Jigsaw machine - how to choose and do it yourself? How to make a homemade desktop jigsaw Machine from a manual electric jigsaw with your own hands.

Sawing small pieces of wood is done with a jigsaw. The device is small and usually has an electric drive. Factory models differ in their characteristics and cost. With small volumes of wood processing, it makes sense to make jigsaw machine independently, from improvised means. This requires a few factory parts.

The jigsaw in the factory version is reliable device which is guaranteed by the manufacturer. Manual models are low cost. Stationary devices are expensive, but provide proper comfort when processing wood. The set of components in the device in more the same for everyone.

The design consists of the following parts:

The part to be processed is placed on the desktop. The size of the workpiece depends on its size. Some models have Rotary table, which makes it easier to work with the part - visibility improves. The presence of graduation facilitates the marking of the material.

Average characteristics of factory machines:

Special purpose models may have radically different characteristics. There are specifications small sizes, for processing small parts. As well as models of large sizes, the industry also produces for retail. But such options will differ in high cost.

Special purpose models may have radically different characteristics. There are specifications small sizes, for processing small parts. As well as models of large sizes, the industry also produces for retail. But such options will differ in high cost.

In the middle class, there is high competition for the consumer, so the devices will be cheaper. Characteristics are also sharpened by typical tasks carpenter. Based on them, you need to make drawings of a jigsaw machine with your own hands. Complex components for it are purchased at the store.

Experts classify jigsaws by type of construction. Features of the execution of the mechanism determine the possibility of processing wooden products.

Classification is carried out depending on the design of jigsaws.

Device types:

- With bottom support.

- Double caliper.

- On a pendant.

- With degree scale and stop.

- Universal.

Models with a lower caliper are most widely used. The bed of the desktop factory device has 2 halves - the lower and the upper. The sawing and chipping model is located on the top of the bed.

Models with a lower caliper are most widely used. The bed of the desktop factory device has 2 halves - the lower and the upper. The sawing and chipping model is located on the top of the bed.

The bottom frame contains a controller, an electric motor, a main gear, an on/off button. Such a machine allows you to work with any materials and any size.

The presence of two calipers in the jigsaw is beneficial in that the upper half of the frame has an additional rail. This jigsaw is ideal for cutting small parts. The thickness of the workpieces on both models should not exceed 8 cm. The desktop of such machines, as a rule, has the ability to adjust in height and angle of inclination.

Suspended devices do not have a fixed frame, but are distinguished by their mobility. The processed material is fixed, and the master moves the working module. since the latter is attached to the ceiling, the thickness of the material is not limited. The tool is moved manually, regardless of the bed. This allows you to make patterns of complex shapes.

The presence of a scale of degrees and stops is suitable for those craftsmen who do the processing according to the drawings. The markup allows you to avoid errors during operation. There are universal machine models on the market that allow you to do several operations. Such a machine allows drilling, cutting, polishing and grinding. The cost of such devices will be much higher, but it is more comfortable to work with them. These are industrial examples.

Designs and drawings of options presented on the web homemade jigsaw are different. Blame the imagination of the authors and the desire to make a device that will stand out from the rest. Only the concept is the same in most cases - they take a manual electric jigsaw as a basis and repurpose it.

Designs and drawings of options presented on the web homemade jigsaw are different. Blame the imagination of the authors and the desire to make a device that will stand out from the rest. Only the concept is the same in most cases - they take a manual electric jigsaw as a basis and repurpose it.

Home woodworking lovers often look for information on how to make a jigsaw with their own hands without special skills. You can use a ready-made manual jigsaw as a base. The mechanism does not require careful refinement. Factory hand device is a drive. But the crank mechanism will have to be developed independently. Manufacturers are trying to offer the consumer a platform for quick rework, but personal needs can only be satisfied with their own product.

Assembly order:

- Make a base table. A sheet of metal is taken as a material and a hole is made in it. The shape is oblong, 3-4 times wider than the saw blade. Holes for fasteners are made side by side.

- A factory device is fixed at the bottom of the support table. Holes for fasteners are made next to the hole for the saw blade. Screws with a countersunk head are used as fasteners. This is necessary in order to ensure a perfectly flat plane of the table. Otherwise, the processed products will cling to the hats of the wines, which will cause inconvenience in work.

- The design is fixed on a wooden table.

The advantage of creating a do-it-yourself jigsaw machine is that the factory tool can be detached at any time. When necessary - in the hands of an ordinary manual jigsaw. Therefore, it is better to buy manual version a tool that can be used on a homemade machine is cheaper that way. Stationary devices are expensive.

Comfortable work with wooden products can be provided by installing guide rails on a homemade support table. Additionally, markings are applied to the table, which makes it easier to measure the distance on the parts during processing.

The manual type jigsaw as the main device for the machine has disadvantages. the main problem lies in the file - it is too wide in manual models. Because of this, fine woodwork is difficult to perform with it - the curvature of the lines is limited.

The previous design is simple and does not have additional details that make it easier to work with wood. The direction of modernization is the possibility of replacing the file with a thin one.

Options for improving the design:

- Build a rocker. The structure will be tensioned by springs on one side. The second side of the rocker is fixed on the file.

- Fix the file between two rollers. They serve as guides for a thin file.

- A stationary factory device is used as a drive system of two rocker arms. Between the latter, a file is pulled. The movement is transmitted from the factory device to the lower rocker of the file.

design upon purchase or self-manufacturing you have to choose based on personal preferences and the desire to poke around in technology. The use of guide rollers is a less popular option - its reliability is lame.

design upon purchase or self-manufacturing you have to choose based on personal preferences and the desire to poke around in technology. The use of guide rollers is a less popular option - its reliability is lame.

Modernization by installing rocker arms is common. It is better that at the same time the factory device serves only as a drive for sawing a jigsaw. To do this, turn off the pendulum stroke in the tool.

The heir to the property of grandparents often gets an old sewing machine. She has already served her purpose in tailoring, as more precise equipment is now being produced. In the absence of a jigsaw in the household, you can not spend money on its purchase. It is made by hand from sewing machine.

Procedure:

Now the jigsaw for figured cutting on plywood is ready. It will be more difficult to work with a manual drive, as your legs will get tired. An additional disadvantage will be vibrations from the force impact on the tool. The electric drive of the machine, converted into a jigsaw, partially solves the problems of vibrations.

An expensive jigsaw can be replaced with a design own production. It will not be inferior to anything in terms of its qualities and functionality, if you take a responsible approach to the assembly process. It is important to make high-quality plywood mechanisms that serve as a support table. It is desirable that the table be able to rotate. For the option with a sewing machine, this will not be possible. If desired, markings are applied to the table to make it easier to measure the details in the process.

If you are into carving and making figures or parts out of wood, plastic or similar material, you cannot do without a tool whose name is reminiscent of the distant Soviet past: this is a jigsaw.

Jigsaw jigsaw strife, now on sale there are also "pioneer" elementary manual models, and electric modern tools, only remotely resembling the usual saws.

You can also make a jigsaw yourself: in the technical literature and the network, many diagrams and drawings of electric jigsaws are offered.

It is not difficult to make such a device, and you will get significant benefits from it. You will be able to independently engage in the production of furniture you need and implement the most daring creative ideas for the interior.

An example of the manufacture of a jigsaw machine.

Homemade jigsaw for you to professionally make smooth details of the most bizarre shapes. First you need to decide on the most suitable design for you.

Technical description and components

The schematic diagram of any jigsaw machine is the same for different models.

It must include the following parts:

- file;

- drive with a power of about 150 W;

- rocker for tensioning the file;

- working surface with graduation;

- drilling block, etc.

Consumables are fixed on the working surface. In advanced models, there are special devices for rotary movements of the part, in which the working surface can change the angle of inclination.

The dimensions of the surface will depend on your production and creative plans: the larger the parts you are going to cut, the larger your production table should be. Traditional sizes are usually around 30 - 40 cm.

The types of saw blades are varied. They depend primarily on consumable. The dimensions of the parts for cutting are also important. Conventional saw blades for working with wood have a length of about 35 - 40 cm. They are able to saw parts made of wood or plastic with a thickness of no more than 100 mm.

WITH different types materials, the files also change, this mainly concerns their width: from 2 to 10 mm. Files can vary in the type of their tails - with or without pins. They are fixed in special device for their tension and smooth sawing. To do this, they have spring-type springs.

Another important one: the crank assembly. Its function is difficult to overestimate: it is he who transmits the movement from the drive to the file, turning the rotational movement into translational.

Assembly drawing of a jigsaw machine.

Due to this, the file begins to oscillate with a high frequency, the speed of such oscillations is on average about 800 - 1000 rpm. It is important to remember about the amplitude of vertical vibrations, it should not exceed 50 mm.

In advanced modern jigsaw models, the speed varies depending on the type of consumable. Most of desktop models operates in two speed modes. Most often it is 600 and 1000 rpm.

Model range of jigsaw machines

Most often, in its electric drive power, the range of values is huge: from 90 to 500 watts.

Also, these devices are divided into varieties based on their fundamental design:

- universal;

- on suspension;

- with graduation;

- with a caliper in the lower position;

- with double support.

Jigsaws with bottom support

Scheme of machine design elements.

The most used and popular models are machines with a lower support. Their feature is the division of the working frame into the upper and lower parts.

While the upper section contains only one sawing and cleaning device, the lower section contains many working elements: an electric motor, a switch, a transmission unit and a control unit. This design makes it possible to cut sheets of materials of almost any size.

Machines with double support

A home-made jigsaw with a double caliper differs from the lower caliper by the presence in the upper section of a special additional bar and desktop with the ability to change the angle of inclination and overall height.

These models are designed to work with oversized parts. Such a machine is easier to make than the previous model. There are limitations in the materials with which you can work on it: their thickness should not exceed 80 mm.

Hanging machines

The name speaks for itself: the model is mobile, it works without a frame. The fundamental point in this design is the movement cutting file and not a consumable. The module itself is attached to the ceiling, the saw is set in motion manually.

All this gives serious advantages: in this way you can create the most complex patterns, the surface dimensions are not limited by anything.

Graduated devices

The presence of stops and a degree scale make it possible to work according to technical drawings, without the slightest error.

Universal machines

Such devices are usually called electric jigsaw. Their feature is the ability to perform several operations such as grinding, polishing, sawing, etc.

How to make a jigsaw machine with your own hands?

We will not stop at the manufacture of the simplest machines: you can easily find such manuals with video support on the net. Let's talk about homemade machines from an electric jigsaw.

Assembling the machine with your own hands.

Here is the sequence of work for their manufacture:

- We make a bed from plywood sheet or plastic.

The main thing is that the thickness should not be less than 12 mm. The function of the bed is a foundation, a working surface and a place for fixing mechanisms and an electric motor. - We place a special rocking chair with an eccentric on the opposite side.

We connect them using a metal bar with bearings. All fasteners in the design are screw. - We make installation of an intermediate shaft.

To do this, you need to prepare two bearings, put the pulley on the shaft as tightly as possible, then carefully fasten it with screws. Similar actions are performed with an eccentric. - At the rocking chair, the amplitude of movements should change.

To do this, you need to change the place of attachment of the screw, for which we drill exactly four threaded holes on the eccentric flange. The holes should be located at different distances from the axis. With a change in the place of attachment of the screw, the swing of the amplitude of the rocking chair will change. - We make a rocking chair: this is nothing more than wooden rocker arms, into whose rear ends the screws that you built in the previous paragraph are inserted, these are tension screws.

The rocker arms themselves are hinged to the rack. We fix the file on the front ends of the rocker arms. The previous and current steps must be carried out with special attention and thoroughness. The fact is that fastening the file is a fundamentally important thing. Rocker arms with plates are subjected to constant loads during movement due to their rigid screed with screws. - For a rocking chair you need a stand.

It will be better if it is made from a whole piece of material. We make a groove for the first rocker arm on the top of the rack. From the lower end we have a special rectangular opening for the second rocker arm.

Your . wish cool ideas and their quality implementation.

After several unsuccessful attempts to cut complex shapes electric jigsaw, I decided to make a homemade desktop jigsaw according to the drawings from the network. It will be very easy to cut complex shapes of small sizes from light materials on it.

To assemble a jigsaw machine with your own hands from a jigsaw, you will need:

- electric jigsaw

- plywood sheet and boards for support

- screws for wood

- bolts with nuts

Tools: drill, sandpaper, clamp, tape measure.

Step 1: Cut out the lid and base

Draw two rectangles 250x300 mm on a sheet of plywood and cut them out with a jigsaw. These rectangles will be the base and top of your machine. Carefully handle the surfaces of the rectangles sandpaper, especially the one that will be the lid.

Step 2: Making the Front Racks

Show 4 more images

Measure the height of the jigsaw from the sole to the handle so that the jigsaw fits in the box of the machine, the racks must be greater than this distance. My jigsaw is 18 cm high, so I made 20 cm long posts from the board. Then I squeezed two pieces together with a clamp and sawed off 5 mm from them on both sides so that both posts were the same height.

Now the racks can be screwed to the base. To prevent the wood from cracking, you must first drill holes for the screws and countersink them.

Step 3: Attach the jigsaw to the lid

Show 7 more images

- Remove the sole from the jigsaw using the supplied hex. There is already one hole in the lid, you have three more holes to drill so that there is a mounting hole in each corner.

- In the central part of the plywood cover, mark the place where you will fix the sole of the jigsaw, and the hole for the jigsaw blade.

- Now you can drill four holes in the plywood, countersinking them with a spade bit so that the screw heads are flush with the surface. It remains to make a hole for the saw.

- Now put the sole back on the skis of the jigsaw, and attach the plywood cover to the sole so that the file goes into the hole intended for it.

- Insert a washer into the expansion of each mounting hole, insert bolts into the holes and tighten them on the other side with nuts. Turning the bolts was a little tricky, so I fixed the head of each bolt with a flathead screwdriver, and twisted the other side with a wrench.

Step 4: Install the jigsaw on the base

Lower the lid with a jigsaw onto the base with uprights and fix it on top with screws, having previously drilled holes for them. Be sure to countersink these holes so that the wood does not crack when screwing. The jigsaw should not touch the base and should have a good grip on the lid. Therefore, the screw heads must be flush with the surface of the cover, otherwise they will unwind during the operation of the jigsaw.

From the remnants of the board, I made an additional two rear racks, so the machine became much more stable.

Step 5: Finishing the Machine

At this stage, the machine is quite functional, it is enough just to fix it with a clamp on the tabletop and you can work.

I identified two features of my jigsaw machine:

- the canvas walked a little to the sides, especially when working at high speeds.

- the width of the blade was greater than that of standard electric jigsaw files, which left much to be desired in cutting particularly thin holes.

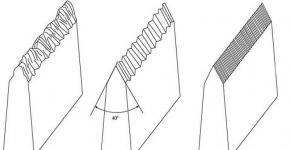

Step 6: Decrease the Canvas Width

A smaller blade will allow you to cut through thin curves and make it easier to cut rounded corners.

- Extend the file to the maximum, do not forget to turn off the jigsaw from the network.

- Mark the point where the blade comes out of the housing. Below this point, nothing needs to be removed.

- Remove the saw blade from the jigsaw and grinding machine grind the fabric to the desired width. While grinding, dip the file in cool water so that it does not overheat, otherwise the metal will lose its hardness, and the file will no longer be able to cut through anything. A change in color is a sign of overheating of the metal.

- When you get the desired blade width, put the file back into the jigsaw.

Step 7: Making a File Guide

The guide will not allow the blade to walk to the sides during cutting, especially at high speeds.

I made the guide out of a small strip of PVC plastic. At one end of the strip, use a jigsaw to make a small cut at an angle to the middle of the strip. We fix the strip behind the file by screwing it to a wooden L-shaped part mounted on the cover of your machine. The guide can be lubricated with oil for better movement.

Remember:

- The guide should never be higher than the blade at the lowest point of the blade path.

- The guide limits the size of the material you are about to cut due to its height and the attachment point on the surface. Therefore, it is better to fix the guide as high as possible (considering the previous remark), and as far as possible from the canvas, with a bias to the side, as soon as possible.

Step 8: Conclusion

With a little effort, you get an almost real desktop jigsaw. Of course, it will not replace a real machine, but given its zero cost, it is an excellent option.

- Hand tool

- Electric jigsaw

- Stencil preparation

- Sawing process technology

- Defects in work

Wood carving with a jigsaw is rapidly gaining popularity: many people want to buy an interesting decor item to decorate their home, furniture and even clothes! Carved objects of various thicknesses organically fit into any style of interior, often people buy photo frames for photos with ornaments, sawn words and letters, or order intricate shelves and others. interesting products. Few people know that artistic cutting out of plywood with a jigsaw is a business accessible to any person, even an unprepared and inexperienced one. You just need to understand how to work with the tool.

What is a jigsaw: a general description

A jigsaw is a tool designed for cutting out various contours from plywood, including curved ones. It is equipped with a blade with fine teeth that can cut the plywood evenly without the formation of significant burrs.

Hand tool

The ancestor of this type of tool is a manual jigsaw. It is a metal arc in the shape of the letter "U", between the ends of which a saw blade is stretched, attached to the clamps. They securely hold the file during operation and allow you to adjust its tension. On one side of the frame is a handle.

The clamps on the tool can rotate, creating different planes for sawing, thereby providing the opportunity for woodcarving of varying complexity.

When sawing plywood with a manual jigsaw, you need to be careful: its design is rather fragile, during intensive work the blade often breaks from effort and heat, so it has to be replaced. To do this, each master must have several dozen spare files.

When working with a jigsaw for carving internal contours, it is convenient to use such an auxiliary board as in the photo: it will help protect the table and solve the problem of conveniently positioning the workpiece.

Electric jigsaw

The tool is powered by electrical network. It is a case in which working mechanisms are located, a handle for control is also made on it. The sawing organ is located in the front lower part. The blade is often protected by a foot, which allows you to cut the contour exactly along the line without deviation. Advanced and professional jigsaw models have various attachments that facilitate the sawing process and level the edges of the plywood.

Blades can have different teeth in shape and size. It is necessary to select saw blades corresponding to the material being processed so that there is no damage and damage to the plywood sheet during the operation of the mechanism.

Classification of jigsaws by power and application:

In the instructions on how to use a jigsaw, or in the technical data sheet, the main parameters of the tool that must be taken into account when using the mechanism should be described.

Wood carving tools

Sawing with a jigsaw is a creative process, but it requires preparation and additional equipment. What is required for work:

Stencil preparation

Jigsaw drawings can be different sizes, depending on the scale of the manufactured product. To create a scheme for a shelf, a piece of furniture or a composite three-dimensional toy, you can take a large sheet of drawing paper A1 or A0, the wallpaper remaining after the repair is also suitable, for small figures they take plain A4 paper or another suitable format.

On the surface with a bright pencil or marker, draw the outline of the future product, adhering to the dimensions. It can be an element for assembling furniture, a shelf or other large product.

There are so many jigsaw templates on the web that choosing the right one can be difficult. It is much easier to come up with your own patterns for cutting and transfer them to paper.

Transferring the image to the surface of plywood or boards

Before you start cutting with a jigsaw, you need to transfer the image from the stencil to a wooden or plywood blank. To do this, cut out a figure from the sheet, apply it to the surface of the plywood and carefully circle it. It is desirable that the line is even and accurate. We use a simple pencil so that, if necessary, we can correct the line by erasing it with an eraser.

We draw the contour with back side to on finished product no lines were visible. The inner area can be shaded so as not to cut off the excess and designate inviolable areas.

It is important to transfer the drawing in such a way as to minimize sawing along the fibers with a jigsaw - it is so difficult to get a straight line.

Sawing process technology

How to use a jigsaw, for sure, many have heard. Working with the tool will not cause difficulties if you prepare for it correctly.

Carving on plywood begins with the inner contours of the pattern. To do this, you need to make slots for inserting the tool blade:

- Plywood is often taken thin, and there will be no problems when cutting a large contour, and tension may occur in a small residue. Sawing with a jigsaw inside can damage the product - chips, burrs, dissection;

- It’s easier to work this way: you always have something to hold the workpiece for. WITH big sheet much easier to handle than trying to hold a small piece of sawn wood while shaping the inside.

How to cut with an electric jigsaw:

Working with a jigsaw is much easier than hand tool, there is no need to make physical efforts and the process goes faster.

How to saw with a jigsaw:

There is nothing complicated, as you can see, in this process.

Defects in work

If you did not follow the technology, held the tool incorrectly, the saw may simply move off the line. Why does the jigsaw saw crookedly:

- tilted the tool during operation;

- saw blade tension loosened;

- with an electric saw, it is possible to loosen the fastening of the saw.

To avoid such problems, be sure to check the tension of the saw and the fastening of all working elements before starting sawing. If the blade is beveled and stuck, it's best to start over and make the line parallel to the faulty one.

A little about safety

Safety precautions when working with a jigsaw for sawing plywood and wood are simple:

- Use protective equipment- goggles, gloves, bathrobe. These things will protect you from dust and small chips.

- Sawing with a manual jigsaw should be done carefully so as not to damage the fingers with a saw. Keep the distance between the body and the instrument.

- If you are a beginner, carefully read the instructions on how to use a jigsaw, the main characteristics of the tool. This information will help to avoid accidental injury and damage to the unit.

Wood carving with an electric jigsaw requires accuracy and attention. Both your health and the integrity of the finished product depend on these qualities.

What can be made from plywood: interesting ideas and drawings

Sawing wood with an electric jigsaw or hand tool is a creative process. You can create multiple decorative items different directions:

Drawings of plywood crafts do not have to be made in exact dimensions. Even taking an example from the Internet and changing its silent proportions, you will get a unique product that no one else has in this form.

DIY plywood crafts can be painted or left in a natural color, you can glue buttons, beads, ribbons and other decor on them to revive the product. To do this, it is worth involving children in the work, their imagination is a bottomless storehouse of interesting ideas.

We offer you diagrams with photos for cutting plywood with a jigsaw.

You can figure out for yourself what you can cut out using a hand or electric tool, make your own sketch and transfer it to paper, then to a canvas of wood or plywood.

Carving plywood with a jigsaw requires certain knowledge and skills. If you don't have them, consider the following rules:

What to do when you need a jigsaw, but there is no need to buy it? You can make a jigsaw with your own hands. There are many ways to make or repair such a tool. Consider the simplest and most accessible of them.

Manual jigsaw - simple, fast and affordable

How to make a jigsaw quickly from available and inexpensive materials? Here is the easiest way.

List of tools and materials:

- plywood sheet (10 mm);

- plywood sheet (4 mm);

- steel sheet (2 mm);

- bolts and nuts;

- drill;

- chisel;

- sanding paper;

- file.

foundation manual jigsaw serves as a bracket, it should be prepared from a plywood sheet (10 mm). Further, it is recommended to make thickenings for the tool handle from thinner plywood (4 mm). These thickenings must be glued to the handle on both sides, which will provide more convenient in the future. The bracket and handle are well processed with sanding paper and a file. It is necessary to cut out the steel plate with a chisel, and then clean the clamping jaws with a file. After that, drill slots in the jaws with a drill, and then cut out notches inside the clamping jaws with a sharp chisel. In the left clamping jaw, modify the slot for the bolt, for this you need to make a thread. Attach the jaws to the bracket, then screw the bolts into the left clamp, securing them with nuts.

Back to index

Desktop jigsaw: two manufacturing options

A desktop fixture can be made both new and with the help of refinement or repair of improvised means.

Making a new desktop mechanical jigsaw will require the following tools and materials:

- duralumin pipe;

- plastic base;

- clamps;

- screws;

- copper sheet;

- drill.

First you need to prepare the frame, for this purpose it is better to use an duralumin pipe. In the manufacture of the frame, it is necessary to provide a passage through which a cord will be laid to provide power. The copper sheet should be taken for the manufacture of a U-shaped frame, which subsequently will need to be attached to the frame itself. At the junction of the frame with the handle of the jigsaw, screw the frame with screws. IN plastic base drill a hole for the file with a drill, as well as slots for fasteners. On the prepared plastic, fix the jigsaw so that the file passes through the hole. Using clamps, attach the finished tool to a flat surface, such as a table.

A hand-held device based on sewing machine, This perfect option if repairing a sewing machine is not as important as making such a tool. List of tools and materials:

- sewing machine (both foot and manual models can be used);

- file;

- file;

- drill.

Having unscrewed the bolts at the bottom of the sewing machine, you should remove the entire thread handling system. Next, knock out the metal fastening rod and remove the drive shaft of the thread weaving system. The panel covering the parts of the sewing machine can be easily removed by unscrewing 2 more bolts. Carefully remove the needle. The needle slot needs a little repair - it should be widened so that a file can be placed in it. To do this, it is better to cut the hole with a needle file, focusing on the size of the file itself. After that, adjust its size to the maximum possible size of the needle by cutting off the upper part of the file. After grinding the upper teeth with a file, and the lower part on the tip, you can proceed to the next step. The prepared file must be put in place of the former needle - in the needle holder. After that, turn the wheel and check:

- so that the saw does not come into contact with the panel and with the presser foot;

- so that in the upper position the plywood passes freely under the saw;

- so that the material flows smoothly.

Such a jigsaw is suitable for working with plywood, balsa wood and plastic materials, and if you use an electric machine, you get an electric jigsaw.