A long-burning stove is a highly efficient and simple device. How to make a long-burning wood-burning stove for your home Long-burning stove from a pipe

Solid fuel boilers, for all their advantages, have one serious drawback. The problem is that fuel burns out quite quickly when using this equipment. Therefore, you have to constantly monitor its operation in order to promptly add the next portion of firewood to the combustion chamber. This leads to fuel being wasted uneconomically, resulting in increased heating costs.

To solve this problem, you should replace the equipment with a more advanced and economical one - a long-burning boiler. Regular wood is used as fuel for its operation. But unlike conventional installations running on the same fuel, the combustion process takes longer. Firewood has to be thrown in less often. The result is fuel savings. You can buy such a boiler, but it’s better to make it yourself. The scheme for its creation is quite simple, so no difficulties will arise during the work. In addition, there are many video instructions on the Internet that show the process of building such boilers.

Operating principle of a long-burning boiler

The operation of such boilers is based on the principle of not combustion, but smoldering of the fuel placed in the combustion chamber. This allows you to get more heat. You cannot count on such a result in brick ovens, since their construction uses a slightly different design scheme. The main reason is that there is no active traction in them.

Long-burning boilers have a number of features in terms of their design, which ensures maximum efficiency of heat release during the smoldering process of logs. Even if you build a homemade long-burning stove with your own hands, one bookmark will be enough to keep it running for 8 hours.

One of the features of solid combustion boilers is the presence of a valve-regulator as part of their design. When firewood is loaded into the combustion chamber and the active combustion process begins, it is necessary to close the valve and minimize the flow of oxygen into the boiler. During the smoldering process, the firewood begins to release flue gas. Its main components are methane, carbon monoxide and hydrogen.

The heat generated during the operation of such furnaces is precisely thanks to flue gas. Once in the ignition chamber, it ignites, after which it burns, releasing a large amount of thermal energy.

How does it all work?

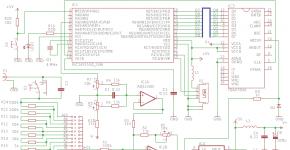

If you decide to build a long-burning boiler with your own hands, then you should not rush to begin work on its creation. First you need to find a drawing for the stove. There are plenty of them on the web. It will not be superfluous diagram of a similar installation. It will make the work of creating a furnace easier. In addition, before starting work, you need to watch a video on how to make a boiler with your own hands.

When creating a long-burning installation, steel pipes should be used as the main material. If they are not available, then you can choose pipes with a diameter of 30-40 cm. In this case, the minimum wall thickness should be 5 mm. If it is less, then during the operation of the metal it will quickly burn out, and then the installation will be unsuitable for further use. The height of the boiler must be at least 1 m.

The created boiler is divided into three parts:

- combustion zone - it is used to remove smoke and smoldering ash;

- combustion zone - it contains smoldering solid fuel;

- loading zone – it decreases in height, which is associated with the gradual burnout of the briquette.

In any scheme of a long-term combustion boiler there is such a component as an air distributor. The duration of combustion depends on it. It limits the area in which the combustion process occurs. The distributor looks like a disk made of sheet steel 4 mm thick. There is a pipe in its middle part. Air enters the combustion chamber through it.

In any scheme of a long-term combustion boiler there is such a component as an air distributor. The duration of combustion depends on it. It limits the area in which the combustion process occurs. The distributor looks like a disk made of sheet steel 4 mm thick. There is a pipe in its middle part. Air enters the combustion chamber through it.

So that as the fuel smolders in the furnace, it can freely fall inside the chamber, its size is made slightly smaller than the combustion chamber. To control the combustion zone, the distributor has an impeller, the height of which is 5 cm. As its height increases, its space will also increase, which will lead to an increase in the rate of firewood burning in the oven chamber.

The pipe through which air will flow must have diameter equal to 6 cm. You can use either a solid pipe or a telescopic one. In this case, the holes in the distributor should not be larger than 2 cm. Otherwise, air will enter the oven chamber in large quantities, which will lead to oversaturation with oxygen. A damper should be installed at the top. It will allow you to regulate the draft in the furnace. You can connect a long-burning boiler to heating in one of two ways:

- a water heat exchanger pipe is passed through the combustion chamber. The water in the tank will be heated through a coil that is connected to this pipe;

- a chimney is passed through the remote tank. The smoke passes through it in a hot state, which leads to heating of the coolant.

Comparing these two methods, it should be noted that the first is noticeably simpler in its implementation, and the second provides high efficiency.

Instructions for making a boiler yourself

Before starting work on the manufacture of a long-burning boiler, you should watch the video instructions for creating the installation yourself in order to avoid mistakes. You must have a drawing of the furnace, with a focus on which all work should be carried out.

Tools

Needed in advance prepare materials and tools that you will need during the work:

- pipes 30 cm, 5-6 cm, 10 cm. Please note that the wall thickness of each pipe must be at least 3 mm;

- steel sheet 4 mm;

- Bulgarian;

- welding machine;

- hand tools.

To place the boiler, choose a place with a hard surface.

Making a homemade stove

Installation manufacturing process includes the following steps:

Chimney and reflector

While using a homemade boiler, its walls will be constantly heated, and, naturally, thermal energy will emanate from them. If the installation of the stove is carried out for a small room, then reflectors will be needed, which will need to be placed around it. Thanks to them, the flow will be distributed, thereby increasing the amount of heat entering inside.

While using a homemade boiler, its walls will be constantly heated, and, naturally, thermal energy will emanate from them. If the installation of the stove is carried out for a small room, then reflectors will be needed, which will need to be placed around it. Thanks to them, the flow will be distributed, thereby increasing the amount of heat entering inside.

If a long-burning boiler will be installed in a room where people are constantly present, the issue of ensuring the safety of the installation should be considered. Lining the stove with brick will solve this problem.

To create a stove chimney, you can use a pipe with a diameter of 20 mm. The diameter of the combustion chamber must exceed the straight section of the pipe by 10 cm. It must be led outside with a minimum of kinks. Optimally - two bends at an angle of 45 degrees.

A few other features:

- When creating a stove chimney, its structure should be made collapsible. In this case, it will be possible to remove and clean its walls from soot during the season;

- sections of the chimney must be connected in the direction opposite to the movement of gas;

- objects and structures that are easily flammable under the influence of open fire must be moved some distance from the installation.

We are building the foundation

The base for the boiler can be made of burnt brick or rubble stone can be used. These materials do not crack when exposed to high temperatures. If a solid foundation is required, then in this case you will have to pour a solid monolithic slab. The equipment is installed on legs. Using a channel, they can be easily welded. You can hide them from view behind brickwork.

Air must be supplied to a long-burning boiler in a certain quantity. This can be achieved only if it is filled in full, without leaving any free cavities. In addition to firewood, peat and sawdust can be added to the furnace firebox.

Adding fuel to the boiler should be carried out according to the following instructions:

- first you need to remove the lid and remove the regulator from the tank;

- then fuel is densely packed into the chamber;

- it is necessary to spray a flammable liquid on top of the stored fuel;

- after installing the regulator, the tank is covered with a lid, and then the damper is opened;

- After this, a splinter is thrown into the air pipe. When the smoldering process begins, the damper can be closed.

Let's sum it up

Now you have a long burning boiler. This equipment can be installed in an unheated room. It will be an excellent solution for heating a garage. By installing such a boiler in your workshop, you can easily provide a warm atmosphere in it. If the boiler was manufactured correctly, then high efficiency and efficiency of its operation are guaranteed.

Solid fuel boilers sometimes become the only option when you need to heat a room. There can be many reasons for this: the inability or economic infeasibility of connecting to a gas main when you need to heat a temporary structure, or solid fuel is more accessible than all other energy resources.

The most economical are long-burning wood-burning stoves, which, unlike conventional boilers, have a higher efficiency. It is quite possible to make such stoves yourself, if you get acquainted with the recommendations of experienced craftsmen. Thus, you will get double savings: on operation and on manufacturing.

What is the difference from conventional ovens?

First, you can consider what disadvantages the owner of a conventional stove faces:

- very low efficiency, the level of which can be increased to 80 percent, no more;

- You constantly need to ensure that you add a new portion of fuel on time (usually this needs to be done every 2-3 hours);

- there is no way to automate the combustion process and thus reduce labor costs.

There are none of the listed disadvantages in top combustion furnaces. We can say that they have become an improved version of the traditional stove, which has not lost its position for many centuries. In addition, it has a lot of advantages, including the almost complete absence of soot, small dimensions of the boiler, and the ability to regulate the combustion process. There are many designs that you can make with your own hands.

A long-burning furnace is designed so that oxygen supplies the fuel in limited quantities. Firewood (coal, pellets) does not burn, but smolders. At this moment they release so-called pyrolysis gas. It goes into a separate chamber and burns out completely. As a result, efficiency increases by another 10-15 percent, and the fuel loading period extends from 8 to 12 hours.

For such stoves, sawdust, firewood, coal and pellets can be used as fuel. That is, it is not difficult to choose it depending on the region and the availability of any type of fuel. When such advanced stoves use pellets, the fuel loading process is easily automated. You just need to monitor the filling of the bunker.

Reference. Pellets are gradually becoming a popular type of fuel. They are easy to use and allow you to save the Earth’s natural resources, as they make this type of fuel from waste from the wood processing industry.

An automated long-burning stove using pellets can operate without human intervention for several days.

Materials and tools

To decide how to make a long-burning stove yourself, you need to prepare all the tools in advance and stock up on materials:

- for the furnace body you will need a metal container of at least 200 liters in volume (sometimes they take an empty, broken gas cylinder for this purpose);

- two pieces of pipe with a diameter of 10 cm;

- metal channel; for body legs;

- approximately 60 pieces of refractory bricks (if it is decided to line the stove with bricks);

- sheet of metal with a thickness of 60 to 80 cm diagonally;

- mixture for masonry (preferably ready-made, but you can make the solution yourself);

- hinges for doors;

- necessary tools that are used when working with metal (for example, a grinder);

- electric welding equipment, electrodes;

- level and plumb lines,

- construction tape and other marking tools.

After all materials and tools have been prepared, you can begin the process of making the stove.

How to make a stove with your own hands

When choosing a room where you can make a long-burning stove with your own hands, you need to keep in mind that for welding work you will need access to 220 V electricity.

The body can be made of stainless steel, cast iron or steel. When you make it yourself using welding, you need to take steel sheets with a thickness of at least 4 mm. The most convenient and stable design will be obtained if the body is shaped like a rectangular parallelepiped. But the main thing is to make it airtight.

However, it is easier and more reliable to choose a ready-made container. For example, even a used fire extinguisher is suitable for a low-power oven.

Important! If a used gas cylinder is used for the housing, special procedures must be followed for safety reasons. An empty cylinder always contains gas vapors, which can lead to an explosion. Therefore, before cutting off the “top” of it, the balloon must be filled to the very top with ordinary water.

Separately, another circle is cut out of a sheet of iron with a diameter 2-2.5 cm larger than the diameter of the body itself. You need to cut a hole in it for a pipe with a diameter of 10 cm. The pipe is immediately welded into place.

The legs are made of metal channel. They will not only support the base, but also “push” the fuel during the combustion process.

The lid is made separately. They also cut a hole in it for a pipe 10 cm in diameter. A “skirt” is provided along the edges for a tighter connection between the lid and the body.

Holes for the firebox and ash pan are cut out on the body. Metal doors are hung on them, to which handles (from a corner or channel) are welded. The firebox and ash pan are separated by a grate on which fuel must be placed.

Oven base

When making a coal stove with your own hands, you need to take care of a reliable foundation. This must be done, even if the stove is not heavy in design.

There is no need to make a recess for the foundation. It is enough to make a smooth concrete “pillow”.

In order to mark the base of the stove, you can use building materials such as ceramic tiles or bricks. In this case, straightness must be strictly observed, controlling the surface of the base using a mounting level.

Chimney device

When it comes to heating equipment that runs on solid fuel, it is imperative to install a chimney. In this case, the chimney is made from a pipe with a diameter of 100 mm.

At a distance of 50–100 mm from the upper edge of the stove, a chimney pipe is cut in. This is a length of steel pipe into which the chimney will fit tightly. The smoke channel is made with a small horizontal section - 50 - 60 cm of a straight pipe is enough to weaken the draft. A large number of knees before leaving the premises is not allowed.

A chimney made of several sections is easy to use. This way you can clean it without any problems.

Important! Sections of the prefabricated chimney pipe are assembled in the direction opposite to the movement of gases.

Final stage

After the stove is assembled and installed in a permanent place, it can be given an aesthetic appearance using refractory bricks. As practice has shown, this does not affect the performance of the boiler in any way. There is an opinion that due to a decrease in heat losses, the fuel burnout period increases. However, this has not yet been proven.

Therefore, the owner of the stove can choose whether it is worth spending additional money on covering the stove with bricks, or doing without this step. Sometimes in this way they make a stove for a long-burning greenhouse with their own hands, which is very convenient and practical.

Whatever fuel is used in a long-burning furnace, the operating principle is the same. The pyrolysis process, with minimal access to oxygen, significantly increases the efficiency of the furnace and increases the burnout period of the fuel.

There are some rules for the manufacture and installation of a stove, compliance with which is important for further operation:

- For safety reasons, there should be no furniture, objects, or other things for a meter around the stove to avoid a possible fire.

- If you install the stove on a small pedestal, then, if necessary, you can easily remove and disassemble the chimney.

- Not much ash is formed in a long-burning furnace, but from time to time it needs to be removed, leaving a small layer for thermal insulation of the bottom (thus reducing the intensity of its burning).

To improve performance characteristics, a heat reflector - a metal or foil sheet - is attached to the wall behind the stove. It not only protects the wall from fire, but also returns heat from the wall back into the room.

Of course, gas is currently the most cost-effective and less problematic to operate. But its connection is not always possible. Many regions are forced to make do with other types of fuel. Electricity, although a convenient energy resource, is very expensive. In such a situation, long-burning solid fuel stoves will help out.

Reading time ≈ 8 minutes

With the onset of cold days, the problem of heating becomes more and more urgent. Owners of private houses who do not have a connection to central heating can solve this problem by building a long-burning wood-burning stove with their own hands. Such homemade structures will ensure the maintenance of comfortable conditions during the cold period. Such units can be purchased in a store and spend a considerable amount of money, or you can build a suitable option yourself.

Features of homemade long-burning wood-burning stoves

Owners of private houses, when dealing with heating issues, have to decide which heating equipment to give preference to.

There are devices characterized by periodic operation. They provide quick heating of the interior space. After this, the unit turns off, and the temperature in the room drops just as quickly. To maintain the combustion process, stove owners often have to add a new portion of firewood to the heating unit.

The second type of stove is characterized by long burning. This includes not only wood-burning stoves, but also gas generating units. When installing such structures, the owner will need to add firewood several times a day, since the burning time reaches 6-10 hours. However, there are models of stoves in which the process of combustion and smoldering with the release of heat can last up to 20 hours.

A homemade long-burning stove is considered the most preferable option, since it can be adapted to a specific space at the assembly stage.

The design of stoves that require long-term combustion and their operation are accompanied by distinctive features:

- for their manufacture, preference is given to steel or cast iron;

- the design involves constructing a firebox from two separate parts (the firebox has sufficient capacity, thanks to which a large amount of firewood can be loaded into it);

- some models are equipped with an air convection system;

- one stack of firewood is enough to operate the stove for a sufficient amount of time;

- such unit designs use different types of fuel (firewood and wood pellets);

- if desired, the design can be improved by equipping it with a mechanism that allows automatic supply of fuel to the firebox;

- such units are characterized by high efficiency;

- When introducing such furnace designs, the need to build a special foundation for them is eliminated;

- such units are characterized by low weight and acceptable dimensions;

- the fuel burns completely, leaving only a small amount of ash;

- modern stoves have a fairly attractive appearance, thanks to which they can be placed in any room, they fit organically into any interior;

- such equipment is designed in such a way that the smell of burning and the presence of smoke is eliminated inside the building;

- the stove is equipped with dampers and sealed doors, preventing the penetration of fuel gas into the rooms.

Owners of private houses will be able to assemble such structures themselves if they have the appropriate drawings and recommendations.

Models made of cast iron can last for more than fifty years. Such a long service life is ensured due to the characteristics of cast iron. It does not corrode. In addition, cast iron is highly resistant to mechanical damage.

Long-term operation of the furnace is ensured by a special design. The firewood in the firebox is not subject to combustion, but to smoldering.

A large amount of firewood is loaded into the firebox, thereby limiting the supply of oxygen. As a result, the firewood first heats up and then begins to smolder, releasing flammable fuel gas.

Unfortunately, this stove design is not without its drawbacks. These include:

- condensation formation;

- the shape of the chimney pipe should only be straight;

- the possibility of using liquid fuel is excluded.

Types of stoves

Such homemade heating devices will be able to provide a normal microclimate in private houses in which their owners permanently reside at any time of the year. You can also equip country houses with homemade stoves, which are often empty in winter. The owners come, but spend minimal time here.

Such furnaces, if necessary, are installed in other buildings:

- greenhouses;

- barns;

- garages;

- pantries.

It all depends on what goals the owners of the buildings are pursuing.

When choosing models, experts recommend giving preference to the design that is accompanied by the presence of a water circuit. In this case, the stove is equipped with a firebox and an additional water compartment. The oven body will gradually heat up, thanks to which the generated heat will be distributed evenly inside the room.

A long-burning wood-burning stove with a water compartment, built with your own hands, is capable of quickly heating the living space, successfully competing with it in terms of aesthetics.

Depending on the space in which the stove is planned to be installed, the dimensions and optimal shape of the future heating unit are determined.

Long-burning heating units are offered for sale in retail establishments, which are accompanied by a high level of popularity. These include:

- Buleryan;

- Professor Butakov;

- Breneran;

- Lachinyanka;

- Slobozhanka;

- Bubafonya;

- Potbelly stove.

Fuel used

It's no secret that firewood is the most environmentally friendly fuel. This category is complemented by dry logs and pellets, since they are obtained by pressing small-sized dried chips and sawdust.

For stoves with long burning, fuel pellets can be used as fuel, which are obtained from the following materials:

- cones;

- seed husks;

- nut shells;

- dried citrus fruit peel;

- tree bark.

You can also use charcoal, but only on condition that when creating the furnace, the walls of the unit are deliberately thickened. If the walls are not thickened, the oven can be damaged, since it will be subject to intense heat during operation.

Preparation for work

The process of constructing a heating unit involves performing work that is accompanied by the formation of a large amount of dust and increased noise. In addition, this task is labor-intensive, so it is important to properly prepare for the upcoming work.

The space in which work will be carried out must be equipped with a source of electricity. This is important, since it will not be possible to do without electric welding.

Depending on the purpose of use, ovens of identical design may have different dimensions. To understand what dimensions will be optimal in a particular case, it is important to determine the location where the stove will be installed.

The following requirements are put forward for the location of the heating unit:

- It is important to provide free space around the stove (the unit gets very hot, so if other interior items are located close together, it can cause them to heat up and deteriorate);

- It is not allowed to place flammable substances near the unit;

- Before starting the unit, it is recommended to check it for serviceability and successful operation of all modes.

You can prevent premature failure of the furnace if you listen to the recommendations of experienced specialists. In particular, they strongly recommend leaving a small amount of ash inside the oven. This will prevent the bottom from burning.

Construction of a furnace from a metal barrel

If the decision regarding the construction of a homemade stove has been made, you must first prepare all the necessary material, namely:

- metal with a volume of 200 liters (it must be made of stainless steel, cast iron or steel);

- two steel pipes of different lengths;

- Red brick;

- metal channel;

- construction mixture;

- cement.

You also need to prepare tools, without which it will be impossible to perform certain actions. These include:

- axe;

- welding machine;

- roulette;

- hammer;

- set of electrodes;

- plumb lines for installation;

- building level;

- Bulgarian.

It will be easier to build a homemade stove if you follow the step-by-step instructions:

- You need to take a prepared cylinder (it is recommended to use an empty gas cylinder).

- Unscrew the valve.

- Fill the bottle with water.

- Cut off the top part and set it aside (it will be used later).

- They take pieces of reinforcement and weld them to the bottom of the barrel, constructing legs.

- A circle with a diameter slightly smaller than the diameter of the main body is cut out of a metal sheet.

- In the cut out circle, another circle is cut out in the middle.

- A pipe is applied to the cut out inner round hole and then welded, which will serve as a smoke exhaust.

- On the reverse side of this metal circle, four sections of channel are welded, which are positioned perpendicular to each other.

- They take the previously cut off upper part of the barrel and cut a hole for the pipe in its center.

- A hole is cut out in the housing, which will be used to load fuel.

- A metal door is welded to the cut hole.

- A handle is welded to the door.

- Below this door, another smaller hole is cut out, and the door is also welded to it.

- Next, prepare the place where the homemade stove will be installed (make a recess in the wall).

- A layer of brick is laid out at the bottom of the constructed niche and filled with cement.

- Check that the constructed site is perfectly level.

- The following steps are aimed at installing a chimney pipe. A straight section of pipe is welded to the hole in the barrel.

- The main part of the chimney is constructed from a curved pipe.

- Asbestos fabric is laid, which will provide reliable insulation.

- Attach the clamp.

- A special cap is installed on the top of the pipe, which will provide reliable protection from pollution and natural precipitation.

- A reflector is installed, which is also called a protective screen for the furnace (it is made of metal or brick).

This completes the process of constructing a long-burning furnace. When operating, such a unit provides a supply of high-temperature air, thanks to which it is possible to heat the interior of the room well.

You can build a long-burning stove that will operate on wood with your own hands. Before starting work, it is necessary to take into account all the recommendations of specialists, prepare high-quality materials and tools. You will also need skills in working with special tools or a specialist of the appropriate level.

With the onset of cold autumn days, it becomes necessary to heat the garage while repairing a car or to keep warm while harvesting potatoes on your site. A long-burning wood stove can be an excellent replacement for expensive stoves and will fit perfectly into small auxiliary rooms where it does not make sense to constantly maintain heat.

In ordinary potbelly stoves, which have long been known to everyone, wood burns quickly, and you need a lot of it to heat the room. In order to make a long-burning stove from a potbelly stove, it was necessary to equip it with an additional device for long-burning fuel. Craftsmen found a way out of this situation, and different versions of such units appeared: Slobozhanka, pyrolysis, bubafonya and others. They are very economical; they can be heated with wood, sawdust, wood chips and other flammable waste from firewood. They can burn, or rather smolder, all day long, and their efficiency exceeds 90%. They do not need constant supervision.

These stoves are convenient to install in greenhouses, garages, cottages and small wooden houses. The disadvantage will be the special organization of the chimney, in which it is impossible to make several outlets. As soon as the wood burns, the potbelly stove cools down, but during combustion it becomes very hot. You can make a potbelly stove from anything, and its design is quite simple. You can cut it out of metal, and then it turns out to be rectangular in shape.

You can make a long-burning potbelly stove from an ordinary steel barrel or a used gas cylinder. The principle of operation is the same everywhere - smoldering. A special feature of such heating devices are two chambers, which are divided into two parts: for fuel and for further combustion of coal and gases. The furnace design includes a piston that:

- supplies air to the firebox;

- exerts uniform strong pressure on the firewood, they smolder and fall evenly down.

The wood in the firebox burns very slowly. At the same time, the gas that is formed during combustion burns in the adjacent chamber. In this slow-action mode, the oven does not heat up much, so the walls should be thin. When heating a large room, the design is chosen to be more powerful, and then more firewood is required, and accordingly, the heat transfer will be higher.

The wood in the firebox burns very slowly. At the same time, the gas that is formed during combustion burns in the adjacent chamber. In this slow-action mode, the oven does not heat up much, so the walls should be thin. When heating a large room, the design is chosen to be more powerful, and then more firewood is required, and accordingly, the heat transfer will be higher.

As the wood burns, the chamber itself decreases, on which the damper that regulates the air circulation presses from above.

In a residential area, such a device is not entirely convenient and profitable. To load fuel or clean soot, you must first remove the dirty piston. And to remove soot, you need to remove the chimney elbow and turn the stove body over.

How to make a wood stove. Potbelly stove efficiency 200%

Preparatory work

Suitable for every garage owner make a homemade stove. You can build a long-burning potbelly stove with your own hands within a few hours from a used barrel. It must be durable, with a smooth surface. If dents or bulges remain in any place, the air duct will not fit tightly to the fuel and will hang over it. The walls of the container must be freed from residual gasoline, paint, glue, etc. using a gas torch or blowtorch, and then cleaned with a wire brush. Then you need to make the piston and blades.

Suitable for every garage owner make a homemade stove. You can build a long-burning potbelly stove with your own hands within a few hours from a used barrel. It must be durable, with a smooth surface. If dents or bulges remain in any place, the air duct will not fit tightly to the fuel and will hang over it. The walls of the container must be freed from residual gasoline, paint, glue, etc. using a gas torch or blowtorch, and then cleaned with a wire brush. Then you need to make the piston and blades.

The grinder will not cope in this case, since the metal is quite thick, and it is better to contact a service center or factory. At home, all that remains is to clean the cutting areas, remove drops and build-ups. The next stage of preparation is choosing a location for installation. Here you need to follow some mandatory rules.

Firstly, the floor must be level, and secondly, the stove must stand on a protected surface: you can use metal sheets or asbestos fiber boards. The potbelly stove is installed away from flammable materials.

The heating device must not be installed under hanging furniture. It is also taken into account how the chimney will be arranged. To prevent heat from escaping into the pipe, when its vertical part passes on the street, its other part is laid horizontally. If it goes around the room, then the potbelly stove can be installed using any method. You also need to decide how the required amount of air will flow to the thermal chamber. You can't do without good ventilation here.

Original long-burning potbelly stove

The first step is to create a firebox: The top round part of the barrel is carefully cut off. After this, the edges of the barrel and the cut part are processed with a hammer or sledgehammer. In this case, the uneven edges of the barrel are rounded inward, and those of the circle are rounded outward. This procedure is necessary to create greater tightness when closing the lid. Next, a round metal disk with the same diameter as the barrel itself is welded onto the body of the future furnace.

This surface can be used to prepare food or boil tea. In place of the plug, which is located on top of the barrel, a sliding damper is installed that regulates the supply of secondary air, which enters the afterburning zone. A hole is cut in the middle of the lid for the air duct, which is welded in a circle with metal. The piston is made from a steel sheet or from the bottom of another barrel.

This surface can be used to prepare food or boil tea. In place of the plug, which is located on top of the barrel, a sliding damper is installed that regulates the supply of secondary air, which enters the afterburning zone. A hole is cut in the middle of the lid for the air duct, which is welded in a circle with metal. The piston is made from a steel sheet or from the bottom of another barrel.

Long-burning potbelly stove.

Additional metal parts are welded onto the upper plane of the piston so that the force of its pressure corresponds to the calculations of air flow into the firebox. A hole is made in the center of the pressure circle, the diameter of which must coincide with the outer diameter of the air duct, and they are firmly welded to each other. Then, blades up to 40 mm high must be attached to the bottom of the piston, which are used to distribute oxygen evenly throughout the firebox.

They are smooth and round. You can use both, but with rounded ones, the smoke flow flows as if in a spiral, and its path slows down. Ultimately, the heat output of the furnace increases. A divider is attached to the center of the piston on the pipe side. A damper with a lock is installed on top of the pipe to regulate the flow of the primary portion of air. A pipe is mounted into the upper opening, which is cut on the body, by welding with a continuous seam. A support frame with legs is constructed from various scrap metals.

An important part when creating a potbelly stove is a chimney with pipes, the diameter of which should be slightly more than 10 cm. You also need to prepare three elbows and a plug and connect everything sequentially to each other:

Manual

In pyrolysis ovens Only dry firewood is used. The fact is that when raw wood is burned, a large amount of water vapor is released, and it greatly reduces the heating temperature of the fuel. In addition, complete combustion of volatile substances does not occur, and when cooling in the chimney, they remain on its walls, which are very difficult to remove during cleaning. When raw wood is burned, many harmful chemicals are released that affect the environment and human health.

With well-dried fuel, the waste consists mainly of carbon dioxide and water vapor, and small, subtle air movement can be seen outside. Before filling the stove with wood, the piston is removed. The operating time of a potbelly stove and its heat output depend on the density of the fuel. Even small gaps between the logs are filled with chips, shavings, sawdust, etc. A rag soaked in kerosene is placed on top of everything, and, having replaced the piston, the heating device is tightly closed with a lid. Only after this they throw a burning match there.

With well-dried fuel, the waste consists mainly of carbon dioxide and water vapor, and small, subtle air movement can be seen outside. Before filling the stove with wood, the piston is removed. The operating time of a potbelly stove and its heat output depend on the density of the fuel. Even small gaps between the logs are filled with chips, shavings, sawdust, etc. A rag soaked in kerosene is placed on top of everything, and, having replaced the piston, the heating device is tightly closed with a lid. Only after this they throw a burning match there.

It is not recommended to put various household waste, except paper, into the stove. All plastic products and shampoo bottles, foam inserts, and plastic bags, when burned, will release many dangerous elements that cannot decompose even during pyrolysis. In addition, they will emit a high percentage of soot, which will clog the chimney ahead of schedule.

close ×

Our climate requires maintaining comfortable conditions in homes during the cold season. The heating system must be of high quality, because in some regions heat comes so rarely that there is practically no time left for repairs. Our ancestors appreciated the advantages of stove heating. Long-burning wood-burning home stoves are common and popular today.

Long-burning home stoves are becoming more and more popular every year. This is due to the fact that standard solid fuel boilers are uneconomical to use. Oxygen easily penetrates into the combustion chamber, the fuel quickly burns out, and the firebox has to be constantly monitored. This design is suitable for a country house, but not for a permanent one. The old type boiler is being replaced by a modern furnace, where the fuel does not burn, but smolders. The models are used not only for heating private houses. Simple designs are great for heating:

- storage facilities;

- saunas and baths;

- country houses.

In another way, a long-burning stove is called a gas generator or pyrolysis stove. It has a lot of advantages over its analogues. The heating stove operates in two modes:

- combustion;

- smoldering (economy mode).

Principle of operation

The slow burning oven consists of two chambers. Firewood is loaded 1-2 times a day. The principle of operation is the process of gas generation, which means smoldering. In the first compartment, fuel is slowly burned, producing pyrolysis gas, which rises into the second chamber and burns. The heat is distributed evenly, slowly, and the stove body remains warm.

At the heart of the heating equipment is a control valve that blocks the access of oxygen during the combustion process to give the “green light” to smoldering. During the process, gases will begin to be released:

- carbon monoxide;

- methane;

- hydrogen.

Once in the second chamber, the gas ignites and releases heat. This is how long-burning wood stoves for homes work. Such devices are made from various metals and alloys, and cast iron products are the highest quality. Their service life is estimated at 50-70 years.

Oven with hob

Oven with hob It is possible to organize a heating process for a wooden house using a long-burning wood stove, provided that space for the equipment is provided in advance. It is important to provide basic installation rules in order to prevent fire:

- The stove should be installed away from the walls, first finishing them with a material that prevents heating.

- Even if the structure has legs, we cover the floor with fireproof material.

- It is prohibited to install flammable objects near the stove.

The pyrolysis process inside a solid fuel furnace occurs at a temperature of 600 degrees.

Long-burning heating stoves are installed even in unheated rooms. When you arrive at your dacha in winter, you will quickly heat the room to a comfortable temperature without consuming a large amount of fuel. This will take no more than half an hour.

Advantages and disadvantages

Long-burning wood stoves have many advantages, which is why they quickly conquered the market. However, we should not forget about the disadvantages. The choice of stove directly depends on the ability to install the equipment and come to terms with the nuances of operation. The advantages are:

- high efficiency of the long-burning furnace reaches 85%;

- wide selection of models, their compact size;

- stoves of this type are economical, fuel is consumed slowly;

- the possibility of combining solid and liquid fuels;

- ease of switching modes and controlling the mechanism.

The disadvantages will help you make sure before choosing that such equipment can be installed in your home, and the operation process will not become problematic:

- a chimney for such a stove must be provided in advance; curved pipes are not suitable for it;

- ready-made models are designed for one type of fuel, they are not universal;

- The chimney of such a stove will have to be cleaned frequently, since the smoldering process involves the release of a large number of combustion products.

Please note that the economical smoldering mode can only be started after the house has warmed up to the optimal temperature. Those who want to install this heating device at home will have to choose a ready-made model from those on the market. However, some “homemade” ones are so well made that they can compete in efficiency with factory stoves.

Furnace interior

Furnace interior Let's talk about how to make a long-burning stove with your own hands. If you have a diagram and the necessary materials on hand, everyone will be able to assemble heating equipment.

Self-production

In order to make a heating device, use any of the available materials:

- refractory brick;

- cast iron;

- steel.

Long-burning stoves made of brick are rare, since this material will not provide the longest possible smoldering process. Depending on the design of the stove, the craftsmen try to achieve the longest fuel combustion possible, up to 12 hours. This factor depends on the amount of oxygen in the combustion chamber - the less it is, the longer the smoldering process.

Homemade long-burning stoves are suitable for heating small country houses and village houses.

Requirements for the work site

To create a long-burning stove, you will need to make your own boiler. Think over and arrange your workplace. The master will need:

- access to the electrical network;

- dry storage room for storing tools and materials;

- free space for work.

In warm sunny weather, work is carried out in the fresh air. It is based on a schematic image (drawing) for the future boiler.

Schemes, necessary tools and materials

To create a high-performance, long-burning solid fuel boiler with your own hands, you need to have some knowledge of how the heating system works. It consists of three parts:

- the area into which fuel is loaded;

- the area where burning and smoldering occurs;

- smoke exhaust area.

The design of a long-burning furnace is simple, the diagram is presented below. Please note that there is an air supply regulator at the top. The better this element is made, the longer the smoldering process takes place.

The design of the furnace may look different:

According to the presented diagrams, we will draw up a drawing of a long-burning furnace on paper and get to work. Tools you will need:

- hammer;

- axe;

- electric welding machine;

- grinder (autogen);

- roulette;

- level;

- black marker.

The materials we use are:

- as a base - a steel or cast iron barrel with a volume of 200 liters without visible damage;

- channels or metal scraps for the legs of a solid fuel stove;

- steel sheet, 5 mm thick - at least 1 m2;

- door for the combustion chamber;

- metal pipe, 100 mm in diameter, 15 cm higher than the barrel.

The chimney is made from a pipe with a diameter of 150 mm. If there is no barrel, it is replaced with a gas cylinder. The base of a stove for a long-burning wood-burning cottage is also made of sheet steel. The thicker the base wall, the longer the service life of the equipment.

The fuel used for such a furnace is:

- firewood;

- coal;

- sawdust and other solid fuels.

The wood stove needs to be cleaned twice a week, leaving a small amount of ash at the bottom. This will protect the bottom from burning out.

Step-by-step instruction

Step 1. A long-burning wood stove is made from a readily available metal cylinder that has a bottom but no lid. If a gas cylinder is used, first remove the upper part with a grinder or autogen. The cut level is drawn in advance so that the top is even.

Be careful when cutting the gas cylinder. Before doing this, you need to unscrew the valve and fill the container with water.

If a long-burning wood-burning stove is made of a sheet of steel, then it is not necessary to weld the structure in the form of a cylinder. The cube shape in this case looks more advantageous and will be more stable. If you like a cylindrical long-burning wood stove, limit its height to 1 meter.

Step 2. A pressure circle is made from a sheet of steel. The diameter of the circle should be slightly smaller than the diameter of the cylinder (by 2 centimeters). A circle is cut out in the middle according to the diameter of the pipe (100 mm). It is inserted into the hole and welded. The pressure circle must have free movement, and on the inside it is necessary to weld an impeller or channel in the form of a cross.

Step 3. In the lower part of the base of the structure from which the wood-burning stove for the home is made, a small hole is cut out through which it will be convenient to remove the remaining ash. Having cut the door to size and fastened the hinges, we make the door.

Step 4. Using this principle, a hatch is cut for loading fuel.

Step 5. A long-burning solid fuel stove has a chimney, which is made of a pipe with a diameter of 10 cm. Achieve a strictly horizontal position.

Step 6. The boiler lid is cut from a sheet of steel. A 10 cm hole is made in it for the air distributor. It is important that all parts have a tight fit - this will ensure maximum performance, since oxygen flow will be minimal.

Homemade long-burning stove from a gas cylinder

Homemade long-burning stove from a gas cylinder A homemade long-burning wood-burning stove has a simple design, and can be easily improved if desired. A solid fuel stove runs on coal, wood and other fuels. It is important to pack it as tightly as possible into the combustion chamber.

The principle of operation of the boiler is simple: by opening the top cover and removing the air regulator, the owner fills the container with firewood, coal, peat or other combustion products. Lighter fluid is often used to speed up the process. The cover is put in place, the fuel is ignited. At this moment the air damper opens. When the fuel is smoldering, you need to close the damper and enjoy the warmth. Before burning a full tank of fuel, the process is repeated.

Sometimes you can hear the name “top combustion furnace” in relation to this design. The air regulator pipe will gradually decrease into the boiler during operation of the heating system. This indicator will allow you to estimate the amount of fuel in the boiler.

Homemade brick ovens

Long-burning brick stoves are not difficult to build yourself. If you take the issue seriously, you can also cook lunch in such a stove. Brick quickly releases heat, making the room warm. Cooking stoves are still common in the suburbs where people live permanently. This type of long-burning design is rarely used for summer cottages.

An important disadvantage of brick is its rapid cooling. Externally, a long-burning brick stove is no different from a classic Russian stove, but the internal structure of the structure is more complicated, due to which the heat is retained longer.

The diagram indicates the presence of a shaft in the furnace leading to the intermediate hood. Gases burn out in it - this is a mandatory requirement for a long-burning stove. It is difficult to do it yourself without special skills - you will need the help of a professional stove maker.

Brick is a heavy material. This is an additional disadvantage of the future design. Install it on the prepared base. Before a long-burning brick stove is built, we must make a foundation. Ready-made country houses rarely provide for the possibility of erecting such a foundation. The steel stove design shown above is perfect for a summer residence. Long-burning wood-burning stoves made of brick are best used for homes where permanent residence is planned.

Brick wood stoves for heating are demanding in terms of foundation construction: 50 cm underground and another 10 centimeters above its base. Additionally, on each side, the space is increased by 5 cm so that the design