The best ways to exterior finish a frame house. How to choose a facade for a frame house? The better to sheathe the walls of a frame house inside

No matter how warm, cozy and comfortable your home is, it will not look good from the outside without high-quality finishes. Modern finishing of a frame house can be made of a variety of materials, both natural and synthetic. Each of the types of exterior finishes has its pros and cons, features of fastening to the wall, differences in prices. There are those that can be easily done with your own hands, while others are best left to a specialist.

What is it for?

Non-ventilated structures are deprived of such an important component as the air gap. They are attached directly to the wall, making their installation much easier. At the same time, the panels also protect the walls well from temperature extremes in winter, and in summer they reflect the sun's rays, maintaining a comfortable temperature in the room.

Hinged structures can be used not only for sheathing new buildings, but also old ones. The principles of fastening the screens to the wall do not cause their damage and deformation. This is especially true for ventilated facade panels.

Before installation work, in order to extend the life of the walls of your house, it is not necessary to carry out additional processing or dismantling of the old cladding.

Wet cladding of a wooden building

Can wet cladding of a frame house be made with additional insulation? To do this, foam boards must be glued to the outer OSB boards. Here you need to be careful and choose the foam specifically for the exterior. Such material is called facade, and in the marking it has the letter F, for example: PSBS-25f. Do not buy extruded foam, which consultants in stores like to recommend. It is more expensive, but completely unsuitable for the exterior of frame houses. The fact is that it does not let steam through at all, which means that the walls will not be ventilated and condensate will accumulate on them in the form of water droplets. And frame walls are already much more airtight than those made of bricks or blocks.

EPPS can only be used for basement insulation, as it is more solid and does not absorb moisture. For better adhesion of the primer to it (it is too smooth by itself), it is necessary to scratch the plates with sandpaper or scratch with something sharp.

We put the foam on the glue butt to butt. With the help of foam, you can create decorative elements on the facade of the building. Successfully they are located near the windows or around the front door.

On sheets of foam (you can take the thinnest - for example, 40 mm, since in the frames, as a rule, there is already mineral wool insulation) a layer of special glue 4-6 mm thick is applied. A fiberglass mesh is embedded in the adhesive, which acts as the so-called base reinforcing layer. From above it is covered with a special quartz primer, which includes fine sand filler.

Only after all these works have been completed, it is possible to apply a layer of decorative plaster, which differ both in color and in composition.

Types of plaster for exterior decoration:

- acrylic

- silicone

- silicate

- mineral

- with various fillers

Important: Pay special attention to the quality of the reinforcing mesh. Adhesives release alkali, which can dissolve the reinforcing layer, causing the entire finish to become unusable.

Facade brick for cladding

Facade bricks can also be of various types. It differs in its composition, color, additional inclusions. The most common types of bricks for exterior decoration are:

- silicate

- hyperpressed

- ceramic

Sand-lime brick has the most reasonable cost, and ceramic brick creates the most stylish and neat appearance of the building due to its surface. It can be smooth, glazed, or even matte. Hyper-pressed brick contains fine limestone and shell rock, which reduces the percentage of moisture absorption. Facade bricks are also divided into:

- hollow

- corpulent

Openings are created in the hollow facade brick, providing an air gap. Therefore, such a brick retains heat better.

External brick cladding can be made in various types of laying. Do not finish at low temperatures, as the mortar may freeze.

Calculate the amount of material needed for the exterior decoration of frame houses in advance, since different batches of bricks may have a slight difference in shades, which will be noticeable after the cladding is completed. After exterior finishing, you can achieve a more even shade of masonry if you treat the wall with a solution of 10% perchloric acid.

Siding and PVC panels - cheap and tasteful

Siding is a panel for the outer cladding of frame buildings made of polyvinyl chloride, the thickness of which is about 1.0 -1.3 mm. This is the cheapest and easiest way to do-it-yourself exterior decoration of frame walls. Thanks to the synthetic structure, the siding is not subject to destruction, and allows you to forget about the protection of the house for a long time. The casing does not deform, does not rot, fungi and bacteria do not like the material. The appearance of the house acquires neat European features, and the use of structural elements and different shades makes the house special.

The frame house, protected by siding, is not subject to corrosion. The lining material and the entire cladding can withstand sudden temperature changes from minus 40 to plus 60.

This is the best way to finish a frame building with a light foundation. The lightness of the finishing material does not give a large load on the walls and base.

Particularly popular is this type of siding, such as PVC front panels under the stone. PVC is a synthetic material that is an excellent base for imitating natural stone, granite, brick, marble. At the same time, this type of finish is perfectly washed, it can be used to protect the base.

Panels with siding can be mounted on a frame that provides an additional air gap. Additional ventilation helps to remove excess moisture from the wall, retains heat. In addition, you can additionally use a heater.

Cladding made of thermal panels with clinker tiles

It is possible to sheathe walls under a stone from the outside using thermal panels. The material is based on polyurethane, and performs not only protective and decorative functions, but also insulation.

The panels are fixed in a seamless way, which improves the properties of the finish. Clinker tiles, which create a beautiful appearance of a frame building, strengthen the walls, improving its shockproof properties. The tile is not subject to abrasion, destruction and deformation by fungus, mold and bacteria. It cleans up easily.

The installation process takes place in several stages:

- Reconciliation of the geometry of the building. All walls should be flat, and the corners should be 90 degrees. If there is a deviation, it is necessary to use an additional crate of the frame house.

- We begin work by fixing the basement profile. The aluminum profile is fastened horizontally to the base of the frame structure.

- The next stage is the corner thermal panels. We attach the panel to the base of the profile.

- We fix the panels with dowels or screws. We fold all the panels using the puzzle method.

- Using polyurethane foam, we seal the panels, removing the gaps between them.

- We process the seams with frost-resistant grout.

The biggest disadvantage of this method of carcass sheathing is the price.

Facade tiles imitating brick, stone and other natural materials

By using wall cladding in this way, you can protect the walls, change the design of the house, and give the old house a fresh look. Tiles are attached to wooden walls with a crate, otherwise moisture can penetrate from the tile to the wall. Tiles must fit together tightly enough to prevent moisture from penetrating. Fixation occurs with the help of adhesive solutions.

Due to its composition, outdoor tiles have the following qualities:

- Variety of colors and shapes.

- Various reliefs and textures, gloss and dullness.

- Inexpensive and easy installation.

- An excellent choice for residential areas.

- The weight of the tile is quite light, so no additional strengthening of the foundation is required.

- It can be used for wooden frame buildings, as it does not weigh them down.

- Protects the wall from condensation and moisture penetration into the frame wall.

- Eco-friendly and harmless.

- Easily repairable.

- It can look like finishing from elite grades of stone, granite and marble, while the price is much cheaper.

Such a tile consists of concrete, sand, plastic fiqatra and coloring pigment.

Block house: a modern look of cladding

To give your home a natural and natural look of a wooden house, using a block house in the decoration will help. It is a rounded log (or beam), inside of which there is a flat surface. A flat surface is attached to the wall, as a result of which the frame house takes on the appearance of a house made of timber. Even inexpensive panel houses look like luxury housing.

In addition to excellent appearance, the blockhouse has the following features:

- It perfectly protects the walls of the house from external environmental influences, including from rain, snow, frost or the scorching rays of the sun.

- Durable and not subject to destruction, thanks to modern high-quality impregnations.

- Exterior finishing with a block house of a frame house can be carried out with simultaneous insulation and soundproofing of the building.

- Quick and easy fixing can be done by hand.

- It is easy to replace one or more elements of decoration and repair.

- It goes well in tandem with plastic, brick, decorative plaster, giving a unique look to the frame house.

Building a house using frame technology is an inexpensive and reliable construction option. With the proper skills or with the help of a construction team, all work can be carried out in a period of several weeks to a couple of months. The final stage will be the interior decoration of the frame house, after which the long-awaited construction will be completed and moving to a new home will become possible.

How should the finishing of a frame house inside proceed correctly, what difficulties will be encountered during construction, which option is more preferable for a particular stage of construction work, we will consider.

Features of the rough finish

Depending on the amount of money available, before fine finishing work, you can choose a less expensive or lighter building material. What difficulties arise when choosing and what are the characteristic features of each?

Drywall

Not so heavy in weight, it allows you to carry out all the work yourself and has an almost perfectly flat surface, which does not need to be processed so hard.

Internal finishing with plasterboard.

Internal finishing with plasterboard. The interior decoration of the frame house with drywall begins with the installation of a light metal frame, with a step of 600 mm, on which drywall sheets are attached using self-tapping screws. The joints between the plates are sealed with putty, the entire surface is lightly sanded with sandpaper.

At the stage of installation of a metal profile, it is possible to carry out additional insulation of the building using mineral or ecowool, or in any other way. Also, before the final installation of drywall sheets, it is required to install plastic boxes to hide cable channels and wiring in order to avoid their damage and damage during further operation of the house and construction work.

On a note

Finishing a frame house inside with plasterboard can use both walls and ceilings. It is not recommended to use this material on the floor due to its light weight and relative strength.

OSB boards

Oriented strand boards - OSB or OSB - are heavier and are assembled by at least two people or a construction team. The metal profile for their fastening is already reinforced, and the screws and nails for installation are at least 50 mm long. The strength of the material allows it to be used for flooring.

Wall decoration with OSB boards.

Wall decoration with OSB boards. The sheathing of a frame house inside the OSB follows the same scenario as the drywall one, only after the final installation, the surface is more thoroughly sanded due to its hairiness. It is also recommended to varnish the plates in several layers, drying them thoroughly each time. If in the future it is planned to paint the surface, lay tiles or plaster, OSB boards are processed with a primer.

clapboard

A more natural, homely and environmentally friendly material in a wooden version, more economical - lining in a plastic form.

Interior clapboard trim.

Interior clapboard trim. Natural wood - cedar and linden will not only allow you to enjoy the beauty of the interior, but also reduce the number of headaches for the future owner due to the created favorable microclimate. Other types of wood will also help create home comfort and transform the interior beyond recognition.

On a note

The indisputable advantage of this building material will be exceptional durability, excellent sound insulation, and the ability to retain heat longer.

An example of how interior decoration of a frame house can be done with the help of lining.

Finishing with attic clapboard in a frame building.

Finishing with attic clapboard in a frame building. When choosing a lining, great attention should be paid to the grade of the purchased building material:

- "Extra" - the most expensive type of wood of the best quality, without any noticeable surface defects.

- "A" - lining may have slight blackouts and small chips.

- "B" - there are knots and minor cracks on the wood.

- "C" - inexpensive wood lamellas with a noticeable amount of surface defects - knots, traces of resin, darkening, which can be beaten due to the style of the future room.

If the frame house is finished inside with a plastic lining, this will prevent the material from premature deterioration, but will not create the same atmosphere as a real tree. Finishing will save a certain amount, but will look artificial and not natural.

Plaster work

Carefully prepared can be decorated with finishing decorative plaster, which has significant advantages:

Plastering work on drywall.

Plastering work on drywall. - Large color palette and choice of shades;

- Heat and moisture - the impermeability of the material will keep the wooden elements of the building longer;

- High strength of the material, which does not depend on the temperature difference and exposure to sunlight.

On a note

The strength of the plaster causes possible difficulties in carrying out repairs in the future. If the owner of the house wants to change the wall covering, he will either have to repaint the plaster with a different color, or knock down layers of material.

Painting works

A more familiar type of finishing is painting a frame house inside. If staining is carried out on the surface of a wooden lining, it is recommended to choose light layers of varnish or paint to emphasize the natural beauty of the material.

Painting the lining with acrylic paint.

Painting the lining with acrylic paint. Before painting the house inside, it is necessary to treat the wood with antiseptics for greater durability of the material. It is recommended to apply paint or varnish from top to bottom, initially processing the joints of the joints, and then the main surface of the parts.

If necessary, the interior decoration of the walls of the frame house, ceiling and floor with the help of paint and varnish can be carried out in several layers, observing the drying time interval.

Wallpaper

Repairing a frame house inside with a photo, vinyl, paper or other type of wallpaper is the most common finishing option. On the market, the footage of rolls with a width of 0.5 to 1 meter is available, at a cost of 100 rubles per roll.

Wallpaper design for the wall.

Wallpaper design for the wall. - Paper - the cheapest, not particularly strong and durable, deform under the influence of liquid and sunlight;

- Vinyl - more durable, resistant to damage;

- Non-woven - consist of foamed vinyl, dense and resistant to mechanical stress, can be covered with a layer of paint;

- Acrylic - bright and durable, resistant to leaks;

- Fiberglass - also suitable for painting, mechanically and fire resistant;

- Liquid - a dry mixture of cotton particles, cellulose and a binder mixture, successfully hides surface defects, a wide choice of shades and textures.

Non-woven wallpaper for walls.

Non-woven wallpaper for walls. If the interior decoration of the frame house is done by hand, you can use the following tips:

- Work is not recommended to be carried out immediately in all rooms of the frame house, it is better to do repairs gradually, from one room to another.

- Finishing work is carried out after the installation of all communication systems, heating, plumbing, electrical wiring.

- It is better to start with, then touch the walls inside the frame house, the final stage is the flooring.

- Work should be carried out from the room farthest from the entrance, to the front door.

- At the preparatory stage, it is necessary to isolate the premises from each other with a polyethylene curtain, or by covering the repaired premises with a film to prevent the spread of debris.

Frame houses are now very popular - inexpensive and easy to build, energy-saving and environmentally friendly. Many are taken for the construction of a frame house with their own hands. The next step after the construction work is completed should be the interior decoration of the frame house. It should be borne in mind that each of the walls of such a house is a carrier, and before making a hole for a window in it, it must first be strengthened.

For the interior decoration of a frame house, you can use wooden lining, drywall, PVC lining and OSB boards.

Preparation for finishing work

The process of interior decoration of the walls of a frame house is practically no different from similar work in standard designs. Before you start finishing, you should draw up a work plan that includes a project. They should contain a list of all upcoming work, marking fixtures and much more.

Interior finishing can be done with any sheet material - this will reduce the time and money spent on finishing work. So, for example, drywall can be used for these purposes - an environmentally friendly and inexpensive material. It is noteworthy that its low cost is also due to the fact that it is a domestically produced material. For this purpose, you can use a block house or decorative lining.

When carrying out the interior decoration of a frame house, several important points should be taken into account: the correct sequence of stages, preparatory work, features of materials and the rules for their installation.

After the erection of the walls and roof, it is the turn of the interior decoration of the premises of the frame house. In order not to make mistakes in the process of repair and finishing work, we recommend that you familiarize yourself with their features in the field of frame construction.

Stages of interior decoration

To ensure high comfort of living in the house, it is necessary to pay attention to each of the three stages of the interior decoration of the frame house.

Aligning posts and beams

To make the subsequent stages of finishing easier, you need to prepare the premises. Under the condition of high-quality construction, all racks and beams in the room should be even. You can check this using the building level.

In case of poor-quality laying of the floor, it is leveled with wooden wedges hammered into the places where the beams are attached.

Warming and soundproofing

The process of warming the floor of a frame house

Recently, these two concepts are increasingly used as a whole, since modern materials have both noise and heat insulation properties. Mineral wool, polystyrene, polyurethane foam, foamed rubber, expanded clay (for the floor) are popular.

If your house is located in an open area, it is recommended to lay a layer of wind protection before laying the insulation - this way you will ensure a higher temperature in the house in winter.

Usually start from the floor. A draft floor is laid out on horizontal beams, the surface of which, in turn, is covered with the selected material. Another layer of the floor is laid on top, usually these are boards with an aesthetic appearance with special impregnation or treatment (if it is not planned to finish the floor), or ordinary boards.

The walls and ceiling are insulated in the same way, sheets of insulation are laid out between the beams, and then covered with a rough finishing material.

To insulate the ceiling, you can purchase foam, its weight is much lighter, so for ease of attachment, you can use a hot glue gun.

In the bathroom, toilet, boiler room, bath or sauna, you must also put vapor protection.

Rough finish

How to properly fix drywall

For rough interior decoration of frame houses for wallpaper, plaster, tile or painting, gypsum boards are most often used. This is an economical, high-quality material that will allow you to create a perfectly flat surface for fine finishing.

At this stage, it is necessary to cover the walls and ceiling with gypsum boards, as well as erect the planned gypsum board structures (partitions, niches, arches).

Drywall sheets are recommended to be fastened according to the step of the frame: each sheet must begin on the frame and end on it. Sheets are fastened to self-tapping screws with a screwdriver at a distance of 20-30 cm from each other. You need to leave a gap of 2-3 centimeters to the floor (then it will close with a plinth).

Before proceeding to the next stage, the joints must be puttied in 2 layers (after each layer has dried, it must be leveled with sandpaper), and the walls must be plastered.

In rooms with high humidity, it is necessary to use a special moisture-resistant drywall for the rough finish of walls and ceilings.

There is another option for the rough finish of a frame house - these are OSB boards. According to their characteristics, they are similar to drywall, but have a more environmentally friendly composition. However, they are quite heavy, so you should not choose this option if you do not have the skills to work with it.

fine finish

The final stage of finishing involves laying finishing materials, or wallpapering, laying tiles or painting walls. Let us consider in more detail the types of possible materials for the interior finishing of a frame house.

Types of wall materials

Wallpaper has been the most popular finishing material for several decades. They are inexpensive, and even an unprepared person can glue them - the main thing is to follow the instructions.

Wallpaper

Types of wallpaper and their characteristics:

- Paper - the most economical type of wallpaper, ideal for budget or temporary repairs. Their main drawback is instability to moisture and drafts.

- Photo wallpapers are recommended to be glued in rooms without windows or small rooms to create the illusion of a larger space or give the interior a more original look. The characteristics are similar to paper counterparts.

- Vinyl wallpapers are more durable and strong than paper ones, but their price is higher.

- Acrylic wallpaper is suitable for rooms with high humidity.

- Non-woven wallpaper creates an ideal surface for finishing wall painting.

- Fiberglass wallpaper is the most fireproof type, which is ideal for finishing a frame house, both for finishing and for painting.

When buying wallpaper, pay attention to the type of glue that is most suitable for them. For different types of wallpaper, certain types of glue are required.

Ceramic tile

Finishing in the bathroom, toilet, kitchen or swimming pool requires high strength and moisture resistance from the finishing material. The perfect combination of these characteristics is ceramic tiles. This material has a low price, but at the same time, the variety of shades and textures will make it possible to realize even the most daring design ideas.

Tiles can be used on both walls and floors. It is easily attached to any plastered surfaces, including drywall.

clapboard

A popular option for interior decoration of a frame house is. Due to the high heat and noise insulation characteristics of this material, it is excellent for cladding the walls of a frame house. In addition, the walls finished with natural wooden clapboard look very cozy and aesthetically pleasing, especially if the house is a country house.

There is also a more budget option - plastic lining. It is very easy to mount it, and it will serve for more than one year. Plastic clapboard can be used to decorate the walls and ceiling in the bathroom if the tile seems to be too expensive an option. It should be borne in mind that such a finish will look simple and without frills.

Liquid wallpaper

One of the recently invented finishing technologies that has already won a lot of fans is liquid wallpaper. They are good for their decorative component and the ability to hide minor flaws and wall irregularities. However, the method of applying them is not easy and time-consuming.

Decorative plaster

If you want to create an original designer wall covering in your frame house, consider finishing with decorative plaster. Thanks to various textured rollers and ease of application, decorative plaster is perfect for creative people who do not have special repair skills. In addition, an important advantage of this material is its low price.

To make the interior more original, you can combine several types of finishes, such as painting and decorative plaster, or wallpaper and wall panels.

The main thing is to know when to stop: it is better to use additional decorative material for zoning individual objects: headboards, TV sets, etc.

Types of materials for the floor

If you want to combine the rough and finish of the floor, while saving time and money, you can cover the floor with a grooved board. This natural material will serve you for a long time and, if properly processed, will have an aesthetic appearance.

grooved board

The best option would be a larch board: it has a higher moisture resistance than a spruce or pine board, but at the same time, unlike oak or ash boards, it is not as attractive to beetles.

The grooved board is laid on a screed or logs.

After purchasing the tongue and groove boards, bring them into the house and leave them there for 2 weeks. This will ensure that the material is perfectly moist and the new floor will not change in size after installation.

Parquet

One of the most environmentally friendly, high-quality and durable materials, especially if it is natural. However, it is expensive, but it is very susceptible to high humidity.

Laminate

The material is average in almost all respects. It is difficult to call it environmentally friendly, and it is not resistant to moisture, so for a nursery it is better to prefer some other option. At the same time, laminate flooring lasts a long time with careful handling, is inexpensive and easy to install. It is perfect for the floor in the living room or in the hallway.

Laminate is laid on a special substrate that gives the floor elasticity and reduces the likelihood of damage.

Tile

For interior decoration of the house, ceramic or cork tiles are most often used.

Ceramic tiles are especially suitable for decorating the floor in the bathroom, in the kitchen, as well as islands at the front door. This is the most wear-resistant material, while one of the easiest to clean.

Ceramic tiles are the best choice if you are going to make a "warm floor".

This material has a high heat dissipation, while it does not deform from constant exposure to heat, like laminate or parquet.

Cork tiles are a fashionable trend for connoisseurs of everything natural. It is quite expensive, but its main advantage is environmental friendliness.

Even a chronic allergy sufferer can live comfortably in rooms with cork floors. Its main drawback is vulnerability to heels.

Linoleum

The most budget option for flooring, widely used in the decoration of houses in the USSR. Its main advantages are good heat dissipation and moisture resistance, but other characteristics are inferior to competitors: it is susceptible to chemical attack and is easily damaged.

Carpet covering

If you want the room to be comfortable to walk barefoot, feel free to buy carpet. It is inexpensive and very easy to install. Carpeting has the highest heat dissipation and good moisture resistance, but at the same time it is not very practical: any stains will be visible on light shades, and it is also very easy to damage the surface.

Whatever materials for interior decoration you choose, you must carefully read the instructions for them. If you are going to finish the house yourself, be sure to study the step-by-step decoration instructions on the Internet to avoid mistakes.

Wall cladding is one of the final stages in the construction of a frame house. And here the choice of material is of great importance: the microclimate in the premises, the mechanical strength of the walls, the reliability of protection against moisture and cold depend on this. In addition, sheathing serves as the basis for finishing materials, and in some cases acts as a finishing coating and is responsible for the aesthetic appearance of the building.

Sheathing gives the frame of the structure a certain rigidity and takes on part of the load. This means that one of the main criteria is the mechanical strength of the material in bending and compression, the absence of shrinkage during operation. The walls must retain their original shape for years, regardless of the surrounding conditions. In addition, the sheathing must be resistant to moisture, sudden changes in temperature, and the effects of microorganisms.

Next, you need to pay attention to the ease of installation of the material and its ductility during processing. If you plan to sheathe with your own hands, this aspect is of great importance, because it depends on how much effort and time it will take to work. The material should be easy to cut and drill, but at the same time keep the density on the cuts, not crumble, not crack. And, of course, it must be durable so that you do not have to change the skin every 10-15 years.

Material selection

There are several types of materials that more or less meet the specified requirements: moisture-resistant plywood, DSP, OSB, edged board, fiberboard. They have similar characteristics and are widely used in frame construction. To make a choice, it is worth familiarizing yourself with the main properties and features of each of them.

Oriented Strand Board (OSB)

OSB panels rightfully belong to the most popular materials in the arrangement of frame structures. They consist of layers of glued wood chips and chips, and in the outer layers the fibers are arranged longitudinally, inside - transversely. Synthetic resins and wax are used to bind the chips, giving the finished boards water-repellent properties.

Standard production provides for the production of these plates in several categories:

- OSB-1 is intended exclusively for interior decoration of dry rooms with reduced mechanical stress;

- OSB-2 is used in the installation of load-bearing structures in rooms with low humidity;

- OSB-3 is a moisture-resistant board of increased rigidity, used in the installation of load-bearing structures indoors and outdoors.

In terms of quality-functionality-price, OSB-3 is the most optimal, and this material is widely used in private construction for wall cladding, the manufacture of load-bearing partitions, and reusable formwork when pouring concrete structures. The plates lend themselves perfectly to grinding, cutting, drilling, tightly hold nails even at a distance of 6 mm from the edge. Such sheathing can simultaneously serve as a decorative coating for walls, it is enough just to treat it with waterproof varnish or paint it.

OSB Advantages:

- dense structure prevents delamination and splitting of the material during processing and during operation;

- plates have elasticity and high strength, perfectly resist vibrations, compressive loads, various deformations;

- the material is resistant to weathering and temperature extremes;

- OSB is resistant to microorganisms, insects and rodents do not like it.

Disadvantages:

- very low vapor permeability;

- combustibility;

- the content of toxic compounds (phenol and formaldehyde).

Main characteristics

Prices for OSB (Oriented Strand Board)

OSB (Oriented Strand Board)

Cement particle boards (DSP)

This material is a compressed mass of M500 cement and shavings (usually softwood). A standard plate has three layers: the outer ones are made of small chips, the inner one is made of large chips. In addition to the main components, the composition contains hydration additives, the mass fraction of which does not exceed 3%. DSP is characterized by resistance to moisture, high strength, long service life. Plates are widely used in private construction, industrial, for work inside and outside the premises.

When sheathing the frame, such plates serve as an excellent basis for cladding, decorative plaster, painting, as they form a perfectly flat and smooth surface. The material endures 50 cycles of complete freezing and thawing without loss of its characteristics; in the future, the strength of the plates decreases by about 10%. Among wood-based materials, DSP is the leader in terms of environmental and technical indicators.

Advantages:

- very low hygroscopicity;

- resistance to mold and other microorganisms;

- DSPs are not damaged by insects and rodents;

- the material does not emit toxic substances;

- low thermal conductivity;

- Fire safety.

Disadvantages:

- mechanical processing of plates requires considerable effort;

- DSP has a large weight compared to other materials;

- when cutting and drilling plates, a lot of fine dust is formed, so you need to work in a respirator;

- high price.

Specifications

Fibreboard (Fibreboard)

The material is sheets of pressed shavings, usually softwood. During the pressing process, the raw material is strongly heated, which makes it possible to achieve maximum density without the use of adhesives. Due to this, fiberboard belongs to environmentally friendly materials, and therefore is suitable for outdoor use and for finishing residential premises. The shavings contain natural resin, which acts as an antiseptic and protects the plates from mold.

In terms of strength, fiberboard is noticeably inferior to natural lining and OSB, but it surpasses them in terms of heat and sound insulation properties.

Windproof plate "Beltermo"

Now in the construction market fiberboards are represented by insulating boards of several well-known brands, the most popular of which are Beltermo and Izoplat. For sheathing a frame house, plates with a thickness of at least 25 mm are used, thinner sheets are used indoors.

Advantages:

- light weight;

- low thermal conductivity;

- ease of installation;

- the material does not exfoliate and does not crumble;

- high vapor permeability;

- resistance to moisture and microbial attack;

- the absence of harmful substances in the composition.

Disadvantages:

- high price;

- a long stay without a decorative finish causes slight deformation of the sheets;

- the outer skin of fiberboard requires the presence of spacer braces in the frame or a rigid inner skin.

Specifications

Prices for wood fiber boards (MDF)

Fibreboard (Fibreboard)

Gypsum fiber sheets (GVL)

GVL consists of pressed gypsum reinforced with cellulose fibers. Due to its high strength, the material is suitable for creating load-bearing surfaces, therefore it is widely used in frame construction. It differs from drywall in greater density, uniformity, and the absence of a cardboard shell. In terms of frost resistance, soundproofing properties, as well as resistance to moisture and combustion, GVL also exceeds gypsum boards by several times.

Installation of GVL is carried out in a frame and frameless way. For external wall cladding, the first option is used, where the sheets are fastened to the bearing racks with self-tapping screws. The material is easy to cut and drill, and, despite its heavy weight, is quite easy to install. Such a sheathing serves as an excellent basis for finishing with tiles and decorative plaster.

Advantages:

- low hygroscopicity;

- vapor permeability;

- the absence of toxic compounds in the composition;

- fire safety;

- high heat and sound insulation properties.

Disadvantages:

- lack of plasticity and brittleness when bending the sheet;

- great weight.

Specifications

Plywood

Plywood is made by gluing thin sheets of veneer of various types of wood (most often coniferous and birch). Sheets are stacked perpendicular to each other relative to the location of the fibers, which increases the mechanical strength of the material and increases resistance to deformation. For the outer cladding of frame walls, plywood of increased moisture resistance is used, which is marked FSF. The thickness of the sheets should be from 9-10 mm, thinner material will not provide the necessary rigidity to the frame.

The grade of plywood does not really matter for sheathing, and the cheapest unsanded 4/4 grade boards can be used.

From the outside, all defects will be hidden under a hinged facade, so there is no point in overpaying. Subject to the sheathing technology, the plywood coating will serve for years without losing its qualities.

Advantages:

- high flexural and compressive strength;

- moisture resistance;

- wear resistance;

- ease of processing and installation;

- frost resistance.

Disadvantages:

- combustibility;

- content of formaldehyde resins;

- tendency to chipping.

Specifications

plywood prices

Edged board

The use of edged boards for sheathing is the most economical option. Wood is an environmentally friendly material, affordable, easy to install. Boards can be filled not only horizontally, but also at an angle of 45-60 degrees. To save material, boards can be fastened in increments of up to 30 cm, although most often the sheathing is made solid. This design perfectly strengthens the frame and is a ready-made base for a ventilated facade.

In order for the sheathing to be reliable, the boards are chosen with a thickness of at least 25 mm, they can be tongue-and-groove, for greater docking density. Do not use raw lumber: in the process of drying, the wood will begin to warp, deformations of the finish coating may appear.

Advantages:

- wood does not emit harmful substances and has excellent vapor permeability;

- boards are easy to process;

- work does not require large financial costs.

Disadvantages:

- combustibility of the material;

- wood is susceptible to damage by insects and microorganisms;

- fitting and fixing elements takes a lot of time.

Edged board prices

Cladding technology

Installation of plates on the finished frame is carried out according to the same technology, regardless of the type of material. Simultaneously with the cladding, vapor barrier and wall insulation are performed, and finishing can be done immediately upon completion of construction or after some time. Consider the installation technology using the example of frame sheathing with OSB boards.

Sheathing can be done in two ways - with and without crate. In the first case, the vapor barrier layer is located between the frame and the OSB, in the second - on top of the skin. The batten option is used in cases where the OSB serves as the basis for plastering, painting or tiling, the second method is used, as a rule, when installing a ventilated facade. Otherwise, there are no significant differences.

Step 1. Start trimming from the very corner. The first sheet of OSB is applied to the racks of the frame so that the lower edge completely overlaps the lower trim of the house. Be sure to control the horizontal level. The plate itself is also recommended to be placed horizontally, and not vertically - this provides the structure with greater rigidity. For fixing the material, galvanized self-tapping screws with a length of at least 50 mm are used. About 10 mm must be retreated from the edge of the OSB, the fastening step along the perimeter of the sheet is 15 cm, in the center - 30 cm.

Advice. For strong fixation of the plates, the length of the hardware must exceed the thickness of the OSB by at least 2.5 times. If the self-tapping screw enters the frame beam by less than 30 mm, under the influence of loads, the sheathing will begin to break away from the supporting base.

Step 2 The next plate is installed next to the first, leaving a gap of 2-3 mm for thermal expansion. In the same way, they set the horizontal level, screw the sheathing to the frame guides. The joints of the plates must necessarily fall in the middle of the rack, only in this case the fastening will be as reliable as possible. The rest of the plates are fixed in a circle, leaving open areas for doorways.

Step 3 The second row of sheathing must be mounted with dressing of vertical seams. Between the lower and upper plates, the same gap of 2-3 mm is observed. When sheathing openings, whole sheets should be used, and not trimmings - the fewer joints, the tighter the sheathing. Cutouts in the sheets are made with an electric jigsaw or a circular saw, having previously marked out to the nearest millimeter. The edges of the cuts after the installation of the slab must ideally coincide with the lines of the openings.

Step 4 The top plates are installed so as to completely cover the top trim. If the house has two floors, the interfloor piping should be closed by the middle of the slab - it is impossible to join the OSB on this line in any case.

Gallery 1. An example of the construction of a one-story frame house with OSB trim

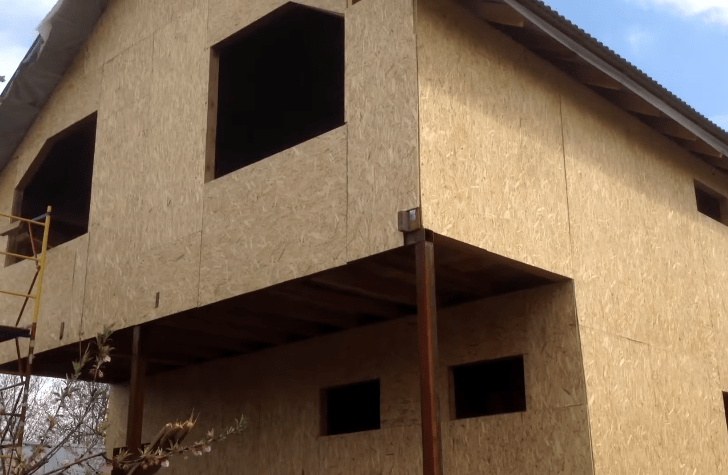

Gallery 2. Sheathing with OSB boards of a two-story frame house. Example

Step 5 After completing the installation, a windproof membrane is attached over the skin. Her canvases are stretched horizontally and fixed with stapler staples to the OSB. At the joints, the film is overlapped and glued with adhesive tape. The material should not be pulled too tight, but there should be no sagging either.

Step 6 Next, the laths of the crate are stuffed for finishing in increments of 50-60 cm. The laths must first be treated with a protective compound and dried. After that, you can proceed with the installation of siding, lining or other decorative coating for the house.

On a note! If it is planned to paint the facade from OSB, then the membrane, respectively, is mounted only on the inside of the house.

With this method of sheathing, the insulation is placed on the inside of the walls into the cells of the frame and covered with a vapor barrier film. Slabs for interior decoration are sewn over the vapor barrier, for example, drywall or the same OSB.

Video - How to sheathe a frame house from the outside