Making a hot smoked smokehouse with your own hands. Homemade smokehouse Drawings of smokehouses

Smoking as a way to preserve food for a long time has been known since ancient times. But even now he has not lost its relevance, however, having shifted from the main functionality towards a variety of tastes.

Today there are many smoking methods that require various labor, time and money costs. Simplest- hot smoking.

Smokehouse and hot smoking - basic concepts

Hot smoking is a process of processing animals and plant products hot smoke in order to give them certain taste qualities. Unlike cold, it requires significantly less time for receipt finished product.

Types of smokehouses

All smokehouses are divided into portable and stationary. But the principle of operation and main components are the same for almost everyone.

Bottom The container is filled with wood chips, and a tray is placed on it to collect fat. Higher - lattice or horizontal fastenings, on which products are placed or suspended for subsequent smoking.

Top - sealed or non-sealed lid. After adding wood chips and food, a fire is built under the smokehouse. Sometimes an electric heating element is used instead of fire.

IN closed space under the influence of heat, hot smoke is produced, which permeates the food. In fact, this is the same oven, only with natural “flavors”. Main difference hot type of smoking from cold - time for preparation and processing. In the “hot version” it usually does not exceed 2-3 hours, and in “cold” - at least three days(average).

Portable devices, as a rule, are a metal cube or cylinder, on the bottom of which wood chips are placed, and products are placed on the grate above. Then this entire structure is closed with a lid and placed on the fire source. Smoking continues until the product is ready.

Stationary devices- usually stone buildings, metal cabinets, or old refrigerators, barrels, etc. adapted for this purpose. Their main task: smoking large volumes of food.

Important. Hot smoking, if done correctly, minimizes the risk of poisoning. In addition to high heat, smoke also destroys pathogenic microorganisms.

Usually the whole process takes place on fresh air, as an integral part of a picnic, as a supplement or replacement for the usual barbecue. Average, smoking takes 1.5-2 hours, and the temperature inside the “cabinet” fluctuates from 80 to 160°С.

How to make a smokehouse with your own hands: from simple to complex

In the manufacture of metal smokehouses make sure is that it does not react with foods under the influence of fire.

Attention! The use of barrels is prohibited from fuels and lubricants, paints or chemicals, galvanized metal.

From the bucket: diagram

If you want smoked food here and now, then the simplest apparatus you can literally make it on your knees without any special skills or tools. For this you will need a steel ( not galvanized in any way) a bucket, a large-diameter metal dumpling maker, thick foil or a steel “bowl” and a lid.

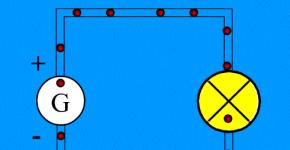

Photo 1. Schematic illustration internal structure hot smokehouse made from a bucket.

Pour wood chips into the bottom, place a “bowl” or foil on it, which will collect dripping fat, and place food on the grate. Close the top with a lid. Place the entire structure on the fire and wait for it to cook.

pros: high production speed, minimum necessary tools and skills. Minuses: small volume, unaesthetic appearance, the risk of spoiling food if you choose the wrong bucket.

Refrigerator device

It is quite possible to give an old refrigerator a second life. To do this, you need to remove all non-metallic “filling” from it, leaving only the body. The wood chips can be heated with an electric heating element, stove, or fire - in this case, the former refrigerator will need to be placed on supports.

Photo 2. Inside the body of the old refrigerator there are already special grates on which it is convenient to lay out products for smoking.

pros: large volume loading products at one time. Minuses: it is difficult to achieve the required tightness of the chamber, there is a risk that the metal will begin to emit harmful fumes.

You might also be interested in:

"Suitcase". Drawing with dimensions

This smokehouse is rectangular box made of stainless steel or ferrous metal, for which it received such a name. If you have a vice, grinders, pliers, welding clamps and welding itself, it’s easy to make the device yourself. You just need to decide on the size of the camera.

And further are possible two options. First - order cutting and/or bending of metal at the company, and they bring you a ready-made “constructor”, which all you have to do is weld it. Second - you buy metal, cut it yourself, then scald it at the seams according to the drawing.

Photo 3. Three-dimensional drawing of a smokehouse in the form of a stainless steel suitcase. Dimensions are indicated in centimeters.

Lattice welded from perforation or wire. It should be located approximately 20 cm above the wood chips, take this into account when making internal stops. Step grate bars - 3 cm. Availability required pallet for fat. It looks like a top cover. The only difference is that the stand is placed at the bottom of the box, has a handle and curved edges. When making it, carefully weld the corners.

Lid made from a sheet of metal so that its curved edges extend beyond the limits by 5-7 mm, a handle is welded on top. Required union for smoke removal.

If desired, you can do water seal- circumcised under 45°C and a corner welded along the perimeter with a continuous seam and a shelf inside. When smoking, water is poured into it and prevents smoke from escaping.

- weld the lattice supports to the end walls from the inside and the handles from the outside;

- manufacturing (welding) of the “box”;

- pallet production;

- production of internal grating;

- production of a cover with a fitting;

- making a water seal (optional).

Be sure to try it on For each subsequent part after manufacturing the previous one, make allowances for deformation.

pros: mobility, high smoking speed for a relatively large number of products, ease of care, durability. Minuses: It is impossible to control the temperature during smoking.

The smokehouse is done in the same way from a barrel, in this case, the body is already ready, all that remains is to make a tray, a lid and stops for vertical or horizontal loading of products.

Brick "cabinet"

The choice of advanced amateurs or those who you need to smoke a lot at once.

As a rule, the firebox is built separately from the brazier, and the stones provide maximum uniform distribution heat.

pros: better taste of products, stationary design durable. Minuses: high labor intensity and price in production.

Possible problems and difficulties when making a homemade smokehouse

Features of the manufacture of smokehouses - welding, which may take up to 60% of the total work time. The welding seam needs to be continuous, so if you are a novice welder or have not welded for a long time, select the current strength very carefully. It doesn’t cost anything to burn through metal, but installing a “patch” takes longer, is more difficult, and spoils the appearance and functionality.

At the dacha, a smokehouse can be made from household items. You need bricks, a supply of iron, and you need to provide the structure with a water seal made from a hose. Such a building will fit in a small area.

Creating a small smokehouse with your own hands has some subtleties, which we will talk about in our review of smokehouses.

Suitable for cooking fish and meat, it is not difficult to make, and it will take little time to build. A gradual slope is required, with a slope of approximately 35 degrees. Dig a hole 200 cm deep. At the initial stage, a fire is built, the smoke goes along a closed path into the smoking chamber; a barrel can be in the form of a compartment.

This is what a simple cold smoked smokehouse looks like

Since the chimney from the chamber to the smokehouse is not in a vertical position, toxic parts of the smoke will be lost into the ground, and condensed water will also remain there. It can also be done on a hike.

It's more difficult to make. The drawing shows the vertical position of the structure, thanks to this the smoking process will go better, so it is necessary to make an additional outlet for the smoke. If you make a lid with a water seal, there will be the necessary pressure so that the products are smoked evenly. The amount of smoke will have to be controlled.

This is what a hot smoked smokehouse looks like

It is better to place food above the tray, otherwise the food will become bitter. For permanent conversion, you need to make gaps in the lid. It is advisable to protect the brick with special fire-resistant clay. This version of the smokehouse is suitable only for summer cottage conditions. For smoking to take place you need a large number of smoke, so a smoke generator is necessary.

It’s easy to make a smoke generator yourself:

- We take an iron can as a basis;

- We make a hole in the lower part;

- To avoid air being drawn in from above, we make a lid;

- A PC fan will do to seal the smoke;

- We do the work by welding, ignite the wood chips and start the fan.

This is what a ready-made smoke generator for a smokehouse looks like:

The smoke generator has characteristic: the cooler drags smoke, but does not push it away! The smoke generator is placed directly to the compartment, because ignition occurs in a separate compartment from which the smoke generator will have to expel smoke.

It is possible to combine a hot smokehouse with a stove (here the price for electric sauna heaters is very low), but for this you need complex design, so we will not describe this in the text.

What materials are needed to create a smokehouse?

You can make smokehouses yourself only of small dimensions. You will need sheets of iron, you need to weld them along the lines. Most projects require brick. In fact, it turns out to be a brick structure with a large capacity. Brick chimney will quickly become saturated with the taste of various dishes, this will be reflected in other products. Therefore, brick is needed only for the rigidity of the structure.

Good welding and stainless steel sheets - perfect option for creating.

Semi-hot smoker from scratch

If you have a stove with a special hood, cut a tin can and place it on low heat, add wood chips. To prevent grease from staining the stove, place a tray; food can be hung on the hood. The smoke will reach the food already cooled to the desired temperature. You won't be able to cook a lot of food this way. If you don’t have a stove, you can use an electric stove instead.

You can use a refrigerator as a basis; the dimensions of the refrigerator make it possible to make a smokehouse for large volumes of food in a summer cottage. We take out all the mechanisms and tear off the facing insulation.

The entire space in the refrigerator will serve as a smoking chamber. The sliver should lie at the bottom on a special platform; place the area for fat a little higher.

You can install a smoke generator in the place where the engine was located. At the bottom of the refrigerator do big hole, put a tube in it, the tubes need to be combined with the exit from the stove, where the wood chips burn.

Small stainless steel smokehouse

From the name it is clear that this smokehouse requires stainless steel, specifically three grill grates and a couple of rods. The rods must be bent in a U-shape, then three pairs of rings must be welded onto each one at the same distance from each other.

We attach 4 short beams of 2-3 centimeters to the gratings by welding, which will then need to be inserted into the newly welded rings. The design should be rigid, that is, it should not “walk” under the mass of products. Outside, dig a fireplace with a chimney and that’s it, you can smoke! Such a smokehouse can be made on gas oven, then you won’t have to worry about the strength of the fire, and just wait for the food to cook.

Why do you need a water seal?

It is used to divert smoke into the water, thereby preventing smoke from spreading throughout the room. A hole is made in the compartment lid, which is then combined with a water source. It is also used to create pressure in the chamber if you need to cook a lot of food at once.

How to make a smokehouse-grill?

It is necessary to make the smoking tank in such a way as to create a path for the smoke. The chamber must have a place where the fat will drain, the main thing is that it drains outside the grill, otherwise the fat can spoil the cooking.

Description of the smokehouse:

- The grill is better if it is wide - it will be easier to remove the coals for smoke.

- On top of the grill we place the tank on a brick stand so that there is access to oxygen. Any tank will do, as long as it is spacious.

- Spacers are made from wire inside the tank to hang food.

- To ensure uniform smoking, you can install a water seal, it is made near the tank, and the compartment is covered with a lid.

A smoke generator is not needed here. This option is only suitable outdoors.

Cold smoked smokehouse in almost any conditions

- No need for iron and no need to make a separate oven.

- Take three to four meters of greenhouse film.

- We drive stakes into the soil a couple of meters high to make a square.

- We connect the stakes standing diagonally with rods.

- We place the products on the rods, then stretch the film.

- We lay out half a bucket of coals on the ground, place bricks to delimit it, hide it with grass - the smoke generator is done.

- Cover the entire structure with film until completely cooked.

Need to: Welding machine, Sander, not thick reinforcement and several sheets of iron.

- We cook the iron so that we get a box of four sides.

- We make the bottom, weld the seams well.

- We use the remaining iron to create a lid so that it is larger in size than the sides of the box.

- We make a tray inside and a row of rods for hanging food.

- We place the finished work on bricks and light a fire under it.

So anyone can make a smokehouse. What kind of smokehouse to make - everyone decides for himself, the main thing is to comply with all execution technologies!

We offer several videos from experienced specialists who will tell you how to make a smokehouse with your own hands

Meat, fish, meat or fish products can be smoked using cold or hot methods. Working according to the first option, you will create a dense dish. And its original structure will not change. In addition, the process using the cold method involves spending a lot of time. The main thing here is to take your time. Because the food may not be completely smoked. And its use will lead to poisoning.

The deeper flavor characteristics of the dish and the unique smoky aroma when working using the hot method are obtained from the heat emanating from the coals. Coals here are a key component in the cooking process.

It is not difficult to purchase a device for such smoking. There are no particular difficulties in his self-creation. It is important to know its structure and basic functioning.

General information

How to make a hot smoked smokehouse (HSS)? The following basic principles of work are laid here: food is cooked using an impressive volume of smoke. It is formed from wood chips. To generate smoke it only needs to be heated. It is important to control this process, because the wood chips should not catch fire. It should gradually smolder.

In the absence of the necessary temperature sensors, it is possible to determine the desired method of smoking food only thanks to personal experience.

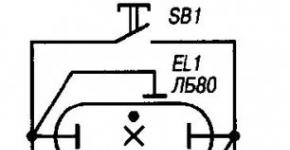

Do-it-yourself hot smoked smokehouse. Device diagram

To prevent the smoking from turning into a regular fire, you need to make sure that the lid fits perfectly (without any voids) on the body of the smoking compartment. For reliability, it is better to put something heavy on top, for example, a brick. If the unit is used frequently metal surface will warp. And the lid will no longer fit tightly. The operation of the smokehouse is based on the chosen smoking method and the recipe of certain dishes.

If you need a model for cold smoking, then make a pit for the hearth a little away from the smoking compartment. And connect these components with a special pipe. If you intend to make a hot smoking apparatus, the position of the hearth with coals should be directly above the designated compartment.

If you do not intend to purchase smoking units, making a hot smoked smokehouse yourself is possible based on:

- Steel sheets.

- Barrels.

- Metal bucket.

- Bricks.

- Refrigerator.

- Gas cylinder.

Smokehouse made of metal sheets

Make a smokehouse using a metal sheet. This activity will require:

- A couple of these sheets. Parameters: 60 – 155 – 2 cm.

- Fittings. It's better to take a thin one.

- Bulgarian.

- Welding equipment.

- The angle used by carpenters.

- Meter.

Before the main work, be sure to create a drawing of the intended device. If this is difficult for you to do, contact a specialist or find templates on the Internet and follow them.

With a competent drawing, errors with calculations of the required volume of materials are practically eliminated. You can set any KGC parameters. The key condition here is that the smoking department must be impenetrable.

Proceed according to the following algorithm:

- The same elements are used. The metal sheet is sawn into four parts - a grinder is used.

- The resulting blanks are fastened to each other. Passes here hot welding using the drip method. The required surface connection angle is 90 degrees. To comply with this parameter, you need to work with a joiner's corner. The remaining sides of the intended unit should be worked in the same way. All internal seams are welded very carefully. A high-quality sealed structure should be formed. This is a box.

- The bottom is attached to it. Material for the bottom - leftovers steel sheet.

- Creating a cover. Cut four sheets of stainless steel. Work with the grinder again. In terms of parameters, they should slightly exceed the external parameters of the box. You should have a lid with good depth. It should fit onto the KGC body without any problems. Weld it.

- Creation of handles and rods. Make the handles comfortable to use; they can be made of wood and coated with a special varnish. Arrange the rods in two levels. On the first there will be a tray for the accumulation of fat flowing from the dishes. Its position is the bottom of the smoking apparatus. On the second there are hooks for products.

This is the final phase. The unit is ready. It can be used for smoking tasks. It produces delicacies from meat, fish and lard.

The question remains regarding the heat generator for the electric smokehouse. Here it is an electric stove. And when the smoking temperature needs to be increased, just build a fire.

KGC from a barrel

Here the basis is a metal barrel. The combustion chamber of a hot smoked smokehouse from a barrel can be concentrated inside it. As a result, it will take up almost a third of the barrel. This is the main area for the smoking compartment. These departments need to be separated. To do this, you can use a metal sheet. Its maximum density is 4 mm. Use welding equipment. Using this method, he attaches himself to the walls of this barrel with his own hands. As a result, the bottom of the planned unit will be made from the sheet.

To organize a firebox in this bottom, you need to make holes here. The required air will penetrate through them. And these are also ways to remove ash.

At the bottom of the barrel, install a firebox door. It can also be cut from the wall. There is no need to set too serious parameters for it. Suitable values are as follows: 20 x 30 cm. Handles are welded to it. They are valves. You should also attach the loops.

And the bottom of the chamber is the place for the chimney. You need to make a special hole for it. The length of the pipe should not be impressive. Extra draft in the combustion chamber does not bring significant benefits.

Further actions proceed as in the work on the first version of the device. It is necessary to arrange a pallet, install a grate or place hooks for products. A lid is also needed. There should be a chimney hole in it.

More rational use of barrel volume is associated with the location of the firebox. This component can be made directly under the barrel. Heat-resistant brick is used here. Holes are also made. They will carry out: laying sawdust and removing excess smoke.

The barrel is placed on the surface of the created firebox. Some space is freed up. You can arrange several gratings in it.

In your work, you may have difficulty determining the required smoking parameters. To avoid them, you can mount a mechanical temperature meter with a remote indicator on the wall. This measure especially helps beginners in the smoking business.

Checking the temperature can be done without this device. A fairly simple method works here: a little water is splashed onto the surface of the device. If the process goes without problems, there will be no hissing.

KGK from a bucket

Here the base is a base made from a bucket.

Smokehouse diagram:

Its bottom is covered with fuel. It could be sawdust or shavings. A grate is placed one level above them.

Holes are created here in the upper zone. Rods with mounted hooks are inserted into them. The result is a modest smoking unit. Products can be placed in it in two ways. A hole is made in the lid to allow smoke to escape. The device is ready. You can start smoking.

It cooks dishes very quickly: 30 – 60 minutes. And this is only on medium heat. And there is no need to create a strong flame here. For high-quality smoking, slow smoldering of sawdust is required.

When the process is noticeable, you can add food. And the device closes tightly with a lid.

This option produces a brick structure. It will have two main functions: a grill and a homemade smokehouse.

The base materials are bricks or stainless steel. For country leisure, this option is considered optimal. The work requires a lot of effort and time. But you will build a durable and very practical structure, convenient for hot and cold smoking.

Stages of work on a smokehouse with your own hands:

- Choosing a location for the planned “hybrid”. Criteria to be taken into account here fire safety. For comfortable work You can arrange a water supply here and make a sewerage drainage.

- Based on the selected zone, create a sketch of the future device, assembled with your own hands from brick. Make drawings. Think over the principles of laying each line of bricks.

- The place for the planned structure is cleared. The foundation is being laid.

Smokehouse diagram:

Since a rather massive building is being planned, it is necessary to make a foundation pit for it. Formwork is made from boards in it. Roofing felt is used for its cladding. Next, rubble stone is used. It is laid in one layer. You can also use concrete. But it will need to be reinforced. Subsequent actions are laying a crushed stone cushion and pouring the working composition.

Its initial layer will dry well within 24 hours. After which you can arrange the next layer. The number of layers is determined by the parameters and mass of the planned structure.

Once you have completed the final layer, give it a level check. Cover it with waterproofing material. It will dry out within a few days.

The most suitable brick for masonry is red stove brick. The first line is laid out without a composition. Marking is indicated. At this stage, you decide on the location of the gratings.

The most optimal composition for the job includes sand, cement and a little lime. After kneading, its consistency should be like thick sour cream.

Laying the material begins from the corners where reinforcement is required - wire is used. The second and subsequent lines are laid out in a run. Strictly observe the horizontality of the created rows. Use angles and plumbs. Check this parameter after each row.

The firebox must be made of cast iron or other similar heat-resistant material. Install the brazier only after installing the corners and reinforcement elements between the walls of your barbecue - smokehouse.

If the smoking chamber is placed above a smoke generator, you will get a KGC. And if you move the mobile hearth a little away and connect it to the chamber (the connection method is a chimney), then you will have a structure for cold smoking with your own hands.

Photo - an example of the constructed “hybrid”:

Issues of its design and decoration are a matter of personal taste.

From the refrigerator

KGC can be built from an unnecessary refrigerator. You can also make a device with a water seal.

In the first case, a refrigerator that is no longer in use is used. It eliminates all plastic components and the freezer. A small electric stove is placed at its bottom. A pallet of sawdust is placed above it. A hole is also created in the lid to eliminate smoke.

To form the second option, a metal box is needed. Its parameters are arbitrary. For manufacturing, iron sheets of suitable density are used: not very thin or thick. The first ones are very fragile and easily deformed. The latter are of little use: the necessary conditions for smoking will not be obtained, and the sawdust may ignite.

Steel strips are welded inside - these are the supporting components of the gratings. There is a small gap between them and the lid.

The specificity of this device is the presence of a water seal. It resembles a small groove. It follows the entire perimeter on the top side of the unit.

Bolts pointing downwards are mounted on the cover by welding. The parameters of the lid must be such that the sides easily fit into the groove of the water seal. A chimney outlet is also installed in the lid.

The bottom of this KGC is removable. It has sides similar to the sides of the lid, only they are curved upward. The purpose of the bottom is to collect draining fat. Legs are mounted to the bottom small sizes. There is a small cavity between the underside and the surface. The device is ready. You can smoke food.

From a gas cylinder

We weld an iron elbow to the neck of the gas cylinder and insert a pipe. To regulate the amount of smoke, install a damper at the top. You can secure it with a bolt or make a removable structure.

We cut a hole in the side of the opposite side of the cylinder. Smoke from the firebox will come in here.

Making a combustion chamber. This will require sheets of metal 4 mm thick or a smaller tank. There should be two holes in the firebox: for sawdust and for the blower. We install a grate between the firebox and the smoking tank so that open fire does not spoil the food. This could be a transition from a small pipe.

Hot smoking is only possible at high temperatures.

Firewood issue

To ensure that you get a wonderful aroma when smoking, which will then be inherited by the prepared dishes, use raw materials obtained from alder or juniper. You can also use (prepare) yourself:

- oak,

- birch,

- pear,

- apple,

- maple,

- pear sawdust.

Each of the listed woods will add an original aroma and taste to the dish. You can create an unsurpassed aroma if you combine several species, such as alder, apple and oak.

Before use, it is correct to remove bark from trees. After all, it contains harmful resin. For this reason, raw materials are not used for smoking coniferous trees.

Before placing the raw material into the machine, it must be crushed into pieces. The dimension of each does not exceed 3 cm. After which they are moistened and evenly laid out on the bottom of the KGC. If the smoking process takes place in a bucket, a modest handful of chopped wood is enough. In some cases, sawdust is enough.

Making a smokehouse yourself is quite possible, even the simplest one. You can watch a video about building a hot smoked smokehouse with your own hands.

A lot of people love hot smoked meat. In addition to the fact that the cooking process itself is quite interesting, it produces many of the most delicious dishes. Of course, in order to prepare a delicious dish, you need to have certain culinary skills. However, this is another question. Today we will look at how to make your own smokehouse for hot food.

So, what does a smokehouse consist of? Of course, the smokehouse must have a chamber in which the meat to be smoked will be located. There must also be a combustion chamber where the fuel will burn. Most often, a smokehouse has a combined combustion chamber and space for food. Now, let's look at how to make it yourself simple smokehouses with your own hands.

Hot smoked smokehouse from a pan

You can take a regular enamel smokehouse from a saucepan. Wood chips are poured into the bottom of the pan. A mesh is placed in the middle of the pan on which the meat will be placed for smoking. If there is no grid, then you can take a dumpling maker that is no longer in use.

Hot smoked smokehouse diagram

Actually, that's all. The primitive smokehouse is ready. If everything is done correctly, then such a smokehouse will produce very tasty meat.

This is the simplest option, on the basis of which other smokehouses are made with your own hands, including.

Video: DIY smokehouse from a pan

Now we’ll tell you how to make an improved smokehouse. There will already be a special baking tray on which the fat will collect. Externally, the baking tray resembles a lid, which is located on the side. A smoker with a baking tray has the advantage of allowing you to smoke fattier meats. During the smoking process, fat can get onto the coals, which interferes with normal smoldering.

As soon as the baking sheet appears, the problem with normal smoldering coals immediately disappears.

It looks like there is nothing difficult about creating a hot smoker. As a rule, the presented options are used by tourists when hiking. But we also need to talk about those home smokehouses that can be stationary. However, the principle of operation of a home stationary smokehouse is not much different from previous smokehouses.

Those smokers that are used at home may be larger in size. This is because they do not need to be moved from place to place. The most common version of the smoking chamber is a product that is created from two barrels. It is worth noting that to create such a structure you need to have skills in welding and iron processing. In order to create a smokehouse from barrels, you need to find the barrels themselves and cut them correctly with a grinder. By connecting the lid and the main part, you can get a normal smokehouse.

Video hot smoker from two barrels

If there is space on the site, you can build a brick smokehouse. This is already considered a professional smokehouse. This building can be built at your dacha. In addition, it should be noted that a DIY stone smokehouse will allow you to retain the heat longer. The firebox will already be located separately from the roaster.

Brick construction scheme

So to create hot smoker, you need to show not only imagination, but also certain skills.

Do-it-yourself hot smoked smokehouse is made quickly, simply and with minimal costs. Smoking meat products on your own means being confident in the quality and freshness of the delicious dishes you subsequently consume. Hot smoking technology, compared to the cold method, requires significantly less cooking time. The design itself, in terms of dimensions and structure, allows it to be used not only outside, but also indoors. The materials and tools used for manufacturing are simple and quite accessible.

Possible options for a hot smoked smokehouse

As containers for smokehouses modern man adapted a significant number of improvised means and devices that had served their useful life direct purpose. The barrels got their second life, gas cylinders, refrigerators, washing machines.

As containers for smokehouses modern man adapted a significant number of improvised means and devices that had served their useful life direct purpose. The barrels got their second life, gas cylinders, refrigerators, washing machines.

One of the most simple options Making a home smokehouse for hot smoking fish and meat products is to use metal buckets with a lid.

Metal bucket

Let's look at an example of how to make a hot smoker out of a bucket for outdoor use. The procedure is as follows:

Let's look at an example of how to make a hot smoker out of a bucket for outdoor use. The procedure is as follows:

- select a metal bucket with a lid of suitable volume (not enameled);

- holes are drilled in the side walls of the bucket for installing skewers or meshes made of wire;

- a tray is attached to the lower tier of wire mesh to catch grease;

- 10-15 holes are drilled in the lid;

- wood chips or sawdust are placed directly on the bottom of the smokehouse;

- to activate the smoking process you will need a fire source (fire, gas-burner) or electric stove.

Metal barrel

Next simple design- This is made from a barrel. Its capacity is many times greater than that of a bucket.

Next simple design- This is made from a barrel. Its capacity is many times greater than that of a bucket.

The procedure for manufacturing and subsequent use is no different from the above example of making a smokehouse from a bucket. The only difference is in size: all structural elements are proportionally larger.

The procedure for manufacturing and subsequent use is no different from the above example of making a smokehouse from a bucket. The only difference is in size: all structural elements are proportionally larger.

Before use, the barrel must be cleaned by firing at high temperature.

Old refrigerator

Homemade smokehouse hot smoking with your own hands can easily be obtained from the refrigerator. In this case, it will require more costs, not only material, but also physical. In return, you will be able to get a large amount of smoked products cooked in convenient adaptation. The choice of device for modernization should be the Soviet models of the “Dnepr” type, since in its manufacture a minimal amount of plastic was used for internal lining. This fact greatly simplifies the modification of the device.

Homemade smokehouse hot smoking with your own hands can easily be obtained from the refrigerator. In this case, it will require more costs, not only material, but also physical. In return, you will be able to get a large amount of smoked products cooked in convenient adaptation. The choice of device for modernization should be the Soviet models of the “Dnepr” type, since in its manufacture a minimal amount of plastic was used for internal lining. This fact greatly simplifies the modification of the device.

Being inside smoking cabinet plastic parts during hot smoking it is not permissible due to the creation high temperature when cooking.

Let's look at an example of how to make a hot smoked smokehouse with your own hands from an old refrigerator:

- the plastic lining of the interior is removed;

- the magnetic seal is inspected and, if necessary, disposed of;

- holders of wire grilles and hooks are attached;

- the refrigerator door locking mechanism is being modified or replaced with a new one;

- all technical holes that appeared after modernization are covered with tape;

- in the upper part of the cabinet, using a drill and metal scissors, make a hole equal to the diameter of the exhaust fan;

- A fan is fixed in the resulting hole, and a pipe is connected to it, removing the smoke to the street.

- a metal tray is installed as the bottom shelf of the smokehouse to collect fat released during the smoking process;

- a smoke generator of this design is an electric stove with a thick-walled container with sawdust or wood chips installed on it;

- the smoke generator is placed at the bottom of the chamber, the power cord is led out through a prepared technical hole in the refrigerator body.

Using a hot smoked smokehouse with your own hands is also possible for indoor installation. In this case, the exhaust pipe is led outside. If necessary, the joint between the door and the body of the smokehouse, after placing the products in it, is covered with tape. Products prepared according to the recipe are placed on grates or hung on hooks, wood chips are poured in and the power supply is connected.

The power of the fan motor used for exhaust must be sufficient to completely remove smoke from the room.

Use of stainless steel

Most durable material for making a hot smoked smokehouse it is food grade stainless steel. Stainless steel allows something made from it to be used for decades. A special grade of stainless steel AISI 304 is resistant to temperature changes, which makes it possible to smoke products all year round.

Most durable material for making a hot smoked smokehouse it is food grade stainless steel. Stainless steel allows something made from it to be used for decades. A special grade of stainless steel AISI 304 is resistant to temperature changes, which makes it possible to smoke products all year round.

The hot-smoked stainless steel smokehouse is resistant to aggressive environments, does not react with salts and acids, and therefore can be used as a stationary structure for the yard. Thanks to these properties of the metal, the appearance of soot on the walls of the smokehouse is minimal. Cleaning and maintenance of the internal and external surfaces is greatly simplified compared to a metal smokehouse, susceptible to corrosion. This allows you to comply hygienic requirements when preparing meat and fish semi-finished products.

The hot-smoked stainless steel smokehouse is resistant to aggressive environments, does not react with salts and acids, and therefore can be used as a stationary structure for the yard. Thanks to these properties of the metal, the appearance of soot on the walls of the smokehouse is minimal. Cleaning and maintenance of the internal and external surfaces is greatly simplified compared to a metal smokehouse, susceptible to corrosion. This allows you to comply hygienic requirements when preparing meat and fish semi-finished products.

Compact smokehouses made of stainless steel are most common among outdoor enthusiasts. Fishermen and hunters deservedly appreciated the ease of operation and maintenance of this type of smokehouse. IN hiking conditions Hygiene is especially important.

Compact smokehouses made of stainless steel are most common among outdoor enthusiasts. Fishermen and hunters deservedly appreciated the ease of operation and maintenance of this type of smokehouse. IN hiking conditions Hygiene is especially important.

There are also hot smokers with a water seal. This variety is common and in demand for home use. The design of this option is a box made of welded thin sheet iron, with a square or rectangular cross-section. The edge of the box ends with a U-shaped groove 15 -30 mm wide and 20 - 30 mm deep into which water is poured. There is also a lid, the same shape as the box, used to create a seal. The lid is wider than the box, but fits freely into the groove filled with water.

The kit of such a device necessarily includes a tray for collecting fat and grids for laying out products prepared for smoking. The water seal also has reinforcing properties, since when heated, the smokehouse body expands, and the corner from which the seal is welded prevents deformation of the box.

The operating principle of a smokehouse with a water seal is based on stopping the smoke from escaping from the body by pouring liquid into the side of the smokehouse. The smoke from the smokehouse comes out through a special fitting in the center of the lid. Sawdust or wood chips suitable for smoking are poured directly onto the bottom of the box, a tray is installed to catch fat, followed by a mesh with neatly laid out meat. Next, the lid is closed, water is poured into the shutter and the smokehouse is set on fire.

During smoking, you should maintain the liquid level by adding it, because it evaporates, heating up along with the body of the smokehouse.

Making a hot smoked smokehouse with your own hands is not difficult. A creative approach, a simple tool, low investment, and most importantly, desire. These are all the requirements to obtain a quality result.

Any hot-smoked design suggested above can be used to prepare magnificent delicacies. Their taste always gets better from the knowledge that home smokehouse hot smoked food in which they were prepared was made personally by your hands and with love for your loved ones. Don't be afraid to experiment. Complex things can be simple!

The production of a hot-smoked smokehouse with your own hands is more clearly demonstrated in the video.

Making a smokehouse - video