All known ways to glue drywall to the wall. How to glue drywall on a wall - a home master can handle everything! How to glue drywall to an uneven concrete wall

Drywall has long become a worthy alternative to plaster and other finishing materials for leveling walls. With it, dirty work is minimized and much less time is spent on repairs.

It is necessary to fasten drywall sheets to the wall on a special profile by mounting or simply stick to glue. The second option is simpler and faster, therefore, at home, it is most often resorted to.

What glue to glue drywall to the wall

Consider the popular types of adhesives for gluing drywall.

- Perflix is a simple and inexpensive drywall glue for home use. Suitable for those who are interested in how to glue drywall to a brick wall.

- Fugenfüller is a putty version of the glue. Requires manual mixing, it must be applied in a thin layer.

- Ceresit CM 11 and mixtures with similar properties. Designed for ceramic tiles, but also works well for drywall.

- Silicone glue - adheres well drywall to mirrored surfaces and ceramic tiles.

- Mounting drywall glue - it is recommended to use it for those who do not know how to glue drywall to a concrete wall... Differs in simplicity and ease of use, affordable.

- Knauf Fugen putty is ideal for gluing drywall to flat walls. The polymer additives included in the composition make the mixture plastic, so the putty can be applied in a thin layer.

What walls should be in order to glue drywall

The use of adhesives, regardless of the materials used, always requires detailed surface preparation work.

First of all, the walls must be cleaned of wallpaper residues, old paint, plaster and other finishing materials down to the concrete or brick base. This is necessary in order for the drywall to hold securely.

Bare walls require cleaning of dust and primer, this will help increase the adhesion of materials, ensure the adhesion of glue and drywall.

Smooth walls are half the battle. But, unfortunately, in modern homes, they are not common, and therefore additional work is required.

If the surfaces are even, the task is greatly simplified, so that the consumption of materials is reduced.

Smooth walls include walls with differences of no more than 5 mm. In this case, you can get by with putty.

If your indoor surfaces are uneven, you must use Knauf-Perlfix gypsum glue. Even with irregularities of more than 20 mm, the drywall will stick.

Instructions - glue drywall step by step

The procedure for gluing, if the walls are even

- Prepare the surface - remove dirt, dust.

- Cut drywall sheets, providing a gap from the floor of 10-15 mm for a heat shrink joint, which will later be sealed with a sealant. It is also necessary to think over the places for the outlets and cut holes for them.

- To avoid mistakes when working with complex areas, including in places of bends, marking and cutting of sheets for them is performed after gluing the previous sheets.

- The sheets are placed face down along the wall. With a notched trowel, putty is applied in strips along the perimeter and in the center. With a sheet thickness of up to 12.5 mm, one strip along the sheet will be sufficient, with a thickness of 9.5 mm, two stripes are applied. In places with increased stress, it is recommended to apply the adhesive in a continuous area.

- After applying the composition, the sheets are lifted, placed on a lining and glued to the wall. Small sheets of drywall are suitable as linings, which then need to be removed. To make the sheets lay flat on the wall, use a long level.

If the walls are uneven

In this case, the order of gluing will depend on the degree of curvature of the walls. Sticking can be done in two ways.

With a deviation in planes of no more than 2 centimeters, Knauf-Perlfix gypsum glue is used for work. It is applied with a trowel in small areas, in the center and along the perimeter of the drywall. Then the sheets according to the previous scheme are placed on lining and glued to the wall.

If the deviations exceed 20 mm, first cut out strips of drywall 10 cm wide, then attach them to the wall with glue at an interval of 350 mm. These overlays will hold the base sheets and should therefore be centered and perimeter. It is more convenient to glue the sheets to the base on Fugen putty.

In panel houses, walls with even larger irregularities are often found. But even in this case, there is no reason to refuse drywall. In this situation, you will need a frame in which the wires will be hidden and the wires will be fixed.

- From a single sheet, it is necessary to cut strips 10 cm wide, which will serve as a base.

- These strips are attached to the wall at a distance of 50 cm from each other using a level.

- The amount of glue applied depends on the size of the irregularities - the larger they are, the thicker the glue layer should be.

- When the base is fully glued, you can attach the main drywall sheets to them with glue or liquid nails.

VIDEO DESCRIPTION

Glue consumption

The consumption of the adhesive composition will depend on the glue itself. So, for the Perlifix assembly mixture, this figure will be 5 kg per 1 sq. M. without taking into account a small margin for possible losses during operation.

For each composition, the manufacturer indicates on the packaging the recommended consumption rates, so you can safely focus on them.

On average, it is 3-5 kg per 1 sq. M. It is important to take into account the speed of drying of the glue, it should be enough for the entire period from application to complete gluing.

In order to reduce the cost of glue, it is necessary:

- apply the composition on a dry surface at a wall temperature of at least -5C,

- remove all dirt from the walls, rinse them,

- repair protrusions and cracks,

- the base must be carefully primed.

Thus, fixing drywall to glue allows you to quickly and inexpensively transform a room, make repairs in the country or in an apartment.

Plasterboard has recently become one of the most demanded materials for renovation work in apartments. Large in area, even and smooth surfaces of the sheets allow you to eliminate the curvature of the walls in a short time, to prepare the room for subsequent finishing. In addition, if the gypsum boards are attached to the frame structure, then it becomes possible to additionally insulate the ceiling as well.

But the creation of a frame is not possible in all cases, since such a structure essentially "steals" the usable area of the room. Therefore, for the owners of city apartments planning repairs, information on how to fix drywall to a wall without profiles is often more useful, so that the loss of space in an already cramped environment is minimal.

There are several methods for such drywall fixing. But for any of them, the wall requires some preparation.

Preparatory work

Any work begins with the preparation of a set of necessary tools and the acquisition of the necessary materials.

Materials and tools

BUT. Of the tools you will need:

- Drywall knife.

- A building level, a plumb line, a marking line, a tape measure, a long ruler or a rule, a pencil or a marker - for preliminary marking and constant monitoring of the verticality of the surface during the installation of sheets.

- Rubber and regular hammer.

- Spatula or trowel

- Container for mixing glue.

- Screwdriver, electric drill with mixer attachment.

- Long-handled roller and soft brush.

- Chamfering planer

B. Materials for work:

- Drywall sheets. Depending on the room, the usual ones can be used - GKL, moisture-resistant GKLV, and if the wall is finished near the stove or fireplace, then fire-resistant GKLO will be required. The number of sheets is calculated taking into account the area of the walls of the room minus the areas of window and door openings from it, and making a margin of about 15%.

The number of drywall sheets will help you quickly and accurately calculate the calculator below.

Many are accustomed to the fact that drywall is attached to a brick or concrete wall using a special frame. This finish has one significant drawback when compared to gluing. This cladding takes up the usable area of the room. This is especially noticeable in small apartments.

To solve the problem of reducing the size of rooms, the question arose: "How to glue drywall to the wall?" Today you will learn in detail the whole process from A to Z and become an expert in this topic.

What is this article about

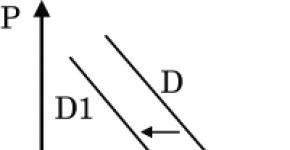

Comparison of glue and frame method

As you already understood, there are two types of installation of drywall on the walls:

- using a metal frame (sometimes a wooden one is used);

- frameless method - gluing.

Each of them has a number of advantages and disadvantages.

Unambiguously, the advantages of frame methods include:

- reliability;

- high quality construction.

The disadvantages of the frame method are as follows:

- high cost due to the use of profiles;

- complexity of installation;

- this method, as already mentioned, steals the usable space of the room.

The advantages of fixing drywall with glue are as follows:

- installation directly on the wall;

- less laborious installation process;

- can be installed in places of high humidity;

- does not reduce the usable area of the room.

There are few disadvantages, but they are:

- the wall must first be leveled;

- the adhesive layer can be destroyed due to moisture.

So you've decided to glue the drywall to the wall rather than mount it to the frame. To do this, you will need to learn several ways. Laying of sheets depends on the surfaces on which the drywall is glued.

Installation on flat walls

Installation of drywall on glue in the first case is carried out on relatively flat walls. Such surfaces are considered to have a deviation from the vertical of no more than 5 mm. Basically, these are walls made of concrete and foam block. Such walls are often found in monolithic new buildings; irregularities are even difficult to notice by eye.

Thus, the layer of glue will be thin, which means that it will not work out to lay the wiring under the sheets. Therefore, it should be carried out before gluing the plasterboard.

On the walls, markings are made for wiring lines. After that, strobes are made with a perforator or other tool. Then the wires are laid in them, and every 50 cm they are fixed with clamps. Also, it is necessary to cut out the holes for the socket boxes in advance so that you do not have to make an extra hole in the sheet. To do this, use a diamond core bit.

Try to think over the wiring so that the strobe needs to be made as small as possible. This is a very time consuming and messy process.

The next step is primer. There are several options for the development of the situation. If the concrete is untreated, then an ordinary primer will do. If it is painted, then you will have to purchase a special one or remove a layer of paint and prime it with a regular one.

You can tinker with removing old paint, or you can get it done quickly, but make your wallet a lot lighter. You decide. But if they decided to buy a special primer, then the name should contain “betankontakt” or “concrete-contact”. The inscription means that by planting drywall to concrete with glue, it will hold for a very long time. You don't have to think about whether it will fall away.

Installation sequence:

- First you need to clean the walls of dust and dirt after installing the wiring. Now you can start with the main steps.

- Stirring the adhesive solution. Read the instructions on the packaging carefully. There are brands of glue that set fairly quickly. Therefore, you must know exactly how much glue you need. Otherwise, the solution will simply dry out while you glue the drywall onto the wall.

- Marking and making holes for sockets. You have already mixed the solution. Now on the sheet you need to markup for sockets and cut out the corresponding shapes. Make sure that the markings on the sheet coincide with the one on the concrete wall.

- Glue application. Take a notched trowel in your hands and apply the solution over the entire surface.

- Installation of linings. To correctly perform the gluing of drywall to the wall, you need to cut out the linings. They can be made of plasterboard or wood. They are parallel to the wall. A glued sheet is placed on them. Wires are threaded into the cut holes, and then it is leveled. For this, a rule is used.

- We glue drywall. We lift and glue the gypsum board. In places where it sticks out, press harder. Check the verticality by level.

Wall mounting with slight irregularities

How to glue drywall to a wall that has irregularities? In fact, you do everything the same, but you need a different glue and a thicker layer. The preparation consists of the points already known to you:

- chipping the wall for wiring;

- drilling for sockets or switches;

- surface primer.

To glue drywall, you will need to apply the glue in parts (heaps). Use a trowel or narrow spatula. Lay out piles around the entire perimeter, keeping a distance of 20–25 cm between them. In the middle, lay out two more rows, the distance between which is 40–50 cm, and between the piles in them - 30–35 cm.

It's important to know! The thickness of the pressed glue layer should be 5–30 mm.

Now place the sheet on the supports, align it with the rule. When everything is ready, it's time to glue the drywall. Attach it to the wall, check with a level, and then apply a rule and tap to align.

You can apply the glue solution directly to the walls. How to glue drywall with uneven surfaces is up to you. But practice shows that it is better to apply heaps of glue to the sheet itself.

Mounting on a very curved wall

It's time to find out how to properly glue drywall if the walls are really uneven.

To do this, you first have to work with the GCR itself. It needs to be cut into strips of 10 cm. After that, put on glue and glue drywall around the entire perimeter and vertically, with a distance between the strips of about 50 cm. So you get a frame. The wiring can be hidden under it. But be sure to secure it.

You already know how to glue drywall. But don't forget to align it vertically. To make the design as even as possible, you will have to put quite a bit of glue in places, and in places - heaps of 2-3 cm.

That's basically all that concerns ways to glue drywall to the wall. It remains to answer the questions that often arise.

When gluing drywall to the ceiling, remember that it must be durable, not wooden, does not freeze, there is no condensation on it, it was not painted with oily oil paint and it is dry. If these conditions are met, then you can safely glue drywall to the ceiling. The process is the same as for the walls. But gluing drywall on the walls is different in that the sheets are glued to the ceiling in a checkerboard pattern so that there are no joints in the form of a cross.

Plasterboard sticker on walls can be replaced with gypsum fiber board. It is also used as a floor covering. It differs from GKL in that it is able to regulate the level of moisture in the room. At high humidity, it is able to absorb moisture, and if insufficient, it can release it. This material is quite plastic, but it does not crumble and is very strong. If you drive a nail into the GVL, it will hold it like a tree.

What kind of glue to use?

The choice of substance depends on the surface on which you want to glue the drywall. Perflix is a unique drywall adhesive as it is suitable for all occasions. Ceresit CM 11 is well suited for ceramic tiles. Silicone can be used for it and mirror surfaces. For brick and concrete walls, liquid nails and polyurethane foam are also used. Both materials will hold better than glue. But in the first case, it will cost more, and in the second, it will take a lot of time and patience, since the sheets need to be pressed every 15 minutes for 1 hour. Which material to use depends on you and your goals.

Specialization: Master in the construction of plasterboard structures, finishing works and laying floor coverings. Installation of door and window blocks, decoration of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

Today I will tell you how to glue drywall. This installation option is very different from the traditional technology with a frame, but if you understand the process and follow all the recommendations, you can get smooth walls without drilling and exposing the structure. For many, it is the frame that is the most difficult element in the work, but if you use the glue method, you can cope with the work much faster and easier.

Work options

Facing the walls with plasterboard on glue is good because you will not oppress your neighbors with the roar of a puncher, and you will not have to check the plane of the frame for a long time. For inexperienced developers, this is the easiest option, the wall is completely closed from floor to ceiling and the work progresses quickly.

Preparatory stage

To begin with, let's figure out what is needed, especially since the list of basic materials and tools is the same for all options for carrying out work, only their number changes. As for the materials, we need the following:

| Materials (edit) | Description |

| Drywall | We will use a wall version with a thickness of 12 mm, it is not worth using ceiling sheets due to their low strength. Naturally, for rooms with high humidity, you will need a moisture-resistant material, it has a green color. As for the height of the sheets, the most common options are 2.5 and 3 meters, you need to choose according to the height of the ceilings so that the surface is covered with one sheet |

| Adhesive composition | There may be many options, I myself have used at least a dozen, but I will recommend you the one that is on sale almost everywhere and is distinguished by quality and reliability. This is "Knauf Perflix", it is most often sold in bags weighing 30 kg, its price is about 300 rubles per pack. Naturally, the consumption depends entirely on the condition of the walls. |

| Primer | With the help of this composition, the base is strengthened, because for the best installation quality we need to achieve maximum adhesion of the glue. Two types of primers are used, and below I will tell you where and which type is best used and how to do it correctly. |

Sometimes you need to level the base with cement mortar or seal the cracks in it with polyurethane foam. We will not consider these options for work, since we mean that you have a more or less finished surface that can be finished.

It is impossible to do without a certain set of tools, its list is not as extensive as in the case of the frame device:

- Since the adhesive sets within 30 minutes, it must be cooked often and in small portions. That is why it is better to have a drill with a mixer attachment at hand, otherwise you will very quickly get tired not from the main work, but from mixing the glue, and it takes a lot of time;

- The composition is best stirred in a convenient container with low sides, its volume should be at least 10 liters;

- It is very important to have a long level or a rule with a level at hand, because we will constantly check the plane of large sheets and we simply cannot do without it. This is the simplest tool; if you wish, you can also use laser devices, which the pros love so much;

- The glue can be applied with a notched or ordinary trowel, trowel, small spatula. You need to choose what is most convenient for you in a given situation.

Technology No. 1 - for flat walls

If your walls are almost perfectly flat, which happens on concrete or plastered surfaces, then the gluing of drywall to them will be done according to the following scheme:

- Since we will fix the sheets close to the wall surface, it is necessary to lay all the wires in advance... So that they do not create interference, grooves of the required size are made on the surface, into which the cable is fixed, after laying the wire, you can cover it with cement mortar. In the required places, wires are brought out and holes are made for sockets and switches, for work, special crowns of the required diameter are used;

- The surface is cleaned of dust, after which a primer must be applied to it, if you have a regular plastered or concrete wall, then it is best to use a reinforcing compound. Sometimes there are situations when the surface is painted with oil or another and the adhesive does not stick to it. In this case, a special adhesive composition with a quartz filler is used, after such processing, the glue will adhere perfectly;

- Before gluing the element to the surface, you need to prepare it. If necessary, a part of the sheet is cut to the desired height, and holes for sockets and switches are cut out. The work is done using simple crowns that cost a penny and can be installed even on a screwdriver, drywall material is not solid, so much power is not needed;

- As noted above, the glue composition hardens very quickly, so you need to cook it for 1-2 sheets, especially at the beginning, when you have not yet filled your hand and entered the rhythm. The composition is applied to the surface using a notched trowel with a tooth size of 8-10 mm, this will ensure good adhesion and economical consumption of the mixture. The excess is removed, they can interfere with the alignment of the element;

- The sheet is placed face down in the place of its installation. In general, you can immediately put it in place and apply glue there, this will even simplify the workflow. Naturally, boards must be placed under the material so that it does not damage the floor and does not get dirty;

- Before gluing the drywall to the wall, you must carefully lift it and pull the wires through the holes, if you forget about it, you will either have to tear off the sheet or cut it;

- Plasterboard gluing is very simple: first, the sheet is gently pressed against the wall, you do not need to press hard. After that, using the rule, the places where the material should be pressed are determined, this can be done by simply tapping with your hand (usually I correct most of the flaws) or by applying the board and hitting it with a mallet or something else. You do not need to be very zealous, it is better to knock out again later than overdo it on the move.

In no case should you hit the level, so you will sooner disable the tool than level the walls. This is a very accurate tool and it is not a good idea to use it for alignment.

Technology No. 2 - for moderately uneven walls

If your level drops on the wall are up to a couple of centimeters, then the previous version of the work will not work. Let's figure out how to attach drywall to the wall with glue in a different way, it has a lot in common with the above option, but there are a number of differences. Instructions for doing work with your own hands consists of the following actions:

- Preparation of the base, its priming and cable laying are carried out in the same way as in the above case. The same applies to the preparation of sheets, so we will omit these points and go straight to the consideration of the workflow;

- Before starting work, you need to prepare an adhesive mixture, in this case its consumption will be much higher, since the application will not be done with a notched trowel, but in dots or heaps on the surface. With their help, you can compensate for irregularities and at the same time firmly fix the material;

- The sheet is placed on pads at the place of its gluing (work usually starts from the most protruding section of the wall), after which glue is applied to it. The points are made around the entire perimeter and are located in increments of 25 cm, in the middle of the sheet - they are placed every 40 centimeters, there should not be large voids, as this will negatively affect the reliability of the fastening;

- Gluing drywall begins with pulling wires, if any, and lightly pressing the element to the surface, it should just hook onto the wall. It is best to carry out the work together, so that one person constantly holds the sheet and helps to press it if necessary, this is both easier and faster;

- Before gluing drywall thoroughly, you need to carefully check the plane in all directions, and then determine in which places you need to press the material. After the initial alignment, another check is made, if necessary, individual sections are knocked out and so on until the result is completely satisfactory to you. If you do not finish the work, then the following sheets will be even more difficult, remember this.

Here you need to consider another option, when drywall is glued to the walls of aerated concrete or foam concrete. In this case, we glue the gypsum board on the contrary, applying the composition not to the sheet, but to the wall, this provides a more reliable fixation of the material. From myself, I note that this option is less convenient and requires more care when installing the sheet, it can be very easily skewed.

Technology No. 3 - for walls with large irregularities

One of the common questions is whether it is possible to glue drywall on a surface with large differences without continuous plastering. Everything is quite realizable, but the technology will differ markedly from the options described above, the process looks like this:

- First of all, you need to remove from the surface all pieces of plaster that do not hold well. That is, there should be no elements on the surface that can fall off later;

- Priming is also a mandatory step, the composition allows you to strengthen loose areas and reduce the absorbency of the surface, thereby improving the adhesion of the adhesive. It is necessary to apply the primer so that it gets everywhere, therefore, on uneven surfaces, it is better to use a brush-brush, and not a roller, it distributes the solution better;

- Next, you need to prepare the beacons, 100 mm wide strips are cut from drywall, and we will use them to create an even base. The number of elements depends on the area to be faced, the elements are located along the perimeter of the wall, as well as vertically every 40-60 cm, based on this, calculations are made;

- Next, you need to set up beacons, for this, first, the surface is marked along the perimeter, so that you can see along which line to expose the elements. They are also fixed with glue, the layer of which is adjusted depending on the level differences of the walls. I recommend first sticking the elements around the perimeter and waiting for them to dry, especially since it only takes half an hour;

- Then you need to glue the vertical posts, they are set in level, it is important to control the position of both each element individually and the surface in general. Check entire sections of the wall and adjust the position of the guides while the adhesive has not yet had time to harden;

- When the glue on the structure hardens, you can start gluing the base material. For this, the adhesive composition is applied in lines along the width of the location of the guides, after which the element is gently lifted and pressed against the surface. If you have leveled the base well, then at this stage it will not be difficult to expose drywall exactly, as a result, you will get a structure, as in the picture below;

- Work is carried out until all surfaces are coated. Further finishing is no different from the usual option, the main thing is that the adhesive composition is dry.

Sometimes, to save drywall, beacons are made not in strips, but in the form of dots, in this case it is easiest to set the uppermost elements first and hang a plumb line from them to control the vertical. How to properly glue the sheets in such a situation? It's simple: the composition is applied not to the sheet, but to the resulting areas, so you don't have to puzzle over how to place the glue where you need it.

The installation method, in which a drywall sheet is attached to a vertical surface with glue, has a number of undeniable advantages. It allows you to simultaneously glue the material and level the walls, protect the coverings on the back from the effects of aggressive environments and the harmful effects of microorganisms, thanks to the ease of installation technology, you save your budget and personal time.

Installing drywall on glue saves space in the room, which, if the frame was installed, would be 5-6 cm less on the side of each wall. To make a quality installation, you will need:

- decide on the choice of glue;

- prepare the surface;

- follow the installation instructions.

To install a drywall sheet on the wall using the adhesive method, use the products of two reputable manufacturers: Knauf (Perlfix series, Germany) or Volma (Installation series, Russia). The use of a domestic brand is preferable for the following reasons:

- the cost is lower;

- the consumption of the mixture for applying a layer with a thickness of 1 mm and an area of 1 m² on a serpyanka is only 2-3 kg, in comparison with 5 kg of the Knauf brand;

- the period of complete drying for Volma glue is 24 hours, for Knauf mixture it reaches 7 days;

- strong adhesion to the surface due to the content of gypsum in the fibers;

- the setting time of the mixture on a flat surface is 1 hour, for Perlfix this threshold occurs 30 minutes after mixing, if the mixture is applied to a serpyanka tape, the setting period is even less (40 and 15 minutes, respectively);

- easily takes the form of irregularities, after hardening it does not shrink.

For DIY installation, it is preferable to use Volma glue. For a beginner, the form of packing of the material is also convenient - 5, 15 and 30 kg. This allows you to easily calculate the material, save on costs, determine the amount of work for yourself in advance and have a certain period of time in stock before the mixture has time to set. Knauf adhesive mixture is designed for a professional approach. Packing form - 30 kg.

To glue a sheet of drywall to the wall with Knauf mixture, professional skills are required to work at a fast pace. Packing form Perlfix - 30 kg. The optimum temperature for the mass to acquire its properties is +5 degrees in conditions of normal humidity.

Form of packing of Volma glue Installation

Form of packing of Volma glue Installation Surface preparation

Before starting to glue a sheet of drywall on Volm's glue, a surface is prepared for it. To do this, using a level or a stretched cord, a number of measurements are made to reveal irregularities at the base of the walls. If the deviations do not exceed 2 cm, proceed to the following steps:

- clean the walls from old finishes (wallpaper, paint, plaster), dust and other contaminants;

- the surface is covered with two layers of a primer that increases the level of adhesion of the material from which the vertical floors (brick, concrete, wood) are made with glue;

- if the deviations in curvature are a little more than 2 cm, a layer of plaster is applied to the wall, this will smooth out irregularities, which will then be filled with glue;

- then the layout of the drywall sheets is calculated so that after installation they do not touch the floor at a distance of 10-15 mm (this space is required for the climatic adaptation of the material);

On the rough wall, you can install a crate or glue a serpentine tape, which will allow the glue to adhere even more firmly to the wall.

Applying plaster over serpyanka

Applying plaster over serpyanka Glue installation

As tools to glue a sheet of gypsum board with your own hands, you will need:

- a bucket or bowl for kneading;

- drill or mixer;

- building level;

- trowel and spatula for applying glue;

- hammer with a wide board.

Installation steps:

- dilute the glue in a bucket of water in the proportions indicated on the Volma package;

- the calculation of the mass of the mixture is carried out depending on the volume of work performed and on the curvature of the walls, on average it is equal to 10-12 liters, so that it does not have time to grab;

- apply the adhesive mixture on the wall or on the drywall sheet itself, evenly distributing it over the surface with small dots in a checkerboard pattern in increments of 40 cm or stripes 15 cm wide.This application will allow you to adjust the location of the gypsum board relative to the vertical and horizontal plane;

- it is recommended to glue the gypsum sheet from the corner of the room, for this it is gently pressed against the wall and leveled;

- if the level shows that the sheet is laid unevenly, by tapping with a hammer on the wooden board, the glue applied on the back is more evenly distributed, reducing the resulting voids.

Distribution of glue over the surface of the gypsum board and its correct consistency

Distribution of glue over the surface of the gypsum board and its correct consistency After the installation is completed, a serpyanka tape is glued to the joints between the drywall sheets for additional reinforcement of the seams. The gaps between the joints are filled with Volma glue or a special putty. Each seam is carefully processed so that subsequently moisture does not get between the joints and does not destroy the structure of the gypsum boards.

After the mass has dried, the serpyanka is treated with trowelled emery to remove excess glue, once again apply a primer and after it dries, putty the surface of the drywall. All the stages of installing the gypsum board with the glue method are shown in the video below.

On a note

Remember, if the unevenness indicators reach 10 cm, it is not allowed to glue drywall onto Volm's mixture, because the end result will not be of high quality: the sheet will not be able to adhere tightly to the surface, the adhesion strength will be broken. And the consumption of glue will be unreasonably high.

Correct measurements of the walls before gluing the gypsum board is the basis for high-quality installation

Correct measurements of the walls before gluing the gypsum board is the basis for high-quality installation In such cases, it is recommended to carry out the standard installation of a metal or wood frame. This installation method will additionally insulate the walls of drywall, hide cables and pipes. When using the glue method, it is not possible to perform such work, or it takes a lot of effort to drill special grooves for electrical wiring.

In contact with