A simple wiring diagram in a private house. How to correctly make the electrical wiring in the apartment Electrical wiring diagram in the house

One of the important and time-consuming repair processes is electrical wiring in a private house. To do it yourself, you need to carefully prepare, understand what materials and tools will be needed for this, what security measures to observe. Then the process will not be dangerous for the master, and the result will make it possible to use light and electricity for a long time in the house.

Adequate and safe electricity in a home is an important condition for a comfortable life in it.

Necessary tools for the job

Before doing the installation of electrical wiring in a private house with your own hands, you need to prepare all the tools and materials that will be used in the work. Without having a clue about electricity and at least basic knowledge of its distribution inside the house, it will be quite difficult to do everything on your own. Careful preparation will make the process safe and easy.

The most powerful cables that can withstand the required load should come from the meter.

Wiring in a private house is performed using the following tools:

- pliers;

- screwdriver;

- shtroborez - grinder with discs, if the wiring will be laid inside concrete walls;

- hammer;

- chisel;

- scissors or a sharp knife for cutting the cable;

- roulette;

- putty knife.

In addition, you need to prepare the following consumables:

- electric meter;

- cables of various cross-sections;

- RCD - automatic residual current device;

- terminal blocks;

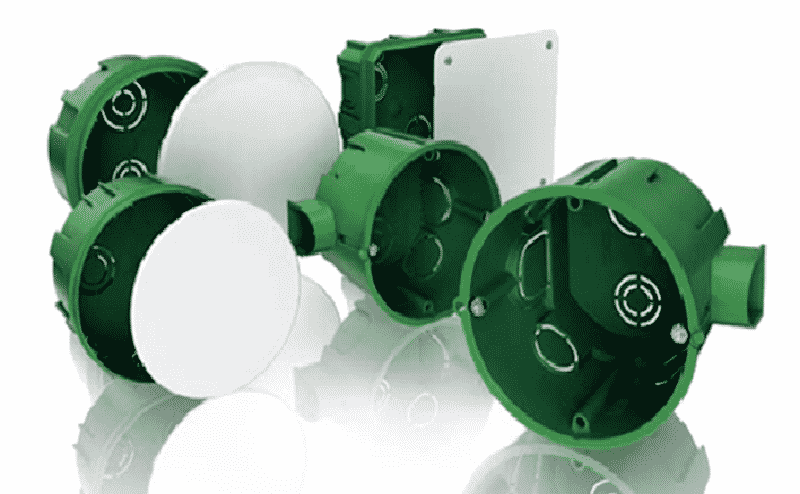

- sockets, switches, installation boxes for them;

- junction boxes;

- alabaster mixture for fixing wires in channels;

- plastic boxes - if the wiring is external;

- self-tapping screws;

- glue.

In order to prepare in advance all the necessary tools and materials, you need to calculate how many of them will be needed in the process of work.

A copper stranded cable should come out from the electricity meter. Depending on the complexity and volume of the wiring, it is brought to several junction boxes. From them will go cables of a thinner cross-section, designed for less power. Before starting the installation of electrical wiring in the house, it is advisable to draw up a detailed plan in order to calculate the required amount of all elements and consumables.

Safety measures during work

In order for an electrician in the house to work properly and for a long time, without causing dangerous situations - a short circuit or fire of wires - it is worth knowing and understanding the basic rules and features of installation. The process of installing from scratch in a new home is a little easier than replacing old wiring, as it takes place before finishing work. The first rule for re-installing electrical equipment is to replace all elements, wires and junction boxes, especially if they have served for more than a dozen years.

In the process of wiring, protective equipment and materials must be used.

In addition, you should remember about such measures during work:

- The house must be divided into several zones. A separate RCD fuse will be responsible for each. This is especially true of areas where powerful household appliances will be connected - a washing machine, an electric oven, a water heating boiler, etc.

- When laying new wires, it is better to hide them in a corrugated hose. It is an effective protection against fire.

- The wires are connected using terminals. Avoid connecting low and high power cables.

- If it is not possible to hide the wires in the grooves and cover with putty, plastic boxes can be used for safety and aesthetics.

- Even if it seems that some section of the old wiring has been preserved in good condition, it still needs to be replaced. This will prevent further problems.

Electricity in a home should not only be functional, but also safe for residents.

The best security measure during work is to hire a specialist who will professionally install the wiring in the house and take into account all the nuances. It is better not to save on this, since the work of a beginner will require a lot of time and effort, and in the future it may cause the need to rework some areas.

Service life of wiring

To understand when it is time to change the wiring of electricity in the house, or to know how many years the replacement work done will last, you need to find out its service life. Today's cables and connecting systems are much better than they were a few decades ago. Therefore, they will last longer. But everything comes on time, and even good wiring will sooner or later require replacement.

The use of RCDs, junction and junction boxes, terminals and other protective elements helps to extend the life of electrical wiring at home.

The generally accepted gradation includes three different types of duration of operation of electrical wiring: nominal, warranty and actual service life. There is a difference between them:

- Nominal Is the period during which the system operability factors must be respected. For example, a copper cable can function properly for 30 years if the voltage does not exceed 0.66 kV, and the temperature is in the range from -50 to +50 degrees.

- Warranty service life- this is the period during which the manufacturer (or seller) is ready to be responsible for this cable. For example, if something happens to the wire in 5 years of operation under the agreed conditions, it will be repaired or replaced free of charge.

- Actual term Is the system uptime, which depends only on the user. It may be less or more than the nominal, depending on the conditions under which the wiring operates.

As a rule, electrical manufacturers provide a 10-year warranty. Although a properly assembled system can last 8-10 times longer than this period.

Project and wiring diagram

In order for the do-it-yourself electrical wiring in the house to be competent, convenient and serve for a long time without interference or alterations, you need to make a project and think over all the nuances. The system diagram starts from the end - how many lamps will be in each room, how many sockets need to be placed on the walls, what load will be on each of them.

The electrical wiring project can be schematic, hand-drawn. The main thing is to understand where and how many electrical elements should be.

How many phases

There are two types of voltage that can be supplied to a private house - two-phase 220V with a maximum power consumption of 10-12 kW, and three-phase 380V with a maximum consumption of 15 kW. The second option is required in rare cases when powerful equipment is supposed to be connected. Then the requirements for installation and operation will be more stringent, because with such a connection, the likelihood of danger increases.

Connection to a three-phase network involves the installation of a special shield capable of carrying and distributing such a load

Wire connection methods

Before proceeding with all the installation work, you need to understand how to connect the wires together. This will have to be done, the connection is made in the junction boxes. There are several simple ways to connect them:

- twisting method- two wires are stripped 4-5 cm, twisted together and covered with a plastic cap, which ensures safety and an additional clamp;

- solder connection using a soldering iron and tin-lead solder - a more reliable method;

- terminal blocks make it possible to connect wires of different metals - copper and aluminum;

- one of the fastest ways to connect is spring terminals- allows you to connect single-core and stranded wires of different cross-sections.

When installing electrical wiring, several different types of wire connections can be used.

Where to install the shield

There are no standards for installing the flap in a strictly defined place. Often it is installed in utility rooms near the exit, so that you can conveniently perform switching. There are several factors to consider:

- The room in which the shield will be installed must be dry and fireproof. Therefore, for example, it cannot be placed in a boiler room. And also where there are gas cylinders or other flammable objects.

- Access to the dashboard is needed all the time - so a pantry or storage room is also not the best option.

- You can just hang the shield on the wall, but it's better to make a special niche for it.

- For large rooms or groups of buildings - a house, a bathhouse, a garage, a utility block - it is better to use several electrical panels.

The modern backsplash is a small, compact box that can be positioned anywhere in the house.

A meter and an RCD are located inside the dashboard, several junction boxes exit from it. Therefore, during installation, it is important to correctly calculate the capacity and further communications.

Breakdown of consumers into groups

Consumers are all electrical elements that will be installed in the house - lamps, sockets, switches, etc. They are divided into groups to distribute the load in the system. The number of elements in each group depends on the thickness of the cable. Lighting devices are "planted" on one or two branches, depending on the configuration and size of the house.

An individual RCD must be installed for each consumer group.

After that, a breakdown into outlet groups takes place. It is desirable that there are no more than 5 sockets on one branch. If a specific outlet is intended for a powerful appliance - an air conditioner or a washing machine, it is better to bring a separate line to it. For example, 3-4 groups can be brought into the kitchen, since there is the largest number of electrical appliances here.

How many lines should you draw for a room?

For rooms, two separate lines are enough: one for the sockets, the other for the lighting fixtures. If it is planned to install an air conditioner, it is better to bring a separate line for it.

The breakdown into groups is done in the process of drawing the wiring diagram and makes it possible to calculate how many automatically RCDs will be installed.

Selection of cables and wires

After the preparatory stage and drawing up the wiring diagram, you can start choosing the cable. They are aluminum and copper. Copper has more bandwidth, they can withstand a higher load, so they are used more often for private houses.

The choice of cable depends on the load that will be assigned to it when operating the electrical system in the house.

There is no difference between round and flat cables, but the latter are used more often because of the ease of installation and the ability to hide it. Especially if the electrical wiring is not done from scratch in a new house, but is changed from the old one. As for the choice of cable cross-section, here you need to take into account the level of load on it. Calculations are made based on the following factors:

- the power cable for lighting fixtures must have a cross section of at least 1.5 sq. mm;

- cables for sockets into which electrical appliances will be connected - with a cross section of at least 2.5 sq. mm.

To determine the required length of all cables, you need to draw on the diagram all consumers of the electrical system. Having on paper the dimensions of all rooms and rooms, you can understand how long each wire will be. In this case, you should take 10-15 cm of allowances for each connection.

How to run cables in the house

The method of electrical installation is an important factor that needs to be determined at the stage of preparatory work. There are two types - open and hidden wiring. In a private house, there may be a combination of these types, although when building from scratch, it is better to immediately hide all cables and systems so that they do not spoil the design of the rooms.

You can hide the electrical wiring in different ways, but it is better to do this at the stage of rough work, so as not to spoil the repairs made later.

To determine which type of wiring installation is better to choose, it is worth considering all the pros and cons of the open and hidden method.

| Advantages | Flaws | |

|---|---|---|

| Installation of open wiring |

|

|

| Installation of hidden wiring |

|

|

After weighing all the pros and cons for yourself, you will be able to choose the best installation option for the electrical system. In an old house, when it is required not to lay a new one, but to replace the old electrical wiring, an open type is often used. However, the new house has every opportunity to hide electrical communications as much as possible.

The process of laying the cable and installing the system

The final preparatory stage is marking. Layout work is the application of cable lines to the walls, ceiling, floor, as well as the location of all elements. Performed with chalk. To make straight lines, you need to use a tape measure and a level. This procedure will also help you verify your calculations for the purchase of cable or consumables.

The layout of walls and ceilings will greatly simplify the further installation of electrical wiring.

After that, you can proceed to the very procedure for installing the electrical system. It consists of several stages:

Depending on the size of the house, wiring can take from several hours to several days. Careful fulfillment of all requirements and safety measures is a guarantee of long-term and quiet operation for several decades.

Checking and commissioning

To check the installed wiring system, you need to invite a specialist from the energy supervision to the house to put it into operation. With the help of a tester, it is necessary to “ring out” all the conductors, the integrity of the conductors, and check the correctness of the insulation. In addition, an energy supervisor will check the ground and zero.

At the end of all work, you need to check the wiring system and make sure it is working properly.

The completion of all work and the launch of the system is confirmed by a corresponding document - a protocol, which is drawn up by a representative of the energy supervision. An agreement is concluded for the provision of services, and further use of electricity is paid according to the current tariffs.

Videos about the installation of electrical wiring in a private house

The do-it-yourself wiring device in the house is demonstrated in the video:

Step-by-step instructions for conducting electrical wiring in a private house in the video:

Installation of electrical wiring in a private house is a long and complex process that includes many stages. Regardless of whether it will be carried out by the hands of a professional electrician or independently, you need to carefully prepare, make all the calculations and comply with safety requirements. You should not save on consumables or specialist services, because the operation of electrical wiring involves more than a dozen years. Therefore, the work must be performed efficiently and reliably.

You can determine the appropriate wire cross-section by dividing the maximum load current in a certain section of the wiring by the current density for this type of conductor, or you can select it according to a special table. Those. with a current of 22.7 A, and a conductor density of 9 A / mm2, a cross section of 2.5 mm2 is suitable.

When calculating the total power of energy consumers throughout the house, you need to take into account the fact that usually everything does not turn on at the same time. In this case, the demand correction factor is used. In the case when the total power is less than or equal to 14 kW, it is 0.8, up to 20 kW - 0.65, up to 50 - 0.5.

Power calculation

Power calculation How to carry out the markup correctly?

Work on the marking for the installation of electrical wiring begins, with marking the main path of the wires from the electrical panel, as well as all their turns, branches and passages through. When marking up, we observe the following rules:

Indented Wire Markup

Indented Wire Markup - the wires on the wall should be mounted either parallel or perpendicular to the floor;

- the marking of the path of horizontal sections should be 0.2 m below the ceiling, which will reduce the likelihood of damage to the electrical wiring;

- when turning the electrical wiring, vertical or horizontal, an angle of 90 ° must be observed;

- when installing the route along the interfloor or attic floors, the shortest path from the junction box to the lighting devices is marked.

To mark the route, you can resort to help, you can buy it, or you can make it yourself, by painting a regular cord with paint, coal or chalk.

When marking, one end of the cord is fixed at the starting point, and the other is pulled parallel to the wall or ceiling, pressing it to the end point of the segment. With the other hand, the middle of the cord is pulled back and thrown. When struck against a wall or ceiling, the cord leaves a clear mark.

After the marking is completed, do not rush to throw away the wiring diagram, it may come in handy in case of repair.

Connecting box

Connecting box The installation of junction boxes is marked out in the places of branching of electrical wiring, descent to sockets or switches.

If you plan to install hidden electrical wiring, in this case, mark the points for the installation boxes, where the switches and sockets of the hidden version will be placed.

Switches, as a rule, are placed at the entrance to the room from the side where the door handle is located, either inside or outside it.

The switches are mounted at a height of 1.5 m or 0.5-0.8 m from the floor - this is the standard. The most popular option is number two. When marking the path of the wires to the switch, it should be remembered that the distance to the door jamb cannot be less than 0.1 m.

- Currently, the mounting height of the sockets is not regulated. Convenience will be the main argument here.

- When you plan to install a desk in the room, then the installation of the outlet must be carried out so that it is above the table top.

- In the kitchen, the sockets are placed above the kitchen countertop at a height of 0.9 m. It often makes sense to install double or triple sockets.

For the washing machine, electric stove, electric water heater, and electric boiler, it is necessary to provide individual sockets, with separate wiring from the switchboard.

When marking the installation of sockets and switches in a room, bathroom, shower or sauna, do not forget that these rooms have high humidity.

The second zone defines a space within a radius of 60 cm around the bathroom, shower, washbasin, sink, even if they have stationary partitions; the third zone is called the space within a radius of 240 cm around the second zone.

It is possible to install switches and sockets only in the third zone; they must be protected by an RCD for a current of up to 30 mA.

Luminaire layout

Luminaire layout The luminaire on the ceiling is usually mounted in the center of the room.

To determine the location of the lamp on the floor of the room, mark out two diagonals, the place of their intersection is the center. Using a plumb line, we transfer the center point to and then mark the path for mounting electrical wiring from the junction box to it.

If you decide to install several lamps on the ceiling of a given room, then first of all determine the center line at the center in the length of the room, and then mark the points for placing the lamps on this line, which are then transferred to the ceiling.

Before starting the installation of electrical wiring, it is worth cutting the wire into pieces, their length will be equal to the space between the junction and installation boxes, lamps and other devices. Cut the wire into pieces with a small margin of 0.1-0.15 m, which is necessary in order to connect them together and connect them to electrical appliances.

You can fix the corrugated hose to the wall or ceiling using plastic holders that are attached with screws, self-tapping screws or dowels - it depends on the material or wall.

To attach the cable channel, it is necessary to immediately fix the lower part, then lay the electrical wiring into it and close it with the upper part of the box, by pressing it against the lower part until the lock clicks. If it becomes necessary to check the wires, the upper part of the box can be easily snapped off.

In the places of branching of the wiring, special junction boxes are installed.

Open way

Open way Installation of sockets and switches, with an open method, is carried out on "socket boxes" made of insulating material, which can be dry wood, plexiglass, textolite or plastic.

The socket is cut out in the shape of a circle, with a diameter of 6-7 cm and a thickness of about 10 cm.First, the socket is attached to the socket using screws with a countersunk head or glue, and then a socket or switch is attached to it, which does not have an outer plastic case.

After that, “phase” and “zero” are connected to the outlet, and “ground” in protected sockets.

The switch is connected to the gap in the "phase", which means that only the "phase" is led from the junction box to it, which, passing through the switch, will return to the junction box via another wire and in it is connected to the "phase" that goes to the lamp, and "zero" is brought directly to the luminaire, bypassing the switch.

You can determine the "phase" by marking the wiring with a tag, or remember the colors of the insulation of the wires. When the wiring is installed and connected, the indicator will help to determine the "phase".

Hidden wiring

Installation of hidden electrical wiring is carried out in monolithic houses, houses made of, as well as artificial and natural stones, etc.

Hidden wiring in a frame house

Hidden wiring in a frame house In houses made of stone or brick, the installation of hidden electrical wiring is carried out in special channels, the so-called grooves, they are cut along the path of future wiring, and at the end of the installation they are sealed.

It should be borne in mind that in the places of the future location of installation or junction boxes for sockets, switches or regulators, openings are made with a depth of about 6-7 cm (this depends on the size of the boxes). You can install and fix the boxes in such recesses using mortar or plaster.

Installation of hidden electrical wiring is very laborious. And when it becomes necessary to revise the wires, you have to spoil the walls. but at the same time it does not spoil the view in the house, i.e. aesthetic. As a rule, if the installation is carried out correctly, there are no operational problems.

For the installation of hidden wiring, all wire connections must be made only in junction boxes, all switches and sockets are mounted in installation boxes, which are already pre-installed and fixed in the marking points.

At the completion of installation and finishing, it is required to ensure free access to the junction boxes in order to control the connections in the future, when operating the wiring.

When buying certain boxes, it is worth giving preference to high-quality devices that have a quality certificate.

Entering the wiring

Entering the wiring The electrical wiring is inserted into the boxes using sleeves made of insulating material or pieces of polyvinyl chloride tubes. This is extremely necessary for metal junction and junction boxes, for the reason that the edge in such boxes is often sharp, which can cause damage to the insulation of electrical wiring during installation.

In junction boxes, the wires must be connected by welding (soldering), crimping in sleeves or clamps.

Switches and sockets are mounted after the installation of installation boxes or socket boxes (with open wiring) is completed and the wiring itself is connected to them. Depending on which installation method was chosen, switches and sockets can be open and hidden.

Installation of sockets and flush-mounted switches is carried out in installation boxes. First of all, remove the top plastic cover from the outlet or switch. Electrical wiring is connected to the terminals of their inner part, in the same way as when open. Then the inside of the socket or switch is attached in the box using spacer clamps, that is, tighten the fixing screws all the way.

Upon completion, screw on the plastic protective cover of the housing.

In connection with the need to supply housing with electrical energy inside the premises, it is necessary to arrange an electrical network. For this, wiring and other elements for connecting, switching and lighting the home are laid. Since this procedure does not require special training, everyone can perform it independently. But first you need to figure out how the electrical wiring is mounted in the house with your own hands, what stages it consists of, and what needs to be taken into account.

Stages of installing electrical wiring in the house

The whole process can be conditionally subdivided into several stages, the sequence of which will provide a high-quality result and save time for performing the corresponding work. There are the following installation stages:

- Determination of the method of laying - external or external installation of the cable;

- Drawing up a power supply diagram in the room;

- Transfer of the drawn up scheme directly to the walls;

- Selection of the most suitable elements and materials for installation;

- Preparatory work on the processing of walls and other structures for the installation of electrical wiring, installation of lighting groups, automatic protection devices and others;

- Directly the installation work itself;

- Obtaining permission from the power supply organization to connect to its networks, if it is necessary to form a new connection point (if you are replacing the wiring with a new one, this procedure is not required).

Now take a closer look at each of the steps in practice.

Which way of laying should you choose?

Of the existing options for laying the cable route, there are two methods of installation in relation to the wires - internal and external wiring. Internal wiring assumes that the cable lines are inside the walls. External wiring is installed on the walls from the outside, while it can be carried out either by wires or by means of protecting the cable from mechanical damage, for example, cable channels in which the conductor is located.

Advantages and disadvantages of the inner lining.

The advantages of hidden wiring include greater reliability and durability due to the inability to cause damage during normal operation. Such wiring requires less financial costs for armored wires and accessories for their installation. In addition, the hidden gasket does not change the interior of the room.

The disadvantages of internal wiring include time-consuming preparatory work for the development of a groove and poor maintainability in the event of any damage.

Advantages and disadvantages of the external gasket.

The advantages of open wiring include a much simpler preparatory process and speed of installation of electrical wiring. During operation, it is easier to repair or change the wiring diagram.

The disadvantages of outdoor wiring are much greater susceptibility to mechanical damage and the impact on the overall appearance of the interior of the room.

How to create a wiring diagram?

The wiring diagram helps to identify switches, lamps, wiring lines. Therefore, when drawing it up, you need to take into account the wiring diagram for electrical appliances in the house. For example, for home wiring, the location of outlets near a TV, electric stove, bed, etc. will be relevant.

Figure 1: Example of a house wiring diagram

By the method of graphic representation, two-dimensional and three-dimensional wiring diagrams are divided. The first option is the simplest, since it does not require the use of graphic editors and other programs. To do this, take a plan of your own tenant and on its copy, mark the connection points and the number of outlets for each room, wires, switches and wiring lines.

A 3D model is a much more time-consuming process, but it helps a lot when creating a power supply project. When, according to a ready-made assignment, the relevant specialists implement such a project (they cut the walls, carry out the wiring and other electrical work).

Rules for installing electrical wiring according to PUE

When determining the locations of the wiring and installation of individual elements, one should be guided by the requirements of the PUE. Regarding the electrical wiring and the rules for its installation, chapter 2.1 is highlighted in the PUE. Therefore, the following requirements must be met for the wiring diagram:

- All lines must be installed exclusively in a vertical or horizontal plane, turns are performed at an angle of 90º. It is strictly forbidden to shorten the distance diagonally or lead the wires in a curve.

- In relation to the structural elements of the room, horizontal lines cannot approach more than 20 cm to the ceiling or floor. Vertical lines should be located at a distance of at least 10 cm from door and window openings, corners.

- The sockets should be located at a distance of 80 to 100 cm from the floor in accordance with clause 6.6.30 of the PUE, in some situations this value can vary up to 150 cm. connection point more than 50 cm.

- Separate requirements are imposed on the device of sockets, switches, electrical wiring in the bathroom and on in accordance with clauses 7.1.46 - 7.1.48 PUE

- The switch is installed at a height of up to 1 m, 1.8 m or under the ceiling in accordance with clause 7.1.49 of the PUE.

- The connection of the wires must be carried out in boxes; it is forbidden to leave them open or close them in the wall, clause 2.1.21 of the PUE.

In-place markup

To transfer the data of the wiring diagram to the existing wall structure, you must use measuring instruments (tape measure, corner, etc.), level, thread and pencil. To do this, retreat the required distance, according to the distances indicated in the diagram, and apply the appropriate marks on the building structures (walls or ceiling).

Figure 2: Wall markings

Figure 2: Wall markings The markings can be done with chalk or a construction pencil. The main requirement for applying the image is to ensure good visibility and the absence of unnecessary details. In the presence of a laser level, this procedure is greatly simplified.

What elements do you need to pick up?

Structurally, the electrical wiring in the house can include a number of elements:

Wires- for laying in the house, brands are used, AVVG, PSV and the like. The most preferable are copper wires due to the best technical parameters: long service life, lower resistivity, etc. But, in some situations, aluminum wires for electrical wiring can also be used. The specific option is selected based on the maximum load and insulation requirements.

To determine the maximum currents flowing through the wiring, the power of electrical appliances that can be connected is added up, and 20 - 30% is added to the safety margin. Based on this, the appropriate cross-section of the core is selected. The insulation resistance must be appropriate for the room in which the cable is used and the installation method. It should be noted that cables must be planned with a margin, since at the points of connection or output of points they are used more than the calculated length of the wire, and the margin should provide the ability to reconnect.

Rice. 3.wires for wiring

Rice. 3.wires for wiring - designed to connect various sections of electrical wiring, separation and distribution of electricity. They are divided into outdoor and indoor models, which are selected in accordance with the project. Depending on the cross-section of the wires, boxes with the appropriate hole size are selected.

Figure 4: Switchboxes

Figure 4: Switchboxes Sockets- may differ in design features: presence or absence of a grounding contact, cover, hole size, etc. Also, different models can be designed for indoor or outdoor installation. Some variants have paired connection point pins.

Switches- can have a design with one, two or three keys, a rotary mechanism or a sensor. It should be noted that some breakers are equipped with a voltage divider that can affect the performance of the lighting fixtures.

Lighting- sold by lamps, chandeliers, spotlights, sconces and others. A wide variety provides a choice for installation in certain premises. By designation, one can single out powerful lighting devices, low-power ones, for the bathroom, kitchen, etc.

Residual current devices- presented on the basis of electromagnetic, semiconductor or microprocessor circuits. Installation is necessary to protect both the electrical wiring itself in the house from short circuits and fire with household appliances connected to it, and people who may be injured in a breakdown.

Metering devices- exercise control over the consumption of electricity. Their installation is required when the electricity is reconnected or if it is provided for by the project. By the number of phases, electric meters can be connected to a three-phase or single-phase network.

Rice. 5: Typical electricity meter

Rice. 5: Typical electricity meter Protective earth- must be provided for all consumers with a voltage of more than 42 V. Therefore, when connecting new wiring, it is necessary to have a ground loop to which a PE conductor is connected from all consumers.

Cable ducts- required for outdoor installation of wiring, according to the material of manufacture, they can be plastic or metal boxes. An option is chosen by size so that when laying the wires, all the necessary conductors are freely placed in them. Structurally, they can be perforated for cooling or made in one piece.

The procedure for installing electrical wiring in the house step by step

Please note that depending on the specific situation, some installation operations may not be performed.

First make a small hole in the center with a drill, and then use a crown.

Figure 9: Drilling a hole with a crown

Figure 9: Drilling a hole with a crown

But at the same time, make sure that excessive force does not lead to damage to the insulation.

In addition to the ones allocated for individual rooms or objects, it is necessary to install an introductory automatic device with a higher setting. It is installed at the input of electricity to the house. You can also use other protective devices (voltage, differential and others, if needed).

Figure 15: Shield with different defenses

Figure 15: Shield with different defenses

To do this, apply voltage at the cable entry to the electrical panel. Then test the flow of electric current at all connection points using a test lamp or test the presence of potential using an indicator.

If your house is not yet connected to an external network, then you do not need to do it yourself. Since the connection to the air main is carried out by employees of the power supply organization. Performing this procedure yourself is prohibited and extremely dangerous.

Video master classes on the topic

Every house today has electricity. It's hard to imagine modern life without him. Therefore, during the construction of a new building, it is necessary to pay close attention to the wiring in it. A similar requirement applies to the acquired private house, which was built many years ago. In most cases, professionals are hired to carry out such work. But in some buildings, the owners decide to do them on their own, so they need to know how to wire the house correctly. Also, this information will be useful in exercising control over the processes performed by specialists.

Development of projects for different types of buildings

This stage is the initial one, and all wiring in the house depends on its correct implementation. Designers are involved in the development of circuits. In the future, projects are approved in special instances. Blueprints are required for newly built houses. In addition, diagrams and specifications are required for buildings in which redevelopment is planned, as a result of which the existing electrical wiring will be almost completely changed. Also, during the implementation of the extension of the additional floor, it is necessary to develop new energy supply drawings. If it is planned to simply replace the existing electrical wiring, then there is no need to develop a project for this. You can use the one that already exists and was used to create the structure.

Cable Installation Methods

To know how to conduct wiring in a house, it is necessary to study two main options for today; it is laid in an open or closed way. In the first case, the wire is laid along the surface of the main supporting structures. These include ceilings and walls. In the second version, grooves are used, which are recesses made with a special tool in supporting structures. In the future, these elements are sealed with plaster. Pipes are also used for wiring. They can be plastic or steel. Their use allows you to protect the cable from possible mechanical damage. Today it is believed that the most correct wiring in the house, which is the safest, is the one made using a hidden installation option.

Completing the object with the necessary material

In order to answer the question: "How to make wiring in the house?" - it is necessary to choose the right electrical cable with a certain section, as well as to know its length. Building power supplies also include switches and sockets, junction boxes and lights, and meters. It is necessary not to forget about cable channels, or you can use a corrugated pipe. In addition, you will need plaster of Paris and electrical tape.

Installer's kit

When answering the question: "How to conduct wiring in the house?" - you must always remember to equip the person who will perform the tool. First of all, he will need to purchase a screwdriver, pliers, indicator and nippers. Also, for successful work, you will need a drill or perforator, which must have special attachments. They are necessary for drilling the sockets used during the installation of switches and sockets.

If it was decided to perform the electrical wiring in a hidden way, then for such a process you will need a wall chaser. It is necessary to make a furrow that will be used to lay the cable in the wall of the building. Such a tool has two special discs capable of cutting a flat indentation in hard materials such as brick or concrete. It also allows you to speed up the installation process. When performing such work, you can do with an ordinary grinder, but in this case there will be more dust, since the tool does not have a special assembly casing for it. In addition, the process will take a long time.

Wire selection

Mandatory when studying the question: "How to conduct wiring in the house?" - you need to pay close attention to the selection of the cable cross-section. The main value for its determination is the total power of absolutely all electrical appliances in the building. In this case, it is imperative to provide for a power reserve. This will prevent the cable from overheating, even if all electrical appliances are turned on at the same time.

Currently, the following wires are selected for wiring in the house:

When a cable is selected and wired in a house, the execution scheme of which can be open or closed, it must be borne in mind that for each unit that consumes a lot of electrical energy, it is imperative to create a separate line. It is also necessary for computer technology to reduce or completely avoid electromagnetic interference.

The length of all wires in the house depends not only on the overall dimensions of the building, but also on the materials that are used to create the electrical network. That is, these include the above switches, boxes, sockets, and so on. In addition, it should be taken into account that in the places where the cables are connected, it is necessary to leave a margin of about 10 cm.

Start of installation work

The wiring in the house largely depends on the correct marking of the route. In order to carry out this process, it is necessary to take a cord of small thickness or twine, which will be rubbed with chalk. With their help, the cable trunk is marked. It is the main wire that runs from the farthest and last outlet. The trunk cable should only be laid horizontally at a height of approximately 150-250 mm from the ceiling level. In addition, the main wire can be placed at exactly the same distance from the floor. Branches that go from the trunk cable to sockets, lamps and switches must be carried out with strict observance of their verticality.

If the wire is laid at a slope, then in this case, when performing any work, it can be very easily damaged. For example, this becomes relevant when the owner of the premises is going to hang cabinets from a kitchen unit or a picture in the living room on the wall.

Selecting the number of sockets and switches

The main indicator that affects the number of devices designed to supply electricity or turn it off is the presence of electrical appliances in the house. So, for each luminaire, usually one switch is installed. The number of outlets is selected based on the conditions for human convenience. They can be counted according to the number of intended and used devices. So, for example, there should be at least three of them for kitchen areas.

Placement of sockets and switches for lighting fixtures

Each fixture for supplying electricity or disconnecting it is usually located on the wall. The points for their placement are at different heights from the floor. So, switches, when the correct laying of cables in the house is performed, as a rule, are located about one meter from the lower surface of the room. For this, the meaning of clear rules has not been established, so each owner chooses it for himself individually. In addition, they should be located 100 mm from the door frame and always on the side where the handle is located. As for the sockets, there is also no exact height for their installation today. Typically, such fixtures are placed 300 to 800 mm from the floor. It all depends on the location of the electrical appliances.

Grooving grooves for cable and electrical panel

Most often, work of this nature is performed when wiring is carried out in a panel house or in a building built of brick. During this stage of installation, there is always a lot of noise and dust. For this reason, it is imperative to have earphones, goggles and a respirator handy. After selecting all the installation locations of the switches, sockets, transfer boxes and the electrical panel, which are marked with a pencil, the slitting is performed. This process is carried out in two steps. If a grinder is used, then 2 strips are made side by side, the distance between which can vary from 1 to 5 cm, and the depth should be 20 mm. Basically, these values depend directly on the number of wires laid down in the future. After that, using a perforator and a special nozzle, brick or concrete is removed between the two cut strips. To carry out use an open way of laying the cable.

To create a niche for the shield, you need to walk along the marked contour with a grinder, and then remove the wall material with a puncher. If the depth is insufficient on the first attempt, then you need to repeat the whole process and repeat it until there is enough space for installation.

Work on the installation of installation boxes

You cannot do without such a stage of work during the installation of an electrical network. House wiring, the scheme of which was chosen at the preparatory stage, always implies the installation of transfer cases. For this, dowels or gypsum are most often used. A device is inserted into a hole of the required depth prepared in advance with the help of a crown, which is fixed with the above consumables. If initially it is not possible to fix the box using a dowel, then a plaster solution is used. A base is created from it, to which an element of the electrical network of the house is subsequently attached. It is necessary to use plaster of paris, which has a setting time of up to three minutes. After applying it to the hole, you must immediately insert the installation box and immediately adjust it to the desired position.

Laying and securing wires

Cables must always be fixed in the building. This does not depend on how the wiring is done in the house. For strobes, two options are used: wet or dry. At the very beginning, one end of the cable is fixed in the installation box, while leaving about ten centimeters of stock. If there are several wires, then they are connected every 300 mm to each other using plastic fasteners. Using electrical tape or a separate piece of cable, a dowel is attached to them. A faster way is to use gypsum, only before that it is necessary to remove all dust from the groove, and then prime it. First, in the recess for the wire, smears are applied every 300-400 mm, and only then the cable is recessed into them.

Electricity in the house is wired in an open way using cable channels, which are made of non-combustible materials. This fixation option takes away the minimum amount of energy from the performer.

Conclusion

Many people are interested in how to wire the house. To be sure of the correctness of all the processes, it is always necessary to contact the specialists if the property owner does not have the necessary skills and knowledge. In no case should a person perform such a responsible job in the absence of the required qualifications, because this can entail irreversible consequences.

Electrical work in the private sector in our country is rather bad than good. For most would-be electricians, protecting a person from electric shock, and property from fire, unfortunately, do not mean anything. At the same time, it seems that ordinary users skipped physics lessons at school and do not at all understand what an electric current is. But they believe very well in marketing tricks and happily pounce on "branded" automation, rejecting any other.

I propose to step by step understand all the issues of power supply of a private country house using the example of a single-phase input. Also, this guide can be applied to use in an apartment. Immediately, I note that my specific solution for certain nodes is the optimal balance between functionality and price, but without sacrificing security!

I hope there is no need to retell the full course of physics and explain what an alternating electric current is. Let's also omit the moments of how this electric current appeared at the power plant and through the step-up transformer got into the power line. I will only note the important nuance that the entire power supply system in Russia is three-phase. The single phase voltage of 220 volts at your outlet is only phase voltage across one of the three phases. And the line voltage will be 380 volts. This circumstance should be taken into account in view of such a phenomenon as "phase imbalance", which is nevertheless relevant only for old wiring that is not designed for modern loads.

2. So, the step-down transformer in SNT. A high voltage of 10 kV comes through three wires. Further, 4 wires diverge (3 phase and one neutral conductor) along the SNT. In the photo you see a modern transformer and branches in the form of a self-supporting insulated wire. At the moment, the air lines in our SNT are undergoing modernization.

3. With a single-phase input, two conductors are connected to each consumer: phase and zero. In the photo you can see the old aluminum wires on the support closest to the house. The outlet to the house has already been made using a self-supporting insulated wire. Particular attention to the fact that all overhead line supports must have a re-grounding of the neutral conductor (top right photo). This is necessary in order to exclude emergency situations, such as "zero break". In this case, you should pay special attention to your own grounding in the absence of repeated groundings on intermediate supports, otherwise in an emergency your own grounding may be the only one for the entire village.

4. Get to the point. The last section of the overhead line from the nearest pole to the building is extended with a self-supporting insulated wire, in our case 2x16. It stands for self-supporting insulated wire, it is aluminum with a cross section of 16 mm². For the convenience of installation and laying in the place of anchorage using special clamps (the self-supporting insulated wire implies the installation of a live line, on special clamps the nut is not energized, and also has a shear thread that guarantees the necessary tightening force) goes into VVG with a section of at least 10 mm² ... It is in this form that two wires fall into the lead-in box. In the dashboard, we have an introductory two-pole circuit breaker and a surge arrester (necessarily on the terminal support for air inlet), which will protect the network when lightning strikes the phase conductor of the overhead line. It is connected in front of the machine to a phase conductor. Here, in the dashboard, the grounding is connected strictly BEFORE the input machine. We are considering the TN-C-S grounding scheme, since the TT system is still designed for mobile buildings, not permanent buildings, and it has its own characteristics in terms of safety requirements. The TN-C-S system has no drawbacks with proper installation. Even if you go deeper into this topic, if you make a TT, then this will only be your final section, while the entire overhead line from the transformer will be TN-C.

5. Mandatory grounding. Three corners with a wall of 50 mm (steel thickness 5 mm), 2 meters long, are driven into the ground with a sledgehammer and welded together in the shape of a triangle. A 40 mm wide steel strip extends to the wall of the house. The last meter to the shield is made with a copper conductor with a cross section of at least 16 mm². It is absolutely impossible to underestimate the cross-section, in the event of any emergency on the line, your grounding may become the only one for the entire line / street / quarter. The switching in the dashboard is as follows. The combined PEN (Protected Earth + Neutral) conductor from the overhead line is divided on two buses into N and PE. After that, the input circuit breaker is switched, next to it is a surge arrester. From the machine, the power line goes to the electric meter. A three-core copper wire with a cross-section of each core of 6 mm² goes directly into the house. The phase and neutral conductors come from the meter, grounding from the corresponding bus.

6. We turn to the internal wiring of the house. I repeat that the principle of reasonable sufficiency was used in the design of the electrical network. Of course, it was possible to make 2 times more sockets and increase the number of power lines by the same amount, but I believe that this is absolutely unnecessary. Explanations for the diagram: red squares - junction boxes, yellow circles - lamps. Blue denotes the wiring in the screed, red - in the walls. Everywhere in the house, only LED lighting is used (the total consumption of all lamps turned on at the same time does not even reach 300 watts). The lighting is supplied from a power line to a specific room, I see no practical need for separation, besides, this significantly increases the volume of installation work. All consumers in the house are marked on the diagram. If you have any questions, ask.

7. So let's get started. This is a temporary electrician for the period of construction work. Let's move on to laying the power lines. There are 10 of them in total. Some of them will go along the walls, some in the floor in corrugation.

8. Let's start with the floor lines of force. We use a NYM cable with a section of 3x2.5 mm² in a corrugation (the gray corrugation does not burn at all, the black corrugation does not support combustion and is protected from ultraviolet radiation - in the screed it is not particularly important what to use, it is not so easy to find a solid gray corrugation, but I would trample the soft one while the preparatory work). A frequently asked question - why not VVG? In terms of performance, they are completely identical, but NYM has the advantage of triple insulation, while it has the disadvantage of not being UV resistant. Therefore, for open wiring, VVG is preferable. Otherwise, NYM is more convenient, including because of its round shape (round VVG also exists, but it is extremely difficult to find it in stock). Round NYM can be pulled into a corrugation with a diameter of 16 mm in an elementary way, which is extremely convenient. As a souvenir, it is worth documenting the routes of laying lines along the floor, although nowhere except for door sills there is not even a theoretical probability that you will need to drive something into the concrete floor screed.

9. Corner of the kitchen area. Aerated concrete is simply an excellent material for processing - you can gouge walls with even an ordinary screwdriver. So, we drill holes for mounting and junction boxes. The wire in the walls made of NON-FLAMMABLE bases is laid as it is. No corrugations are required. All attention to the tracks. Lines of force are laid only at right angles. The main line runs along the floor at a height of 20-30 cm, then rises strictly VERTICAL to the sockets and switches. Diagonal gasket is prohibited and there is a risk of getting into the wire, for example, when driving a nail into the wall (and so you know for sure that you cannot drive nails exactly under the sockets and above the switches). The cable is fixed to the wall using plastic round brackets (two holes are drilled, the bracket is inserted).

10. The floor screed is poured. The question at what stage to lay the cable along the wall is solely from your personal preferences. Someone first plasters the walls, then makes a line, lays a cable and seals the line back. I prefer to do the wiring before plastering the walls. This method may seem inconvenient because you will need increased attention during plastering work to the points with mounting boxes (you need to plug them with something, and then pick them open). Pay attention to the left corner - all the commutations on the through-line outlet lines are made not in socket boxes, but in separate junction boxes.

11. I will repeat with the type of wires. NYM is the perfect and versatile cable. The section is selected in accordance with the load. Usually a 3x2.5 mm² cable is used. For powerful consumers, such as an electric hob, a wire with a cross section of 4 mm² may be required. For lighting lines, where, in my case, LEDs are used (the maximum power consumption in the largest room is 80 watts), I use a PUNP cable 2x1.5 mm² (there is no need for grounding in the lighting network, there is nowhere to connect it). In general, the standards prohibit the use of the PUNP due to the fact that the technical conditions allow to underestimate the cross-section of the conductors by up to 30% in comparison with the standards, and with general savings everywhere and in everything, this can cause a fire due to exceeding the permissible load. In my case, my maximum load is more than 30 times less than it is capable of safely passing a cable with a cross section of 1.5 mm². Therefore, a larger cross-section is not required, and this cable is most convenient for mounting the lighting line. Yes, keep in mind that only solid mono-core cables are used for fixed wiring. Socket boxes and junction boxes are wall mounted on plaster of paris (alabaster), as the fastest drying mortar.

12. Now directly the stage of assembly and installation of power lines. It will take a few handy tools. The topmost one is used for crimping the terminals of multicore cables, for example PV3 (currently being replaced by PGV), which are used in the assembly of the electrical panel. The middle tool is useful for quick stripping of NYM cable sheath - pinch, twist, pull. Below is a simple tool for stripping the terminal veins, not very convenient, but more than enough for a one-time job.

13. It is also imperative to have such a thing as an indicator screwdriver. There are two types of them. The original device with a neon lamp without a power source is capable of detecting only the phase voltage. This same simple Chinese device with a power source has more advanced functionality and allows you to determine not only the phase (important! To determine the phase, you must not touch the screwdriver cap with your fingers), but also the integrity of the line, as well as the place where the conductor is broken. On the right is the initial blank for the electrical panel. When switching, it is important to distribute everything in such a way that it is intuitively clear where everything is.

14. Immediately I will note the nuance that the "specialists" will surely get to the bottom of - the zero conductor should be blue, and I have it black, since in our tree called Moscow there is never anything available at the moment when I need it (since the shield obviously one-phase, there is no obvious catastrophe and error to confuse zero with the second phase). For switching in the electrical panel, I use a PV3 wire (you can take a modern PGV) with a cross section of 6 mm². Also, you will need special NSHVI tips (insulated pin sleeve tip), they are needed in order to put together a stranded wire before switching under a screw (the wires will spread out - there may be poor contact). It is also convenient to use special single-pole and double-pole busbars (in the right photo in the background) to connect a number of circuit breakers.

15. Switching in junction boxes is as follows. The terminals WAGO 2273 (left) are used on conductors with a cross section of 3x1.5 mm² (why and why - further) and WAGO 222 (on the right) on conductors with a cross section of 3x2.5 mm². Always observe the color coding of the conductors. WAGO 222 series is perhaps the best option if there is no desire to fiddle with soldering and crimping.

16. Installation of sockets and switches. I really like the products of Schneider Electric, the Unica series. Switches according to modern standards must be turned down. Turning on upwards is an old school since the days of knife switches, the turning on of which upwards was due to their design. Unica series switches turn down, this is their nominal position.

17. Switching of double sockets standing nearby is as follows. The power wire comes to the terminals of one outlet, and then a branch is made to the next one. Good form rules prescribe when installing outlets to connect the phase conductor to the right.

18. We return to the electrical panel. I want to draw your attention right away - always take a shield with a very large margin, it will definitely not be superfluous. I seemed to do everything to a minimum, but almost all 36 positions (3 rows of 12 positions) were occupied. Be sure to leave a supply of power line wires equal to at least one and a half height of the shield. On the right you can see the first version of the switching, but in fact this is the moment when the house was switched from a temporary electrical circuit to a permanent one. In the process, a couple of consumers appeared and the scheme was slightly modified.

So, I will tell you in detail what, how and why. Go!

A few words about the components of the shield.

A circuit breaker or just an automatic machine. Provides protection against short circuits and also provides protection for electrical wiring. Consequently, it contains two releases - electromagnetic and thermal, respectively. The first is triggered in the event of a short circuit on the line, the response time is determined by the time-current characteristic, which in any case is several times higher than the current rating of the machine. The thermal release is a bimetallic plate with different coefficients of thermal expansion and is designed to protect electrical wiring. It is in accordance with the cross-section of the cable and the sockets used that the rating of the machine is selected. The most popular mistake is to put a 25A automatic machine on a power line with a 2.5 mm² wire on the basis that the cable will withstand. No. And the reason lies in the sockets. Regular sockets are rated for current up to 16A. Therefore, this should be the nominal value of the machine. And in general, in general, it is better to play it safe and reduce the value of the machine, because it is he who will be able to protect the wiring from overheating or, even worse, fire.

RCD is a protective device that detects leakage current. The simplest mechanical device is a differential current transformer. If you explain on fingers, then the amount of current that "came" through the phase conductor should be equal to the amount of current that "went" through the neutral conductor. If "left" is less than "come" - there is a leak, protection is triggered. If there is a grounding, the RCD will work as soon as a dangerous voltage appears on the device case, if there is no grounding, the RCD will work as soon as a person touches the case (it will be slightly electric shock). From this it follows that the RCD must always be used, and the presence of grounding only increases the level of safety. At the same time, it is categorically impossible to do home-made grounding in the apartment in its absence, the consequences can be very sad. It is worth noting about the RCD that it itself needs to be protected from short-circuit current, therefore, after it, there must be an automatic device (s) in the line with a lower rating than the RCD itself. The rating of the RCD itself implies what maximum current it is designed for, it is better to focus on a 20-30% margin of a constant load. The easiest way to check the operation of the RCD and the correct grounding is to close the neutral and grounding conductors in the outlet. The RCD should turn off immediately.

To summarize: the circuit breaker protects the wiring and equipment, the RCD protects the person. There are also difavtomats (here and earlier I use the terminology that has developed in our country, although it is not entirely accurate), a device that combines the functions of an automaton and an RCD.

Now let's move on to the dashboard:

We start at the top left corner. This is where the 3x6 mm² cable comes from the street panel. Introductory RCD with a leakage current of 300 mA. Popularly called "fire-fighting". It is used in conjunction with an RCD for a lower leakage current, firstly, to ensure selectivity when disconnected (first of all, it will knock out the "junior" RCD), and secondly, to increase fault tolerance. Behind him is an ABB C11 meter used by me exclusively for technical metering of electricity (report to you the consumption figures of an air heat pump and do not run to the street panel for this). After it, there are two bipolar machines that also act as circuit breakers. The left one, with a rating of 40A, is used to de-energize the entire electrical system of the house, with the exception of the air source heat pump. The right one, respectively, controls the air heat pump). To the right is the thermostat of the anti-icing system (20 meters of the heating cable in the gutter and gutters) and three automatic machines: for it and two lines of street sockets (which, in turn, are powered from one RCD from the next row).

Second row. In the left corner there is a common ground bus for all lines. Pay attention to the commutation. It is not necessary to lay wires behind the rails, it is better to conduct them as openly as possible. Next, we have a line of RCDs in the amount of 6 pieces, according to which all consumers in the house are evenly divided. The leakage current of all RCDs is 30 mA, although ideally for a bathroom it is worth using an RCD with a leakage current of 10 mA.

Third row. Finite state machines of consumers along lines. On the left, right and below, there are corresponding zero buses extending from a specific RCD for each line. They must be separate, otherwise there will be no sense in dividing the RCD along separate lines. The machines are grouped by load type.

How to choose the rated current of the machine? As we learned above, the rating of the machine is selected based on the cross-section of the conductor (a copper conductor with a cross-section of 2.5 mm² withstands 25A long-term load) and switching devices (household sockets are designed for current up to 16A). Everyone knows how to convert amperes to watts - multiply by voltage (220 volts).

20. Close-up of the bottom row of machines. Single-core cables are connected directly to the screws, multi-core cables must first be crimped with a ferrule. There are many unfounded claims of "specialists" to IEK products and in vain. This is an excellent option in terms of price / quality ratio. They are made in China, Russia and Turkey. And they perform their function no worse than the "racially faithful" ABB and Legrand. Don't believe me? Ask real electricians, not charlatans who sell something more expensive. All of Moscow, after the recent modernization, is electrified using IEK automatics, of course, the quantitative statistics of failures will be higher on a millionth scale than in the case of other brands, which are used in the housing stock by several orders of magnitude less. What bad can happen to IEK? And nothing that can harm a person. The RCD or the machine, after being triggered, simply will not turn back on and will require replacement. That's all.

21. Assembled shield assembly.

22. And layout along the lines with signatures. Simple and functional. Groups by lines are highlighted in color. If an accident occurs, for example, on a line with a pump, then only it will turn off, and the power supply of the whole house will not be affected. To many, such a number of RCDs may seem redundant. Indeed, a sufficient minimum is one lead-in RCD for the entire facility with a leakage current of 30 mA. Remember - there must always be an RCD. Even if you do not have a modernized input in your apartment and use a TN-C connection with two wires. Yes, you do not have a separate grounding, but the RCD will not work out the situation of phase leakage to the device case without the "help" of a person. But the RCD will protect the person.

23. Well, the final types of outlets in the premises. Let me remind you that on the outlet lines the vending machine should not exceed the rating of 16A (for me, for example, the line to the bedroom is made with NYM 3x1.5 mm² cable (I do not see the need to include a load of more than 2 kW there), and therefore the machine on this line has a rating of current 10A.

24. And a couple of words about lighting. There are inexpensive GU10 fixtures everywhere in the house. For tests, I ordered several models from China from LED lamps, and also took "Russian China" under the Camelion and Woltra brands. With the price of the latter about 230 rubles per lamp, I will honestly say that it is pointless to buy anything from China. All samples at a price of less than 150 rubles apiece have a serious variation in color temperature, not to mention too low (Ra<70) индексе цветопередачи.

Everything related to electrical networks is described in detail and clearly in the PUE (Electrical Installation Rules). There is some disagreement between the chapters, but in general, everything is correct.

Have questions? Ask!

Need help with electrical work? Contact us!

Construction partners: