Can be made from a jigsaw. DIY desktop jigsaw

Desktop jigsaw is an indispensable thing for any owner who is accustomed to independently cope with household chores. Especially electric jigsaws are good for residents of the private sector, lovers of manual labor and country rest. From its prototype, ordinary manual jigsaw, the desktop electric model has gone far enough. A desktop jigsaw makes it easier and faster to cut, not to mention improving quality.

The concept of desktop jigsaw

The jigsaw is a saw, which is characterized by reciprocating movements of the saw blade, which acts as a working body. It has a ski designed to guide the saw blade when moving over the surface that is being processed, and making movements at a frequency of up to 3000 vibrations per minute.

This tool was invented in 1946. Its creator is Albert Kaufman, who replaced the needle in sewing machine on the blade. The tool appeared on sale in 1947. The manual electric jigsaw has a body with a flat platform and a handle. Main difference electric jigsaw from manual is its greater functionality and cutting quality.

Inside is an electric motor and a special mechanism that drives the blade. In stationary jigsaws, there is no handle, and the platform is located on top. In front of the mechanism there is a guide, in the lower part there is a retractable blade that moves and makes cuts.

The tool works as follows: a table jigsaw file is securely fastened with clips in the slider. Reciprocating movements have a frequency of up to 3000 strokes and can be adjusted. The support platform allows the jigsaw to focus on the part being cut, so the work is carried out very accurately.

The purpose of the desktop jigsaw

The jigsaw is an essential accessory for every workshop and every hobbyist. His thin file can successfully cut plywood, copper, iron, thick boards, brass, steel. Tools can be motorized, foot or hand-operated and are more productive. An electric jigsaw is simply indispensable for carpenters, woodworkers, furniture designers, drywall workers who make complex parts.

An electric jigsaw can perform straight and curved cuts on workpieces with complex shapes and various sheet materials without breaking the outer contour. Most often, desktop jigsaws are used for cutting wood and wooden boards, figures with a complex outline of laminate and drywall, plastic blanks, also for cutting sheet metal.

Desktop electric jigsaw makes clean cuts complex shape and works with small

details. Due to the stable and fixed position during operation, high accuracy cut. The file has a stable course thanks to the tension system and guides, which manual jigsaws lack. Big size table makes it stable, so that exactly the specified direction of sawing is observed.

Types of jigsaws

Today, a wide variety of electric jigsaws are presented on the power tool market, which differ in the nature of the application, technical specifications, type of power supply and design features. In hardware stores you can buy a desktop jigsaw for every taste and budget.

By design features, it is difficult to classify, because each manufacturer seeks to provide its products with features that are designed to facilitate and improve the operation of the tool. In this regard, the shape of the handle is an important parameter.

Two types of handles have settled - mushroom-shaped and D-shaped. A jigsaw with a staple-like handle requires one-handed operation. This increases the possibility of using a jigsaw, but somewhat negatively affects the quality of the material cut.

Mushroom handles allow for more accurate cuts when holding the jigsaw with both hands, after fixing the workpiece to be cut. The choice of a jigsaw with a certain shape of the handle depends on the financial capabilities and personal preferences of the buyer. It is worth choosing the jigsaw with which it will be more convenient to work.

Household jigsaws are not intended for intensive use, but the low price of a desktop jigsaw and the power that is enough for domestic needs make them indispensable in the household.

Professional jigsaws are characterized by high wear resistance and the possibility of many hours of daily use (up to 8 hours). The significant power of such jigsaws allows you to process materials of great thickness. Extended equipment and improved features are reflected in the price.

Among professional jigsaws, industrial ones also stand out, which are characterized by greater adaptability to complex operations and drive features - for example, increased power supply voltage. Industrial models are machines that are designed for the woodworking industry.

By type of power supply, there are network and battery electric jigsaws. network models are powered from the mains supply with standard voltage. If performance is important to you, then you should choose a corded power tool.

Cordless jigsaws provide independence from the presence of sockets and greater mobility during work. When buying a battery model, you should pay attention to the type of battery. elevated performance characteristics inherent in lithium-ion batteries. Battery capacity is responsible for the duration of work without recharging.

Advantages of desktop jigsaws

Desktop electric jigsaw is fixed structure, so this type of cutting tool has many advantages. Modern models can work with wooden materials 40-50 mm thick. A narrow saw acts as a working body, which performs vertical reciprocating movements. Due to the peculiarities of the notching of the teeth and the mechanics of the movements of the file, the material is cut out by moving upwards.

The desktop electric jigsaw allows you to cut out complex decorative details, to make longitudinal, straight, oblique and transverse cuts. The wide tabletop allows you to process large parts and make cuts inside wide workpieces. Reliable fastening protects the body from unnecessary vibrations and allows you to have a good position of the material, so the motor can work without overloading.

The advantages of desktop jigsaws include good accuracy and clarity of cuts, high safety and ease of use, wide opportunities settings from the material and the required detail of the cut blanks.

If you need to cut out details small size, a manual jigsaw will not be very convenient. It is quite heavy, so you have to hold it with one hand and guide the workpiece with the other. And the desktop jigsaw is devoid of this drawback. Perhaps the inconveniences are too large sizes and the difficulty of working with large details.

The desktop jigsaw is a kind of mini-machine for cutting workpieces. If you buy a jigsaw in a store, most likely there will be an opportunity to select the power and adjust the frequency of the saw strokes. However, you can make the simplest homemade desktop jigsaw, and very quickly. You will need a manual jigsaw, a few screws, a piece of plywood small sizes and only one hour of work.

Making a desktop jigsaw

A carefully made jigsaw will not be inferior to a factory-made one, and in some respects even surpasses it. It is not difficult to assemble such an electric jigsaw if there is necessary materials. Next, we describe a simple circuit such manipulations.

The design of the jigsaw includes the following components: a handle, a switch button, an insulating washer, a power cord, a frame, a heating thread, a screw clamp and an earring. First you need to make a frame. You will need a duralumin pipe with an outer diameter of up to twelve millimeters.

You can also use textolite with a thickness of at least ten millimeters or thick plywood for the base. But keep in mind, the lighter the frame, the more convenient the jigsaw will be to use. Be sure to provide a channel so that you can later lay the power cord. most the best form A frame is one whose side is bent 45 degrees.

Next, you need to make an earring. It is made of copper sheet with a thickness of one millimeter. After that, it is fastened with screws to the frame, where it connects to the handle. Thus, the screw, wing nut and earring will form a clamp in which the heating thread can be fixed. The thickness of the duralumin sheet should be up to 0.8 millimeters. It is necessary to make clamping cheeks from it, between which there is a button-switch.

After that, you need to cut a gap in the plywood through which the file can pass. It can be done with a drill. To do this, it is necessary to drill holes along the marking line, and smooth the transitions. Instead of plywood, you can use plastic, metal, plexiglass and others. Next, you place and drill mounting holes on the plywood and the base plate of the jigsaw.

Then you need to fix the jigsaw with screws on the plywood base so that the file can pass through the gap. You attach the structure to the table with a clamp so that the file is pointing up. You can also secure the platform in any way you can.

The jigsaw file remains conventional, but the possibilities for good sawing are expanded by freeing up the hands.

You can use a nichrome coil from any household heater(iron for example) as a heating thread. It must be secured with tension between the ends of the frame bends. To heat up the thread, you need to apply a tension of about 14 V. To control the operating mode, you can use a rheostat.

The current is determined by the thickness and length of the nichrome filament. With the help of a rheostat, it will be possible to set the optimal current strength (no more than 3-5 A), which will affect the temperature to which the thread is heated. Before starting work, it is necessary to determine the current strength. But keep in mind, if too high strength the cut material can be caught by the flame, and if it is insufficient, it will not be taken. A do-it-yourself desktop jigsaw will allow you to cut out figures with complex contours from different kind materials.

Rules for using a desktop jigsaw

When working with a desktop jigsaw, you must adhere to some rules:

- Do not press hard on the tool while cutting, otherwise best case the needle will break, at worst, you will spoil the work.

- Change blades from time to time. An old saw can spoil and destroy the surface of the material.

- If you work with organic glass and non-ferrous alloys, the surface of the product must be moistened with water. Such an operation will speed up the process and extend the life of the saw.

- If you are cutting a surface with a thickness of less than one millimeter, place a sheet of wood or plywood under the material being processed.

- Before cutting, it is necessary to fix the material. It is better not to make long cuts by hand, the line may turn out to be crooked.

- For cutting different materials appropriate blades are needed, with a special pitch and length.

- Rotate the tool by turning only the back of the tool.

- When cutting the laminate, an adhesive tape is glued to the cut line, which protects the material from chipping.

- If the need arises for curved cuts, set the jigsaw pendulum to a minimum.

If you have not yet fully understood how to make a desktop electric jigsaw, watch a video about this procedure. This tool allows you to cut complex parts from wood and other materials, to make longitudinal, oblique, straight and transverse cuts. With the help of an electric jigsaw, you can process large parts, wide workpieces and small products, which is not superfluous at home.

Jigsaw machine allows you to quickly and efficiently cut wood. consists of working surface, racks, motor and spindle assembly. Some devices are made on stands. Clamps are quite often installed in the side of the work surface. It is also worth noting that the models differ in power. The manufacture of a jigsaw machine can only be carried out if the instructions are followed.

Desktop devices: expert reviews

If you believe the reviews, then making a desktop modification is very simple. First of all, a rack is prepared for the work surface. Its width should not exceed 30 cm. It is more expedient to select a motor of a single-phase type with ultimate stress 220 V. A home-made jigsaw machine (desktop) produces an average operating frequency of 55 Hz.

Reviews of experts say that yews are best used from steel, if desired, they can be cut out on their own. The file is mounted on a spindle assembly, which is attached to the rack. Many models use a latch that plays the role of a stop. To fix the file, a small screw is used.

Models on legs

If necessary, you can do this with your own hands. Modification drawings include frames different sizes, and spindle assemblies are usually used with guides. Many models are made on a wide bed. Legs can be installed from tubes. There are also machines with plates. After cutting out the working platform, you should take up the spindle assembly.

If we consider devices with control units, then the model will require a controller. It is more expedient to use a motor of a collector type for 220 V. Yews are installed on jigsaw machines of a rotary type. The direction must be welded to the edge of the plate. The file in this case must be securely fixed. Optimal Height spindle assembly is 2.2 cm. At the end of the work, it is important to install power cable and equipment connection.

Feedback on devices with a wide frame

Professionals are able to assemble a jigsaw machine with their own hands. Device drawings indicate the presence of wide stops. However, first of all, you need to install the frame. If we consider a simple machine, then the latch for modification can be selected for a small length. Reviews of experts indicate that two racks are enough for the model. Used to assemble the machine welding inverter. The spindle assembly itself is installed in the central part of the working platform. The hole for the file can be made with a cutter. It is also worth noting that experts do not recommend the use of two-phase motors.

Compact modifications

Following the instructions, you can assemble a compact jigsaw machine with your own hands. Device drawings include double racks and narrow frames. Beds are applied with a low profile. Many models have a spindle assembly without a holder. In this case, the guides are set to a short length. For self assembly Models are recommended to choose a high-quality frame first.

Additionally, a clamp is soldered under the work plate. To reduce the level of vibration, you can use the lining. To fix it, ordinary glue is used. The file for modification should be selected with a small thickness. The optimal installation distance of the central node is 14 cm. At the same time, the width of the platform is on average 17 cm.

Jigsaws for 2 kW

If you wish, you can make this jigsaw machine with your own hands. Drawings for assembling modifications are very easy to find. As a rule, frames are used with a width of 35 cm or more. The thickness of the plate should be about 1.5 mm. The hole for the file must be made before installing the central node. If we consider models without stops, then the frame is used with a low profile. It is also worth noting that it is more expedient to install the spindle assembly on a lining.

A casing is used to reduce the noise level. Many models use multiple stops. In this case, the node is installed at a height of 10 cm. It is better to fix the file on the plate. The clamp can be screw type. After fixing the central node, the motor is placed. For modification of this type, a device with a single-phase unit is suitable.

Models for 3 kW

At 3 kW, a do-it-yourself desktop jigsaw is quite simple to make. Experts recommend using racks with wide stops. Fasteners need to be installed only after the central node. The file for modification can be picked up by 1.2 mm. Some experts make a hole after installing the frame. In this case, the supports are soldered on the sides of the table.

Next, it is important to evaluate the size of the spindle. It is more expedient to use the motor with a protection system and a casing. It is also worth noting that collector devices that operate at a frequency of 45 Hz are very popular. They have low energy consumption and do not overheat. Holders are used to fix workpieces. The optimum spindle height is 15 cm. It is also worth noting that there are models with tuning plates. A flywheel is used to control the rack. To install the control unit, there is a conventional controller.

How to make a 5 kW device

Having prepared a few stops and you can make a jigsaw machine with your own hands. Expert reviews indicate that 5 kW models are well suited for longitudinal cut. Before starting work, all essential tool. You will need a saw as well welding machine and cutter. It is more expedient to assemble a frame for a jigsaw machine from steel plates with a thickness of 1.3 mm or more. For the motor, you need to immediately provide a place. The beds in the devices are installed with a high profile.

At this stage, you can immediately cut a hole for the file. The plug assembly must be mounted on the top of the plate. Additionally, it is worth noting that the file will require a large holder. If we consider a simple model, then the racks can be installed on the sides of the frame. Yews are used rotary type. At the top of the frame must be a rack. A small casing is selected under the motor. On average, the frame width should be 35 cm. If we consider professional models, then they use adjustable clamps.

Modifications for two quills

How to make a jigsaw machine with your own hands? The model with two quills is assembled only on a wide frame. First of all, plates are cut out under the bed. If we consider a desktop modification, then it is more expedient to install the control unit at the top of the device. The optimal frame width is 45 cm. In this case, the spindle assembly is installed behind the stops.

Must be provided for racks. Many models use transfer blocks. In this case, the motors are suitable only for a collector type with a frequency of 30 Hz or more. The file is installed as standard in the holder. The optimal height of the spindle unit for models is 35 cm. Quills for adjusting the bed are used with flywheels.

Models for three quills

On the basis of a single-phase motor, it is easy to do this one with your own hands. Tools should be prepared in advance. Many models are equipped with frames for four stops. They have long length and high profile. It is also worth noting that the spindle units are selected with. At the beginning of work, it is very important to calculate the length of the frame. If we consider ordinary spindle assemblies, then the rack for them is prepared for a short length.

The central support must withstand heavy loads. A welding inverter is used to install the plates. The motor will require a casing that will significantly reduce the noise level of the device. A saw for modifications of this type is suitable for 1.2 mm. With a power of 3 kW, a device for three quills will produce a frequency of 55 Hz. Brackets are needed to fix the flywheels.

For slotted thread and sawing small parts from wood, plywood, plexiglass, plastics and other materials use jigsaws various designs and types. It can be manual ("pioneer"), mechanical and electric jigsaws. Various magazines cited diagrams of home-made jigsaws driven by electric motors and even electric drills. How to make a homemade jigsaw, read this article.

Using a desktop jigsaw at home, you can make furniture, beautiful patterned shelves and much more. The mechanism allows you to cut smooth and sinuous parts from wood, plastic and dense foam materials. In order for a home-made device to fully meet the requirements, it is necessary to carefully select the appropriate design.

Design and specifications

The device of any model of an electric jigsaw machine must contain:

- saw;

- crank assembly;

- drive unit;

- saw tension device;

- Desktop;

- auxiliary mechanisms.

The processed material keeps within on a desktop. Some models are equipped with a rotary device that changes the slope of the surface. To make it easier to mark the material with your own hands, graduation is applied to the surface.

The larger the table, the longer the cut can be made. On average, this figure is 30 - 40 cm.

Drive power for homemade desktop machine is about 150 watts.

The crank assembly converts the rotational movement of the drive into reciprocating and transfers it to the saw. On average, the oscillation frequency of the file per minute is 800 - 1000. The vertical movement amplitude is not more than 5 cm. Some models allow you to select the movement speed depending on the properties of the material.

A manual jigsaw file can work with wood, plastic with a thickness of not more than 10 cm, having a length of up to 35 cm. For different types materials and works of the file vary, their width is 2 - 10 mm.

The manual tension device secures the saw blade for uniform sawing, it is a helical or leaf spring.

Types of machines

Structurally, all jigsaw devices can be divided:

- with bottom caliper;

- with double support;

- on suspension;

- with degree scale and stops;

- universal.

The most common are models with a lower caliper. Their bed is divided into two halves: lower and upper. At the top there is a cutting and cleaning module. At the bottom - a control module, an electric motor, a transmission mechanism and a toggle switch. Allows you to process sheets of material of any size.

Double caliper models differ in that there is an additional rail on the upper half of the bed. Such devices are good for creating oversized parts. They are easier to install than previous version. Both models allow you to process material no thicker than 8 cm. A working table with angle and height adjustment is attached to the machine.

Suspension machines are not equipped with a monolithic bed, they are very mobile. During processing, the cutting module moves, not the material. The working module is usually attached to the ceiling with its own hands, so the size of the material is unlimited. Cutting tool moves manually independently of the bed, creating very complex patterns.

Machines with a degree scale and stops are good for precise work on drawings. The design allows you to avoid errors. Universal jigsaws can perform several operations associated with cutting: drilling, polishing, grinding.

Making a machine with your own hands

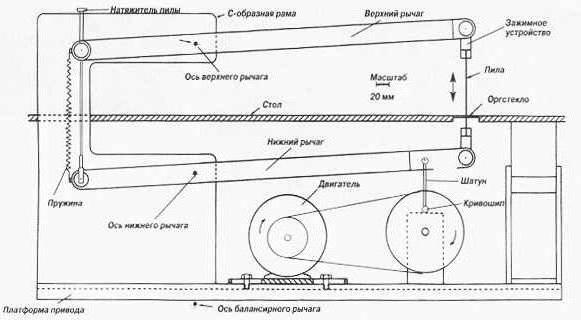

Drawing homemade desktop jigsaw: 1 - rocker insert (2 pcs.), 2 - earring (2 pcs.), 3 - table, 4.6 - screws, 5 - thrust, 7 - eccentric, 8 - base, 9 - axes of earrings, 10 - upper rocker , 11 - axis of the rocker, 12 - lamb, 13 - cross member of the tension screw (2 pcs), 14 - tension screw, 15 - rocking stand, 16 - lower rocker, 17 - box, 18 - two-strand pulley, 19 - intermediate shaft, 20 - stand bushing, 21 - table plate, 22 - bearing with cover (2 pcs.), 23 - electric motor pulley.

In the drawing of a do-it-yourself desktop machine, the number of nodes must be minimized, these are: a rocking chair with a fixed saw, a frame and an electric motor. You can take the engine from an old electric machine.

Owners of a manual jigsaw were more fortunate. From a sheet of plywood, you can make a stand and attach a jigsaw to it. To fix the jigsaw with your own hands, you will have to make holes in the base of the tool. The most simple model ready.

Now about more complex and functional ones. The do-it-yourself bed is made of 12 mm plywood, thick plastic or textolite. It is a base, a box for placing the engine and mechanisms, and a work table. On the other hand, we have a rocking chair with an eccentric. They are interconnected by a metal plate with bushing bearings. The whole structure is fixed with screws. To mount the intermediate shaft, prepare a pair of bearings. The two-strand metal pulley is mounted on the shaft as tightly as possible, the screw connection is fixed. In the same way, you can make an eccentric.

To change the amplitude of the rocking chair, four round ones are made on the eccentric flange. through holes with threads, remote from the axis by different distance. By changing the installation location of the screw, the swing of the rocking chair is adjusted. It is a pair of wooden yokes hinged to a rack. The rear ends of the rocker arms contain through cuts, tension screws are inserted into them. A file is fixed to the ends in front, movable due to metal hinges. Before fastening, the file is inserted into the groove of the working surface of the table.

The saw blade attachment mechanism is very important. In the manufacture homemade device with his own hands he should be given Special attention. The insert plates of the rocker arms carry constant loads during movement, therefore they are rigidly fixed and tightened with screws and Grover washers. The fastening earrings should not be strongly compressed by the screws, allowing the hinge axis of the plate to move.

It is advisable to make a rocking stand from whole piece material. A groove for the rocker arm is made on the upper side, at the lower end an opening in the shape of a rectangle is cut out for the second rocker arm. To make it easier to cut holes, you can fold the stand in two parts.

Video on how to make a jigsaw machine with your own hands:

Having made a jigsaw with your own hands, it will turn out not only to purchase practical tool but also save cash: it will be much cheaper than the factory counterpart, while having a full range of functions. A home-made electric jigsaw will allow you to create products of complex shape from wood, plastic and other materials, the production of which with a hand tool in normal conditions would take a lot of time and effort.

A homemade jigsaw allows you to make cuts of complex shapes.

You should consider the structure and sequence of manufacturing a simple desktop electric jigsaw, assembly features and the procedure for working with it.

How is a desktop jigsaw arranged?

As the name implies, this tool is designed to be placed on the surface of a desktop or workbench. Compact dimensions allow you to work with a jigsaw both in the workshop or garage, and at home. An electric jigsaw is an indispensable tool for making complex wood ornaments, figured plywood carvings, and the like.

Kinematic diagram of the jigsaw drive.

It is necessary to consider in more detail the structure of a factory-made desktop jigsaw. This will allow you to understand the main features of the device and apply them in a homemade model.

The components of an electric jigsaw can be divided into 3 parts:

- movable frame with a saw;

- fixed base;

- Electrical engine.

The principle of operation of the tool is as follows: an electric motor rotates a crank mechanism, which converts rotational movements into reciprocating ones. Movements are transmitted to a movable frame on which the saw is stretched.

A homemade device works using the same principle. To simplify the design, the movable frame can be replaced with a conventional manual jigsaw.

Back to index

Details for an electric jigsaw

When assembling an electric jigsaw, it is important to find a suitable motor that will drive the working tool - the saw. For this purpose, a motor from a drill, blender, food processor or other equipment of the same type.

The jigsaw frame is best made from aluminum pipe.

The movable frame is made of metal profiles, wooden planks or slats made of durable plastic. It is most convenient to work with square-section aluminum tubes, as they are easy to process, light in weight and have a significant margin of safety.

To fix the jigsaw in the desired position, a reliable frame made of wood or metal should be made for it. The dimensions of the frame do not have much effect on the operation of the jigsaw. They depend only on which version of the tool you need - a compact desktop or full-size, installed on the floor.

The jigsaw table is made from a thick sheet of plywood, in which a small diameter hole is made where the file will move (Fig. 2).

Between the case and the table place a gasket made of elastic material - rubber or leather, which will dampen the vibration.

There is also an easier option on how to make a homemade jigsaw. It consists in the fact that a manual electric jigsaw is mounted in a vertical position in a table-stand, while its file is attached tightly to the movable guide rails - levers.

Back to index

Assembling a desktop jigsaw

Construction homemade jigsaw begins with the assembly of the body, which can be made of plywood, chipboard or metal. The simplest model of this tool can do without a case, but in this case strong vibrations occur, which can significantly affect the comfort of work. In this case, two holes are made in the jigsaw - one for attaching the crank to the tool, the second for movable fixation of the jigsaw itself to the table. After starting the engine, the jigsaw begins to produce reciprocating movements that contribute to sawing the material.

Such a spring will provide the desired tension on the jigsaw saw.

A more elaborate model includes two separate strips, at the ends of which wing nuts are installed. From the opposite end, the bars are pulled together by a strong spring, which ensures a constant tension of the saw. Such a device works from a separate engine or, for example, from a drill.

A vertical bar runs inside the case, which is fixedly attached to its bottom or one of the walls. Two holes are made in it, the distance between which should be 2-3 cm less than the length of a standard file. Bolts or studs are threaded into the holes, on which straps are put on to hold the file.

The engine is built into the body and is attached to the lower bar by means of a disk with a connecting rod mechanism. A table with a hole for a saw acts as a housing cover.

The main drawback of a jigsaw with a separate engine lies in its most intricate part - the crank mechanism. The file with it makes not only vertical, but also inclined movements, which cannot but affect the accuracy of cutting. If you want to get an accurate tool, then it is better to replace the engine with an inexpensive factory-made manual electric jigsaw. It is fixed under the surface of the case and a file is threaded through the table, clamping it with one end in a jigsaw, and with the other in the upper bar of the structure. This design provides sufficient cutting accuracy, bringing this parameter closer to factory models.

Back to index

Advantages of working with an electric jigsaw

The electric jigsaw allows you to make complex cuts very accurately.

Unlike hand tool, an electric jigsaw has clear advantages, including:

- higher speed of work;

- the ability to work with two hands, thereby increasing accuracy;

- security - with proper organization labor stationary tool is much safer because it can not escape from the hands.

Besides, independent production an electric jigsaw will save money, since factory machines of this type are quite expensive.

I didn’t want to put my expensive Makitovsky jigsaw on the table all the time, so I decided to buy another one to create a table. I very successfully turned up a jigsaw in the store "Our House" Caliber LEM-610E for only 862r. Included: wood file, side stop, vacuum cleaner adapter, spare brushes for the motor.

There was an outlet next to the display case and I looked at it in operation. Quite decently made, convenient, there is an adjustment of speed with a wheel, the inclusion is fixed with a button. The saw holder moves clearly without backlash.

It’s very fortunate that I was able to twist it in my hands before buying it, I wouldn’t risk ordering it from the Vseinstrumenty.ru website without knowing what it is. (Although the reviews about it are good) By the way, it costs more there and also pays for delivery ... so I successfully bought it in Our House. :)

Despite the advantages, he has a number of shortcomings that he saw on closer examination:

1) The file does not fit into the file holder. Apparently this is a copy of the marriage, but I did not waste my time on the exchange. Each saw has to be sharpened. (Although on the second jigsaw I won’t be able to use them after turning - it doesn’t matter, they are relatively inexpensive)

2) And this drawback can be seen even in the picture. The canvas is tilted strongly forward. (This was also corrected by placing tin strips under the back of the sole, achieving 90 o.

3) The speed control wheel turns hard, not very clearly and with jamming. At the minimum speed value, the tool cannot start at all (However, the same garbage with the start-up of my other "caliber" drills. This is unpleasant, but does not spoil life much)

As always, everything is in the spirit of minimalism. I did not make a separate switch. It is quite conveniently turned on with a standard button and fixed.

To do this, I bought a bracket in KrepMarket (this is a fastener from some kind of iron structure system)

By the way, I love CrepeMarket. Any screws, nuts, screws, fasteners. Every time I design something, I wander there in thought and collect the necessary details for myself.

The excess was cut and trimmed.

Back view. Now the distance between the bearings has a fixed file clearance of 1.2mm. I have a plan for the future: make a clearance adjustment.

For thin materials can be omitted below.

As an experiment, I drew an asterisk and tried to cut it out evenly

For a 130mm file, the maximum possible thickness is 5cm. It turns out that there are very long files, I recently saw a 300mm file on the market

Sawed off a 1.5mm slice from a 40x40mm bar

Which is what I did. Now it can cut long workpieces with a width of 11.5 cm. The old L-shaped design also remained, and if more strength of the holder is needed, it can be installed again, although the new design has remained quite strong and reliable.

I also came up with the idea of making a knife out of an old blunt file, grinding off its teeth and sharpening it.

They can figuratively cut material like a sealant. The cut is even. Much better than a utility knife. Pictured is a mouse pad.

Well, perhaps that's all. The table turned out to be reliable and comfortable. Now I have a tool on which I can do finer work than on a circular.