What kind of concrete is needed for the foundation of a house. Composition and proportions of concrete for the foundation How to properly prepare a concrete solution for the foundation

Concrete comes in various grades, which are classified depending on its strength, such as M100, M150, M200, M300, etc. Both the composition and the proportions of its components largely depend on the brand of concrete.

Honestly, if you use purchased concrete, then you don’t have to worry about its composition and proportions. You only need to name the brand of concrete, the fraction of crushed stone used in it and the address where it should be delivered, and the manufacturer, in turn, is obliged to take into account your wishes and prepare the concrete mixture strictly following the technology.

What determines the composition of concrete for the foundation?

It is not always possible to order ready-made concrete due to various difficulties. In this case, you will have to prepare the concrete for the foundation yourself, and in order to prepare a high-quality mixture, you must strictly observe the proportions of all components.

So what should be the composition of concrete for the foundation in order to give it maximum strength and reliability throughout the entire life of the building?

It is impossible to answer this question unequivocally, because much depends on the components used, the type of foundation, its area of application, soil moisture, and many other factors.

We have already talked about how to pour a foundation and save on it, and we will not repeat ourselves; today we will look at the components that make up concrete, as well as their exact proportions.

The main components that make up concrete

Generally, good quality concrete should contain the following components:

1. Cement

2. Sand (river or washed)

3. Crushed stone (gravel)

4. Water

5. Various additives

The main connecting link in concrete is cement. With the help of water, he binds individual grains of sand into a single creamy mass - a solution. Cement comes in various types and brands, the most popular are M400 and M500, which will be discussed further. Also on sale are the M200 and M300 brands, but they are rarely used in private construction.

The main connecting link in concrete is cement. With the help of water, he binds individual grains of sand into a single creamy mass - a solution. Cement comes in various types and brands, the most popular are M400 and M500, which will be discussed further. Also on sale are the M200 and M300 brands, but they are rarely used in private construction.

The next component is sand. It, as already mentioned, is necessary to dilute the cement and obtain a solution. The sand used should not contain various impurities, vegetation and foreign objects. Therefore, it is advisable to use “washed” sand or river sand. The most common impurity in sand is clay or lime. If there are lumps or stones in the sand, it must be sifted.

The next component is sand. It, as already mentioned, is necessary to dilute the cement and obtain a solution. The sand used should not contain various impurities, vegetation and foreign objects. Therefore, it is advisable to use “washed” sand or river sand. The most common impurity in sand is clay or lime. If there are lumps or stones in the sand, it must be sifted.

An admixture in sand, such as clay, for example, will not allow the laid concrete to fully shrink before its initial hardening. Thus, the already relatively hard concrete will continue to shrink, causing it to develop cracks.

Crushed stone, or as it is called, gravel is the main component that is part of the concrete for the foundation and is its basis. In other words, crushed stone is to concrete as a brick is to a brick wall. It comes in different fractions (size of one stone) from 5 mm, depending on the purpose of the future concrete structure. The average size of the fraction used in foundation concrete is (5 – 10) mm or (10 – 20) mm.

Crushed stone, or as it is called, gravel is the main component that is part of the concrete for the foundation and is its basis. In other words, crushed stone is to concrete as a brick is to a brick wall. It comes in different fractions (size of one stone) from 5 mm, depending on the purpose of the future concrete structure. The average size of the fraction used in foundation concrete is (5 – 10) mm or (10 – 20) mm.

Often crushed stone in concrete is replaced by other components, such as expanded clay, slag, etc., but such concrete is not used for foundations, so we will not consider them.

Water– an irreplaceable component; not a single construction project can take place without it. Water is the element with which all other dry components are mixed. Water also participates in the hardening process of concrete, so it must also be added, observing the proportions. It is necessary to stock up on water in advance, because during pouring, there simply will not be enough time to carry it from outside the construction site.

Water– an irreplaceable component; not a single construction project can take place without it. Water is the element with which all other dry components are mixed. Water also participates in the hardening process of concrete, so it must also be added, observing the proportions. It is necessary to stock up on water in advance, because during pouring, there simply will not be enough time to carry it from outside the construction site.

Various additives are used in concrete to improve its characteristics, both during curing and in the final stage. In other words, if, for example, you need a deep strip foundation, then frost-resistant additives are added to the concrete; if you need to obtain a plastic concrete mass, then various plasticizers are added. Additives can also be used to accelerate hardening, to increase final strength, and many others.

Various additives are used in concrete to improve its characteristics, both during curing and in the final stage. In other words, if, for example, you need a deep strip foundation, then frost-resistant additives are added to the concrete; if you need to obtain a plastic concrete mass, then various plasticizers are added. Additives can also be used to accelerate hardening, to increase final strength, and many others.

Proportions of components in concrete

We have already figured out what is included in concrete, now let's talk about what proportions of components to use, how to mix it all correctly and in what way.

Almost always, when talking about the proportions of concrete, we mean the ratio of one volume of cement to a certain amount of the same volumes of sand, crushed stone and water.

First of all, as I already said, the proportions of the components directly depend on the brand of concrete required. The brand of cement itself also plays an important role.

First, let's look at the proportions of components for Portland cement brand M400, since it is the most popular:

In the process of preparing concrete for the foundation, there is no need to use high-precision scales and measuring cups; it is enough to measure volumes with ordinary metal buckets, for example, 10-liter ones.

| Concrete grade | M100 | M150 | M200 | M250 | M300 | M400 |

| Water volume, l | 11 | 10 | 9 | 7,5 | 6,5 | 5 |

The amount of water added depends not only on the proportions of the other components and the brand of concrete, but also on how wet the sand and crushed stone is on your site. The table shows the approximate volume of water per 1 volume of cement. But it is possible to determine exactly how much water per volume of cement only experimentally.

As a rule, in practice, pouring concrete for a foundation in normal soil such precise calculations are not used, but average proportions are taken - 1 bucket of cement, 3 buckets of sand, 4 - 4.5 buckets of crushed stone and about 1 bucket of water.

- Since the foundation must be monolined, it must be remembered that 2 people manually, using a concrete mixer, can prepare and pour a maximum of 2-3 m 3 of concrete per day. It is advisable to foresee this and find the required number of assistants in advance.

- It is better to mix concrete using mechanical or electric mixers. Mixing the concrete mixture well with a shovel in the bathtub will not work.

- When using a concrete mixer, it is not always convenient to mix the dry mixture first and then add water. This approach threatens sand “sticking” to the back wall of the mixer. It is best to first pour most of the necessary water, then cement, and then sand and crushed stone.

- Naturally, M400 concrete will be much stronger than M100, but a foundation made from such concrete will also be much more expensive. Therefore, there is no need to immediately chase the strongest one; in most cases, M200 with a good reinforcement frame may be suitable.

- If you are pouring concrete at sub-zero temperatures, then I advise you to read my article on this topic. Properly arrange concrete heating and insulation.

- Concrete that is too liquid for a foundation levels well and is more convenient to work with in some cases, but too much water in the concrete will have a detrimental effect on its structure and final strength. Too little water and there will be enormous difficulties in leveling and moving the concrete. Therefore, always stick to average viscosity values.

- To construct a conventional strip foundation on good soil, you can use concrete of about M200 grade, but for a strip foundation that is not buried, high-strength concrete is used.

Concrete- an important component of any construction. The operational characteristics of the structure being built largely depend on the foundation. Therefore, it is very important to properly prepare the solution for pouring it. Concrete mortar for large-scale construction projects is prepared in a factory.

Private developers, when building a house with their own hands, usually prepare it themselves in order to at least slightly reduce construction costs. Having chosen to prepare it yourself, it is important to observe the proportions for the concrete for the foundation. After all, the strength of the foundation of the house often depends on this.

Choice

The foundation is the load-bearing part of any building. To make it resistant to various loads, you need to choose the right concrete composition for it. In this case, its resistance to compressive loads will be sufficient, which means it can withstand the pressure of the entire house. Various are produced, therefore there are several composition options. Which one to choose for pouring the foundation? This question must be answered taking into account two factors:

- Features of the structure (number of floors, weight, size of the basement).

- Features of the soil on the site.

The choice of composition taking into account the first factor is made as follows:

- M 150 is used for pouring foundations for frame and panel buildings.

- For light houses made of logs and timber, M 200 is selected.

- M 300 for block and brick buildings.

The dependence on the characteristics of the site is as follows. The more complex the soil on the site, the higher the grade of concrete you need to choose. So, for rocky soil it is enough to prepare a solution of M 150. For loamy soil, the composition M 200 is suitable.

Components

Any concrete, regardless of its brand, consists of the following components:

- Cement.

- Sand.

- Crushed stones or gravel.

- Water.

All these components must have the necessary characteristics, taking into account which they must be selected. Cement is the main ingredient in a concrete mixture because it is a binder. It is produced by cement factories. Cement is divided by grade and by the number of various additives it contains. The most popular Portland cement, it contains many special additives to improve the properties of the material. When pouring the foundation of a house, experts recommend that private developers use cement M 400 or PC 400.

You need to keep in mind, like many building mixtures, the shelf life of cement is limited. After a year of storage in packaging, it significantly loses its activity, which determines the properties and brand of the material.

Sand is one of the fillers for concrete mixtures. To obtain a high-quality solution, you need to take its choice seriously. It is worth noting that at the moment the choice of sand on the construction market is huge. If you wish, you can even purchase sand from the seabed, but not every sand material is suitable for concrete.

Thus, experts do not recommend using sand with clay admixtures for this purpose. Because of this, concrete is less durable and frost-resistant. But with river sand you can prepare a solution that is ideal in condition. It is often of very high quality and consists of homogeneous fractions.

and gravel just like sand in the solution acts as fillers. Thanks to them, the solution “shrinks” less, which makes the concrete structure stronger and more durable. When choosing crushed stone, you should pay attention to its shape. Because the convenience of pouring concrete mortar depends on it.

Flat and angular crushed stone is usually not used for mixing concrete. Because it requires more consumption of other components, which affects the strength of the structure. The best option for pouring the foundation is the use of crushed gravel. It consists of particles ranging in size from 3 to 70 mm. In addition, it is affordable for private developers.

Water. This component can have any characteristics, the main thing is that the water is clean without any impurities. Having all the above components and knowing the proportions of concrete for the foundation, you can prepare a solution of any required brand.

Video

Video on how to make concrete, as well as proportions in buckets.

Component proportions

The correct ratio of components in a concrete solution is the key to obtaining high-quality material. The optimal composition of concrete for the foundation for the construction of a private house is considered to be one part cement powder to four parts crushed stone (1/4). And in the proportion of cement and sand, the ratio is 1/3, that is, for 1 part of cement (M 400) there are 3 parts of sand. In general, the weight of cement in the cement mortar should be 1/4 of the total mass.

But concrete still needs water to harden. An important characteristic of concrete is the proportion of water and cement (the so-called water-cement ratio). The strength of concrete depends on this ratio: the lower its value, the stronger the material. For a concrete mixture used for concreting foundations, the maximum water-cement value is 0.75.

For private developers, for a small amount of work, it is easier to mix the mortar on the construction site. One batch of foundation mortar is made in a concrete mixer in approximately the following proportion:

- 300 kg of cement powder.

- 600 kg of sand.

- 1300 kg of crushed stone.

But the developer does not have the ability to weigh bulk materials when he is at the construction site. A completely reasonable question arises: how to make a foundation mortar correctly. To do this, you need to know the proportions of concrete for the foundation in buckets. Since all components have approximately the same bulk density, you can measure them and then the composition of the concrete for the foundation, the proportions in buckets will be something like this:

- Cement 25 buckets.

- Sand 43 buckets.

- Crushed stone 90 buckets.

When determining the amount of water, they are guided by the measure of cement: for one bucket of cement powder you need to add an incomplete bucket of water. This volume may vary depending on the situation. For example, if it is reinforced, then the concrete is mixed with more plasticity so that it penetrates inside the frame more easily.

It is more practical to make it rigid, this will speed up the hardening. In both cases, you need to add enough water so that there are no puddles in the finished solution. To obtain one cube of concrete of different grades, the optimal ratio of components in volumetric terms is presented in the table.

| concrete grade | cement M 400 | sand | crushed stone |

| M 150 | 1 bucket | 3 buckets | 5 buckets |

| M 200 | 1 bucket | 2.5 buckets | 4 buckets |

| M 300 | 1 bucket | 1.7 buckets | 3 buckets |

In these volumetric indicators, the bucket can be replaced by any volume measure, provided that the proportion is maintained.

When deciding how to prepare concrete for the foundation, you need to keep in mind that in addition to the proportions, you need to know in what sequence to lay the components. First, water is poured into the concrete mixer, slightly less than normal. Then half a portion of crushed stone is poured. And only then, cement with sand and again all components are thoroughly mixed.

At the very end, the remaining crushed stone is poured. After this, you need to give the concrete mixer a little time so that it thoroughly mixes all the components. And finally, having assessed the thickness of the solution, depending on the situation, add the rest of the water or leave it as is and mix everything thoroughly again.

Conclusion

After the foundation casting has reached the calculated hardness, to get rid of doubts about the correctness You can check the proportions and grade of concrete. To do this, place the chisel on the surface of the casting and hit it with a hammer. On ordinary concrete M 200 there should be a dent no more than 5 mm deep.

In contact with

When starting any construction, we want the constructed building to be strong and reliable, and for this it is necessary, first of all, to make a high-quality and durable foundation. It is pointless to build high and strong walls if, when laying the foundation, you do not provide the required quality and proportions of the concrete solution. And given the considerable weight of the building and the load, for the foundation they become a “golden key”, which opens up the opportunity to build up the walls of the building, regardless of weather factors, alterations and modifications, if the structure is installed on a powerful and durable foundation.

Types of foundations

Depending on the weight of the building being erected and the type of soil on which construction is being carried out, the type of foundation is selected:

- Tape - performed along the perimeter of the building under the main load-bearing walls of the structure;

- Slab - poured with a continuous slab covering the entire area of the building, the most expensive option in terms of materials and labor intensity;

- Columnar - used mainly for small structures, outbuildings, gazebos and other options that do not have much weight;

- Ribbon-column– is a combination of elements of both a columnar and strip foundation; in terms of material costs it will be cheaper than a strip foundation.

Important! The concrete mixture often behaves in the most unpredictable ways when poured and hardened, so the best way to get a high-quality foundation structure is to pour the formwork in one go.

In this case, the shrinkage of the material will be more or less uniform, even if the proportions of ingredients spent on concrete for the foundation with your own hands were not maintained exactly.

Composition of concrete for foundation mixing proportions

It is not always worthwhile to strive to obtain a foundation of the highest strength and rigidity. In some cases, this approach is a waste of money, and sometimes such a decision directly contradicts the requirements for the foundation system of a particular building.

To make it easier to navigate the different proportions of preparing concrete mixtures, an index or grade is assigned to a specific concrete composition to characterize the strength and rigidity. M150 concrete is used for concreting minor objects, for example, you can make supports for a fence or the foundation of a light frame building. Brand M200-250 is widely used for the foundation of most private houses, one-story buildings with low load on the ground. M300 - suitable for two-story brick houses, M-400 is used in industrial construction.

Requirements for concrete for foundation

To prepare concrete of any grade, the same ingredients are used:

- Cement is the main active element of a concrete mixture; it acts as a binder and holds together all other components into a single whole;

- Sand is a filler that fills voids and acts as a cheaper cement substitute;

- Gravel or crushed stone– it is better to use fractions with sizes from 1 to 5 cm, preferably a material with a rough surface, it helps to increase the strength of concrete;

- Water – pure drinking water is used, not containing any impurities or additives.

Important! Please note that cement, like food, has its own expiration date. After just a year of storage in packaged form, the strength of cement in finished concrete decreases by 20-25%. Moreover, the decrease in characteristics occurs unevenly, in different packages in different ways, even within the same batch.

Typically, cement grades M400 and M500 are used in construction work.

The sand for preparing concrete must be clean; you can use river or quarry sand; you must check that it does not contain clay impurities, as this will negatively affect the strength of the foundation.

To check the purity of the sand you are going to use, pour some sand into a clear bottle, add water and shake. Then evaluate the clarity of the water in the bottle. If the water is clear or slightly cloudy, this sand can be used to prepare a concrete solution for pouring foundation structures. If the water in the bottle is cloudy or colored, the sand will have to be rinsed or replaced.

In addition, the sand used to build the foundation must be sifted before mixing the concrete mixture. No plant debris, twigs, leftover leaves, or pieces of soil should get into the concrete foundation solution. All these plant inclusions negatively affect the quality of the poured foundation.

Crushed stone or gravel used in concrete for the foundation must also be clean, without soil or organic matter. Before mixing the mixture, you can rinse the gravel with clean water to ensure its cleanliness.

To mix the concrete solution, use only clean water. To avoid problems with the strength of the foundation system later, water from ponds and lakes, especially sea water, should not be added to concrete. The water should not contain salt impurities or any organic residues.

What proportions to use

If you need to prepare concrete yourself, use the proportions given in the table. A construction site is not a store, and no one will weigh the ingredients, and the proportions must be maintained as accurately as possible. To maintain proportions, it is enough to use information about the volumetric ratio from the second column.

Two words about the cost of concrete for the foundation

The work of preparing concrete mortar for pouring the foundation has always been very difficult and quite monotonous. Even with a 100-liter electric mixer, pouring, for example, the foundation of a 6x6 house, 120 cm deep, will require at least 15 cubic meters of concrete. In this case, it is necessary to deliver almost a hundred 50-kilogram bags of cement to the construction site, maintain the proportions and mix the mixture.

If we take the price of the ingredients cement - 150 rubles per package, sand - 500 rubles and crushed stone -700 rubles per ton, in this case the cost of a cubic meter of concrete for the foundation according to the proportions of cement, sand and crushed stone 1-3-5 will be just over a thousand rubles. Purchasing concrete from a construction organization will cost at least 2 thousand rubles. The difference is 15 thousand for hard work and a guarantee of exact compliance with the proportions of concrete, and therefore the quality of the foundation.

For large volumes of foundation pouring, it is still better to buy a ready-made solution. The question of the quality and proportions of concrete remains open. It is possible to study the quality of a sample only in a laboratory; moreover, the design strength of the foundation casting occurs only after 28 days, so the issue of compliance with proportions can be objectively assessed at the level of indirect signs.

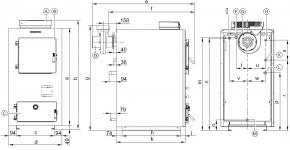

For example, you can determine the nature of the plasticity of a concrete solution using the method given below. To do this, you will need a small container, the dimensions of which are shown in the figure. It is enough to fill the form with concrete and turn it over onto a flat metal sheet. The quality of the material can be judged by the degree of spreading.

The second option is to check compliance with the proportions and grade of concrete after the foundation casting has reached the design strength and hardness. If you try to prick the surface of the sample by hitting a chisel with a hammer, a mark no more than 5 mm deep will remain on ordinary M200 concrete, subject to the proportions and quality of the cement.

Concrete is a building material unique in strength and durability, obtained by mixing and hardening several components. In terms of performance, it is practically not inferior to such natural stones as granite or marble, but, unlike them, it does not have a radiation background.

Concrete is widely used not only in construction work on arranging the foundation, but also for the production of piece goods, such as paving tiles, garden vases and figurines. To produce high-quality concrete, you need to follow the correct technology for its production, this is especially important when preparing the material yourself.

High-quality concrete looks solidBasic parameters of concrete

The main indicators of concrete quality are its grade and class. Its properties such as resistance to low temperatures, water resistance and ductility are considered secondary. To correctly select the parameters of concrete, you need to be guided by the principles of its classification. The class of concrete determines its resistance to loads, expressed in megapascals (MP), and shows its guaranteed strength. The grade of concrete shows its average strength and is expressed in kg/cm3. The main parameters of concrete are summarized in the table below.

| Summary characteristics of concrete | |||||

| Class | Brand | Strength, kg/cm2 | Waterproof | Frost resistance | Mobility |

| B7.5 | M100 | 98 | W2 | F50 | P2-P4 |

| AT 10 | M150 | 131 | |||

| AT 12 | M150 | 164 | |||

| B15 | M200 | 196 | W4 | F100 | |

| IN 20 | M250 | 262 | |||

| B22.5 | M300 | 295 | W6 | F200 | |

| B25 | M350 | 327 | W8 | ||

| B30 | M400 | 393 | W10 | F300 | |

| B35 | M450 | 458 | W8-14 | F200-300 | |

| B40 | M550 | 524 | W10-16 | P2-P5 | |

| B45 | M600 | 589 | W12-18 | F100-300 | |

Comment on the table:

- An important characteristic when constructing a foundation on freezing soils is the number of freezing and thawing cycles the concrete can withstand. It is designated by the letter F and characterizes the frost resistance of concrete; the higher the F value, the better.

- The resistance of concrete to penetration of water into its structure is designated by the letter W and characterizes its water resistance. W values can range from 2 to 20; the higher this number, the fewer microscopic cavities in the internal structure of the material that contribute to its destruction upon freezing.

- The convenience of laying concrete is characterized by its plasticity, which is designated by the letter P. The values of P can range from 1 to 5. The plasticity of a solution is a temporary characteristic showing its ability to fill the cavities of a building structure under the influence of its own weight. Mortars with high plasticity are used to fill hard-to-reach areas of the foundation.

Concrete mix components

To make concrete, you need cement, sand and crushed stone, pebbles, gravel and other fillers that increase its strength. Currently, to give the material unique properties, special additives called plasticizers are added to it.

To protect the main body of the foundation from subsidence and the aggressive effects of water, a substrate made of a solution of cement and sand is often used. Cement mortar without crushed stone and reinforcement is not very strong, but it is capable of performing protective functions.

When thinking about how to make concrete with your own hands correctly, you need to understand that its strength depends on the quality of the cement, sand and filler fraction, as well as on the purity of all its components.

The main component is high-quality cement

The binding component of all cement mortar ingredients is cement. Portland cement is famous for its excellent quality, containing up to 80% calcium silicate, which provides excellent adhesion to the treated base and has adhesive properties. The higher the grade of cement, the stronger the concrete will be. When arranging strip foundations of private houses, cement M 500 is often used.

High-quality cement is the basis of concrete

High-quality cement is the basis of concrete When using grade M 400, the service life of the constructed foundation is reduced. If construction work is carried out at subzero ambient temperatures, Portland cement is well suited, but at temperatures below 17 degrees it is necessary to add plasticizing additives. In extreme heat, Portland cement filled with slag is used.

The letter D on the cement marking indicates the amount of impurities in its composition, expressed as a percentage of its total volume. High-quality cement has no more than 20% impurities in its composition; it must be free-flowing and dry, and not have damp lumps in its mass. When purchasing cement, you need to pay attention to ensure that its packaging is undamaged and has a label with markings on it.

Choosing better sand

In addition to gravel or crushed stone filler, sand is necessarily used to prepare the mixture. It can be excluded from the mixture when the large aggregate can be compacted so that the gaps between the components are very small. Particles of high-quality sand should not differ greatly from each other in size and have a cross-section from one and a half to five millimeters. Vegetation roots, paper and other fragments in its composition that decompose and rot reduce the strength of the finished product, so before use the sand must be sifted through a sieve.

Sand also affects the strength of concrete

Sand also affects the strength of concrete River sand has good performance qualities; it does not contain clay inclusions, being a material mined in ravines. Clay inclusions in a concrete mixture reduce its ability to adhere to filler elements, but they are the ones that ensure the strength of the cast product. It is quite difficult to remove clay particles from sand; to do this, it needs to be soaked and settled, which is very labor-intensive and unprofitable, so it is better to use river sand, although it is more expensive.

In the areas where quarries are located, you can purchase artificially prepared sand from finely crushed stone, which has a large mass and density. If it is thoroughly sifted through a sieve, then its performance qualities will be superior to sand from the river. When using it, it is necessary to take into account that the weight of the finished product will be significantly higher than when using ordinary sand. Background radiation may also be increased.

We select crushed stone according to the purpose of concrete

The strength of concrete is given by the crushed stone filling it. Crushed stone excavation material is well suited. Pebbles ground with water do not provide good adhesion of the components of the mixture, so they should not be used.

Ideally, crushed stone of different fractions is needed

Ideally, crushed stone of different fractions is needed The size of individual particles varies from eight to thirty-five millimeters; large fragments are rarely used, most often in industrial production. The crushed stone should also not contain clay inclusions; it must be cleared of construction debris before use. Depending on the purpose of the concrete structure, lightweight expanded clay and other similar components can be used as its filler.

When mixing the solution yourself, it is better to use crushed stone, the particles of which have different sizes, or it is necessary to pre-mix its large and medium fragments.

This will prevent the formation of voids, which reduce the strength of the concrete product, and will ensure closer contact of the filler particles. The more dense their contact is, the less cement mortar will be consumed when preparing the concrete mixture. When storing crushed stone or gravel near a construction site, a tarpaulin should be laid under the embankment so that the filler does not absorb moisture from the soil.

Proportional composition of concrete.

To make concrete with the required performance characteristics and performance qualities, it is necessary to ensure the required proportions of the constituent ingredients. The table below will help you prepare concrete with your own hands of the desired brand based on M500 cement. If we want to mix concrete manually, we can keep track of the volume of constituent materials in buckets. The numbers reflect volumetric proportions taking into account one bucket of cement and half a bucket of water.

When are supplements needed?

Special additives called plasticizers must be used when preparing concrete mixtures at low ambient temperatures or high humidity. They ensure reliable curing of the mortar under these adverse conditions. Sometimes, for the convenience of laying and leveling concrete, slaked lime is added to it during mixing, but it can have a negative effect on the cement and filler.

Plasticizer makes working with concrete easier

Plasticizer makes working with concrete easier Plasticizers are also used to give the concrete mixture greater fluidity or viscosity; with their help, you can regulate the required amount of water for its preparation. Flowable concrete mortar is used to treat hard-to-reach surfaces of a building structure; it quickly and reliably fills all its cavities.

Polyvinyl chloride or polypropylene fibers added to concrete mortar improve its reinforcing qualities. These components help avoid cracking of concrete surfaces at their interfaces.

Determining the required amount of concrete

The amount of concrete required to construct the foundation of a building is determined based on the geometric volume of the foundation, taking into account the loss of material during delivery and pouring. So, to calculate the volume of a rectangular strip foundation, it is necessary to multiply the total length of the perimeter of the strip by its width and height. In the case of a more complex base design for a house, it is necessary to calculate the volume for the tape of each section, and then add the results.

Calculation of the required amount of concrete for arranging a foundation in the form of a monolithic slab is carried out by simply multiplying the three sizes of a concrete parallelepiped. The volume of a pile foundation can be easily calculated by multiplying the cross-section of the piles by their height and number.

Calculation of the amount of concrete for the foundation

Calculation of the amount of concrete for the foundation Note that the reinforcement frame of the base for the house somewhat reduces the required volume of concrete. In this case, the losses are still greater, and in practice, another two percent is added to the amount of material obtained as a result of the calculation. The illustrations above clearly demonstrate that the amount of concrete for strip, slab and pile foundations is easy to calculate yourself.

Mixing concrete for the foundation by hand

In order to mix the concrete mass with your own hands, you need to select a container of suitable volume that is convenient for work. A proportional part of sand is placed in it, the furrow in the center of which is filled with sifted cement. These components are thoroughly mixed together until a homogeneous mass of gray color is obtained. After moistening it with water and mixing, add crushed stone and knead again until the resulting mass completely covers the filler.

Mixing concrete in a trough is a common practice

Mixing concrete in a trough is a common practice During this process, water is gradually added, the amount of which is determined by the required plasticity qualities of the concrete mixture. It is ready for use when its composition becomes as homogeneous as possible, and the edges of solid components are not visible on the surface.

When mixing concrete yourself at home, it is necessary to use the prepared solution for its intended purpose as quickly as possible, since it may delaminate and lose some of its performance qualities.

Even with the very simple operation of making a concrete mixture by hand, there are some techniques that make the job easier. Watch how an experienced master does it.

Preparing the mixture in a concrete mixer

The best way to make durable concrete yourself is to prepare a homogeneous mixture in a concrete mixer. To do this, cement is placed in the mixer, moistened with water, and the composition is stirred until it turns into an emulsion substance, to which sand is added in accordance with the required proportion. Then a fraction of the filler is placed into the concrete mixer, and the mixer is rotated. With this method of preparing the mixture in a concrete mixer, it does not lose its performance qualities and does not delaminate.

A concrete mixer significantly simplifies the process of preparing concrete

A concrete mixer significantly simplifies the process of preparing concrete Thus, based on what kind of foundation is planned, it is necessary to decide what kind of concrete will be needed. Then you should calculate the required volume of material. Based on the specific situation, concrete can be made manually or made using a concrete mixer. The following video will help resolve any remaining questions.

Composition of concrete for the foundation

Concrete consists of three main components: cement, sand and gravel (crushed stone). The strength and durability of the load-bearing part of the structure depend on the proportions of the components. There is one problem. It lies in the fact that the same components can produce concrete of different grades.

Cement

So, the first thing you need for the foundation concrete mixture is Portland cement grade M 500. It can be purchased at any hardware store.

Sand

The second component that is added to the concrete for the foundation is sand. Particular attention must be paid to its granularity. Its grains should be from 0.15 mm to 3 mm. If they are dusty, the cement will not adhere well to the sand, and if they are large, then there will be a lot of air bubbles in the concrete. All this contributes to a decrease in the strength and bearing capacity of the foundation.

Gravel

And finally, the third component is gravel with a grain size of up to 10 mm; you can use crushed stone, the size of which should be from 5 mm to 70 mm. Often, instead of them, broken bricks are added to the foundation concrete, which worsens the load-bearing capacity. But if the load is relatively small, then this is allowed. If the construction of a building is carried out in winter, the concrete for the foundation includes special additives for better hardening at low temperatures, such as “Emulsol EKS-M”, “Plastil U”, “Lignopal B2”.

It's easy to prepare. For this it is better to use an electric concrete mixer. If you don’t have one, you’ll have to make do with a couple of hands, a shovel and a bucket.

Proportions

When preparing the mixture, it is necessary to observe the proportions of the components, they should be 1: 2: 3, i.e. For 1 bucket of cement you need to add 2 buckets of sand and 3 buckets of crushed stone (gravel). Pour the first two components into a concrete mixer or tub in the specified ratio and mix until smooth. Then add crushed stone (gravel), also following the proportions, and mix again. Next, add water; you need to do this in parts, while controlling the thickness of the mixture. If the preparation and pouring of concrete will be carried out in the winter season, special additives should be included in the composition. Their proportions and method of addition should be written in the instructions for use. To check the readiness of the concrete solution, take it with a shovel. It should settle, but not spread and not be in the form of a lump from which pieces fall off. If all conditions are met and the mass is similar in description, then the concrete for the foundation is ready and you can begin pouring it.

Pouring the foundation

Before pouring the foundation, the formwork from the boards should be knocked down. To improve the strength of the structure, it is recommended to install inside it a reinforced frame made of A500C brand reinforcement with a cross-section of 10 or 12 mm. Then you need to mix the concrete solution for the foundation, which is poured into the formwork. During pouring, it should be compacted with a stick. This is done in order to squeeze out air bubbles from the solution that have entered there; they negatively affect the strength of the concrete. After the foundation is poured, the mixture should be allowed to harden. When the solution has set, remove the formwork and leave the foundation until it hardens completely.