How to make a belt sander with your own hands. Making your own belt sanding machine

I made a website about homemade products myself. On our website you will find homemade products; clear instructions will help you easily assemble and use the homemade product you have chosen at home or at work.

The large drum turns the machine into a kind of surface planer grinding device.

Homemade wood sanding machine with sanding drum large diameter allows you to process workpieces thinner than 3 mm. This machine, compared to a wide-belt machine, does not require a labor-intensive belt guide mechanism to manufacture.

Homemade wood sanding machine with sanding drum large diameter allows you to process workpieces thinner than 3 mm. This machine, compared to a wide-belt machine, does not require a labor-intensive belt guide mechanism to manufacture.

Sanding drum manufacturing procedure

The grinding drum of the machine is glued together from separately sawed and milled discs. The skin is attached and stretched with a special clamp. To change the thickness of the wood being removed, the machine's work table moves relative to the drum. The back of the workbench is hinged, while the front is supported by a threaded rod for adjustment. The workpiece is supported and guided by a feed table that slides along the work table. The feed table is moved manually, so there is no need for a special power-driven feed mechanism, and this greatly simplifies the design,

How to make the body of a wood sanding machine with your own hands

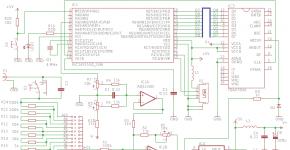

The body is assembled from nine main steels: two side and rear panels of the front strut and two pads, a dowel-spacer at the front rib and two reinforcement discs. All parts are cut to the dimensions shown in Fig. 1.

Since the work table must be strong enough and not bend when pressed against the drum, we made it from two sheets of chipboard glued and fastened with screws. In addition, on the feed side, the work table was reinforced with a thick cross member made of hardwood, which at the same time creates a supporting surface for the adjusting pin.

A feed table runs along the work table, directly supporting and guiding the workpiece during calibration. It is made of 20 mm chipboard and is 38 mm narrower than the work table and of the same length. The table serves to support the workpiece after the passage of the drum. In order for the feed table to move along the work table without distortion, a groove 6 mm deep and 20 mm wide is selected in the middle of its lower side, and a 5 mm thick guide bar is attached to the work table.

Two slats at the ends of the falling table hold it on the surface of a long work table. To ensure smooth movement of the table, a thin veneer spacer is inserted between the slats and the work table, providing a small gap. To prevent the workpiece from slipping back during grinding, a limiter bar made of 5 mm hardwood is inserted into a 3 mm groove in the table (Fig. 1).

The desktop is attached to the rear panel of the case with two hinges. The crossbar on the workbench should align with the adjusting pin. The drum is made of chipboard. Its width is 460 mm, Ø400 mm, which provides a wide grinding area. The drum is assembled from 24 discs, roughly cut individually, and then glued and fastened with screws (Fig. 2). The drum is balanced after installing the sandpaper clamp.

To reduce the weight of the drum, most of all discs are cut into rings 50 mm wide. Two external drive and one in the middle - solid and holes drilled in them for a steel axle Ø20 mm. The drum is covered with dense rubber 1.5 mm thick. It serves as a backing for the skin and provides it with a better fit to the part.

Attaching the sandpaper for wood sanding

To make installation and removal of the skin easier, we have developed a simple spring-lever clamp.Fig. 3).

Installing the Drum Sander

The drum rotates on a Ø20 mm axis (an Ø16 mm axis can be used), supported by four bearings in cages bolted to the side panels of the machine. To make it easier to align the drum, the holes for them are drilled with a diameter slightly larger than the diameters of the bolts.

We chose a single-phase 1750 rpm motor as the drive. The motor base is attached directly to the rear panel, and the switch is attached to one of the covers on the front of the machine. A 2*75 mm pulley was put on the motor shaft, the driving and driven pulleys were inserted into the same plane and secured.

V. Laskin, D. Ren. Canada

Based on materials from CAM magazine

Chapter: Various homemade products Date of publication: 2-03-2012, 03:58

Belt sanding machines for wood are a technique that is used at the final stages of production of parts and structures made of wood and wood materials. The equipment is used for finishing machining of workpieces.

Since the need for it exists in a variety of industries, wood sanding machines have become widespread.

Such units are of particular value for manufacturers of furniture and other consumer goods made from wood. Modern grinding machines are capable of processing various types of wood, which indicates their versatility and multifunctionality.

What is this equipment mainly used for?

The key purpose of using grinding machines is final leveling. wooden surface, elimination of irregularities and roughness, creation of smooth, even surfaces, removal of minor mechanical defects, varnish deposits, burrs.

Also, belt grinders are often used when processing curves, as well as for internal grinding of workpiece elements.

The basic areas of application of these machines, depending on the type of feeding and processing, are as follows:

- Treatment of curved surfaces, providing for free movement of the belt;

- Grinding of flat parts on a stationary table, as well as with manual or mechanized movement work surface;

- Grinding of block and panel elements;

- Treatment paint coating details.

To understand what wood belt sanding machines are, it makes sense to study their design in more detail.

Let's look at this issue in more detail below.

Design features of the grinding machine

Today, belt sanding machines are produced by both domestic and foreign companies. The range and variety of this type of equipment is quite wide, as are its prices. Models vary depending on performance and other parameters.

How to make a belt sanding machine with your own hands?

Their designs also differ, but still, there is something that unites them and makes them similar to each other. It's about about the main processing tool - an abrasive belt.

In the vast majority of models of wood sanding machines, it is a closed ring of the processing blade, which is fixed between two rotating drums, one of which plays the role of a leading element connected to the power unit.

The drive drum is usually equipped with a mechanical transmission, the basic element of which is a belt drive. It is this that receives torque from the electric motor.

At the same time, the design of the wood belt sanding machine provides the ability to select the intensity of rotation of the drive drum, which allows you to select the most suitable format for processing a specific workpiece.

Depending on the design features a certain model machine, the abrasive belt can be positioned horizontally or vertically.

There are also special modifications of the units, the design of which provides for the location of the belt at a certain angle. The belt is installed on the bed, where the workpiece is polished.

In simplified machines, the workpiece is held manually by the master. However, this format of grinding is increasingly becoming obsolete, since it is not safe enough and is unproductive. Models in which the workpiece is fixed using special additional devices are characterized by increased productivity and processing efficiency.

The work table of a wood sanding machine is one of the key design elements.

It is usually made from wood or metal. In the second case, the unit will be convenient when working with more complex shapes. An important parameter of the table is its size.

It is the dimensions of the working surface that will determine how large parts the master can process using the machine. An experienced specialist knows that if a part is longer than the work table, it will not be easy to process it. Of course, this inconvenience will affect the quality of the final product, and the operating time will be longer.

Nowadays, manufacturers of wood belt sanding machines offer two main types of devices - with a fixed and movable working surface, as well as machines with a movable abrasive belt.

In all this diversity, a separate group of units stands out - wide-belt machines, in which the table combines the functions of a working surface and a feeder. Machines equipped with a table have a horizontal belt, while machines with a free abrasive belt can provide any angle of inclination.

It is no secret that when sanding a wooden workpiece, a large amount of chips is formed.

So that it does not interfere with the master doing his work, domestic and foreign equipment manufacturers equip machines with special high-performance hoods, which remove most of the waste during operation.

As for power units for grinding machines, then most manufacturers limit themselves to electric motors with a rated power of 2.5-2.8 kW.

The average speed of the belt when installing such a motor is about 20 meters per second.

conclusions

Today, belt sanding machines are produced in large numbers throughout the world. European and, in particular, German companies are considered leaders in terms of the quality of structures and the intensity of innovation in them. Among the flagships, it is worth highlighting such brands as Fein, Loeser, WAHLEN, SALTEC, NIEDERBERGER, BM.

If you are looking for more affordable technology, then you should pay attention to domestic achievements in this area.

Units of decent price and quality are supplied to the CIS market by the Lipetsk Machine Tool Plant. Equipment produced by MS-GROUP and NEVASTANKOMASH LLC is also in demand. A compromise choice between expensive German cars and domestic units lagging behind in a number of parameters could be Czech products trademark PROMA.

Obviously, for a master, finding suitable equipment will not be difficult.

You just need to decide how much you are willing to spend on equipment and what exactly you expect from it.

Assembling a homemade grinding machine

Process Features

A homemade grinding machine is not that uncommon; assembling it with your own hands is quite possible.

A sanding machine is indispensable when finishing wood parts.

A grinding machine is a necessary thing and will always come in handy in the household.

If you come across spare parts in large quantities, and also have free time and a desire to try yourself as a design engineer, then the homemade grinding machine in your hands will be suitable for work.

So, you will need:

- motor (its role can be played by any other motor taken from any electrical device);

- electric drive (the most ordinary battery from a computer Ups is suitable for these purposes);

- screws;

- wires;

- switch;

- board;

- sandpaper;

- glue;

Assembly and installation stages

Grinding machine diagram

Once you have all the necessary tools, you can begin to make the grinding unit.

To start with wooden board, pre-treated with varnish, you need to attach the motor. Finding it is as easy as shelling pears; many people probably have an old, non-functional computer hard drive at home. By disassembling it, removing the top cover and removing the head block, you will get an ideal blank - a motor. If you want your sander to have more power, then it makes more sense to use a more powerful motor.

For example, from a fan. And if you plan to make a serious stationary grinding machine, then in this case you need to take an electric motor from an unnecessary washing machine. Then, in addition to the grinding function, it will also be able to act as an angle grinder.

The next step will be the installation of the electric drive.

Wood sanding machines: belt, disk, drum

In order for the motor to work, you need to provide it with an uninterrupted power supply. If your grinder has a small motor, then the power supply to it must be done in a special way. For example, through a battery.

After the main components of the homemade product are sufficiently firmly fixed to the board, they will need to be connected to each other. This operation can be performed using ordinary wires. Don’t forget about the switch; be sure to integrate it into the overall circuit.

If you attach a felt attachment to a sanding machine, you will get a polishing machine.

Now you need to make your own grinding wheel.

To do this, take sandpaper and cut out two circles of suitable diameter. After that, glue them together. You now have a finished grinding wheel, made by yourself. Of course, you can buy a ready-made circle at any specialized store.

By the way, they also sell circles in small sizes.

Next, we proceed to attach the circle to the motor using two simple bushings. When attaching, be guided by the diameter of the motor axis, as there is a possibility of a mismatch in diameter. In this case, you can simply select plastic bushings according to the diameter of the axle.

As you can see, the process of making a grinding machine with your own hands is quite simple and does not require special effort and costs.

After all, it can be made from scrap materials. With this machine you can easily sand various metal or wooden parts.

Do-it-yourself wood grinding machine drawings video

There is a huge amount of sanding equipment that can make any wood surface very smooth.

It consists of a frame on which there is a special frame with an electric motor (washing machine motors are used for homemade products) and a mechanism. The mechanism itself, in turn, includes shafts, pulleys and an abrasive belt.

Application area

They are used in all industries where wood is processed.

Often, any rough products have an uneven and rough surface. Such blanks cannot simply be painted and put up for sale or installed anywhere.

Belt Sanding Machine

These shafts are driven by an asynchronous electric motor. During wood processing, the abrasive belt does not sag, but rests against the working plane, which has a low coefficient of friction. The tape can be positioned both horizontally and vertically.

The advantage of this equipment is the processing of long workpieces.

Disc grinding machine

The working area of this equipment is an abrasive wheel.

A circle with Velcro is attached to the axis of the electric motor, onto which the abrasive is attached. After starting the motor, the abrasive wheel rotates around its axis, thereby carrying out grinding. This type of machine has the ability to regulate the processing speed, and the number of axis revolutions will not decrease.

grinding machines . And that’s not all, in order not to spend money on machines, people came up with grinders from a drill, from Bulgarian.

The fact is that attachments are attached to these tools and the same grinding is carried out.

Calculation of power for the motor

Important! Before creating any homemade creation that performs grinding functions, it is extremely important to correctly calculate the power of the electric drive.

After all, if the motor power is weak or, on the contrary, strong, then you will not be able to do any work.

P=qS(K+k)U/1000n

Blueprints photo scheme. As an example for visual study, consider a belt sanding tool.

Grinding machine drawing

The other side of the frame is designed to accommodate the shaft, with a pulley for the belt and rollers for the abrasive belt. The tape itself is installed with a slight slope.

This is done so that the abrasive comes into smooth and accurate contact with the workpiece plane being processed.

Tip: Before installing the abrasive strip on the rollers, you need to wrap a thin strip of rubber around them. This will reduce the strip slipping during operation.

- Wood board.

- Ball bearings.

- Electric motor.

- Rubber belt.

- Rubber belt.

- Metal pulley.

- Self-tapping screws, fasteners.

- Abrasive element.

After we have decided on the materials and working tools, we can begin assembling all the parts and elements into one mechanism. To do this, the frame is assembled. It can be metal (consist of a metal profile pipe) or wood (consist of wooden blocks and solid wood).

When the bed is ready

You can begin installing the motor. The motor power should be no less than 2.5 kW and no more than 3 kW, with an engine speed of 1200 to 1500 rpm. A belt pulley is installed on the motor shaft. The motor is installed on one side of the frame.

Grinding machine - all its varieties

Motors are often used from washing machines used in everyday life.

On the other side

There is a shaft with bearings, on one side of which a pulley is attached, and on the other side a roller, on which an abrasive belt will later be placed. The shaft pulley and motor must be located in a flat horizontal plane. The belt tension mechanism should be located in the same area.

Next from wood

After that

Once everything is done, you can make the first start and configure the equipment properly. When the settings are made, the first workpiece is run and the result of the work is checked.

If everything was successful, it means that you did everything right.

download video instructions.

Video reviews

Belt sanding machine for wood and metal

Belt sanding machine for wood and metal  Do-it-yourself drum sander for wood

Do-it-yourself drum sander for wood  Do-it-yourself wood sanding machine: drawings

Do-it-yourself wood sanding machine: drawings  DIY - plywood sander.

DIY - plywood sander.

with your own hands  50 facts about me (I wanted 10, but I got carried away) My success. Blog

50 facts about me (I wanted 10, but I got carried away) My success. Blog  Battlefield 2 "Editing bots" - Files - patch, demo, demo, mods

Battlefield 2 "Editing bots" - Files - patch, demo, demo, mods

How to make a grinding machine with your own hands: instructions with step-by-step photos

Nowadays, there are no surfaces that are not smooth.

Smoothness is achieved through various grinding devices. Professional equipment costs big money and not everyone will be able to purchase it, moreover, such machines have a fairly high weight and dimensions.

Fortunately, the skillful hands of our country have adapted to producing analogues of equipment for such a modest budget. The grinding machine also did not stand aside and was subjected to modernization of manual skills. It is with this homemade machine that we will continue to get acquainted.

There is a huge amount of sanding equipment that can make any wood surface very smooth. It consists of a frame on which there is a special frame with an electric motor (washing machine motors are used for homemade products) and a mechanism. The mechanism itself, in turn, includes shafts, pulleys and an abrasive belt.

Application area

They are used in all industries where wood is processed. Often, any rough products have an uneven and rough surface. Such blanks cannot simply be painted and put up for sale or installed anywhere.

Guide to choosing sanders

Therefore, for further processing of wood, all its surfaces can be sanded.

Grinding machines are also used for processing sagging and chamfering, and rounding corners. In addition, the grinding tool gives any surface a smooth leveling and calibration.

Types of wood sanding machine

Depending on the surface being processed, the following types of grinding machines are distinguished:

Belt sanding tool

Belt Sanding Machine

This equipment uses an abrasive belt that is tensioned by two shafts.

These shafts are driven by an asynchronous electric motor. During wood processing, the abrasive belt does not sag, but rests against the working plane, which has a low coefficient of friction. The tape can be positioned both horizontally and vertically. The advantage of this equipment is the processing of long workpieces.

Universal grinding unit

Universal grinding machine

In this case, the machine has two working grinding surfaces.

One is a tape surface, and the other is circular (disc). This universal machine was created for ease of use. By the way, this configuration will significantly save your budget. This device uses only one motor.

Based on this, when working on two working surfaces, the load on the motor will not increase much.

Drum grinding tool

Drum Sanding Machine

In this case, the abrasive belt is wound on two rollers in a spiral manner.

Under the rollers there is a tabletop with a smooth surface. The gap between the tabletop and the rollers is adjustable to the required distance. Using such a machine, you can calibrate the surface of a wood piece.

Disc grinding tool

Disc grinding machine

The working area of this equipment is an abrasive wheel. A circle with Velcro is attached to the axis of the electric motor, onto which the abrasive is attached.

After starting the motor, the abrasive wheel rotates around its axis, thereby carrying out grinding. This type of machine has the ability to regulate the processing speed, and the number of axis revolutions will not decrease.

On each of four types machines can perform certain operations. Now that we have an idea of what grinding equipment looks like, it's time to disassemble the design of the machine.

In addition to the above machines, there are also portable ones. grinding machines.

And that’s not all, in order not to spend money on machines, people came up with grinders from a drill, from Bulgarian. The fact is that attachments are attached to these tools and the same grinding is carried out.

Advice: If you decide to purchase a factory grinding machine, then decide in advance on the work and loads that your device will undergo, and only then make the purchase.

The same applies to homemade tools.

Calculation of power for the motor

Important! Before creating any homemade creation that performs grinding functions, it is extremely important to correctly calculate the power of the electric drive. After all, if the motor power is weak or, on the contrary, strong, then you will not be able to do any work.

Power calculation is carried out using a special formula, which belongs to the category of complex mathematical calculations.

The formula is as follows

P=qS(K+k)U/1000n

Where each designation means the following

- q – Means the pressure of the processed wood part on the plane of the abrasive blade (N/ square centimeter).

- k – Index of friction of the reverse side of the abrasive on the working surface.

- n – Coefficient useful action the entire system.

- K - Indicator of the working plane of the abrasive relative to the workpiece. The priority is the density of the wood and its grain size. The limits of this indicator range from 0.2 to 0.6.

- S – The area of the workpiece that comes into contact with the abrasive, measured in square centimeters.

- U – Abrasive rotation speed, measured in meters per second.

When you calculate using the formula required power electric drive of your future unit, you can safely start assembling the machine as a whole.

It's time to get acquainted with the design homemade machine. Blueprints all four types of equipment can be found in free access for viewing and downloading, as well as downloading all kinds of photo scheme.

As an example for visual study, consider a belt sanding tool.

Grinding machine drawing

Machine design and diagrams

Any assembly of homemade equipment begins with the construction of a frame or foundation for future machine equipment.

This can be done using metal material, either from wood material. The standard dimensions of the frame are 500 mm x 180 mm, and the thickness should be 2 cm.

After making the base, you can proceed to the next steps. An asynchronous motor can be installed in several places so that its operation is complete. Prepare a plane on the frame itself or make a platform for the motor, which will be attached to the end of the frame.

The other side of the frame is designed to accommodate the shaft, with a pulley for the belt and rollers for the abrasive belt. The tape itself is installed with a slight slope. This is done so that the abrasive comes into smooth and accurate contact with the workpiece plane being processed.

Belt sanding machine diagram

Tip: Before installing the abrasive strip on the rollers, you need to wrap a thin strip of rubber around them.

This will reduce the strip slipping during operation.

As we can see from the diagram and drawing, the design of the grinding equipment is quite simple. All varieties of these machines are assembled according to the same scheme.

Tip: When assembling your future grinding unit, you must comply with all required dimensions, and also the calculation of all parameters must be done extremely seriously.

When the design is familiar to us, we can move on to the assembly process.

Grinding machine assembly process

To assemble the grinding tool, you will need the following elements:

- Wood board.

- Wooden blocks or metal profile pipe.

- Ball bearings.

- Electric motor.

- Rubber belt.

- Rubber belt.

- Metal pulley.

- Self-tapping screws, fasteners.

- Abrasive element.

- Working tools (drill, grinder, screwdriver, jigsaw, etc.).

- Welding machine (if the frame structure consists entirely of metal).

After we have decided on the materials and working tools, we can begin assembling all the parts and elements into one mechanism. To do this, the frame is assembled.

It can be metal (consist of a metal profile pipe) or wood (consist of wooden blocks and solid wood).

When the bed is ready

You can begin installing the motor. The motor power should be no less than 2.5 kW and no more than 3 kW, with an engine speed of 1200 to 1500 rpm.

A belt pulley is installed on the motor shaft. The motor is installed on one side of the frame. Motors are often used from washing machines used in everyday life.

On the other side

There is a shaft with bearings, on one side of which a pulley is attached, and on the other side a roller, on which an abrasive belt will later be placed.

The shaft pulley and motor must be located in a flat horizontal plane. The belt tension mechanism should be located in the same area.

Next from wood

Either a stand is constructed from plywood or metal, on which the remaining rollers will be placed and the sanding tape will be put on. There must also be a tension mechanism. In addition, there must be a working bar against which the abrasive belt will rub.

A start button is installed on the frame, usually at the end.

The electrical circuit of the machine must be grounded.

After that

Once everything is done, you can make the first start and configure the equipment properly. When the settings are made, the first workpiece is run and the result of the work is checked. If everything was successful, it means that you did everything right.

For visual clarity and a complete understanding of the entire assembly process, you can download video instructions.

General reviews and summary

As a rule, there are only positive reviews about this type of equipment on the Internet. Indeed, when in everyday life it is necessary to give this or that wooden thing a smooth surface, then the presence of sanding tools is indispensable.

Video reviews

Video review of a homemade grinding machine:

Video review on choosing grinding equipment:

Video review of the belt sanding machine:

Video review of eccentric sanders:

DIY grinding machine: drawings, photos and videos

DIY grinding machine: drawings, photos and videos  Do-it-yourself belt sanding machine - Easy job

Do-it-yourself belt sanding machine - Easy job  How to make a grinding machine with your own hands: instructions, description Cheap do-it-yourself grinding machine

How to make a grinding machine with your own hands: instructions, description Cheap do-it-yourself grinding machine  Do-it-yourself wood grinding machine drawings video

Do-it-yourself wood grinding machine drawings video  Do-it-yourself grinding machine Video on the Zaporozhye portal

Do-it-yourself grinding machine Video on the Zaporozhye portal  Belt grinding machine: study and do it yourself

Belt grinding machine: study and do it yourself  How to make a grinding machine with your own hands With our own hands How to assemble a wood grinding machine with your own hands

How to make a grinding machine with your own hands With our own hands How to assemble a wood grinding machine with your own hands  GRINDING MACHINE WITH YOUR HANDS Video!

GRINDING MACHINE WITH YOUR HANDS Video!

— t-Video surfing

Wood grinder: types and performance characteristics. Angle, vibrating, grinding and drilling machines

Sanding wheels for wood

The size of the discs may vary depending on the size and "Bulgarian". They can be sanding wheels for wood with diameters of 115, 125, 150, 180 and 230 mm.

Advice. Never use wood plates intended for metals.

They have a completely different structure, and such measures will not only give the desired result, but can lead to injury.

- Favorable price, especially for models with small wheels whose performance is sufficient for working with wood.

- Comfort of cylindrical beam walls.

Grinding round surfaces

Advice. When sanding, use personal protective equipment, as wood dust can damage the respiratory tract and mucous membranes.

But here, for leveling flat horizontal surfaces, the “Bulgarian” is not very convenient due to the asymmetry of its structure.

drilling

Drill with head grinding

Such a tool is very unusual for use in this field, but can still be handled well in small quantities.

For them, special rubber-based circles with a rectangular pin fixed in the rod are used. While doing this, do this by shooting and fixing it.

- Cheap and easy to use.

- Extended. You can find exercises in almost every home.

- Convenient handling of hard-to-reach cities.

Large areas of the same appliance varnish will be very problematic.

Vibration grinding machine

Handheld Vibratory Sanding Machine for Wood

This version of the equipment is much more suitable for processing smooth surfaces.

The electric motor controls the working part of the device through a transition eccentric, so that its translational movements are performed from one side to the other, which perform grinding.

You can select sanding paper of any grit size, cut it and secure it with a specially secured fastening system.

A characteristic disadvantage is that due to the small amplitude of brush strokes, removing thick layers of wood is very stressful.

Explosive machine

Hand Sander for Wood Belts

It is the most effective tool for high-quality finishing of wooden floors and vertical structures, even wooden structures.

The operating principle is similar to that of a desktop computer and a stronger representative of abrasive equipment and includes the following:

- There is a round belt of sandpaper mounted on two rollers.

Spare belts for belt sanders

- When the engine is turned on, the drive cylinder begins to rotate so that the pillow moves.

- Bring to selected surface and grind.

Bottom grinding

The advantages of such equipment:

- Simplicity and practicality of work.

- High performance.

- Cost of consumables.

- Availability of a special bag for collecting wood dust.

Device with a bag for collecting dust from wood

- Possibility of use as stationary equipment.

To do this, the tool is installed on a platform with special frame or a clamp.

Portable Wood Chipper

Stationary equipment

If you need to polish a lot of small parts, instead of a massive plane, it is more rational and convenient to use a stationary wooden grinder securely mounted on a flat surface and has great potential.

DIY wood sanding machine

Many of them are mainly used in the wood processing industry.

Let's look at some of them:

- Draw machine. The basic operating principle of such devices is similar to their small masters.

This means that there are also two rollers, one of which is powered by an electric motor, and an abrasive belt is mounted on them. But let's take a closer look at the structure of such equipment:

Narrowband Fixed Mill Machine

LBSM 2505 ESE for wood polishing

- Drum machine.

In this case, the abrasive material is not distributed between two pulleys, but is wound on one drum. The main difference between such equipment is the ability to remove the most precise layer of wood, which is very important when processing parts of different models.

Drum type grinding and sizing machine

Home car

It’s also worth thinking about how to make a homemade milling machine:

- We take an electric motor from an old washing machine.

Example of a suitable electric motor

- Prepare a metal rod with a cross section of 2cm, a diameter of 10cm PVC, plate, screws, rubber and glue, and then assemble the drum:

- A section of a piece of pipe that is slightly inferior to the selected strip.

- Two plates with a diameter of 10 cm were cut into a plate and 2 cm holes were drilled in them.

- We insert plugs into the tube and insert rods into it.

All joints are impregnated with glue.

- From the top glue tube with rubber, which in the future will serve as a suitable substrate for recording tape.

- The bag and desk are pulled out from a thick, durable board. Please note that all connections are securely attached and that the entire structure is stable. To ensure that the workpiece moves relative to the drum, secure it with the key loop and tighten the screw to the screws provided by the power supply.

- We assemble all the elements into one piece, we supply the wiring and switch.

Easy to Install Self Leveling Wood Sanding Machine

conclusion

The tree can work with manual and stationary equipment.

The first group includes tools that can be found in the workshop of any guardian: a drill, a grinder, a vibrating and sanding belt for wood. They are very suitable for polishing floors, walls and other large structures.

If you need to precisely remove wood from certain parts, then you will need one of the above machines. in this article you will find Additional materials. Make your choice according to the situation.

Work for wood sander

Nowadays, there are no surfaces that are not smooth. Smoothness is achieved through various grinding devices. Professional equipment costs a lot of money and not everyone can buy it; moreover, such machines have a fairly high weight and dimensions.

Fortunately, the skillful hands of our country have adapted to producing analogues of equipment for such a modest budget. The grinding machine also did not stand aside and was subjected to modernization of manual skills. It is with this homemade machine that we will continue to get acquainted.

There is a huge amount of sanding equipment that can make any wood surface very smooth. It consists of a frame on which there is a special frame with an electric motor (washing machine motors are used for homemade products) and a mechanism. The mechanism itself, in turn, includes shafts, pulleys and an abrasive belt.

Application area

They are used in all industries where wood is processed. Often, any rough products have an uneven and rough surface. Such blanks cannot simply be painted and put up for sale or installed anywhere. Therefore, for further processing of wood, all its surfaces can be sanded.

Grinding machines are also used for processing sagging and chamfering, and rounding corners. In addition, the grinding tool gives any surface a smooth leveling and calibration.

Types of wood sanding machine

Depending on the surface being processed, the following types of grinding machines are distinguished:

Belt sanding tool

This equipment uses an abrasive belt that is tensioned by two shafts. These shafts are driven by an asynchronous electric motor. During wood processing, the abrasive belt does not sag, but rests against the working plane, which has a low coefficient of friction. The tape can be positioned both horizontally and vertically. The advantage of this equipment is the processing of long workpieces.

Universal grinding unit

In this case, the machine has two working grinding surfaces. One is a tape surface, and the other is circular (disc). This universal machine was created for ease of use. By the way, this configuration will significantly save your budget. This device uses only one motor. Based on this, when working on two working surfaces, the load on the motor will not increase much.

Drum grinding tool

In this case, the abrasive belt is wound on two rollers in a spiral manner. Under the rollers there is a tabletop with a smooth surface. The gap between the tabletop and the rollers is adjustable to the required distance. Using such a machine, you can calibrate the surface of a wood piece.

Disc grinding tool

The working area of this equipment is an abrasive wheel. A circle with Velcro is attached to the axis of the electric motor, onto which the abrasive is attached. After starting the motor, the abrasive wheel rotates around its axis, thereby carrying out grinding. This type of machine has the ability to regulate the processing speed, and the number of axis revolutions will not decrease.

Each of the four types of machines can perform certain operations. Now that we have an idea of what grinding equipment looks like, it's time to disassemble the design of the machine.

In addition to the above machines, there are also portable ones. grinding machines. And that’s not all, in order not to spend money on machines, people came up with grinders from a drill, from Bulgarian. The fact is that attachments are attached to these tools and the same grinding is carried out.

Advice: If you decide to purchase a factory grinding machine, then decide in advance on the work and loads that your device will undergo, and only then make the purchase. The same applies to homemade tools.

Calculation of power for the motor

Important! Before creating any homemade creation that performs grinding functions, it is extremely important to correctly calculate the power of the electric drive. After all, if the motor power is weak or, on the contrary, strong, then you will not be able to do any work.

Power calculation is carried out using a special formula, which belongs to the category of complex mathematical calculations.

The formula is as follows

P=q*S*(K+k)*U/1000*n

Where each designation means the following

- q - Means the pressure of the processed wood part on the plane of the abrasive blade (N/ square centimeter).

- k - Index of friction of the seamy side of the abrasive on the working surface.

- n - Efficiency of the entire system.

- K - Indicator of the working plane of the abrasive relative to the workpiece. The priority is the density of the wood and its grain size. The limits of this indicator range from 0.2 to 0.6.

- S - The area of the workpiece that comes into contact with the abrasive, measured in square centimeters.

- U - The speed of rotation of the abrasive, measured in meters per second.

When you calculate the required power of the electric drive of your future unit using the formula, you can safely begin assembling the machine as a whole.

It's time to get acquainted with the design of a homemade machine. Blueprints all four types of equipment can be found in free access for viewing and downloading, as well as downloading all kinds of photo scheme. As an example for visual study, consider a belt sanding tool.

Machine design and diagrams

Any assembly of homemade equipment begins with the construction of a frame or foundation for future machine equipment. This can be done using metal material or wood material. The standard dimensions of the frame are 500 mm x 180 mm, and the thickness should be 2 cm.

After making the base, you can proceed to the next steps. An asynchronous motor can be installed in several places so that its operation is complete. Prepare a plane on the frame itself or make a platform for the motor, which will be attached to the end of the frame. The other side of the frame is designed to accommodate the shaft, with a pulley for the belt and rollers for the abrasive belt. The tape itself is installed with a slight slope. This is done so that the abrasive comes into smooth and accurate contact with the workpiece plane being processed.

Tip: Before installing the abrasive strip on the rollers, you need to wrap a thin strip of rubber around them. This will reduce the strip slipping during operation.

As we can see from the diagram and drawing, the design of the grinding equipment is quite simple. All varieties of these machines are assembled according to the same scheme.

Advice: In the process of assembling your future grinding unit, it is necessary to comply with all the necessary dimensions, and also the calculation of all parameters must be done extremely seriously.

When the design is familiar to us, we can move on to the assembly process.

Grinding machine assembly process

To assemble the grinding tool, you will need the following elements:

- Wood board.

- Wooden blocks or metal profile pipe.

- Ball bearings.

- Electric motor.

- Rubber belt.

- Rubber belt.

- Metal pulley.

- Self-tapping screws, fasteners.

- Abrasive element.

- Working tools (drill, grinder, screwdriver, jigsaw, etc.).

- Welding machine (if the frame structure consists entirely of metal).

After we have decided on the materials and working tools, we can begin assembling all the parts and elements into one mechanism. To do this, the frame is assembled. It can be metal (consist of a metal profile pipe) or wood (consist of wooden blocks and solid wood).

When the bed is ready

You can begin installing the motor. The motor power should be no less than 2.5 kW and no more than 3 kW, with an engine speed of 1200 to 1500 rpm. A belt pulley is installed on the motor shaft. The motor is installed on one side of the frame. Motors are often used from washing machines used in everyday life.

On the other side

There is a shaft with bearings, on one side of which a pulley is attached, and on the other side a roller, on which an abrasive belt will later be placed. The shaft pulley and motor must be located in a flat horizontal plane. The belt tension mechanism should be located in the same area.

Next from wood

Either a stand is constructed from plywood or metal, on which the remaining rollers will be placed and the sanding tape will be put on. There must also be a tension mechanism. In addition, there must be a working bar against which the abrasive belt will rub.

A start button is installed on the frame, usually at the end. The electrical circuit of the machine must be grounded.

After that

Once everything is done, you can make the first start and configure the equipment properly. When the settings are made, the first workpiece is run and the result of the work is checked. If everything was successful, it means that you did everything right.

For visual clarity and a complete understanding of the entire assembly process, you can download video instructions.

General reviews and summary

As a rule, there are only positive reviews about this type of equipment on the Internet. Indeed, when in everyday life it is necessary to give this or that wooden thing a smooth surface, then the presence of sanding tools is indispensable.

Video reviews

Video review of a homemade grinding machine:

Video review on choosing grinding equipment:

Video review of the belt sanding machine:

Video review of eccentric sanders:

I have been making knives for several years now and always use 2.5 x 60 cm and 10 x 90 cm belt sanders in my work. For a long time I wanted to buy another one, with a tape width of 5 cm, as this would simplify my work. Since such a purchase would be expensive, I decided to make it myself.

Problems when designing a future machine:

Three limitations had to be overcome. Firstly, there was no 10 cm wide tape available locally; it could only be ordered online. This didn't seem like a very viable option to me, as there is no greater disappointment than finding out that the tape has worn out and needs to be replaced, and you have to wait a week or two for a new one to arrive. Secondly, there was a problem with the rollers. I searched but couldn't find any tape suitable for 10cm. Thirdly, the motor. A belt sander requires a fairly powerful electric motor, and I didn't want to spend too much money on this project. The best option for me was to use a used motor.

Solutions to design problems:

The first problem with the tape had a simple solution. Since a 20 x 90 cm belt was available for sale in hardware stores at a reasonable price, I could make two 10 cm ones from it. This imposed restrictions on the size of my machine, but due to price efficiency, this option was the best. The second problem was solved using a lathe. To do this, I watched a video on the Internet and realized that I could make the videos I needed myself. With the engine the task was more difficult. I had several electric motors in the garage, but for some reason I had to give them up. Finally, I decided on an old tile cutting machine that had a 6-amp electric motor. At that time, I realized that this power might not be enough. But since the work was at the experimental stage, I decided to first achieve a working version of the machine, and the motor could be replaced later. In fact, the motor is suitable for small amounts of work. But if you're going to be doing more intensive sanding on it, I'd recommend the 12 amp minimum.

Tools and materials

Tools:

- Angle grinder with cutting discs.

- Drill and drill bits.

- Wrenches for 11, 12 and 19.

- Lathe.

- Vise.

Materials:

- Electric motor (6 A minimum, or 12 A recommended).

- Various bearings.

- Nuts, bolts, washers, lock washers of various sizes.

- Metal corner.

- Sanding belt 20 cm.

- 10 cm pulleys.

- Powerful spring.

- Steel strip 4 x 20 cm.

- Beam 2.5 x 10 x 10 cm made of wood or MDF.

Electric motor for machine

I had a choice of several motors, but the electric motor that was on the tile cutting machine had a more suitable casing. To some extent, working on the machine was like an experiment, because I was not sure that the motor had enough power. Therefore, I settled on a modular solution with the frame for the belt mechanism as a single element, which can be removed and rearranged on a more powerful base. The rotation speed of the motor suited me quite well, but I was worried that 6 A would provide weak power. After a little testing, I saw that this electric motor was suitable for simple work, but for more intensive work, you need to choose something more powerful. When designing your machine, pay attention to this point.

As I mentioned, the motor casing was very suitable as it allowed the creation vertical machine, which will be easy to move.

First you need to free it by removing the work table, saw, protection, water tray, leaving only the electric motor. Another benefit of using this motor was that it had a threaded core with a nut to hold the saw in place, allowing the pulley to be installed without using a key (I'll explain what a key is later).

Since I had a pulley that was too wide, I decided to use the large clamp washers that are usually used to secure the saw, turning one over so that there was a wedge-shaped groove between them. I found the space between them to be too narrow, so I put a lock washer between them to widen it. Advantage in this method is that the pressure washers have a flat edge that locks with the flat edge to rotate simultaneously with the core.

Belt

I used a 7 x 500 mm drive belt. You can use a standard 12 mm, but a thin one is more flexible and will put less strain on the motor. He doesn't need to rotate the grinding wheel.Device of a belt grinding machine

The device is simple. An electric motor drives a belt, which rotates a 10 x 5 cm “main” pulley, which drives the abrasive belt. Another pulley 8 x 5 cm is located 40 cm above the main one and 15 cm behind it and is mounted on a bearing. The third 8 x 5 cm pulley rotates on a lever and acts as a tension roller, holding the abrasive belt tightly. On the other side, the lever is attached to the frame by a spring.

Determining the drive type

The main question was to rotate the main pulley directly with an electric motor or with the help of an additional pulley and drive belt. First of all, I chose a belt drive because I wanted to have the option of replacing the engine with a more powerful one, however, there was another reason. When you do intensive metal processing, there is a risk of encountering some problems. The belt drive will slip in such cases, while the direct drive will create big problems. With a belt, the device will be more secure.Frame manufacturing and installation

It is important to mention that using a metal corner as a frame can have both advantages and disadvantages. The obvious advantage is that it is convenient to assemble, like a construction set in childhood. But the main drawback is that it is strong only in two directions, but weak when twisted. This means that we need to take this weakness into account and calculate what torque can be transmitted from the pulleys to the frame, and compensate for it using additional jumpers.

Cutting:

You can use a hacksaw to cut the corner, but an angle grinder with a cutting disc will make the job faster. After cutting all the pieces, I would recommend sanding down all the sharp edges to avoid cutting yourself during assembly. The holes can be drilled using a conventional drill and cutting fluid.

Main video

The main video is the most important detail project, since it receives torque from the motor and transmits it to the tape. I used an old bushing to secure it, but I recommend using a bearing instead. The bushings do their job, but they constantly overheat and require regular lubrication. Moreover, they can scatter dirty lubricant, which can be annoying during operation.

Shaft:

There are threads on the sides of the shaft with different directions so that the mounting bolts do not unscrew when rotating. If you cut off one threaded side like I did, leave the one that goes counterclockwise, otherwise you'll have to make a locking bolt (I'll describe how to make that later) and a cotter pin. The main pulley will be placed on the cut edge.

Pulley:

Continuing the topic reuse, I found an old pulley from another project. Unfortunately, I prepared it for the threaded pin that it was supposed to be held on, but, in fact, this is not a problem. I made a rectangular cutout in this pulley. I then used an angle grinder to cut a groove on the end of the shaft. By placing the key in the hole formed by the shaft groove and the rectangular cutout of the pulley, I securely fixed them relative to each other.

Making rollers for a grinding machine

I made the rollers from several pieces of 2.5 cm thick hardwood. But you can use MDF, plywood or other material. When laying layers, you need to make sure that the fibers are perpendicular, this will give the rollers additional strength and the layers will not crack.

It is necessary to make three rollers: the main roller, the top roller and the tension roller. The main roller is made of two 13 x 13 cm pieces of 2.5 cm thickness. The top and tension rollers are made of two pieces of wood measuring 10 x 10 cm.

Process:

Start by gluing together pairs of 13 cm and 10 cm pieces of wood, clamping them together with clamps. After the glue has dried, trim the corners with a miter saw, then find the center of each piece. Secure them in lathe and process until they measure 5 x 10 cm and 5 x 8 cm.

Upper and tension rollers:

Next, you need to install bearings in rollers measuring 5 x 8 cm. Choose a core or spade drill, and drill a recess in the center to the width of the bearing. The inner race of the bearing must rotate freely, so you need to drill a hole that goes through the roller through the inner race of the bearing. This will allow the bolt to go through with a minimal hole.

Main video:

This part is done a little differently. There are no bearings on it, but if the shaft extends less than 5 cm from the roller, you will need to grind the roller down to width. Measure the diameter of the shaft and drill the same hole in the center of the roller. Try to insert the shaft, it must hold tightly, otherwise the roller will shake.

Bolting the rollers

Next, you should fasten the two halves of the rollers with bolts; do not rely only on glue. Remember that the bolt heads need to be recessed into the wood, since the roller rotates in close proximity to the frame.Tension lever

The lever is made of a metal strip measuring 10 x 30 x 200 mm with rounded edges. It is necessary to drill quite large holes in it, so I recommend using drilling machine and lots of lube. A total of 4 holes are needed. The first is at the pivot point. It is not in the center of the bar, but 8 cm from its edge. The second hole will be located on the edge closest to the rotation point. It will serve to attach the spring. Two additional holes need to be drilled at the opposite end, approximately 5 cm apart. They need to be a little wider in diameter as they will be used for tuning, which I will talk about next.

When all the holes are made, you can attach the arm to the vertical angle between the top roller and the base. The end on which the spring will be attached is directed towards the main roller. It should rotate freely, so I recommend using two nuts for fastening, not tightening the main one completely, and using the second one as a locknut.

Installation of rollers

The upper roller is attached statically and must be clearly in the same plane along with the tension roller and the main roller. You can do everything by eye, but I recommend checking everything well with a level. To align the roller, you can add a washer, or, if it is not enough, a bolt. They are inserted between the frame and the roller.

There is no need to install the tension roller completely. We still need to make a stabilizing device.

Belt stabilization

Wear on the rollers or uneven surfaces can cause the abrasive belt to gradually come off during operation. The stabilizing device is a device on the tension roller that allows it to be at an angle that keeps the abrasive belt centered. Its design is much simpler than it looks and consists of a locking bolt, a slightly free-playing tension roller and an adjusting bolt.

Drilling holes in bolts:

For this purpose, I made a device in the form of a wedge-shaped cutout in the board, which will help hold the bolt in place during drilling. You can do this manually, but I don't recommend it.

Fixing bolt

The retaining bolt is a simple bolt with a hole drilled in it and is installed on the bar through a wide hole that is located closer to the pivot point of the lever. Since it is located between the lever and the roller, its head must be ground off so that the roller does not catch it. The bolt must be secured as shown in the figure.The bolt on which the roller is attached

It needs to be loosened a little so that the tension roller has a slight play. But to prevent it from unwinding, you need to make a castle nut. To do this, you just need to make cuts on the edges of a regular nut so that it looks like a crown. There will be two drilled holes in the bolt itself: one for the adjustment bolt and it will be lined up with the locking bolt hole, and another for securing the castle nut with a cotter pin.Bolt for setting:

Once the tension roller is in place, you can install the adjusting bolt, which will pass through the holes of the retaining bolt and the bolt on which the tension roller rotates. The system works when you tighten the adjusting bolt, causing the axis of rotation of the tension roller to shift its rotation angle outward, thus causing the belt to move closer to the mechanism. A spring at the other end of the lever adjusts the tension in the opposite direction. I recommend securing the adjusting bolt with a locknut as vibrations can loosen it.

Note: You can add a spring with reverse side tension pulley, but I haven't found any reason why this should be done. A small advantage will be that in this way the roller will have less play. But I will add that I did not do this, and I did not have any problems.

Completing the work of making the machine yourself

When everything is done, you need to check all the bolts again and make sure that the stabilization mechanism is assembled correctly. Then you have to turn the device on for the first time, which can be scary. It's like driving a car where the steering wheel and transmission don't work. I highly recommend a short time turn the motor on and off so that the machine does not rotate at full power.

In fact, the hardest part for me was adjusting the spring. If it is pulled too tightly, the tape will not be able to rotate... Too loosely and it cannot be held, it will fly off, which in itself is dangerous.

Ready!

That's all. You should end up with a decent, medium-power belt sander that can be converted to a more powerful one if desired.

I hope you enjoyed this master class. Thank you for your attention.

When carrying out construction and repair work, men often need to process wood, stone or metal. For quality work It is advisable to purchase a belt sander. But what to do when finances do not allow you to make such a purchase? To do this, it is enough to build a belt sanding machine with your own hands.

Purpose of a belt sanding machine

Wood is widely used in a wide variety of manufacturing organizations. Many different parts and products are made from wood. In order to properly process a wooden blank and give it the appearance of a finished product, it is customary to use various equipment, including belt sanders.

Belt grinding equipment is usually used at the final stages of production, when parts are finished machining. Such devices are convenient to use in the production of furniture and various consumer wood products. Depending on the material used, belt sanders work with wood or metal.

The main purposes of using wood grinding machines are the final leveling of the surface, bringing their roughness level to the required value, obtaining even and smooth surfaces of wood products and wood materials before veneering or after coating with varnish and other finishing materials, removal of local irregularities in the form of depressions and elevations, peeling off burrs and removing local deposits of varnish and primer, deburring, internal grinding and grinding of curves.

Belt grinding machines for metal work with various materials and formats that are common in metalworking: plain and alloy steel, non-ferrous metals in the form of quadrangular, round and flat workpieces. Grinding machines allow you to grind round timber and large diameter pipes efficiently and with minimal time.

Depending on the type of processing and type of feed, belt grinding machines are intended for:

- for grinding curved surfaces with a free sanding belt;

- for processing a flat surface with a fixed table, manual movement of the iron and table, as well as mechanized movement of the work table and manual movement of the iron;

- for processing panel and block parts, their ends and side edges;

- for intermediate sanding of paintwork.

Belt Sanding Machine Design

Belt grinding machines are produced by modern foreign and domestic manufacturers in a wide range. Grinding machine prices vary widely. They also differ in possible performance and design. However, they also have something in common. They are united by the fact that absolutely all machines have an abrasive belt as a working element, which is most often connected into a ring and placed between rotating drums.

One drum is the master drum and the other is the slave drum. This means that the first of them is equipped with a mechanical transmission, which is most often based on a belt drive, with the help of which the torque from an electric motor. Any belt sanding machine is designed in such a way that the speed of movement of the drive drum, and therefore the speed of movement of the abrasive belt, can be changed, ensuring different modes surface treatment.

The abrasive belt can be positioned vertically or horizontally. In addition, equipment modifications are available for sale in which the working element is installed at a certain angle. The abrasive belt is mounted on a frame, on which the workpieces are usually located. Workpieces can be held by the operator manually or with the help of special devices that make the work easier for consumers and make the processing procedure more efficient and safe.

The machine table is made of metal sheets or thick boards. If the design provides for the table to be made of metal, then it will be possible to sharpen more complex products. The length of the working part of the belt grinding machine and the grinding belt itself primarily depends on the length of the products that will be sanded on the machine.

If the part has a shorter length than the working surface of the machine, then it will be much more convenient to process, and the processing will be of higher quality. For example, with a sanding belt length of 4.5 meters, you can easily process wooden workpieces that are 200 centimeters long.

Belt grinding machines are divided into equipment with a fixed and movable work table and devices with a free belt. A special group is wide-belt grinding machines, in which the caterpillar-shaped table is also a feeder. For machines with tables, the belt is placed horizontally; for designs with a free belt, it is installed in different ways.

Since the grinding process inevitably generates a lot of dust, all belt grinding machines are usually equipped with special powerful hoods that remove most of it during the technological process itself. Grinding machines are powered by an electric motor, which has a power of about 2.8 kilowatts. With a high-power motor, the normal speed of the belt reaches 20 meters per second.

Abrasive belts for grinding machines

The cutting tool of belt grinding machines is a sanding belt, which consists of a fabric or paper base and abrasive grains that are attached to it using adhesives. Abrasive belts are manufactured using two methods: mechanical and electrical. The first method consists of uniformly pouring abrasive grains onto a base that is covered with glue, and the second method occurs in electric field, which orients the grains upward with their sharpest edges to improve the cutting properties of the grinder.

Abrasive grains are poured onto the base in a bundle tightly or sparsely. The most effective is considered to be an abrasive belt with a sparse backfill, when the grains occupy less than 70% of the area, because wood dust generated during the grinding process is not able to get clogged between their grains. Natural minerals or artificial materials, which have high hardness, for example, green and black silicon carbide, white and normal monocorundum, as well as normal electrocorundum.

For the purpose of gluing grains, synthetic resins and hide glue are used. As a base, fabric such as calico and twill, or special grade paper is used. The size of the abrasive grains is indicated by a number that corresponds to the size of the sieve cells in which these grains are retained, and is displayed in hundredths of a millimeter.

If you are interested in how to make a belt sanding machine, then you should pay attention to the following sizes of grinding powders and abrasive grains and their classification: grinding grain - from 2000 to 160 microns, grinding powders - from 125 to 40 microns; micropowders - from 60 to 14 microns, very fine micropowders - from 10 to 3 microns.

Sanding paper is supplied to woodworking enterprises in sheets or rolls. On the non-working surface of the skin there is a marking with the specified characteristics of the skin and the manufacturer. For a belt sanding machine, skins are used in rolls and cut into strips of a certain length and width. The length of the cutting tool is determined depending on the method of its connection - lap or butt at an angle.

The ends are cut off when gluing end-to-end at an angle of 45 degrees and then glued onto a canvas lining with a width of 80 to 200 millimeters. At one end of the tape, when gluing with an overlap, the abrasive grains are removed with hot water over a distance of 80 to 100 millimeters, then the other end of the tape is applied to the exposed base lubricated with glue. Squeeze the joined ends and dry them when using special device or size press.

Sheet sandpaper is used for combined belt-grinding machines. For grinding discs, it is customary to cut the sandpaper in the form of a circle according to a template, the diameter of which is 60 - 80 millimeters larger than the diameter of the disc. Using a rectangular template, blanks are cut for the reel. After cutting, they have smooth edges without tears. The presence of unglued ends or seals when gluing tapes can cause premature rupture of the tape.

The skin is cut into sheets using wide-belt sanding machines according to a template made of plywood or aluminum sheet. The skin is cut in such a way that the edges are smooth and the difference in the length of the side edges is no more than 1 millimeter. One of the beveled edges is cleaned, removing abrasive to a width of 20 millimeters. The cleaned edge and longitudinal edges are covered with a strip of tracing paper, 40 millimeters wide, which protrudes beyond the edge of the sandpaper by about 10 millimeters.

Lubricate the beveled edge with tracing paper with glue and leave it in the air, depending on the viscosity and type of glue. Then the beveled edges are joined and a strip of sandpaper is applied to the joint, the joint is compressed and held in a press. It is customary to hang finished endless belts on special brackets and keep them for at least a day in a dry room before installing them on a grinding machine.

Operating principle of a belt grinding machine

A belt sanding machine consists of a table top with a work table for mounting the cutting tool. This table is fixed in different positions relative to the tabletop. The material for the tabletop is usually laminated chipboard with a thickness of 25 millimeters. The worktable on rollers is moved manually or laterally by a mechanical drive along round guides that are attached to supports.

Above the table there is a working belt mounted on non-drive and drive pulleys. The sanding belt is tensioned and adjusted using screw device with pneumatic cylinder. Double belt sanders have two identical sanding tools that are placed in series on a bed and have sanding belts that move towards each other.

Grinding is carried out by the transverse movement of the work table and the longitudinal movement of a short iron, which presses the belt to the material being processed. The sanding belts are driven by an electric motor via a belt drive. The waste generated during grinding is collected by a dust collector, which is connected to the exhaust network.

When assigning a grinding mode, it is recommended to select the grain size of the sandpaper, the feed speed and the pressing force of the belt to the product based on the specific roughness and properties of the material being processed. The grain size of the skin is usually chosen depending on the hardness of the materials being processed and the required surface roughness. The clamping force and feed speed are interdependent quantities. With little force and high feed speed, some areas of the surface may not be sanded; with high pressure and low feed, burns and blackening of the material are possible.

Before installing the tape, check the quality of its gluing. Do not use incorrectly glued or torn sanding belts with uneven edges. Using the handwheel, you can reduce the distance between the pulleys and put on the belt. The gluing area is placed so that the outer end of the seam on the abrasive side is directed against the working movement of the sanding belt.

The belt tension can be adjusted by moving the tension roller for the belt grinder or the non-drive pulley. It is not advisable to tighten the tape too much, as this will cause it to break. But the sanding belt, with low tension, slips along the pulleys and heats up very quickly. The tension force is set depending on the strength of the base of the cutting tool and is determined by the arrow of its deflection with slight pressure on it.

How correctly the belt runs can be checked by turning the pulley manually or briefly turning on the electric motor. When the belt slips, the pulley axis is turned by a handle at a small angle and secured with a locking device. After setting up the belt grinding machine, the dust suction system is turned on, a trial processing of the parts is carried out and their quality is checked.

A manual feed belt grinder can be operated by one worker. By moving the product relative to the cutting tool in the longitudinal direction and rotating the part around its axis, the operator sequentially brings into contact with the tape all areas that form the surface to be processed. If you slow down or move carelessly, sanding may occur.

It is customary to grind individual sections of a part in several passes. High-quality leveling can be achieved by properly regulating the pressure applied to the handle of the iron and the speed of movement of the table and iron. The pressure must be reduced as you approach the edges to prevent them from being sanded off. To increase the quality and productivity of grinding, small bars are placed on the table in a row, several pieces at a time.

Belt grinding machines with mechanical feed of products are serviced by two operators. One of them places the part on the conveyor, orients it along the width of the work table and directs the product under the clamping elements of the machine. When being picked up by a conveyor, parts must not be moved laterally.

It is not allowed to feed into the machine workpieces that have unequal thickness and parts with gross surface defects. The feed rate and pressure of the clamping beam, as a rule, are not regulated during processing. The second operator receives finished parts and ensures that unacceptable edge rounding and sanding does not occur.

Making a Belt Sanding Machine

The price of belt grinding machines from an industrial manufacturer is quite high, so when they are used infrequently, craftsmen involuntarily think about whether to buy the equipment or not. An alternative to buying an expensive machine is to assemble it yourself. The main parts of the machine are the frame, rollers and engine.

The motor can be removed from an old washing machine. Cut the frame from thick iron measuring 500 by 180 by 20 millimeters. Cut one side evenly on a metal milling machine; it is required for attaching the platform with the motor. The dimensions of the working platform are approximately 180 by 160 by 10 millimeters. Make markings and drill three holes in the end of the evenly cut frame. It is necessary to tighten the platform to the frame with three bolts.

Remember that the longer the work table is, the more options you will have when choosing a technological method for grinding and processing the product. If the length of the workpiece is less than or equal to the length of the work table, then you can achieve a perfect grind much easier than when moving a large workpiece.

The engine must be placed tightly on the frame. It should have a power of approximately 2.5-3.0 kW and a rpm of about 1500. If you choose a sanding belt speed of approximately 20 m/s, then the diameter of the drums should be about 200 millimeters. Thus, if the engine speed is sufficient, a gearbox for the grinding machine is not required.

One of the two drums will play the role of a drive drum, which should be firmly fixed to the engine shaft, and the other tension drum should rotate freely around a fixed axis on bearings. The table on the side of the driven drum should have a certain bevel, which will ensure smooth contact of the sanding belt with the surface of the work table, this is especially true for a glued joint.

You can make a tension drum and a drum that guides the sanding belt from chipboard. To do this, you need to saw blanks from the slab overall dimensions 200 by 200 millimeters and from them assemble a package of 240 millimeters. Square tiles or a package of them should be folded on an axis and machined to a diameter of about 200 millimeters.

Remember that in the center the diameter of the drum should be 2-3 millimeters larger than at the edges. With a similar surface geometry, the flexible sanding belt will be located in the middle of the drum. The optimal tape width is 200 millimeters. From a roll of emery cloth that is 1 meter wide, you can easily glue 5 similar tapes together.

Glue cutting tool it is necessary end-to-end, placing a thin dense material, for example, a tarpaulin, underneath. It is recommended to use the highest quality glue you can get. Be sure to stretch rubber onto the rollers, the width of which reaches 30 millimeters. Rubber can be taken from the inner tubes of a moped or bicycle.

On a homemade belt sander, except for sanding wooden products, for which it is actually intended, it is very convenient to sharpen tools with cutting surfaces - chisels, knives, axes, pruning shears. Another advantage of this grinding machine is the ability to work with parts that have a curved surface - to do this, you need to grind the workpiece with the back side of the work belt.

All materials in any production, in addition to manufacturing, require additional and finishing processing. Vivid examples of such treatments include grinding and polishing the product. These two types of mechanical impact on the surface of the part bring it appearance to perfection. However, everyone knows that performing these operations by hand will take a lot of time and effort, and even processing can only be ensured by very experienced master. To facilitate this kind of work, people have come up with various devices and mechanisms to help them. Some of them will be discussed further.

General purpose and types of machines

The machine is intended for final processing of parts and blanks from different materials by exposing them to an abrasive or diamond-coated surface. The machine, its component mechanisms and devices make it possible to maintain the accuracy of size and shape, and also ensure the creation of an ideal surface for a part or workpiece.

Using the machine, you can process flat parts, surfaces outside and inside, parts of various geometric shape, grind or polish threads and teeth gear wheels. According to their characteristics, grinding machines are divided into:

- Cylindrical grinders.

- Internal grinding.

- Centerless grinding.

- Surface grinding.

- Special machines (for grinding threads, gears).

Grinding process

Grinding is the process of removing the top layer from the surface of a workpiece using abrasives or diamond chips. They are collected into a common mass on the working surface and fastened binder composition. They ultimately form a grinding wheel or belt.

Grinding is the process of removing the top layer from the surface of a workpiece using abrasives or diamond chips. They are collected into a common mass on the working surface and fastened binder composition. They ultimately form a grinding wheel or belt.

During operation, the abrasive surface is driven in a circular motion using an electric motor. When the surface of the workpiece comes into contact with the abrasive, the processing process occurs. There is a common belief that grinding with abrasives is friction processing. However, this is not true.

Each abrasive particle has sharp edges; when it touches a material (metal, plastic, wood, stone), it works like a cutting tool and removes chips, like a milling cutter or drill. If we take into account the considerable rotation speed of grinding wheels, as well as the occurrence of chips as a product of grinding, it is necessary to take into account the possibility of injury from these very chips.

Safety precautions during operation

When working on the machine, the following safety rules must be observed:

Necessity at work and at home

Today, grinding machines are used constantly in production shops. Depending on the scale of production, either one machine or all its varieties in complexity and size can be installed.

Today, grinding machines are used constantly in production shops. Depending on the scale of production, either one machine or all its varieties in complexity and size can be installed.