How to close a hole in the floor with a depth of 60mm. Repair of an old concrete floor: from small to major

In order to lay a new floor covering, it is necessary that the floor itself be sanded and smooth. Along with repairing or replacing floorboards, you will likely need to patch up cracks and holes in plank floors, as well as to remove roughness and, possibly, to deal with the dampness of monolithic concrete floors. Any flaws left uncorrected may eventually affect the quality floor covering and damage it.

Seal holes in wooden floors

Holes from buried nails and screws can be easily sealed with an elastic putty to wooden surfaces using a spatula for this. If you plan to leave your plank floor unfinished and rub it down with appropriate cleaners, try matching a putty or sealer to match the color of the wood the floorboards are made from; however, apply a layer of putty after each floor sanding cycle.

Deeper cavities can also be eliminated with an elastic putty, however, if a knot has fallen out of the board, leaving behind a large round hole, insert a short wooden cork, and then clean this place with a planer. Corks match the color of the floor or paint over after cutting them flush with the floor.

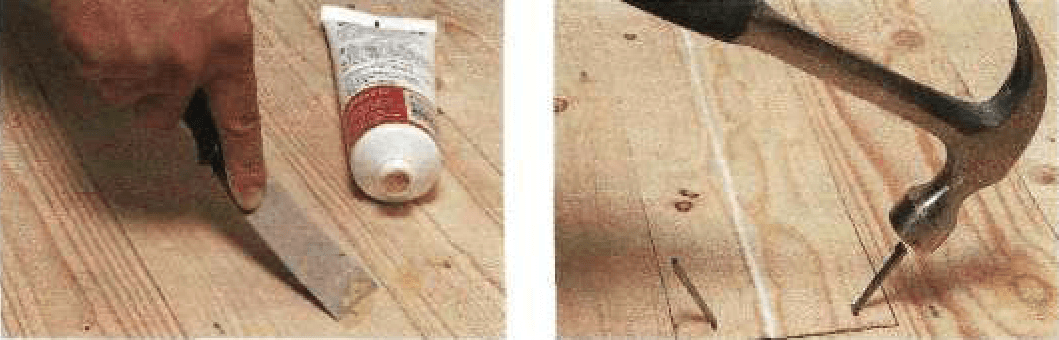

There are two main types of cracks you'll find in plank floors: gaps from cracked ends along the edges of the boards, and gaps between the boards themselves. Such cracks can most often be eliminated by pulling them together with nails: one nail must be hammered into each edge of the board near the end and further into the beam at an angle to its center. As the nails are driven in, these cracks should disappear.

Eliminating gaps between boards is more difficult. If they are not wide, you can use wood putty; however, for wider gaps, you will have to prepare thin slats and hammer them, after smearing with glue, into the resulting gaps. When the glue is dry, planer or sand the edges of the slats that protrude above the floor; if necessary, paint over the installed wedges.

If there are many wide gaps between the floorboards, the most the best solution- pick up all the boards in turn, starting from one side of the room and ending with the other. Special clamps will help you put the boards back together as they will press them against each other while you nail or screw them.

Seal gaps in the floor. To seal wide gaps, hammer glued slats between the boards. When the glue dries, use a planer to plan the edges of the slats that protrude above the floor.

Use a flexible wood putty to repair holes left by driving in nail or screw heads. When closing a crack at the end of a board, first fill it with glue, then pull it off by hammering nails near the end.

Leveling a wooden floor

Individual uneven areas of the floor can be sanded by hand - what you did after using putty - however, where depressions or a thick layer have formed on the floorboards old paint, fat and mastic, the most best way out- borrow an industrial grinder for temporary use and cycle the floor again. Start sanding the floor with a coarse sanding belt, then gradually move to a finer abrasive by guiding the machine across the boards. Finish sanding by running along the floorboards with a fine-grained emery cloth.

For hard-to-reach surfaces, also rent a special sander (if you do not have a belt sander), because Grinder does not capture areas of the floor located directly near the baseboards.

Sealing cracks and holes in monolithic concrete floors

Provided the screed is generally in good condition and dry, you may be able to repair cracks and holes using a quick setting repair mortar. Before this, all unbound particles must be removed from the slots, and the edges of the slots, if necessary, should be cleaned to provide a surface for the mortar to set. The edges of cracks and holes should be treated with a PVA (white) solution in combination of one part glue to five parts water to reduce the effect of the concrete's absorbent properties and help the solution soak into the floor.

To prepare a cement mortar, use PVA glue and water in the same ratio as the base; then cover the cracks with the resulting solution, and apply two or more layers to areas with large depressions. Level the surface with a spatula.

To help the freshly prepared mixture "grab" the edges of the crack, treat them with a brush with a solution of PVA (white). Apply a coat of quick setting repair mortar to cracks in the monolithic concrete floor. Rub the solution on the damaged surface and leave it to harden. If the floor surface is excessively porous, apply an insulating layer consisting of a PVA adhesive solution with a brush.

Leveling monolithic concrete floors

It doesn't take much skill to create a smooth, flat surface, as the self-levelling floor compound does the job for you. There are two types of such a mixture: these are dry powders that must be diluted either in water or in a special latex ( synthetic substance used for the production of adhesives, paints, foam rubber) emulsions.

Before you start pouring, clean the room, and also remove the doors and baseboards. Attach slats (shingles) to the entire length of the thresholds with nails to prevent unwanted spreading of the mixture. Treat all cracks and holes with a depth of more than 6 mm with a solution of PVA and water, as described earlier. Dilute the self-levelling compound in a bucket of water and pour it onto the floor, then level the resulting layer with a spatula or plaster trowel. Allow time for the mixture to settle. As soon as it dries - after at least 24 hours - you can install skirting boards and doors; however, make sure that the door does not touch the floor when you open it: you may need to slightly trim the bottom of it.

Dilute the self-levelling floor compound according to the manufacturer's instructions. Start pouring the floor with a mixture from the corner farthest from the door. Using a plastering trowel, level the layer of the mixture to a thickness of 3 mm.

How to fix a hole in the floor from the boards? What about the hole punched in the plywood flooring? How to repair a deep pothole in concrete screed or through hole in reinforced concrete slab overlap?

In the article we will try to answer these questions.

The reasons

First, let's find out where a hole in the floor can come from.

Agree that the situation when the surface suddenly falls under your feet is quite unlikely.

- Falling heavy objects. A very real situation for weightlifting halls and for industrial premises with wooden decks(which, however, is rather an exception).

Note: Platforms in sports halls are usually assembled from timber, strapped with staples. The platform is laid directly on the screed and covered with a hard rubber sheet. In general, if a fallen bar breaks through the floor, this indicates either a gross violation building codes, or about poor discipline of athletes training with large weights outside the platform.

- rotten boards. The picture is typical for houses built more than half a century ago. Harmless antiseptics were not yet available at that time, and creosote and impregnations based on petroleum products were not used in residential premises.

- cracked boards. Actually, in this case, we do not have a hole in the floor, but a gap.

- Defects in slabs and screeds due to flaws in their casting or laying. AT apartment buildings gaps between hollow core panels predominate in this category.

- Finally, holes are punched in ceilings for laying communications - during construction or overhaul. They, of course, also have to be sealed - for reasons of heat and sound insulation.

elimination

How to fix holes in a concrete floor? In the general case, it is quite logical to use the same concrete for this. More precisely, a cement-sand mixture.

Hollows in the screed

- The pothole is cleared of debris and dusted with a vacuum cleaner.

- If you have on hand - great idea will prime the recess. This will improve adhesion to the cement-sand mortar.

- Then the pothole is filled with mortar; the surface is smoothed with a spatula, trowel or ordinary plank. The ratio of cement and sand suitable for these purposes is 1:3.

- With a large volume of potholes, you can use a backfill made of fragments of bricks, stones and rubble.

As you can see, some universal solutions does not exist for all occasions. Everything is determined by the cause of the problem.

You can learn a little more about floor repair from the video in this article. Good luck!

" width="640" height="360" frameborder="0" allowfullscreen="allowfullscreen">

Exist different techniques impact on the material, which answer the question of how to repair cracks in concrete.Headings. Concrete. Concrete floors. Blocks. Kinds. 7 Cracks in concrete, how to repair them and prevent the destruction of concrete. All types of repair of concrete floors Very good file"Concrete Floor Repair Tips" has pictures. To fill a hole with putty or cement mortar you will need narrow and wide spatulas. Strong and dense in structure, the composition allows you to qualitatively repair large chips in concrete wall.Floors. Guests. It must be repaired. To do this, make a wooden cork to size, spread it with glue and insert the cork into the hole. How to level a concrete monolith. It is not difficult to make a smooth concrete floor, especially now that the modern market offers. They said that the holes in the ceiling and floor after this operation will be patched up by the residents themselves.2. Clean holes from dust and crumbling dirt. 3.

Wet the concrete surfaces to which you are going to apply the foam with a spray bottle. How to patch a hole in a concrete wall? 0 Concrete is a durable and reliable material, but even it is subject to deformation over time in the form of holes, crevices and other damage. How to close a hole in the floor from the boards? Before filling a hole in a concrete floor, it is necessary to prepare the surface Next, before closing a hole in a concrete floor, the damaged area must be treated with a primer using a paint brush. closed forums. Repairmen. So, as a result of drilling and for natural reasons, holes of various diameters and depths are formed, requiring an individual answer to the question: “How to close holes in a concrete wall yourself?” holes in concrete slabs bituminous mastic— Duration: 4:00 sasha barsukov 13,555 views. How to make a concrete floor in a garage — Duration: 4:10 smoldacha 673,064 views. Along with repairing or replacing your floorboards, you will likely need to patch up cracks and holes in your plank floors, as well as clean up roughness and possibly dampness in cast-in-situ concrete floors. The choice of methods for sealing holes. It is necessary to understand in more detail how to close holes in concrete in specific situations. Scheme with concrete mortar. To close the hole, pick up a piece of cotton fabric right size. How to patch a hole in a concrete wall? 0 309. Concrete is a durable and reliable material, but even it is subject to deformation over time in the form of holes, crevices and other destruction. Please tell me how to close the hole correctly? The riser goes into a hole in the floor of the toilet, that is, as if further than the hole, the filling from the riser is independent; the riser still has to be tinkered with, because there is also a hole around it. You can repair cracks and eliminate other defects on your own, saving on hiring professionals, and not on quality. The most common defects in a concrete floor screed.

Therefore, I am interested in how to close up holes in the floor so that they dry out quickly, since this is a walk-through zone, a lot of people walk. No floor leveling. The concrete floor has several small indentations and a couple of large ones. This problem occurs in many residents of old houses that have basements. At the same time, it should immediately be noted that the use of toxic substances practically does not help. Repair of concrete floors allows you to return the coating to its original appearance and high performance. In the course of work, deep deformation and shrinkage holes and cracks will have to be repaired, and chips removed.

Author Topic: How to fix a hole in concrete? (Read 2751 times). It seems to me that I myself can fill this hole with concrete. Only I need this concrete (or some other suitable mixture) quite a bit. Repair of an old concrete floor: from small to major. Do-it-yourself concrete floor repair How to fix cracks in the floor? If the floor itself is not dusty, and the circle is a little tight, then a home-made repair mixture will fit perfectly. Knowing the rules of work, you can close up any hole in the wall. The main thing is to approach such a process as sealing holes in ceilings responsibly. Concrete floor laying scheme. View full version: The better to close up holes in the floor under the linoleum. The floor is a concrete slab. Surprisingly smooth (I did repairs myself - there were such steps, which is terrible) But there are many small shells - from 5 to 20 mm, well, plus a few big holes. How to close a through hole in the wall? It is possible and even necessary to close a through hole. In this case, we will work on both sides of the wall. How to make a concrete floor? On the cement-sand mixture there is little hope, I have seen many times how cracks and holes in the floors were filled with mortar, a little time passed. For emergency repairs, a dry mix of sand concrete is used, but I advise better with reinforcement and ordinary concrete mortar. Seam repair. expansion joints, located in the concrete floor, lose their strength over time and begin to crumble and collapse. Floor screed repair: how to repair cracks, potholes and stop delamination? Do-it-yourself concrete floor repair can be done if there are small holes on a relatively flat surface. Subsequence repair work next: To fill small holes, you need to use a tool with a diamond wheel to expand the pothole. Filling a small hole in a concrete wall. A medium-sized hole in a concrete wall can be easily repaired with mounting foam. Leveling wooden and concrete floors under the laminate. First, let's look at how to close a hole in a concrete wall. Let's come closer to our wall and take a look at it and it is very strong cement mixture designed for sealing deep chips in walls, concrete floors and other concrete structures. Along with repairing or replacing your floorboards, you will likely need to patch up cracks and holes in your plank floors, as well as clean up roughness and possibly dampness in cast-in-situ concrete floors. Filling holes in concrete floor. Repair of concrete floors begins with the expansion and deepening of the pothole along the perimeter. The recess is thoroughly cleaned with a vacuum cleaner and primed. You can close up the pothole after the soil has dried. How to close up a large through hole in the floor of an apartment. Piece concrete slab, sticking out from under the wall to the right of the door, was left on purpose, because when I tried to pull it out with the help of a miracle tool, I realized that the wall in the corridor could simply collapse. were on the floor). Fills the rest of the hole with cement mortar. How to close a through hole in a concrete wall. Holes in the walls can be Advised on how to repair chips, potholes, pits in the concrete floor. Soviet-era building. On the floor of the warehouse we roll a rohl with a load of 350 kg, the wheels fail, the load falls, the floor is dusty. My HOA changed the risers, as a result, I became the owner of gorgeous holes in the floor and ceiling. I bought a "sausage" - foam rubber insulation for the pipe (the most small size), I had a mixture of M-150 - from pouring the floor and a bottle of foam. How to fix a hole in the floor from the boards? What about the hole punched in the plywood flooring? How to eliminate a deep pothole in a concrete screed or a through hole in a reinforced concrete floor slab? Have you seen the closing process? How exactly was it closed up and with what? Unfortunately no. I only saw the consequences - now the formwork is still hanging on each floor on the ceiling. On the floor, over the closed hole, what is planned? I have a hole in the floor around the riser after the repair. Rats constantly climb out of it, since I live on the first floor. Tell me what and most importantly how to close a hole in the concrete floor so that these rodents no longer enter the apartment. I have a hole in the floor around the riser after the repair. Rats constantly climb out of it, since I live on the first floor. Tell me what and most importantly how to close a hole in the concrete floor so that these rodents no longer enter the apartment. We kicked out landing provider who drilled holes in concrete floors under their pipes. How competently

to lay them with cement mortar a la "Hercules" - a self-leveling floor? How to close a hole in concrete, brick and plasterboard wall. Content: Covering holes in the wall. Closing other types of holes. Cracks in the junction of the floor with the wall. Holes in the ceiling after falling plaster. How to fix cracks and holes in concrete. concrete pavement are used in a wide variety of areas: when installing floorsIf in concrete surface a hole has formed in which reinforcement is visible, then the defect can be repaired as follows. Before leveling the concrete floor, it is necessary to determine its level. Features of working with cracks on a wooden surface. The larger the crack on the balcony, the more difficult it is to repair it. Deep holes and crevices often form on the walls of the loggia. Scheme of laying a concrete floor. The same method is used to close up old holes from pipes and mounting boxes. Huge holes in the walls resulting from the removal dormer windows or ventilation hatches, it is best to close up at How to close a through hole in the floor. Fills the rest of the hole with cement mortar. How to close a through hole in a concrete wall. Holes in the walls can be seen in several sizes

The appearance of cracks is one of the most pressing problems of plank floors. Squeaky floorboards, heat leaks, dust and insect infiltration are all backfire such defects, and if measures are not taken in a timely manner, the floor will have to be completely changed. Meanwhile, there are several effective ways close the gaps in the floor between the boards and significantly extend the life of the coating. All of them are quite simple, they do not require special skills, and therefore everyone can do it. So, why do gaps form in the floor and how can they be eliminated?

To pick up best way sealing gaps, you first need to accurately determine and eliminate the cause of their appearance. If this is not done, the result of the repair work will be short-lived and after a while everything will have to be repeated again.

The following factors contribute to the occurrence of cracks:

- natural shrinkage- any wood is subject to shrinkage, only with different intensity. Boards that have been processed in vacuum chambers hardly change their geometry during their service life, but ordinary lumber can dry out by 5-10%, or even more, depending on the initial moisture content and wood species;

- low indoor humidity- if the air in the house is too dry, the boards will intensively give off moisture and decrease in size. For wooden floors optimal humidity air should be kept within 40-65% at a temperature of 18 to 25 ° C;

- incorrect installation- violation of laying technology leads to loosening of the boards, their subsidence and deformation, resulting in gaps between the floorboards. The most common mistakes are non-compliance with the plane when installing the log and weak fixation of the flooring;

- rodents living under the floor- Mice and rats are able to gnaw through the thickest boards to get into the room. The more active the pests, the more slots and they will make holes, and it is most difficult to repair such damage;

- laying raw lumber- drying of the boards during the operation of the floor almost always leads to significant deformations of the flooring and the appearance of gaps between the floorboards. That is why, when choosing, it is necessary to give preference to well-dried, even boards with a relative humidity of 8-12%.

Depending on the number and size of cracks, as well as the general condition wooden elements, repair may have varying degrees complexity - from sealing individual damage to a complete replacement of the flooring.

Troubleshooting Methods

The choice of termination method should be approached thoroughly, taking into account the cause of the damage, the location of the cracks, as well as the labor costs and time it takes to repair. Equally important is the financial aspect, because the larger the work, the more funds you will need.

| termination method | Description |

|---|---|

| It is used to eliminate small cracks and cracks in the floor. Adhesive tape is needed not simple, but reinforced, 50 mm wide. The floor is cleaned of dirt, degreased and dried, after which the gaps are sealed with adhesive tape, the edges of which are fixed to the floor with a stapler. The method is very simple and budget, takes a minimum of time. Minus: the floor with tape stripes does not look aesthetically pleasing, so carpet, carpet or other rolled covering must be laid on top |

| It is used to eliminate gaps between the floor and walls resulting from the drying of wood. It is carried out after dismantling the skirting boards and cleaning the gaps from debris and dust. If the slots are too wide, pieces of foam are placed in them before foam is blown. After the foam has dried, its excess is cut off at the level of the floorboards, the cuts are puttied so that dust does not accumulate in the pores of the material, and the skirting boards are installed back. The method is convenient, does not require much physical effort, and takes a little time. Cons: high foam costs, fragility |

| This option is suitable for small gaps between the floorboards. Only special wood putty is used. The composition is applied with a spatula, carefully filling all the recesses and gaps, after drying, the surface is polished. The method is fast, does not require special skill, and is quite affordable at a cost. The downside is fragility - putty tends to crack and crumble, especially with heavy loads on the floor |

| Homemade repair compounds are often used to seal wide gaps and cracks in the floor. Traditionally, a mixture of carpentry glue and sawdust is used, which is applied with a spatula to problem areas, tamped into recesses, and polished after drying. For sealing cracks gnawed by mice in adhesive solution add cement and broken glass. To speed up the curing process, epoxy is used instead of wood glue. This method embedding is very affordable and durable, moreover, it is easy to perform |

| With wood sealant, both narrow and wide gaps between floorboards can be easily sealed. The nozzle in the form of a syringe allows you to effortlessly evenly distribute the composition and fill all the recesses. Due to its elasticity, the sealant will not come off the boards during temperature deformations and will reliably serve for more than one year. To mask the repaired areas, putty is applied over the sealant to match the color of the coating. The method is convenient, simple and durable, material costs are low |

| This method allows not only to eliminate cracks, but also to effectively get rid of squeaks in the floors. In hardware stores, a special synthetic cord of various thicknesses is sold, which is selected according to the width of the gap. Instead of a cord, you can use a regular hemp rope. To seal the defect, the cord is liberally lubricated with carpentry glue, laid on the floor and tightly hammered into the slot with a corner of the spatula so that 2-3 mm remains from the cord to the floor surface. This recess is filled with a mixture of sawdust and glue, leveled, and polished after drying. Similarly, you can use sanitary tow. The method is reliable, inexpensive, although a little laborious |

| Used to fill wide gaps in the floor. Wooden slats they are hewn in the form of wedges according to the size of the gaps, thickly coated with glue and hammered into the gap with rubber or wooden mallet. After the glue dries, the part of the wedge protruding above the floor is removed with a planer, the working surface is polished and painted. One of the most practical ways- Inexpensive and durable. Cons: trimming and fitting take extra time, some effort and skills in working with carpentry tools are required in the process |

| It is used in case of significant drying of the floorboards and the appearance of wide cracks in the floor. To do this, the boards are carefully dismantled and then laid again, compacted with wooden wedges, clamps, a jack or a special lever. As a result of tightening, additional 2-3 floorboards will be needed, depending on the degree of floor shrinkage. The way is different high reliability, durability and low cost. The disadvantages include the duration of the process and its complexity. |

| It is used in cases where there are many gaps and appearance The floor leaves much to be desired. Plywood is laid on the floor so that there are gaps of 1-2 mm between the sheets, and the joints in each row are displaced by at least a third of the sheet. The sheets are fixed with self-tapping screws, sinking the hats into the tree, then the recesses are putty, the flooring is polished and laid top coat. This method allows not only to close all damage, but also to insulate the floor, as well as level the base under decorative coating. Cons: high material costs, labor intensive work |

Reinforced tape prices

reinforced tape

All the described methods have been repeatedly tested in practice and are widely used by home craftsmen. And now let's take a closer look at the most popular options for sealing gaps: what tools to use, how to properly prepare the surface and workflow technology.

Prices for silicone sealant "Moment"

sealant silicone moment

Gap sealing technology

Most often, gaps are eliminated with the help of sealants or putties, which are presented in a large assortment in hardware stores. Like more a budget option many prefer embedding with wooden wedges.

Sealing cracks with sealant

The effectiveness of this method directly depends on the type of sealant. In residential areas, silicone or acrylic-based compounds are used for wooden surfaces. The former have greater elasticity, and therefore better withstand the deformation of the coating when changing humidity and temperature conditions. But they publish bad smell during application and are unsuitable for subsequent staining, so that in order to mask the treated seams, it is necessary to initially buy a composition that matches the color. Acrylic sealants can be puttyed and painted, have no smell, are applied easily and quickly. Their disadvantage is the tendency to shrink and lower elasticity.

Advice. Acrylic sealant is best suited for heated rooms with little fluctuation in humidity levels. For unheated rooms, or irregularly heated, it is worth choosing a silicone-based composition.

In terms of quality, Ceresit, Tytan, Moment and Bostik sealants are considered the best.

In addition to the sealant, you will need a narrow and wide spatula, a clean, dry rag and a protective impregnation, such as parquet oil, for work.

The floor is well cleaned of dirt, Special attention giving cracks. If necessary, the surface is degreased or washed with water, after which you should wait for the wood to dry completely.

Carefully cut off the tip of the nozzle along the width of the gap between the boards, insert the tip into the gap and squeeze out the sealant in an even continuous strip.

After filling the cracks in a certain area of the floor, they take a narrow spatula and level the composition by running the tool along the cracks. The trowel blade should be held at a slight angle to the surface to remove the sealant flush with the boards and not leave any projections or indentations at the seams.

Step 4 After leveling, wipe off excess mixture with a clean, dry cloth.

Not poured on the floor a large number of parquet oil and a wide spatula spread over working surface. The movements of the spatula should be arcuate, across the boards, so that the protective composition fills the smallest depressions with high quality.

Now it remains only to wait for the surface to dry. If everything is done correctly, the cracks in the floor will not bother you for a long time.

Elimination of cracks with putty

What you need for work:

- putty on wood;

- wide spatula;

- Sander.

| Step, No. | Procedure |

|---|---|

| The floor is vacuumed or wiped with a well-wrung cloth to remove dirt. |

| Stir the putty and pour a small amount onto the floor. |

| With a spatula, gently spread the mixture over the floor, starting from the corner. The spatula blade is pressed firmly against the surface and drawn along the junction of the wall and floor across the floorboards. The floor is treated with wide stripes, moving from the far corner to the doors. The putty layer should be as thin as possible so that the texture of the wood shines through. The main thing here is to fill the gaps, so the putty is carefully rubbed into the gaps and recesses, and the excess is removed with a spatula. |

| After the process is completed and the putty has dried, the floor must be treated grinder. If the room is small, grinding can be done manually. |

| Now it remains to vacuum the floor and cover the boards protective composition. If there are few cracks, it is not necessary to putty the entire surface. In this case, the composition is applied small rubber spatula exclusively on the crack, carefully filling all the recesses. |

Sealing a gap with a wooden lath

In the process of work you will need:

- thin wooden rail;

- a large awl or screwdriver;

- PVA glue;

- hacksaw with fine teeth;

- a hammer;

- putty on wood;

- sandpaper.

The gap between the boards and the floor surface is cleaned of dirt and dust.

The tip of a screwdriver or an awl is inserted into the slot and is forcefully drawn several times along the entire length of the board so that the rail fits more tightly into the gap.

Step 4 They take a rail, insert it with an edge into the slot and knock it out with a hammer. For convenience, the lower edge of the rail can be hemmed in the form of a wedge - so it will go deeper between the boards and fill the gap more densely.

Advice. If there is no wooden mallet, you can knock out the rail with an ordinary hammer, turning it on its side. You can also use wooden block as a lining - so on the rail there will be no dents from the hammer.

When the glue dries, the protruding part of the rail is cut off with a hacksaw flush with the surface, then cleaned with a planer.

The treated area is covered with putty to eliminate the smallest defects, then polished with fine-grained sandpaper.

After that, it remains to clean the dust and treat the boards with any protective compound - oil, varnish, stain or floor paint.

Video - How to close the gaps in the floor between the boards

Good afternoon. I have a hole in the floor around the riser after the repair. Rats constantly climb out of it, since I live on the first floor. Tell me what and most importantly how to close a hole in the concrete floor so that these rodents no longer enter the apartment.

This problem occurs in many residents of old houses that have basements. At the same time, it should immediately be noted that the use of toxic substances practically does not help. It is necessary to completely block the access of rodents to the apartment, which means that you need to close up a hole in the concrete floor using materials that rats cannot gnaw through.

Training

First of all, you should examine the room and determine if there are other openings through which rodents enter the room. The fact is that in some old houses the sunbed, which departs from the riser pipe, is located below the floor level. Therefore, there may be several holes, which are used by rats.

Usually access to the basements of such buildings is difficult or there is almost no approach to a specific place. Given this, it is necessary to work on expanding the hole so that it can be sealed from above. At the same time, it is very important to do this in such a way that a kind of funnel with a narrow neck to the bottom is formed. This will make it easier to seal holes in the concrete floor without worrying that the created plug will fall out after a certain time.

Advice! Since all work will be done near the pipes, you must be very careful not to damage them. Many houses have long had plastic plumbing systems, which are very poorly tolerated by physical impact.

materials

To complete the work you will need:

- cement;

- sand;

- water;

- gravel;

- pieces of reinforcement or thick wire;

- small plywood, although glass can also be used in the case of rats.

It must be said right away that when deciding how to close holes in a concrete floor, preference should be given concrete solutions. The fact is that rats cannot gnaw through rubble, and in addition to glass, you can get the maximum result.

Reinforcement

At this stage, you need to lay plywood or glass on the bottom of the resulting funnel. This overlap will serve to hold the solution in the hole and perform the function of a kind of formwork.

Next, place the armature. Usually it is used only in cases where the hole in the floor is too large. It strengthens the cork and serves to connect with the floor slabs. If the floor is made of two panels, then it is installed in the space between them. Some masters prefer to use a reinforcing mesh. This is considered ideal option, but it is not worth acquiring it only for such purposes.

If a water or sewer pipe enters the hole, then it must be protected from the loads that will occur when the concrete expands as a result of heating from climatic conditions. To do this, use a special damper tape, wrapping it around the pipe at the level of its passage through the ceiling.

Mortar and filling

Determining how to close a hole in a concrete floor, many begin to invent their own formulas for creating concrete and use various additives. In fact, everything is quite simple. We take three parts of sand, which we mix with one part of cement. Add a little water to the dry mixture so that the solution turns out to be thick sour cream in consistency.

Then pour into the bottom of the hole ready mix, a layer of one centimeter. After that, we begin to lay out a layer of gravel, making the stones close to each other. Next, pour more mortar to cover the rubble. As a result, the solution should occupy half the depth of the hole.

Advice! It is very important to ensure that the mixture penetrates into all the gaps between the gravel. Some craftsmen use a small stick or thick wire to trample down the concrete. As a result, there should be no empty spaces or air bubbles.

Some masters, answering the question of how to close holes in a concrete floor, recommend pouring in one go. This saves a lot of time and allows you to get a monolithic cork. This solution is considered correct when working with thin floor slabs and shallow holes. If the hole is quite large, then the filling is carried out in two stages, so that the solution in its volume does not crack or shrink strongly.

Given this approach, you need to let the first layer harden. Usually it takes no more than a day. Since the final hardening does not need to wait.

Advice! If the filling will be carried out in several stages, then you should not immediately prepare a large amount of the solution. The rest will have to be thrown away, which will lead to an overrun of materials.

The second stage of pouring is carried out according to the principle of primary concreting. In this case, you can also put glass on the bottom of the pit to completely eliminate the possibility of rats entering the room. After that, a layer of mortar, crushed stone and mortar is poured again.

When the hole is filled flush with the floor, the mortar is leveled with a spatula, creating a smooth surface. It is worth noting that if the surface is covered with tiles or other coating, then the alignment is done on the same level with the screed.

At the final stage, tiles or the coating used in this room can be laid on the floor. Usually, after repairs, there are always small pieces that should not be thrown into the trash.

Bottom line: answering the question of how to close a hole in a concrete floor and at the same time block access to the room for rodents, we considered the option of making a concrete plug. At the same time, the composition of the solution includes crushed stone, which rats cannot bite through, and the presence of glass bridges completely eliminates this problem. However, it must be remembered that such work should be done only after the rodents have left the premises. Otherwise, they will remain in the apartment and will not be able to go to the basement on their own.