How to correctly install the heating pump with an arrow. Scheme for installing a pump in the heating system of a private house

An additional pump in the heating system will be the best way out of a situation where home owners have problems heating their home. Installing the unit will help distribute heat evenly in the pipeline. The great advantage of the pumps is their versatility, because they can operate not only on coal, but also on diesel fuel, fuel oil, gas, wood and electricity.

What are the advantages of an auxiliary pump?

The use of additional equipment to improve the operation of the heating system provides residents with many benefits. Firstly, the overall efficiency of the system increases. This affects not only the uniformity of heat distribution, but also the temperature in living spaces. Secondly, the air in the rooms warms up much faster. Thirdly, heat circulation inside the main pipeline is improved.

Another advantage of an additional pump is the elimination of the possibility of air accumulation in one of the channels through which heat circulates. Owners of apartments on the upper floors suffer most from this problem, however, if you install an additional unit, it will help create the necessary pressure and supply heat to the entire building. The big advantage of the pump can be confidently considered its efficiency. In practice, it has been proven that together two units (standard and additional) will consume less fuel.

In addition, if the building is provided with heat by a pair of pumps in the system, then residents can install useful devices such as towel dryers and thermostats. The inhabitants of such a building also have the opportunity to use small-diameter pipes - the quality of heating will not deteriorate as a result. Another important advantage is the low price of the equipment. An additional circulation pump can cost from 5 to 20 thousand rubles. This is not too much money, considering that money will be collected for the unit from all residents of the house.

What device parameters should be considered when purchasing?

Before purchasing and installing equipment, it is worth studying its most important parameters. In order not to make a mistake when choosing, familiarize yourself with such characteristics as coolant density, pressure force and water temperature. You will also need to know the diameter of the pipes used to heat the building.

You can find out exactly what characteristics the pump you have chosen has on the packaging, side wall or in the technical data sheet of the unit. Manufacturers designate pressure with the letter “H”. This indicator means the device’s ability to raise water to a certain height. It is measured in meters. The second characteristic is the fluid consumption of the system. It is designated by the letter "Q" and is measured in cubic meters. This parameter is equal to the boiler power and depends mainly on the diameter of the pipeline.

Circulation equipment is not designed to lift fluid. Because of this, when purchasing a unit, special attention should be paid to the “Q” parameter. If the installed boiler is not equipped with a pump, then further liquid consumption will have to be calculated independently. Most modern heating devices already have similar equipment. Installing 2 devices to improve heat circulation is optimal if the house already has a boiler of an older modification, but over time the building was completed and the heating structure increased.

There is no need to purchase very expensive equipment. In any case, the device will not be used to its full potential. In addition, the installed unit has a high noise level. Most often, the length of the pipe determines the power characteristics of the equipment: for every 10 m of pipe, the device must provide 0.5 m of pressure. In practice, a 100-meter ring will work effectively if the pump produces a pressure of 5 m. When buying a unit for a pipeline, do not forget that the power of the device should be 10% more than the figure calculated by the residents.

Types of additional pumps - choosing the appropriate unit

For efficient media circulation, it is best to use “wet” or “dry” pumps. In the first case, the rotor is located inside the coolant, that is, it pumps water while being directly in it. As the fluid circulates, it cools the engine. A stator is used to supply electricity. Wet pumps have many advantages. Firstly, they are able to last for a fairly long period of time. Secondly, such devices do not require frequent maintenance. Thirdly, they make less noise. And fourthly, they are not large in size.

Disadvantages include not very high efficiency, limited scope of use, and the inability to use pumps for drinking water and other food-related devices. Such units are used only in mansions and residential high-rise buildings.

In the design of dry-type pumps, the rotor is located outside the coolant. Such devices use a seal that is designed to separate the motor and the pump itself. The approximate efficiency of the equipment is 75%, which is why these units are used in situations where it is necessary to regularly pump large amounts of water. Such units are used more in manufacturing and shopping centers than in residential buildings.

Preparing to install equipment

Before you begin installing the pump, carefully read the operating algorithm. The first step is to prepare for installation. To do this, purchase split-type threads and a filter for deep cleaning. Also, before installing the equipment, you need to prepare a check valve. It stabilizes the operation of the heating system. To work you will also need:

- a set of keys;

- a set of large and small flat screwdrivers;

- pliers;

- a pipe whose diameter will be equal to the diameter of the riser;

- fittings

It is worth deciding in advance on the installation location. Modern units can be installed not only on the water supply pipe, but also on the return pipeline. If you plan to install the device on a section of pipe between the return and direct radiator-type wiring, then before doing so you will need to check the ability of the unit to withstand a powerful pressure of hot liquid. It is also worth remembering that in buildings where the premises are equipped with “warm floors”, the injection device is placed at the hot water supply point. In this way, it will be possible to eliminate airiness in the pipes.

If there is a membrane tank, then the pump with a bypass is mounted on the side of the return pipeline, closer to the expander.

Installation of the unit - algorithm in detail

The installation of an additional circulation pump in a standard heating system does not depend in any way on the type and material of the latter. In any case, installation will have to be done using the bypass method. If the house is equipped with a metal pipeline, then you can purchase a ready-made structure that allows you to bypass the main highway. Before installation, you will need to completely drain the liquid and clean the pipes. To do this, the pipeline must be flushed several times. After this, a piece of pipe bent in the shape of the letter “P” is installed on the side of the main pipe.

Fix the pump in the middle of the pipe. Place ball valves on both sides of the device. What are they needed for? First of all, the water circulation will return to normal if you turn off one of the taps. Secondly, in case of repair of the unit, you will have to drain the water; if there are taps, this will not be necessary. During installation, pay attention to the direction in which the liquid moves. It is marked on the pump body with a special arrow. Upon completion of installation, the system is filled with water and the operation is checked. If any problems are detected, they should be eliminated at this stage of the operation.

Next, using the central screw, we expel the stagnant air from the pipes. If everything is done correctly, water will begin to flow from a separate hole in the pipeline. To install a unit with manual control, the air must be removed from the pipes before installation begins. To do this, the device is turned on for a few minutes, after which the equipment valves open. This procedure should be repeated several times. As soon as the pipeline is filled with a sufficient amount of liquid, the pump itself will start. In this case, the presence of air in the pipes is strictly unacceptable.

Device connection technique – what to connect to what?

Residents of the house will not receive high-quality heating if the pump is not connected correctly. When connecting the device to the power grid of natural circulation systems, an automatic fuse is used. To install the latter, you should choose a place at a distance of at least 70 cm from the main boiler. In forced circulation systems, the pump will start working after the thermal relay is turned on. In order to ensure simultaneous operation of the built-in and additional pump, the second device will need to be connected to a relay or routed in parallel to the first device.

In electric-type boilers, circulation devices should be connected directly to the boiler. In this case, the pump will only operate when the liquid is heated. The cleaning filter must be installed in front of the pump housing. A valve screwed into the upper part of the bypass makes it possible to ventilate the pipeline, removing any air that has accumulated there.

A modern heating system is economical, convenient and controllable. However, the practice of its organization often contradicts the principles of constructing such structures. In the average apartment or one-story cottage it is difficult to implement the classical gravitational mechanics of coolant movement. Installing a circulation pump will allow you to achieve a good level of stability and efficiency from your heating system. Such a device is also useful in structures with a gravitational component of coolant movement, and a warm floor without a forced blower simply does not work.

A modern circulation pump is a fairly technologically advanced device. It uses components and materials that can operate at high temperatures for a long time. Therefore, the installation of a supercharger in the heating system of a private house can be carried out practically without regard to the parameters of the coolant and other criteria.

To extend the service life of the device and provide it with optimal operating conditions, it is recommended to install the pump according to standard requirements, namely, on the return of the heating system, where the coolant has a lower temperature. At the same time, there are several simple rules for organizing circulation systems, both open and closed.

- A circulation pump must be installed on each closed heating circuit. This rule is always observed when heating individual parts of a private house or when supplying coolant to apartment radiators and heated floors.

- Installing an additional pump produced in buildings where the pipeline network is quite extensive. It is recommended to install another supercharger if the pipe length is 80 meters or more.

- If the supply and return differ in temperature by more than 20 degrees, this means it is necessary to install a supply pump in a system with natural circulation additional supercharger, if the existing one does not cope with the task.

- Controlling the circulation pump by changes in its speed can not only provide the best heating mode, but also save money due to optimal boiler operating conditions.

The supercharger is easy to install with your own hands. In this case, you need to choose the right installation location according to the requirements for optimal operation of the equipment. At the same time, convenient adjustment of the heating pump and access for its quick dismantling for repairs should be provided.

Advice! The correct strategy when choosing a device for installation in a new or existing heating system lies not only in the correct calculation of its parameters. The circulation pump should be selected according to its level of functionality. Options such as speed control are useful, and if you purchase a model with frequency control, you can very finely tune heat output and resource consumption.

The rules for choosing a point in the heating system where the forced circulation device is installed are quite simple and understandable.

- The pump must be as close as possible to the heating equipment.

- It is recommended to install the device on the return pipe.

- Both when installed on the supply line and on the return line, there should be no pipe bends between the boiler and the circulation pump, with the exception of special ones intended for servicing the system.

According to standard rules, the connection diagram of the supercharger must provide for the possibility of isolating the installation point for dismantling, ensuring the operation of the equipment in normal mode, guaranteeing easy maintenance of the system, and carrying out commissioning work.

Heating system wiring diagrams

When building a line of presentation for a quick understanding of the organizational features of certain heating systems, it is reasonable to start with the option with forced circulation.

With forced circulation

This scheme has a number of features.

- Height differences, pipe slopes, and the location of radiators relative to the heating boiler are not regulated in any way.

- The system uses multi-point technology or a single-point air exhaust system (Mayevsky taps on heating radiators or one outlet point with the highest level of height).

- It is possible to organize as many isolated circulation circuits as desired, each of which is served by a separate pump.

The main distinguishing feature of a system with forced circulation is that its operation is impossible without the functioning of the circulation pump. Therefore, when the power is turned off, the coolant stops and the rooms are not heated.

Important! If a power outage occurs at subzero air temperatures, a forced circulation system requires an emergency drain if the time until operation is restored allows the coolant to freeze. For this purpose, emergency drain points must be provided in several places in the pipe structure with a low level. This does not need to be done if the system is closed and the coolant does not allow for freezing at subzero temperatures.

With natural circulation

A natural circulation system has a number of advantages, but requires strict adherence to the rules of the organization. Its features are as follows.

- After the heating boiler, an accelerating line is provided, a vertical pipe that allows creating pressure as the coolant expands for its movement through the network.

- A clear slope parameter is regulated for both the supply and return pipes.

- With several heating circuits, it is difficult or impossible to achieve optimal heat transfer in each of them.

Controlling a circulation pump for the movement of coolant can dramatically increase the functionality, efficiency, and customizability of a heating system with natural circulation.

This system allows you to solve a number of standard problems:

- level out design errors and overcome hydraulic resistance of the pipeline network;

- optimize the loading of heating circuits when installing several pumps, regulate heat output;

- improve operating conditions of heating equipment.

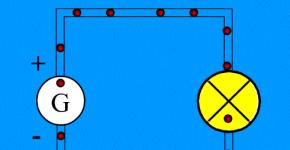

The main advantage of a system with natural circulation, despite all the complexity of its organization, is the ability to work when the power supply is turned off. To achieve this, the circulation pump installed in bypass. This is a fairly simple structure.

The bypass is a separate unit for installing a circulation pump with a bypass loop and shut-off valves for maintenance.

The bypass assembly provides several convenient features.

- When the ball valves are closed, the blower can be removed without draining the entire system in order to repair the circulation pump or replace it.

- The system operates without power supply.

- It is possible to carry out the initial heating start without the participation of a circulation pump.

- It is easy to organize a structure to protect the pump from impurities entering its turbine by installing a coarse filter or a mesh-type unit.

The water heating circuit of a private house can use either a manual or automatic bypass. In the latter case, in the circulation pump bypass circuit a check valve is installed.

When the circulation pump operates, excess pressure forms at the outlet of the check valve. The unit shuts off the supply, providing an optimal flow pattern for the coolant. When the power is turned off, water begins to move through the valve due to the natural gravitational component. This scheme does not require adjustment or configuration, including during commissioning.

Advice! Since the check valve is a device quite sensitive to the ingress of scale and mineral deposits, in open heating systems it is recommended to duplicate its operation with a sequentially installed ball valve.

Connecting the pump to the power supply

Connection to the power supply network can be done in two ways.

Direct connection

The first one is standard, it is a direct connecting the power cable to an outlet with the desired voltage type. Wherein:

- select a wire with a cross-section of at least 2 sq.m;

- conductors should be multi-stranded to reduce the likelihood of fractures when bending;

- The connection must be made using a grounding wire.

The specific cross-section of conductors should be selected based on the manufacturer’s recommendations and the rated power of the pump. The socket into which the device is connected should be located as close as possible to the installation point, and it is recommended to install RCDs and emergency shutdown circuit breakers between it and the pump.

Advice! If the pump voltage supply cable is located close to the heating network pipes and the coolant temperature exceeds 90 degrees, select a special heat-resistant wire to power the equipment.

UPS application

When the supercharger is operating, especially under load, power failures, power interruptions, and changes in input voltage parameters are possible. This may negatively affect the service life of the device, its efficiency, and lead to breakdowns. Therefore, if possible, it is worth using a connection diagram through an uninterruptible power supply.

When choosing an uninterruptible power supply model, a simple calculation is made. The basic conditions include the power of the circulation pump and the time during which its operation must be maintained. Based on the calculation results, the battery capacity or UPS model is selected. Many manufacturers of such equipment offer graphs and tables on their official resources that make it easy to determine the optimal power source option.

Advice! To power the circulation pump, it is recommended to use a UPS only with a sinusoidal output signal or close to it. The best results are shown by On-Line UPSs that provide zero response time and an ideal voltage curve.

Setup and commissioning

Commissioning work after installing the circulation pump is not difficult, but must be carried out in a certain order.

- The pump is mounted in the bypass or embedded in the return or supply pipe.

- The device is connected to the electrical network.

- The heating system is filled with water.

- Air pockets are removed by opening shut-off valves on specially made bends or Mayevsky taps installed on heating radiators.

- Air is removed from the circulation pump housing by opening the valve and unscrewing the screw on the device housing cover.

As soon as water begins to come out of the special outlet of the pump, the device is ready for operation. After this, it is enough to start the heating boiler, check the passport to see what speed is best to turn on the heating pump, set the optimal mode and adjust the pressure parameters in the system during the heating process of the coolant.

Possible malfunctions of circulation pumps

The circulation pump is a fairly simple device. Its serious breakdowns include wear of the turbine wheel, physical damage to the elements, or failure of the electrical circuit. Some heating pump malfunctions can be fixed with your own hands. For this you need a device dismantle and disassemble. The procedure is as follows.

- Turn off power to the equipment.

- If the pump is installed in a bypass or there are taps on both sides, the coolant supply is shut off and the device is removed from the installation point.

- For long-term repairs, a spare pump should be installed.

Advice! If the heating system does not allow you to shut off the liquid supply in a limited area where the pump is installed, it is recommended to completely drain the coolant before dismantling the device. This measure will allow for faster commissioning according to the standard scheme.

When disassembling the circulation pump, you can gain access to its main functional parts:

The pump makes a loud noise, but there is no coolant circulation

This malfunction occurs during long equipment downtime. Sealing devices and bearings lack lubrication and dense mineral deposits form. To start, the pump must be disassembled according to the manufacturer's instructions. The housing and electric drive are removed. Using a screwdriver or any clamping device, turn the rotor and ensure that it rotates relatively freely. After this, the pump is installed in its normal place and turned on.

The device makes a lot of noise during operation

Cause of excess noise - debris ingress into the area of the electric motor shaft and turbine wheel block. The problem can be resolved by completely disassembling and cleaning the device.

Advice! To prevent troubles in the future, it is recommended to install cleaning filters at the pump inlet, and for idle equipment, start-ups for 20-30 minutes at least once a month.

The pump does not turn on

There may be several reasons for startup failure. The most common one is Power failure. You should check the power cable (by turning off the circuit breakers or unplugging the plug from the socket) for breaks or damage, and test the voltage of the power source.

Another reason for startup failure is protection triggered. To eliminate the problem, replace the fuses or other components specified by the manufacturer. Before starting the pump, carefully check the condition and power supply parameters of the network, and make sure that other systems associated with the supercharger are operating correctly.

The device starts and stops working after a short period of time

The reason for the automatic stop is exceeding the permissible load. This is caused by scale deposits on wet rotor parts. To restore normal operation, the pump should be disassembled and mineral deposits removed using special means.

Loud noise, vibration, heat generation

The reasons for the sudden change in sound and other operating parameters are the air in the circulation pump. This problem may be caused by incorrect commissioning or exceeding the minimum cavitation limit. Troubleshooting is done by adjusting the parameters of the heating system. Air plugs are removed from the pipes; a similar operation is carried out with a valve on the top of the pump housing.

Advice! To prevent the formation of cavitation bubbles, the inlet pressure should be adjusted (make it higher than the minimum specified in the pump passport) in the supply pipe.

Constant, increased vibration level

Excessive vibration may be caused by bearing wear. These structural elements have a limited service life even with ideal coolant parameters. The recommended interval for replacing bearings in circulation pumps must be indicated in the passport of a specific model.

It is worth remembering that you can remove a bearing pressed into the mounting hole using a special puller. Reinstallation at home is done with a wooden mallet. The new bearing is placed on the mounting hole and driven in with light, precise blows.

Insufficient pressure

A properly installed, operating circulation pump in some cases is not able to provide sufficient pressure. The reason may be incorrect rotation speed setting, which is often observed with high viscosity of the coolant or excessive length of pipelines. If there is such a possibility, the device is adjusted; if the model is chosen incorrectly, it is replaced.

For three-phase pumps The reason for insufficient pressure may be an incorrect connection diagram. Therefore, the first phase of troubleshooting should be checking the phasing, the condition of the neutral wire, and the power supply voltage.

It is always worth remembering that the circulation pump does not reach the user immediately after production. Therefore, knowing how to disassemble and clean the device, as well as its components, is useful. For example, such information will easily help to cope with the case when a shutdown occurs due to oxidation of the fuse contacts. In this case, the partial disassembly and stripping operation can be carried out even without dismantling the device.

Important! If simple troubleshooting methods do not help, you should seek professional help. To determine the gap (the degree of wear of the turbine wheel) between the impeller and the housing, special tools may be required. The same applies to evaluating the parameters of the motor windings. In some cases, complex, professional repairs may be required.

Conclusion

In order not to encounter problems with the heating system, not to freeze, and not to waste money and time on making changes to the piping, you should not skimp on the design and proper organization of installation sites for circulation pumps. Bypasses equipped with shut-off valves, filters, check valves, and the correct choice of installation point will help simplify heating settings, provide automatic control, guarantee optimal operating conditions for the equipment and significantly increase its reliability and service life.

The principle of forced circulation of coolant has become an indispensable attribute of modern water heating systems. The fact that pumping water has an advantage over old gravity systems is no longer in doubt. Therefore, in most private homes, a circulation pump has already been installed or will soon be installed in the heating system. Not to mention newly installed utility networks, where it has been present since the design stage. Let's look at how to properly install the pump and connect it.

Where should the pump be installed?

The role of the pumping device in heating systems is clear to everyone. But questions often arise about the place of its installation. There are only two options here:

- on the supply pipeline after the boiler and safety group;

- on the return line directly in front of the boiler.

The number of supporters of installation in the return pipeline is large, but few of them can argue their position, just like those who like to install the unit in the supply. So, in practice, the installation location plays absolutely no role and does not have any effect on the operation and thermal power of the system. Also erroneous are the statements that, due to the lower return temperature, the pump will last longer, that it is easier to pull than to push, and other statements in the same spirit.

In private homes, the temperature in the supply line rarely reaches 70 ºС, not to mention the estimated 90 ºС. The exception is the cold northern regions, but there the approach to heating buildings is somewhat more serious. The circulation units themselves are designed for high water temperatures and they jam for other reasons, for example, due to the low quality of the coolant containing various impurities. From a hydraulic point of view, the circulation pump can be installed on any of the two branches; the system parameters will not change.

Then why is the unit most often placed on the return line? Everything is quite simple. In the event of some malfunction and overheating of the boiler, the water in its tank will begin to boil, and the steam-water mixture will move into the system. But the pump can only pump an incompressible medium, that is, liquid. When steam gets into it, the pumping process will stop, the coolant in the network will stop, and the boiler will explode if measures are not taken.

Important. Most modern heat generators are well protected from overheating, there is nothing to worry about. In this regard, only solid fuel boilers pose a danger, so near them it is necessary to install a return pump only.

The pumping unit is installed in the network in compliance with certain rules and requirements. For the purpose of familiarization, we list all the rules for installing pumps:

- The unit can operate in both vertical and horizontal positions. During installation, the direction of fluid flow indicated by the arrow on the housing must be observed;

- When installing the unit, it is necessary to observe its orientation in space. The pump must be placed so that its rotor is in a horizontal position, and not with its head up or down, as shown in the figure below;

- so that the pump can be removed for maintenance or repair, shut-off valves are installed before and after it;

- the unit is installed on the bypass line, and a tap is placed on the direct line, then if it is turned off, the system will be able to continue operating without forced circulation;

- if a circulation pump is installed in an open heating system, then it is better to place a strainer (dirt filter) on the bypass, in front of the pump, but after the tap. In pressure networks, the mud trap must be installed in front of the bypass, and when piping a solid fuel boiler - in front of the three-way valve.

There is one subtle point. In a scheme where forced circulation of the coolant was originally conceived, installing a bypass often does not make sense. After all, without a pump, water will still not flow through the pipes, since the slopes, diameters, and so on are wrong. Therefore, you can safely build the unit into the return pipeline between the expansion tank and the boiler, as demonstrated by the diagram for installing a circulation pump in the heating system shown in the figure:

The bypass line for the pump should be installed only in systems previously designed as gravity flow. The figure below shows the installation diagram corresponding to this case:

Advice. Sometimes, instead of a ball valve, a reed-type check valve is installed in a straight line of the gravity system. While the pump is operating, it presses the valve petal with its pressure and the straight line is closed. But as soon as the electricity is turned off, the pumping unit stops, the pressure drops and the valve in the straight line opens. Thus, the system switches to natural circulation mode automatically.

Work order

To install and connect the pump yourself, you need to follow the following procedure:

- if the boiler is running, then you need to stop it and give the coolant time to cool;

- empty the system or boiler circuit, if possible. When the piping of the heat generator is done correctly, there is no need to drain the water from it; it is enough to cut it off from the system using the appropriate fittings;

- if the system is gravity-fed, then the bypass unit with a pump and taps can be assembled in advance;

- insert the unit or just the pump into the supply or return pipeline, adhering to the rules set out above;

- make an electrical connection to the circulation pump.

Advice. We will not reinvent the wheel and offer a wiring diagram here. This is available in the operating instructions for any unit, even those made in China.

Further actions consist of filling the system with water and bleeding air from it using Mayevsky taps and valves. Next, it wouldn’t hurt to inspect the installation site to detect leaks. If they are not there, then you can safely put the circulation pump into operation. Do not forget to open the valves that shut off the unit and shut off the direct line if it is installed on a bypass.

Conclusion

At first glance, you might think that installing a circulation pump correctly is not difficult. This is actually true if you have experience in installation work. When there is no such experience, we advise you to carefully study the documentation supplied with the product by the manufacturer.

Content

In small country houses, a stove is used for heating, usually solid fuel, which can directly heat one or two rooms. But a multi-room dacha or private house requires the installation of an autonomous heating system. Installing a circulation pump is a prerequisite for high-quality, uniform heating of all rooms that need heat.

Circulation pump in the heating system

The need for a pumping unit

If the house is not connected to the central heating network, the homeowner must solve the problem of creating a heating circuit that can evenly warm all the rooms where radiators are supposed to be installed.

In a system with natural circulation of coolant, the heated liquid moves through the pipeline slowly, and in rooms far from the boiler, radiators are much colder compared to heating devices located closer to the heat generator. The larger the house, the greater the difference - even raising the temperature of the coolant in the boiler jacket to critically high values will not help to increase the efficiency of heating air in distant rooms.

In some cases, changing the angle of inclination and diameter of the pipes will help improve natural circulation of the entire system. But this requires major changes in the house. It is much easier and cheaper to install a circulation pump, which will make the liquid in the pipeline move much faster.

In a closed-type system with forced circulation, pumping units are installed according to the design - on the main heating circuit with radiators, on each of the water-heated floor circuits.

The disadvantages of using a pump in heating systems include energy dependence. Therefore, in areas where power supply interruptions are regularly observed, it is recommended to install an autonomous heating system with natural circulation based on a solid fuel heat generator, and install a circulation pump as an additional element. In the event of a power outage, heating and movement of coolant through the pipes will continue, albeit with a loss of speed.

Pump design and operating principle

A circulation-type pump unit provides additional liquid pressure in a closed heating circuit. An electric motor is attached to the pump housing; inside the housing there is a motor shaft on which the impeller is mounted. The rotation of the impeller creates pressure due to centrifugal force. Due to this, the coolant pressure in the system increases. Based on their design features, there are two types of circulation pumps - “dry” and “wet”.

Circulation pump device

Circulation pump device "Dry" units

In devices of this type, the pumped liquid medium does not come into contact with the rotor. Its working part is separated from the coolant by stainless steel sealing rings. When the unit is turned on, the connection is sealed with a thin film of coolant, which is formed due to the pressure difference in the heating system and outside it.

Dry-type pumps are rarely used for heating systems in private houses. The unit makes a lot of noise during operation, which is why it is necessary to soundproof the boiler room. In addition, the device is sensitive to mechanical contamination of the coolant and fails if damaged by suspended matter that gets into the water. The advantage of the “dry” mechanism is 80% efficiency.

"Wet" units

When the pump operates, the liquid medium passes through the brass or bronze body of the unit, which houses steel and ceramic elements for which the coolant serves as an additional lubricant.

“Wet” pumping units are distinguished by their simple design, low noise, and long service life. They are affordable and inexpensive to maintain. The disadvantages include low efficiency - it is about 50%. But this is enough for successful operation as part of an autonomous heating system in a private home.

The device of a “wet” circulation pump

The device of a “wet” circulation pump Principles for selecting pumping equipment

Having decided on the type of heating pump unit, you need to correctly calculate its optimal power. There is no point in installing a circulation pump with a large power reserve - it is more expensive and makes more noise during operation.

The circulation pump unit performs the following tasks:

- creates a liquid pressure capable of overcoming the hydraulic resistance of the heating circuit components;

- pumps through the pipeline the volume of coolant necessary for high-quality heating of all rooms.

- pump performance (flow rate, measured in m 3 / h) - the volume of coolant that is pumped by the device in one hour;

- pressure (measured in meters) is an indicator that determines the hydraulic resistance overcome by the pump.

For a cottage with several floors, with complex architecture, the calculation of the power of the pumping unit should be carried out by specialists. But for small houses, calculations are carried out using simple formulas and tables.

Determining power

Standard calculation formula: Q=0.86R/TF-TR, where

- Q – pump flow (m 3 /h);

- R – thermal power (kW);

- TF – coolant temperature (°C) in the supply pipe;

- TR – coolant temperature (°C) in the return at the entrance to the boiler.

It is difficult to determine the thermal power yourself, so it is more convenient to use ready-made solutions:

Method 1. According to European standards, the thermal power indicator (R) for a small private house is 100 W/m2, for a multi-storey building - 70 W/m2, for buildings with good insulation - 30-50 W/m2. These standards are suitable for Russian regions with a mild climate.

Method 2. Russian SNiP standards are designed for climates with frosts down to -30° C. The thermal power indicator for one- and two-story houses of a small area is 173-177 W/m2, for houses with a height of 3-4 floors - 97-101 W/m2 .

Method 3. The value for calculation is selected according to the table presented, based on the characteristics of the building:

Calculation table of thermal power for different rooms

Calculation table of thermal power for different rooms Note! Some errors in calculations will not affect the functioning of the heating system if you purchase a circulation pump with adjustable capacity.

There is another method for determining coolant flow (pump performance). The flow rate (Q) is equal to the boiler power (P). For example, 20 liters of coolant pass through a boiler with a power of 20 kW per minute. And each 10 kW radiator passes 10 liters of liquid per minute. To calculate the coolant flow in each heating circuit, you need to sum up the indicators of all radiators and add the indicators of the pipeline. The coolant flow in the pipeline depends on its length and diameter. The smaller the diameter, the higher the hydraulic resistance. A table compiled for the standard coolant speed of 1.5 m/sec will help you calculate the pipeline performance.

| Water consumption | Diameter in inches | Water consumption | Diameter in inches |

| 5,7 | 1/2 | 53 | 1 1/4 |

| 15 | 3/4 | 83 | 1 1/2 |

| 30 | 1 | 170 320 | 2 2 1/2 |

For every 10 meters of pipeline, 0.6 m of pressure is required, which is provided by a circulation pump. For example, if the length of the heating circuit is 100 m, the pump must provide a head of 6 m.

Pumping unit installation technology

The installation of a circulation pump in the heating system can be done independently.

In addition to the pumping unit itself, elements are needed for its piping:

- two ball valves;

- deep cleaning filter;

- check valve;

- a piece of pipe for bypass (if pumping equipment is used for installation or modernization of a gravity system).

To ensure that the rooms are heated evenly regardless of their location relative to the boiler, it is necessary to properly install the pumping equipment. They begin installing a circulation pump in the heating system by choosing a location for tapping into the system.

Installation location of the circulation pump in the heating system of a private house

Installation location of the circulation pump in the heating system of a private house Selection of installation location

When deciding how to install a circulation pump, it is important to remember that the device must be freely accessible for regular maintenance. Pumping equipment can be installed on both the supply pipe and the return pipe - the materials from which modern devices are made are designed for operation at high temperatures.

It is considered advisable to install a circulation pump in the heating system on the return pipeline directly next to the boiler for the following reasons:

- A device installed on the return line supplies coolant into the water jacket, displacing air pockets that may occur in the upper part of the boiler. If the pump is located on the supply pipe, when air accumulates in the boiler, it can create a vacuum and cause the coolant to boil.

- If the boiler malfunctions, the coolant in the water jacket may overheat and boil. The circulation unit is not able to pump the steam-water mixture, so it stops. This threatens the boiler explosion if the safety group does not work.

Attention! Wood and coal solid fuel boilers, unlike gas, electric and pellet boilers, do not have reliable protection against overheating. Therefore, when installing such a heating system yourself, the pump is installed only on the return line.

It is mandatory to use a separate pump in the underfloor heating system - the device is mounted on the manifold to which the circuit is connected.

When reconstructing the gravity system, the bypass with the pump unit is cut into the return pipe near the membrane expansion tank. If the location does not allow for normal access to the pump, the bypass with the device is placed on the supply pipe, cutting in a check valve located vertically.

In a heating system with separate circuits for different sides of the house or different floors, pumps are mounted on each circuit. The same principle is used - the device should be located before the first branch, located closer to the boiler.

Harness

Autonomous systems with forced supply of coolant cannot function in the absence of electricity, so the pump unit crashes into the pipeline itself.

If the system is gravity-based, a special installation of a circulation pump in the heating system is required.

The photo below shows the installation diagram corresponding to this case:

Piping the circulation pump in the heating system

Piping the circulation pump in the heating system A bypass is inserted into the pipeline, on which shut-off ball valves, a dirt filter (in front of the pump in the direction of the coolant flow) and the pump unit itself are mounted. Shut-off valves are also installed in the main pipeline - while the pump is running, this ball valve is closed and the system operates in forced mode. In the absence of electricity, the ball valve is opened and the system is operated as a gravity system.

Thanks to shut-off valves on the bypass, the pump unit is available for maintenance and replacement without draining the coolant from the circuit. The filter traps mechanical contaminants - solid suspended particles can damage the moving elements of the pump.

Installation work

Considering how to install the circulation pump correctly, pay attention to the progress of work:

- The coolant is drained from the system, and the pipeline is cleaned if necessary.

- A bypass is cut into the selected location, and the diameter of the pipe for the jumper must be less than the diameter of the pipeline.

- All elements of the pump piping must be installed on the bypass - ball valves, mud pan;

- Correct pump installation requires:

- install the housing in accordance with the designation of the direction of coolant flow (arrows on the housing);

- place the “wet” unit strictly horizontally - so that it operates without loss of power and overheating due to incomplete immersion of the rotor;

- Position the unit so that the power supply terminals face upwards.

- The connections are sealed using special gaskets, plus an additional sealing compound is used.

- The unit is connected to a grounded electrical outlet.

- Having completed the installation, coolant is poured into the system and air pockets are removed, for which the central screw is opened in the cover of the pump unit.

Permissible (top) and prohibited positions of a circulation pump with a “wet rotor”

Permissible (top) and prohibited positions of a circulation pump with a “wet rotor” Attention! It is necessary to bleed the air from the pump before each time it is turned on. For this purpose, the system, completely filled with coolant, is turned on for 5 minutes without closing the valve on the pump, and then stopped so that all the air leaves the pump.

You can do without the “de-airing” procedure by installing it on the pump unit, if the design of the device allows it.

Power supply

The pumping unit operates from a 220 V household network with grounding. To connect, use a three-pin plug and a corresponding socket (phase-neutral-ground), or connect the wires to the terminals of the unit - they are located under a plastic cover. For reliable operation, it is recommended to allocate a separate line for the pump and install a circuit breaker.

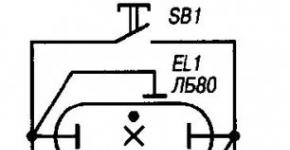

The electrical circuit for connecting the circulation pump is shown in the figure.

Connecting the circulation pump to power supply - zero, phase, grounding

Connecting the circulation pump to power supply - zero, phase, grounding Results

Pumping equipment installed in accordance with all the rules will make the heating system of a private home efficient. To increase reliability, it makes sense to take care of a backup power source - batteries for the pump.

In order for the unit to work properly, we must not forget about de-airing before starting, and regularly cleaning the mud filter from accumulated dirt.

The construction of a private country house usually involves the construction of an individual autonomous heating system. If installed correctly, such equipment will be much more economical and efficient than connecting to the main heating system. In particular, in an autonomous system, the distance that the coolant travels from the place of heating (heating boiler) to the location of heating devices (radiators) is significantly reduced.

An individual heating system can be built either using the principle of free circulation of coolant (hot water flows through pipelines by gravity) or using pumping equipment. In the latter case, the house owner is faced with the question: how to install it for heating?

Do we need a pump?

Of course, an individual heating system can work perfectly for many years without including pumping equipment. However, the use of circulation heating pumps significantly increases the heating efficiency.

- First of all, including a pump in the system reduces the inertia of the coolant movement. When hot water moves by gravity, the heated coolant can reach distant heating radiators after a considerable time. As a result, the temperature of the liquid in the pipelines has time to decrease, and the radiators do not heat the rooms as effectively. The difference in coolant passage time can reach an hour or more. Using the pump, all radiators in the house will heat up evenly.

- Also, when using a pump, there is no need to build a pipeline system with exact observance of the slope angle. Even if in some part of your house the heating pipe goes uphill, the coolant under the action of the pump will easily overcome this section and air pockets will not appear in the system.

But any technical solution may have its drawbacks.

- Electricity in our country is not yet free, so running a heating system will eat up money from your budget. The power of pumping devices can range from 55 to 100 Watts.

- The presence of a pump in the system immediately makes it energy-dependent, so that with any power outage you will have problems with heating.

- Stopping the pump may cause excessive heating of the coolant, which will cause rupture of heating circuits or defrosting of remote segments of heating pipelines.

How does circulation heating pump equipment work?

Pumping devices are installed in closed home heating systems. A typical pumping device has a stainless metal housing. The housing houses an electric motor. An impeller is located on the motor shaft; it moves the coolant through the pipes. The design of pumping equipment for heating systems is generally similar to conventional water pumps.

Types of circulation pumping devices

According to the operating principle pumping devices that circulate coolant in heating systems can be divided into “wet” and “dry”.

- IN "dry pump" the electric motor rotor, located behind the sealing partition, does not contact the coolant. During operation of the “dry pump”, when the sealing rings rotate, a film of water forms between them, which prevents the coolant from penetrating the engine rotor. Such a pumping device operates with an efficiency of about 80%. The disadvantage of such equipment is increased noise; it is recommended to install it in a separate room.

- "Dry" circulation pumping devices can be vertical, horizontal or block type. The type of pumping device affects the technology of its installation and is usually indicated in the technical data sheet of the equipment. In addition, a distinctive feature of “dry” type pumping devices is the need to install them in clean rooms, due to the fact that they are very sensitive to the presence of dust. “Dry” pumps should only be started when there is liquid coolant in the system, otherwise the sealing rings may be destroyed.

In circulation pumping equipment made using “wet” technology, the rotating elements (impeller attached to the rotor) are immersed in a heat carrier liquid. Hot water in this case simultaneously acts as a lubricating and cooling liquid. Such pumping devices are more reliable and unpretentious in operation, but have much lower efficiency - about 50%. Such equipment performs well in domestic heating systems; their efficiency is quite sufficient to create coolant circulation in a private home.

Choosing a circulation heating pump

The main criterion for choosing a circulation pump device for heating is its power. It must correspond to the volume of the autonomous pipeline system. Insufficient power will not allow you to effectively use all the benefits of a forced circulation heating system. Excessive power will be a waste of money.

In order to calculate the required power of the pumping device, it is necessary to collect the following information:

- heating pipeline cross-section;

- coolant temperature;

- heating boiler performance;

- pipeline capacity.

In order not to use complex formulas, the required model of the circulation pump device can be selected according to the output pressure.

The required pressure is calculated using a very simple formula: 0.5 units (meters) of pumping pressure = 10 meters of heating pipeline length.

Circulation pump prices

circulation pump

Installation options for circulation pump devices

To the heating system circulation pumping equipment can be installed according to two main schemes: single-pipe and double-pipe.

- IN single pipe system there is a constant flow of coolant. The temperature difference in it is not very large.

- IN two-pipe system coolant flow depends on the operating mode, and the difference in liquid temperatures in the system can reach large values.

Components of the heating system

- Boiler.

- Air valve.

- Thermostat device.

- Heating radiator.

- Balancing valve.

- Expansion tank.

- Shut-off valves.

- Filter device.

- Circulation pump device.

- Device for measuring pressure in the system.

- Safety valve device.

Self-installation of a heat circulation pump

When installing a pumping device, remember that it needs to be serviced from time to time. Therefore, convenient access must be provided to its location. The most convenient location for installing pumping equipment will be the section of the return pipeline (return), located in front of the inlet pipe of the heating boiler.

Such an installation location will ensure that the pump operates with a relatively cold coolant, which will significantly increase the service life of the device. In addition, installing a pump on the return pipe prevents the accumulation of air in the heating boiler tank. This extends the life of the equipment and prevents liquid from becoming trapped in the storage tank.

Algorithm for installing a pumping device

Step 1. Drain the heating system. If necessary, carry out hydrodynamic cleaning of pipelines and heating radiators.

Step 2. An additional pipeline bypass is placed at the selected installation location of the pumping device; it is called a bypass. The purpose of the bypass is to ensure the circulation of coolant in the system when the circulation pump is turned off or broken. The cross-section of the bypass pipeline must be smaller than in the main system.

Step 3. We install a circulation pump device. During installation, it is necessary to orient the pump so that the entire working part (shaft and impeller) is covered with coolant. Remember that running the pumping device dry without load can cause serious damage to the equipment. Also, incorrect orientation of the pump leads to a decrease in its efficiency. The actual power output of the pump may decrease by 30%. You can find a diagram of the correct orientation for your specific pump model in the instruction manual.

When choosing the location of the pumping device and when installing it, it is also necessary to take into account that the terminal box should be located at the top of the equipment. Otherwise, even with a small leak or condensation, it may flood with water. The result is a short circuit.

Step 4. Ball valves must be installed at the inlet and outlet pipes of the heating system pumping device. They facilitate the procedure for dismantling and repairing equipment.

Step 5. Install a water filter in front of the inlet pipe of the pumping device. It will prevent small particles suspended in the coolant from entering the pump. This will significantly delay the timing of repair work.

Step 6. Install a valve device on the bypass bypass pipeline. It will bleed air pockets if any occur in the system.

Step 7 Treat all joints with silicone sealant. This will prevent leaks from occurring.

Step 8 Fill the heating system with liquid coolant, bleed any air pockets from it by opening the central valve device.

Note! Bleeding of air pockets must be done before each start of the pumping device.

Maintenance of circulation pumping devices in heating systems

Typically, circulation pump devices in home heating systems do not require regular maintenance. In case of breakdowns, you can contact service center specialists. But in order for your equipment to work without breakdowns, you must follow some rules.

- Do not turn on the pumping device if there is no coolant in the heating system.

- Make sure that the pump operates with the volume of water and the power for which it is designed according to the passport data.

- Do not leave the pump switched off for a long time. Even in the summer, perform a monthly preventative run. 15 minutes of operation of the equipment will be quite enough to prevent stagnation of parts of the mechanism.

- Make sure that the temperature of the coolant at the installation site of the pumping equipment is not very high. The maximum permissible temperature is 65 degrees. When the heating is exceeded, hard salts precipitate in the liquid heat carrier, which significantly wear out the equipment.

Installation and operation of pumping equipment in individual heating systems does not pose any particular problems. To learn more about this issue, watch the training video.

Video - How to install a heating pump