Air compressor for fine painting from an old refrigerator. Do-it-yourself compressors from the refrigerator - an algorithm of actions and all about home-made compressors Air compressor from the refrigerator

A small-sized compressor is a very necessary thing for a garage or personal workshop. It is used to solve many problems.

For painting with a spray gun and applying a layer of glue on large surfaces, for art work with an airbrush, for blowing dust from a workplace or simply for inflating tires ...

At the same time, the need for this unit for many is not one-time, but episodic. Therefore, if you, for example, are not an airbrush artist, buying an industrial compress is simply unprofitable.

However, having certain master skills, it is easy to make such a device yourself. In this article we will tell you how to make a master compressor from a refrigerator.

There are many examples of such artifacts. technical creativity. It is enough to type the appropriate request and look at the photos on the Internet. To build a compressor from a refrigerator with your own hands, you must first understand what all these designs have in common.

What are the design elements and why do they contain? Of course, the question of whether or not you possess the necessary artisan skills is not even discussed here. Of course you have!

All these structural elements can be very conditionally divided into basic and additional. "Conditionally" - because it all depends on the purposes for which you will use the compressor.

If it's just to inflate the tires of a car, then practically only one compressor is enough. Although in this case it must be fixed on some basis.

Perhaps it is better to install this base on wheels in order to more conveniently move the compressor around the garage. It will need to be equipped with inlet and outlet pipes, air filters on them.

You need to put a manometer at the outlet and think over secure fastening air hose.

Important! But if you work with an airbrush, then the most important thing for you is the stability of the air flow. Therefore, you will inevitably have to install a receiver in the system.

The receiver is, roughly speaking, a cylinder into which air is supplied from the compressor. And already from this cylinder it is consumed as needed.

Here you already need to clearly understand what air pressure you are going to work with. The working pressure of the compressor of a typical refrigerator is 15-20 atmospheres. Although it’s better to clarify according to the documents for the unit ... 3 atmospheres are enough to inflate tires.

Interesting! To solve most other problems, 6-8 atmospheres are enough.

Unless you are going to work with some particularly powerful pneumatic tool. But in this case, for example, for a jackhammer, even 20 atmospheres may not be enough.

That is, when installing a receiver in the system, you need to think about two things:

- What pressure rating is it designed for? Of course, the maximum pressure must be higher than the working one! For example, a receiver from a cylinder of a carbon dioxide fire extinguisher was initially designed for the highest operating pressure at 15 MPa or 148.04 atmospheres. For a powder fire extinguisher cylinder, for example OP-8, this will be 15.79 atmospheres. At the same pressure, a receiver from a cylinder for domestic liquefied gas can also work. And the receiver from the KAMAZ brake system operates at 16 atmospheres. These are proven options. More difficult with homemade or theoretically not designed to work with high blood pressure containers.

- How will the receiver be protected from excess pressure in it? There are two options here. The first is the release of excess pressure into the surrounding atmosphere using a bypass valve. Second, this automatic shutdown compressor.

These are all the main points that you need to think about when thinking about how to make a compressor.

In order not to "everything like clockwork" ...

The main difference between a refrigerator compressor and industrial compressors is that it was originally designed to work in a closed system. Therefore, he is literally bathed in oil!

Oil is mixed with freon, freon with oil, then separated, then mixed again ... That is, the lubrication system in the refrigerator compressor is in no way isolated from the flow of the main reagent that this compressor pumps!

Therefore, when you start pumping air with this compressor, oil will inevitably splash out of the outlet pipe. The first thing to do is to make this pipe in the shape of an inverted letter "G".

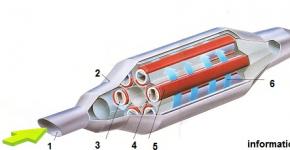

At the top, in front of the second L-shaped bend, behind which the receiver is located, an oil filter is installed.

In it, just below the middle, a conical plate directed upwards is installed. Gaps are left between the plate and the chamber walls. The air flow from the compressor, entering the chamber from below, is decelerated on the conical plate and the oil drops that it carries with it roll back down.

Important! Although it must be understood that the microparticles of oil and moisture in this air flow still remain. Therefore, first of all, do not even think about “filling” air into scuba cylinders with this compressor!

And secondly, the receiver will be gradually filled at the bottom with oil-water condensate. In order not to unwind the entire system each time to clean it, it is better to provide a drain hole in the bottom of your supposedly fire extinguisher.

Next is a matter of fantasy

Anyone who has ever ridden "for power" on a moped or motorcycle without an air filter knows what deep scratches this seemingly "clean air" leaves on piston skirts and cylinder walls.

Therefore, when thinking about how to make a compressor with your own hands, you must inevitably think about the air filter at the inlet. It is enough to make an inlet pipe for the inner diameter of the car air filter.

It must be done in the form of the same inverted letter "L" to avoid splashing oil out. Of course, it is also necessary to make a seal in order to exclude air leakage from below. Surely there is something suitable for this in the corner of your garage?

It must be done in the form of the same inverted letter "L" to avoid splashing oil out. Of course, it is also necessary to make a seal in order to exclude air leakage from below. Surely there is something suitable for this in the corner of your garage?

... So, let's trace the path of air through the compressor we are creating. Through air filter from the car and the inlet pipe, air enters the “pump”.

Coming out through another pipe already under pressure, the air gets rid of oil dust in the oil separator and oil filter. The air then enters the receiver.

It should be noted that the air must pass through the receiver in order to dampen pressure surges. Therefore, if you simply screw a tee into the neck of your fire extinguisher - into the inlet, outlet and pressure gauge - this will not give any result.

Ideally, this scheme looks like this. Air enters almost to the bottom of your fire extinguisher through one of the two, longer tubes - and exits through the second, shorter one. Between the inlet and outlet is a third, which has a pressure gauge screwed into it to show the air pressure in your fire extinguisher.

In parallel with the pressure gauge, a bypass valve or relay is included in the circuit. There are also pressure gauges that combine the relay option. Further, from the outlet pipe of the receiver, air enters a hose that can withstand a pressure of 6 - 8 atmospheres for use.

With a frequent change of the tool connected to the compressor, it is reasonable to install a special pneumatic lock-connector at the end of the hose. It allows you to connect and disconnect the tool with one simple movement of your fingers.

Interesting! If you work every time with only one thing, then you can get by with an ordinary ball valve in front of the hose. In the same way - convenient, useful, but not included in the "required package" - the second pressure gauge showing the pressure in the hose.

As already mentioned, this is the required level of configuration. These are the tasks that must be solved if you decide to build a compressor for your workshop yourself. Further - it is only a matter of the master's imagination.

You can, for example, install a cooler for cooling. It's no secret that air heats up when compressed. You can, instead of an air car filter at the inlet, put a water one, according to the principle of a hookah.

You can install two in series - instead of one receiver. Or make a salt filter, dehumidify the outgoing air ... For each purpose - its own means.

Often, an old unused refrigerator has a fully functional compressor. It can be slightly upgraded to get a complete installation suitable for use in various purposes - most often they are used for painting, pumping car tires, performing airbrushing or powering pneumatic devices. Consider how to make a compressor with your own hands from an old refrigerator.

Parts and tools needed to make a compressor

To make a compressor from the refrigerator with your own hands, you will need the following tools:

- Welding machine (inverter).

- Electric drill, screwdriver.

- Drill, engraving mini-drill with a set of cutters.

- Brush with metal bristles to remove rust.

- Pliers, set wrenches, wrench.

From materials it is necessary to prepare:

- Steel plates 2–3 mm thick, 3–4 cm wide.

- Two bases on wheels.

- Adapter for 1/4 inch.

- Blind half-inch socket with female thread.

- Check valve and connector for it.

- Two copper half-inch connectors for copper tube.

- Clamping bolts, nuts, other fasteners, fum-tape.

In the course of work, it may be necessary to use other tools or materials. So, instead of a propane tank, a case from a fire extinguisher or a ready-made car receiver can be used. Some craftsmen suggest installing plastic containers, which should be refrained from, since compressors from refrigerators can create high pressure capable of breaking such a receiver.

The process of manufacturing a compressor from a refrigerator

The technology for manufacturing a homemade compressor from a refrigerator consists of several stages.

Receiver

To make a compressor out of a refrigerator, you need a high-quality receiver. For this, a metal container with a sealed outlet is used - empty gas bottle for 11 liters. First of all, it is necessary to get rid of the remnants of the gas mixture in the cylinder, for which it is thoroughly washed from the inside with water. Then a 1/4 inch adapter is applied to the hole in the end and butt welded with maximum tightness of the seam. The finished adapter should be plugged with a bolt.

In the lower part of the cylinder, supports with wheels are welded. For stability, a support is welded in the upper part, providing a horizontal line. The result is a cylinder supported on three points (two wheels and a support bracket), equipped with an outlet fitting.

Compressor installation

The next step is to install the compressor on the receiver. To do this, you will need to weld two mounting brackets on top of a horizontally located cylinder. The distance between them corresponds to the position of the mounting holes on the compressor, which will be fixed on the brackets by the clamping bolts. To ensure silent operation, which is distinguished by home-made compressor units made from old refrigerators, rubber gaskets should be installed between the device body and the brackets.

Important! Before installing the compressor, it is necessary to replace the oil inside it with another one that is neutral to the action of air (Lukoil 10 W-40 is suitable). The oil is changed through a soldered outlet, which should then be sealed again. To prevent oil from entering the air, it is necessary to install a filter at the outlet of the compressor.

Check valve and adapter for equipment

Installation of check valves - scheme

The next step in the manufacture of a homemade compressor is the installation of a check valve and an adapter for connecting control equipment. To do this, you need to drill the appropriate holes in the receiver housing - under check valve it is more convenient to place it on the side, and under the equipment - from above, close to the compressor.

A coupling with an internal thread, the same as that of the check valve, is welded into the receiver body. It is necessary to plug the pressure relief hole on it, since a similar device is available in the control equipment unit taken from an old refrigerator.

The hole is plugged with a screw, under which the thread is pre-cut. The screw is wrapped with fum tape and screwed tightly into the hole. The check valve is then connected to the compressor outlet using a ½-inch copper coupler. The ends of the tubes with pre-inserted parts of the coupling are flared, after which the coupling is tightly connected.

Installation of control equipment

It is best to use the control equipment that was installed on the refrigerator complete with a compressor. They are optimally suited to each other. The control assembly usually includes a pressure switch, pressure relief valves, pressure gauges and several regulators.

First, a pressure switch is installed. This is a black box with a pressure gauge, it is connected through an extension cord with external thread to the outlet at the top of the cylinder next to the compressor. Then all other parts of the assembly are attached to the relay.

Control equipment on the compressor

Electrical connection

The compressor power wires from the refrigerator are connected to the corresponding contacts of the pressure switch. To do this, remove the cover from the relay, after which the contacts will become visible. The three-core compressor wire (with grounding) is connected to the appropriate contacts (they are marked with a special marking), in a similar way the power wire is connected, equipped with a plug for a power outlet. The strength of the connection of the contacts is checked, the relay cover is installed in place.

Checking the operation of a homemade compressor

After connecting all the parts and connecting the power wires, a test run and setting the operating mode are performed. The compressor is connected to the network, using the adjusting assembly, the device is turned on / off when a certain pressure is reached.

It is not recommended to immediately set high values, since a leak in the welded joint on one of the fittings may be detected. Found flaws are subject to elimination, for which the device is disconnected from the network, the pressure accumulated during the test run is reset, and the identified shortcomings are eliminated. After that, the device is reconnected to the network and put into operation.

Recently, compressors have gained popularity among tinkerers. They are made on the basis of almost any engine, calculating the power of the base unit depending on the number of consumers. For home workshops, do-it-yourself self-made compressor units are in demand.

Compressors from refrigerators often remain operational after the breakdown or obsolescence of the refrigerator itself. They are weak, but unpretentious in work. And many masters make quite worthy home-made installations from them. Let's see how we can do it ourselves.

Details and materials

Required details:- 11 kg propane tank;

- 1/2" Female Coupling with Plug;

- Metal plates, width - 3-4 cm, thickness - 2-4 mm;

- Two wheels with mounting platform;

- Refrigeration compressor from the refrigerator;

- 1/4" adapter;

- Brass check valve connector;

- ¼ inch copper pipe connector - 2 pcs;

- Compressor pressure control equipment;

- Bolts, screws, nuts, fumlenta.

- welding inverter;

- Screwdriver or drill;

- Milling cutters for metal with titanium coating;

- Turbine or drill with abrasive nozzles;

- Metal brush;

- Roller for copper tubes;

- Adjustable wrenches, pliers.

Assembling the compressor

Step one - prepare the receiver

Rinse an empty propane tank thoroughly with water. It is very important to remove all residues of the explosive gas mixture in this way.

In the end hole of the cylinder, we overlap the adapter by 1/4 inch. We scald it from all sides by welding, and muffle it with a screw.

We put the receiver on wheels and support. To do this, we take pieces of metal plates, bend them at an angle and weld them onto the body from the bottom side. We weld wheels with a mounting platform to the corners. In front of the receiver we mount the support bracket.

Step two - mount the compressor

On top of the receiver, we expose the mounting frames for the compressor from metal plates. Checking their position bubble level, and boil. We sit the compressor on the clamping bolts through rubber shock-absorbing pads. For this type of compressor, only one outlet will be involved, through which air is forced into the receiver. The other two, sucking in air, will remain intact.

Step three - we fix the check valve and the adapter to the equipment

We select a cutter for metal that is suitable for the diameter, and make a hole in the housing for the coupling with a screwdriver or drill. If there are protruding forms on the coupling body, we grind them with a drill (you can use a regular electric emery or a grinder with a grinding disk for this).

We expose the coupling into the hole and scald it around the circumference. Internal thread it must correspond in pitch and diameter to the seat thread on the check valve.

We use a brass check valve for small compressors. We plug the pressure relief outlet with a suitable bolt, since a bleed valve is already provided on the adjusting assembly.

To install a pressure switch or pressure switch with all the control equipment, we mount another 1/4 inch adapter. We make a hole for it in the center of the receiver, not far from the compressor.

We twist the check valve with an adapter 1/2 inch.

We connect the outlet of the compressor cylinder and the check valve with a copper tube. For this special tool we flare the ends of the copper tubes, and connect them with brass threaded adapters. Tightening the connection wrenches.

Step four - install the control equipment

The control equipment assembly consists of a pressure switch (pressure switch) with a control sensor, safety valve or a pressure relief valve, an adapter-coupling with an external thread and several taps and pressure gauges.

First of all, we mount the pressure switch. It must be slightly raised to the level of the compressor. We use an extension-coupling with an external thread, and we twist the relay through the sealing tape.

Through the adapter, we install a pressure control sensor with pressure gauges. We complete the assembly with a pressure relief valve and two taps for the hose outlets.

Step five - connect the electrician

We disassemble the pressure switch housing with a screwdriver, opening access to the contacts. We bring a 3-core cable to contact group, and distribute each of the wires according to the connection diagram (including grounding).

Similarly, we make the supply cable, equipped with a plug for a power outlet. Screw the relay cover back into place.

Step Six - Refinement and Trial Run

To carry the compressor unit, we attach a special handle to the compressor frames. We make it from scraps of a profile square and round pipe. We fasten it to the clamping bolts and paint it in the color of the compressor.

We connect the installation to a 220 V network, and check its performance. According to the author, to obtain a pressure of 90 psi or 6 atm, this compressor needs 10 minutes. With the help of an adjusting sensor, the inclusion of the compressor after a pressure drop is also regulated from a certain indicator displayed on the pressure gauge. In my case, the author set up the installation so that the compressor turns on again from 60 psi or 4 atm.

The last step is to change the oil. This is an important part Maintenance such installations, because they do not provide a revision window. And without oil, such machines can work for a very short time.

We unscrew the drain bolt at the bottom of the compressor, and drain the waste into a bottle. Turning the compressor on its side, fill in a little clean oil, and screw the plug back on. Now everything is in order, you can use our compressor unit!

Almost all motorists who make something every day in their garage understand perfectly well that with tools and components in their hands, you can always create something you need.

In the same way, it is possible to create a whole compressor for painting a car from a conventional compressor for a Soviet-style refrigerator.

That's just how to do it in technical terms, and in what order?

Therefore, due to the frequently asked questions of beginner self-taught masters, in this article you will learn how to make such a compressor on your own and from manual materials.

Which compressor to choose (factory or homemade)

The main criterion that should be followed when choosing a station for painting is uniform distribution air without foreign particles.

If such impurities come across, then the coating will be with small defects - graininess, shagreen, cavities. At the same time, streaks and stains can form due to these particles, so it is best to entrust the painting to a branded air compressor, but there is only one catch - such a device is too expensive, which many motorists cannot afford.

Save money and at the same time create functional model You can by creating functional equipment, which is described in many videos and articles.

You will only have to spend your precious time studying the material, and then creating equipment that must be of at least high quality.

The model presented by the factory or homemade does not play a role, because the principle of its operation is the same and it consists in creating excessive pressure. That's just the method of air injection is completely different - it can be extracted manually or mechanically.

In the second case, this is a significantly higher cost of funds, manual way economical, but time-consuming, requiring constant monitoring.

Automatic inflation does not consume your strength, but the product requires periodic maintenance, which is worth only the process of changing the oil for the compressor.

This is the only way to achieve uniform air supply and distribution. After studying the theory, you realize how easy it is to make a compressor station that will work well, while it does not take much time.

Collecting compressor unit from improvised means -

If you decide to create equipment for painting your own car, then you should stock up on certain materials for this:

- The reverse function will require a car camera;

- For the supercharger function, you will need a pump with a pressure gauge;

- chamber nipple;

- Repair kit and awl.

When all the components are prepared, you can begin to create a compressor station. To check how tight the chamber is, it is necessary to pump it.

If the problem still exists, then it can be solved in two ways - by gluing or by vulcanizing with raw rubber. In the resulting reverse, it is necessary to make a hole for supplying compressed air so that it comes out evenly.

A special nipple is placed in the hole for this. The repair kit will serve for the implementation of additional fasteners of the fitting. To check the uniformity of the air supply, it is enough to unscrew the nipple. Native nipple allows you to get rid of excessive pressure.

The level of pressure is determined during operation, when the paint is sprayed. If the enamel on the metal lies evenly, then the installation is functioning. At the end of the procedure, it is worth determining the pressure indicators, for this it is enough to spray paint on the body of your car.

If the enamel lies without tubercles, then the device is functioning efficiently. In addition, pressure indicators can be monitored using a special device - a pressure gauge. But, its indicator after pressing the aerator should not be chaotic.

As you can see, special tools and knowledge are not required to create such a compressor. At the same time, repairing and painting a car in this way is more effective than using a spray can.

Remember that neither dust nor water should get into the car chamber. Otherwise, you will have to re-paint the car.

If this installation is used correctly and with the use of all knowledge, then it will last a long time, and if you also automate the pumping of air, then the process itself will go quickly.

Alternative to a professional device (compressor from the refrigerator)

Home-made compressor devices serve much longer than the presented time, even in comparison with installations of domestic and foreign production.

This is quite natural, because creating it with our own hands, we do everything for ourselves on highest level. Therefore, people even thought about how to create a compressor from a refrigerator, which will be on a par with the installations of popular companies.

But to create it, you should stock up on such components as a pressure gauge, a relay, rubber adapters, an oil and moisture separator, a fuel filter, a gearbox, a motor, a switch, a hose, clamps, brass tubes, but also little things - nuts, paint, furniture wheels.

Creating the mechanism itself

Buying a compressor from an old refrigerator from the Soviet era can simplify the whole procedure. This will not pull too much on the budget, while there is already a compressor start relay.

Foreign competitors are inferior to this model, because they are not able to develop such a high pressure. But the Soviets cope with this task.

After removing the execution unit, it is advisable to clean the compressor from layers of rust. To avoid the oxidation process in the future, it is worth using a rust converter.

It turns out that the working motor housing is ready for the painting process.

Installation scheme

The preparatory process is completed, now you can change the oil. Since the refrigerator is old and it is unlikely that it underwent constant maintenance, it is worth updating this moment.

Since the system was always far from external influence, no maintenance work has justifiably been carried out there. For this procedure, expensive oil is not required, semi-synthetic is enough.

At the same time, it is not worse in terms of the presented characteristics of any compressor oil and has many additives used with benefit.

Inspecting the compressor, you will find 3 tubes, one of them is already soldered, but the rest are free. Open are used for air inlet and outlet. To understand how air will circulate, it is worth connecting the power to the compressor.

Write down for yourself which of the holes draws in air and which releases it. But the sealed tube must be opened, it will serve as an opening for changing the oil.

The file is necessary for the implementation of the tube file, while making sure that the chips do not get inside the compressor. To determine how much oil is already there, drain it into a container. With the subsequent replacement, you will already know how much it will have to be poured.

Then we take a spitz and fill it with semi-synthetics, but this time expect that the volume should be twice as much as it has already been drained. When the container is filled with oil, it is worth turning off the engine lubrication system; for this, a screw is used, which is pre-formed with a fum tape and placed simply in the tube.

Do not be alarmed if drops of oil periodically appear from the outlet air tube. This situation is not so difficult to resolve, find an oil and moisture separator to homemade installation.

The preliminary work is over, only now you can proceed to the direct assembly of the installation. And they begin with strengthening the engine, it is best to choose wooden base for this and in such a position that it was on the frame.

It is worth noting that this part is very sensitive to position, so follow the instructions on the top cover, where the arrow is drawn. Accuracy is important in this matter, because the correctness of the mode change directly depends on the correct installation.

Where is compressed air located?

A cylinder capable of withstanding high pressure is a container from a fire extinguisher. At the same time, they have high strength indicators and can be used as attachments.

If we take as a basis the OU-10 fire extinguisher, which holds 10 liters, then we should count on a pressure of 15 MPa. We unscrew the locking and starting device, instead of which we install an adapter. If you have identified traces of rust, then these places should be treated without fail with a rust converter.

Externally, it is not difficult to remove it, but it is more difficult to clean it internally. But the easiest way is to pour the converter itself into the cylinder and shake it well so that all the walls are saturated with it.

When the cleaning is done, the plumbing cross is screwed in and we can assume that we have already prepared two working parts homemade design compressor.

Carrying out the installation of parts

Previously, it was already stipulated that for fixing the engine and the fire extinguisher housing, wooden plank, it is also even easier to store working parts.

In terms of mounting the engine, threaded studs and washers will serve, just think in advance about making holes. Plywood is required to fix the receiver vertically.

A recess is made in it for a cylinder, the second and third are fixed to the main board using self-tapping screws and hold the receiver. To give the design maneuverability, you should screw the wheels from the furniture to the base.

To prevent dust from entering the system, its protection should be considered - the use of a coarse gasoline filter can be considered an excellent option. With its help, the function of an air intake will be easily performed.

Since the pressure indicators are low at the opening with the inlet of the compressor equipment, it will not be necessary to increase it.

After creating an inlet filter for the installation work on the compressor, do not forget to install an oil / moisture separator at the end to avoid water droplets in the future. Since the outlet pressure is high, you will need car clamps.

The oil-moisture separator is connected to the inlet of the reducer and the pressure outlet of the supercharger. To control the balloon pressure, the pressure gauge itself should also be screwed in on the right side, where the outlet is located on the opposite side.

To control pressure and power at 220v, a relay is installed for adjustment. As an actuator, many masters recommend using PM5 (RDM5).

This device responds to work, if the pressure drops, then the compressor turns on, if it rises, then the device is pumped out completely.

To set the proper pressure, the springs on the relay are used. The large spring is responsible for the minimum indicator, but the small one for the maximum, thereby setting the framework for the operation and shutdown of the self-made compressor installation.

In fact, PM5 are ordinary two-pin switches. One contact will be needed to connect to the zero of the 220 V network, and the second to combine with the supercharger.

A toggler is needed to disconnect from the network from it and save yourself from constant running around in the direction of the outlet. All connected wires must be insulated for safety reasons. When these works are carried out, you can paint over the installation and check it.

Pressure regulation

When the design is assembled, it is quite natural to check it. We connect the last components - an airbrush or an air gun and connect the installation to the network.

We check the operation of the relay, how well it will cope with turning off the engine, and monitor the pressure with a pressure gauge. If everything works properly, proceed to the leak test.

The easiest way to do this is to use soapy water. When the tightness is checked, we bleed the air from the chamber. The compressor starts when the pressure drops below the minimum limit. Only after checking all the systems and bringing them into working condition, you can proceed to the procedure for painting parts.

For painting, you only need to determine the pressure and not load yourself with pre-treatment of the metal. To carry out painting with a uniform layer, it is necessary to experiment and determine atmospheric indicators in this way.

It is important to use the supercharger as little as possible. Each motorist will deal with the components and begin to manufacture an automobile compressor.

Can choose different variants production, but the use of starting the navigator, automatic pressure control is more complex structure, but its use is one and pure pleasure.

You don't have to take the time to control the receiver, which opens up more possibilities, and you can start painting the car, the fence or even the gate.

Routine maintenance is a mandatory procedure in order to extend the life of your homemade compressor.

To change the oil - drain or fill it, you can use a regular syringe. Replacement of filters is carried out only if necessary, when the speed of filling the reservoir chamber is reduced.

Connecting components of the compressor

When it is decided which compressor to choose and reverse, it is worth considering the issue of combining them. At the same moment, it is worth determining how the air will flow to the airbrush. The unit that is mounted to the receiver is responsible for the distribution of air.

The main thing is that these components are compatible with each other. The pressure switch is responsible for turning the compressor off and on. RDM-5, although it is used for water supply systems, but this perfect option for our case - for the relay.

The bottom line is that the connection element fits the external inch thread. To find out what pressure is in the receiver, you must use a pressure gauge and first consider the size that is suitable for the connection. We apply pressure to the air preparation unit and adjust it within 10 atmospheres, at this stage it is necessary to attach the oil separator filter.

The pressure gauge allows you to check the pressure, and the filter allows you to prevent the ingress of oil particles from the receiver. Elbows, tees and even fittings are the next components that will have to be prepared for installation. To understand the exact number, you need to think over the scheme, choose an inch as the size.

After resolving the issue with adapters, it is important to consider the moment of installation of the structure, most often they use chipboard. The design of your station should be maneuverable, because it will have to be moved around the workshop, in order to simplify your work, you should attach roller legs to it.

You won't have to invent here for a long time, just visit the furniture store, where there are a lot of such furniture wheels. To save space in your workshop, you can build two-story structure. But here it is better to stock up on large bolts to fix the structure. To make it easier to prepare for this step, make a list of required items.

Assembling a semi-professional air blower

The assembly begins with the removal of the fire extinguisher twist and the installation of the transition device. After removing the fire extinguisher valve, install the adapter there.

Four components are immediately installed on a durable hose - a reducer, a pressure switch and an adapter.

The next step will be fixing the wheels to be installed on a chipboard sheet. Since the design is planned on two levels, it is necessary to make holes for the studs where the fire extinguisher will be placed.

The accumulator is easier to assemble, because there are brackets on both sides. Bottom part fixed to the base, and for installation homemade equipment serves as the top.

To reduce vibration when installing the compressor, silicone gaskets are used. The hose connects the outlet and the inlet of the air preparation.

The next step will be the connection work. Jumper, protective elements - all this needs to be thought out.

The entire connection chain is carried out through the relay and the switch, assuming that the entire connection goes according to the scheme: the phase wire goes to the switch, the next connection is the relay terminal. To carry out grounding on the relay, a special wire is wound up.

Which is better: buy or make a compressor yourself?

Compressor equipment on the market is represented by a large assortment. Piston components, vibration units, screw stations - all these are components that are used in other areas.

If you wish, you can not waste your time creating the installation, it is presented at any point of sale of auto parts or on specialized sites.

Such an extensive range greatly complicates the choice of the desired product. But if you decide to purchase a station, in this matter you should be guided by technical indicators, cost and reviews of those who have already managed to evaluate it.

If you are chasing warranty periods, then you should pay attention to the models of popular brands. Expensive products should be purchased if you are professionally engaged in repair work.

Products that do not have a name and status can let you down, so it’s better to spend money once and not take risks in this matter again. Many manufacturers budget options save on components.

As a result, you will encounter frequent breakdowns and replacement of parts, while warranty repairs will take a long time. Therefore, many motorists are well aware that a do-it-yourself installation is sometimes more reliable than a factory one.

Such products with technical indicators win. For example, the components homemade device for painting a car it lasts much longer - compressors from refrigerators can work for decades, a fire extinguisher also has a colossal margin of safety.

You can always improve the performance of your compressor yourself, everything is in your hands, but you can’t experiment like that with a factory device.

Garage neighbors will probably get it when they see a well-made and well-thought-out device.

When working indoors, a conventional compressor makes a lot of noise. Of course, you can spend money and buy a quiet model, but it will cost you 3-4 times more than a regular one, while it is unlikely to give you the same pressure. How to make a compressor from a refrigerator motor to a garage with your own hands?

For homemade models it's not a problem at all. By taking a compressor from an old refrigerator or cooler and having basic soldering skills, you can assemble almost silent compressor, giving almost 8 atmospheres without the threat of exploding. Of course, it works slower than conventional mechanical ones, but not by much. This builds pressure in 4 minutes.

You can make a basic model in about an hour, it can be supplemented and improved as you like. All these refinements and improvements will improve the product, but do not affect performance. Such a homemade compressor has almost no vibration and it makes noise like a refrigerator.

Step 1: Tools and equipment

Equipment:

- Flat casing compressor with pressure switch

- Compressor from an old refrigerator or cooler (any one will do)

- Copper tube 6mm

- Adapters

- Various cable connectors

- Plastic clamps

Note: when you remove the compressor from the refrigerator or cooler, seek the help of a specialist. You can’t just take and cut the hoses, this will cause great harm environment, and inhalation of the resulting gases is very dangerous.

The best option is to find a unit sent for recycling, usually coolers stop working properly due to a refrigerant leak, and they are simply written off. Compressors usually remain fully operational. In any case, you need to remove it from the equipment in a well-ventilated area.

Tools:

- Soldering torch with solder and flux

- Teflon Tape

- adjustable wrench

- electric motor

- Stripping pliers and wire cutters

Step 2: Power and protection connections, tubing

Electrician

On one side of the device are the connections for power and protection against overheating, they are shown in the second photo. Mark yourself somewhere the connection order, so that later you can correctly connect the wires to the device you are assembling. Each has built-in overheating protection. The compressor in refrigerators has one drawback: if you first turn it off and then turn it on again, the overheating protection will work. If this happens, do not worry, but try turning it on again after a few minutes. This protection also protects the compressor from voltage peaks (it will work if you connect the power incorrectly).

tubes

There are usually three 6mm tubes, one on one side and two on the other. To understand which tube is intended for what, the easiest way is to plug the compressor into the network and bring your palm to the ends of the tubes. On most appliances, a separate tube takes air, and the pressure relief tube is the lower of the two on the opposite side of the compressor. The third tube is not responsible for anything, it is usually used only for factory testing, and it is better to solder or bend it.

Step 3: Decide on the optimal type

The choice of compressor that you will use in your project is extremely important. I put together some silent models for friends and found out that the best option There will be a flat case compressor. Larger models have an automatic pressure switch, with a built-in pressure relief valve that releases pressure into the cylinder.

Unfortunately, for the relay to work, you need high pressure, which the compressor from the refrigerator simply will not gain. The valve will constantly release pressure, so the balloon will fill more slowly. If you turn off the relay, you will deprive your device of the ability to turn off when the cylinder is full. This is quite dangerous, and you will constantly have to control the level of pressure in the tank.

I think all this will convince you that the pressure switch is a very convenient and useful thing.

Step 4: Install

Installing the compressor on the cylinder

For simplicity and cheapness, I simply fastened the compressor to the cylinder with plastic clamps. Since there will be no vibration during operation of the device, you can not worry that the fasteners will loosen. For aesthetics, you can make a bracket.

We solder the tube

It may happen that you have to solder a new tube, but much more often you can use the tube that was used with the compressor in the cooler or refrigerator. The photo shows the tube used in air compressor, its inner diameter is 6 mm. The external diameter of the tube from the compressor is also 6 mm, so for the connections it was only necessary to sand its surface a little. Then you just need to solder the tubes - apply a little flux to the junction, heat the junction soldering torch, let the solder fill the gap - the tubes are soldered.

It is possible that the tube will need to be bent to get to the air intake, I usually use a flexible shaft from a trimmer for this. Thread it into the tube, bend it as you need it, and pull it out of the tube. This is very good way avoid kinks that will interfere with airflow.

We eliminate leaks

It is extremely important that you do not have leaks. To eliminate them, you will need Teflon tape. Due to the fact that refrigeration compressors produce a small volume of air, even the smallest leak will affect the rate of filling the cylinder. Therefore, I advise you to simply seal all the joints with tape.

Step 5: Connect Power and Pressure Switch

I am attaching a simple understandable scheme connections.

Step 6: Finished fixture

Now you know how to make a compressor from a refrigerator engine. Since we have not changed anything else in the design, you can connect to it as to a conventional device.