Frame for acrylic bathtub. Secrets of making a bathtub frame Do-it-yourself bathtub frame from a profile

To install a bathtub, it is often necessary to prepare a reliable and durable frame. With such strong supports, the plumbing fixtures will last for years and remain stable. However, not all owners know how to make the base for such items.

Peculiarities

Many people are confident that installing a bathtub does not require unnecessary manipulations; it is quite possible to get by with the legs holding the bowl. Of course, in many cases this is true, and installation of additional frame structures is simply not required.

However, it is worth considering that only a heavy and expensive cast iron model will stand securely and firmly on legs, because it really does not need a frame.

The stability of such plumbing is ensured by its massiveness and impressive weight. Lighter and more affordable models made of steel and acrylic cannot boast of such stability, so for their installation it is necessary to prepare a frame.

Very often frame structures come complete with bathtubs. If these are not included in the set, then all parts must be purchased separately.

Such design solutions look original and stylish. In this case, the plumbing configuration itself does not play any role. With this design, the frame will also need a cast iron structure.

Not all bathtubs have simple symmetrical shapes. Today, stores sell many original options of non-standard shapes. Included with these options are unusual frames, and entire platforms of a suitable structure. In addition, such plumbing fixtures most often have wide sides, which make installation of the model faster and more convenient.

Without a high-quality and reliable frame, a light and unstable bathtub will be subject to deformation. Because of this, the enamel on the plumbing may begin to crack and peel.

In order for the product to lose its original appearance, it is necessary to place it on a frame base. You can do the installation of the frame under the bathtub yourself. This kind of work cannot be called difficult. Moreover, the frame can not only be installed, but also made with your own hands. To do this, it is necessary to use exclusively high-quality and durable materials - the platform must be as strong and durable as possible.

Materials

Different materials can be used to prepare the frame. The main requirement that they must meet is increased strength and wear resistance.

Wood

Wooden beams are often used to make the frame. This material is environmentally friendly, lightweight and quite durable. To work with such raw materials, you do not need to use expensive professional tools.

Wooden structures are considered the most economical, but no less reliable. However, these frame options have their weaknesses. For example, wood does not tolerate high humidity. In a bathroom environment it cannot be avoided. For this reason, over time, the frame may begin to rot and deteriorate. In addition, mold and mildew may appear on such a basis. It will be very difficult to get rid of them. To prevent the base from turning into “dust”, it must be regularly treated with special protective solutions.

Metal

No less popular are frames made of metal profiles. According to experts, the wear resistance of such foundations leaves much to be desired, since iron and aluminum elements are not designed for impressive loads. For this reason, they are recommended to be used only for creating auxiliary supports and further installation of a decorative plasterboard faucet along with legs.

Profiled pipe, corners

Experts say that frame structures made of profiled pipes and metal corners are the most reliable and durable. They can withstand impressive loads, especially if they are thick enough.

When choosing a material for making a frame for a bathtub, you must take into account that welding will be required to assemble the metal elements.

An all-welded base will make the entire structure more reliable and durable, but it will be much easier for any craftsman to work with a wooden block that does not need to be welded.

Dimensions

The dimensions of the frame structure largely depend on the dimensions of the plumbing fixtures. For example, models with dimensions 170x80, 170x70, 100x70 cm must be installed on bases with similar dimensions. The dimensions of the bathtub depend on its shape. For example, parameters of 170x80 cm are typical for simple rectangular products, 194x100 cm for oval ones, 130x130 cm for corner ones.

Be sure to measure all necessary surfaces before designing the frame.

You should try not to make a mistake with the dimensions if you make the base yourself. Otherwise, the plumbing will be unstable.

How to do it yourself?

Making a frame is not a difficult job. To make a wooden structure, you will need 40x40 cm pine bars, moisture-resistant plywood, and 28 mm thick edged boards. Frames from these components are created using a wood saw, hammer, plane, screwdriver and chisel.

This process includes several stages:

- First you need to make the top trim of the wooden frame. This is necessary so that the structure does not wobble in the future and does not “play” under the weight of the bathtub.

- The racks must be placed in a vertical position. On the shorter part of the structure there should be at least one supporting part, and on the long side - 3-6 racks (it all depends on the dimensions of the bathtub itself). The bars should be fastened together using nails and self-tapping screws.

- You can proceed to assembling the upper trim. It needs to be secured to the walls with dowels. You need to position the bars so that the sides of the bathtub rest on it. The most reliable designs are those in which steel fonts rest simultaneously on 3 wall ceilings.

- After this, you can proceed to installing the bath.

- To make a frame from metal profiles, you need to put the bathtub in its main place, take all measurements, cut off the excess parts of the profiles and fasten them together.

- It is necessary to adjust the frame to the bathtub in order to achieve the tightest possible fit of all the constituent elements. Then you need to weld the profiles together.

- The metal frame should be made taking into account that the drywall and tiles are then in the same plane.

- At the end of all work, it is necessary to seal all joints between the bathtub and the ceilings with a special sealant or rubber.

Lined bricks can also serve as a frame for the bathtub. They do not need to be boiled or made into complex boxes, as is the case with metal or wooden options.

- You need to build two brick supports. They should be at a distance of 50–60 cm.

- As for the width of the support, it should not exceed the dimensions of the font itself.

- It is advisable to make the supports so that they follow the shape of the bottom of the bathtub bowl.

- In the place where the drain is located, the support should be lower by a couple of centimeters to improve the outflow of water.

- It is necessary to ensure that the sides of the bath are horizontal. There is no need to achieve a slope, because such elements, as a rule, are used at the stage of manufacturing plumbing.

- At the end of the work, the bathroom must be placed on brick foundations as legs. To make the structure more reliable, it can be additionally attached to the walls.

- If gaps appear between the brick structure and the bottom of the bathtub, they should be filled with tile adhesive or regular foam.

- If a metal profile is used to make the frame, it should be further strengthened. To do this, you can use wooden blocks soaked in antiseptics.

- A stand for plumbing fixtures made from a profile pipe also requires welding. This is perhaps the only difficulty that a home master may encounter.

- It is very important to foam the steel frame from the outside. In such cases, a frame for the screen is constructed. This design is simple and can be made without dismantling the font.

- To distribute the weight of the bath evenly, you can use more than just the legs. A simple backing made of bricks and boards will also cope with this task.

- After connecting all communications, it is recommended to hide them behind decorative skirting boards.

- It is worth considering that all-welded structures (both homemade and factory-made) are less reliable than prefabricated ones, since assembling a base with bolts with your own hands is the same as making connections that are not inferior in strength to solid metal.

- It is recommended to provide a separate access door to the drain equipment so that it can be inspected and repaired.

- For fastening, you should use self-tapping screws treated with an anti-corrosion compound.

- To cover the frame in the bathroom, you must use only moisture-resistant plasterboard. Ordinary material in such an environment will very quickly fail.

To increase the reliability of the position of the bathtub in the bathroom, its bowl must be secured to a special base called a frame. There are many options for supporting structures designed for various types of bath bowls and made from various materials.

Frame functions

The bathtub frame used as a supporting structure must at the same time:

- ensure uniform distribution of load on the floor base;

- eliminate the possibility of deformation of the bathtub body;

- protect its bowl from mechanical damage.

If there is a box, a decorative screen can be easily mounted on it, giving the entire structure a well-appointed and attractive appearance.

Without a reliable and stable base, any bathtub will look lonely and unkempt, but sometimes, in order to save money, ordinary stands with legs are used. Along with brick-lined racks, this method is considered one of the simplest and cheapest.

For the manufacture of capital supporting structures, wooden beams or metal profiles are traditionally used.

Advantages and disadvantages

The advantages of arranging a frame for an acrylic bathtub include:

- reliable fixation of a not very massive product;

- the ability to improve the appearance of the bathroom;

- the presence of free space inside the frame structure.

The niches that appear after installing the frame can be used for storing household utensils and even for making shelves for bathroom accessories.

The structure has its drawbacks:

- reducing the total volume of the room;

- the need to monitor the safety of the wooden frame and the screen installed on top of it.

The second of the disadvantages is explained by the special operating conditions in the bathroom, the humidity and temperature in which are noticeably higher than normal.

Materials used

Common materials are traditionally used in the manufacture of frame bases:

- wood;

- metal profile or corner;

- profiled pipe.

Each position has its own characteristics.

Tree

The good thing about the wood used in assembling the frame is that it is not very expensive and can be easily machined, cut and assembled. In some cases, well-preserved blanks left over from dismantling old partitions or doors can be used for self-production.

Note! Wood is good because all known types of protective screens can be easily mounted on it.

The only drawback of this natural material is poor protection from moist air that accumulates in the bathroom. To avoid rotting of wood blanks, they must be treated with antiseptic compounds before installation.

Metal

One of the popular materials on the basis of which a do-it-yourself bathtub stand is made is a metal profile in the following versions:

- U-shaped channels;

- profiled pipe;

- corner profile.

When working with metal, you will have to face a number of difficulties regarding the methods of joining workpieces.

Additional Information! People who do not have special welding equipment can connect structural elements using a bolted joint.

Any design of the frame for a steel bathtub must meet the requirement to protect the body from deformation and destruction. It should be attached to the frame elements through rubber gaskets.

Profiled pipe

Boxes made of profiled pipes are one of the varieties of the previously discussed option of manufacturing from profile blanks. In this case, installation of the structure becomes somewhat more complicated due to articulation problems (bolts are used only in extreme cases).

To make a frame for a bathtub from a pipe-type profile, you will need a welding machine, which under normal conditions is not available in every home. The option is the most labor-intensive.

To make a metal frame with your own hands, the easiest way is to use a classic corner.

Installation

It is better to consider self-assembly of a frame for a bathtub using the example of wooden blanks made from timber.

When using them, it is important to consider:

- the quality of bowl support depends on the number of support points;

- the thinner the walls of the bath, the more of these points there should be;

- The easiest way is to make a support box for bathtubs of complex configuration (with many protrusions and recesses).

Before starting work, you will need to draw a sketch, on the basis of which it will be possible to cut a complete set of wooden blanks of the required length.

Typical cast iron frame

To secure a cast-iron bathtub on a wooden base, you will need timber blanks (preferably made of pine) with a cross-section of at least 40 x 40 mm, as well as an edged board 25 mm thick. From the tools you need to prepare a hammer, a hacksaw, as well as a screwdriver and a set of chisels.

The process of manufacturing a wooden frame includes the following mandatory operations:

- The top trim is made in the form of two beams, one of which is fixed on the wall adjacent to the bathtub.

- The second or outer beam is placed under the outer edge of the bathtub, after which three racks made of blanks of the same section are placed under it.

- The racks resting on the floor board are positioned strictly vertically.

Note! A 25 mm thick edged board is pre-attached to the floor screed using special dowels.

At the final stage of work, the racks are fastened to horizontal beams using nails or self-tapping screws. The outside of the frame is sheathed with sheets of any finishing material (moisture-resistant plasterboard).

For acrylic bathtub

Installation of a wooden frame under an acrylic bathtub is carried out according to a similar scheme. The difference lies in the design features of modern acrylic bathtubs. Some product samples have areas with thickenings designed specifically for attachment to the frame.

When arranging supports for acrylic bowls, two options are possible. In the first case, the frame is assembled in the same way as for a cast iron product, that is, by placing horizontal and vertical bars under the installed bathtub.

The second approach is to first turn the bowl upside down, after which the previously assembled frame is put on it. In both cases, special hardware with a limited depth of penetration into the body of the bowl is used to articulate them.

Important! When drilling holes, you must use drills with a special stop. Their diameter and penetration depth are indicated in the instructions for the acrylic bathtub.

Upon completion of fastening the frame, it is turned over to its normal position, leveled, and then additionally fixed to the base of the floor screed.

There is another good, albeit simpler way to secure an acrylic bathtub. It consists of using two supports made of ordinary brick. There is no need to worry that the design will be unreliable. If you lay out the supports one brick thick, you can be sure of its stability.

Some craftsmen reinforce the brick support with additional masonry placed under the outer part of the bathtub bowl (including the side edges). Upon completion of the blind lining, the walls of the structure are finished with tiles chosen to match the floor covering.

Inside it, the supports are positioned in such a way that their contours completely follow the contours of the bottom of the bowl.

Note! The part of the structure located on the side of the sewer drain is made 1.5–2 cm lower in height, which ensures natural water flow.

The choice of method for fixing the bathtub is largely determined by the dimensions and configuration of the room itself. This circumstance must be taken into account both when purchasing a new product and during its installation.

The bathtub frame is an alternative to standard legs and prevents unfilled containers from tipping over. Such support structures are produced on a production scale for the installation of bathtubs of various configurations made of quarryl, acrylic and multilayer fiberglass. For steel and cast iron bathtubs, the frame is made by hand.

When is it necessary to install a frame under the bathtub?

Standard bath frames.The structure consists of several vertical supports with 2-3 horizontal strappings. Industrial production models are designed for statistical averages, taking into account human weight and the volume of liquid in the tank.

Some builders make the mistake of installing bathtubs too low. This prevents normal drainage of water. In such cases, due to the frame, the container rises to the required height.

The area of standard legs is 10 cm². Some people seek to create an additional supporting surface to stabilize the bathtub. For these purposes, a factory frame kit or a structure made independently is suitable.

For bathtubs of a non-standard configuration, the support not only serves as a means of protection against tipping, but also performs a decorative function. The construction of a podium around the jacuzzi begins with the installation of a supporting device. If you want to assemble a screen to mask communications, you cannot do without a frame.

Frame materials

Sometimes it can be difficult to choose the dimensions of a finished kit. In such cases, you can make a frame for an acrylic bathtub with your own hands.

Builders advise using the following materials for this:

- Rolled metal. Profiled pipes with a round or rectangular cross-section allow you to create an elegant, neat supporting frame of small dimensions. The disadvantage is the need to use a welding machine to connect individual elements, which requires knowledge and skills.

- Lumber. Cutting a square beam of wood with an edge length of 40-60 mm does not cause any difficulties even for a novice craftsman. Fixation of fragments and formation of knots are performed quickly with a minimal set of tools.

- Galvanized metal profile designed for creating plasterboard systems. Rigid, strong and durable strips simplify the installation of a frame system under acrylic and steel bathtubs. This material is used to construct screens. It is also possible to create supporting structures with its help.

When making a frame from lumber, it is easier to correct mistakes made during the work process. If it is necessary to purchase additional timber to redo defects, the costs are much lower than when replenishing the stock of metal products.

When using wooden elements, it is necessary to take into account the characteristics of wood as a material susceptible to decay. Before installation, you need to treat all parts with an antiseptic. Assembly is carried out using special corners or galvanized hardware. Master carpenters connect the elements with a notch.

Pipes made of metal profiles are also not resistant to the negative effects of dampness. Since the bathroom is a high humidity area, you need to consider protecting the material from corrosion. To do this, you can galvanize existing parts or buy new ones with a zinc coating. If it is not planned to finish the frame made of profiled pipes with decorative panels, painting with a powder composition will help protect the metal structure from rust.

Profiles made of aluminum or galvanized steel do not require additional processing. The material has anti-corrosion qualities. Subsequent sheathing with plasterboard sheets extends the service life of the frame by decades. PVC panels, mosaics or tiles are suitable for finishing.

Some craftsmen practice a combination of several materials. It is allowed to combine metal racks with wooden frames. Brick supports or foam concrete blocks are installed on the floors when it is necessary to raise the bathtub to improve the efficiency of water drainage.

How the shape of the bathtub affects the complexity of the frame structure

Structures are divided into the following types:

- Rectangular frame. Features a simplified installation diagram. It is used in the construction of a support system for containers installed in a niche or corner between adjacent walls.

- Triangular support. Mounted for additional stability of bathtubs with corner placement. The outer edge has a different configuration. The other two sides form the legs of a right triangle. In most cases, they are combined with the corners of the room. A frame of several connected frames is installed along the outer part of the structure.

- Oval. Complex structure, including a combination of 2-3 or more individual supports. It is built along the contour of the bathtub. It is allowed to use broken strapping technology.

Installation of a rectangular support system followed by finishing with plasterboard sheets makes it easier to arrange a frame for oval containers and non-standard plumbing fixtures. A hole is cut in the upper horizontal panel of the cladding material to the size of the bathtub. In this case, its sides should rest on the frame.

Assembling a factory kit for an acrylic bathtub

The factory package includes a prefabricated structure. It outperforms the homemade version in terms of the possibility of repeated dismantling and installation without damaging parts.

The assembly is performed according to the following algorithm:

- The welded frame is fixed to the bottom of the bath. The structural elements are laid out on the floor. The number and type of parts are checked against the list included with the kit.

- Vertical racks are installed. Studs with screwed nuts are inserted into the corner holes of the frame and screwed into the plastic legs. A small gap left during fastening between the frame and the supports will allow you to set the required height of the frame structure.

- The design is horizontally adjustable. The procedure is carried out at a building level.

- The frame is connected to the bathtub with self-tapping screws. First, a reinforced plate is fixed on the bottom of the container. After this, the embedded fragments located in the corners are fixed.

- Legs are mounted on the frame. Fastening is done with studs that are screwed into special holes. Use a ruler or tape to adjust the required height. Nuts are used for effective fixation.

- At the final stage, the bath is turned over to its original position and moved to the installation site. Areas for fixation are marked on the wall. The factory package of the acrylic bathtub includes several fastening plates that secure its sides. For plumbing products of standard shape, there are 4 clamps in length and 2 in width.

In some cases, the finished structure is supplemented with homemade elements that increase the stability of the support. To create a reinforced frame, an additional stand is constructed from large-sized timber, brick or foam concrete blocks.

DIY metal profile frame

Installation of a metal profile frame for plasterboard.

The profile used when installing plasterboard systems is suitable for self-manufacturing a frame device for a bathtub.

Equipment preparation and marking

The preparatory stage includes the following steps:

- the container is turned upside down;

- profiles to which the legs are screwed are fixed with self-tapping screws on the plywood-reinforced bottom;

- The drain and overflow system is being installed.

Upon completion of the preparatory work, the bath is brought into the room where the installation area is marked. To do this, the outline of the equipment is drawn on the floor.

The next step is to adjust the height by twisting the legs. For horizontal orientation, a laser level is used.

The final stage of preparatory work is marking the area of the frame wall mounts. To do this, mark a line on the wall corresponding to the location of the lower edge of the bathtub.

Frame installation

To perform the installation correctly, you must adhere to the following algorithm:

- holes are cut in the profile sections for subsequent fixation;

- According to the marks, dowels are inserted into partitions made of brick and concrete, onto which metal slats are fastened with self-tapping screws;

- installation of side support strips is carried out;

- After treating the outer shelves of the profiles with sealant, the bathtub is installed and connected to the communications.

At the next stage, supports are created for the bottom. They are laid out of brick, cinder block or foam concrete using cement mortar. In this case, the bottom of the container should not come into contact with the masonry. Polyurethane foam fills the gap. After the composition has hardened, the installation of the frame is completed and a decorative screen made of plasterboard sheets is installed.

Instructions for arranging a frame made of wooden blocks

The technology is similar to the previous version.

The differences are due to the characteristics of the material:

- the preparatory stage consists of treating the lumber with an antiseptic or oil impregnation;

- during the preparation process, the walls are leveled and primed;

- horizontal bars are fixed on vertical supports, increasing the rigidity of the structure.

The final stage of installation is treating the wood with a waterproofing agent. The walls adjacent to the bathroom are coated with the same composition. If used for tile cladding, additional waterproofing is not required.

Homemade welded frame

The welded structure is made from a metal profiled pipe of rectangular cross-section. It is used when it is necessary to construct a support of increased strength.

Manufacturing technology:

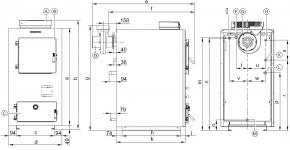

- a frame drawing is drawn up corresponding to the dimensions and configuration of the bathtub;

- Profile sections are prepared according to sketch dimensions;

- the base of the structure is formed from 3 support pipes with 2 horizontal guides by welding;

- according to the markings, adjustable legs are welded to the profile sections in designated areas to adjust the bathtub horizontally and vertically;

- on the supporting base, vertical posts are fixed by welding, on which horizontal supports for the sides of the bathtub are fixed;

- if you plan to install a screen, front profiles are welded to the outer part of the structure;

- After leveling the frame, the bathtub is installed.

Covering with decorative panels is carried out after checking the operation of the drain-overflow system. Polyurethane or silicone sealant is used to glue the bathtub to the frame structure. Sealing is also required in the area where the edge meets the wall.

How to do a frameless installation yourself

Simplified installation technology allows you to complete the job without turning to a plumber for help.

Preparation

Frameless bathtub installation.The first stage is turning the bowl over. The factory package of the acrylic bathtub includes metal slats. They are fixed horizontally across the bottom with self-tapping screws from the same set. By using longer hardware, you can pierce through a plumbing fixture.

Using nuts, legs, pre-adjusted in height, are installed on the transverse profiles. The inlet pipe of the sewer drain should be located below the siphon outlet.

If you plan to install a decorative screen that hides communications, a guide is fixed on the side to secure it. It is difficult to perform this procedure after the installation is complete.

The last stage of preparation is assembling and connecting the drain-overflow system.

Bath installation

For correct installation you need to follow the algorithm:

- in the bathroom the bathtub is connected to communications;

- diagnostics of the drainage and tightness of the drain pipe is carried out;

- the gap between the side and the wall is filled with sealant;

- the bath is weighted with water or several sandbags;

- a support cushion of brick or cinder block fixed with cement mortar is constructed under the bottom;

- the gap between the body and the masonry is filled with polyurethane foam.

A filled bathtub will not be able to rise due to the expanding foam that fills the intermediate surface, securing the support.

After the time required for the liquid compounds used in the frameless installation of the acrylic bath to harden, you can begin finishing. Most craftsmen install a screen made of plasterboard sheets, plastic panels or other materials with increased moisture resistance on the outside.

In many homes, a bathtub is a must-have element. For attractiveness and durability, a frame is used for the product. You can either buy it or make it yourself. More details about the bathroom frame are described in the article.

Why is it needed?

Bathtubs are made of stone, wood, copper, silver and gold. But the most popular products are steel and cast iron coated with enamel or acrylic. To make the interior of the room have a certain style and make the room comfortable, you can use a bathroom frame. This structure holds the bowl and sides. Why do you need a frame for an acrylic bathtub? If it is durable and suitable for the bathroom, then the fastening will be reliable and stable.

The frame is needed when purchasing a product of the original shape:

- Multifaceted.

- Round.

- Oval.

Products of unusual shapes cannot be fixed on walls. A frame in the form of a platform is required. The wide sides of the product are attached to the frame, so that it will be installed stable.

Advantages and disadvantages

Bath frames have their advantages and disadvantages. The advantages include:

- Guaranteed stability of the product installation. Support is needed for both acrylic bathtubs and cast iron and aluminum ones.

- You can choose any frame for an acrylic bathtub or other plumbing fixtures, since the structure is made of bricks, metal or wood, but in the latter case treatment with protective agents is required.

- The space under the bathroom is closed, which spoils the appearance of the room. The outside of the structure can be finished with tiles or other materials.

The disadvantages include a significant mass, especially if bricks are used. Then the load on the floor increases, so before work you should check whether the additional weight will be supported. The disadvantages include the difficulty of working independently. To do this, you should perform calculations in advance and select materials.

If wooden slats are used, you should check that they are properly dried. Before use, they are coated with an antiseptic to protect them from rotting. If metal slats are purchased, they should be protected from corrosion by applying a special compound. With treatment, the product will last much longer.

Design

The product consists of the following parts:

- The base of the frame is a wooden beam that follows the shape of the bathtub.

- Vertical elements are called racks. Rarely, if there are installation inconveniences, there is a need to attach braces.

- There is an upper belt that protects against load transfer through the racks to the base. This is also necessary for spatial rigidity.

- There is a sheet of chipboard with a hole that coincides along the contour with the vertical surface of the bowl. The tolerance is made to the larger side. This element is used for rectangular bathtubs.

- All parts are attached to each other.

Materials

A reinforced bathtub frame is a reliable way to secure the product so that it does not wobble or slide during use. There are universal designs in stores, but they cannot be used for all models, especially since without adjustment they do not perform their functions. It is much easier to create a support yourself. The following materials are used for this:

- Wooden beam. Wood is considered an environmentally friendly, lightweight, durable material. You don't need a special tool to work with it. Assembly and installation can be easily done by yourself. This option is the most economical. The only drawback is considered to be low resistance to moisture and fungus. To prevent the frame from rotting during operation, the timber is repeatedly treated with an antiseptic.

- Metal profile. It has low strength and load-bearing capacity, therefore it is used for the manufacture of auxiliary support products and installation of decorative plasterboard taps.

- or metal corners. According to experienced craftsmen, this is the most reliable frame. Depending on the thickness of the pipes, it can withstand heavy loads, so they are able to support heavy bathtubs.

If profiled pipes are selected, welding is required. Although an all-welded product is the most durable, it is still easier for an inexperienced craftsman to work with timber, which only requires a hammer and a saw. The frame for an acrylic bathtub is created from the specified materials. The product will serve as a reliable support.

Are there any differences between the frames?

The installation rules are almost the same for different baths:

- Cast iron.

- Steel.

- Acrylics.

To fasten a steel or cast iron bathtub, you can use legs or attach it to the walls using an iron corner. The most solid support is considered to be made of bricks, which is covered with a ready-made or homemade screen.

Acrylic products need stable support to protect them from load and deformation. This bathtub has an elastic bottom, but it is not strong compared to other materials, so it can sag. Moreover, the sides are constantly deformed, which will lead to moisture getting into the joints between the bathroom and the walls. There will be mold and other negative consequences. Therefore, a frame for a bathtub is desirable to extend its service life. And its necessity arises when the thickness of the product is no more than 0.5 mm.

Kinds

Stores offer frames for certain bathtubs that are on sale. But not all support products can withstand the weight of the bathtub. Therefore, it is important to choose a suitable frame. Support products are:

- Prefabricated.

- Whole-welded.

If there is no suitable model in the store, then you can create a frame for an acrylic bathtub or other product with your own hands. Wood, galvanized profile or profile iron pipe are suitable for this.

It is necessary to take into account the ratio of strength and quality of the bathroom, as well as the number of support points for the frame. It is believed that the thinner the bathtub, the better support it needs. A fully welded product indicates a lack of strength. It is desirable to have 4 points. If the font has an unusual design, then a special platform is needed, since a standard frame will be unreliable.

Device

The frame frames that come with the bathtub are made of square-section metal profiles and have a special coating. The main frame details include:

- Supports that hold the bowl in the corners.

- Legs with adjustable height.

- which an acrylic bathtub must have.

How to do

If the finished product is not suitable or it is unreliable, then you can make it yourself. How to make a frame for a bathroom? At home, you can create a product from wood, moisture-resistant plywood or chipboard. The procedure is as follows:

- Create a base around the perimeter of the bathtub from timber.

- Attach vertical posts to it.

- Boards or timber are laid on them - they serve as a top.

For a rectangular bathtub this is enough; if it is, for example, oval, then the frame is covered with a sheet of chipboard or plywood, in which a hole of the required shape is then cut out.

Assembly

How to assemble a frame for a bathroom? Before installing a wooden product, you need to determine the height of the racks, which depends on the height of the frame. It should be small so that the bath is comfortable for the whole family. It is not difficult to determine the number of racks: they should be in each corner and additionally fastened every half meter at the sides.

A building level should be used to help. Installation is as follows:

- Self-tapping screws with anti-corrosion coating should be used to attach the wooden base to the concrete floor.

- Secure the posts to the base with metal corners or wooden blocks.

- If the stand is attached to the wall, it is also attached to it.

- The timber should be laid on top of the racks and secured with screws to the walls and racks.

- A sheet of 15 mm plywood or 25 mm chipboard is attached on top around the perimeter.

- Using a template that is included in the kit, or a pattern, a hole is created with a saw or electric jigsaw.

- The frame must be covered on the sides with shields.

Installation

It is more convenient to install the bathtub after finishing decorating the surfaces with different materials:

- Drywall.

- Plastic.

- Tiled.

The choice of material depends on the material capabilities and taste preferences of the owner. A cement pad is poured onto the bottom of the frame and the bath is immediately placed on it. Installation will be more difficult if there is no cladding:

- You should place plywood or wood pads under the sides that are suitable for the thickness of the tiles and the adhesive layer.

- The spacers are evenly distributed around the perimeter.

- The bathtub should be lowered into the hole onto a cement base.

After the solution has hardened, plumbing work should be carried out: connecting to the water supply and sewerage. This completes the installation of the frame and bathtub.

The shape, size and configuration of acrylic bathtubs can be very different - there are no longer any restrictions in the production of bathtubs. Acrylic plumbing is attractive due to its price and ease of maintenance, but its main drawback is its softness and flexibility. In addition to the bowl itself, you will have to purchase or make your own frame for the acrylic bathtub. This is the only way you can be sure that the bowl is stable, and the bottom and sides will not bend under the weight of the swimmer and will not break.

The frame is an additional structure that redistributes the load and protects the bowl of the acrylic bathtub from deformation. In addition, the base serves for installation and fixation of plumbing fixtures. Acrylic bathtubs very often have a complex asymmetrical shape. Correctly calculating and choosing the right frame is not so easy. When purchasing a bathtub in a store, the seller will most likely offer a suitable model from those available.

The frame makes the bathtub rigid

Types of supporting structures

It is important to know what types of bathtub frames there are, to take into account their advantages and disadvantages. The assortment in stores is quite large.

The simplest and most popular type is an ordinary stand with legs. It is made from a metal profile. Most often, rectangular or U-shaped pipes are used. The stand consists of several individual elements that support the bowl.

The set also includes legs. Their height is adjustable. This allows you to level the bath exactly, even if the floor in the bathroom is uneven. The disadvantage of this type of design is that the frame takes the load only from the bottom of the bath, and there is no support for the sides of the bowl.

Flat frame with legs

This type is more complex and durable than the previous one. The bottom of the bathtub rests on a flat frame made of metal profile. The shape of the stand matches the bottom of the bowl. Transverse ribs add rigidity. The design contains additional vertical elements. They support the sides of the bowl at several points.

The stand is often sold unassembled. Connecting all the elements of the metal profile using bolts is not difficult. This type of frame is best used for bathtubs of complex shapes and corner bowls.

The spatial all-welded bathtub frame is the most durable structure offered by manufacturers. It is a complex three-dimensional structure that securely holds the bowl. Such a base has several support points and distributes the load both from the bottom of the bowl and from its sides. Stiffening ribs are located in areas of greatest load. Thus, the weight is completely distributed over the metal parts of the structure.

Base for corner model

How to choose the right model for a specific bowl

When choosing a frame for an acrylic bathtub, you need to take into account its size, configuration, and wall thickness. Of course, a product made from a thick layer of reinforced acrylic more than 5 mm can withstand a significantly greater load than an inexpensive item with 1 mm walls. The thinner the bathtub, the greater the need to strengthen it with additional supporting structures.

If you purchased a traditional-shaped bathtub, then there will be no problems. You can buy a universal rectangular frame for a rectangular bathtub or a pentagonal frame for a corner one. The only thing you have to take into account is the dimensions of the bowl. As a rule, stores have a wide selection of simple frames, which differ in the country of origin and the thickness of the metal. The choice in this case depends on the financial capabilities and desires of the buyer.

Universal design option

If the acrylic bathtub has a complex shape, you plan to install hydromassage and other accessories that weaken the structure and make the bowl heavier, then you won’t be able to get by with a universal model. This can be a reinforced frame or a whole metal platform.

In addition to the shape and strength of the structure, you need to pay attention to the material from which it is made. High-quality products are made of metal of sufficient thickness. The frame will be placed in the bathroom - a room with high humidity, so the manufacturer is obliged to take care of anti-corrosion protection.

If you cannot find a stand in the store that is suitable for your bathtub model, you will have to consider alternative installation options.

Algorithm for installing a bathtub on a finished frame

Once the bathtub and a suitable frame have been purchased, installation can begin. Any self-respecting manufacturer will supply a finished bathtub frame with assembly instructions, as well as all the necessary fasteners.

Installation of an acrylic bathtub is carried out in the following order:

- Unpack the stand, check the package contents with the declared one. Arrange all the elements according to the order of assembly according to the instructions. For high-quality installation you will have to use a drill and a screwdriver or screwdriver.

- Some base options require attachment to a bowl. Figure out in advance at what stage of the assembly it will be easier to do this. It is more convenient to turn the bathtub upside down and put the frame on top.

- You can screw the fasteners into the acrylic bowl only if there is a drill depth limiter. The diameter of the holes and the required drilling depth are indicated in the instructions. It is not recommended to screw fasteners into acrylic without preparing the holes. Brittle material may not withstand stress and crack.

- The next step is to directly install the frame in place. At this stage you need to fix the bath. The bowl is installed in the base, the entire structure is leveled using a building level. The height of the legs is adjustable.

- The final stage is the installation of a siphon and mixer.

The instructions indicate the sequence of actions

Assembling a bathtub base with your own hands

Bathtub frames offered by manufacturers do not always satisfy consumers. And it's not just about the price. Often the frame is designed to withstand loads during moderate use, but is not tested under critical loads. Therefore, industrially produced products seem to be insufficiently strong and stable. If you want a frame “with reserve” and so that it will serve for a long time, it makes sense to make it yourself.

Wooden construction - cheap and simple

The simplest and most inexpensive option for a homemade bathtub stand is a wooden frame. To make it you will need a wooden beam with a cross section of 40×40 mm and a sheet of plasterboard. Take care of a set of tools for working with wood: hammer, drill, wood drill, hacksaw, screwdriver or screwdriver. In addition, the wood will need to be treated with a special impregnation to protect it from moisture.

DIY wooden structure

- Take measurements and cut the material. Please note that the upper and lower belts of the frame repeat the shape of the upper part of the bathtub. Vertical racks are calculated so that the distance between the nearest supports does not exceed 50 cm. In addition, there should also be vertical racks in the places where the bathtub is attached to the wall.

- First of all, assemble the stand under the bottom of the bathtub. It is a flat frame with several stiffeners. It is not necessary to use only wood; the bottom can also be fixed to bricks. The main thing is to ensure stability of the bowl.

- When the lower belt is ready, you can begin installing the upper one. To do this, a beam is screwed to the wall along the perimeter of the bathtub. The frame is designed so that after installing the bowl, the outer side of the screen is flush with the outer edge of the bathtub.

- Now you can start installing the vertical elements. The corner posts are installed first. The rest are distributed evenly along the length of the bathtub frame. The racks need to be fastened perpendicularly; for this you can use metal corners.

The main part of the structure is ready

- Before covering with drywall, all communications must be installed. Don't forget that water pipes tend to break down and leak. That is why it is unacceptable to tightly close access to the wiring. You can make a secret window that will be invisible after finishing work is completed.

- You can purchase a ready-made plastic bath screen or use drywall. The latter option involves subsequent covering of the screen with tiles or other finishing.

A reliable option is a metal holder

Another popular material for making a frame for an acrylic bathtub with your own hands is a metal profile. There can be several profile options: square pipe, U-shaped section, corner. The algorithm by which a metal frame is erected is practically no different from the procedure for installing a wooden structure. A few points to consider:

- The metal profiles must be connected to each other by welding (which is difficult to do at home) or by bolting.

You will need a screwdriver to connect.

- The edges of the metal parts are sharp and may damage the bowl. There is no need to place the bathtub on the frame for “try-on” until all the raw edges are covered.

- The bottom of the bathtub should rest on the base of the frame in several places. To distribute the weight evenly, it is better to build a platform under the bathtub made of bricks, boards, sand or foam.

- To prevent the bowl from wobbling, some craftsmen recommend making a layer of rubber for shock absorption. To eliminate gaps between the bathtub and the floor, it is convenient to use polyurethane foam.

Metal withstands high loads

An alternative method is to install the bathtub on bricks

The most reliable frame for an acrylic bathtub can be built from ordinary brick. Do not worry that the brick base will begin to deform or lose strength under the influence of moisture. The structure of a brick stand is fundamentally different from structures made of wood or metal.

In this case, installation is reduced to the construction of two brick supports at a distance of 50-60 cm from each other. The width of the supporting structure should not be larger than the bathtub itself. The supports are laid out so as to repeat the shape of the bottom of the bowl as much as possible.

Bathtub on brick supports

The part of the structure that is located on the drain side should be 1.5-2 cm lower. This ensures water flow. Make sure that the side of the bowl remains strictly horizontal. The slope is set by the manufacturer during the production of the bathtub.

When the supports are ready, you can begin installing the bowl. In order to firmly fix the bathtub, it is screwed to the wall. This can only be done with pre-drilled holes so as not to damage the acrylic. The gap between the brickwork and the bottom is filled with tile adhesive or polyurethane foam.

The quality of installation of an acrylic bathtub cannot be neglected. Its service life and your safety depend on this. Make the frame yourself or purchase a ready-made one – it’s up to you. If you are not satisfied with the choice in stores, and you have neither the time nor the opportunity to arrange the arrangement yourself, you can turn to an experienced craftsman for help.