Stages of construction of a concrete porch in a private house. How to make a concrete porch on your own? Step by step guide

In order to comfortably climb into the house, you need to make a porch. It can consist of one or two steps, or it can be at a decent height - it all depends on the basement of the house. In any case, the structure must be strong, therefore, before filling the porch, the site should be freed of all unnecessary things - the old porch (if any), debris, grass, young growth of nearby trees. Construction technology begins with this.

Preparatory process

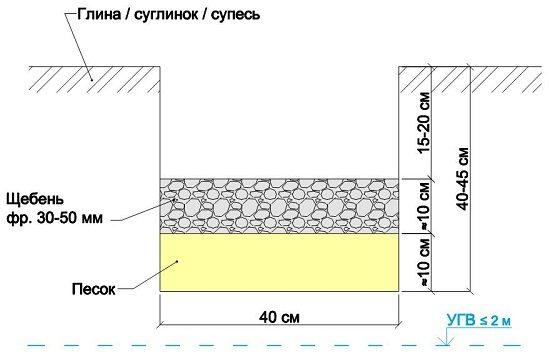

To build a comfortable porch in a private house, you should calculate the dimensions of the entire structure, prepare the site, and you can begin to build the foundation. The latter must be present, albeit small. And if the soil on which the house stands is clay, the pit under the foundation is pulled out deep enough (up to 70 cm) and strengthened with a mixture of sand and gravel. They are laid on the bottom, forming a kind of pillow, and only then they form the main foundation for the porch of a private house.

With dense soil, a hole 30-35 cm deep is enough. A porch made of concrete should be comfortable and safe - the site should be leveled, and only high-quality materials should be used. Since this structure will be constantly exposed to temperature changes and the influence of precipitation, it must also be especially durable, therefore the process of creating a porch is an exact adherence to technology and calculation.

Types of concrete porch

In addition to the size, you should also decide on the shape. It can be rectangular, square, round, oval. You can also attach a trapezoidal concrete porch to the house. It all depends on the taste of the owners and their imagination. But you need to make sure that the shape is in harmony with the overall appearance of the facade, otherwise it will look alien. A porch with a staircase can be located either on the side or on the front facade of the house (by the way, you can make several entrances, but then the process of building the porch will take a little longer).

Concrete is an excellent choice of material for creating a porch. It can be faced with stone, tiles, even wood and is stronger than other materials. It is not so difficult to create a monolithic concrete porch with your own hands if you follow the technology, but some nuances should be taken into account.

If the staircase is designed higher than 5 steps, you should leave holes for future railings even at the stage of concrete hardening. The same goes for the canopy - the supports for it are installed during the manufacture of the porch.

Design

- the width of the porch is made more than the door by 3-5 cm in each direction;

- and the height of the porch should not reach about 5 cm to the door frame;

- the pit for the foundation will be even slightly wider than the platform - by 4-5 cm (this is an allowance for the thickness of the boards for the formwork);

- you also need to count very carefully. It should be at least 30 cm - designed for an average foot size. And the height of the steps is about 20 cm. With a larger one, it will be difficult for children and people in old age to climb into the house;

- the upper platform is convenient with a width of 80-100 cm;

- the ladder should be made inclined - 30-45 degrees is quite enough. So the ascent will be comfortable, and the water after precipitation will not linger;

- the width of the staircase itself can be equal to the size of the upper platform - 80-100 cm.

Calculation of materials for the porch

At this stage of construction, you should find quality materials for assembly, pouring, reinforcement, and so on.

You will need:

- Formwork boards.

- Reinforcement mesh.

- Crushed stone and sand.

- Cement brand M400, and better M500.

- Waterproofing materials.

- Water.

- Fittings (screws and corners).

You can also take ready-made concrete. But mixing it with your own hands (more precisely with a concrete mixer) and controlling the amount of components, you can achieve better quality. To obtain a good solution, you should mix 1 part of cement with 2 parts of sand, but crushed stone needs 3.5 parts of the cement norm. For 1 cubic meter of concrete, about 190 kg of M400 cement will be needed. Therefore, in order to calculate the amount of material, you need to understand how many cubes of ready-made concrete will be needed for pouring. And do not forget about the layer of rubble and sand at the depth of the foundation.

As for the reinforcement, it is believed that at least 2 rods should be consumed for each step. Most often, they take material with a cell size of 10x10 cm. It fits best into the formwork. For reinforcement calculations, it is worth measuring the quadrature of the lowest step and multiplying this figure by the number of steps.

The boards will be used to create the formwork. For each tier, that is, steps, you should take 3 boards about 2 cm thick.Do not take too dry material - it will crack under the pressure of concrete. The frame blocks for the porch should be fastened together with self-tapping screws, and the corners will help to install them evenly. The latter are needed only for a square or rectangular porch.

Design features

If the foundation is deep, you can scatter any non-combustible debris along the bottom - foam blocks, broken brick, even glass. But from above, all this is covered with an even layer of a mixture of sand and gravel.

The reinforcement should be cut into pieces of the desired size in advance, it is laid not on the bottom, but on single-standing gas blocks or bricks - so it is all evenly covered with mortar and the concrete porch will be stronger.

Formwork on all sides can be additionally reinforced with pieces of timber or thick boards. The material for the formwork should be lubricated from the inside with a special compound - then it will be easier to remove it upon completion of construction work.

The concrete solution is sometimes supplemented with various additives, which give the required level of plasticity, make it frost and water resistant.

If a porch with steps is attached to an already erected house, it is necessary to leave a gap of about 10 cm between them. This is done so as not to damage the foundation of the house in case of possible deformation and create a so-called "expansion joint". In this space, you can lay a wooden shield and hammer it with glass wool.

Design advantages

- The main advantage is that you can make a concrete porch device with your own hands. If you correctly calculate the amount of materials, follow the technology and do not save on quality, it will be durable and beautiful.

- Materials for the arrangement need the most common, which can be easily bought. They are not a deficit.

- Such a porch is easy to make original, since it can be revetted with stone, tiles, wood, and other materials. You can also use a mixed version.

- The end result is relatively inexpensive. You can choose the shape and size.

Cons of construction

Sometimes the porch quickly begins to collapse - crumble, settle, loosen. This means that in the process of pouring its technology was violated. The porch of the house should be properly filled. As an option, a low-quality material came across, so its quality must be monitored especially.

Making the foundation

To make the porch foundation easier and faster to fill, in addition to materials, a small concrete mixer is needed. The solution must be developed within about an hour and a half after its manufacture, then it will harden and crumble.

The reinforcement rods are cut into pieces of the required size and fastened together with a wire. So the concrete staircase of the porch turns out to be durable and does not disintegrate over time. The finished porch steps can be additionally secured with corners.

You need to dig a hole according to the size of the foundation with an allowance of 2 cm from each side. Next, crushed stone with a layer thickness of 7-10 cm is placed on the bottom (you can add any construction waste to save material). The same layer of sand is laid on top, carefully tamping it. Sometimes sheets of roofing material are also placed on the sand. The site should be flat. This is followed by gas blocks, reinforcement and finally concrete.

Site preparation

It is thoroughly cleaned of everything superfluous - garbage, bushes, grass. If we do the foundation with our own hands, we dig a hole 30 cm deep (if the soil is strong enough). In case of doubtful soil, the depth of the foundation should be greater. Waterproofing and leveling of the site with sand and gravel are required. Pegs should be hammered along the perimeter of the site for the future formwork.

How to prepare concrete?

It is a mixture of cement, sand, and crushed stone in certain proportions. All this is poured into a concrete mixer and water is added. The consistency of the concrete should be doughy - not spilled, but also not too dry. It should be easy to spread with a shovel and tamp. Sometimes concrete is supplemented with special additives to improve its technical properties.

Reinforcement principles

The consumption of reinforcement for a medium-sized porch is about 160 meters. Its thickness should be at least 10-12 centimeters. Reinforcement is the binding of reinforcement with wire in a specific configuration. You cannot save on its quality, like other materials. At the edges, pieces of reinforcement should be left under the future railings.

Installation of a concrete porch

After preparing all the components, as well as the area under the porch, you can begin to install it. To know exactly how to make a concrete porch with your own hands, you can watch a tutorial video or work with experienced craftsmen.

The weather should be clear and moderately warm. You should go through all the stages one by one, without missing anything. 6-7 days after the end of work, you can begin to finish the porch.

We install the formwork

Boards for it are installed around the perimeter of the pit and secured with spacers. They should be wider than future steps due to the fact that part of it will go into the depth of the pit. The formwork for the porch is placed straight, fastened with self-tapping screws and, if necessary, corners. Stiffeners will also be needed - they strengthen the sidewalls.

If only dry boards are available, they should be moistened with water. The form of the formwork must exactly follow the outline. A trapezoidal concrete porch with your own hands is more difficult to create than a rectangular one, but it looks much more spectacular.

On concrete blocks or other support of at least 5 cm in height, reinforcement rods are laid, cut as needed. They are tied together with wire, preferably steel. Make sure that the fittings are not corroded.

Making a solution

It requires a cement grade of at least 400. The solution is strong enough. Cement is mixed with sand and crushed stone in proportions of 1: 2: 3.5, respectively. Then water is added for the required viscosity of the solution. The mixture is thoroughly mixed in a concrete mixer and after that it is considered ready. It should have a uniform, fairly plastic consistency.

Before making a concrete porch with your own hands, you should think about and check everything. Directly to concreting, you need to start fully armed, because after it there is already little that can be fixed. After the pit has been dug, a layer of sand and crushed stone is filled in, reinforcement and formwork are installed, concrete mix can be poured.

It must be compacted in the process of pouring the steps, carefully distributing it with a shovel over the pit. It is imperative to get rid of air bubbles that appear in the solution. It is better to place the stirrer as close as possible to the pouring point. We fill the porch of concrete in layers: we leave the first layer to freeze a little, then the second, third, and so on according to the number of steps follow. At the end, we cover the finished structure with tarpaulin or roofing felt.

Concrete porch cladding

To finish a concrete porch, you should first clean it to smoothness, you can manually, you can use special devices. After that, it is painted, revetted with stone, tiles or wood. Everyone chooses the color, shape and type of surface of the facing material independently.

Clinker tiles look great, besides, they also do not slip. Many people opt for porcelain stoneware tiles. The veneering process is the same in both cases. The surface of the tiles is lubricated with special glue and firmly pressed against the desired section of the porch. When the cladding is finished, cruciform spacers are inserted into the seams to prevent the tile from slipping. Then they are removed, and the seams are rubbed with a special mixture. On this, the device of the concrete porch can be considered complete.

Final step-by-step instructions

So, in order to properly fill the porch with concrete, you need to do the following:

- Clear the place.

- Dig a pit.

- Install the formwork.

- Make waterproofing, fill the bottom with rubble and sand, you can debris, compact.

- Make sure that the surface of the concrete floor is even, cover it with pieces of roofing material.

- Install gas blocks, lay the prepared fittings on them, tie the rods with wire.

- Repeat all steps starting from the formwork by the number of steps.

- Fill all the steps with concrete solution in stages.

- Cover the finished structure with roofing felt or tarpaulin.

- After a week, you can remove and clean the surface.

- Make the cladding to your liking.

The result is one of the most beautiful structures - a do-it-yourself porch that you can be proud of.

Making a porch of concrete with your own hands is not difficult. But first you need to think over all the details so that, entering the house, you do not stumble over uncomfortable steps, and the structure itself will serve you for many years. The concrete porch is very popular with private home owners as it does not rust or rot. The materials are inexpensive, and you can assemble the formwork and pour concrete into it on your own. In addition, manufacturers offer a wide variety of finishes, so no one will ever know what your porch is built from.

It's always hard to get started. Questions about the shape, decoration, the number of steps and other things will immediately arise in my head. A good drawing and calculation of all materials will simplify the work itself.

First, it must be comfortable and safe to walk. Therefore, equip a small area in front of the door, it should be 50 mm lower than the door. Build the stairs at an angle of 25 to 45 degrees. The recommended step height is 200, and the width is at least 300 mm; these are the stairs that are made in multi-storey buildings. If the steps are higher, children and the elderly will not be able to walk in easily. The porch itself should be no narrower than 0.8 m, this place is enough for one person to walk freely on it.

2. Foundation.

The question of whether to build a foundation for a concrete porch or not has no unambiguous answer. It all depends on the structure itself and the type of soil. If you need a regular staircase of 3-5 steps with a small landing in front of the door, and your house is located on good soil, you do not need to make a deep foundation. But if you have already drawn a drawing of a huge staircase with a canopy, and the house is on clay soil, you will have to pour concrete on a reliable foundation. Since it would have to write a whole book to consider all the options, in this instruction we will analyze how to make a porch from concrete with a small foundation.

Clear debris and plants from the area. Dig a hole at least 300 mm deep. We recommend insulating the future structure with expanded polystyrene or other material that does not allow steam and moisture that forms in the soil to pass through. This will not only add strength, but also extend the life of the finish.

If you decide to completely fill the future porch with concrete, pour a layer of rubble 50 and a layer of sand 100 mm soaked in water into the pit. To reduce the consumption of materials for a medium-sized structure, you can not do a complete concreting of the entire space, for this add sand to the height of the upper platform and stairs, compacting it well.

To build a solid large porch on unstable soil, it is necessary to build at least a columnar foundation; there are detailed instructions on the Internet on how to correctly make and fill the pillars with concrete. Otherwise, the system will be unreliable.

Another question that can only be answered by knowing all the characteristics. It is better to tie the porch to a new private house, which did not have time to settle, ideally fill the foundation and the landing with the stairs at the same time. The problem of binding to an already settled house is resolved on an individual basis, since due to the uneven rate of shrinkage in unstable soil conditions, there is a high probability of rapid cracking. The formwork design will depend on the decision you made.

3. Formwork.

For the side and bottom edges of the formwork, plywood reinforced with a bar or solid boards no thicker than 20 mm is suitable. If the wood is dry, moisten it, and shave off the places that will touch the concrete. The formwork should be 200-300 mm higher than the future porch, depending on the strength of the soil. Use screws and corners to fasten the parts. Make sure that there are no gaps. Strengthen the system with strong supports.

First, the side formwork is installed, it should be at a distance of 100 mm from the wall, if you decide not to tie the porch and the house. Roofing material is attached to this space and a layer of sealant is applied. Then the boards are mounted to outline the contour of future steps. After that, the formwork is lubricated from the inside with a special mixture to facilitate the analysis of the structure.

4. Reinforcement.

We recommend using ribbed fittings. The elements are connected to each other with soft wire or welded. To make the porch one whole with the house, drill small holes in the adjoining wall and insert the ends of the fittings there.

The distance between the reinforcement layers is 150 mm, and the step in either direction is 150-200. Additionally, it is necessary to outline the contours of each step. The minimum distance to the formwork is 40‒50 mm.

5. Preparation of concrete mix.

If you decide to buy ready-made concrete, the M150 ‒ M200 grades are suitable. To save money, you will have to dilute the mixture yourself. It is better to take a household concrete mixer from someone, since the material instantly freezes if it is not in motion.

To make concrete, you need:

- cement М400 ‒ М500;

- crushed stone 10 - 35 mm in size;

- sand with particles 1.2 - 5 mm;

- water.

Table of proportions for the preparation of concrete mix:

The proportion of water can vary from 0.5 to 1 part depending on the materials. Do not overdo it, otherwise the concrete will lose strength.

For concreting to be successful, it is important to follow the technology from start to finish. There are special additives to improve the properties. If you are not using a vibratory compactor, add plasticizers to make the job easier.

6. Concreting.

To properly fill the porch, start concreting at the bottom of the stairs. After pouring each step, spread the concrete evenly over the formwork using a stick or vibrating compactor.

7. Stripping.

Since the concrete will reach its stated strength after 28 days, ideally wait a week after you have poured the structure. If time is running out, leave the mixture for at least 2-3 days.

1. If it is very hot during work, pour water on the concrete every day to avoid cracking.

2. When concreting, it is convenient to use a vibrating compactor. This procedure will give the structure strength, and it will be easier for you to evenly distribute the mixture.

3. To save money, some builders suggest using crushed bricks, broken glass, stones and other debris instead of sand and gravel. If you want to build a porch that will fall apart after the first winter, give it a try.

4. It is more convenient for a person to start and end the ascent with one leg, so make an odd number of steps.

5. It is better to pour concrete in clear weather, a suitable temperature is +20 degrees.

6. The surface of the steps is equipped with a slope of 5 mm so that water can flow freely from them.

7. If you decide to make a semicircular porch, it is convenient to assemble the formwork for the degrees from thin plywood, galvanized.

Finishing options

The advantage of a porch made of concrete is a wide selection of finishing materials. Economical craftsmen make drawings immediately after concreting using templates or lay out patterns from pebbles, it is inexpensive, but requires attention and patience. There are other options as well.

- Granite and marble cladding. Looks gorgeous and holds well. Another thing is that a small private house against the background of this splendor can be lost.

- Clinker tiles. Durable, non-slip, looks very presentable.

- Porcelain stoneware. In terms of quality, it is not inferior to clinker, but is cheaper.

- Concrete and paving slabs. An inexpensive option, but it gradually crumbles, and made by the vibro-casting method slides.

- Wood. It is not always reliable, but it looks harmonious with a wooden house.

You can combine several options to create a homely and inexpensive porch. For example, wood and concrete tiles or granite and ceramic tiles. It is important to choose a reliable material so that its beauty will delight you for a long time.

Every home owner wants to make a reliable porch that would last for several decades. One of the most reliable materials is concrete. A concrete product can be attached to both brick and wooden houses without much difficulty. To decide on the creation of such a porch, it is worth considering the advantages of structures from the described material.

Advantages of a concrete porch

Even a person who has no experience of such work can build a porch from concrete. Concrete structures have the following advantages:

- Strength. Unlike other building materials, concrete can last for decades and retain its previous condition. Moreover, the materials that are needed for its construction have an acceptable cost.

- Ease of creation. You don't need to hire a technician or use professional tools to build a concrete porch. For work, you will only need materials for creating a solution, reinforcement and wood for formwork. A distinctive feature of a concrete porch is its solidity, which contributes to an increase in strength.

- The ability to experiment with the look. For finishing a porch made of concrete, you can use wood, tiles and other materials. The owner of the house can choose any material that will look good with the decoration of the house.

The construction of a concrete porch takes a small amount of time, but in order to do all the work correctly, you need to find an assistant.

Porch design

To properly build a concrete structure, it is necessary to accurately design its dimensions. The number of steps, their height and width are also calculated. The optimal width of the entire porch is a distance of one and a half meters. If the porch is narrower, it will be difficult for two adults to disperse when they meet near the entrance to the house.

The height of the steps is usually 15-20 cm, depending on the average height of the people living in the house. The width of each step should not be less than 267 cm, otherwise it will be uncomfortable for an adult to move along them. The drawing describing the structure device must contain the dimensions of all elements of the future structure.

If the porch is being made for a new wooden house, it should be below the level of the door. This is due to the fact that after shrinkage, the door may be lower than the created structure. Only after a drawing has been drawn up, which describes in detail the device of the porch, can you begin to create the formwork.

Making a solution

A concrete porch is created in much the same way as a strip foundation. When using the mortar, it is important to ensure that it completely fills the voids in the frame. If empty spaces remain in the structure, it may deform during operation. To prepare the solution, you need the following components:

- crushed stone;

- sand;

- cement.

The solution is mixed in a ratio of 5: 3: 1. To calculate the required amount of concrete, it is worth determining the volume of the future structure. In order not to waste time creating a mixture, you can buy a ready-made concrete solution. After mixing, the concrete should have such a consistency that it flows off the shovel, but does not fall apart.

Since reinforcement is made to create a solid structure, it is worth purchasing metal rods before construction. You can even fix the frame with your own hands. To do this, it is enough to correctly calculate the location of each rod and fasten them with wire.

Porch construction stages

The process of creating a concrete structure is divided into several stages:

Advice! The metal frame should be placed not just on crushed stone, but on wooden pegs, so that after the process of pouring concrete, the frame is completely in the solution. This prevents corrosion on the material.

After the work carried out, the rest of the formwork elements are fixed, after which the frame becomes suitable for pouring concrete. When building a porch, you should not associate it with the foundation of the house, since in the spring the foundations may suffer during defrosting.

Pouring solution

Do-it-yourself pouring only after the frame is completely created and well fixed. In order for the porch to be reliable and not have voids in the concrete, it is worth pouring the material at a time. After preparation of the solution, pouring and leveling takes place.

To prevent voids from forming inside the material, you can use a wooden stake, piercing the space between the reinforcement rods with it. But it is best to use a construction vibrator. Due to vibration, the composition will be evenly distributed throughout the entire space of the formwork. If this is not done, voids may appear in the concrete, which will lead to cracks in the finished structure.

After the end of the pouring, the concrete is covered with a film. At this stage, it remains only to wait until the material is completely dry. It is worth remembering that the top layer should not completely dry out, as this will lead to cracks.

The formwork is removed after about 5 days, but the strength increases over the next month.

Construction options and construction finishes

If you want to make your home beautiful, you should consider creating a semicircular concrete porch. In this case, not wood is used as the material for the formwork. And the tin sheets. The rest of the construction process is no different from that described. With the help of formwork, you can create various forms of the structure, making it more suitable for a particular house.

The cladding can also be different. Most often, porcelain stoneware is used as a finishing material. This is due to the fact that it is durable and can be made in various shades. At the same time, you can do everything with your own hands even in the absence of experience.

Other materials such as natural stone, wood or composite materials can be used. But in any case, it is worth paying attention to several requirements for finishing the porch:

- The porch surface should not be slippery. If you use material with a smooth surface, moving around the porch during rain or ice may cause injury. Even if you have chosen a beautiful material that matches the style of home decoration, first of all, you should evaluate its safety.

- Resistant to wear and tear. To prevent the porch from losing its former appearance after a few years, it is worth choosing a material that will not scratch or fade with frequent use.

- Aesthetic characteristics. After determining the most reliable material, you should think about its beauty.

Laying cladding material

In order to install the cladding, it is not at all necessary to have experience in construction. To do this, it is enough to clean the concrete surface from dust and dirt, and then fix the material. If tiles are used, a layer of glue is applied to the concrete, after which each trim element is gently pressed against the surface. Plastic crosses are placed between the tiles so that the distance between them is equal, and each element is located exactly relative to the others.

Massive structures like concrete porches are capital structures that, subject to all technologies during pouring, will serve their owner for many years. Despite the apparent simplicity and rudeness, you can create truly beautiful and original products from this material, of course, with subsequent cladding, which we will talk about a little later.

So, today's article will tell you how to fill a porch with concrete - videos, photo galleries and detailed instructions are attached.

A porch is a necessary element of any structure, even if it is installed on a very low foundation. Entrances in multi-storey buildings, in fact, are also porches, simply perceived by residents a little differently.

Porch purpose

We will not go into simple arguments about the indispensability of this element of the facade of buildings, we will name only the most basic of them.

- A beautiful porch in front of the house is, first of all, a weighty accent spot that attracts the attention of not only its inhabitants, but also frequent guests and passers-by, unless of course you have surrounded the site with a three-meter fence.

- It follows from this that a small porch or a massive terrace is a decoration of the facade of the house, endowed with functional duties.

- This element provides a safe ascent to any base / plinth height, and can be composed of both several steps and impressively sized heavy flights of stairs of various configurations.

- The porch, equipped with a canopy, prevents rainfall of all types from entering the adjoining area and the entrance group, and also protects them from exposure to ultraviolet radiation.

- Closed structures are light extensions to the main structure, completely protecting the entrance from the vagaries of bad weather. Inside, such a veranda can be equipped with wardrobes for outerwear, shelves for storing dirty shoes, arrange a place for storing sports and household equipment from it, create a portable greenhouse or make a place for relaxation.

All of the above is just a small part of the possible advantages of a porch. For the most part, in this matter, everything depends on the owner's imagination, his hobbies and specific needs.

What is the best way to build a veranda

Traditionally, four types of material are used for the manufacture of this structure:

- Concrete;

- Brick(concrete blocks, artificial and natural stone and other similar materials with a block structure);

- Metal;

- Wood.

Each of which has certain advantages and disadvantages.

You can also often see structures that combine the above materials.

For example, wood is combined with stone. The photo shown shows a "heavy" outwardly structure with a clear contrast between the materials.

Here's another example of a heavy construction. However, to visually make the composition easier, transparent lace is forged from metal. Pay attention to how many different materials were used to decorate the porch and all this looks harmoniously against the background of the main red brick facade.

So what to use for construction? We will answer immediately, without hiding. The first thing that determines the type of material is the type of building, and the material used to build it.

The porch is an integral part of the facade and should harmoniously blend into its style. If you do not know the basics of design in order to fit the veranda into the overall picture with emphasis, that is, by combining the texture and color of the details, then there is only one piece of advice - concrete to concrete, wood ... well, you get the idea.

Advice! Never forget that an attached porch can not only decorate the appearance of a building, but also spoil it. Therefore, with a lack of experience, it is better to turn to specialists or try to avoid extravagant ideas, since an inexperienced person is unlikely to be able to imagine in advance what the building will look like after.

Although, perhaps, we will not resist and name the main advantages of concrete structures.

As you know, the porch is operated in difficult conditions that negatively affect it:

- Constant moisture that is transferred to the substrate through the soil;

- Contact with atmospheric precipitation, from which even the canopy over the structure cannot protect one hundred percent;

- Temperature drops - the effect of frost is especially negative, in combination with icing of the surface, to combat which (due to the impossibility of using brute physical force, so as not to damage the cladding material), salt and chemical reagents are used;

- Constant mechanical loads - people regularly walk on the stairs and the platform and bulky massive loads can move: furniture, building materials ... pianos and so on.

Concrete is one of the most durable building materials

Concrete structures cope with all these troubles with a bang! Increased humidity over time only strengthens the concrete, it easily tolerates severe frosts and is resistant to abrasion.

Besides:

- With the help of concrete, you can fill in figures of any geometry - it all depends on the skill and imagination of the master who forms the formwork;

- Concrete construction, although laborious, does not require super professionalism - it is enough to comply with all norms and requirements;

- The material does not burn and has a high fire safety score;

- Affordable price of basic materials.

Well, if we compare the terms of its operation, say, with wood, then concrete is several times superior in this parameter to a competitor.

Concrete porch construction

Well, now, let's take a closer look at how to fill the porch with concrete. And we will start with the most important thing ...

Design

Layout is an integral part of any serious work, so we will not even talk about its importance in the construction of a porch.

It is best when the veranda is designed during the construction phase of the main structure. It can be attached or erected together with the house in the form of a monolithic structure. But if you did not take care of this issue in advance, it's okay, everything is fixable - the main thing is to make sure that the extension does not in any way affect the strength of the foundation of the house.

Let's list the basic requirements for concrete verandas, which must be taken into account in advance.

First, about the dimensions:

- Maximum porch height must correspond to the distance from the surface of the ground to the doorway, without reaching 5 cm, taking into account the subsequent cladding. This technological gap is necessary for the unhindered opening of the door in the season of strong soil movements under the porch.

- Width of the area in front of the house depends on the type and width of the door: for a single-leaf door, 1.6 m is taken as the minimum value; for double doors - 2 meters. If the specified parameters are observed, the door will open without hindrance.

- Depth (distance from door to steps)- should allow a person standing on the site to open the door without hindrance. The maximum width is not limited, but do not forget to take into account the total length of the veranda along with the flight of stairs. For convenience, you can orient the steps so that they run parallel to the wall, not perpendicular.

- If not only adults live in the house, but also small children, or people with disabilities, then you can plan a ramp with a slight tilt angle of 1:20, along which it will be convenient to lift a stroller or bicycle.

- The width of the flight of stairs should not be less than 80 centimeters- this parameter is designed for the movement of one person. If you need to make a passage for the simultaneous consumption of two people, then the minimum value increases to 1m 20 cm.

- The steps also have the recommended parameters., observing which you will ensure an acceptable angle of inclination, and make movement on the porch safe: the height varies from 15 to 20 cm, and the depth - from 25 to 33 cm.

- Also note that the ratio of height and depth should fit into the following formula: 2x + y = 60 (64), where x is the height of the step, and y is its depth... This requirement is purely related to the physiology of the average person who has a stride width in the specified range.

Now, a hundred touches the shape of the future porch:

- In fact, it has no limitations. The main requirement is that the structure is successfully combined in size and shape with the main building.

- Any porch with more than two steps must be equipped with a parapet and railings for safe movement on it.

- A canopy is also welcome. It will not only decorate the facade, but also make the entrance group more comfortable for a person to stay. Agree, looking for the right key in the pouring rain is not a pleasant occupation.

Canopies can be built capital, planned even before the construction of the house, or light - based on wood and metal frames. It all depends on the design project.

Concrete porch foundation

Whatever the design of the planned porch, it must be equipped with a foundation. Especially thoroughly this issue should be approached when erecting buildings of brick and concrete, since they have an impressive weight.

What you need to know before you start pouring:

- Any foundation always sinks into the ground below the freezing point of the soil, at least 15 centimeters. You can find out such information in geodetic bureaus or on the Internet - it differs for each region.

- A sand and gravel cushion is prepared for the foundation, protecting it from excess moisture.

- The foundation can be strip, in the form of a solid slab or made of blocks. The last option is made faster than the others.

- A columnar option is also suitable, which will greatly reduce material consumption.

Advice! If the porch is small, then you can make a monolithic structure, filling both the foundation and the staircase at the same time. To do this, a pit is dug, a reinforcing bundle is installed and the formwork is immediately mounted on the entire structure.

It is best when the foundation under the porch is poured simultaneously with the foundation of the house, forming a monolithic structure. But if you have not taken care of this in advance, then you will have to decide whether you need to link these constructions together.

Both options are possible, but with specific caveats:

- If you are going to build a massive porch, then it is worth considering the degree of its shrinkage. It will differ from the drawdown of the main structure due to the difference in masses. As a result, very often in the places of abutment, the foundations give cracks, which negatively affects the strength of the foundation of both the building and the extension.

- This usually happens in cold seasons, when the force of heaving of the soil, affecting the buildings, is greatest. It is worth noting that not only the capital parts of the structure suffer, but also the cladding. Very often you can see a picture on the street with tiles falling off on the facade of a building.

- A similar problem also arises as a result of improper waterproofing - after complete hardening (28 days), the foundation is covered with a waterproofing layer of rolled covering materials, for example, roofing material.

- To avoid such consequences, the pouring of the steps of the porch with concrete and its foundation is carried out with the organization of an expansion joint, which is filled with hard mineral wool or rubber seals.

- The optimal width of such a joint is 20 mm - this is quite enough to compensate for the difference in the shrinkage of structures.

But if the ligament is not completed, the structure can sag heavily and become uncomfortable. From here we will derive a certain rule.

If you are making a lightweight structure, then you can safely perform a bundle using powerful anchors or pieces of reinforcement for this purpose. If the porch is heavy and oversized, we must make an expansion joint.

How to make a concrete porch

There are three technologies that can be used to build a concrete porch:

- Pouring a concrete porch from monolithic reinforced concrete is perhaps the most widespread and attractive technology today. With its help, you can make a porch of almost any shape, taking into account the final strength and the skill of the master who performs the pouring.

- The use of ready-made reinforced concrete products for construction is the fastest option that allows you to complete the work as soon as possible. Such a porch is made quickly, but its aesthetic component suffers greatly, since the finished forms greatly limit the designer's imagination.

- Well, the last, prefabricated-monolithic version is a symbiosis of the two above-mentioned methods, which means it has their pros and cons.

Do not forget that concrete is only the basis of the porch, which in 99% of cases will be lined in the future.

Installation of a monolithic porch

Now let's take a closer look at the listed methods and list the order of the work performed.

Pouring a porch is not much different from creating other monolithic structures.

- First of all, we mount the formwork. Usually boards are used for these purposes, but for the steps it is better to choose the option from plywood or OSB panels, which will make the walls of the steps smoother. In addition, these materials can be used to create bent structures for radial or curved steps.

Advice! Fasten each part of the structure carefully so that it can withstand the large mass of concrete poured into it.

- Next, we place a reinforcing frame inside the structure. For this, reinforcement is used that can be welded or tied with a steel bendable wire - the strength of concrete does not change from the tying method, but the second option is performed faster than the first.

- It is mandatory to install clamps for the concrete cover, which will raise the reinforcing cage above the ground and hold its position during pouring.

- If necessary, attach embedded elements to the reinforcement.

- Having finished the frame, fill the structure with concrete. For small volumes, you can use a compact concrete mixer, and for some serious ones, you can order a mixer.

- Pouring requirements are standard: work is performed without long interruptions, concrete is carefully compacted.

- In order for the mixture to evenly fill the voids, and all the air out of it, the structure is subjected to vibration. For this, special vibration machines are used, in the absence of an electric tool, the formwork is tapped around the entire perimeter with a hammer.

After pouring, we level the concrete surface with a trowel and a trowel, removing excess if necessary. Further, the concrete remains to dry, and we only need to cover it from precipitation with plastic wrap, which, moreover, will reduce evaporation. We periodically moisten the concrete surface so that it does not crack.

After the main mass has hardened, the demountable formwork can be dismantled.

Advice! If you do not plan on further exterior finishing, it is recommended to sand the concrete to a smooth state.

Prefabricated structure

A porch made of ready-made reinforced concrete parts cannot be carried out independently. This is due to the fact that some elements can weigh several tons, which implies the use of heavy lifting equipment. Plus, you need the services of a professional welder.

But with proper organization of work, it will take a minimum of time - an average porch can be assembled in a few hours.

The procedure is familiar to us from childhood - we learned it by collecting constructors:

- The element is put into place;

- It is securely welded to the mortgages - the seam is not made along the entire length, so that tension does not form between the elements;

- The joint is sealed with mortar.

Now you can decorate your porch however you want. The third method does not need separate comments. We have already announced everything that you may need.

Concrete porch cladding

Concrete surfaces can be finished with a variety of facing materials. Let's list the most popular ones and provide a few photos.

- Ceramic tile. I would especially like to note the clinker grades, which are almost the best option for cladding. Such a porch will always attract the attention of the viewer, and will delight the owner with its appearance for many years in a row.

- Another popular material with excellent performance characteristics. Such tiles can imitate various natural materials, and also have a large assortment of colors and textures.

- Made of concrete and molded to imitate natural stone. It fits like a regular tile.

- Rough concrete tiles go well with equally heavy facades.

- But to this state, you can polish the concrete. Such a coating does not need maintenance for many years.

- Rough natural sandstone is solid, beautiful, and most importantly practical. This solution will very well fit into the facade of a country cottage.

- Tiles made from natural materials are made by cutting from whole pieces of the mineral. As you might guess, this is not a pleasure for everyone.

- WPC garden parquet is an excellent modern solution. Such a terrace is not afraid of scratches, water and ultraviolet radiation, which means that it will retain its original appearance for a long time.

- Where are we without a tree. This material does not lose its relevance for hundreds of years in a row, and is perfect for cladding concrete surfaces.

Seamless rubber tiles are an original, practical, comfortable, safe modern product that will transform the look of your porch beyond recognition.

Here's a short summary. After reading the material, you learned how to pour concrete steps for the porch - the procedure will be within the power of any person "with hands". If you also want to see the process in action, then watch the video in this article. That's all! Good luck!

How to make a concrete porch with your own hands?

An integral element of a country house, a stylish cottage and a private building is an attractive porch equipped with a canopy to protect from precipitation and sun rays. Among the materials that can be used for its construction, reinforced concrete stands out. It ensures the durability of the structure and is practically unaffected by natural factors. It is not difficult to build a solid and original porch made of concrete with your own hands, following the recommendations of professional builders. In the presented article, we will dwell on this issue in detail.

Making a concrete porch - preparing materials and tools

Thinking about solving the problem of how to make a porch of concrete with your own hands, you should first of all purchase the materials necessary for the work, prepare construction tools.

Familiarization with home improvement begins with its appearance and porch. A solid building requires a secure and solid entrance

The main position in the list of building materials is occupied by a concrete solution of the M100 – M200 brand, which can be purchased ready-made or prepared independently from the following ingredients:

- Portland cement grade M400 – M500, which binds the components of the mixture;

- sand cleaned of impurities, which determines the consistency of the solution;

- gravel or crushed stone of the middle fraction, which are the filler;

- technical water introduced according to the recipe.

To complete the work you will also need:

- steel reinforcement, 0.6–0.8 cm in diameter, used to strengthen the array;

- knitting wire that allows you to combine the elements of the power frame;

- wooden blocks used for the manufacture of the formwork frame;

- planed boards required for sheathing beams;

- nails or screws holding together the elements of the wooden formwork;

- fragments of used bricks, facilitating the filling of the volume;

- sheet roofing material that acts as a waterproofing material.

Instead of boards, it is allowed to use sheets of moisture-resistant plywood when constructing the formwork. Most of the tools and equipment needed to complete the work are present in the arsenal of home craftsmen.

The use of reinforcement can significantly improve the strength characteristics of the porch

You need to prepare:

- concrete mixer, facilitating the process of mixing components;

- shovels for feeding the components into the container and loading the ready-made solution;

- vibration compactor, for ramming the poured solution;

- a grinder with a cut-off wheel for cutting steel bars;

- a saw for wood, necessary for cutting beams and planks;

- building level and tape measure for control operations;

- traditional set of tools (hammer, spatula, perforator).

After determining the need for materials to perform the work and preparing the tool, you can proceed to the next steps.

Concrete porch - preparatory work and calculations

Before starting work, it is necessary to complete a set of preparatory measures:

- Dismantle the existing entrance structure.

- Free the area of work from construction debris.

- Measure the distance from the zero mark to the door threshold.

- Calculate the height of the steps by dividing the height of the platform by their number.

- Calculate the dimensions of the door platform, focusing on the width of the door opening.

Before buying materials and tools that will be needed in the work, you should initially decide on the type and shape of the porch being made.

Determining the minimum possible dimensions of the site, it is necessary:

- add 15–20 cm to the width of the door opening;

- the depth of structures should be at least 100 cm.

At the design stage, it is necessary to decide on the following parameters:

- the configuration of the entrance staircase;

- constructive performance.

The shape of the entrance staircase may resemble the following figures:

- trapezoid;

- a circle;

- square;

- rectangle.

Execution options:

- open access;

- in a closed version;

- with glazing;

- with railings;

- without railings.

Design and shape are decorative characteristics. They are determined depending on the aesthetic views of the owner of the premises and his financial capabilities.

The size of the area in front of the entrance to the house should be such as to ensure optimal opening of the front door.

When carrying out work on the design of the entrance staircase, you must pay attention to the observance of the recommended dimensions, which should be:

- entrance width - 0.8-1 meter and more;

- staircase slope - no more than 40-45 degrees;

- step width - more than 250 mm;

- the distance between the steps is 16–20 cm;

- overhang of the step support platform - up to 30 mm;

- the distance from the door opening to the level of the upper platform is up to 50 mm.

Based on the results of preliminary calculations and determination of structural parameters, the need for mortar is calculated, as well as the approximate number of steel bars for the construction of the reinforcing cage.

Before starting manufacturing activities, remember the main rules:

- the depth of the foundation for the main staircase must correspond to the distance from the zero mark to the lower plane of the base of the building;

- must represent a single structure with the building, which is ensured by mutual reinforcement with steel bars;

- the durability of the concrete structure depends on the brand of the solution used, as well as the high-quality waterproofing.

Shapes and lines of the concrete base must match the architectural style of the house

Making a porch from concrete - preparing the foundation

Work on the construction of the foundation is carried out according to the results of preliminary calculations, as well as after determining the size and shape of the structure.

Prepare the foundation for the construction of the main staircase on your own according to the following algorithm:

- Mark the platform using the outline.

- Remove the soil, ensuring that the pit is at least 0.5 m deep.

- Fill the base of the trench with a sand and gravel cushion in a layer of 0.2 m.

- Plan the surface, compact the array, spill with water.

- Fit the wooden formwork frame in the excavated trench.

- Waterproof the formwork surface with foil or roofing felt.

- Drill holes in the adjacent wall, hammer in the reinforcing bars.

- Provide a distance between the horizontal rods of at least 100 mm.

- Install the vertical reinforcement 0.2 m above the zero mark, fix it.

- Prepare a mortar of sand and gravel cement, taken in a ratio of 1: 3: 3.

- Fill the panel structure with concrete, compact it, plan to level.

- Keep it still until moisture evaporates and the curing process is complete.