dry components for concrete: in one 10-liter bucket, it is contained from 15 to 17 kg of rubbish, sand - from 14 to 17 kg, cement - from 13 to 14 kg.

The formwork is placed in such a way that the concrete foundation molded into it performed above the soil level by 100 mm. As the concrete mixture is poured into the prepared formwork, its mass must be repeatedly pierced with a bayonet shovel or wire probe, to overtake the hammer of the formwork (eliminate the air sinuses). Then you need to wait for a complete rejection of the foundation, from about 5 to 7 days. When conducting fundamental work during the cold season, the formwork after the fill of the concrete you need to cover the PVC film and fall asleep on top of sawdust or other insulation.

After the expiration of the term allocated to the drying of the cast foundation, proceed to its waterproofing and lifting with brick rows (if the bath rise is not required, then, after waterproofing, go to the cement screed). The following materials will be needed:

- Ruberoid.

- Pipe is about 2 m (plastic or metal), cross section from 32 to 57 mm.

- Masonry mesh.

- Red brick.

- Masonry solution.

Ruberoid (Tol) cuts into strips sufficient for flooring on a concrete foundation, then laid out on top of the foundation on bitumen mastic (for roofing - tarmatory mastic). Brick is put on a single-row dressing way: a layer of rubberoid is laid out a masonry solution, it is the first brick row "in the post" (across the foundation axis), then the masonry mesh is settled, the solution is put on the solution and the next brick range, but already "in spoons" (along the axis foundation). Each new row of brickwork is accompanied by a filling mesh flooring, laying "in spoons" and "in the post" alternate with each other. In the 3rd or 5th chip rows of masonry, you need to install ventilation products from pipe cutting - 5-7 of the foundation is enough. The number of brick series depends on the desired height of the foundation.

The last row of brick masonry is covered with a cement screed (the composition of the sand solution: cement as 1: 2 or 1: 3), a 20 mm layer.

Independent Foundation for Kamenka and Paul Bath

Create a foundation for stove-Kamenka and collect a bathhouse. If a major layout is assumed - it is necessary for it an independent foundation, that is, not related to the main foundation.

The floor in the bath can be clay, earthwood, wooden or concrete. By and large, it does not need heat insulation, since the temperature at its level is practically no higher than 30 ° C. A wooden lattice, cork mats or mats are usually laid on the surface of the bath floor - their task to save visitors to the baths from a sharp feature of a cold caused by touch to the floor at the outlet of the steam room. For self-hazing, the flooring is raised above the main floor.

The main minus of the wooden floor of the bath is its frequent convergence - water, penetrating through the slots between the boards, will accumulate in them, causing rotting and the appearance of an unpleasant odor. Wood flooring is quickly wearing, acquiring an unsightly appearance, after 6-8 years it may require replacement. A tile is more practical for a bath flooring - it is easier to care for it, it is not exposed to moisture, easily flowing on its surface.

Floors in the bathrooms need to be located at different levels: Paul steam room - above the floor level is 150 mm (we save heat), the floor washing - below the floor level in the pre-banker by 30 mm (we take away from water from entering water).

Since the concrete floor is coated with ceramic tiles in the washing and steam room more profitable than the wooden floor - we will consider this option.

You can arrange a concrete floor in a bath in several ways. First of all, we prepare the reason for the formation of a warm floor - it consists of 100 mm layer of sand and 100 mm layer of a crushed stone of the middle fraction laid sequentially. Each layer should be well tumped and aligned. Then to wave on top of the runneroid, closing the walls to the height of the future floor.

Next steps:

- First option - 50 mm layer of felt layer, clamzite or slag, on top of 50 mm layer of concrete with the formation of a slope to the drain hole. After setting the concrete, it should be aligned with a solution of cement, after which you can start tiled.

- Second option - 50 mm Cement screed containing perlite (strolled sand). The composition of the mixture: perlite: cement: water like 5: 1: 3. After a complete week, from the moment of laying a pelitobetone, we apply a layer of concrete on top of 30 mm with a slide slope. When dealing with perlit, you need to respect special caution - this material is extremely lung, even a light breeze blossoms, so it is necessary to work with it in a closed room without drafts. Meet the proportion of water!

With a significant approach of the base of the bath above the ground level (from 300 mm), wooden lags of a square section will be required for flooring (150 mm side). If the size of the rooms of the baths do not exceed 2000x3000 mm, then the owls for lag will be bricken salary. During large sizes, additional supports for sexually lags will be required, they are pillars from concrete or brick (250x250 mm) and are placed at a distance of 700-800 mm. The support pillars for lag should be set on a multilayer base from sand, rubble and concrete - each 100 mm.

Important! Before forming the base for the support of the lag, you must perform the foundation for the Kamenka stove and build a sewage system.

Wood for lag may be oak, larch or coniferous rocks, lags should be treated with tar or antiseptic to installation.

The solution of the floor covering in this case is: the concrete space between the foundation is covered with a rubberoid with a flood of walls to the height of the floor, falling asleep by slag or clay (between the layer of rubberoid and bulk insulation, can be laid a layer of 200 mm of foam), to the lower side of the lava, the draft floor from 29 mm can be mounted Edged board. Then the PVC film is laid, foil mineral insulation, again a layer of films - for vapor barrier. On top of the 5 mm layer of concrete with a shallow fraction filler, create a slope under the drain hole - after 3-4 days we put the ceramic tiles.

Do not forget to bring the foundation for the furnace to the floor level.

The floor in the pre-tribades are created from a 19-29 mm t-shutty boards of coniferous wood.

Important moment: when finishing clean floor, and the entire steam room and washer, do not use synthetic building materials - the condition is especially important for the pair of room!

Sewage system bath

To remove wastewater from the bath, it will be necessary: \u200b\u200ba veil with a hydrotherapy, a wastewater well and pipes, removing dirty water into the veil on and then into a waste well.

The pita is cut off outside the foundation of the bath, from the premises of the steam room and the washer in it are breeding in plastic pipes, cast iron or ceramics (metal pipes quickly rust).

The pit should defend from the foundation by 500 mm, its depth is 700 mm, the cross section is 500x500 mm. The veil walls are covered with 100 mm layer of concrete, in it under the foundation there is a drain 110 mm tube (pipes) from a bath. The main well well, containing at least 2 m 3, must be opened at a distance of at least 2.5 m from the pit - the further, the better. The tube was supplied to it from the pit, laid under the slope at a depth of 1.5 m (below the depth of the freezing), its output from the pit should be located 100 mm from its bottom. After entering the drain pipe, the mainstream well is filled with gravel or sand 1 m from the bottom, the ground is poured - a layer of at least 500 mm. When laying, carefully confuse each layer.

Before conclusion of the drain pipe in the pit, the hydraulic was installed from galvania, located under a stupid angle to the plum pipe from the bath. Its edges and the upper side are hermetically attached to the veil walls, the distance from its bottom edge to the bottom should be no more than 50 mm - due to such a design of unpleasant odors and cold air will not penetrate into the pair (washing) through the waterproof hole.

To exclude the freezing in the winter, the veils must be closed with two caps of the appropriate size (wooden or metal), there is felt between them, and the upper cover fall asleep on top of the clay, slag or sawdust.

Circuit, Roofing and Soul

The bathhouse for the bath is better to order from professional performers, its manufacture is quite difficult. A finished log house in a disassembled form must be brought to the construction site and assemble it according to the login numbering. The attachments of the crowns are performed by steel 25 mm brackets-spikes with a total length of 150 mm, a length of the tooth is up to 70 mm.

The roof design of the bath includes rafters, the lamp is attached to them, then the roofing material. The choice of the final design of the roof depends on the roofing coating, which it will overlap. The rafters are attached to the last crown of a church (better to the penultimate) using brackets. As a rule, the construction of a bath involves the arrangement of a single or duplex roof, the angle of the slope (from 10 ° to 60 °) of which depends on the abundance and amount of precipitate in this area. Consider - the steep roof, the more the material is required to create it.

Single rafters located at an angle are attached to two outer or inner and outer supports. If the length of the span of the rafter exceeds 5 m, they are supported by additional subtairs. The rafting of the bartal roof is based on the bottom ends on the walls, the tops are connected to each other, forming a horse.

The roof of the bath can be covered with any material (slate, tiled, rubberoid, galvanized, etc.), with a wall at a wall at least 500 mm.

An attic room must be done ventilated, i.e., to equip two doors at opposite ends of the roof.

On the perimeter of the foundation, we perform a breakdown: completely remove the upper layer of the soil, deeper by 200 mm at a distance of 600-800 mm from the base of the bath, lay 100 mm layer of gravel (rubble, clay) with its subsequent alignment. We lay the temperature seams (19 mm board coated with a resin or bitumen, with a pitch of 2-2.5 m perpendicular to the foundation), pour 100 mm layer of concrete. Before setting the concrete, its surface is needed to eliminate - fall asleep dry cement with a layer of 3-5 mm. After 3 days, the line of contact with the breakfast and the foundation of the bath must be covered with bitumen for its waterproofing.

Canopate Ban Srub

It is performed for the warming of a cut - sealing the slots between its logs, the material for the cacopa traditionally serves a linen package, a red moss, hemp from cannabis, woolen felt. Natural materials for cacopate can be replaced by factory, produced from jute and flax fibers: flanutin and felt - jute and flax. The advantage of factory materials for cacopate before natural is the resistance to the damage to the mole and fungus, and it is easier to work with the factory material, since it is produced in the form of a solid tape of a given thickness and width.

The cutting of the cutter is performed when it is assembled - the pure material is paved between the logs during their laying. After the construction of the roof, a complete cacker is performed - from the outer and inside of the log cabin, after a year - repeated cavulus (the log house is hesitated - the brica will dry).

Basic tools for cacopate - a blade and a beater, they can be made or purchased ready for them. Both of these tools are made of wood (ash, oak or beech). The shovel for the cacopa looks like a wedge with a handle with a length of 200 mm and a pointed blade of 100 mm, the thickness of the handle of 30 mm, the width of the blade at the base is 65 mm, at the end - 30 mm. The wooden beater has a rounded shape: the diameter of the handle is 40 mm, its length is 250 mm, the diameter of the shock part 70 mm, the length is 100 mm.

Konopka is performed in two ways - "in a set" or "stretching". In the second way, cavalid so: we collect panties in a strand, we deprote in the gap between the logs and pushing there with the help of a blade, filling the gap completely, without spaces. Then we collect a roller with a roller, we apply to the cocointed groove, take out small strands of the material from it, wind the roller and drive it into the groove with the blades and roller - with force, to complete confidence in filling the groove (crack).

The first method of cacopate of the log cabins is designed to overlap the grooves (slots) of a large width. The material for cacopate is twisted by 2 mm strands, of which we form several loops and drive them into the gap. The loops are recruited in an amount sufficient to fully fill the gap.

Rules for carrying cavity:

- initially, the material is clogged on the upper edge of the log and only after - at the bottom;

- work on cacapatka is starting with the slits of the lower crown, on both sides. Then go to the lower crown of the next wall and so on. After having finished the caulp of the slots of the lower crowns, we start working on the next height, moving from this crown to neighboring in the nearest wall (right to left or left to right, no matter).

In no case, do not carry out the caispite of only one wall - it will rise and cause a soul break, it will have to disassemble it / collect again. Recall again: the cachatka is performed in the direction of "bottom-up" along the perimeter of the cut.

Put a stove

Options for bathing furnaces for baths set, they can be heated with firewood, gas, liquid fuel or use built-in tanes and heat from electricity, can be brick, cast-iron or metal. Brick furnaces in the baths are performed with a wall thick "in Polkirpich" or "into a whole brick", the masonry seams need to be tied up especially accurately, striving for their lowest thickness to achieve the greatest efficiency of the furnace. For masonry stoves only red bricks are used. The furnace furnace is removed into the pre-banner, its remaining three walls are in the washing (steam room), while the distance from them to the walls of the washing should be at least 250 mm - in this case the heat will not leave "into the wall".

For a cast iron or metal furnace, the formation of an independent foundation is not required - only for bricks.

Kamenka, installed for lovers to shake, are equipped with a chamber containing stones of various weights (from 1 to 5 kg). To fill the chamber of Kamenok fits boot, goats, boulders and granite. The design of these furnaces is extremely simple - similar to the kitchen stoves, the stones differ from them with a pipe of greater width or the presence of a chamber with stones.

To get the highest temperatures in the steam room, you need to add cast-iron pigs over a percentage of 80:20 (stones: khushchi). For each 1 m 3, the steam rooms will need not less than 6 kg of stones and cast-iron saues.

Under the observance of 40-50 mm distances in the furnace between its walls and a water heating boiler, the effect of a comprehensive blowing of the boiler with hot gases and the speedy water heating is achieved.

For better thrust you need to remove the smoke pipe as close as possible to the roof of the roof. Conducting a smoke pipe through the attic room, be sure to perform a 380 mm tube roller. Remember that the pipe should not take place near the roofing roofing and rafted closer than 150 mm (fire standards).

Electrician and Water Supply Bath

To wash a single user bath requires at least 8 liters of hot water. You can provide such a number in several ways: heating the capacity with water on the heater, use the gas column, install the electric heater - the boiler. If there is central water supply, the pipeline to the bath lead from the main house - water from such a system of the pipeline must be drained in winter, otherwise it will leave and rupture the pipe.

Water can be taken from the well or well by installing the submersible pump for its injection and supplying such a water supply system with cleaning filters. And in this case, in the winter time, water should be either merged after each use of the bath, or insulate the supply pipes.

To the bath you need to stretch an independent line for the supply of electricity and the easiest way to do it through the air (air). For the air will need a special cable - "naked" aluminum We note immediately, stopping at two versions: SIP (self-supporting insulated wire) and WEGN. The first type of cable is very good, he has a long service life (more than 30 years), it is durable and does not need a support for the carrier cable. But it is extremely difficult to carry out installation work, since it is too thick (the minimum cross section is 16 mm 2). Aluminum SIP can not be stretching through the attic bath on fire standards, it is necessary to fix it on special anchor clips - in terms of costs and hassle with its installation, its value will cost expensive.

A simpler solution is a Copper Cable Bulk Cable, fixed on the carrier steel cable. The cable is suspended to the cable on the insulated plastic wire, its service life is up to 10 years, after which it needs to be replaced (!). For a single-core BBN cable (of course, there should be two veins - each of them should be in an independent double overtake), the aircraft extended to the bath, the optimal cross section will be 2.5 mm 2 - it is unknown exactly what electrical equipment of the dacha wants to drive from it Future.

All Tuso-wrinkle boxes, sockets and switches, electrical stops should be only an outdoor installation. According to the fire safety rules, it is prohibited to install splash boxes, switches and sockets in the washing / steam room - only in the pre-banker. Do not joke with the possibility of a short circuit in a wooden structure - the entire inner wiring of the bath must be performed only in a non-combustible corrugation, fixed on special clips, the passage of cable through partitions is only through the steel pipe.

Try to locate cables in a sawn box, a socket or lamp so that they come there from below or side, but not from above - a drop of condensate, sliding on a fever, can cause a short circuit.

All electrical appliances must have a waterproof class not lower than IP44 (better maximum - IP54). Install simple lamps - metal case, only glass ceiling. All connections of the inner wiring of the cable - only on the terminal, no twists. And install in the shield of the RCD, exposing it to 30 mA.

For work in the electrical protection and installation of the UZO, be sure to invite a qualified electrician if you are not available!

Installation of partitions, ceiling, interior decoration, installation of windows and doors

Internal partitions in the bath can be brick or wooden, followed by heat and moisture insulation in both cases. The partition between the washer and the pre-bake, in which the furnace is installed, must be brick, or it takes brick inserts with masonry in one brick - on the sides in contact with the furnace housing.

Interior decoration is usually performed in cases where the bath itself is built of bricks, stone or timber - here the classical decoration scheme: insulation, vapor barrier film and lining. In addition, when performing an external and interior decoration, it is necessary to re-arrange the ventilation system of the bath, because the cutting birings will be closed with trimming and will not be able to carry out full ventilation.

The ceiling is formed by two layers - rough and finishing. The draft ceiling is attached to the horizontal lags of the roof, if necessary, the reinforced intermediate beams. Its area is covered with insulation - clay or slag. From the inside the room washing / pairing to the rough ceiling, the insulation and a vapor barrier film is fastened, after which the ceiling is overlapped with a finishing trim - a linden, pine circulating board (with a thickness of 20 mm - the thicker the board, the longer it will save the woody odor).

In the bath you need to arrange the windows of a small size (on average 500x700 mm) and to embed them low - enough so that through them you can look out to sit on the bench. The windows in the bath always perform with double glazing, depending on the size - with the window or fully swinging - to carry out fast ventilation.

Doors in the rooms of the bath must be installed so that they open up - for the reasons of fire safety. Material for door flaps is a pinned board (40-50 mm) or a board with a chosen quarter, the attachment of the boards is performed on the key. The size of the sash should be intentionally reduced by 5 mm - more than it is necessary for the actual distance between the quarters of the jambs - otherwise, with increasing humidity, the sash will swell and open (close) it will be difficult. The optimal size of the door in the washing bath of the bath is 600x1600 mm, in the pair - 800x1500 mm, with a threshold height of about 300 mm above the floor level (walking uncomfortable, but heat will keep). Loops for hanging door leafs - brass, leaving for a prebator (room washing) and in the washing room (pair room). Door handles - wooden (especially in steam room).

The shelf material is linden, pine, poplar or aspen. The minimum length of the regiments is 1800 mm, the width is 500-800 mm. The distance between the "floors" of the two-row regiments should be at least 350 mm, the minimum distance from the second row to the ceiling coating is 1100 mm.

The surface for lying is formed by a black-width of 80 mm wide, from 40 mm thick, a lumen of 15 mm width is formed between the boards. From the wall to the shelf, a distance of 10 mm is withstanding. The boards for the shells of the regiments are attached to the frame from the bar with a cross section of 50x70 mm in two ways: from above - with the help of nails whose caps are taken into a tree; bottom - with screws. For fastening, nails and stainless steel screws or copper are chosen.

All angles in the design of the regiments are spinning, the surfaces are carefully cleaned with zero sandpaper.

For more convenience, the shelves in the steam room are equipped with headboard: the height at the beginning of the rise is 30 mm, the head of the head of the head - 460 mm, the final highest height is 190 mm.

When choosing a material to create regiments, be careful - it is believed that the bumping sections have greater density and can lead to a skin burn. Therefore, try to pick up the boards and a bar at all without dumping sites or with the minimum amount.

Fire fighting measures

Confine bathrooms from the threat of a fire - Severe a steel sheet in front of the furnace furnace, make sure that the fastening of the furnace door is relieved, set the fire extinguishing tools (water, sand and fire extinguishers). Make sure you can freely open the pair and washer doors during the battery. Do not block the passages, space in front of the doors and windows.

For a Russian man, a bath is not a luxury, but a vital necessity. Even historians are convinced that the love for a bath broom and good heat we have literally in the blood, and even in the poorest villages near the smoked dilapidations, new pairs (old burned) were regularly built every five years. And Peter I, during a trip to France, could not stand without a native couple and two days, urgently ordered to build a Russian bath right on the shore of a foreign river than a very shocked natives. But what to do if it is so expensive today, and public pairs are not all soul? And if rest in the steam room is not just useful procedures, but also valuable communication with friends, kebabs and the opportunity to breathe fresh air? Then we will learn the cunning tricks of modern Russian masters who manage to build their pairs literally for vacation.

So let's consider the most successful projects of building a bath and their embodiment, where the main task was to save as much as possible, but at the same time not to lose the comfort of bath procedures. After all, as they say, the budgetary bath is a vestibule of a summer suburban train.

What can and cannot be saved when building a bath?

Agree, no savings are worth losing health, property or life. But the saddest situations occur when the question is suitable for cheapness, it is immenticated: such baths first slowly etch their owners the release of hazardous substances, and then either burn, or quickly deteriorate. But this does not mean that it is better to lower your hands to give all the blood on the conscience of a construction team - it is better to refuse to refuse dangerous use from the very beginning:

- Unattended materials and fakes for which unscrupulous sellers are assessed at times less. And at the same time, they convince the buyer that "there is no difference with expensive material, there is simply no cheating for the brand, my brother / matchmaker / son-in-law is already half a century worth it, and nothing."

- Materials are categorically not intended for construction and trim. So, if it is impossible to insulate the walls in the sauna, it is impossible, and this is not a whim of the manufacturer. Again, a neighbor, which at his own fear and risk insulated in this way and now boasts - not an example.

- Unsuitable components for electricity in a bath (wires, sockets), unprotected lamps or cheap Chinese products.

- Homemade furnaces and water heaters, which no one checked for fire safety.

- Combustible materials and those that are not indicated that they can be used in conditions of high humidity and heat.

If you build a bath with your own hands and are forced to save the materials as much as much as possible, try well every step, advise with experts and leave nothing without attention "seems to work." And finally, save with a limited budget better on the cubic meters of steam room, but not on the materials of its finishes. Such a board.

Let's figure out a little with affordable insulation. So, basalt cotton wool makes stone (basalt). Its main advantage is that the fibers inside the insulation are not connected by a chemical method, and another technology, and therefore, hazardous substances will not be released to the steam in the steam room. This insulation is not a fuel and well isolates the furnace. For a bath - the best option. If you want to save, then on the ceiling, put one layer of basalt wool and a couple of the layers of another, cheaper material.

Used as an economical version also foam-porous propylene with polyethylene film and foil spraying. You can buy it in a roller form, and secure immediately on a bare wall. This material is a good bridge of heat between the wall itself and insulation.

- The furnace is purchased without remote furnaces - so on the heating of the wage will leave much less than firewood, and there is such an assembly inexpensive.

- For sure to install the water tank is the fastest and most economical way.

- Foundation for a bath Make a cheap removable: it is much cheaper and easier to carry out repair work and change to another.

- Pay a maximum of attention to the insulation of the bath - the less you will "warm the street", the more economically the heating itself will be.

- On the window in the living room in the winter, cover the packaging film with bubbles - this is at least 50% will retain heat.

- Instead of an ordinary soul or shower, put the traditional Russian ears. And it is more useful for health, by the way. And it is not necessary to pour only icy water at all.

- By purchasing the lining, take the brushes of short sizes - they are cheaper and look no way worse.

- The roof at the bathhouse build a low, no more ratio of width and height 1: 3. There will be much less materials on such a design, and the chimney will not need to be high too.

Project # 1 - Compact Bath at a minimum cost

So, step-by-step process:

- Step 1 - Foundation. Foundation will be tally. To do this, you will need to get a screw car for 2 meters. As a casing, take the usual cheap sewer tubes by 110 mm. Insert the reinforcement of two connected rods.

- Step 2 - Vent. Under the strapping lay the studs with a length of 500 mm. Collect the strapping of 150x150, and prepare frame racks with a height of 2200 mm. Treat the frame to the neomide 440 or other suitable for the same purposes.

- Step 3 - walls. Walls can be refined directly on the strapping, and just raise them. We are trimmed. For this, the plates are pre-drilled, and then screw them with a semicircular head screw.

- Step 4 - Roof. The roof is covered with eightwall slate. Save after all!

- Step 5 - insulation. Now put any inexpensive insulation that is suitable for the bath. In this project - Lainrock Light.

- Step 6 - oven. We put an inexpensive oven, can be self-made. But under any necessarily additionally lay out the brick angle.

- Step 7 - finishing. Fresh lining, plinth, detection.

That's ready compact and inexpensive pair.

If the walls in view of the savings are not too strong, the smaller the sauna will be, the better - so its structural properties will be higher.

Project # 2 - Arbolit

But a good example of building a budget bath from Arbolita is not much more expensive than a frame technology. So, the outer walls of the pair will be 20 cm thick, inside - the brick partition from the furnace.

Here's what the process of construction is:

- Step 1. Pump the drain pit with dimensions of 1.2x1.8x1.4 m. From two sides, we fall asleep OCGS with stones, we make a formwork, pour.

- Step 2. Copier the foundation 30 cm wide, a depth of 50 cm. I fall asleep sand and trambra.

- Step 3. We put a formwork, reinforcing two rods on top and bottom. Vertical rods put through the meter. Fill the foundation.

- Step 4. We put the EPPS in the washing and steam room, the grid and pour floors. In the washer additionally organize drain.

- Step 5. We put the blocks, check the evenness of the walls with the level.

- Step 6. We make a roof using boards 50x100. The optimal distance between rafters is 55-80 cm. Covered.

- Step 7. Cook the oven or buy a budget ready. The ventilation scheme is suitable for this: outside the air goes to the gap between the stove and the brick wall, where heats up.

- Step 8. Install the shower tank in the attic.

- Step 9. We finish the walls from the inside. If you have the opportunity, use the FB isesan - a special material for baths, plus heat-resistant tape. For the ceiling is good isolon, which can withstand temperatures up to 150 ° C.

Such is the budget and quite successful, the bath turns out.

When choosing Arbolit, pay attention: in its density it is thermally insulated and structural. The first has a density of 400-500 kg / m, the second - 500-850 kg / m. This material is used to erect self-supporting walls and has good heat and sound insulation.

Project # 3 - Miniature Banke of Bruus National Style

And if you do not imagine the Russian steam room from another material, like a bar, you can build this relatively budget option.

- Step 1. Align the site under the foundation from the dropout, pinch the "formwork" and leave only the opening for draining water from the washing room.

- Step 2. Put the EPPS, knit the reinforcement frame. Fill with concrete, we make a scat for water and the foundation is ready.

- Step 3. We put the log house. Under the first crown, we put the blackboard processed by the antiseptic, which is closing the rubberoid from three sides. You can put moss on the board itself - it has antiseptic properties, and therefore the crown of the bath will serve even longer.

- Step 4. We build walls and leave so for several months to shrink.

- Step 5. Breeping rafters and cover the roof. Through the overlap we make the passage of pipes - it is easy to make from a metal corner and a sheet of stainless steel.

- Step 6. Between the steam room and the pre-tribades, we make a frame partition, insulate it with mineral wool and we are wearing with clapboard on both sides.

- Step 7. Putting the floor to the floor strain in front of the stove. We leave a special hole in the floor - for supply ventilation.

- Step 8. Take the pipe from the furnace through the roof. Passage from rubber Master Flash, which is a rack to temperature. Box with roofing coating seal MS polymer.

- Step 9. Krepim shelves in the steam room and carry out electricity.

Remember: the first step to a huge savings during the construction of your own bath is to build it yourself!

Project # 4 - steam room on a light frame of girlfriend

Brux for a bathhouse can be made even from the collected firewood, if desired. The main thing is only to choose from them without defects and bitch, and be sure to handle the antiseptic.

So, we build a budget bath from the remedies:

- Step 1. We make bars for the frame, process and envy.

- Step 2. We are building a pile-butt foundation: we break the grommet on the meter, we forget the thick pine colas there and on top we make a shelter from concrete and stones. Next, fill the poles already before the top.

- Step 4. Collect the frame.

- Step 5. ROOM Yamu under the drain, insert inside the barrel with broken brick and rubble, we take the ladder there. This is a summer non-insulated option, and for the winter you can pave a insulation or warming cable.

- Step 6. And the ceiling, put the film over the insulation. On the walls and the ceiling, let the Finnish foil paper for the sauna.

- Step 7. We put the oven. Take with the register, because We need water heating for washing - in order not to acquire a separate boiler. So, well proven itself - inexpensive and warm well.

Such a sauna is surprisingly for a long time, the couple pleases and spend time in it - one pleasure. And the cons will always find.

Miniban: cheap and angry

But if there is no pair of steam tool at all, it is not worth a despair - today there are a lot of options to build a steam room literally from nothing. Let's consider in more detail.

Banya-barrel

This is the most common, only more solid sizes. Some of it overlaps a wooden grid screen, followed by a furnace. In front of the screen - a small bench. Starting at the same time in such a bath can even three people. But this option is only summer: rolled out on the site, put horizontally, they abandoned firewood into the oven and you can pour water on stones. But as a low-cost version - it is very different.

Hiking bath

Such a bath is taken predominantly hiking, but in the absence of another alternative can be used in the site. It will cost inexpensively, because it represents a conventional tent in which a stove or electric is no longer the mild Russian bath, but as a temporary phenomenon also has the right to exist.

Built-in mini sauna

It also appeared fashion to do in the bathroom. So, we transfer the washing machine into the kitchen, and in its place we build something similar to the closet. This is a small design, 1.5 m height, made of frame and fastened by clapboard. Inside - one seat shelf and built-in steam generator. A man sits down, closes the door, turns on the device. But his head remains outside - for the sake of security. When using special aromatic oils and other SPA elements - a good way to improve. You can say it is the smallest and cheap bath in the world.

Baths in cars

If you have the opportunity to get a non-working minibus or a car with a body, you can constitute a small bath right in them. On our site there are even detailed master classes, how to do this, and this idea will turn out much more profitable than the construction of a steam room start with the fill of the foundation. Experiment!

Almost every owner of the land plot, sooner or later, thinks about the construction of a bath. After all, the bath is not just a washing room, but also an important element of the country's holiday. The construction of the "turnkey" bath can be ordered from professionals for a round sum, or try to build a bath with your own hands.

After reading this article, you can choose a project, learn the sequence of the construction process, get acquainted with the boilers models and find the best option for your cottage.

Because to proceed with construction, it is necessary to develop a banani project. To do this, it is not necessary to contact the architect, a simple project you can develop and ourselves, especially since there are many computer design programs.

Think what size bath will be optimal for your family. What premises will be inside the bath. From which materials to make the foundation, walls and roof, do not forget also, about the trim. An important point in the design is the placement of the boiler and the method of its firebox.

Below you can familiarize yourself with the popular Ban projects:

- Bath project size - 4x4 meters.

- Bath project - 4x6 meters.

- Bath project - 5x6 meters.

- Bath project - 6x3 meters.

- Bath project - 3x3 meters.

After you have determined with the sizes and materials for the bath, you must create an estimate of expenses.

Foundation

For the construction of the bath, use several types of foundations. Depending on the weight of the walls and the characteristics of the soil, the foundations of the following types are manufactured:

- Foundation from plates.

- Foundation columnar for light walls.

- Pile foundation.

- Concrete belt foundation.

As practice has shown, the most reliable foundation is almost for all types of soil, is a concrete belt foundation, reinforced by reinforcement.

For the manufacture of a ribbon reinforced foundation for a bath you will need:

- Cement.

- Sand.

- Gravel.

- Armature.

- Formwork.

- Ruberoid.

- Wire.

- Shovels.

- Concrete mixer.

- Harness.

- Stakes.

- Tools (pliers, hammer, roulette and others).

In the place selected for the construction, make the marking of the trench for the future foundation. For marking use the harness, stretched between the pegs. Trench width is based on the weight of the material for the walls. For a single-storey bath of wood or brick, it is enough to make a trench width of 30-40 centimeters. By setting markup, make the following:

- Focusing on the markup, haul a trench with a depth of 50-80 centimeters.

- Failure the bottom of the trench and fill it with water to shrink soil.

- Ship the bottom of the tale tale for waterproofing.

- Put the trench by gravel by third of its depths.

- Install the formwork at the edges of the trench.

- Make a fountain-enhancing framework, from reinforcement rods connected with a wire.

- Install the reinforcement frame in the formwork.

- With the help of concrete mixers, make a cement solution in proportion: one piece of cement per part of the sand and two parts of gravel.

- Fill cement to formwork, trying to prevent air emptiness.

- After drying the concrete, remove the formwork.

The foundation for the bath is ready!

Walls

The following materials are used to build walls:

- Wooden timber.

- Brica.

- Boards.

- Brick.

- Blocks from various building mixes (slag block, aerated concrete, arbolit and so on).

Since the construction of a bruis or brick bath is already quite widely described on the Internet, let's consider the construction of a frame bath from a bar 15x15 and 5x10 centimeters and a cross-section of 2x15 centimeters:

- Make the bottom strapping, for this, take the bars with a cross section of 15x15 cm. And install them on the foundation, connecting with special metal plates and corners. There is another way to connect bars, by drinking on their ends of spikes, grooves and subsequent fastening with screws or nails. Doing the strapping, do not forget to put waterproofing under the bars.

- Install the vertical racks from the 5x10 vertices. The distance between the racks is usually made 50-60 centimeters. First, determine the position of the window and doorways and install the framing racks.

- In the process of work, fix the temporary struts already installed racks so that they do not bother.

- Make upper strapping, securing it at the ends of vertical racks.

- Making the final fastening of the upper strapping, take care of the position of vertical racks, checking their levels levels.

- Be sure to strengthen all the angular connections with diagonal racks, it will help to avoid carcass throwing.

- Make a ceiling cut.

- After the framework of the frame, make the outside of the walls of the wall with a cross section of 2x15 centimeters. If you do not want the appearance of the gaps between the boards, then make the skin - "flashes", laying the bottom edge of the boards on a nithe board. In appearance, this method resembles the walls of the walls by siding.

- Saving a bath from the outside, go to the installation of the insulation. Foam or mineral wool sheets are installed along the vertical frame racks.

- On top of the insulation, it is necessary to install a layer of vapor barrier which is attached to vertical racks with thin regions.

- After installing vaporizolation, make the internal trim bath with clapboard or slats.

- Heat the ceiling by setting on the inner covering sheets of vapor insulation, then the insulation. Cut the ceiling from the outside, plywood sheets.

Note that the manufacture and insulation of the ceiling can also be performed after mounting the roof.

Roof

The roof for the bathhouses is three species:

- Single.

- Double.

- Complex - consisting of four and more rods.

Usually for the baths use the first two options. Let's look at a variant of a bartal roof covered with metal troops:

The manufacture of the roof begins with the installation - Mauerlat. In cases of frame walls, the role of the Mauerlat performs the upper stroke.

- Install the vertical stands on the layer.

- Connect the racks using runs and tightens.

- Install the rafter legs by attaching them to Mauerlat, run and connecting the upper ends. The distance between the rafters should be 50-60 centimeters.

- Install metal tile sheets.

- Cut the frontoths with wooden slats or leaf iron.

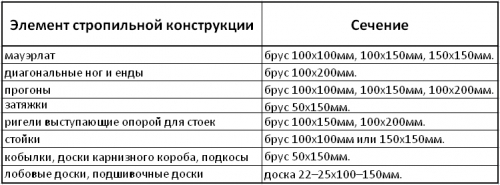

For more visual acquaintance with the roof mount, drawing is shown:

All sizes of roof elements are listed:

Please note that the less you take the root slope, the more snow loads will have to have snow. Also, a small tilt of the roof can lead to poor water plum and leaks.

Floors

Floor design depends on the type of room. In the room of rest, ordinary wooden floors are manufactured. In the waxing and steam rooms, the floors make out of two levels:

- The first level is made of concrete, it has a bias towards the drain hole.

- The second level is the purple floor of the boards with gaps for draining water.

If you want to make floor stonework or tile, then they simply fit to the first level under a slope to the drain hole.

In order to make concrete floor and draining in the bath you need:

- In the center of the steam and wetting, install plastic pipes with a diameter of 5-10 centimeters with a field at the end. Pipes should pass into the street through the foundation and connect to the sewage system.

- Put the layer of waterproofing material.

- Throughout the area of \u200b\u200bthe rooms, pour a gravel layer 10-15 centimeters thick.

- Make a cement solution and fill the floor with a bore slope mounted on a plug-up pipe.

- Reinstall the grille to the drainage of garbage in the sewer.

In the second stage, wooden floors are made:

- Install wooden lags in all rooms. Distance between lags Make 30-40 centimeters. As a lag, you can use the bars with a cross section of 3x5 cm. Or 4x6 cm.

- On the lags, approach the board with a cross section 2x15 cm. Or 5x20 cm.

- In the rooms, where water drain is assumed, leave the gaps between the boards at 0.5-1 cm.

Do not forget, before installing wooden floors, handle all the parts impregnated for wood. Maching floors, note that they must be higher, or at the level of the top edge of the foundation.

Boiler

The boiler boiler model will largely depend on your financial capabilities and fuel that you will use for heating. If you know how to use welding, then a simple boiler can be made from thick sheet iron. If you prefer more advanced colas on gas or electricity, they can be purchased in specialized firms.

The boiler in the steam room is installed in such a way that loading the combustion chamber with fuel, was carried out or from the street, or from the rest room (pre-banker). The boiler itself, for the purpose of fire safety, is located in 10-15 centimeters from the nearest walls. Walls on the height of the boiler are closed with iron sheets. A successful solution will make the boiler brick, there you most reduce the time of cooling and secure the walls from fire.

Having arrange the chimney for the boiler, pay special attention to the place where the pipe comes into contact with the ceiling. Hole for chimney, it should be isolated with refractory material. Also, pay attention to the place where the chimney pipe goes through the roof. Usually, this place is subject to leakage, so it should be carefully smeared. Below are options for boilers for a bath:

- Homemade metal sheet boilers.

- A gas boiler.

- Electric boiler.

- Boiler on hard fuel.

Bath arrangement

After the sauna is built, it is necessary to equip it:

- Move to the bath all available on the site - electricity, sewage, plumbing.

- Place inside the sink, shower cabin, light sources, leisure furniture.

- Finish the walls with curly slats and make stepped shelves.

- Buy wooden tubs, hayk, buckets and brooms.

After the arrangement, you can safely invite guests, shake in your personal bath!

Miniban assembly instructions for giving without foundation, you can also look in the video:

Options for beautiful and unusual baths

In addition to traditional materials and designs for the bath, there are many alternative solutions. Below we will give photos of the most unusual bath:

- Mobile bath from "Lining", built on a car trailer.

- Bath in a huge wine barrel.

- Bath of plastic bottles.

- Bath dug, built straight in the ground.

- Bath arranged in an iron container.

- Forest bath from raw logs.

- Beautiful sauna sauna.

- Bath of non-edged board.

At the end of the article I would like to remind you that the heating of the bath is associated with fire and high temperatures. Therefore, building a brick bath, brica, slagoblock or boards, pay great attention to fire safety. This warning also concerns the electrical wiring device, since indoors inside the bath have increased air humidity and the risk of closing the power grid due to condensate is very large.

We hope that reading our article will push you on an independent building of the bath!

Bath is one of the inalienable parts of Russian life. Despite modern technologies and development, it is unlikely that our compatriot will refuse to get into the bathhouse, which he built his own hands on the site. Even if you are not a happy owner of the urban mansion, it can be built in the country. Many dream of her own bath, but how to bring dreams to reality?

Bath from the foundation to the roof with her own hands. Features Building

Classic Russian baths, of course, wooden buildings. They have some similarities with the Finnish sauna. For their facilities, the logs are cut and coated from the inside. On the territory of Russia to build as a building material, pine and some other wood breeds are used. The main indicator when choosing is the minimum number of resinous substances, since when heated and humidity, such a material begins to "sweat".

The brave bath technology itself has its own characteristics and differences from the construction of a residential hut. First of all, these are increased requirements for the characteristics and quality of the material. The logs must be weathered, direct and able to provide a high-quality connection.

Special attention is paid to tightness. Unnecessary heat loss will be very noticeable, which reduces efficiency. For maximum safety, the walls are carried out with moss or packle.

The bath, built with a bar or logs, has an impressive and attractive look, but also the price of such a facility is far from everyone. The cheaper option is to use frame-panel technologies. It requires a small amount of materials, and the foundation itself will be less costs, since mineral wool or similar analogs are used as insulation. In this case, there is no need to build a massive foundation due to a minor weight of the whole design.

The advantage of the frame walls for the bath is the absence of a building of the building. Nevertheless, there are also cons of the use of frames - this is the appearance of moisture during the snowballs and rains. It is formed in the process of condensation of vapors. To avoid similar troubles, use waterproofing.

Before building up, you need to deal with the main stages that must be executed:- The correct approach begins to compile estimated documentation. It will display prices for all types of work and the necessary materials. In addition, the estimation will allow the correction and redistribution of the budget.

- After that, you can start creating a bath project. Without skills and skills in this area, you cannot think about everything to the smallest detail. Because of this, it is best to invite a professional architect, which will draw up drawings with the basic requirements and wishes of the client.

- One of the main steps during the construction of the bath is the selection of materials for the foundation. This element of the construction directly affects the durability and fortress of the whole structure.

- Next, it is necessary to choose the most optimal and quality materials for walls and roofs. To date, the construction market has a lot of proposals that can satisfy everyone's wishes.

- Special attention in the construction of the bath requires internal communications, such as electricity and water supply.

- Depending on the size of the bathroom and personal wishes, it is necessary to choose a stove and think about its place of installation.

- The compririsonment stage in the construction of the bath is finishing work indoors.

Bath from the foundation to the roof with your own hands

First you need to decide on the location in the site. This requires special attention to the owner. The selection itself depends on the size of the territory and evenness of the surface. It is also worth considering the geometric parameters of the bath itself. It is worth consider the most optimal conditions for the supply of communications in the future. To support bath traditions, it is built in the proximity of the reservoirs to feel the whole charm and contrast of sensations, plunging into cool water.

Project Development for Bath Building

In the classic style, the bath consists of three rooms: a pre-banker, a steam room and a washing. Quite often, the latest rooms are combined into one. The pre-banker is necessary for the location of the locker, shops, tables and chairs. It is in him that a company is going for friendly gatherings. Here also installed shelves of bath accessories, wood or coal.

The choice and development of the Bani project depends on the wishes, free territory and material opportunities. It is quite difficult to draw up a qualitative and thoughtful plan. To do this, it is best to invite an architect that will be able to quickly realize your dreams into a real project. It should be noted that the dimensions may be arbitrary. But for maximum convenience, it is necessary to carry out calculations. For comfort, about 5-6m 2 should be designed for each packaged. However, the reality builds the baths of both greater and smaller.Foundation for baths do it yourself

Like other buildings, the bantal requires the construction of the foundation, which must be put on the depth of the soil freezing. At the same time it is necessary to determine the material for the walls. This is necessary to calculate the maximum loads, since the weight of the wall will differ the massiveness of the base itself.

If you plan to build stone walls, it will take a ribbon foundation from the butt stone. As a material for the foundation, Concrete, Zheleznyak and Brick can act. At the same time, it is necessary to understand that the red and silicate brick is destroyed in the ground due to the impact of moisture.

By selecting the material, it is necessary to build the foundation half a meter above the soil level. Cement-sandy solution is used to align the surface. After drying, you need to put the rubberoid on mastic. This will allow you to cut off the moisture building coming from the Earth.

What type of foundation to choose for a bath

For the bath you can use several options for the foundation. Their choice depends on the depth of groundwater, the geometric dimensions of the structure and materials of the walls. The most effective for baths are:

- Lightweight tape from concrete with reinforcement belt. It is used when equipped with simple structures that have a small proportion. To create a ribbon foundation, use buttone or concrete. They are fastened with mortar. For the device, it is necessary to prepare a boothel with a gravel or sandy pillow, 15 centimeters thick. As for the width of such a foundation, it depends on the size of the bath and type of construction.

- Column with support concrete brick or metal columns. This type is used with a deep occurrence of soil waters. It consists of reference pillars located on the corners and around the perimeter. The distance between such columns should not exceed two meters. As a material for supports, concrete, brick, asbestos-cement or metal pipes are used. They are burned into the ground to a certain depth, and then poured concrete.

- Floating. This is an alternative for which the monolithic plate is used. It can be used on any soil, regardless of the depth of the soil moisture. To improve such a foundation, it suffices to pull out the trench with a depth of 50-60 centimeters, on the bottom of which gravel or sand fall asleep. After that, the layer of waterproofing lies and poured concrete.

- A screw foundation is used when building a bath on loose or unstable soil. It is created using screw pipes that have a pointed tip for the lighter passage in the ground. It should be noted that the depth of the pile immersion may differ. The pillars are screwed into the soil with two or three people.

- Piahno-helical screened. It is used as an additional strapping using metal chawls or timber.

In practice, people wish to build a wooden bath due to its unique properties. In this case, the most optimal type of foundation for the construction of the bath with their own hands is column. Unlike other options, has a number of advantages:

- The device of a column foundation is almost to everyone. This requires special knowledge or use of construction equipment.

- A wide range of materials that can be used: concrete, brick and metal pipes.

- The minimum cost of strength and time on its construction. Unlike concrete fill, it dries very quickly.

- This option is most effective for the bath, because ventilation and drain drain systems are very easily organized.

Preparation of trench for foundation

For example, we will take conditions in which the soil freezes up to 70 centimeters, and the soil waters are located at a depth of one meter. In this case, it is necessary to use the reference pillars with a diameter of 200 millimeters, depressed for one meter in the soil.

First you need to create a preliminary location scheme of all support pillars. On the perimeter of the future building they must be positioned in a step of one and a half meters. Additional supports are installed at the intersection of walls and corners. After the mark of all columns you need to drill pit. They must have a diameter of 50 millimeters more than the pipes themselves. The bottoms are filled with sand with a thickness of 20 centimeters with a subsequent tamper.

After that, they prepare pipes that should perform from the ground, at least 40 centimeters. As a result, they will have a length of 1.4 meters. Before installing in the ground, piles are wrapped in rubberoid. In the process of mounting the pipe, they fall asleep with small rubble or explosion, which will give an additional fortress of the structure. The supports are mounted for reinforcing design. The last step is concreting.

Features of the foundation under the bake of the bath

The design of the foundation is greater extent depends on the type of heating furnace, which will be used. If you plan to use a device with a mass above 500 kilograms, it is worth thinking over the creation of a separate concrete cushion for the furnace. For this you can use two options:

- All over the entire furnace area, create a columnar or ribbon foundation with an additional reinforcement of the design.

- Another widely used option is a monolithic pillow with concrete. It is placed exclusively under the furnace.

Creating water removal in the bath with your own hands

When creating a bath, you need to consider an effective water removal system from the room. As you know, the moisture is the enemy of buildings and reduces the service life of materials. By virtue of this, water must be discharged at least 3-5 meters from the structure. In the bath bath, it is necessary to equip the drain, which through the pipe system will remove moisture into the sewage system. Pipes must be laid below the line of freezing with a slope of 3 centimeters for each meter. You can also use surface trenches with a depth of half a meter, the walls of which are lined with clay.

The option of arrangement of the discharge system to a large extent depends on the volume of water and, of course, material capabilities. Next, it is necessary to understand that when using surface gutter there is risk of icing. This situation can lead to an uncontrolled stream on the surface of the soil.

If water leaves with a drain from the bath, in the floor, it is necessary to carefully calculate the slopes. If the floors are filled with cement, then the removal does not represent a special problem, since modern systems of the lower drain using pipes will be assigned the required volume.

Another element is a sewer well, which has several versions. If there is no drain well on your site, then for the bath it is necessary to build a separate system. It is sufficiently size from 1 cubic meter.

Distribute the well will not be particular problems. So that it does not face during operation, you need to lay walls from brick or slag block. Many owners use automotive tires. For better filtering of the allotted moisture in the wells, additional horizontal channels need to be equipped.

Floor floor in the bath

First of all, under the future floor it is necessary to cut the living layer along with the turf. If the bath is built on the summer site, the land should not be taken out, because it can be used on the site in the future. The soil must be cut to a depth of 15 centimeters. After the alignment of the surface can be proceeded to work.

The best material for the floor in the bath is a wooden board. The flooring should not be made above the level of the foundation, but also strong lowering is unacceptable, because the flooring will absorb moisture from the ground. Under the wooden lags you need to install additional columns with bricks. On all frames, the tank board is stacked.