How to create a hydrogen generator at home? Do-it-yourself hydrogen burner Homemade hydrogen generator for a car.

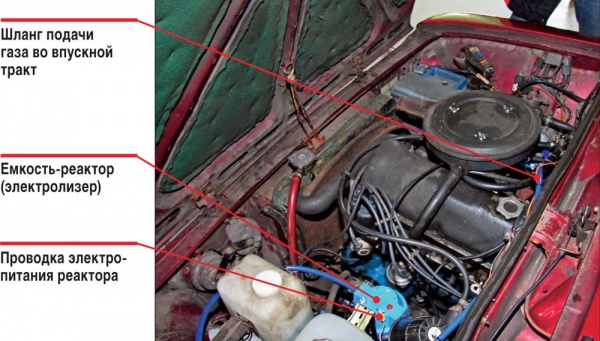

A device that allows you to get hydrogen from water is a hydrogen generator. Often they are used in cars. The use of such a device in a car is justified. The generated hydrogen enters the intake manifold of the engine. This allows you to save fuel and sometimes increase its power. In the USA, such generators are produced in factories. They are not cheap - from 300 to 800 dollars. In our country, it is preferable to make the generator yourself.

The principle of operation of the hydrogen generator

The water molecule is a combination of hydrogen and oxygen. Atoms have the ability to create ions. If you have watched experiments that use a Tesla coil, then you should know that atoms are ionized when exposed to electric field. In this case, hydrogen will form positive, and oxygen negative ions. in hydrogen generators electric field used to detach water molecules from each other.

So, by placing two electrodes in water, we need to create an electric field among them. For this they must be connected to the battery terminals or any other power source. The anode is the positive and the cathode is the negative electrode. The ions that are formed in the water will be pulled towards the electrode, whose polarity is opposite. When ions come into contact with electrodes, their charge is neutralized due to the addition or removal of electrons. When the gas that appears between the electrodes comes to the surface, it must be sent to the engine.

Hydrogen cells for cars include a vessel with water, which is located under the hood. Plain tap water poured into a vessel and there add a teaspoon of catalyst and soda. Plates connected to the battery are immersed inside. When turned on in auto ignition, the design (hydrogen generator) produces gas.

What electrodes are best to use?

The world's first electrodes were made of copper, but it turned out that they were far from ideal. In addition, copper gives a strong reaction when in contact with water. There is a selection a large number pollutants, so the use of copper is far from the best way. We recommend that you use stainless steel electrodes. To reduce the chance of corrosion choose stainless steel High Quality

. The thickness of the sheets should be about 2mm to reduce resistance.

The world's first electrodes were made of copper, but it turned out that they were far from ideal. In addition, copper gives a strong reaction when in contact with water. There is a selection a large number pollutants, so the use of copper is far from the best way. We recommend that you use stainless steel electrodes. To reduce the chance of corrosion choose stainless steel High Quality

. The thickness of the sheets should be about 2mm to reduce resistance.

Description of the hydrogen generator assembly process

Having understood the intricacies of the hydrogen generator, let's move on to its creation. In order to assemble a hydrogen generator with our own hands, we will need:

- polyethylene canister;

- wires for connection;

- silicone rubber;

- special sealant;

- hoses with clamps.

Having picked up everything you need, let's start making a generator with our own hands.

Making a hydrogen generator with your own hands turned out to be quite simple. In addition, thanks to the “do-it-yourself work”, it turned out to save a lot. A generator made in this way will not cost more than $100. In modern conditions, you can find a lot of devices that use hydrogen. Since the reserves of hydrogen in water are almost limitless, this allows you to see the prospect of mass application similar or upgraded installations in the future.

Depending on the purpose for which you needed it, a hydrogen generator, according to by and large, now available in the store. But often the industrial options are such that it is highly likely that you will not be able to perfectly adapt them to your needs. The model choice is very limited, and the characteristics, especially the efficiency, do not allow us to talk about efficient use. In addition to this, the price of these products, especially if we are talking about intended for use in the heating system of the house, the downward trend at least to the average level does not differ.

Why did an abundance of offers and practical advice on how to make such a device with your own hands, moreover, at home . Each author often tries to add something of his own, to place advice on a particular nuance. Many describe their own way of building a home-grown device, introducing it into the fuel system of a car, a home heating circuit, etc. One way or another, the validity of any recommendations can really be confirmed only from one's own experience. Most of the tips can be grouped into a few main topics:

- search for a scheme that allows, at the lowest cost and with most efficient produce gas;

- selection of materials from which the components of the device should be made;

- choice of reagents used for hydrolysis;

- geometric, electrical and other parameters of the components (requirements for the dimensions of the elements, power supply, etc.).

Simple homemade schemes

If we do not take into account the sophisticated and difficult-to-reproduce units at home, but limit ourselves to improvised means and materials that can be found without leaving home, then it turns out that making a compact but efficient hydrogen generator with your own hands is not an unsolvable task. One of the most simple circuits includes components available to almost everyone. These are the things that can easily be left lying around in your home:

- power supply (12 V, 1-2 A);

- glass jar with a metal screw cap (~0.5 l);

- plastic bottle (~1.0 l);

- rectangular ruler made of plastic (10–15 cm);

- razor blades (lamellar, such are in rectangular cassettes of 10 pieces);

- a pair of medical dropper systems;

- connecting wires (made of copper, small section);

- water and common salt.

To make a hydrogen generator out of this set of items with your own hands, you will need a simple tool, such as a clerical knife, sandpaper, a soldering iron with the appropriate soldering materials, filled with glue gun. You should start with the preparation of the blades, which consists in one-sided cleaning along their non-sharp edges (2–3 mm) and tinning. Then it is necessary to apply notches-grooves evenly (after 3-4 mm) on the ruler. Blades will be placed in them.

It should be borne in mind that increasing the distance between the grooves will entail a greater current consumption and, accordingly, a more powerful power source will be required.

Each blade should be perpendicular to the main plane of the ruler. They are fixed on it with glue so that electrical contact is excluded. Visually, it turns out a kind of ribbed heating battery in miniature. After the glue dries, it is necessary to supplement the resulting structure with wired connections. Simply put, you need to connect all the odd blades to one wire, and all the even blades to the other (similar to how it is done with the plates inside the batteries).

Further, holes should be made in the metal cover for this pair of supply wires, and one more, larger one for the hydrogen outlet (the diameter is specified by the size of the dropper filter, which will be built into the cover). The ruler with blades can be fixed here, on the free inner plane of the lid. All holes made after passing wires and droppers through them must be filled with glue, fixing these elements. So that the lid after screwing closes the volume of the jar completely tightly.

A plastic bottle must be equipped so that it performs the function of a bubbler-hydroseal (there may be more than one). The hose from the glass jar, passed through the lid, should almost reach the bottom of the bottle. Accordingly, the second hose for the removal of hydrogen is located in the upper part. The passage of the connectors in the cover must also be sealed.

Now you need to pour water into a bottle (not to the very top) and a jar, pour a few tablespoons of salt into the last one and stir. After that, it remains to close the lids tightly and start testing this DIY mini-generator. Shortly after turning on the power supply to the network, you will be able to observe the process of hydrolysis and the release of hydrogen. It should be enough that when you bring a lit lighter to the tip of the needle located on the outlet hose, the flame is picked up by this small burner. Of course, this is just a mock-up demonstrating the fundamental possibility of creating such a device at home.

For serious purposes such as heating a house or gas cutting metal, you will, of course, need to scale it. Instead of blades, take larger full-fledged plates, instead of a can with a bottle, appropriate containers, etc. Other popular schemes that you can also do yourself at home (at least in garages), in principle, everything is similar to that described. Containers can be taken different shapes and from various materials, metal compounds, alkalis and acids, etc. can act as reagents. In a word, there is plenty of room for experiments.

Where to send

Depending on what goals you set for yourself, how subtly and deeply you master the schemes proposed by the craftsmen for doing it yourself, how far you go in your experiments, depends on how and where you can apply the results of your work. In general, there are several main directions:

- metal gas cutter;

- enrichment of fuel in the car;

- heating in the house.

The practice of desperate motorists shows that these devices, including those made by hand, can be very effective both in terms of fuel economy and in terms of reducing the level harmful substances in the exhaust. And recently, in the open spaces of blogs and forums, a rather new application for such products has been hotly discussed - in heating systems. This is embodied mainly as an addition to the main appliances.

For example, underfloor heating or walls. When creating with your own hands at home such a device as a hydrogen generator, take the trouble to take care of the elementary safety rules. If it is intended for a heating system, then it must be designed for round-the-clock operation. This is especially true if you decide to use non-harmful chemical compounds as reagents.

Electrolyzer, that is the name of the device, also called a hydrogen generator. It is a device whose operation is based on the use of the physical and chemical process of water decomposition under the action of electric current to hydrogen and oxygen. This process is called electrolysis, it has long been known and studied in high school.

The electrolyzer is one of the most common hydrogen generators.

Description and principle of operation

In general, a hydrogen generator is a set of metal plates immersed in distilled water. The design is enclosed in a sealed housing with terminals for connecting the power supply and a fitting for gas outlet.

Theoretically, the operation of a hydrogen generator can be represented as follows: an electric current passes between plates of different polarity (anode, cathode) immersed in distilled water. In this case, water is split into oxygen and hydrogen. How more area plates, the more current passes through the water and the more gases are released. The plates are connected in turn (+-+-, etc.).

Application area

Due to the fact that the electrolysis process itself is associated with the use of a large amount of electricity, the industrial use of electrolyzers is significantly limited. It is more economically advantageous to use chemical methods to produce hydrogen.

Currently, hydrogen generators are used for:

- gas welding and gas cutting with hydrogen in the conditions of jewelry workshops;

- reducing the toxicity of internal combustion engines (ICE) and increasing their efficiency (efficiency factor);

- increasing the efficiency and reducing the toxicity of liquid fuel boilers.

Device

A few industrial electrolyzers, which are used to produce hydrogen and oxygen, are made in the form of stationary plants. The electrodes in them are switched on bipolar, and their number depends on the method of connection to the network (transformer or transformerless).

The designs of small-sized hydrogen generators, which are produced by both domestic and foreign companies and are used to increase the efficiency of internal combustion engines and for other purposes, are very diverse. In addition, there are a huge number of designs made by hand. You can find a lot of information about them on the Internet.

Considering that the design of the electrolyser is simple and it is not difficult to make it yourself, we will consider the designs of several similar devices:

- The simplest electrolyzer.

- Hydrogen generator for car.

The simplest electrolyzer

In order to make the simplest hydrogen generator, it is enough to have knowledge of physics and chemistry in the volume of a high school.

Materials and tools

- Stainless steel 03X16H15M3 size 500x500 mm. It is possible to use stainless steel of any other brand.

Important: ordinary steel in water will corrode. In addition, instead of water, it is possible to use an alkaline electrolyte, which is quite aggressive, especially when an electric current passes through it. Under these conditions, ordinary steel will not last long.

- Transparent polyethylene tube with a length of at least 1 m and a diameter of 8 mm.

- 2 bolts M6x150, washers and nuts.

- 3 herringbone fittings with an outer diameter of 8 mm.

- Plastic container with a lid with a volume of at least 1.5 liters.

- Cleaning filter running water(you can use a filter from a washing machine).

- Check water valve.

- Silicone sealant.

- Bulgarian or hacksaw for metal.

- Wrenches for M6 bolts.

Manufacturing process

- We carry out cutting steel sheet so that 16 plates of the same size are obtained.

- In one of the corners of each plate, you need to drill a hole for the M6 bolt. With this hole, the plates will be fastened together, so the center of the hole in all plates must be on the same axis.

- In order to properly connect the plates, it is necessary to cut off the corner in each plate, which is located on the side opposite the bolt hole.

- Alternately install the plates on the bolts according to the diagram, isolating the “+” and “-” plates from each other with a polyethylene tube and washers. At correct installation plates, cut corners will not allow plates of different poles to contact each other.

- After installing all the plates, the structure must be tightened with nuts.

Important: after completing the assembly, you need to make sure that the plates of different poles are not connected to each other (ring the structure).

- We fix the resulting structure in plastic box using washers and nuts, having previously drilled 2 holes for the “+” and “-“ bolts. To ensure the tightness of the holes, treat with silicone sealant.

- We drill holes in the lid of the box and insert the fitting. Holes must be sealed with silicone sealant.

- It remains to check the performance of the resulting electrolyzer. To do this, fill the container with water up to the fixing bolts and close it with a lid. Then we put a polyethylene hose on one of the fittings and lower it into some container with water. Having connected the power source to the bolts, we observe the appearance of bubbles of the evolved gas. In order to increase the amount of gas released, it is necessary to increase the strength of the current passing through the water.

- After checking the operability of the device, it is necessary to drain the water and fill Plastic container alkaline electrolyte. This will allow you to get a much larger amount of gas released.

ATTENTION: when operating the electrolyzer, it must be remembered that the process of splitting water into oxygen and hydrogen is explosive. Therefore, certain safety rules must be observed.

Hydrogen generator for car

The electrolysis process in a car cell is carried out using a special catalyst. During operation of the device, oxyhydrogen (Brown's gas) is released, which has the formula HHO. Further, the gas through the engine air supply system enters its combustion chamber, where it mixes with fuel and burns. As a result, the octane number of the fuel-air mixture increases, which contributes to more complete combustion of the fuel.

The device of modern electrolyzers

Brown's gas generator includes:

- the actual electrolyzer;

- circulation tank.

The entire gas production process is controlled by:

- current modulator;

- an optimizer that controls the ratio of Brown's gas to the air-fuel mixture.

Types of catalysts

There are several types of catalysts, among which there are:

- Cylindrical- their design is not much different from the design of the simplest hydrogen generator and it is quite possible to make it yourself. They differ in low productivity (up to 0.7 liters of gas per minute) and a primitive control scheme.

- with separate cells– the most efficient design with a capacity of over 2 liters of gas per minute. Differs in high efficiency and is established on cars with a continuous mode of operation.

- With open plates (dry)- with a capacity of up to 2.1 liters of gas per minute. The design provides additional cooling of the device in severe operating conditions.

All processes occurring in a hydrogen generator are carried out in automatic mode and function in accordance with a special program sewn into the computer control system of the car.

Advantages

The use of modern electrolyzers in a car allows:

- save up to 50% fuel;

- reduce exhaust toxicity;

- reduce the temperature of the motor;

- increase traction and power of the power unit;

- increase the life of the engine.

The principle of operation of the hydrogen generator

The principle of operation of the hydrogen generator Security measures

Electrolysis plants are devices of increased danger. Therefore, in the process of their manufacture, installation and operation, both general and special safety measures must be strictly observed.

Among the special requirements, the most important are:

- The formation of explosive concentrations of a mixture of oxygen with hydrogen or air is not allowed.

- The operation of hydrogen generators is not allowed if the liquid level is not visible in its viewing window.

- By doing repair work it is necessary to make sure that there is no hydrogen at the end point of the system.

- Near electrolyzers it is not allowed to use open fire, electric heating devices and portable lamps with a voltage of more than 12 V.

- When working with electrolyte, it is necessary to use overalls, gloves and goggles.

- Experts do not recommend making automotive hydrogen generators on their own. This is motivated by the fact that an automotive electrolyzer is a rather complex and unsafe device, in the manufacture of which it is necessary to use special materials and reagents.

- At self installation in a do-it-yourself electrolyzer car, it is necessary to exclude the possibility of gas entering the combustion chamber of the fuel-air mixture with the engine turned off. When the engine is turned off, the hydrogen generator must be automatically disconnected from the car's power supply network.

- At self-manufacturing car cell, do not forget to equip it with a special water valve - a bubbler. Its use will significantly improve the safety of vehicle operation.

The use of hydrogen as an energy source for heating a house is a very tempting idea, because its calorific value (33.2 kW / m3) is more than 3 times higher than natural gas(9.3 kW / m3). Theoretically, in order to extract combustible gas from water and then burn it in a boiler, a hydrogen generator can be used for heating. What can come of this and how to make such a device with your own hands will be described in this article.

The principle of operation of the generator

As an energy carrier, hydrogen really has no equal, and its reserves are practically inexhaustible. As we have already said, when burned, it releases a huge amount of thermal energy, incomparably more than any hydrocarbon fuel. Instead of harmful compounds emitted into the atmosphere when natural gas is used, hydrogen is formed during combustion. ordinary water in the form of steam. One problem: given chemical element does not occur in nature in a free form, only in combination with other substances.

One of these compounds is ordinary water, which is completely oxidized hydrogen. Over her splitting into constituent elements worked by many scientists over the years. It cannot be said that it was ineffective, because a technical solution for the separation of water was nevertheless found. Its essence is chemical reaction electrolysis, which results in the splitting of water into oxygen and hydrogen, the resulting mixture was called explosive gas or Brown's gas. Below is a diagram of a hydrogen generator (electrolyzer) powered by electricity:

Electrolyzers are mass-produced and designed for gas-flame (welding) work. A current of a certain strength and frequency is applied to groups of metal plates immersed in water. As a result of the ongoing electrolysis reaction, oxygen and hydrogen are released mixed with water vapor. To separate it, the gases are passed through the separator, after which they are fed to the burner. In order to avoid a kickback and explosion, a valve is installed at the supply that allows fuel to pass only in one direction.

To control the water level and timely make-up, the design provides a special sensor, on the signal of which water is injected into the working space of the electrolyzer. Overpressure inside the vessel is monitored by an emergency switch and a relief valve. The maintenance of the hydrogen generator is to periodically add water, and that's it.

Hydrogen heating: myth or reality?

Generator for welding work- it's on this moment the only thing practical use electrolytic splitting of water. It is not advisable to use it for heating a house, and here's why. Energy costs during gas-flame work are not so important, the main thing is that the welder does not need to carry heavy cylinders and fiddle with hoses. Another thing is home heating, where every penny counts. And here hydrogen loses to all currently existing types of fuel.

Important. The cost of electricity for the separation of fuel from water by electrolysis will be much higher than the explosive gas can be released during combustion.

Mass-produced welding generators cost a lot of money because they use catalysts for the electrolysis process, which include platinum. You can make a hydrogen generator with your own hands, but its efficiency will be even lower than that of a factory one. You will definitely succeed in getting combustible gas, but it is unlikely that it will be enough to heat at least one big room, not like the whole house. And if enough, you will have to pay fabulous electricity bills.

Rather than spending time and effort on getting free fuel, which does not exist a priori, it is easier to make a simple electrode boiler with your own hands. You can be sure that in this way you will use much less energy with greater benefit. However, home masters - enthusiasts can always try their hand and assemble an electrolyzer at home in order to conduct experiments and see for themselves everything. One of these experiments is shown in the video:

How to make a generator

The mass of Internet resources publish the most different schemes and drawings of a generator to produce hydrogen, but they all operate on the same principle. We will provide you with a drawing. simple device, taken from popular science literature:

Here, the electrolyzer is a group of metal plates bolted together. Insulating spacers are installed between them, the extreme thick plates are also made of a dielectric. From the fitting, mounted in one of the plates, there is a tube for supplying gas to a vessel with water, and from it to the second. The task of the tanks is to separate the steam component and accumulate a mixture of hydrogen and oxygen in order to supply it under pressure.

Advice. Electrolytic plates for the generator must be made of stainless steel alloyed with titanium. It will serve as an additional catalyst for the splitting reaction.

Plates that serve as electrodes can be arbitrary size. But we must understand that the performance of the apparatus depends on their surface area. How more electrodes will be able to engage in the process, the better. But at the same time, the current consumption will be higher, this should be taken into account. Wires leading to a source of electricity are soldered to the ends of the plates. Here, too, there is a field for experiments: you can apply different voltages to the electrolyzer using an adjustable power supply.

As an electrolyzer, you can use a plastic container from a water filter by placing electrodes from stainless tubes in it. The product is convenient in that it is easy to seal from environment, leading the tube and wires through the holes in the cover. Another thing is that this homemade hydrogen generator has a low performance due to the small area of the electrodes.

Conclusion

At present, there is no reliable and efficient technology, allowing to implement hydrogen heating private house. Those generators that are commercially available can be successfully used for metal processing, but not for the production of fuel for the boiler. Attempts to organize such heating will lead to an overrun of electricity, not counting the cost of equipment.

From TV screens we are told that the amount of oil is rapidly decreasing, and soon gasoline cars recede into the distant past. That's just not entirely true.

Indeed, the number of proven oil reserves is not very large. Depending on the degree of consumption, they can last for a period of 50 to 200 years. But these statistics do not take into account hitherto unexplored oil production sites.

In fact, there is more than enough oil on our planet. Another question is that the complexity of its extraction is constantly increasing, which means that the price is also growing. In addition, the environmental factor cannot be discounted. Exhaust gases pollute the environment a lot and something needs to be done about it.

modern science created many alternative energy sources up to the engine of nuclear fission in your machines. But most of these technologies are still concepts without the ability to real application. At least that was the case until recently.

Every year, machine-building companies produce more and more machines that run on alternative power sources. One of the most effective solutions in this context is a hydrogen engine from the Toyota brand. It allows you to completely forget about gasoline, making the car an environmentally friendly and cheap vehicle.

Hydrogen engines

Types of hydrogen engines and their description

Science is constantly evolving. New concepts come up every day. But only the best of them come true. Now there are only two types of hydrogen engines that can be cost-effective and productive.

The first type of hydrogen engine runs on fuel cells. Unfortunately, hydrogen engines of this type still have a high cost. The point is that the design contains expensive materials like platinum.

The second type includes hydrogen internal combustion engines. The principle of operation of such devices is very similar to propane models. That is why they are often reconfigured to work under hydrogen. Unfortunately, the efficiency of such devices is an order of magnitude lower than those that operate on fuel cells.

At the moment, it is hard to say which of the two technologies for creating hydrogen engines will win. Each has its pros and cons. In any case, work in this direction does not stop. Therefore, it is quite possible that by 2030 a car with a hydrogen engine can be bought at any car dealership.

Principle of operation

The hydrogen engine works on the principle of electrolysis. This process occurs in water under the influence of a special catalyst. As a result, hydrogen is released. His chemical formula the next one is NHO. The gas is not explosive.

Important! Inside special containers, the gas is mixed with the fuel-air mixture.

The generator includes an electrolyzer and a tank. The current modulator is responsible for the gas generation process. To ensure the best results, an optimizer is installed in injection hydrogen engines. This device is responsible for regulating the ratio of the fuel-air mixture and Brown's gas.

Characteristics of catalysts

The catalysts used to create the desired reaction in a hydrogen engine can be of three types:

- Cylindrical banks. This is the most simple design, running on a rather primitive control system. The performance of a hydrogen engine operating with this catalyst does not exceed 0.7 liters of gas per minute. Such systems can be used on cars with a hydrogen engine up to one and a half liters. Increasing the number of cans allows you to exceed this limit.

- Separate cells. It is believed that this type of catalyst is the most efficient. The performance of the system is more than two liters of gas per minute, the efficiency is maximum.

- Open plates or dry catalyst. This system designed for a long period of work. Productivity fluctuates in the range from one to two liters of gas a minute. The open position provides the most efficient cooling.

The efficiency of hydrogen engines is growing every year. Hybrid devices operating on hydrogen and gasoline are now beginning to be put into operation. In turn, designers do not stop looking for the most efficient catalyst model that provides even greater performance.

DIY hydrogen engine

Generator

To create an efficient hydrogen engine for a car with your own hands, you need to start with a generator. Simplest homemade generator- it sealed container liquid into which the electrodes are immersed. For such a device, a 12 V power supply is sufficient.

The fitting is installed on the cover of the structure. It removes a mixture of hydrogen and oxygen. Actually, this is the basis of the generator for the hydrogen engine, which is connected to the internal combustion engine.

To create a complete system, you will also need an additional drive and battery. It is best to use a water filter as a housing, or you can buy a special installation. In the latter, cylindrical electrodes of increased productivity are used.

As you can see, isolating the right gas for the reaction is not so difficult. It is much more difficult to produce it in the amount needed for a hydrogen engine. To increase the efficiency it is necessary to use copper electrodes. In extreme cases, stainless steel is also suitable.

During the reaction, the current must be supplied with different strengths. Therefore, without an electronic unit can not do. In addition, there must always be a certain amount of water in the tank so that the reaction takes place under normal conditions. The automatic feeding system in the hydrogen engine solves this problem. The intensity of the electrolysis provides a sufficient amount of salt.

Important! If the water is distilled, there will be no electrolysis at all.

To make water for a hydrogen engine, you need to take 10 liters of liquid and add a tablespoon of hydroxide.

Hydrogen engine device

First of all, you need to take care of additional tanks and pipelines. The hydrogen engine needs a water level sensor, which is installed in the middle of the cover. This will prevent false triggering when moving up and down. It is he who will give the command to the automatic recharge system when needed.

The pressure sensor plays a special role. It turns on at 40 psi. As soon as the internal pressure reaches 45 psi, the pumping is turned off. Above 50 psi the fuse will trip.

The fuse for a hydrogen engine must consist of two parts: an emergency release valve and a rupture disk. The rupture disk will activate when the pressure reaches 60 psi without causing any harm to the system.

To remove heat, you need to use the coldest candle. Candles with platinum tips are not suitable. Platinum is an excellent catalyst for the reaction of hydrogen and oxygen.

Important! Take Special attention creation of crankcase ventilation for a hydrogen engine.

Electrical part

An important role in wiring diagram the hydrogen engine is played by a 555 timer. It acts as a pulse generator. Moreover, it can be used to adjust the frequency and pulse width.

Important! The timer has three frequency ranges. The resistance of the resistors is within 100 ohms. The connection takes place in parallel.

The hydrogen engine board should have two 555 pulse timers. The first one should have larger capacitors. The output from leg 3 goes to the second generator. He actually turns it on.

The third output of the second timer of the pulsed hydrogen generator is connected to 220 and 820 ohm resistors. The transistor amplifies the current to the desired value. The diode 1N4007 is responsible for its protection. This provides normal work the entire system.

Results

Now the hydrogen engine is no longer a figment of the imagination of scientists, but a very real development that you can do yourself. Of course, in terms of characteristics, such a unit will be inferior to the factory model. But the savings for the internal combustion engine will still be noticeable.

Hydrogen engines not only help reduce gasoline consumption, but are also completely environmentally friendly. That is why, in the first quarter, sales of Toyota's hydrogen car broke all records in Japan.