How to properly drill a concrete wall: technology. Choosing a tool for work

Good material concrete is durable. But strength also has a downside: it is difficult to make holes for fastening something in it. It is easy to drive a nail or screw a screw into a tree, but how to drill concrete wall? There is no need to rush to buy a hammer drill, and an impact drill is not needed, you can do without a drill, but you definitely cannot do without the tool with which the wall will be drilled - a punch, a drill and a drill.

Drilling concrete walls: tool selection

There are several ways to drill concrete:

- Chiseling with a hand punch.

- Drilling with an electric drill.

- Chiseling with a puncher.

To begin with, the most time consuming method will be considered. It was used when it was not possible to use electric / pneumatic tools, and it is still used now. A special set of punches is purchased - sharpened metal pins of a four-lobed shape with diameters from eight to twenty millimeters.

The pins can be made independently from any steel that can be hardened. But it is imperative to make 2-4 grooves on the side surface, which, on the one hand, form cutting edges, and on the other, serve as channels for the output of concrete chips. The shank of the pin is often made square - turnkey from the vice. Putting the pin at a right angle to the wall, they begin to hit it with a heavy hammer, turning it around the axis, first with a hand in a mitten, then, when deepening 15 millimeters, with a key from the vice.

So - until the complete victory of the world revolution. First, they work with a pin about eight millimeters in diameter. If necessary, re-pass the hole with a pin with a larger diameter. It is clear that it is usually not plastic dowels that are inserted into such holes, but wooden chops or full-fledged bolt anchors.

In this way, it is, of course, possible to drill concrete, but a lot of effort is expended - it is better to run to a familiar neighbor for a cordless drill.

Now about the drills. An electric drill (you must forget about manual in the case of concrete - it will take more forces than the above-described masochism) needs a drill. For concrete, conventional HSS drills are not suitable: it is also an abrasive, against which they will wear off, and even burn from friction if they are not cooled.

Therefore, it is necessary to buy a tool with a carbide insert in the store. Just do not steal at the VK-8 factory - they do not tolerate vibration. Often these drills are not sharpened - a green circle is required to sharpen carbide tools. Diamond drills are also suitable. But this layer is thin and they will go out of order quickly. If a percussion mechanism is included in the design of the drill, it should be used: the cement passes without problems, but the granite needs to be broken.

If there is no impact mode, you can do without it: for dowels up to 40-50 mm long, the hole is usually drilled without problems. At longer distances, there is a high probability of encountering a granite "asteroid". It can be smashed with a hand punch, feeling like Bruce Willis. And then - again to work with a drill. But now purely hammerless electric drills are a rarity.

But in general, the best tool for drilling concrete is a hammer drill. He more powerful than a drill, its drills are specially designed for the vibration mode of operation - it is better to use it. This type of tool was created when home craftsmen had not yet thought about how to drill a concrete wall - pre-drills were used by miners, and there are strong rocks. Previously, hammer drills looked intimidating, but times have changed - now models of home dimensions have been developed. The advantages of the rotary hammer:

The impact energy is an order of magnitude higher than that of an impact drill.

- More powerful engine.

- Vibration-resistant design - the shock mode of operation is the main one for it, and not an additional one, like with drills.

The design of the chuck and the shank of the slotting tool excludes cranking at high loads - in the case of cam chucks, which are used in drills, you often have to flatten the shank of the drill.

The slotting tool is specially adapted to work in vibration conditions - carbide insert all the same does not like them and crumbles.

Outcome

A manual punch should be used only in absolutely wild working conditions - when there is no alternative. And also for auxiliary operations when drilling deep holes without hammer drill.

The hammer drill is excellent for lightweight concrete and shallow holes. For heavier work, you need a tool with a percussion mechanism. And even then - a hole with a diameter of more than 12-14 mm with a drill is already difficult to drill: and the drill turns in the chuck, and the load becomes high.

The hammer drill is an excellent tool for drilling concrete walls because it is designed to work with similar materials. But, of course, more expensive than drills - the price difference for models of one category is almost twofold.

Master's tips

Prev Next

To Oil paint during storage does not dry out and so that a film does not form on it, put a circle of thick paper and "fill it with a thin layer of linseed oil.

" Polyethylene film, covering a balcony or greenhouse, is protected from being cut off by the wind by a string stretched on both sides with intervals of 10-15 cm. "

"To work with concrete mix was easier, clay is usually added to it, but clay reduces the strength of the mixture. Add a spoonful of detergent to it per bucket of water. "

"To prevent the screw, the head of which is hidden behind an obstacle, from rotating together with the tightened nut, you need to put several turns of thread on it or thin wire and pull the ends slightly. Friction holds the screw well in place. The ends of the thread can be cut after tightening. "

"You can cut out a birdhouse notch without a brace. It is enough to split the front side of the board in the center and cut out half-holes with a chisel or a hatchet required size, and then reconnect the halves. "

Wooden corks for screws crumble and fall out of the wall. Take your time to cut a new plug. Fill the hole in the wall tightly with a capron from an old stocking. With a red-hot nail of a suitable diameter, melt the hole for the screw. The fused nylon will turn into a solid cork.

"A carpenter's level is not difficult to turn into a theodolite, equipping it with a sighting device from a slot and a front sight."

"In order for two strips of linoleum to lie end-to-end, it is convenient to use a self-adhesive decorative film, placing it under the base of linoleum."

"To keep the nail in the right direction and not bend when driving into a deep hole or groove, place it inside the tube and secure it with crumpled paper or plasticine."

Before punching a hole in the concrete wall, secure a piece of paper just below. Dust and concrete debris will not fly around the room.

"To cut the pipe exactly at right angles, we advise you to do this. Take a straight strip of paper and screw it onto the pipe along the sawing line. The plane passing through the edge of the paper will be strictly perpendicular to the axis of the pipe."

"Roll over logs or wooden beams A simple attachment will help - a segment of a motorcycle or bicycle chain, supplemented with a hook on one side and attached to a scrap yoke on the other side. "

"In order for one to be able to work with a two-handed saw, we advise you to use a simple technique: move the saw handle from the top to the bottom."

You can cut a piece of slate of the required size with a saw, but it is better and easier to punch holes with a frequency of 2-3 cm along the line of the proposed cut with a nail, and then break off the slate on the support.

" The best way glue the tile to the wall: take bitumen, melt and drip just four drops at the corners of the tile. Sticks on dead. "

Shaped holes in the manufacture of curly window frames are most conveniently cut out with a hacksaw with a turned cloth.

"Making stained glass is a long and difficult task. You can make a quick imitation of stained glass. To do this, take thin laths or twigs of a vine, stick to a sheet of glass, and then paint the glass and cover it with varnish."

"If you don't have a dowel at hand, you can make it from a piece of plastic tubing. The body of a ballpoint pen can also work for this. After sawing off a piece of the desired length, make a longitudinal cut, about half, and the dowel is ready."

"It is known how difficult it is to hang a door working alone. But just shorten the lower pin by 2-3 mm and it will become much easier to work."

"A very strong, non-shrinking and sufficiently waterproof putty is obtained from bustilate mixed with any powder - chalk, gypsum, cement, sawdust, etc."

"If you need to screw a screw into the end of the chipboard, drill a hole slightly smaller than the diameter of the screw, fill the hole with Moment glue (but not epoxy!), Screw the screw in a day. The board does not delaminate. day. "

"Attach portraits, photographs, paintings in wooden frames with glass it is more convenient not with studs, but with the help of stationery bent at right angles. The buttons are gently pressed with a screwdriver. Compared to nails, the risk of splitting thin frames is minimized. "

"It is not so easy to wrap a screw in hard wood. If you poke a hole for the screw with an awl, and rub the screw generously with soap, then after such an operation the work will go like clockwork."

To save time, the wallpaper can be trimmed with a sharp knife without unrolling the roll. To do this, you must first align the end of the roll and use a simple pencil to draw a circle outside the border of the Edge. Working with a knife, the roll must be gradually turned in the direction of rolling.

For carrying at home large sheets It is convenient to use a wire holder with three hooks at the bottom and a handle at the top for plywood, glass or thin iron.

IF you need to cut a round stick into the distance, it is most convenient to do this work using a template. It is made from a metal tube with a groove in the middle. The diameter is chosen so that the template slides freely on the stick.

It will become better to work with a hacksaw, and it will be easier if, in its middle part, the height of the teeth is increased by 1/3 of the height of the teeth.

If you attach a load weighing about a kilogram to the front of the bow saw, it will become easier to work. The load must be made removable so that the saw can also perform other work.

“A wax-like finish can be obtained by painting the surface with diluted PVA glue. desired color, you need to dilute the glue with water tinted with watercolors. "

"Make a blade cover ax - easier simple. A piece of rubber tube is taken, cut lengthwise and put on the blade. It is protected from jumping off by a ring cut from old car mobile camera. "

"Do without clamps when gluing wooden frames the laundry cord will help. It is necessary to put on four short loops at the corners of the frame and pull the frames diagonally with two long loops. The corners are adjusted using the sticks that twist the middle loops. "

"How to silence a creaking floorboard? Between the floorboards you need to drill a hole at an angle of 45 ° with a diameter of 6-8 mm, hammer in a wooden pin, greased with wood glue, cut off the protruding end with a chisel and putty on the floor surface."

"To make it easier to scrape a floor covered with varnish or paint, iron it through a damp cloth - and the job is a hundred percent easier."

"A slight decay on wood can be eliminated as follows: the affected wood is removed from the healthy layer, and then impregnated with a 10% formalin solution. After drying, the area is putty and painted over."

The renovation process in an apartment includes many works associated with creating holes in the walls: a tool can be used for this. of various designs and power. Many craftsmen and those who are going to carry out repairs on their own want to know how to drill a concrete wall conventional drill and is it possible at all. For such work, a perforator is usually used, but it is not always suitable for this, besides, if the tool is to be bought, then its cost is much higher than that of a drill.

Features of the choice of tool

In most cases, it is better to use a hammer drill for it: it has increased power, is designed for punching hard surfaces, and allows you to make large holes in diameter. The use of the tool is impractical in the following cases:

- the need to drill the wall to a depth of 10-12 mm;

- work with, which crumbles when processing with a perforator;

- in work it is required to make no more than 10-15 holes.

Before drilling a wall, it is important to choose the drill itself: it should not be shock-free, since this type is ineffective when drilling concrete, the nozzle and cartridge become unusable almost immediately. The nozzles themselves must be victorious, intended for concrete work, the tip must be hard-alloyed.

In some cases a good decision there will be an acquisition of a hammer drill: the device is more expensive classical model, but differs in increased power, which can be adjusted.

Which attachments to choose?

Before drilling a hole in a concrete wall, you need to select a nozzle of the appropriate design. The following varieties are used for work:

- Impact-type tooth crowns for drilling. When working with concrete, it is recommended to use a variety of separate soldering teeth, made from the most durable metal alloys. Many bits are equipped with SDS shanks for installation in keyless drills. The drills are well suited for concrete walls, however, when in contact with metal, they can begin to collapse, therefore, before drilling a reinforced concrete wall, you need to check that there is no reinforcement in the place of work.

- Diamond core bits, which are designed for hammerless drilling of holes. Such nozzles are more modern, with their help it is easier to make a hole in a concrete wall. The edge of the crowns has an abrasive structure and special cutouts; during production it is processed by spraying diamond chips or corundum. Before making a hole in the wall, you just need to select the desired length of the nozzle: in everyday life, varieties with a diameter of up to 100-120 mm are used, in professional work, larger crowns are used. Distinctive feature is the ability to drill without the risk of damaging the fixture with fittings.

- KS-crowns that have cutting edge with crystalline diamond particles. Such nozzles are used for most solid walls, including drilling with them concrete plates, external walls and stone structures.

Before drilling or a partition, you need to make sure that during the work the wires or cables, if they are laid inside, will not be touched.

How to properly drill concrete with a drill?

Typically, such work is performed in the following cases:

- rough finishing of premises;

- installation of built-in furniture and appliances;

- installation of wiring and plumbing when communications are required to be concreted.

When using a victorious nozzle during work, it is required from time to time to use a metal punch, which is selected to the size of the hole being formed. Such a tool allows the drill not to jam when the drill is deeply immersed: the punch is placed in concrete and deepened by hammer blows to make a hole in the wall, destroying the seal.

This process is quite long, an alternative can be the use of diamond bits: a drill equipped with such nozzles will not get stuck in concrete.

Algorithm of actions:

- Before drilling a hole in the wall, you need to install the desired nozzle, after making sure that the tool is in good working order and the drill is intact.

- It is required to drill the concrete carefully; when using low-power equipment, the duration of the continuous operation of the drill should not be more than 10-12 minutes. If the drilling is delayed, it is required to take breaks so that the motor of the device cools down.

- After drilling a concrete wall, it became clear, then in addition it is worth considering that for each new hole it is required to process a nozzle. You can moisten the surface with water to facilitate the procedure and save the metal from deformation.

The whole process of work can be seen in the video:

If you encounter a jammed drill, do not pull it out by force: this will break off the fixture, leaving the tip in the concrete. The nozzle needs to be disconnected, select a crown with a reduced diameter and use it to pull out the stuck element.

Before deciding how to drill concrete walls and getting started, you should pay attention to the following recommendations:

- if the hole diameter exceeds 12 mm and the depth is 10-11 cm, it is better to use a hammer drill or a hybrid device (drill-hammer drill);

- if holes are made for plastic dowels, the depth should be 7-10 mm greater than the size of the fastening element, since concrete dust and small particles of stone remain inside;

- it is recommended to start work at low speeds so that the nozzle does not move due to the increased torque, and the impact mode is turned on when the drill goes 2-4 mm in depth;

- the dust generated during the drilling process can be removed with a vacuum cleaner, it is advisable to do this in the process, periodically stopping the drill and cleaning the hole from concrete particles;

- it is imperative to observe safety precautions during work: it is required to wear gloves to eliminate the risk of the handle sliding and goggles so that the crumb does not get into the eyes and does not damage the mucous membrane.

In most cases, a concrete wall is drilled with a perforator, without a drill. If, as part of the repair, you need to make no more than 15-20 holes or the wall is made of foam concrete, using a drill - optimal choice which will save you time and money.

Before punching a hole, you need to make sure that there is no wiring in this place, and check whether the nozzle is suitable for such work (the duration and efficiency of work depends on which drill the drill is equipped with). When deciding how to drill the wall, you should pay attention to the victorious crowns: with such a drill using a drill, you can easily punch a hole up to 10-12 cm deep.

If your house or apartment has concrete walls, then most likely you will need to hang something on them someday. It is clear that in this case there is no need to "reinvent the wheel", because you just need to know exactly how to drill a concrete wall.

Concrete wall

In one hundred percent of cases, the wall will be reinforced with metal rods, the thickness of which usually exceeds 12-14 mm. Such material is inherently plain concrete is no longer, passing into the category of "reinforced concrete", which refers to more durable materials than its "parent".

In addition, do not forget that the material is more than 90% coarse aggregate. This role is played by crushed stone of rocks, which have an increased density and, accordingly, strength. But since rubble stones cannot be pressed together too tightly, there is sand and cement in the space between them, which turn the concrete into a single monolith.

Tool

Simply put, deciding to drill concrete, you must understand that you will be working with a rock, which was first disassembled into "spare parts", and then glued back together, reinforced with metal rods.

In such conditions, trying to drill with an ordinary drill is fraught not only with a ruined mood (not all attempts will be successful, and drills will be durable), but also with a broken tool.

It is much more efficient to use a hammer drill that is designed for just such a job. Combining impact and rotational action, this tool will do the job quickly and easily, unless, of course, you remember to equip it with a special concrete drill.

You can buy a suitable drill at any hardware store, and there you will be offered a choice of drills from several manufacturers. Which of them will be better than its competitor can only be determined empirically, so in such a situation it is better to use the seller's advice. But you should follow his advice only if he really understands this issue (to be sure of this, ask him to tell how this drill differs from his shelf neighbor).

You will learn about the differences in the work of a drill and a hammer drill in this article.

We drill the wall

- If wallpaper is pasted on the wall that you need to drill, so that they do not get dirty during operation, use a vacuum cleaner (you will also need an assistant who will hold this vacuum cleaner). If there is no assistant, glue newspapers or old wallpaper under the future hole using masking tape. The paper covering the wall from dust and dirt should be wide enough (at least 50 centimeters).

- Use a pencil to mark the location of the hole. Make sure that this place does not pass electric wires, otherwise you will have to deal with the repair of electrical wiring later. "Collision" with a live wire will also not go unnoticed for the hammer drill.

- Having picked up the drill of the diameter you need, fix it in the hammer drill.

- Switch the hammer drill to hammer drilling mode for faster work.

- Have your assistant remove the brush from the vacuum cleaner, turn it on and maintain metal pipe just below the future hole.

- Place the rock drill against the wall and start drilling it, pushing down on the rock drill with your weight. Check the horizontal and depth of the hole at all times.

- After reaching the desired depth, carefully remove the drill so that the concrete dust does not scatter.

- After removing the hammer drill, use a vacuum cleaner to get rid of the remaining dust in the hole.

Video

This video will show you how to use a punch.

Are you going to hang something on a concrete wall? Watch this story first.

Sometimes when doing finishing works it becomes necessary to make holes in the wall, for example, to fix a metal profile when installing drywall. If the wall is concrete, then this procedure can cause certain difficulties, since this material has high strength, has an inhomogeneous structure and contains metal reinforcement. Next, we will consider in what ways you can solve this problem.

Required tool

Due to the nature of concrete, you will need special tool :

- (hammer drill) - provides rotary-translational movement of the drill.

- Drills for concrete for hammer drills made of hard alloys. Their shank and screw part are made of tool steel, and the cutting working area is a carbide metal plate, sharpened at 60 degrees, which is soldered into the groove of the cutting part of the tool.

- (needed when drilling with a conventional drill).

It must be said that it is possible to cope with the task at hand with a tool without a strike function. Below we will take a closer look at how to drill a concrete wall with a drill.

Drilling procedure with a hammer drill

The procedure for drilling a wall using a punch and a special drill is quite simple:

- The concrete drill should be switched to hammer drilling mode and the operation should be started. The drill should be positioned strictly at a 90 degree angle to the wall, unless the drilling is specifically done at a certain angle.

- After a while, the drill must be soaked in cold water and continue working.

- If the tool rested on something solid and stopped going deep, then you will have to try to drill the wall in a different place.

- After the desired immersion depth has been reached, pull out the drill without turning off the drill. To clean the hole from dust, it is necessary to deepen and pull out the drill a few more times.

This completes the procedure.

Advice!

The hammer drill can be used not only for drilling hard materials.

There are special attachments that turn this tool into a mixer.

Thanks to them, the drill - concrete mixer does an excellent job of stirring the solution.

Drilling with a drill

Many home craftsmen doubt whether it is possible to drill concrete with a drill? Of course, this procedure will take much longer than when working with a hammer drill, however, it is quite possible to make a hole.

To perform this operation, you will need a special punch. This tool is a bar with a pointed hard end. It is used to break the surface in the drilling area.

The instructions for doing this work are as follows:

- First of all, to the place where the future hole will be located, you need to attach a punch and hit it several times with a hammer.

- Then, a drill is inserted into the resulting funnel and a hole is drilled. As with the hammer drill, care must be taken to ensure that the tool does not overheat.

- If the drill stops deepening, you must again use the punch and insert it into the hole and hit it hard with a hammer several times.

- In this way, drilling is carried out until the desired hole depth is reached.

Advice!

Often there is a need to cut concrete, in which case a grinder is used.

However, it should be borne in mind that cutting of reinforced concrete with diamond wheels is performed.

As a result, although an ordinary drill for concrete is not suitable, in the absence of a perforator, it can also be used to drill a reinforced concrete wall with its help.

In the photo - working with a punch

Advice!

The drill can be used not only for making holes, but also for some other purposes.

For example, on our portal you can find out how to make a vibrator for concrete with your own hands from a drill.

This technology implies the use of special equipment, which is a set of the following elements:

- Electric motor;

- Rack, which is fixed to the base;

- Drill bits.

With this design, water is fed directly to the drill to cool the tool. Therefore, there is no need to interrupt the process. In addition, water washes away dust, so that it does not have time to get into the surrounding space.Often, such a unit includes a water vacuum cleaner, which allows you to remove the mixture of water and dust from the surface.

Of course, it makes sense to use diamond drilling of holes in concrete only for industrial purposes, where it is necessary to make a large number of holes, especially of large diameter. For domestic purposes, the equipment is unlikely to come in handy.

In addition, the price of the kit, like any other professional tool, is quite high. Therefore, if it is necessary, for example, to fix a shelf on the wall, it is more expedient to use a puncher. (See also the article.)

Conclusion

With a reasonable approach, it will not be difficult to make a hole in concrete. The most important thing is to use the right equipment for this and follow a specific procedure. In addition, of course, safety precautions must be followed so that the work does not end in injury.

From the video in this article, you can get more information on this topic.

Concrete is a durable and reliable material. Many, if not most, buildings are constructed of monolithic or precast concrete. Typically gasket holes engineering communications, pipelines, as well as recesses for the installation of electrical and low-current fittings are provided during the molding process concrete structures... But their location often does not suit the owner of the premises, and they have to drill holes in new points. We will try to figure out how best to do this.

Choosing a tool

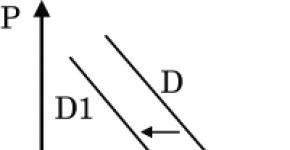

Initially, you should determine which tool is better and more efficient to drill a concrete wall. In a global sense, the choice is small - an impact drill or a hammer drill. But there can be many nuances, since the power tool can be of different power and functionality, there are also many attachments for it. Therefore, you should define goals and objectives, and then decide what tool you might need. So:

- To roll into the wall small screw a big effort is not needed under the picture. In this case, you can drill a concrete wall with a conventional drill, equipped with a drill with a victorious tip.

- When a small amount of work is expected, and the diameter of the punched holes does not exceed 12 mm, then an impact drill should be chosen.

- The hammer drill is used to drill holes of large diameters in concrete, as well as of any size, but in significant quantities.

The advantage of a hammer drill over a drill, even with an impact function, is not only more power and endurance. This tool uses not only drills of various sizes and qualities, but also drill bits as a working bit. This is the main device than you can drill a hole in concrete for a pipe.

Professional installers, punching large-diameter holes in concrete, use special units, which include:

- high power electric motor;

- sturdy bracket with guide structure;

- drilling drive;

- drill bits with diamond working area.

Such equipment allows you to make a hole or recess in a concrete wall with a diameter of up to 40 cm.

Which will win more effectively or the diamond?

When you need to make only a few holes for the construction dowel, and there is no perforator at hand, then using a conventional drill with a victorious drill is quite realistic. Also this option fit better in total, if the working surface is concrete, but made of cellular material. The puncher will destroy it. But when working with a victorious drill, remember that it is short-lived and requires periodic replacement. In addition, such a drill can be "drilled" in concrete. Then he needs to be helped by hand with a punch and a hammer.

Drilling a concrete wall with an impact drill equipped with a diamond drill is much more effective. Diamond drills are slightly more expensive than victorious ones, but they also last longer. And further important point... Unlike the victorious diamond drill punches holes not only in concrete and stone, but also in ceramic tiles, porcelain stoneware and metal. When working with diamond tools, it is not scary to stumble upon reinforcement cage in the wall. It is better to purchase drills in a set, which includes drills of various diameters. It is more profitable than buying them one by one.

When a hole with a diameter of 35 to 120 mm is drilled in the wall, diamond bits are used as a cutting device. They represent steel rings Carbide tipped on a diamond coated work area. For household purposes, crowns with a diameter of 6.8 cm are usually used, holes of this diameter are needed for installation electrical outlets and switches.

How to properly drill concrete

Hole punching work, like any other, requires preparation. In addition to tools and accessories, you should stock up on water to cool drills and crowns. Before drilling concrete with a drill or hammer drill, inspect the wall for:

- hidden heating pipelines, water supply;

- electrical wires, cables.

The search is carried out with a metal detector, identify the identified communications along their entire length. Electrical wiring work surface better to turn it off. Further:

- Mark the locations of future aisles. If holes of large diameter are assumed, then the designation is made along the contour and axes.

- The depth of the hole for the construction dowel is made 8-10mm longer than its length.

- For a more accurate result, the concrete must be drilled correctly. This means that the start of drilling should be done at low engine speed.

- After a small depression is obtained, the revolutions are increased and the instrument is transferred to the impact mode.

- If possible, provide a water supply to the drilling site. In the absence of such an option, periodically moisten the drill with water in a previously prepared container.

- If drilling with a drill is carried out in one position of the tool, then when drilling with a crown, the perforator must be slightly wiggled. This way, waste will be easily removed from the resulting hole and the crown will not jam.

The most difficult obstacle that has to be overcome when drilling a concrete wall is the reinforcement cage. The diamond bit cuts steel rods of small diameter on its own. When drilling with a hammer drill, metal drills should be used to counter the reinforcement.

Wear protective goggles and a respirator. It is convenient to vacuum the resulting dust. After every 15 minutes of drilling, give the tool a break for about the same amount of time. To continue working, moisten the drill with water.