Water deironing system based on a homemade aerator. Types of homemade aerators for the lawn Do-it-yourself compressor for aeration on the board

A private pond is a worthy decoration of any site, a great place to relax with family and friends, as well as an excellent haven for a variety of flora and fauna. In order for the country pond to always remain clean, it needs to be looked after. One of the most important components of pond care is the organization of the aeration process.

By reading the information below, you will general idea about aeration as such and consider the features of its organization in cold period of the year.

The aerator in its traditional sense is a hydromechanical device, through which the forced supply of oxygen to the reservoir is carried out and the water flow is organized, which minimizes the risk of the pond "blooming" due to stagnation.

There is no need to talk about the need to supply air to the reservoir: firstly, the inhabitants of the pond breathe oxygen, and secondly, aeration contributes to additional water purification - reacting with oxygen, pollution collects in foam on the surface of the water or accumulates in sediment.

Factory-made aerators are relatively expensive - they, in fact, account for one of the most significant cost items for arranging a private reservoir. But here, as they say, it is better to spend money once and not know the problems than to constantly think about how you can once again reanimate the pond.

Features of devices for pond aeration in the cold season

Aeration must be adequate throughout the year. The situation remains relevant even in winter: the ice shell on the surface of the reservoir does not allow oxygen to penetrate into the water, and this already threatens the death of the inhabitants of the pond.

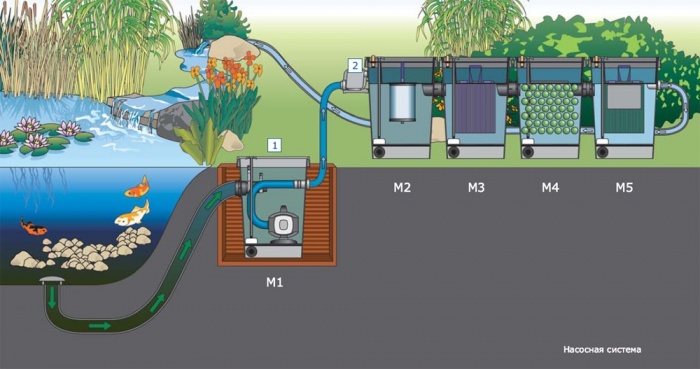

Pond aeration - scheme

In addition, if you leave the pond without aeration for the winter, there will be no current in the pond and it will most likely freeze through, which is also unlikely to benefit your pets.

Factory aerators

The modern market presents a large selection of aerators for private ponds. Of the factory-made units, it is worth noting the bottom models, which the best way suitable for winter use.

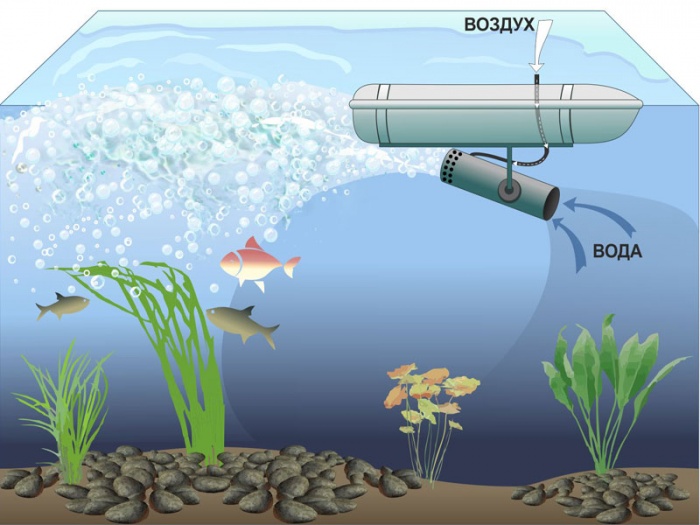

The setup is this: the air atomizer is placed at the bottom of the reservoir at its deepest point, it is connected by means of a hose to a compressor installed on the shore or in the room, the latter is connected to the mains and the aeration process starts. The air supplied directly under the ice floats up, at the same time creating a current and eliminating the possibility of freezing of the reservoir.

In terms of their power indicators, bottom aerators noticeably outperform even the most productive surface models, because. are capable of delivering oxygen more intensively while simultaneously ensuring its most uniform distribution in the water.

Important advice! When choosing an aerator, consider not only its power and the size of an artificial reservoir, but also the needs and life preferences of the inhabitants of the latter. Not all representatives of flora and fauna will favorably react to a surface aerator. The installation of a bottom unit will avoid such problems and eliminate the risk of adverse effects on plants, fish and animals.

Homemade aerators

If you wish, you can give preference to a homemade aerator. In the case specifically with the cold season, the choice will be limited to submersible type devices and wind deflectors. About them in the table.

Table. Types of homemade pond aerators

| Varieties of models | Description |

|---|---|

| Assembled like this: take Automobile compressor, connect a supply hose to it, connect the other end of this hose to the membrane. The membrane can be made from a perforated pipe, plugged on one side. The car compressor is located above the level of the pond. The plug and hose are lowered into the water. The compressor is connected to the mains and the aeration process begins. In winter you can use a hose greater length to be able to install the compressor indoors. In this case, the hose will need to be pre-buried below the freezing level of the soil. If a excavation seems too laborious, you can run the hose on the ground, wrapping it with any suitable thermal insulation, and tie a load of such weight to the spray head so that the membrane sinks to the bottom and stays there. |

|

| From their factory wind aerators homemade variety differs, first of all, in the absence of a compressor: the transfer of wind energy is carried out on the blades installed in the water. The model cannot boast of a beautiful appearance, but it copes with its tasks by 100%. The design is somewhat more complex in execution compared to the above option. Here you will have to assemble the bed, the movable shaft, and the blades into a single complex. When determining optimal length shaft, we focus on the depth of the reservoir. The main disadvantage of this design is the dependence on climatic conditions. For regions with prolonged and severe frosts, models with a compressor are best suited, though. in such conditions, wind deflectors are often covered with ice - even a few hours of calm weather will be enough. |

Having decided on suitable type design, pay attention to its key technical characteristics. About them further.

What to consider when choosing an aerator?

Firstly, decide on power. To do this, we need to know the volume of the artificial reservoir. We determine it and compare it with the information given in the manufacturer's instructions for the aerator you like. We buy a structure with a certain power reserve - if we take everything accurately and under the calculation, the structure will work for wear, which will lead to a significant reduction in its service life.

Secondly, we pay attention to climatic conditions of the area. Even a "winter" aerator will have its own lower permissible temperature limit.

Thirdly, we take into account the features of the aerator. It is unlikely that you will be happy to install a device that is too noisy near your home. And the inhabitants of the pond will not like such tests with sound.

Fourth, we pay attention to the presence / absence of the possibility of changing the modes of operation of the structure. Do not forget that in winter and summer water requires a different degree of aeration.

Fifth, pay attention to the manufacturer of the design. German brands are recognized world leaders. But, if you are planning to purchase a modest aerator to service a miniature country pond, focus more on the budget and elementary prudence - it is unlikely that a quality product will be sold too cheaply.

Aerator for reservoirs "AQUA-MINI". Instruction. Download file

Remember a few helpful tips:

And the last point that you also have to decide: buy an aerator in ready-made or do it yourself. Decide for yourself: a professional design for aerating a medium-sized pond costs at least 40-50 thousand rubles, for a large pond - from 100 thousand rubles, depending on specifications, manufacturer and other important points. Along with this, if the issue of improvement is being solved small pond on the suburban area, with a high degree of probability, a design with a power of about 100 watts is enough. Buying equipment with such characteristics, it is quite possible to meet 10 thousand. For the rest, the choice is yours.

Video - Aerator for a pond in winter

AT recent times it became fashionable to arrange various artificial reservoirs on individual plots. However, few people initially imagine that they require quite a lot of care. With improper maintenance of the pond, various putrefactive processes occur in it, the dominance of algae, which causes the water to bloom, increased bottom sediments (siltation).

One of the most effective and simple ways Prevention of all these problems is the forced saturation of water with oxygen. It is for these purposes that aerators for reservoirs are used. These hydraulic mechanisms have another name - air compressors.

Their role can hardly be overestimated, especially in winter, when the ice shell prevents both the entry of air into the water and the removal of waste products of microorganisms and plants from it. And if there is fish in the pond, then an aerator is simply necessary for it. In the summer period, the decay of the reservoir also negatively affects the biobalance of the entire area. In addition, various unpleasant odors coming from the water are unlikely to contribute to a good outdoor recreation.

Types of aerators for a reservoir

Injection

Saturation of water with oxygen occurs in the process of suction of air, which evenly mixes with the liquid and dissolves in it. They are characterized by low performance with significant power consumption. The main "plus" - they work almost silently.

Surface

Such models of aerators for reservoirs are the most common. There are many products on the market that differ in performance. The principle of operation is based on the spraying of water over the surface of the pond (like a fountain). Going down, it is saturated with oxygen. The advantages are economy and efficiency. In addition, in this case, air ionization occurs in a certain radius from the reservoir. But the drawback is significant - they work too noisily.

Bottom

Aerators of this type are a relatively new constructive development. From the name it is clear where it is installed. Thanks to this arrangement, the product not only supplies the water with oxygen of high quality, but also mixes its layers, equalizing the temperature throughout the entire thickness of the pond. This prevents the processes of decay of the microflora and reduces the likelihood of an ice crust appearing on the surface of the reservoir. But there is still a “minus” - a rather high cost of the product.

Aerators of this type are a relatively new constructive development. From the name it is clear where it is installed. Thanks to this arrangement, the product not only supplies the water with oxygen of high quality, but also mixes its layers, equalizing the temperature throughout the entire thickness of the pond. This prevents the processes of decay of the microflora and reduces the likelihood of an ice crust appearing on the surface of the reservoir. But there is still a “minus” - a rather high cost of the product.

They are also divided into floating and coastal models.

Video instruction - how to make a compressor for a pond with your own hands

What to consider when choosing an aerator for a pond

1. Product power. It depends on the volume of water in the pond. It is very important to choose best option, otherwise problems such as oversaturation or, on the contrary, undersaturation with oxygen cannot be avoided.

2. Climate in the region. different models aerators for reservoirs are designed for their temperature regime use.

3. How it works. It is clear that a home "noise generator" located nearby will not bring pleasure. And not only the owners of the site, but also the inhabitants of the reservoir.

4. Ability to switch from mode to mode. It is clear that the intensity of water saturation by the aerator in summer and winter periods is not the same.

5. Manufacturer reputation and a certificate of quality for the product. Experts consider the most best models aerators for reservoirs of the German brands.

The cost of aerators for a medium-sized pond starts from 41,000 rubles / piece. The price of more powerful products starts at 120,000 or more. For individual sites, devices with a power of 100 W to 0.1 kW are sufficient. Enriching the water in a small pond is enough. Such models can be purchased at prices ranging from 3,400 to 9,800 rubles.

Given the simplicity of the design of these devices, if desired and with some skills, you can make an aerator for the pond with your own hands.

water pump

This is a bottom version of the aerator for the pond. Experts recommend that the unit itself be installed indoors, and only an air diffuser should be placed in the pond. The pump can be picked up at any store that specializes in gardening equipment.

Any artificial reservoir has some kind of water source (pipe). It is necessary to position the sprayer so that it is below the liquid supply level, but at least 15 cm from the bottom.

hydraulic pump

Quite an effective version of the aerator for the reservoir. The only difficulty is in high-quality waterproofing all electrical equipment (if it is placed directly in the pond). All power cables are connected to the terminal box, which is desirable to be closed with a rubber cover (seal).

When installing next to a reservoir, it is necessary to make a “correction” for the distance when determining the power. The pump will have to drive the liquid back and forth, therefore, its performance needs to be increased.

How to choose an atomizer

If it is envisaged that the home pond has many decorative aquatic plants, then it is desirable that the sprayer (diffuser) of the aerator for the reservoir with your own hands has the shape of a geyser, a bell, and the like. It is mounted either on the end of the pipe submerged in water, or on a flexible hose by adding a weight.

If it is envisaged that the home pond has many decorative aquatic plants, then it is desirable that the sprayer (diffuser) of the aerator for the reservoir with your own hands has the shape of a geyser, a bell, and the like. It is mounted either on the end of the pipe submerged in water, or on a flexible hose by adding a weight.

There is another option. It suffices to take, for example, plastic pipe and drill several holes in it, observing the same distances, and muffle the end.

- Aerators for reservoirs should be operated throughout the year. Regardless of the period, they are involved in maintaining the necessary biological balance, qualitatively saturate and mix the water, ridding it of accumulating harmful gases.

- When choosing a model, you still need to take products with a certain margin of power. Then undersaturation will not occur. And excessive performance can be reduced in several ways. For example, power through a rheostat.

- It is advisable to place the aerator itself outside the reservoir, and keep only the diffuser in the water. It is much more convenient in terms of maintenance and repair of the product.

Artificial reservoirs are very popular today, they are widely used by designers in the design of landscapes. Almost every owner of a suburban area tries to equip at least a small pond or fountain in his garden.

But probably everyone knows about the difficulties of such an event, and the main one is the stagnation of water and the flowering of reservoirs. A foul-smelling pond with muddy green water is unlikely to promote relaxation and have a rest.

Why water stagnates in artificial ponds, why aerators are needed, and how you can assemble such a device with your own hands - this will be the article.

Purpose of aeration

Pond aerators are compression units that mix water with air, thereby saturating it with oxygen, which is why these devices are also called air compressors.

As you know, without oxygen, life on the planet would be impossible. Everyone needs to breathe: humans, animals, birds, plants and even fish. The plankton and algae that every pond needs a constant supply of fresh air. And if fish live in the reservoir, the need for oxygen will double.

In natural rivers, seas and lakes, the process of air exchange is clearly established: oxygen constantly enters the water when water flows mix, when rivers flow into the sea, for example, or it rains, a strong wind blows. Fresh portions of water saturated with oxygen and useful minerals are regularly added to the reservoir from underground sources and springs.

At the same time, artificial ponds differ significantly from lakes and rivers, as they are an autonomous, isolated ecosystem. The bottom of a home pond is usually lined with a layer of insulation, which makes it impossible for oxygen to enter from the soil. The surface area of the reservoir is usually small, and it is located in the garden among the trees, so the wind and rain cannot properly saturate the water with air.

Due to the lack of oxygen, fish, plankton, snails and other inhabitants of the pond begin to die, but there is plenty of silt, putrefactive formations and bottom sediments - beautiful pond turns into a swamp.

Attention! The owner can find out about the lack of oxygen in his pond by the following signs: a film appears on the water, fish stick out to the surface to breathe, snails rise up from the bottom, the pond silts up.

If water stagnation in the pond has begun, an aerator will help.

Varieties of aerators

For ponds, various aeration installations are used, the purpose of which is to mix water layers, create artificial flows, and saturate the reservoir with oxygen.

All aerators are divided into two large groups: mobile and stationary devices. Mobile aerators can be used temporarily, seasonally, they can serve several reservoirs at once. These compressors are used for small ponds or where there is no constant need for artificial water saturation.

Stationary aerators are capital devices that are installed on a specific body of water and operate continuously or in accordance with a given regime.

According to the method of location and principle of operation, all aerators are classified into several groups:

Advice! Wind aerators are simply indispensable for summer residents or those who rarely visit their site. Devices can work all year round without any intervention from the owner.

How to make a do-it-yourself pond aerator

Homemade aerator - great solution for owners of small home ponds. A purchased installation is quite expensive, in fact, an aerator is the most expensive part of an artificial reservoir.

For small home-made ponds, purchased powerful pumps are not needed; the simplest aeration device that can be assembled from improvised materials will be enough here.

How to make an ejector aerator for a home pond

First of all, you need to look around in your garage and pick up the necessary details:

- drainage pump (not very high power);

- two-meter segment sewer pipe(diameter 32 mm);

- forty-centimeter pipe (of the same diameter);

- elbow tee at 45 degrees;

- Good double braided cable.

Important! The tee must be exactly forty-five degrees. If you connect the aerator pipe at a right angle, water will constantly be thrown into the device.

Assembling a homemade aerator is simple:

- The sewer tee is connected to the drainage pump by means of the fitting supplied with the kit. For reliability, you can use silicone sealant.

- On the other hand, a branch pipe of shorter length is inserted into the tee.

- Insert a 45 degree angle into the top outlet, and then attach a long pipe.

- Now you need to connect to the aerator electrical cable. The wire must be airtight, so it is wrapped with several layers of electrical tape and placed in a hermetically sealed corrugation.

- The pump must always be at a depth of 70-100 cm from the surface of the water, while the intake pipe must be located above the water level. To ensure this, it is necessary to metal pipe weld the mast and fix it on the bottom of the pond.

- It remains to attach the aerator to the mast and apply voltage.

Advice! If there are fish in the pond, it is better to enclose the pump in a mesh box.

Do-it-yourself bottom aerator for a pond

Such a device will cost quite inexpensively, especially if the owner has an unnecessary car compressor with a receiver. So, for a homemade bottom aerator you will need:

- compressor (from a car, vacuum cleaner or refrigerator);

- high pressure hoses;

- clamps;

- tees;

- sprayers or nozzles.

Advice! You can make nozzles from simple improvised means. For example, empty plastic bottles are suitable, in which you need to make small holes. If you need to further reduce the size of the air bubbles, you can wrap the bottles with thin foam rubber.

Assembling an aerator with your own hands is not difficult at all:

- The compressor unit is placed in a convenient place (it can be a barn located next to a pond).

- A central hose is connected to the compressor and pulled towards the pond.

- Using tees, it is necessary to make taps according to the number of nozzles. For a secure connection, it is better to use clamps.

- Fix sprayers to tees.

- Attach sprayers to the bottom of the pond. They can be pressed with cobblestones or metal pins with a bent end can be driven into the bottom.

Attention! Such an aerator will not be able to work continuously, moreover, the device will make a lot of noise. Therefore, a homemade bottom aerator is suitable for irregular saturation of ponds.

DIY wind aerator

AT winter time motors and compressors do not "feel" very well. If you need to enrich the pond with oxygen in winter, it is better to use a wind aerator, and you can assemble it from the most common parts.

For work you will need:

- metal square with sides 30x30 cm;

- a long smooth metal rod with a cross section of about 20 mm;

- bearings closed type, corresponding to the diameter of the rod;

- two strips of metal 2 mm thick, the length of which slightly exceeds the dimensions of the bearings;

- plastic barrel;

- a fan from the car's cooling system or something similar;

- fasteners and tools.

Assemble the wind aerator as follows:

- From the metal you need to cut 8 identical squares, and then weld cubes from them.

- A crossbar should be installed inside each cube, a hole should be cut in it and a bearing should be installed inside it. The centers of the holes in both bearings must be exactly on the same line.

- A metal rod is inserted into the bearings.

- The plastic barrel should be cut into two equal parts - these are the blades of the windmill.

- Using metal loops, the blades should be fixed at the top of the rod.

- Fan blades are fixed to the bottom of the metal rod - they will be located under water.

- They assemble a mast for a wind aerator and install it in a pond, fix a device with blades assembled with their own hands.

Attention! The wind aerator can be made floating. To do this, foam plastic, plastic barrels or bottles are attached to the bottom of the mast.

This aerator design is relevant for large ponds, and so that the device does not swim too far, you can tie a rope.

Conclusion

Aerator - indispensable for small artificial reservoirs device. It prevents stagnation of water, the appearance of a bad smell, silting of the bottom and walls, saturates the water with oxygen and creates favorable conditions for the life of plants and animals.

It is not at all necessary to spend a lot of money on the purchase of an aerator, it is quite possible to make it yourself using the simplest materials and tools. You can watch the video story on how to assemble a pond aerator:

The popularity of artificial ponds has never faded. Now such reservoirs have reached a new level, they can be found in many private estates. Sizes can be very diverse, depending on the purpose of their creation. For the normal functioning of reservoirs, it is necessary to take care of creating an aerator for the pond with your own hands, which is quite possible so as not to spend money on ready-made models.

What are aerators for?

First of all, they provide purification and simultaneous saturation of water with oxygen, and this, in turn, prevents water from stagnating. In addition, without purification, the water will bloom, and the smell from it will become unbearable.

Factors indicating the need to install an aerator

Pond and reservoir aerators are compression-type installations, the main task of which is to mix water with oxygen. Such units are also called air compressors.

In natural waters this process occurs by itself, since air constantly penetrates into the water as a result of the mixing of water flows: rivers flow into the seas, waters are filled with precipitation, blow strong winds, filling occurs through underground springs with natural trace elements. Accordingly, in artificially created ponds, such interchanges do not occur, so they must be created with your own hands.

Home ponds have their own ecosystem, which operates on a different principle. This is due to the fact that when creating a pond or lake, the bottom is lined with waterproofing material, which becomes an obstacle to the penetration of oxygen from the soil. The surface area of artificial reservoirs is often small, and they are located mainly surrounded by trees, in this regard, neither air currents carried by winds, nor precipitation can fully saturate the water with everything necessary.

The lack of oxygen in the water leads to the death of plankton, fish, snails, frogs and other living creatures. As a result, silt, rot, bottom sediments appear in the water, and only a swamp remains from a beautiful reservoir.

Note.

The lack of oxygen in the reservoir is indicated by the formation of a film on the water, fish are often shown on the surface of the water, snails rise from the bottom, silt appears.

Types of pond aerators

The aerators are divided into two groups:

- Stationary- units of a capital type of installation, which are intended for installation in a specific pond and carry out their work on an ongoing basis in a given mode.

- Mobile devices are designed for seasonal use, their power is enough to fully serve several ponds. Aerators of this type are best suited for small ponds or for those that do not need constant oxygen filling.

Pond aerator classification

According to the type and place of installation, as well as the features of work, it is carried out into several types.

outdoor aerators compressors for ponds . These installations look like fountains small sizes or waterfalls. Often used for installation in domestic ponds, in order to add an attractive appearance. An important point of such units is that not all the inhabitants of the pond will appreciate the noise of falling water. Features of the operation of outdoor aerators are that the pump draws water from the pond, and then releases it in the opposite direction. When a stream of water is in the air, oxygen saturation occurs.

Ejectors.

The principle of operation of these units resembles the features of outdoor compressors, with the difference that water is not sucked from the pond. The process of saturating water with oxygen is carried out by blades, which are driven by a motor. The blades hit the water with a certain force, mixing it and saturating it with air. It should be noted that these installations also emit a lot of noise.

Ejectors.

The principle of operation of these units resembles the features of outdoor compressors, with the difference that water is not sucked from the pond. The process of saturating water with oxygen is carried out by blades, which are driven by a motor. The blades hit the water with a certain force, mixing it and saturating it with air. It should be noted that these installations also emit a lot of noise.

Bottom aerator for pond . This is a new device for ponds, which has gained a reputation as the most efficient to date. A compressor that makes noise is installed on the shore of a reservoir, and a tube with a diffuser is lowered into the water. Oxygen enters through small holes, passing through layers of water. The result of this operation of the installation is the saturation of the pond with oxygen and the mixing of all layers of water. This aerator is quiet.

Combined aerator. The principle of operation of the installation is based on the operation of a pump or compressor. The compression unit is installed on the shore of the reservoir, and the diffuser is mounted in the water. The head of the diffuser remains above the surface of the water, and air saturation is carried out due to the flow of water, which beats like a fountain.

Wind aerator for pond . This installation differs from all other types of aerators by autonomous operation. The unit is driven by the force of the wind. The design is mobile and stationary, it is created from large blades located on the water surface, as well as a propeller immersed in water. The principle of operation is as follows: the wind drives the blades, they activate the course of the propellers, which mix the water and form a seething.

Note.

Wind-type aerators are most often used in the country, as well as in those areas that remain without the participation of people for a long time. The installation is able to function year-round without process adjustment by the owner of the reservoir.

We create an aerator for the pond with our own hands

Making an aerator for a pond on your own is not difficult. The main thing is to study the assembly instructions, as well as stock up necessary materials. Price ready installations not small, but with self-production you can decently save money.

For small ponds, it is enough to use an aerator of a simple design, which can be assembled from materials that the summer resident always has at hand.

Assembling the ejector aerator

Materials:

- drainage pump with low power;

- a piece of pipe with a cross section of 32 mm and a length of 2 m;

- branch pipe 40 cm long and 32 mm in cross section;

- tee angle 45º;

- double braided cable.

Note.

The importance of choosing a tee with an angle of 45º is explained by the fact that when the pipe is connected at an angle of 90º, there will be a constant flow of water into the unit.

Assembly process:

- The sewer tee is attached to the drainage pump using a fitting for connecting the aerator hoses for the pond. To ensure the reliability of the connection, a silicone-based sealant is used.

- FROM reverse side a branch pipe is inserted into the tee, the length of which should be less.

- An angle of 45º is inserted into the upper outlet, then a two-meter pipe is fixed.

- An electrical cable is connected to the aerator. The wire must be sealed with electrical tape, which is wound in several layers, after which it is placed in a corrugation.

- The pump is placed at a depth of 70 - 100 cm of the water surface, and the water intake pipe should be on the surface of the water. In order for you to succeed, steel pipe make a kind of mast and fix it at the bottom of the reservoir.

- At the last stage, an aerator is attached to the mast and electric current is supplied.

Assembling the bottom aerator

The cost of assembling an aerator of this type with your own hands is small. To do this, you will need to find a compressor from a car with a receiver.

materials:

- High pressure hose;

- collar;

- Tees;

- Nozzles, sprayer.

Note.

The nozzle can be made from a plastic bottle, after making a hole in it. To reduce the size of air bubbles, the bottle is wrapped with foam rubber of small thickness.

Assembly process:

- The compressor is placed near a reservoir or hidden in a nearby outbuilding.

- The central hose is connected to the compressor and stretched to the pond.

- With the help of tees, bends are made depending on the number of nozzles. Staples are used for secure fixation.

- Diffusers are attached to tees and placed at the bottom of the reservoir. To prevent them from rising to the surface, you can put heavy stones on them or fix them at the bottom with pins with curved ends.

Note.

The work of bottom aerators for the pond cannot be continuous, in addition, the unit makes an annoying loud sound. Devices of this type are used to periodically saturate the water in ponds with oxygen.

Assembling a wind aerator for a pond in winter with your own hands

Installations of this type are best suited for operation in the winter season. It is not difficult to assemble it, you will need the most common parts that can be found on the farm.

materials:

Assembly process:

- Cut out eight pieces of squares from metal and connect them into cubes. A cross member is installed inside each of them, in which a hole is cut out and a bearing is inserted. The central parts of the bearings must be in line.

- A steel bar is placed in bearings.

- A plastic barrel is cut into two parts and blades for a windmill are obtained.

- With the help of metal loops, the blades are fixed at the top of the rod.

- At the bottom of the steel bar, blades are attached, which as a result will be located above the surface of the water.

- The assembly of the mast for the wind-type aerator is carried out at the last stage and after that it is installed in the reservoir.

A floating wind aerator for a pond is created using plastic barrels, bottles or polystyrene attached to the mast.

There is practically no one left on earth. natural source, which would contain water suitable for long-term consumption. This fact has been repeatedly confirmed by the relevant departments. Therefore, the organization of water treatment is one of the main tasks facing the owners of suburban areas. Of course, you should create a water treatment plant only based on a comprehensive laboratory analysis of water from your source. But given that the iron content exceeds allowable norms almost everywhere, without an aerator, not a single water treatment system can be called a full-fledged one.

Today we will talk about assembling a water treatment plant based on an aerator (non-pressure aeration column) on our own.

Briefly about aeration

Aeration is usually called the process of saturating water with oxygen (basically, the process is forced) in order to purify it from iron, manganese and other oxidizable compounds. Simply put, we are talking about substances that, after reacting with oxygen, take insoluble forms and precipitate as a precipitate. Subsequent filtration or settling allows you to rid the water of the resulting sediment, which contains harmful impurities.

In the process of aeration, the main catalyst for removing harmful impurities from the water is the oxygen contained in the air. In other words, aeration means non-reagent deironing of water - the most economical of known ways iron removal.

Another cleaning method, the effectiveness of which is beyond doubt, is the following: iron removal using chemical catalysts (passing water through activated carbon, porous aluminosilicate with a special coating or other special filler).

Together, both of these methods help to achieve excellent results.

MTT FORUMHOUSE user

In serious water treatment systems, aeration is only one of the stages in the process of iron removal and demanganization. At this stage, the water is saturated with oxygen (for further and complete oxidation of iron with the help of catalysts), and the removal of dissolved gases occurs.

Distinguish between non-pressure and pressure aeration systems. The design of pressure aeration systems provides for the presence of a closed aerator (contact chamber), in which water is saturated with oxygen using a compressor. In such a system, there is no loss of water pressure, therefore, water enters the distributing line under pressure, which creates a pump (pumping station) of the first lift. For a pressurized system, a second lift pump is not needed.

The main elements of the pressure aeration system:

- The supply line with a mud filter.

- Compressor that pumps air into the aeration column.

- Aeration column with air valve (with air vent).

- Iron filter.

It is more difficult to make a pressure aeration system on your own than its non-pressure counterpart. At the same time, its reliability in comparison with a non-pressure aeration system can also be called into question.

Andre.voda FORUMHOUSE user

Non-pressure aeration works better and more reliably than pressure! Consider the option with pressure aeration: what are the leaks arising from clogging of the air vent .... And the failure of check valves, and failures of the flow sensor .... If the compressor stopped in pressure aeration, then everything is kirdyk: there is no oxidation, and iron does not fall out.

Considering all of the above, we will consider the option of installing a pressureless aeration system, especially since most of the "experimenters" of our portal practice.

In the case of non-pressure aeration, an aerator is used open type where water pressure is lost. That's why similar systems need an additional pump (pumping station) of the second lift, which supplies water to the distributing line. The aerator in this case performs the function storage capacity, while simultaneously allowing to solve the issue of providing a certain supply of water for the plumbing system.

Scheme of a water treatment system based on a non-pressure aeration column

Schematically, a water purification system operating on the principle of non-pressure aeration is as follows.

- Supply line with first lift pump and mechanical sump filter.

- Aeration unit with second lift pump.

- Iron filter.

- Block of fine water purification.

- Drainage line for flushing the system.

Let's consider the presented elements in more detail.

supply line

The main element of the supply line (if you do not take into account the pipes themselves) is the pump (pumping station) of the first lift. This device can be dispensed with only if water is supplied to the installation from a centralized water supply system. If the water is pumped from a well or a well, then an ordinary deep pump can be installed in the supply line.

Everyone determines the need to install a mud filter for himself.

If a float valve is used to regulate the water supply in the aeration tank, then the coarse filter (sump), retaining large mechanical impurities, protects the valve from sticking. If automation is used to control the first lift pump, then the supply line can even work without filters.

Operator FORUMHOUSE user

Installing filters is the time to wash and maintain them. Without filters, all debris from the well and iron deposits remain in the storage tank. For a year, I have about 5 cm sediment at the bottom there. In the summer, I open the drain and flush all the sediment down the drain. Otherwise, all this will have to be cleaned out of the filters. So I removed all the filters that I foolishly put in the filling system. I pump everything from the well into the tank. Debris remains at the bottom.

aeration block

The main element of the aeration block is the aeration tank, in which water is saturated with oxygen, iron is oxidized and primary sediment is deposited.

To create an aerator, you can use a container that has a specialized purpose and has a design that provides for the possibility of backwashing. For example, the photo shows a specialized container with a volume of 1 m³.

Also, an aerator can be made from a container designed to filter water in pools. At the same time, some users of our portal use ordinary plastic barrels for food storage.

valexs FORUMHOUSE user

From the well, water is supplied by a deep pump into a barrel of 250 liters.

The volume of the working capacity is a very important indicator. According to user valexs, an aerator with a capacity of 250 liters provides water for a family of 4 people. At the same time, no one experiences a shortage of water. Approximately 94 m³ of water is consumed per year (200-300 liters per day).

As you can see, the system is quite efficient. If you have more planned water consumption, then the volume of the tank can be increased. A 1000 liter aerator, for example, allows you to provide purified water not only Vacation home, but also a system for watering the garden. Some users practice the creation of an aeration unit from two containers: water is settled in one, and water is consumed from the other.

The ordinary showering method will help start the aeration process in the tank. It's about about spraying water entering the tank under a certain pressure.

Operator FORUMHOUSE user

A very simple way: from the well you collect a tank through a shower diffuser. Water does not just pour, but pours out of the shower under great pressure, saturated with oxygen. Almost immediately, the water becomes cloudy, and iron begins to precipitate.

It is very important to let the water settle after filling the container. Otherwise, all main filters located in the cleaning system after the aeration tank will quickly become clogged.

According to our users, it takes at least 36 hours to fully settle the water. Therefore, the larger the volume of the aeration tank, the more convenient it is to operate. After all, if you adjust the equipment to fill the aerator in small portions, then the time spent on settling water will practically not be felt.

The efficiency of the shower head can be significantly increased. So, for example, the user valexs did. He installed an ordinary plastic bucket (upside down) on top of the aeration tank. Water from the sprayer under high pressure hits the bottom of the plastic bucket. This leads to the formation of water mist and more efficient mixing of the liquid with oxygen.

The atomizer is built into the lid of the container, in which holes are drilled for draining water enriched with oxygen.

A corrugation is mounted on top of the bucket. It provides a connection of the tank with the atmosphere and prevents splashing of incoming water.

Water extraction and aerator filling

The water outlet from the tank must be installed at a level that will not allow the formed sediment to enter the water main.

Operator

Water from the tank should not be taken from the bottom, but about 30% above the bottom. Then the sediment does not enter the system.

Concerning the activation and deactivation levels of the first lift pump: the pump activation sensor must be located above the level of water withdrawal from the aerator. This will create a certain reserve of settled water, which can be used even in the process of filling the tank. In this case, the amount of unsettled water entering the water main will be minimal, and fine filters can easily cope with mechanical suspensions.

kilby FORUMHOUSE user

The water supply switch-on level sensor is installed so that between it and the water intake level at pumping station there was at least 100 liters of water. This volume and contact time is quite enough for the smooth operation of the system.

The water supply control system is of two types: mechanical and automatic (based on electronic sensors).

An example of a mechanical system is a conventional float from a toilet bowl. Its design is extremely simple, and the shortcomings are immediately evident. It is almost impossible to adjust: the pump turns on as soon as the water drops below the upper level. This process occurs with an "enviable" frequency, which does not allow water to settle qualitatively.

An automatic system, consisting of electrical sensors, allows you to turn on and off the water supply when certain levels are reached. Which is much more practical.

Konstantin11 FORUMHOUSE user

A bar with control frogs (there are four frogs in total: two working and two emergency). The tank is filled to 80% (maximum). The deep pump turns on when about 100 liters of water remains in the tank, and turns off when about 800 liters of water are collected.

Reinsurance in the form of installation of emergency sensors is important point. If the pump does not turn on in a timely manner, nothing terrible will happen. A real disaster can befall the owner of the aeration unit if the pump does not turn off after filling the tank.

This is how one of our users insured his premises against a possible “flood”.

Operator

I also have a three-level barrel overflow insurance system: an electric float, a mechanical float, and a drain to the street into a storm drain.

Second lift pump

The second lift pump provides a stable pressure throughout the plumbing. Also, with its help, water is supplied to the deironing filter and fine filters.

To operate the pumping station of the second lift, you should use a pump equipped with an automatic on-off system, triggered by a signal from pressure sensors (which it is desirable to duplicate).

Konstantin11

The photo shows the pump of the second lift (it stands to the right of the tank). The drain line is clearly visible. Pressure sensors are also clearly visible, which, due to the tendency to stick, stand with the covers removed. It's good that they are duplicated, and their sticking does not affect the performance of the system. Poorly visible mud trap and check valve but they are needed.

In almost all systems, the pump is located at the outlet of the aerator. But the users of our portal have their own view of things. For example, there is an opinion that if the pumping station is located immediately after the aerator, then underoxidized iron accumulates in it, which clogs not only the pump, but also the control sensors. For this reason, it is advisable to place the pumping station after the deironing filter. It is difficult to disagree with this conclusion, especially since the author of the concept (user - Operator) was able to collect working installation in accordance with such a non-standard scheme.

The second lift pump should be selected based on the hydraulic characteristics of the device. Also important is the reputation of the manufacturer.

Filter-deironing agent with filler

The bulk of the iron contained in the water precipitates to the bottom of the aeration tank. But for better cleaning, we will definitely need a system of additional filters. To get rid of the remnants of unoxidized iron, an iron-removing filter is used. It is a vertical column with bulk content.

morteh FORUMHOUSE user

The column is a plastic pipe with a diameter of 300 mm and a height of 2000 mm. The bottom (stainless steel b = 8 mm) is screwed through the rubber seal with M8x40 bolts with a pitch of 40 mm. The lid is the same as the bottom, only in the center a 3/4" stainless steel screw is welded in, and the second one is the same 60 mm from it.

In this case, used polyethylene pipe, while the design of serial units involves the use of fiberglass.

When determining the volume of the filter for your system, you should be guided by the dimensions standard settings: Their diameter varies from 6 to 16 inches, and their height is 17 to 65 inches. The exact volume of the filter (as well as the volume of the media) can be calculated by knowing the characteristics of the backfill, the water flow and the level of impurities.

When determining the level of filter loading, it should be taken into account that during washing or regeneration, the filler layer increases under the action of the back pressure of water. Taking into account the expansion coefficient, the filter should be filled with catalytic filler to approximately 60%.

The internal design of the iron remover is designed in such a way that water enters it from above, then passes through a layer of catalytic backfill and only then enters the water main (through the lower intake pipe).

morteh

A pipe is screwed to the central bend of the cover, and a slotted filter is assembled at the end of the pipe. When the cover is installed on the column, this filter does not reach the bottom by about 30–50 mm. A slotted filter is also placed on the drainage squeegee screwed into the lid. It is needed so that during backwashing, backfill is not washed out of the column.

The intake tube passes through the entire layer of catalytic filler.

In some cases, it is possible for mechanical impurities to slip from the aerator into the deironing filter (if the water in the aerator has not yet had time to settle, if the tap was turned on in the house at the time of filling the aeration tank, etc.). Therefore, it is desirable to protect the iron remover by installing a mechanical filter at the outlet of the aerator.

Konstantin11

For example, after the tank (or rather, between it and the second lift station) I have an ordinary mud sump.

It is better to choose a filler for an iron remover that does not need additional regeneration. It is characterized by ease of maintenance, which comes down to periodic washing of the filter with a reverse flow of water. On the market, fillers of this type are presented in large quantities.

With a low iron content for iron removal, you can use quartz sand. The following fillers have also proven themselves well: activated carbon and aluminosilicate coated with iron and manganese oxides.

An example of a filler that requires periodic regeneration with acids or common salt is an ion exchange resin.

In order to determine the type of filler and its quantity, it is necessary to conduct a comprehensive analysis of the source water in the source and study the properties of a particular backfill.

Konstantin11

I chose the filter materials myself - based on water analysis and technical descriptions filter media. In the left column: quartz sand at the bottom (a tube sits in it), then industrial filler. On the right is a softener.

User implemented two-stage system cleaning with combined filler. The first stage is used to remove iron residues (which have not had time to oxidize in the aerator) and for mechanical cleaning, the second stage is used to soften water.

Pressure gauges built into the line allow you to control the degree of clogging of the filters.

Filter washing

Even if the backfill of the deironing filter does not need regeneration, the owner will still have to periodically rinse it during operation. Therefore, all self-cleaning filters (including iron removal and aeration tanks) must be equipped with a bypass and drain lines.

It is worth installing a few additional taps, and the flushing line will allow the flow of water to flow in the opposite direction (almost directly from the source). Drain lines can be brought out to sewer system or a storm drain.

Operator

The catalyst barrel is regularly backflushed. There's a six-position tap on the barrel. And at the exit from the iron remover there is a regular filter - a cartridge of 0.5 microns. For the aerator, I made the following flushing system: at the bottom of the barrel, a drain with a tap, once a year I open the drain and at the same time pour it, washing the sediment down the drain.

The frequency of washing the iron remover and other filters, everyone determines for himself. It depends on the degree of water contamination, on the volume of its consumption and on the characteristics of the backfill (on its tendency to caking). You can read more details in a special section of our website.

To ensure high-quality flushing, the water flow rate in the return flow should be 2–3 times higher than the flow rate of the working flow. The pressure in the flush line must be at least 2.5–3 atm. (more is possible, but at the same time it is necessary to ensure that the backfill does not end up in the drainage).

If the second lift pump does not have sufficient power, an additional pumping station can be installed for flushing.

Filler regeneration is a little different from normal flushing. Indeed, in the process of regeneration, special reagents must be added to the flushing line (which ones - depends on the type of filler). First, the filler is washed with water from mechanical impurities and loosened at the same time (for 15–20 minutes). Then, a reagent (a solution of salt, acid, etc.) is supplied to the flushing line using a pump and an additional container. At the last stage of regeneration, the filler is washed from the reagent.

You can read about how in the corresponding FORUMHOUSE topic. Here, users of our portal share their tips and practical experience. can be found in a section specially created for this purpose. The article will talk about a simple and affordable way to provide water to your country house. And in the video about the creation of the caisson, practical idea, allowing you to organize a modern and reliable system water supply from a well to a country house.