Design decorative products from plywood laser. Laser cut of plywood

Thickness over the specified in the price is discussed individually

Submit your application

Laser cut Plywood - progressive technology cutting wood plates, providing high-precision creation of parts and elements complex shapes. Our studio performs in Moscow cutting plywood laser by individual orders. Experience and modern equipment allow us to create not just beautiful figures, but real masterpieces that can decorate any object.

Features

The cutting of plywood laser is widely used in the production of various products of decorative and functional purposes. This technology is especially popular with furniture makers and decorators. With a special machine and a focused coherent radiation beam, our specialists are performed by our specialists. openwork cutting Plywood with the creation of flat and bulk figures of varying complexity. This technology is suitable for both pieces and serial production of products not only from plywood, but also from MDF and other materials. Due to the features of the equipment, the cutting of plywood laser allows you to make elements of the standard and big size. It can also be used to create highly artistic thumbnails up to 3 cm high.

Figure cutting plywood is actively used for manufacture:

- accessories;

- promotional products;

- furniture elements;

- building structures.

Advantages of technology

Laser cutting plywood has a huge amount of advantages. The machines used by us are capable of processing sheets of up to 2050x3050 mm and a thickness of 0.5-12 mm. In addition to cutting plywood, we also cut out products from other wood materials: veneer, natural array, MDF, chipboard. After loading the workpiece on the table and the introduction of the main parameters powerful laser affects the material with a focused beam, burning the desired figure along the contour. Figure cutting plywood to order possesses such advantages:

- the ability to create figures in templates of any complexity;

- excellent detail and clarity of patterns and ornaments;

- high-quality cutting with the creation of a clean, smooth and smooth edge;

- no need for additional processing edges;

- exceptional accuracy up to the hundredths of millimeter.

The advantages of ordering figure cutting in our studio

- Modern equipment. Laser cutting plywood to order is carried out on automated machines with high-tech computer control.

- Affordable prices. The absence of intermediary surcharges and the transparent calculation of the cost is excluded by overpayment and allow you to save the budget.

- Qualified specialists. Laser cutting services Plywood show experienced and responsible masters who have passed special training.

- Operational. Due to the high performance equipment, we are capable of carrying out orders of any scale and complexity in a short time.

- Individual approach. Wishing to order laser cutting from plywood We offer quality service, which takes into account all the wishes of the client.

Cooperate with us is convenient and profitable! Check out our price list and order the laser cutting of plywood in Moscow, contacting our manager to the phone indicated by phone.

The wood is gaining increasingly popular. Such a feature is explained simply enough. In the production of souvenir, advertising, furniture and joinery products, it is often necessary to quickly, efficiently perform sophisticated elementscuts. A not every tool will be able to cope with the task with his own hands, and here it can come to the rescue.

Laser cut of plywood "Tree"

Tree cutting laser machine

The tree is considered the most beautiful of all materials known to humanity. In addition, wood belongs to environmentally friendly, safe and more high quality materialwhich is used for a long time. It is used in various fields of production, in particular in construction. Of the wood today produce a variety of products that we use both in everyday life and as decorative elements.

Not so long ago, each manipulation: cutting, engraving, burning, was conducted across the old man - do it yourself. The process was, of course, labor cost, but very interesting and exciting. Today, any action with wood can be produced using laser machines and a girlfriend tool.

The laser has a thermal impact on the tree. By cutting, the machine splashes the edge, thereby protecting the tree from microbes and bacteria, providing a longer service life of the product. Unlike plumbing tools, there are no waste, chips, sawdust, blank or layout when working with equipment, and the pattern is not fully complied with the original.

However, each breed of wood is processed by different ways. It all depends on the breed, thickness, humidity, hardness, as well as from the delivery season.

Types of laser and plywood

Machines with numeric software control

Perfectly cope with billets from any tree will be able to modern Laser CNC laser machines. However, despite its multifunctionality, each model has its own characteristics and characteristics.

- Outdoor machines

The machine desktop can vary from 0.5 meters to 2 meters. Such machines are designed to be installed in a specialized room and are used, as a rule, in difficult industries. Machines have a monolithic case, which provides them with the stability of the entire structure, and also effectively reduces the vibration background arising from operation. The main purpose of such equipment is cutting, engraving, cutting wood. - Table machines

Small size layout that does not require installation in the industrial premises. Ideal for processing at home or in the walls of a small office. Excellent optical system allows you to cope with high-quality sharp and decorating blanks. - Compact machines

With the help of a marker, you can apply decorative items to various bulk products (knobs, key rings, decorations, any layout, etc.), while each item will be clearly visible, and the drawing will be different in durability. Such a feature is achieved due to the special design of the marker with a high-tech optical system.

Principle of operation

Layout, the workpiece is processed using a beam, which looks like a stain on the surface of the material, the diameter of which is several microns. The ray is formed due to the lens, which is installed at a small distance from the base part of the part.

The beam moves due to the drive that is pre-programmed in advance technical specifications processed element.

Most often when processing wood uses:

- Gas, with a ray diameter of 10 microns formed using a gas tube.

- Solid state laser. The diameter of the beam in 1 micron is created using neodymium glass.

Advantages and disadvantages

Modern machines have a lot of advantages:

- High accuracy

Engraving or cutting with the machine is considered a high-precision process. The thickness of the cut is no more than 2 mm. To perform cutting or apply engraving with your own hands, you do not need to make physical efforts more and use a healthy tool. - High efficiency

The speed of work allows you to minimize the time when performing various volumes of work, which saves energy resources. - Economy

Such an indicator refers to the consumption of materials and the energy consumption. Due to high precision Works, laser machines brewly saved wood, reducing waste to a minimum. - Universality

In addition to cutting, the machines can carry out engraving work.

Only one factor can be attributed to the main disadvantage - this is its cost and increasing. Not every amateur will be able to allow you to buy such an expensive laser metal processing machine, but everyone can try to make it yourself.

Approximate cost of laser cutting services. Prices are in rubles for 1 raman meter cut. The engraving price is indicated in rubles per 1 square centimeter.

Laser machine with their own hands

As mentioned above, to purchase equipment on a laser based on a laser is not for everyone, but it is quite possible to make it alone from the girlfriend.

Tool and assembly material

- laser diode;

- pencil, best mechanical;

- radiator, as a cooler;

- optical fiber;

- thermal lubrication;

- batteries of the form D or 2 AA;

- protection for eyes.

Most main moment In the work is to protect the eyes. Under no circumstances look at the ray, so as not to damage the vision.

Regarding the diode ... High power IR diode with 1W output, capable of burning any material, except metal. Diode should work on 2V with dC 1,7A. You should pay attention to the fact that the diodes have different polarity (plus and minus). In the case of incorrect connection, the diode will simply burn.

Layout and its assembly

Connect a diode with a radiator. For better thermal conductivity to treat thermal lubrication. Next, go to a mechanical pencil. It is best for a pencil with a metal case, which will continue to avoid melting when overheating. We disassemble the pencil, insert optical fiber and fix with the tip. epoxy resin Or glue.

For a laser, it is better to take a thin pencil under the size of the optical fiber. We collect: fiber optic with a tip insert back to the pencil and firmly twist. Thanks to such a simple, but fast designs each can burn various patterns with their own hands and make engraving on wooden products.

If you did not change my mind and decided that the laser machine is simply necessary for you, then you need to approach the choice of a particular model with a special responsibility. Explore full information About each model, compare the parameters you need, and only then proceed to the purchase. You can also find information about how to make equipment based on a laser from an ordinary pencil or an old DVD or CD drive.

✅ Before buying a laser machine for cutting plywood, find out how to choose it and correctly use it. This will help you accurately decide on the characteristics of this equipment and understand what the price should have. Only helpful information, Video reviews, Lifehaki and advice from experienced laser cutting specialists.

Before buying a laser machine for cutting plywood, find out how to choose it and correctly use it. This will help you accurately decide on the characteristics of this equipment and understand what the price should have. Only useful information, lifehaki and advice from experienced laser cutting specialists plywood.

How to choose a laser plywood cutting machine

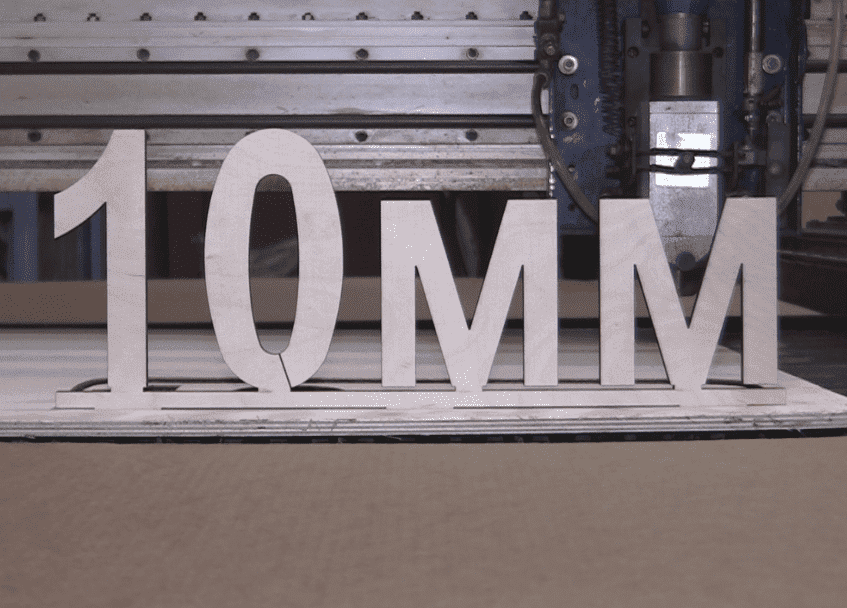

Choose a laser machine for cutting plywood experienced specialist is very easy. After all, he has extensive experience, knowledge, and most importantly, practice. But what to make a newcomer, where to start searching for your laser equipment with CNC for cutting and cutting plywood? How to buy really what is needed at the appropriate price, including additional options? As experienced specialists tell about everything in order. At first you need to know, plywood sheets of which area you will color. For a large, choose a laser machine with a large working field, under a smaller one - with a small (type mini, bench-top). The price of the laser machine for cutting plywood depends on its size. On the other hand, if you have the opportunity to cut the large-format sheets of plywood into small parts, for example, with a mill or circular, you can immediately pay attention to the medium or even small-format devices of laser cutting. So, for example, comes on the production of small elements and parts from plywood. Such machines are suitable for home. However, in this case, you will need to take care of the ventilation system. In addition to the square you need to know, what thickness you will be cut. At the same time, remember that if on the Laser CNC laser to paint a thick phanener, then the edges of the cut will remain charred. Yes, there is one lifehak that will help you solve this problem, but just below it. On the other hand, some finite products with black edges are attractive. When you need a clean end, it is better to use other machines for cutting thick plywood, among which there may be milling, and laser equipment is already used for engraving. The thickness of the plywood that you will cut, affects the power of the CO2 laser emitter and, as a result, the cost of a laser machine for cutting plywood. To choose, you can focus on this data:- Plywood up to 6 mm - 50 W

- Plywood up to 8 mm - 60 W

- Plywood up to 10 mm - 80 W

To apply a laser on the phanee of images (engraving) you can stay on a 50 W laser tube. But, as they say, the economy must be economical, so if the task is to produce more products per unit of time and establish profitable production, then it is better to buy a CNC laser machine for cutting plywood with emitter more powerful.

VIDEO. Comparison of plywood laser cutting machine

Professional industrial and semi-professional model.

VIDEO. Budget laser and plywood laser

Little-format models.And now we will tell about the plywood itself for laser cutting, how it is better to paint and nuances of processing.

The perfect grade of plywood for laser machine - 1/1 or 1/2. When choosing plywood, pay attention to its variety. So, the marking sh1 suggests that it is plywood polished on the one hand, and sh2 - from 2 sides. For cutting with a laser machine, the so-called indoor plywood is suitable (the abbreviation is decrypted as "plywood + carbamide-formaldehyde glue"). Moisture-resistant faeer or FSF for a laser is better not to take. It is very hard to cut the laser. Thus, this plywood 4 millimeter thick cuts on the same parameters as the usual FC plywood with a thickness of 12 millimeters. In other cases, it just burns. And it, as they say, do you need? Such a fane is easier to process the milling machine. In addition, there is a bakilite plywood for manufacture, for example, spacer. It is cut either by a milling machine or hydroabrasive or diamond cutting equipment. At the same time, it is ideally used to use hydroabrosit, because the same milling processing in the processing of bakilite plywood grinds are burning (we read - spend a lot of money for consumables), and all due to the fact that it is impregnated and covered with special strengthening chemical compositionIn some cases, epoxy resins. There are still special varieties of lightweight aviation plywood. It is just space for a laserist. Her plus is that it cuts very well, and at the same time very durable, because it is intended for aircraft modeling. In a word, she is ideal. Such plywood is produced by a thickness of 2 millimeters. Than quality plywoodThe easier you will process it. Choose Phaneur with a minimum amount of bitch. They impede normal cuts. Phaneur for cutting on a laser machine must be ordered in specialized companies. In conventional construction stores and hypermarkets, a plywood is sold, which is not suitable for laser processing.

How best to cut the fane on a laser machine

When you cut Phaneur on the laser machine to avoid yellow plaque along the edge of the cut, it is necessary to use a compressor more powerful, with an air supply to a nozzle of 1.5 -2 atmosphere. If you need a cut without "shootings" on the other hand, the Phaneru from the desktop must be raised at least 1 cm. Then the beam when shooting from the table, no trace remains on the material. Perfectly smooth plywood does not happen, each leaf leads, spins. To avoid the defocusing of the laser beam with a cutting of uneven plywood, either a long-phocus lens is used, or pressed the plywood to the table. Click can with neodymium magnets that perfectly stick to the cellular table, or fasten the plywood sheet to the corners, which can be made independently. The easiest way to align the sheet of plywood on the table, with the avoidance of shootings on back side - This is an exhibition on the table of neodymium magnets, the location on the top of them is the sheet of plywood and consolidate this sheet on top of one more neodymium magnets. Then the sheet is located at the desired distance from the cellular table and fixed on top of other magnets. With intensive cutting of plywood, you often clean the ventilation grid, because the combustion and soot products from plywood glue are much more than from the plexiglass. In this regard, the extract is clogged faster. For the same reason, when cutting plywood on a laser machine, you need to often clean lenses and mirrors.

Lifehak on cutting thick plywood laser

If you want to cut into the Laser Machine to the Faneer more thick, which allows the power of CO2 tube, then you can do it in 2 clips. But, there is one big but. When cutting from the first right, you will have to cut without a forced air supply, otherwise the laser machine will not exist and will simply light up the phaneer, with oxygen, as is known, everything burns better. But at the second occasion, you include the flow of oxygen. And this is, but: remember, in the absence of air supply to the nozzle, the lens of your laser machine is very quickly smoked and burst.

Where to buy a laser machine for cutting plywood

Our company sells a large number of laser cutting machines and cutting plywood with various characteristics. In addition to typical serial laser equipment, we can run a laser machine for your technical task and make it at an affordable price. Have questions? Ask them to our technicians.

- Useful tips on laser cutting and engraving

- Secrets and Lifehaki

- Laser equipment reviews

- Laser cutting layouts

- Current promotions and discounts

|

Plywood (FC) veneer |

|||||

|

Material |

Material thickness in (mm) |

Laser cut long, p.m. |

|||

|

up to 100. |

up to 500. |

up to 1000. |

over 1000. |

||

|

Plywood FSF, Plywood Moisture Resistant, Bakelite Plywood |

|||||

|

Material |

Material thickness in (mm) |

Laser cut long, p.m. |

|||

|

over 1000. |

|||||

|

Cost of laser cut, rub. |

|||||

|

Plywood moisture resistant |

|||||

Minimum order 5 000 rubles

The cost of the sings is 3.5 rubles.

We carry out laser cutting of large formats from 1650 to 3010 mm

Examples of work on a laser cutting on a tree to order

12 000 rubles

23 000 rubles

4 000 rubles

6 000 rubles

32 000 rubles

8 000 rubles

14 000 rubles

39 000 rubles

57 000 rubles

HOW WE ARE WORKING

The client sends an email drawing

On the scale of 1: 1 in DWG, DXF format, AutoCAD 2007 software, indicating the material and number of parts, the cost of the order is calculated automatically (a special program is applied) and a commercial offer is being developed.

Specified drawings in other formats or CorelDRAW13 or the scanned product pattern increase processing time and order cost.

File Requirements for Laser CutThe client leaves its coordinates

(phone number for a call) or comes to an office at a consistent time for a more accurate order discussion.

The company makes the calculation of the cost

The minimum order amount is 3000 p.

The client makes prepayment of 50%

From the cost of laser processing and brings its material.

The company reports on the readiness of the order,

As a rule, the term of manufacture from 1 to 5 days (depending on the volume);

The client pays the remaining 50%

And takes the order

Order Laser cut of plywood or MDF from the company "Lumus Laser"!

Although the materials created from the wood fiber are always distinguished by the available price, economical flow issues always remain relevant. Ordinary mechanical methods of processing wood materials are accompanied by a huge amount of waste, the mass of which can exceed even volumes ready Product. Using the progressive tool that the laser beam is allowed to solve this problem. In addition, the focused light stream ensures the degree of accuracy that is not available mechanical methods Processing. Laser cutting of plywood is already due to the characteristics of the methodology itself, it offers an extremely high speed of operations. In fact, all operations within a particular workpiece are performed during one sheet setting and require minimal operator's participation after starting the CNC processing program.

For professional approach To the organization of work, even despite the fairly high cost of operation of the equipment, the implementation of structures and samples of the most complex forms remains much more convenient and financially accessible to our customers. The price of plywood laser cutting, as for other materials, is formed predominantly the thickness of the workpiece and total length Contours of details. With a professional approach to the design of the template, the selection of type and nature of the impact can be successfully avoided any additional costs.

We are carefully monitored modern materials And we determine the possibilities and features of their processing, so our company is always carried out the most professional and rational approach. The price of laser cutting MDF remains available for both small and most voluminous orders, so cooperation with us is extremely profitable and convenient.

Video of our work

Laser cut is far from new method artistic processing Woods, which since the appearance immediately won great popularity. Compared to a similar process performed by the feeder manually, such a method demonstrates a number of advantages, the main of which is the speed of operation during its high accuracy provided by modern multifunctional equipment.

Also laser cutting and engraving plywood makes it possible to achieve the uniqueness of a drawing, distinguishing aesthetic attractiveness and beauty, while the cost of the service provided by a professional master with the help of expensive techniques is available for most customers. The minimum width of the cut here does not exceed 0.01 mm, which is almost impossible when processing wood with a hand tool.

Example of cutting plywood with a laser:

Laser cutting technology implies the directional impact of the laser beam on the Faneru, which allows you to form a different complexity and configuration. This method is non-contact and consists in increasing the temperature at the place of contact of the beam with a tree, after which the material is removed by evaporation.

The use of equipment that in this case is a laser machine guarantees the preparation of perfectly smooth edges after processing, which is very important when cutting art elements and complex openwork patterns. There is also no wood dust and chips, delivering a stole mass of inconvenience. In the process of cutting a tree with a laser under the influence of high temperatures, the plunke cuts usually darkens, which can be regarded both of advantages, and as the deficiencies of the method, it all depends on the artistic vision of the wizard. If necessary, it is possible to get rid of such a feature by supplying laser ventilation and blowing system that removes combustion products.

The principle of the laser beam

To obtain a laser beam, it is necessary to use a tube from gas and a mixture of helium, nitrogen and carbon dioxide. When the voltage is supplied, the monochrome radiation of the directional action carried out with the help of technological mirrors occurs. Experienced masters cut the tree with devices whose power starts from 20 watts, but amateurs at home often use less powerful equipment. As mentioned earlier, the accuracy of the laser cutting of wood is very high, and the specified drawing is obtained almost jewelry.

To achieve smooth and clear edges of the pattern according to specified parameters Without manual labor, it is enough to install the appropriate program. Minimum size The laser beam in combination with numeric programs allows the process of cutting plywood with a laser in a matter of minutes. Modern machines equipped with CNC require only the compilation of the sketch from the master, the wood cutting itself is performed quickly and simply in automatic mode.

Additional components

By type of configuration, the equipment on which the laser cutting of non-metals is carried out can be divided into units with numeric control programs and without that. There are also additional devices that optimize the cutting, processing and manufacture of parts. Devices extending functional purpose Laser machines are:

- chillers, finding the cooling process of a glass laser tube, according to which a gas mixture is served. To ensure optimal temperature mode, the tube is closed by a kind of shell, which circulates the coolery liquid, and the device itself consists of a water pump, water and freon;

- the blowing systems that remove combustion products, thanks to which the plywood in places of contact with the beam does not darken, and the products acquire an attractive appearance.

We draw your attention to the fact that the laser cutting of MDF or any other wood material requires continuous cooling of the focusing lens, but such a system is not an additional option And necessarily present on all types of machine tools without exception. The cost of professional chillers, which was discussed above, is quite high and starts from 500 dollars.

Often, homemade masters make a cooling system independently, using the pump for pumping water. Thanks to this reception, laser cutting of veneer, plywood, MDF or chipboard will be available without unnecessary financial spending. By the way, standard work The cutting of nonmetals may require more than a hundred liters of water. If possible, water is desirable to replace the freon more suitable for such purposes, which will be significantly more efficient.

The process of laser cutting

Qualitative production of decorative elements, where the laser cutting of MDF is used or others are used. wood materialsIt is impossible without modern equipment to which a high quality requirement is presented. The process itself cannot be called simple, because it takes attention and artistic talent when creating sketches. No less strict requirement is extended to the treated surfaces. Plywood should not contain any flaws in the form of cracks, chips and other flaws, otherwise the result may be deplorable, and the master will make their efforts in vain.

Cutting veneer with a laser, as well as the processing of any wood using a point light beam, you can exercise both manual and automated equipment. Despite the fact that in this case the surrounding space is not contaminated with chips and woody dust, some inconvenience are still present. The thing is that such production is associated with the heating process, due to which the cutting laser beam burns out a tree and, as a result, highlights smoke. That is why it is impossible to allow consideration to fill the room, be sure to ensure exhaust system. Also laser cutting of plywood can provoke insignificant foci of fire, and to avoid a fire, it is better to put a capacity in advance with water, which will come to the aid in case of unforeseen circumstances.

Materials, products and prices

The laser cutting method is specifically designed to process plywood, and indeed any wood, with the aim of giving it decorative effect. For example, the laser cutting of MDF is capable of converting an ordinary unsightly preparation into the masterpiece of carpentry art. In addition to the manufacture of interior elements, this technique allows processing a tree in the production of souvenir and gift products. There is a huge amount of products, the main material of which is inexpensive plywood, however high level The quality of laser processing is so modifying the primitive workpiece that it looks like a precious exclusive thing. Most popular items in this category of goods can be called all sorts of stands, panels, photo frames and paintings, boxes, vases, etc.

Having a laser machine in his arsenal, the master will be able to regularly allow the creation of unique distinctive things for sale or for personal use, but what should I have special equipment or there are no necessary skills? The answer is obvious. Cutting wood with a laser can in hundreds of workshops who work according to the sketches of the customer, it is enough just to voice their wishes. Such a service is quite accessible, and on average its cost is 30 rubles per meter of the tempo, with a material thickness of 5 mm.

Table: Prices for Laser Cutting Services

|

MM thickness. |

Cutting length meter |

|||

To fluctuate the price in one direction or another directly affects the thickness of the wood, the handling and complexity of the pattern.