The structure of the molecules of surfactants. Surfactants (surfactants)

Figure 1: Surface active substances: action diagram

Sodium and potassium salts higher fatty acids (soaps) are surfactants capable of forming persistent soap films. Surfactants (surfactants) can be located in a certain way at the interface of two phases, for example, such as water-air or water-oil ... This behavior of surfactants is explained by the peculiarity of their structure: the surfactant molecule, for example, soap, includes both a polar hydrophilic group capable of ionizing and a non-polar hydrophobic part - a hydrocarbon one. At the interface, the hydrophilic group is oriented toward water, and a hydrocarbon radical toward the oil phase or air.

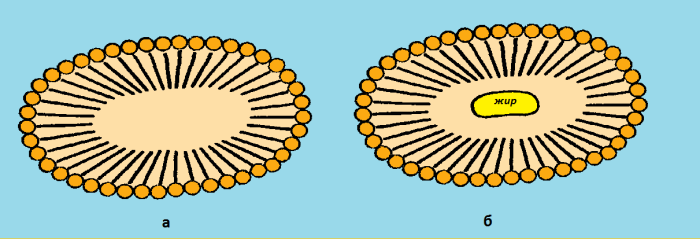

Figure 2: Micelles of Soaps

V aquatic environment at a certain concentration, surfactant molecules no longer exist in the form of isolated particles, but as large aggregates - micelles, in which all hydrocarbon groups are located in the center of the micelle, and hydrophilic groups - outside (Fig. 2a). A micelle is able to "capture" particles of water-insoluble substances and create persistent ones, since the adhesion of micelles is prevented by the same charge on their surfaces (Fig. 2b). This principle is the basis for the washing effect of soaps. Contamination is a grease film with dust particles. Soaps emulsify impurities, after which the emulsion is easily washed off with water.

Synthetic surfactants and detergents

The production of soap requires a large amount of fat - a valuable food and technical product. Meanwhile, other organic compounds, which have a similar structure to soaps, also have surface activity.

These include:

- anionic surfactants(for example, sodium salts of alkyl sulfates, alkyl sulfonates);

- cationic surfactants(e.g. quaternary alkylammonium salts)

Figure 3: Synthetic Surfactant Formulas

Anionic and cationic surfactants necessarily contain a long alkyl radical in the molecule (C 12 - C 14)

Synthetic surfactants are produced in industry from available hydrocarbon raw materials, mainly oil, so they are inexpensive. Another virtue detergents based on synthetic surfactants lies in the possibility of their use in hard water, in which ordinary soaps give insoluble calcium and magnesium salts, which reduces the effectiveness of the washing action and increases the consumption of soap.

Twins

Figure 4: General Twin Formula

V recent times surfactants are widely used in industry (for example, in textiles) twins... In pharmacy, they serve as a synthetic emulsifying base in the manufacture of ointments.

Twins built by general principle, like other surfactants, that is, their molecules have non-polar and polar parts. The molecule is based on a cyclic tetrahydric alcohol sorbitan, in which one to three hydroxyl groups are esterified with higher fatty acids. The radicals of these acids make up the non-polar part of the molecule.

The remaining hydroxyl groups form an ether bond with the residues of polyethylene glycol - (CH 2 CH 2 O) n CH 2 CH 2 OH, where n = 40-80... Fragments of polyethylene glycol represent the polar part of the tweens.

Bibliography: Organic chemistry, A.P. Luzin, S.E. Zurabyan, N.A. Tyukavkina, 1998

Surfactants (Surfactants)

Surfactants (Surfactants)

- organic compounds, the molecules of which have a polar hydrophilic part in the structure (functional groups –OH, –COOH, –O, etc.) and a hydrocarbon hydrophobic part. Thus, they are soluble in organic solvents and water.

Micelle

The main quantitative characteristic of surfactants is the ability of a substance to reduce surface tension at the interface. But the surfactant has a solubility limit ("critical micelle concentration" or CMC), upon reaching which, when the surfactant is added to the solution, the concentration at the interface remains constant, but at the same time self-organization of surfactant molecules in the bulk solution (or aggregation) occurs. As a result of this aggregation, micelles are formed. Hallmark micelle formation is the turbidity of the surfactant solution. Aqueous solutions of surfactants, during micelle formation, also acquire a bluish tint (gelatinous hue) due to the refraction of light by micelles.

Among anionic surfactants, alkylarylsulfonates are the most common. Primary dodecyl sulfate and straight-chain dodecylbenzenesulfonate have optimal surfactant properties. These substances are thermally stable, low toxic (LD 50 1.5-2 g / kg, white mice), do not irritate human skin and are satisfactorily biodegradable in water bodies, with the exception of branched alkyl arylsulfonates. They combine well with other surfactants, showing synergism, their powders are non-hygroscopic. Secondary alkyl sulfates have good foaming properties, but are thermally unstable and are used in liquid form. Secondary alkyl sulfonates have high surface activity, but are very hygroscopic. Surfactants in which the hydrophilic part consists of several functional groups are promising. For example, disodium salts of sulfosuccinic acid have good sanitary and hygienic properties along with high colloidal-chemical and technological indicators when dissolved in hard water. Surfactants containing a sulfonylamide group have biological activity. Good properties also possesses dodecyl phosphate.

In the production of ISK, in addition to binders, fillers and fillers, additives in mixtures, called additives, are widely used.

In stages technological production they:

- facilitate the performance of operations;

Reduces the amount of energy expended;

Reduces the consumption of expensive components;

Reduce material consumption;

Contribute to ensuring the required indicators of material properties;

They favor the acceleration or deceleration of the processes of structure formation and hardening.

At the stage of operation of structures, additives introduced earlier by ISK are designed to:

Strengthen, stabilize the structure of the material;

To inhibit as much as possible the inevitable destruction that occurs and develops in the material under the influence external environment and internal spontaneous phenomena.

The main functional purpose additives, and this is how they differ from aggregates and fillers, is that that they always actively interact with one or more components of the mixtures in the process of forming the structure of the binder or the macrostructure of the ISC. As a result of the reaction, new compounds arise that were not previously in the mixture, and the additives are either completely consumed or lose their individual characteristics. It is clear that with an excessive amount of additives can partially remain in the mixture and in the formed material without any changes, which is not desirable.

Surfactants (Surfactant ) call such chemical compounds, which are adsorbed on the interfaces between liquids and solids and affect their physicochemical or Chemical properties... Surfactants are, as a rule, compounds whose molecules consist of two main parts - a radical and a functional group.

Radical- is a group of atoms, which is unchanged during a number of chemical transformations and passes from the molecule of one compound to the molecule of another.

Radicals are formed, for example, by cleavage in hydrocarbon molecules organic compounds hydrogen atoms. So, if in any limiting (saturated) compound belonging to the class of paraffins such as C n H 2 n +2, a hydrogen atom is split off, then the remaining group of atoms C n H 2 n +1 is an aliphatic (fatty) radical

H - C - C - ... - C -, which is denoted by the letter R.

The place of split-off hydrogen in a molecule can be taken by another atom or a group of atoms with certain properties associated with a stationary displacement of electrons in atomic orbits, which determines the presence of a certain electric dipole and the dipole moment of the entire molecule. Such atoms or groups of atoms are called functional groups .

The most common functional groups in surfactants:

Hydroxyl: (- OH);

Carboxyl: (- COOH);

Amine (amino group): (- NH 2);

Nitro group: (- NO 2);

Sulfato group: (- SO 3 H).

According to the number of functional groups in the surfactant molecule, they can be mono-, double- and polybasic.

Compounds in which the aliphatic radical contains less than 10 carbon atoms, as a rule, do not have surface activity, i.e. the ability to adsorb and lower the surface tension of liquids or the surface energy of solids. When the radical contains more than 10 carbon atoms, they are usually surface-active and are called higher fatty surfactants ... The type of the functional polar group and the structure of the radical determine the solubility of surfactants in various solvents and the ability to dissociate into ions.

Surfactants in which functional groups carry a positive charge are active in an acidic medium and inactive in an alkaline medium, while surfactants with negatively charged functional groups, on the contrary, are active in an alkaline medium and inactive in an acidic medium.

CLASSIFICATION OF surfactants

In principle, all surfactants are divided into two large groups: inogenic compounds, which, when dissolved in water, dissociate into ions, and non-inogenic ones, which do not dissociate into ions.

Depending on which ions determine the surface activity of ionic substances - anions or cations, ionic substances are subdivided into anionic, cationic, ampholytic. Anionic surfactants are active in alkaline solutions, cationic - in acidic, ampholytic - in both.

Anionic substances in alkaline solutions, forming negatively charged surfactant ions (anions):

RCOONa ↔ RCOO - + Na +

Cationic substances upon dissociation in acidic solutions form positively charged surface-active ions (cations):

RNH 3 Cl ↔ RNH 3 + + Cl -

Anionic surfactants include: carboxylic acids (RCOOH) and their salts (RCOOMe), etc.

Cationic surfactants include amines, ammonium bases:

RNH 2; RNH 3 Cl.

Ampholytic surfactants contain two functional groups, one of which is acidic, the other is basic, for example, a carboxyl and amine group.

Depending on the environment, ampholytic compounds have anionic or cationic properties:

Alkaline environment, acidic environment;

RNH (CH 2) n COO - RNH (CH 2) n COOH↔RNH 2 (CH 2) n COOH;

Anionic properties Cationic properties.

Nonionic surfactants, dissolving in water, do not form ions.

The group of non-iogenic surfactants includes oxyethylation products of fatty acids, alcohols, and amines.

RCOO (C 2 H 4 O) n H; RCH 2 O (C 2 H 4 O) n · H; RC 6 H 5 O (C 2 H 4 O) n OH.

CLASSIFICATION OF SAS BY THE MECHANISM OF ACTION

Depending on the action of surfactants in dispersed systems, they are divided into 4 groups:

To the first group include low molecular weight, truly water-soluble surfactants, such as alcohols. They are weak wetting and defoaming agents.

To the second group include surfactant dispersants and emulsifiers. When adsorbed, they effectively lower the free surface energy of a liquid or solid and thereby facilitate the formation of new surfaces and dispersion. These substances also have some stabilizing effects.

As a result of oriented adsorption, surfactants of the second group hydrophobize solid surfaces and, conversely, hydrophilize hydrophobic surfaces. The effect of hydrophobization of these surfactants is especially pronounced, which is enhanced by a chemical bond - the fixation of polar groups of surfactants on the corresponding areas of the solid surface.

The surfactants of the second class include fatty acids, their water-soluble salts, cationic organic bases and salts.

To the third group combined surfactants, which are good stabilizers. Their surface activity is comparatively low.

These surfactants are also good adsorptive plasticizers - they plasticize the structure, reducing their strength and structural viscosity. V cement slurries and in concretes, this allows the transition to rigid and at the same time homogeneous mixtures, promotes uniform mixing, increases density and durability (frost resistance), leads to an increase in strength and to a decrease in cement consumption.

Calcium lignosulfonates are used as plasticizers (sulfite-alcohol stillage - SSB and sulfite-yeast brew - SDB), etc.

The fourth group of surfactants- this is detergents with high surface activity, wetting and hydrophobic action. They are also effective emulsifiers and emulsion stabilizers. This group includes fatty acid and amine soaps.

In construction, surfactants of the second - fourth groups are mainly used.

Surfactants for cement concrete mixtures and cement concrete are divided into the following types:

1. Regulating properties of concrete mixes

1.1. Plasticizing groups 1-4 (super-, strong-, medium- and weakly plasticizing). Increase mobility concrete mix, slow down the setting of concrete and increase strength.

1.2. Stabilizing. They increase the homogeneity of concrete, reduce the permeability.

1.3. Water-retaining. They increase the mobility of the mixture, reduce the permeability and strength of concrete, and increase the homogeneity of the concrete.

1.4. Improving pumpability. They increase the homogeneity, reduce the water separation of the mixture and the strength of the concrete.

1.5. Setting retardants. They increase the mobility time of the mixture, slow down the setting by a factor of 2 or more at + 20 ° C. Increase in strength in the long term of hardening.

1.6. Accelerating setting. They accelerate the setting by 20% or more at 20 ° C. Acceleration of hardening.

1.7. Poisoning - for lightweight concrete.

1.8. Air-entraining. Improving workability and frost resistance, reducing delamination.

1.9. Foaming and gas-forming. Foaming additives provide technical foam. Gas-forming surfactants are able to release gas due to chemical interaction with the products of cement hydration.

2. Regulating concrete hardening

2.1. Accelerating hardening. Strength increase at the age of 1 day by 20% or more. Deceleration of curing at a later date.

2.2 Retarding hardening. Reduction of concrete strength by 30% or more at the age of up to 7 days.

3. Increasing strength and (or) corrosion resistance, frost resistance of concrete, reduction of concrete permeability

3.1. Water-reducing (1-4 groups). Reduction of water consumption (by 20-5%). Improving frost resistance and corrosion resistance.

3.2. Colmating. Increasing the grade of concrete in terms of water resistance and corrosion resistance.

3.3. Air-entraining and gas-generating. Increase frost resistance by 2 or more times, plasticization of the mixture.

3.4. Increasing the protective properties of concrete in relation to reinforcement (steel corrosion inhibitors). Increase in mix mobility and decrease in diffusion permeability of concrete.

4. Concrete imparting special properties

4.1. Antifreeze (providing hardening at low temperatures).

4.2. Water repellent (1-3 groups). Reducing water absorption by 1.5-5 times or more, slowing down the setting.

The introduction of surfactants into cement paste, mortar or concrete mixture significantly changes their structure and properties both in the plastic and hardened state. Different kinds The surfactants noted above change the properties of concrete mix or concrete in different ways due to their adsorption on the surface of clinker grains and neoplasms, as well as on the surface of stone materials.

The microstructure of the hydrated cement also changes as a result of the developing adsorptive modification. The surface of the crystals formed in the cement paste and stone is covered with an adsorption passivating film of surfactants, the growth of crystals slows down and a finer crystal structure is formed with a change in the very shape of the crystals.

Thus, using surfactants, it is possible to significantly expand the possibilities of producing asphalt and cement concrete mixtures. In this case, the main thing is the right choice materials and additives, as well as in their dosage.

You can buy surfactants (surfactants)we have. Call: (+38 044) 228-08-72.

Surfactants (surfactants)- chemical compounds, which, concentrating on the interface, cause a decrease in surface tension.

Due to the detergent, wetting, emulsifying, dispersing and other valuable properties of surfactants are widely used in the production of detergents and cleaning products, cosmetics and pharmaceuticals... Latexes. Rubber. Polymers. Chemicals protection of plants, textiles, leather and paper, building materials, corrosion inhibitors, during the extraction, transportation and processing of oil, etc. Most of the surfactants (estimated 55-60%) are used for the production of synthetic detergents (CMC).

Currently used synthetic surfactants (surfactants) are divided into 4 classes:

- anionic surfactants - compounds that dissociate in aqueous solutions with the formation of anions, causing surface activity... Among them, the most important are linear alkylbenzenesulfonate, sulfates and sulfoesters of fatty acids;

- amphoteric (ampholytic) surfactants - compounds that ionize in aqueous solutions and behave depending on the conditions (mainly from pH - the environment), i.e., in an acidic solution they exhibit the properties of cationic surfactants, and in an alkaline solution - anionic surfactants. Among the main amphoteric surfactants, it should be noted alkylbetaines, alkylaminocarboxylic acids, derivatives of alkyl imidazolines, alkylaminoalkanesulfonates.

- nonionic surfactants - compounds that dissolve in water without ionizing. The solubility of nonionic surfactants in water is due to the presence of functional groups in them. As a rule, they form nitrates in aqueous solution due to the occurrence of hydrogen bonds between water molecules and oxygen atoms of the polyethylene glycol part of the surfactant molecule. These include: polyglycol esters of fatty alcohols and acids, polyglycol esters of fatty acid amides, acylated or alkylated polyglycol esters of alkylamides.

- cationic surfactants - compounds that dissociate in an aqueous solution with the formation of cations that determine surface activity. Among cationic surfactants, the most important are quaternary ammonium compounds, imidazalines, and fatty amines.

The main raw materials for the large-tonnage production of surfactants are products of oil refining and petrochemical synthesis: low molecular weight and higher paraffins, olefins, synthetic fatty acids, higher fatty alcohols, alkyl derivatives of benzene and phenol, ethylene oxide, etc.

It is a well-known fact that the first surfactant - soap - has been "living" for almost 4000 years, but in the 50s it gave way to detergents and cleaning agents based on alkylbenzenesulfonate. Nevertheless, 9 million tons of soap are consumed in the world annually. Thus, soap remains the most widespread surfactant in the world, followed by ABS. Soap, according to strategic marketing estimates, has been in the so-called "saturation phase" for many years. The "phase of degeneration" will probably never come as long as humanity lives.

Surfactants in cosmetics

The concept of "Cosmetics" unites a wide range of various products intended for hair and body care. These are shampoos for hair and liquid soap; hair coloring products; hair care products after washing; rinses, balms, etc .; cosmetic creams for face, body, hands, including therapeutic and prophylactic action.

Modern shampoos are multifunctional products that contain various ingredients that provide softness, stability, foaming, improving appearance and hair bar.

The basis of the raw components of cham-punas are surfactants (surfactants), as well as various useful additives, including biologically active ones.

The main surfactants are anionic substances, which provide a sufficient washing effect and foaming with a gentle effect on the skin and hair.

For conventional commercial shampoos, anionic surfactants (alkyl sulfates and alkyl ether sulfates)

In order to obtain "soft" sham-punas in a mixture with them, alkylamido ether sulfates, sulfosuccinates, and, to a lesser extent, isothionates, sarcosinates, etc. are used.

Auxiliary surfactants include amphoteric, nonionic and cationic substances. They are necessary in shampoo formulations to increase the compatibility of the main surfactants with the skin and hair, increase the foaming properties, regulate the viscosity, and reduce the degreasing effect. For this purpose, imidazoline derivatives, betaines, alkylolamides, and amine oxides are widely used.

Alkylolamides, glycol ethers of fatty alcohols are used as solubilizers for the introduction of perfumes and other hydrophobic components (oils, biologically active substances).

Cationic, non-ionic surfactants, beta-ins are used as conditioning agents that release static electricity and make it easier to comb dry and damp hair.

The most effective antistatic agents are cationic surfactants - quaternary ammonium compounds, although there are problems of incompatibility with anionic surfactants. However, in a mixture with non-ionic and amphoteric substances, it is possible to achieve the desired effect and maintain the stability of the finished product.

Amine oxides, oxyesters of alkyl phosphates are also used to soften hair, reduce its electrification.

A separate group among shampoos, liquid soap, bath foams are especially "soft" formulations intended for children and adults with sensitive skin, that is, formulations of increased softness in terms of the effect on the skin. The requirements for raw materials are particularly high here. Most often, a mixture of alkyl ether sulfates with amphoteric surfactants - imidazoline derivatives, as well as betaines and monoalkyl sulfosuccinates - is used as an active principle. The same base is used in anti-dandruff and medicated shampoos.

Anionic surfactants

The main types of surfactants used in the composition of CMC are alkylbenzenesulfonates with a linear alkyl chain (LABS) and derivatives of C12-C15 alcohols (ethoxylates, sulfates, ethoxysulfates of alcohols). LABS and alcohol sulfates, along with soap, are anionic surfactants, alcohol ethoxylates are nonionic (nonionic) surfactants.

Nonionic surfactants

Second important species Surfactants for CMC are nonionic surfactants obtained by oxyethylation of higher fatty alcohols or alkylphenols

The most commonly used nonionic surfactants are fatty alcohol oxyethylates, which can be based on both linear and branched alcohols. While ethoxylates based on long-chain alcohols (C12-C15), due to their better detergency, are more used in CMC formulations for laundries, then ethoxylates based on short-chain alcohols (C9-C11) are preferable for cleaning hard surfaces. These ethoxy-lathes are distinguished by better wetting ability and wetting angle in relation to hard surfaces. In general, nonionic surfactants, due to the variability of their base and the degree of oxyethylation or propoxylation, can be ideally tailored to a specific task. As a rule, they are superior to anionic surfactants in both cleaning and degreasing action and, depending on the profile of use, emulsify more or less oils and fats.

Amphoteric surfactants

Of the group of amphoteric surfactants, betaine derivatives are most often used (for example, coaminopropyl betaine)). In combination with anionic surfactants, they improve foaming ability and increase the harmlessness of formulations, and when combined with cationic polymers, they enhance the positive effects of silicones and polymers on hair and skin. These derivatives are obtained from natural raw materials; therefore, they are rather expensive components.

We offer such surfactants (surfactants):