Cationic pav. Nonionic pav

Why do some washing formulations wash off the pollution well, even without mechanical impact, others do it poorly or not at all, why the same car shampoo on some machines forms a divorce, and the others do not, why are compositions that wash well in Moscow working poorly in Volgograd? Turn to science. Open any reference book on organic chemistry, section surfactants.

Electrostatic interaction occurs at a certain orientation of the dipoles of polar molecules. By its electrical properties, a molecule can be approximately considered as an electric dipole, i.e. set of two equal and opposite point charges. Due to the fact that the charges of the dipole are in different points of space, they do not compensate each other in intensity and each of them creates its own electric field. Two electric dipoles interact with each other with a force that is in the fourth degree inversely proportional to the distance between them. This is a very important point; attention should be paid to this. In non-polar molecules, an induced dipole moment occurs in an external electric field and the molecules are polarized. The result is a polarization or induction interaction. Mainly due to the above interactions, adhesion forces are formed, which determine the strength of adhesion of surfaces to each other.

Surface-active substances (surfactants) are chemical compounds that, while concentrating on the interface, cause a decrease in surface tension.

The main quantitative characteristic of surfactants is surface activity - the ability of a substance to reduce surface tension at the interface, this is the derivative of the surface tension with respect to the surfactant concentration as C tends to zero. However, surfactant has a limit of solubility (the so-called critical micelle concentration or CMC), with which when the surfactant is added to the solution, the concentration at the interface remains constant, but at the same time the self-organization of the surfactant molecules in the bulk solution (micelle formation or aggregation) occurs. As a result of this aggregation, so-called micelles are formed. A distinctive feature of micelle formation is the clouding of the surfactant solution. Aqueous solutions of surfactants, when micelle formation also acquire a bluish tint (gelatinous tint) due to the refraction of light by micelles.

Typical surfactants are organic compounds of diphilic structure, that is, containing atomic groups in a molecule, which differ greatly in the intensity of interaction with the environment (in the most practically important case, water). So, in the surfactant molecules there is one or several hydrocarbon radicals that make up the oleo or lipophilic part (it’s also the hydrophobic part of the molecule), and one or more polar groups, the hydrophilic part. Oleophilic (hydrophobic) groups weakly interacting with water determine the tendency of a molecule to transition from an aqueous (polar) medium to a hydrocarbon (nonpolar) medium. Hydrophilic groups, on the contrary, keep the molecule in a polar medium or, if the surfactant molecule is in a hydrocarbon fluid, determine its desire to transition to a polar medium. Thus, the surface activity of surfactants dissolved in non-polar liquids is due to hydrophilic groups, and dissolved in water by hydrophobic radicals.

Examples By the type of hydrophilic groups, surfactants are divided into ionic, or ionic, and non-ionic, or nonionic. Ionic surfactants dissociate in water into ions, some of which have adsorption (surface) activity, while others (counterions) are adsorptionally inactive. If anions are adsorption active, surfactants are called anionic, or anionic, in the opposite case - cationic, or cation-active. Anionic surfactants - organic acids and their salts, cationic - bases, usually amines of various degrees of substitution, and their salts. Some surfactants contain both acidic and basic groups. Depending on the conditions, they exhibit the properties of either anionic or cationic surfactants; therefore, they are called amphoteric, or ampholytic, surfactants.

Ionogenic surfactants.

Anionic substances make up the majority of global production of surfactants. This group of detergents is the most incompatible with dirt, and it is precisely it that is most criticized by soap-fouls. Anionic and cryptoanionic compounds (acetyl peptides, lauryl– and laureth sulfates of sodium, potassium, magnesium or ammonium) better than all other surfactant groups remove dirt from contact surfaces. Therefore, no effective cleanser can do without them.

People learned to make this group of washing substances earlier than others (remember the passage about the ashes, which the ancient sages sprinkled their heads on). As progress progressed, anionic toxides were boiled from proteins and fats, alkalized (sodium hydrolization) with the help of ash (the most popular alkaline natural raw materials are Salasola soda ash) and other alkaline compounds. Coconut, palm, rapeseed, soybean oil, lard oil, spermaceti, butter from cow and goat milk are used as raw materials for anionic and cryptanionic surfactants.

The outstanding purifying qualities of anionic toxoids are explained by the structure of their molecules, which consist of two parts - hydrophilic (water-loving) and, conversely, hydrophobic.

The former allow them to dissolve in water (or polar solvents) and completely wash it off from the skin, and the latter in contact with non-polar substances (hydrocarbons, resins, urea, dust, fats, oils). During washing with shampoo or soap, hydrophobic "jaws" bind trapped particles of dirt, placing them in the center of the micelle (a hollow ball formed by a number of molecules, the hydrophilic "tails" of which are directed outwards, and inwards - the hydrophobic "heads").

Fast, full-fledged, high-quality evacuation of dirt from the surface of the skin and its appendages, foaming, bactericidal (eliminating gram-positive microorganisms) and bacteriostatic, lipolytic (dissolving the oxidized fat secretion of the sebaceous glands and tar-mineral contamination of the skin) action.

Industrial surfactants of this type can be divided into the following. main groups: carboxylic to-you and their salts (soaps), alkyl sulfates (sulfonic esters), alkyl sulfonates and alkyl aryl sulfonates, other products.

In the production of soaps and many ionic and non-ionic soap-like surfactants, carboxylic to-you, obtained by hydrolysis from vegetable and animal fats, and synthetic fatty to-you. Pitch and fatty to-you of tall oil - a by-product of cellulose production - pitch to-you rosin among which abietinovy \u200b\u200bprevails have industrial value also.

The most important as surfactants from monocarboxylic salts are t-soaps (sodium, potassium and ammonium) fatty-tones of ROOH, where R is a saturated or unsaturated normal aliphatic radical with 12-18 carbon atoms, and soaps (sodium, less often potassium) resin kt. Practical importance also dicarboxylic to-you, for example. alkenylsucate obtained in the industrial condensation of unsaturated hydrocarbons with maleic anhydride.

Alkyl sulfates are usually synthesized by sulfoesterification of higher fatty alcohols or α-olefins, followed by neutralization of primary or secondary alkyl sulfuric acids, respectively.

Alkylaryl Sulfonates, Ch. arr. mono- and dialkylbenzene sulfonates, as well as mono- and dialkylnaphthalene sulfonates make up the majority of synthetic anionic surfactants.

Alkylsulfonates are usually obtained from saturated C12-C18 hydrocarbons of normal structure, which are sulfochlorinated or sulfo-oxidized, followed by saponification or neutralization of the product.

Cationic IIAV.

Cationic tensides are compounds that dissociate (dissolve) in an aqueous solution to form cations (positively charged molecules).

Quaternary ammonium bases, are polysaccharides derived from dairy products, lanolin, potatoes, corn, sugar cane, beets, sunflower.

By virtue of their positive charge, cationic tensides attract negatively charged hair and horny scales of the epidermis, accelerating their wetting, fix valuable medicinal components contained in a cosmetic preparation on their surface, and also have a bradykinase effect (eliminate irritation, itching, burning, swelling). They capture and hold negatively charged particles, kill gram-negative bacteria.

Cationic detergents are valuable components of cosmetic products (shampoos, balms, conditioners): they activate foam formation, increase the productivity of skin and hair oxygen exchange, emulsify oil and aromatic substances in an aqueous solution, have a bactericidal effect, eliminate the residual electrical charge on the hair after washing (antistatic effect ), provide easy combing, styling and increase the efficiency of therapeutic components on the skin and hair.

They can be divided into the following. main groups: amines of various degrees of substitution and quaternary ammonium bases, other nitrogen-containing bases (guanidine, hydrosines, heterocyclic compounds, etc.), quaternary phosphonium and tertiary sulfonium bases.

The raw materials for cationic surfactants of economic importance are amines derived from fatty alcohols and alcohols, alkhalides, as well as alkylphenols. Quaternary ammonium salts are synthesized from the corresponding long-chain halide alkyls by reaction with tertiary amines, from amines by chloroalkylation or by other routes from synthetic alcohols, phenols and phenolic mixtures.

Greater importance as cationic surfactants and as starting materials in the synthesis of non-ionic surfactants (see below) are not only mono-, but also diamines, polyamines and their derivatives.

Amphoteric surfactants

Manufacturers of high-quality cosmetics in order to soften the effect of the best, i.e. anionic cleansing ingredients (in particular, so that anionic surfactants do not damage the lipid complex of the lipid mantle) and at the same time not reduce even one iota of the cleansing activity of the preparation, they must be introduced into the SOAP formula, which is being washed. Amphoteric and non-ionic detergents neutralize the acid reaction of anions, promote their rapid decomposition, while increasing the density and reducing the "airiness" (diameter) of foam bubbles.

Amphoteric surfactants are one of the most expensive ingredients lathering basis. They are obtained by squeezing, extraction, infusion, rectification and oxidation of natural raw materials (both vegetable and animal). The most well-known raw material sources of amphoteric surfactants, namely cocoamphoacetate, lactate, alpha-amino acids, pectins, waxes, are soapstone, algae, apple fruit pulp, root crops (beets, carrots, Jerusalem artichoke), palm oil, dairy products, lanolin.

Even elementary knowledge of chemistry gives rise to doubts about the possibility of combining cationic and anionic surfactants in a single formula, since oppositely charged substances, pairwise attracted to each other, reduce their affinity for water (precipitate), and, naturally, purifying activity decreases. Only due to amphoteric detergents, this problem was resolved: these surfactants, due to their ability to easily give and attach an electron pair, exhibit both acidic and basic properties depending on the reaction of the medium in which they are located (so in an alkaline medium they become anions, and in acid - cations).

properties of amphoteric surfactants

Amphoteric detergents protect the skin and hair from dryness and irritation, restore the stratum corneum of the epidermis and hair keratin, soften, increase the elasticity of the connective tissue, make the hair silky, and the foam of the lathering substance has a creamy texture.

Obtained from anionic by introducing amino groups into them or from cationic by introducing acidic groups.

Such compounds, for example, RNHCH2CH2COONa, are obtained by reacting a primary amine and methyl acrylate with subsequent saponification of the ester group with an alkali.

Induced amphoteric surfactants are produced in small quantities, and their consumption expands slowly.

Nonionic surfactants

Compounds that dissolve in water without the formation of ions are called non-ionic. Their group is represented by polyglycolic and polyglycolic esters of fatty alcohols (for example, disubstituted - Disodium Laurethsulfosuccinate - a flowable liquid consisting of citric acid and fatty alcohols). Non-ionic surfactants are obtained by oxyethylation of vegetable oils (castor, wheat, flax, sesame, cocoa, calendula, parsley, rice, St. John's wort). Non-ionic surfactants exist only in liquid or pasty form, and therefore cannot be contained in solid detergents (soap, powders).

Aqueous solutions of esters of fatty acids are dispersion micelle solution, which is often called “smart soap”, because it emulsifies dirt and grease, removing them from the surface of the skin and hair, without damaging the protective mantle.

Properties of non-ionic surfactants

This type of surfactant adds to the detergent softness, safety, environmental friendliness (biodegradability of non-ionic detergents is 100%). They stabilize soap suds, have soft thickener properties, have a bradykinase and polishing effect, restoring the outer layers of the epidermis and hair, and contribute to enhancing the effect of therapeutic additives of the cleansing drug.

This is the most promising and fast-growing class of surfactants. Not less than 80-90% of such surfactants are obtained by adding ethylene oxide to alcohols, alkyl phenols, carboxylic acids, amines, and other compounds with reactive hydrogen atoms. Polyoxyacrylate alkylphenol ethers are the most numerous and widespread group of non-ionic surfactants, including more than a hundred trade names, the most well-known drugs OP-4, OP-7 and OP-10. Typical raw materials are octyl, ionyl and dodecylphenols; cr. In addition, cresols, cresol-to-that, β-naphthol, etc. are used. If an individual alkylphenol is taken in the reaction, the finished product is a mixture of surfactants of the total fi rly RC6H4O (CH2O) mH, where t is the degree of hydroxyethylation, depending on the molar ratio of the initial components.

All surfactant. can be divided into two categories according to the type of systems they form when interacting with a solvent medium. One category includes micelle-forming surfactants. in., to the other - not forming micelles. In solutions of micelle-forming surfactants in. above the critical micelle concentration (CCM), colloidal particles (micelles) consisting of tens or hundreds of molecules (ions) arise. The micelles reversibly decompose into individual molecules or ions when the solution is diluted (more precisely, the colloidal dispersion) to a concentration below CCM.

Thus, solutions of micelle-forming surfactants. occupy an intermediate position between the true (molecular) and colloidal solutions, so they are often called semi-colloid systems. The micelle-forming surfactants include all detergents, emulsifiers, wetting agents, dispersants, etc.

Surface activity is conveniently assessed by the greatest decrease in surface tension divided by the corresponding concentration - CMC in the case of micelle-forming surfactants. Surface activity is inversely proportional to CMC:

The formation of micelles occurs in a narrow concentration range, which becomes narrower and more defined as the hydrophobic radicals lengthen.

The simplest micelles of typical semi-colloid surfactants, for example. salts of fatty acids, at concentrations not exceeding CMC, have a spheroidal shape.

With an increase in the surfactant concentration of anisometric micelles, it is accompanied by a sharp increase in structural viscosity, which in some cases leads to gelation, ie complete loss of fluidity.

Action detergents. Soap has been known for thousands of years, but only relatively recently chemists have understood why it has detergent properties. The mechanism for removing dirt is essentially the same for soap and synthetic detergents. Consider it on the example of table salt, ordinary soap and sodium alkyl benzene sulfonate, one of the first synthetic detergents.

When dissolved in water, salt dissociates into positively charged sodium ions and negatively charged chloride ions. Soap, i.e. Sodium (I) stearate, substances similar to it, as well as sodium alkylbenzenesulfonate (II) behave in a similar way: they form positively charged sodium ions, but their negative ions, unlike chloride ion, consist of about fifty atoms.

Soap (I) can be represented by the formula Na + and C17H35COO–, where 17 carbon atoms with hydrogen atoms attached to them are stretched into a winding chain. Sodium alkylbenzenesulfonate (Na + C12H25C6H4SO3–) has about the same number of carbon and hydrogen atoms. However, they are located not in the form of a winding chain, as in soap, but in the form of a branched structure. The significance of this distinction will become clear later. For the detergent action, it is important that the hydrocarbon portion of the negative ion is insoluble in water. However, it is soluble in fats and oils, and in fact it is thanks to fat that mud adheres to things; and if the surface is completely free of grease, dirt does not linger on it.

Negative ions (anions) of soap and alkyl benzene sulfonate tend to concentrate on the interface of water and fat. The water-soluble negatively charged end remains in the water, while the hydrocarbon portion is immersed in fat. In order for the interface to be the largest, the fat must be present in the form of the smallest droplets. The result is an emulsion - a suspension of droplets of fat (oil) in water (III).

If there is a film of fat on a solid surface, then upon contact with water containing detergent, the fat leaves the surface and passes into the water in the form of tiny droplets. The anions of soap and alkyl benzene sulfonate are at one end in water and the other in fat. The dirt held by the grease film is removed by rinsing. So in a simplified form, you can imagine the effect of detergents.

Any substance that tends to collect at the oil-water interface is called a surfactant. All surfactants are emulsifiers because they contribute to the formation of an oil-in-water emulsion, i.e. “Mixing” oil and water; they all have detergent properties and form a foam - because foam is like an emulsion of air bubbles in water. But not all of these properties are expressed in the same way. There are surfactants that form a lot of foam, but are mild detergents; there are those who barely foam, but are beautiful detergents. Synthetic detergents are synthetic surfactants with particularly high detergency. In industry, the term "synthetic detergent", as a rule, means a composition comprising a surfactant component, bleach and other additives.

Soaps, alkyl benzene sulphonates and many other detergents, where the anion is soluble in fats, are called anionic. There are also surfactants in which the cation is fat soluble. They are called cationic. Typical cationic detergent, alkyl dimethyl benzyl ammonium (IV) chloride

is a quaternary ammonium salt containing nitrogen bound to four groups. The chloride anion always remains in the water, so it is called hydrophilic; hydrocarbon groups associated with positively charged nitrogen are lipophilic. One of these groups, C14H29, is similar to a long hydrocarbon chain in soap and alkyl benzene sulfonate, but it is attached to a positive ion. Such substances are called "reverse soaps." Some of the cationic detergents have a strong antimicrobial effect; They are used in the composition of detergents intended not only for washing, but also for disinfection. However, if they cause eye irritation, then when using them in aerosol formulations, this fact should be reflected in the instructions on the label.

Another type of detergent is non-ionic detergents. The fat soluble group in detergent (V) is a kind of fat soluble group in alkyl benzene sulfonates and soaps, and the residue is a long chain containing many oxygen atoms and a OH group at the end that are hydrophilic. Typically, non-ionic synthetic detergents exhibit high detergency, but weakly form foam.

Synthetic surfactants (Synthetic Surface-Active Substances) are an extensive group of compounds, different in structure, belonging to different classes. These substances are able to adsorb on the interface and, as a result, lower the surface energy (surface tension). Depending on the properties shown by synthetic surfactants when dissolved in water, they are divided into anionic substances (the anion is the active part), cationic (the cation is the active part of the molecules), ampholytic and non-ionic, which are not ionized at all.

It is no secret that the main active components of laundry detergents are surface-active substances (surfactants). In truth, these active chemical compounds, entering the body, destroy living cells by disrupting the most important biochemical processes.

The future for the synthetics? Apparently, yes. In confirmation of this, surfactants are being improved more and more, there are so-called non-ionic surfactants whose biodegradability reaches 100%. They are more effective at low temperatures, which is important for gentle washing modes. Since many artificial fibers do not withstand high temperatures. Besides washing in more cold water saves energy, which is more important every day. Unfortunately, most non-ionic surfactants are liquid or pasty, and therefore are used in liquid and pasty detergents. Nonionic surfactants are introduced into powdered CMC in the form of additives of 2-6% wt. Important advantages of synthetic surfactants are that they do not form water-soluble calcium and magnesium salts. So, it is equally well washed both in soft and hard waters. The concentration of synthetic detergents even in soft water can be much lower than that of soaps derived from natural fats.

Probably from the products household chemicals We know most of all synthetic detergents. In 1970, for the first time in the world, synthetic detergents (SMS) produced more than regular natural soaps. Every year its production all decreases, while the release of SMS is constantly increasing.

For example, in our country, the dynamics of growth in the production of SMS can be displayed by the following data: in 1965 they produced 106 thousand tons, in 1970 -470 thousand tons, and in 1975 almost one million tons will be produced.

Why, then, does the production of natural, sound, soap, which faithfully served man for many years, fall so much? It turns out that he has many flaws.

First, soap, being a salt of a weak organic acid (more precisely, a salt formed by a mixture of three acids, palmitic, margarine and stearic) and a strong base, caustic soda, hydrolyzes in water (i.e., is split by it) into acid and alkali. The acid reacts with hardness salts and forms new, water-insoluble salts, which fall in the form of a sticky white mass onto clothes, hair, etc. This is not a very pleasant phenomenon well known to everyone who tried to wash or wash in hard water. .

Another product of hydrolysis - alkali - destroys the skin (defats it, leads to dryness and the formation of painful cracks) and reduces the strength of the fibers that make up various fabrics. Polyamide fibers (capron, nylon, perlon) are destroyed by soap especially intensively.

Secondly, soap is a relatively expensive product, since its production requires food raw materials - vegetable or animal fats.

There are other, less significant disadvantages of this until recently completely irreplaceable substance in everyday life.

Unlike natural soap, synthetic detergents have undoubted advantages: greater detergency, hygiene and cost effectiveness.

About 500 items of synthetic detergents, produced in the form of powders, granules, scales, pastes, liquids, are known on the international market.

The production of SMS gives a great economic effect. Experiments have shown that one ton of synthetic detergents replaces 1.8 tons of 40 ° / oh household soap, produced from valuable food raw materials. It is estimated that one ton of SMS saves 750 kg of vegetable fats for the food industry.

The use of SMS in the household can reduce labor costs for hand and machine washing by 15-20%. It is much better than using conventional soap, the strength and initial consumer properties of the fabric (whiteness, brightness of color, elasticity) remain.

I must say that SMS is not just for washing clothes. There are special products for washing and cleaning various household items, toilet synthetic soaps, hair washing products-shampoos, bath-washing additives, in which biostimulants are introduced that have a tonic effect on the body.

The main component of all these products is a synthetic surface-active substance (surfactant), whose role is the same as the organic salt in ordinary soap.

However, chemists have long known that an individual substance, no matter how versatile it is, cannot satisfy all the requirements for it. Small additives of other related substances help to find very useful qualities in this basic substance. That is why all modern SMS are not individual surfactants, but compositions, which may include bleaches, fragrances, foam regulators, biologically active substances and other components.

The second most important component of modern detergents are condensed, or polymeric, phosphates (polyphosphates). These substances have a number of useful properties: they form water-soluble complexes with metal ions present in the water, which prevents the possibility of the appearance of insoluble mineral salts that occur when washing with ordinary soap; increase the washing activity of surfactant; prevent the sedimentation of suspended particles of dirt on the washed surface; cheap in production.

All these properties of polyphosphates make it possible to reduce the content of the more expensive main component-surfactant in SMS.

As a rule, fragrance is a part of any synthetic detergent - a substance with a pleasant odor, which is transferred to the laundry when using SMS.

A substance called sodium carboxymethylcellulose is injected into almost all SMS. It is a high molecular weight synthetic product, soluble in water. Its main purpose is to be, along with phosphates, antiresorptive, that is, to prevent the sedimentation of dirt on already washed fibers.

Most of them have a number of advantages over soap, which has long been used for this purpose. For example, surfactants dissolve well and foam, even in hard water. Potassium and magnesium salts formed in hard water do not impair the detergent action of surfactants and do not form a white residue on the hair.

The main active ingredients of all washing powders, so-called. Surfactants (surface active substances) are extremely active chemical compounds. Possessing some chemical affinity with certain components of the cell membranes of humans and animals, surfactants, when ingested, accumulate on the cell membranes, covering their surface with a thin layer and at a certain concentration can cause disruption of the most important biochemical processes occurring in them, disrupt the function and integrity cells

In animal experiments, scientists found that surfactants significantly alter the intensity of redox reactions, affect the activity of a number of the most important enzymes, break down protein, carbohydrate and fat metabolism. Surfactant anions are especially aggressive in their actions. They can cause gross violations of the immune system, the development of allergies, damage to the brain, liver, kidneys, lungs. This is one of the reasons why strict restrictions on the use of a-surfactants (anionic surfactants) in detergent compositions are imposed in Western European countries. At best, their content should not exceed 2-7%. In the West, more than 10 years ago, they refused to use in everyday life powders containing phosphate additives. In the markets of Germany, Italy, Austria, Holland and Norway only non-phosphate detergents are sold. In Germany, the use of phosphate powders is prohibited by federal law. In other countries, such as France, Great Britain, Spain, according to government decisions, the content of phosphates in SMS is strictly regulated (no more than 12%).

The presence of phosphate additives in powders leads to a significant increase in the toxic properties of a-surfactant. On the one hand, these additives create conditions for more intense penetration of a-surfactant through intact skin, contribute to enhanced skin defatting, more active destruction of cell membranes, drastically reduce the barrier function of the skin. Surfactants penetrate the microvessels of the skin, are absorbed into the bloodstream and spread through the body. This leads to a change in the physicochemical properties of the blood itself and impaired immunity. A-surfactant has the ability to accumulate in organs. For example, 1.9% of the total amount of a-surfactant on unprotected skin settles in the brain, 0.6% in the liver, etc. They act like poisons: in the lungs they cause hyperemia, emphysema, damage the function of cells in the liver, which leads to an increase in cholesterol and increase the effects of atherosclerosis in the vessels of the heart and brain, disrupts the transmission of nerve impulses in the central and peripheral nervous systems.

But this does not exhaust the harmful effects of phosphates - they represent a greater threat to our environment. After washing, together with the wastewater, into the water bodies, phosphates are taken to act as fertilizer. The "harvest" of algae in water begins to grow by leaps and bounds. Algae, decomposing, emit in large quantities methane, ammonia, hydrogen sulfide, which destroy all life in water. Overgrowing of water bodies and clogging of slowly flowing water leads to gross violations of the ecosystems of water bodies, deterioration of oxygen exchange in the hydrosphere and create difficulties in providing the population drinking water. Also for this reason, in many countries, the use of phosphate SMS has been prohibited by law.

The traditional disadvantage of surfactants is stiffness, expressed in irritation of the skin, the appearance of dryness and discomfort after using a shampoo or shower gel.

The skin of the hands, in contact with the active chemical solutions of laundry detergents, become the main conductor of the penetration of hazardous chemical agents into the human body. A-surfactants actively penetrate even through intact skin of the hands and with the assistance of phosphates, enzymes and chlorine intensively disinfect it. Restoration of normal oiliness and moisture of the skin occurs no earlier than in 3-4 hours, and with repeated use due to the accumulation of a harmful effect, the lack of fatty skin covering is felt for two days. Barrier functions of the skin are reduced, and conditions are created for intensive penetration of not only a-surfactant into the body, but also any toxic compounds - bacteriological toxins, heavy metals, etc. After several washings with phosphate powders, skin inflammations often develop - dermatitis. The conveyor of pathological immune reactions starts.

Bibliography

Van Krevelen DV, Properties and chemical structure of polymers, trans. With English, M., 1976;

http://provisor.com

http://pharmvestnik.ru

http://darnitsa.ua

http://ru.wikipedia.org/

http://wiki.laser.ru

http://ximicat.com

Author Chemical Encyclopedia b. I.L.KnunyantsSURFACE-ACTIVE SUBSTANCES, substances, the adsorption of which from a liquid at the interface with other phases (liquid, solid or gaseous) leads to a significant decrease in the surface tension (see Surface activity). In the most general and practical case, adsorbed molecules (ions) of surfactants have a diphilic structure, i.e. they consist of a polar group and a non-polar hydrocarbon radical (diphilic molecules). The hydrocarbon radical, which is pushed out of the polar medium, has a surface activity with respect to the non-polar phase (gas, hydrocarbon liquid, non-polar surface of a solid body). In an aqueous surfactant solution, an adsorption monomolecular layer with hydrocarbon radicals oriented toward the air is formed at the air interface. As it is saturated, the molecules (ions) of the surfactant, condensing in the surface layer, are arranged perpendicular to the surface (normal orientation).

The surfactant concentration in the adsorption layer is several orders of magnitude higher than in the liquid volume, so even with negligible content in water (0.01-0.1% by mass), surfactants can reduce the surface tension of water at the air interface from 72.8 10 -3 to 25 10 -3 J / m 2, i.e. almost to the surface tension of hydrocarbon liquids. A similar phenomenon occurs at the boundary of an aqueous surfactant-hydrocarbon liquid solution, which creates prerequisites for the formation of emulsions.

Depending on the state of the surfactant in the solution, conditionally distinguish between truly soluble (molecularly dispersed) and colloidal surfactants. The conditionality of this separation is that the same surfactant can belong to both groups, depending on the conditions and chemical nature (polarity) of the solvent. Both groups of surfactants are adsorbed at the phase boundaries, i.e., surface activity is shown in solutions, while the bulk properties associated with the occurrence of the colloid (micellar) phase are shown only by colloidal surfactants. These surfactant groups differ in the value of a dimensionless quantity, which is called the hydrophilic-lipophilic balance (HLB) and is determined by the ratio:

where is the affinity (free interaction energy) of the non-polar part of the surfactant molecule to the hydrocarbon liquid (b-dimensionless parameter depending on the nature of the surfactant, is the free energy of the interaction per CH 2 group, v is the number of CH 2 groups in the hydrocarbon radical), a -the affinity of the polar group to water. For colloidal surfactants (b + or, where the indices m correspond to the minimum affinity values \u200b\u200bat which the colloidal properties of surfactants begin to manifest. The minimum number of carbon atoms in the radical for different types of colloidal surfactants lies between 8 and 12, i.e. colloidal surfactants have a rather large hydrocarbon radical. However, colloidal surfactants must also have true solubility in water, i.e. the polarity of the hydrophilic group must also be sufficiently high. This corresponds to the condition:

![]()

In the beginning. 60s. 20 in. D. Davis developed the HLB scale with values \u200b\u200bfrom 0 to 40. Surfactants with lipophilic properties have low HLB values, with hydrophilic-high values. Each group of atoms entering the surfactant molecule is assigned a group number. When adding these numbers get HLB by the formula:

HLB \u003d hydrophilic group numbers + 4-hydrophobic group numbers + 7.

Although the concept of HLB is quite formal, it allows you to determine the scope of the surfactant. So, for the formation of water / oil emulsions HLB is in the range of 3-6, oil emulsion / yes-8-16, for wetting agents-7-9, for detergents-13-15.

The surface activity of surfactants belonging to different groups is determined differently. For truly soluble surfactants, it is equal to max. derivative value

![]()

and measured by the initial portion of the adsorption isotherm s (c) at c0 (T is the number of moles of surfactants adsorbed by a unit of surface, R-gas constant, T-abs. temperature). For colloidal surfactants, surface activity is G min \u003d (s 0 - s min) / s min, where s 0 is the surface tension of the pure solvent, s MIH is the smallest (constant) value of s, and c min is the corresponding surfactant concentration. Further introduction of the surfactant into the solution leads to an increase in the number of micelles, and the concentration of the molecularly dispersed surfactant remains constant. The value from the min-critical concentration of micelle formation (KKM). It is defined as the concentration of surfactant at which a large number of micelles in thermodynamic arise in solution. equilibrium with molecules (ions), and the properties of the solution change dramatically (electrical conductivity, surface tension, viscosity, light scattering, etc., see. Mycellosis).

Surfactant classification.This article describes the classification adopted at the III International Congress on Surfactants and recommended by the International Organization for Standardization (ISO) in 1960. It is based on the chemical nature of molecules and includes four main classes of surfactants: anion-active, cation-active, non-ionic and amphoteric. Sometimes emit also vysokolom. (polymer), perfluoror. and silicone surfactant, however, by the chemical nature of the molecules, these surfactants can be attributed to one of the above. classes.

Anionic surfactants contain one or more polar groups in the molecule and dissociate in aqueous solution to form long-chain anions that determine their surface activity. These groups are: COOH (M), OSO 2 OH (M), SO 3 H (M), where M is a metal (mono-, divalent, or trivalent). The hydrophobic part of the molecule is usually represented by the limit or unsaturated aliphatic. chains or alkyl aromatic radicals. There are 6 groups of anion active surfactants.

1) Carboxylic acid derivatives (soap): RCOOM, ROOC (CH 2) n COOM, RC 6 H 4 (CH 2) n COOM, RCH \u003d CH - - (CH 2) n COOM. 2) ROSO 3 M, R »R: CHOSO 3 M primary and secondary alkyl sulfates, RC 6 H 4 C 2 H 4 OSO 3 M alkyl aryl sulfates, RC 6 H 10 C 2 H 4 OSO 3 M alkyl cyclohexylesulfates, etc. (see Avirol, Alizarin Oil, Alkyl Sulphates). 3) Alkyl and alkyl benzene sulphonates, sulphonates of esters of mono- and dicarboxylic acids: RSO 3 M, RC 6 H 4 SO 3 M, ROOCCH 2 SO 3 M, ROOCCH 2 CH (COOR) SO 3 M (see Alkyl benzene sulphonates, Naphthalene sulphonates, Sulphonates). 4) Sulfo- and carboxy-ethoxylates of alcohols, sulfoethoxylates of carboxylic acids, sulfoethoxylates of alkylphenylethyl alcohols, dimethyl-lich. salts of sulfosuccinic acid, salts of sulfates of unsaturated acids: RO (C 2 H 4 O) n SO 3 M, RO (C 2 H 4 O) n CH 2 COOM, RCOO (C 2 H 4 O) n SO 3 M, RC 6 H 4 (C 2 H 4 O) 2 SO 3 M, ROOCCH 2 CH (COOM) SO 3 M, RCH (OSO 3 M) \u003d CH (CH 2) n -COOM. 5) Nitrogen-containing surfactants: amidosulfonate RCONR "-R: -SO 3 M, amides of sulfonic carboxylic acids RR" NOC-R: -SO 3 M, amidosulfates RCONR "- R: -OSO 3 M, amidocarboxylates RCO (NH-R" -CO ) n OM, substances with carboxy and sulfo groups RCONH-R-OCOR: (SO 3 M) -COOM. Instead of an amide group in many of these substances, there may also be a sulfoamide group, for example, RC 6 H 4 SO 2 NHCH 2 CH 2 SO 3 M. 6) Perfluoride salts. carboxylic acids, perfluoror. sulfoacetate, mono - and dialkyl phosphate and phosphonates, perfluoride. phosphonates and other compounds.

In anionic surfactants, a cation can be not only a metal, but also an organic base. Often it is di- or triethanolamine. Surface activity begins to occur when the length of the hydrocarbon hydrophobic chain C 8 and with increasing chain length increases up to a complete loss of solubility of the surfactant in water. Depending on the structure of the intermediate functional groups and the hydrophilicity of the polar part of the molecule, the length of the hydrocarbon part can reach up to C 18. The benzene nucleus corresponds to about 4 C atoms, the perfluorinated methylene group CF 2 is approximately 2.5 to 3 methylene groups.

The most Alkyl sulfates and alkyl arylsulfonates are common. Optim. primary dodecyl sulfate and straight chain dodecylbenzenesulfonate possess surface-active properties. These substances are thermally stable, low-toxic (LD 50 1.5-2 g / kg, white mice), do not irritate human skin and satisfactorily undergo biological degradation in water bodies (see below), with the exception of alkylaryl sulfonates with a branched alkyl chain. They are well combined with other surfactants, while showing synergism, their powders are non-hygroscopic. Secondary alkyl sulfates have good foaming ability, but are thermally unstable and are used in liquid form. Secondary alkyl sulfonates have a high surface activity, but are very hygroscopic. Perspective surfactants are those in which the hydrophilic part consists of several functional groups. For example, the disodium salts of sulfosuccinic acid have good hygiene. properties along with high colloid-chemical and technol. indicators when dissolved in hard water. Surfactants containing a sulfonylamide group have biological activity. Dodecyl phosphate also has good properties.

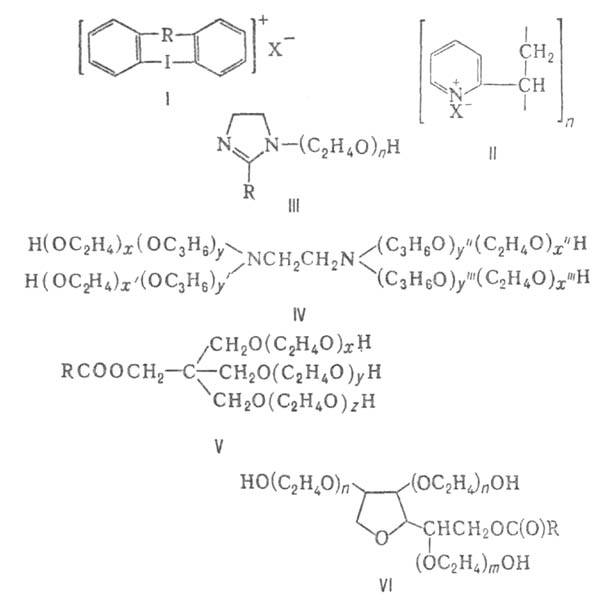

Cationic surfactants are called surfactants whose molecules dissociate in aqueous solution to form a surfactant cation with a long hydrophobic chain and an anion — usually a halide, sometimes an anion of sulfuric or phosphoric acid. The nitrogen-containing compound is predominant among cationic surfactants; Nitrogen-free substances also find practical application: the sulfonium compound + X - and sulfoxonium + X -, phosphonium + X -, arsonium + X -, iodonium (formula I). The nitrogen-containing compound can be divided into the following main groups: 1) amines and their salts RNR "R: HX; 2) mono- and bis-quaternary ammonium compounds aliphatic. structures + X -, 2+ 2X -, compound with mixed aliphatic. and aromatic structure 2 + 2X; 3) Quaternary ammonium compounds with times l. functional groups in the hydrophobic chain; 4) mono- and bis-quaternary ammonium compounds with a nitrogen atom in the heterocyclic ring. The latter group includes hundreds of surfactants having prom. value. The most important of them is the compound of pyridine, quinoline, phthalazine, benzimidazole, benzothiazole, benzotriazole, derivatives of pyravvortadine, imidazole, piperidine, morpholine, piperazine,

benzoxazine and others; 5) amine oxides RR »R: N + O - (started industrial production); 6) polymeric surfactants (II). Apply to the main polyvinylpyridinium halides.

Cationic surfactants lower surface tension less than anionic surfactants, but they can interact chemically with the surface of the adsorbent, for example, with the cellular proteins of bacteria, causing a bactericidal effect. Mutual polar groups of cationic surfactants with hydroxyl groups of cellulose fibers leads to hydrophobization of fibers and impregnation of tissues.

Nonionic surfactants do not dissociate into water into ions. Their solubility is due to the presence of hydrophilic ether and hydroxyl groups in the molecules, most often a polyethylene glycol chain. Apparently, when dissolved, hydrates are formed due to the formation of a hydrogen bond between the oxygen atoms of the polyethylene glycol residue and water molecules. Due to the breaking of the hydrogen bond with increasing temperature, the solubility of non-ionic surfactants decreases, so for them the cloud point is above. The temperature limit of micellization is an important indicator. Mn. a compound containing a mobile H atom (acids, alcohols, phenols, amines), reacting with ethylene oxide, form non-ionic surfactants RO (C 2 H 4 O) n H. The polarity of one oxyethylene group is significantly less than the polarity of any acid group in anion-active surfactants. Therefore, from 7 to 50 oxyethylene groups are required to give the molecule the required hydrophilicity and HLB value depending on the hydrophobic radical. A characteristic feature of the non-ionic surfactant-liquid state and low foaming in water solutions.

Nonionic surfactants are divided into groups that differ in the structure of the hydrophobic part of the molecule, depending on which substances formed the basis for the production of polyglycolic esters. On the basis of alcohols, ethoxylated alcohols RO (C 2 H 4 O) n H are obtained; based on carboxylic acids - ethoxylated fatty acids RCOO (C 2 H 4 O) n H; on the basis of alkyl phenols and alkyl naphthols - ethoxylated alkyl phenols RC 6 H 4 O (C 2 H 4 O) n H and compound RC 10 H 6 O-- (C 2 H 4 O) n H; on the basis of amines, amides, imidazolines-ethoxylated alkylamines RN [(C 2 H 4 O) n H] 2, compound RCONH (C 2 H 4 O) n H, compound of formula III; on the basis of sulfamides and mercaptans - surfactants of the type RSO 2 NC (C 2 H 4 O) n H] 2 \u200b\u200band RS (C 2 H 4 O) n H. A separate group consists of proxanols (p lyu r o nik) - block copolymers of ethylene and propylenoxy oxides BUT (C 2 H 4 O) x (C 3 H 6 O) y (C 2 H 4 O) z H, where x, y and z range from a few to a few dozen, and proxamines (tetro-niki; formula IV) - ethylene- and propylene-oxoxy-block copolymers obtained in the presence of ethylenediamine. Alkyl acetylene colli serve as the basis for the preparation of surfactants of the type H (OC 2 H 4) n -OCR "R: CCCR" R "" O (C 2 H 4 O) n H; phosphoric acid esters of the type (RO) 2 P (O) O (C 2 H 4 O) n H; Type-V pentaerythritol esters. Nonionic surfactants are the condensation products of glycosides with fatty alcohols, carboxylic acids and ethylene oxide. Also, surfactants of the sorbitals group (tweens, formula VI) are products of the addition of ethylene oxide to the sorbitone monoester and fatty acid. A separate group consists of organosilicon surfactants, for example (CH 3) 3 Si n - (CH 2) 3 O (C 2 H 4 O) m H.

The production of nonionic surfactants in most cases is based on the addition reaction of ethylene oxide with an increase. temperature under pressure in the presence of catalysts (0.1-0.5% CH 3 ONa, KOH or NaOH). This turns out the average. the content of polymer homologists, in which the molecular weight distribution is described by the Poisson function. Individual substances are obtained by addition of polyhalogenated polyethylene glycols to the alcoholates. The colloid-chemical properties of surfactants of this class vary widely, depending on the length of the hydrophilic polyglycol chain and the chain length of the hydrophobic part in such a way that different representatives of one homolog. A row can be good wetting and emulsifying agents. The surface tension of homologues of ethoxylated alkylphenols and primary alcohols with a constant content of ethylene oxide groups decreases in accordance with the Traube rule, that is, with each additional CH 2 group, the surface tension decreases. In the best. option, it can reach (28-30) 10 -3 N / m at a critical concentration of micelle formation. The micellar mass is very large; for tweens, for example, it reaches 1,800. Non-ionic surfactants are less sensitive to salts, causing water hardness, than anion-active and cation-acid surfactants. The wetting ability of non-ionic surfactants depends on the structure; optimal wetting ability has a surfactant branched structure:

The ethoxylated C 10 -C 18 alcohols with n from 4 to 9, and plumes form spontaneous oil / water and water / oil microemulsions. Nonionic surfactants are well combined with other surfactants and are often included in the formulation of detergents.

Amphoteric (ampholytic) surfactants contain a hydrophilic radical in the molecule and a hydrophobic part capable of being an acceptor or proton donor, depending on the pH of the solution. Typically, these surfactants include one or more basic and acidic groups, and may also contain a non-ionic polyglycolic group. Depending on the pH value, they exhibit the properties of cation-active or anion-active surfactants. At some pH values, called the isoelectric point, surfactants exist in the form of zwitter-ions. The ionization constants of acidic and basic groups of truly soluble amphoteric surfactants are very low, however, cation-oriented and anion-oriented zwitterions are most common. The primary, secondary or tertiary ammonium group, pyridine residue or imidazoline residue is usually used as a cationic group. In principle, instead of N m. B. S, P, As atoms, etc. The anionic groups are carboxyl, sulphonate, sulfoester or phosphate groups.

According to the chemical structure and some similarity of properties, ampholytic surfactants are divided into 5 main groups: 1) alkylaminocarboxylic acids RNH (CH 2) n COOH; The alkyl radical of an amine is usually normal (straight-chained), but if it is located between the amine group and the carboxyl group, it sometimes has a branched character. Alkylamino-phenylcarboxylic acids RNHC 6 H 4 COOH; alkylaminocarboxylic acids with primary, secondary or tertiary amino group RCH (NH 2) COOH, RCH (NHR) COOH, R (CH 3) NCH 2 COOH; with intermediate hydroxyl, ether, ester, amide or sulfoamide group; substances with two or more amino and amido groups, with several amino and hydroxyl groups.

2) Alkyl betaines are the naib, an important group of zwitterionic surfactants. They can be divided into 5 main groups: a) alkyl betaines — C-alkyl betaines RCH COO - and N-alkyl betaines RN + (CH 3) 2 CH 2 COO -; b) sulphite-, sul-foo-, sulphate- and phosphate betaine RN + (CH 3) 2 CH 2 CH 2 RN + (CH 3) 2 CH 2 CH 2, RC 6 H 4 CH 2 N + (CH 3) 2 CH 2 CH 2 RN + (CH 3) 2 CH 2 CH (OH) CH 2 OP; c) amidobetaines RCONH (CH 2) 3 N + (CH 3) 2 COO -; d) ethoxylated betaines RN + [(C 2 H 4 O) p H] [(C 2 H 4 O) g H] CH 2 COO -; e) other zwitterionic surfactants.

3) Derivatives of alkyl imidazolines, in whose molecules the anionic and cationic groups have approximately the same ionization constants (formulas VII and VIII), where R is alkyl C 7 -C 17, R ″ —H, Na, CH 2 COOM (M-metal). The structure and methods of synthesis produce betaine surfactants, including carboxy, sulfo, sulphate or sulfoester group [formula IX; R »\u003d (CH 2) n COO -, (CH 2) 3, CH 2 CH (OH) CH 2] and other (" non-betaine ") imidazoline surfactants [formula X; R ″ \u003d CH 2 COONa, (CH 2) 2 N (CH 2 COOH) 2, (CH 2) 2 N \u003d \u003d CHC 6 H 4 SO 3 H, (CH 2) 2 OSO 3 H]. Balanced ionization The groups provide these compounds with a good colloid-but-chemical and sanitary-hygienic. properties.

4) Alkylaminoalkanesulfonates and sulfates (AAAC 1 and AAAC 2, respectively). Anionic landmark. substances easily transform into the zwitterionic form, which allows them to be isolated in pure form. The ionization constant of the acid group is much larger than the main one, so they are used in an alkaline medium. However, in the case of several main groups, and in the presence of other hydrophilic groups along with the acid group, these substances are similar in properties and uses to ampholytic surfactants and have a bactericidal effect. Depending on the ionization constants, you can distinguish the salts AAAC 1 RN (R ") - R: -SO 3 M, AAAC 2 RN (R") - R: - OSO 3 M, derivatives of aromatic amino sulfonic acids RR "N-Ar-SO 3 M , aminosulfonates with an N atom in heterocycles (formula XI); aminophosphates, aminophosphonates, etc. amine compound: a compound of the type RR "R: P (O) (OH) 2, RR" R "" OP (O) (OH) 2, where R and R "are long and short hydrocarbon radicals, R : - short bivalent radical; the compound RN (CH 2 CH 2 SO 3 Na) 2. Their difference is a good ability to disperse calcium soaps and resistance to salts of water hardness.

5) Polymeric ampholytic surfactants: natural (proteins, nucleic acids, etc.); modified natural (oligomeric protein hydrolysates, sulfatir. chitin); stepwise condensation products of amines, formaldehyde, albumin, fatty acids; cellulose derivatives obtained by introducing carboxyl and diethanolaminoethyl groups; synthetic, in molecules of which the structural features of all the above amphoteric surfactant groups are combined (see, for example, formulas XII-XVI).

The use of surfactants.The global production of surfactants is 2-3 kg per capita per year. Approximately 50% of the surfactants produced are used for household chemicals (detergents and cleaning products, cosmetics), the rest in industry and with. x-ve. Simultaneously with the annual increase in the production of surfactants, the ratio between their use in everyday life and industry is changing in favor of industry.

The use of surfactants is determined by their surface activity, the structure of the adsorption layers and the bulk properties of the solutions. Surfactants of both groups (truly soluble and colloidal) are used as dispersants for grinding solids, drilling hard rocks (hardness reducer), to improve lubricity, reduce friction and wear, oil recovery rates, etc. An important aspect of using surfactants is the formation and destruction of foams, emulsions, microemulsions. Surfactants are widely used to regulate the structure formation and stability of dispersed systems with a liquid dispersion medium (aqueous and organic). Micellar systems formed by surfactants in both aqueous and non-aqueous media are widely used, for which not the surfactant surface activity of the surfactant and not the properties of their adsorption layers are important, but bulk properties: pronounced viscosity anomalies with increasing surfactant concentration for example in the aquatic environment, crystallization. solid soap or solid-shaped structures (in greases based on petroleum oils).

Surfactants are used in more than 100 sectors of the economy. Most of the surfactants produced are used in detergents, in the manufacture of textiles and synthetic-based products. and natural fibers. The major consumers of surfactants include the oil and chemical industries, the industry is building. materials and a number of others. The most important surfactant applications:

Drilling with clay solutions and reversible water / oil emulsions. To regulate aggregative stability and rheological. characteristics of the solutions used high-brine. Surfactant-water-soluble cellulose ethers, poly-acrylamide, etc., natural calcium and synthetic salts are introduced into the emulsion. fatty acids (C 16 -C 18 and above), alkyl aromatic sulfonates, alkylamines, alkylamido amines, alkyl imidazoles;

Enhance oil recovery by micellar flooding (ethoxylated alkylphenols and alcohols, alkylaromatic sulfonates);

Antioxidant, extreme pressure and other additives in the production of mineral oils (synthetic soaps. Fatty acids, petroleum sulfonates, hydroxyethyl alcohol, alcohols) and plastic. lubricants (derivatives of phenols, arylamines, alkyl and aryl phosphates);

Regulation of wetting during flotation of iron and manganese ores (natural and synthetic fatty acid soaps, higher aliphatic amines), rare metal ores (alkylaronic and alkylphosphonic acids, alkylaromatic sulfonates);

Emulsion polymerization, production of polystyrene and other vinyl polymers (carboxymethyl cellulose, poly vinyl alcohol, synthetic fatty acid soaps, alkyl sulfates, ethoxy alcohol and alkyl phenols);

Production of chemical fibers (hydroxyethyl. Amines and amides, proxanolamines and proxamines, higher alcohols and acids);

Mechanical processing of metals: adsorption decrease in strength, increase in cutting speeds, planing, milling (natural and synthetic fatty acid soaps, alkyl aromatic sulfonates, hydroxyethyl alcohols, etc.);

Industry builds. materials: regulation of mechanical and rheo-logical. properties of concrete mixtures due to the adsorption modification of components (esters of synthetic fatty acids, sulfonates, alkylamines, alkyl sulfates, hydroxyethyl. fatty acids);

Production of synthetic detergents;

Improvement of soil structure, prevention of erosion processes (surfactant-polyelectrolytes are products of incomplete hydrolysis of polyacrylonitrile, amidation products of polyacrylic and polymethacrylic acids, and amide, cyclic imide, carboxyl, and other groups vary in the polymer chain).

Biological decomposition of surfactants.Aqueous solutions of surfactants in greater or lesser concentrations enter the effluent of the industrial grade. waters and ultimately into water bodies. Cleaning up wastewater from surfactant much attention is paid, because due to the low rate of decomposition of surfactant harmful effects of their impact on nature and living organisms are unpredictable. Wastewater containing the products of hydrolysis of polyphosphate surfactants can cause intensive growth of plants, which leads to pollution of previously clean water bodies: as plants die, their decay begins, and water is depleted of oxygen, which in turn worsens the living conditions of other forms of life in water.

Sewage treatment methods in septic tanks include transferring surfactants to foam, adsorption by active carbon, using ion-exchange resins, neutralizing cationic substances, etc. These methods are expensive and not effective enough, therefore, purification of sewage from surfactants in septic tanks is preferred. conditions (in reservoirs) by biological oxidation under the influence of heterotrophic bacteria (the predominant genus Pseudomonas), which are part of the activated sludge. In relation to this process, surfactants can be divided into "soft" and "hard." Hard alkyl surfactants include some alkyl benzene sulfonates (for example, tetrapropyl benzene sulfonate) and hydroxyethylir. isooctylphenols; currently they are practically not produced. The degree of bio-oxidation of the so-called soft surfactants depends on the structure of the hydrophobic part of the surfactant molecule: when it is branched, bio-oxidation deteriorates rapidly. Theoretically, bio-oxidation proceeds until organic substances are converted into water and carbon dioxide, the practical problem is reduced only to the time of oxidation, i.e., to the kinetics of the process. If you graduate. oxidation occurs slowly, surfactant has time to produce a harmful effect on living organisms and the natural environment.

During biochemical purification of spent surfactant solutions, oxidation is carried out in the presence of enzymes. With an increase in temperature, the oxidation rate increases, but above 35 ° C the enzymes are destroyed. Anionic surfactants are adsorbed on the interfacial interfaces, as a result of which enzymatic hydrolysis of fats, proteins and carbohydrates is reduced, leading to the inhibition of the vital activity of bacteria.

The mechanism of biooxidation of surfactants is established by studying the intermediate decay products. Thus, in the intermediate decomposition products of alkyl benzene sulfonates, the following were found: alkyl benzene sulfonates with a short alkyl chain; sulfophenylcarboxylic acids with an average of 4 C atoms in the chain; sulfo carboxylic acids with 5-6 C atoms; sulfodicarbonic acids and sulfonic acids. This suggests that biodegradation begins with a terminal methyl group. The closer the residue moves to the benzene ring, the slower the oxidation. The final stage is the decomposition of the benzene ring into an unsaturated compound, which oxidizes rather quickly and completely.

Alifatich Surfactants are oxidized faster than cyclic ones, and sulfonates are more difficult to oxidize than sulfates.

Apparently, this is due to the fact that the sulfates in water are hydrolyzed. Straight chain primary and secondary alkyl sulfates for 1 h completely destroyed in the wastewater. The branched-chain alkyl sulfates oxidize more slowly, and straight-chain alkyl benzene sulfonates decompose completely in only 3 days. Biodegradation of cationic surfactants has been little studied, some researchers do not recommend dumping them into wastewater.

The increase in surfactant production has led to the emergence of large enterprises that are local sources of water pollution. Highly concentrated. The wastewaters of these enterprises can be purified by a microbiological method based on the use of highly active cultures of microorganisms. Bacterial strains that destroy alkyl sulphates, alkyl sulphonates, alkyl benzene sulphonates, sulfoethoxylates, etc., have been obtained. Intermediate decomposition products have been identified that are analogues of natural substances, are non-toxic and do not adversely affect the environment. One of the important results of bacterial cleavage is the absence of substances among intermediate degradation products with a pronounced diphilicity of molecules. Method gave put. results for wastewater containing 500 mg / l surfactant. The cleaning efficiency was 95-97% for a period of not more than 12 hours. Among Gramotritsat. bacteria found microorganisms (destructors), which absorb the surfactant as a feed. substrate

Literature: Colloidal surfactants, trans. from English by ed. A. B. Taubman, 3. H. Markina, M., 1966; Physico-chemical bases of the use of surface-active substances, Tashkent, 1977; Surfactants. Handbook, ed. A.A. Abramzon and G.M. Payevoy, L., 1979; Micelle formation, solubilization and microemulsions, trans. with English, M., 1980; A b r and m z o A. A, Surfactants. Properties and application, 2nd ed., L., 1981; Successes of colloid chemistry, ed. I.V. Petryanova-Sokolova and K.S. Akhmedov, Tashkent, 1987. S.I. Faigold, V. SURFACE-ACTIVE SUBSTANCES Tikhonov.

Chemical encyclopedia. Volume 3 \u003e\u003e

for several orders of magnitude higher than in the volume of liquid, so even with negligible content in water (0.01-0.1% by weight), surfactants can reduce surface tension water at the border with air from 72.8 · 10 -3 to 25 · 10 -3 J / m 2, i.e. almost tosurface tension hydrocarbon fluids. A similar phenomenon takes place at the border. water rr Surfactant - hydrocarbon liquid, which creates prerequisites for the formation of emulsions.

The main quantitative characteristic of a surfactant is - the ability of a substance to reduce surface tension at the interface, this is the derivative of the surface tension with respect to the surfactant concentration as C tends to zero.

In the volume of the liquid phase surfactant may be

- or as individual molecules (truly soluble surfactants),

—or uniting into groups of several dozen molecules — The ultimate concentration of surfactant in a solution at which the formation of micelles begins is called).

Surfactant structure

As a rule, surfactants are organic compounds having amphiphilic structure, that is, their molecules have in their composition the polar part, the hydrophilic component (functional groups -OH, -COOH, -SOOOH, -O-, etc., or, more often, their salts -OH, -COONa, -SOOONa and etc.) and non-polar (hydrocarbon) part, a hydrophobic component. An example of a surfactant is ordinary soap (a mixture of sodium salts of fatty carboxylic acids — oleate, sodium stearate, etc.) and SMS(synthetic detergents), as well as alcohols, carboxylic acid, amines, etc.

Surfactant classification

- Ionogenic surfactants

- Cationic Surfactants

- Anionic Surfactants

- Amphoteric

- Nonionic surfactants

- Alkylpolyglucosides

- Alkyl polyethoxylates

Anionic surfactants

- contain in the molecule one or several polar groups and dissociate in aqueous solution with the formation of long-chain anions, determining their surface activity. These are groups: COOH (M), OSO 2 OH (M), SO 3 H (M), where M is a metal (single, double or trivalent). The hydrophobic part of the molecule is usually represented by limit or unsaturated aliphatic chains or alkyl aromatic radicals.

In anionic surfactants cation m. not only metal, but also an organic base. Often it is di- or triethanolamine. Surface activity begins to occur when the length of the hydrocarbon hydrophobic chain C 8 and with increasing chain length increases up to the complete loss of solubility of surfactants in water. Depending on the structure of the intermediate functional groups and the hydrophilicity of the polar part of the molecule, the length of the hydrocarbon part can reach C 18

.

Cationic Surfactants

- dissociate in aqueous solution with the formation of a surface-active cation with a long hydrophobic chain and an anion (usually a halide, sometimes an anion of sulfuric or phosphoric acid).

Among the cationic surfactants, nitrogen-containing compounds predominate; Nitrogen-free substances are also used: sulfonium + X- and sulfoxonium + X-, phosphonium + X-, arsonium + X-, iodonium compounds.

Cationic surfactants reduce surface tension less than anion-active, but they chemically interact with the surface of the adsorbent, for example. with cellular proteins of bacteria, causing a bactericidal effect.

Ampholytic surfactants

- depending on the pH value, they exhibit the properties of cation-active or anion-active surfactants.

The molecule contains a hydrophilic radical and a hydrophobic part capable of being an acceptor or proton donor, depending on the pH of the solution. Typically, these surfactants include one or more basic and acidic groups, and may also contain a non-ionic polyglycolic group. At some pH values, called. isoelectric point, surfactants exist in the form of zwitter-ions. The ionization constants of acidic and basic groups of truly soluble amphoteric surfactants are very low, however, cation-oriented and anion-oriented zwitterion are most common. The primary, secondary or tertiary ammonium group, pyridine residue or imidazoline residue is usually used as a cationic group. Instead of N m. S, P, As atoms, etc. The anionic groups are carboxyl, sulphonate, sulfoester or phosphate groups.

Nonionic PA

- high-molecular compounds that do not form ions in aqueous solution.

Their solubility is due to the presence of hydrophilic ether and hydroxyl groups in the molecules, most often the polyethylene glycol chain. When dissolved, hydrates are formed due to the formation of a hydrogen bond between the oxygen atoms of the polyethylene glycol residue and water molecules. Due to the breaking of the hydrogen bond with increasing temperature, the solubility of non-ionic surfactants decreases, so for them the cloud point is the top. The temperature limit of micellization is an important indicator. Many compounds containing a mobile H atom (acids, alcohols, phenols, amines), reacting with ethylene oxide, form non-ionic surfactants RO (C2H4O) nH. The polarity of one oxyethylene group is significantly less than the polarity of any acid group in anion-active surfactants. Therefore, from 7 to 50 oxyethylene groups are required to impart the required hydrophilicity to the molecule and the HLB value depending on the hydrophobic radical. A characteristic feature of non-ionic surfactants - liquid state and low foaming in aqueous solutions.

Non-ionic surfactants combine well with other surfactants and are often included in formulations.

Thanks to detergent, wetting, emulsifying, dispersing and other valuable properties, surfactants are widely used in the production of detergents and cleaning products, cosmetics and pharmaceuticals. latex, rubber. polymers, chemical plant protection products, textiles, leather and paper, building materials, corrosion inhibitors, in the extraction, transportation and processing of oil, etc. Most surfactants are used for the production of synthetic detergents (SMS).

Surfactants have relatively low toxicity to humans and animals. According to the degree of increase in the toxicity of surfactants can be distributed in the following order: non-ionic, anion-active, cation-active. When exposed to the skin and mucous membranes, synthetic surfactants can be irritating and resorptive. It has been established that compositions from anionic and non-ionic compounds have a less pronounced biological and toxic effect. Non-ionic surfactants reduce the adsorption of anionic substances and only in large doses can have a damaging effect on the skin. The greatest danger of surfactants and preparations based on them for people is their sensitizing effect, the ability to cause allergic reactions. Sensitization can occur in any way the surfactant enters the body.

Sources of surfactant in the aquatic environment

Surfactant water bodies come in significant quantities from household (use of synthetic detergents in everyday life) and industrial wastewater (textile, oil, chemical industry, production of synthetic rubbers), as well as from runoff from agricultural lands (included in insecticides, fungicides, herbicides and defoliants as emulsifiers).

Surfactants are widely used in industry, agriculture, medicine and life. The global production of surfactants is increasing every year, and the share of non-ionic substances in the total output is constantly increasing. All types of surfactants are widely used in the preparation and use of synthetic polymers. The most important area of \u200b\u200bconsumption of micelle-forming surfactants is the production of polymers by emulsion polymerization. The technological and physico-chemical properties of the resulting latexes largely depend on the type and concentration of the surfactants chosen (emulsifiers). Surfactants are also used in suspension polymerization. High molecular weight surfactants are usually used - water-soluble polymers (volivinyl alcohol, cellulose derivatives, vegetable glues, etc.). Mixing varnishes or liquid oil-resin compositions with water in the presence of emulsifiers produces emulsions used in the manufacture of plastics, leather substitutes, nonwovens, impregnated fabrics, waterborne paints, etc. High-molecular water-soluble surfactants, in addition to the use of the above technologically. processes used as flocculants in various types of water treatment. With their help from wastewater, as well as from drinking water remove suspended matter.

Information was borrowed from the following sources:

1) www.wikipedia.org

3) www.hydrodynamictechnology.com

08:05 pm - Performs like .. SAWSSurfactants (surfactants) remove fat from the surface of the skin. They are introduced with the composition of shampoos, lotions, toothpastes, gels and foams for washing. Unfortunately, not all detergents are equally useful (or harmless).

I suggest to understand.

Surfactants are divided into 4 types: anionic, cationic, non-ionic and amphoteric.

Currently used anion surfactants of the new generation, for example, very soft sodium lauroyl sarcosinate (sodium lauroylSarcosinate / Crodasinic LS30).

2. Cationic Surfactants

(amines and their salts) are used together with anionic surfactants, neutralizing their aggressive action. Cationic surfactants are introduced into the shampoo as a conditioning agent.Another advantage is bactericidal.

Laurdimonium Hydroxypropyl Hydrolyzed Collagen, Laurdimonium Hydroxypropyl Hydrolyzed Wheat Protein

3. Nonionic surfactants

The main advantage is a favorable effect on the skin and 100% biodegradability. A characteristic feature of nonionic surfactants is low foaming in aqueous solutions, therefore anionic surfactants are added to the composition with nonionic surfactants ..

Glyceryl Laurate (Glyceryl Laurate),

ethoxylated alcohols.

4. Amphoteric surfactants

The main advantage is a mild effect on the skin - their particles change the charge depending on the environment in which they fall. Possess washing, bactericidal and anti-stabilizing activity.

From the group of amphoteric surfactants, betaine derivatives are most often used. eg, cocamopropyl betaine (cocoaminopropyl

betaine) and imidazoline (sodium cocoamphoacetate). In combination with anionic surfactants, they improve the foaming ability and increase the safety of formulations, and when combined with cationic polymers they increase the positive effect of silicones and polymers on hair and skin. These derivatives are obtained from natural raw materials (for example, cocamopropyl betaine - a derivative of coconut oil), so they are quite expensive components.

cyclimide, amidobetaine, alkyldimethylcarboxybetaine