Heating element for moonshine. Heating element for a moonshine still: which one to choose and how to install

A heating element is a device for heating mash in the distillation cube of a moonshine still. Installed into the tank through a convenient clamp connection. Thanks to this, it is very convenient to remove it for washing and maintenance, and then mount it back into the cube. The entire installation will take no more than 10 seconds.

Unique advantages of heating elements

1. Has protection against burnout when boiling over

If there is not enough mash left in the tank, the blue indicator on the control unit will indicate this.

2. Sophisticated control unit design

The internal components of the device are coated with a protective varnish that will protect them from splashes and steam. And thanks to a well-thought-out cooling system, the heating element can operate indefinitely without the threat of overheating and burnout.

3. Convenient installation and removal from the tank

The heating element is attached to the tank using a clamp connection, allowing it to be quickly removed and installed.

4. Smooth heating adjustment

The heating element has a power of 3 kW and power adjustment. It is easy to customize to suit your specific needs.

For Wein 4 and Wein 5 devices, the heating element is installed only in cubes with a volume of 30, 37 and 50 liters.

Heating with a heating element is the safest heating method. The heating elements are made entirely of AISI 304 stainless steel. Huge service life. The most convenient way to attach the heating element to the distillation cube has been implemented. In a few seconds, you can disconnect the heating element and calmly wash the distillation cube without fear of flooding the electrical contacts. Unlike brass heating elements, AISI 304 stainless steel does not react with mash and raw alcohol and does not release harmful impurities into the drink.

3,500.00 R ub. 3,500.00 R ub.Double heating element - made entirely of AISI 304 stainless steel. Unlike brass heating elements, AISI 304 stainless steel does not react with mash and raw alcohol and does not release harmful impurities into the drink. Eternal body. Replaceable heating elements.

3,500.00 R ub.Double heating element - made entirely of AISI 304 stainless steel. Unlike brass heating elements, AISI 304 stainless steel does not react with mash and raw alcohol and does not release harmful impurities into the drink. Eternal body. Replaceable heating elements.

3,500.00 R ub.Double heating element - made entirely of AISI 304 stainless steel. Unlike brass heating elements, AISI 304 stainless steel does not react with mash and raw alcohol and does not release harmful impurities into the drink. Eternal body. Replaceable heating elements.

3,500.00 R ub.Double heating element - made entirely of AISI 304 stainless steel. Unlike brass heating elements, AISI 304 stainless steel does not react with mash and raw alcohol and does not release harmful impurities into the drink. Eternal body. Replaceable heating elements.

In addition to heating the distillation cube with mash on a gas, electric or wood-burning stove, you can use a heating element for a moonshine still and operate it wherever there is electricity, without being tied to a specific place.

If earlier built-in electric heaters were rarely used in man-made ones, today both home craftsmen and manufacturers of equipment for distillers install them in their products.

By searching the Internet, you will find many models of devices equipped with heating elements from various manufacturers. This is not a tribute to fashion, but a desire to create competitive equipment suitable for a demanding client. Let's look at why they are attractive and learn about their shortcomings.

The self-heating still for making moonshine has both its loyal supporters and fierce opponents. To understand why this is so, let's look at its strengths and weaknesses.

pros

Among the advantages it is worth noting:

- mobility of the device. He can stand somewhere in a corner and quietly do his job. At the same time, without occupying the stove, on which it is impossible even to cook lunch for several hours (and sometimes the whole day);

- possibility of installation in distillation large volume cubes– from 40 liters and above. If you install heating elements in them, you won’t have to ask for help to lift them onto the stove with mash or remove them after moving;

- another problem disappears: often a moonshine still with and/or does not fit on the stove under the hood, and one equipped with its own heater does not need this;

- Acceleration time accelerates mash to the operating temperature at which alcohol vapor begins to actively evaporate;

- full possible automation distillation process.

Flaws

There is no perfection in the world, so heating elements also have dark sides:

- high energy consumption, which will not have the best effect on utility bills;

- the possibility of particles of mash sticking to the heating element, especially if it is thick, and burning. As a result, an unpleasant aftertaste appears in the final product;

- the cost of devices with heating elements and electronics that control heating is higher than conventional ones heated on a stove.

Note. To reduce the cost, you can independently equip the moonshine still with a heating element (or, which is sometimes more convenient, two).

What does it consist of and how does it work?

TEN is an abbreviation, and the full name is tubular electric heater. The device consists of:

TEN is an abbreviation, and the full name is tubular electric heater. The device consists of:

- metal tube of various shapes: loop, curved, twisted in the form of a spiral or double loop. The tube is often made of stainless steel, but is also found in copper and alloys;

- the internal filling is a heat-conducting electrical insulator (magnesium mixture, quartz sand), and in the depths there is a nichrome (sometimes fikhral) thread wound in a spiral. The power of the device depends on its thickness. The internal spiral must have a high electrical resistivity for heating;

- two output pins;

- sealing bushings;

- nuts for fastening;

- terminals for connecting an electrical cable.

After assembly, sealing and electrical insulation, the heating element can be put into operation.

Carefully. Heating elements designed to operate in liquid (and these are the ones installed in cubes) cannot be used “dry”.

This will invariably lead to their failure, and also threatens with explosion and fire.

In fact, an electric boiler is also a heating element. And the operating principle is the same:

- Electric current passing through the filament heats it up.

- The thread (spiral) transfers temperature to the filler.

- The filler heats the walls of the tube, which in turn heats the liquid in which it is immersed.

How to choose?

In order not to be disappointed in the purchase, you need to take the choice of a heating element seriously and take a number of points into account.

In order not to be disappointed in the purchase, you need to take the choice of a heating element seriously and take a number of points into account.

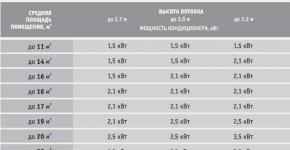

1. Power. For moonshine stills, heating elements from 1 to 3-5 kW are selected, depending on the volume of the cube and the desired distillation speed. In fact, there is even a special formula for selection; if you are interested, you will find it on the Internet. But, based on practice, they are most suitable for a cube with the following volume:

- up to 10 liters (7 – 8 liters of mash can fit in it) – 1 kW;

- up to 20 l – 1.5 – 2 kW;

- up to 30 l – 2.5 – 3 kW;

- 35-40 l – 3.5 – 4 kW. 5 kW is also possible, but in this case it is better to take 2 heating elements (for example, 3 and 2 kW), and during initial heating, turn on both, and when the temperature of 63°C is reached, turn off one of them.

2. Method of operation of the device. For this you need a heating element to work in liquid.

3. Design configuration. It is important that the heating element fits normally into the cube and that the mash completely covers it “with a reserve” and does not boil away until the heater is exposed.

Installing a heating element in a distillation cube

This task is not difficult and anyone who has at least a minimal understanding of the operation of electrical appliances can cope with it.

- At a distance of 5 cm from the bottom of the cube, make holes for the mounting brackets of the heating element. It is better to do this with an electric drill using a suitable crown. Clean the holes.

- Place sealing bushings on the output studs, then insert the end switches into the holes.

- Also put on sealing bushings on the outside.

- Place a little heat-resistant sealant or prepared epoxy glue into the hole between the bushings and only then tighten the nut, but without fanaticism, so as not to break the heating element before starting operation.

- Place the stripped wire between the terminals for connecting the electrical cable and clamp it.

- If you have a thermostat, connect that too.

- Securely insulate connections.

Carefully. Terminals clamped with excessive force can cause premature failure of the heating element.

Therefore, do it tightly, securely, but do not overdo it.

Temperature regulation

The first way to regulate heating is to monitor and turn on/off the heating element. This is exactly what they did about 20 years ago, since it was very difficult, not to say impossible, to get special household appliances that would monitor and themselves act as switches and switches.

But why bother yourself so much if a thermostat today is not a novelty, and it’s not so expensive that it’s “unaffordable” for your wallet.

Today, many online stores offer thermostats. Typically, those that allow you to regulate the temperature up to 140°C cost from 2 thousand rubles. For the same money, you can find one and a half kilowatt copper heating elements online along with a rod thermostat equipped with protection (single or double).

Separately, a thermostat up to 95°C can be found at a price of 680 rubles. For moonshine equipment, this is more than enough, because the mash is not brought to the boiling point of water.

It is precisely because of the possible burning of the mash, especially if the wort is thick, that home craftsmen make combined heating. On one side, a heating element is mounted into the cube, and on the other (possibly next to the electric heater) there is a steam generator tube twisted at the bottom with an open end in the middle of the cube.

When distilling liquid (for example) mash, use a heating element; for distilling thick wort (grain, jam, etc.) use a steam generator.

Important. It is possible to equip the steam generator itself with a heating element and even make a common connection to the thermostat for the heating elements of two devices.

DIY device - subtleties of the process for beginners

If you decide to equip the distillation cube with a heating element, then make sure that the components of the apparatus make it possible to obtain high-quality homemade alcoholic distillate or raw alcohol.

If you decide to equip the distillation cube with a heating element, then make sure that the components of the apparatus make it possible to obtain high-quality homemade alcoholic distillate or raw alcohol.

To do this, be sure to equip it according to all the rules by adding to the system:

- with a coil. This part does not raise questions, since it is mandatory for distillers;

- , in which most of the fusel remains and the final product becomes cleaner from impurities;

- tsargu () - with or without filler. Although not an obligatory part of the apparatus, it helps to purify the moonshine and obtain raw alcohol of 80 - 85 degrees;

- a bimetallic or electronic thermometer, under which a capsule made of a metal tube is installed in the upper part of the cube.

To understand why a thermometer is required in a distillation cube, it is enough to know. Alcohol evaporates at temperatures from 78.4 to 85°C. Everything that evaporates below this indicator (and begins to drip already at 65°C) are heads saturated with poison: methyl alcohol, acetone, and other light components. It's better to send them to the sewer.

Reference. An experienced moonshiner will determine the number of heads not only by temperature, but also by smell.

Typically these first drops make up up to 10% of the total distillation. You can calculate it another way - 50 ml from every 10 liters of mash in a cube.

When the heating passes the 85°C mark, harmful fractions begin to be actively released along with the vapor of ethyl alcohol (which is what we need). These are tails that still contain alcohol, but are already saturated with fusel, which can cause severe illness and even... Tails are selected separately. You cannot add them to the body of moonshine. But you can not pour it out, and add it to it during the next distillation - the yield of moonshine will increase.

To obtain moonshine that is superior in quality to store-bought brew (not to mention counterfeit), a thoughtful, modern approach to distillation is required. A heating element with a thermostat, a thermometer and properly selected attachments will help with this.

Was the article useful to you? Like and share information with friends on social networks.

Hi all!

Today I would like to talk about ways to heat the distillation cube of a moonshine still. There are several of these methods and you need to know about them. This knowledge is especially important for beginners who are just planning to purchase moonshine equipment.

Otherwise, it may turn out that a person wanted to make whiskey, but bought a cube unsuitable for this purpose. Or, on the contrary, he unnecessarily overpaid for equipment on which he intended to distill only sugar moonshine.

What influences the method of heating the distillation cube?

It is necessary to select a heating method depending on what kind of drink you want to get in the end. Or rather, on the raw materials you are going to use. For example, in one way you can very quickly distill sugar moonshine, but it is not suitable for distilling mash from grain or fruit.

The thing is that mash is made from grain, flour, grapes, etc. are the so-called “gentle” mashes. They are very thick and contain various inclusions and suspensions. So, with some methods of intense heating, the mash begins to burn, which has an extremely negative effect on the taste and aroma of the final product.

Conversely, in some cases you can use very effective methods that can significantly reduce distillation time and save you and me time.

Gas heating

Probably the most common heating method. There’s not much to say, so I’ll briefly list the pros and cons.

Pros:

- Easily accessible. There is one in almost every home.

- The heating method can be used on a cube of almost any design.

- It does not waste time on heating the burner and immediately heats the container (unlike electric stoves).

- Can be used for “delicate” mash. The mash practically does not burn, especially if the cube has a thick bottom.

- Gas is quite cheap.

Minuses:

- Very low efficiency (from 30% to 60%), and therefore the heating rate. The power of gas burners is on average 1.5-2 kW. With this efficiency, at best 1.2 kW will be delivered to the cube

- Not safe. We should never forget that we are dealing with a highly flammable liquid and its vapor. And you need to be very careful when boiling alcohol over an open fire. Especially if you work on low-quality and poorly sealed equipment.

- Limited space. Very often there are cases when a moonshiner buys equipment, but it does not fit the height of the stove - the hood on top is in the way. Of course, try installing at least such a thing.

But this one is weak?

Heating on heating elements

The toughest, but very effective way. Heating elements are built directly into the cube. Abbreviated as TEN. They work from the network. Depending on the design, one or more heating elements are installed. Power varies from 0.5 to 10 or more kW. The temperature of the heater walls reaches 300 degrees, the liquid on them boils and burns.

Inside the cube:

Inside the cube:

Pros:

- 100% efficiency. All heat is transferred inside the cube, which ensures high speed operation.

- Due to its high power and efficiency, it is practically indispensable for large volumes of moonshine.

- Some manufacturers offer cubes in which the heating element can be easily replaced with a steam bubbler (read about the bubbler below).

Minuses:

- The mash is burning mercilessly. The temperature of the heater walls reaches 300 degrees, causing the liquid on them to boil and burn. Even sugar mash can burn, especially if it is not clarified.

- To be able to change the heating power, you need to purchase a special regulator.

- If the liquid level drops below the heating element level, the latter will burn out. Just like a regular boiler. Therefore, an irreducible liquid residue must always be present in the cube.

- The presence of heating elements increases the cost of the equipment. Although they are relatively inexpensive.

Heating on an induction hob

An induction cooktop heats metal cookware using a high-frequency magnetic field. Powered by mains electricity. The most common models are 1.8 and 2 kW. Convenient as gas and more efficient. Can only be used with cubes that have a special bottom.

Pros:

- Safe. No open fire. When you remove the dishes from it, it turns off automatically.

- High efficiency - approximately 90%. Does not require heating - immediately heats the container.

- Provides uniform heating of the bottom, thanks to which it is “gentle” with the mash. Even “more gentle” than gas.

- Allows you to adjust power. The one in the photo has a range from 0.4 to 2 kW

Minuses:

- You need a cube specially designed for this heating with a bottom made of ferromagnetic material. Such dishes are marked with a special sign. It is worth noting that such cubes are also suitable for heating with gas.

- You need to purchase the tile itself. At the time of writing, the average price of a 2 kW stove is 2000-3000 rubles.

Steam heating

The most gentle way. Heating is carried out by supplying water vapor directly into the cube. The steam temperature (100 degrees) is, in principle, not capable of worsening the organoleptic properties of the final product. Steam is supplied from the steam generator through a special pipe with holes - a bubbler (pictured below).

Installation

Installation

Pros:

- Very gentle heat. Absolutely does not harm the taste and aromatic qualities of moonshine. Allows you to get the most delicious product.

- Some manufacturers offer cubes in which a heating element can be installed in place of the bubbler. Thus, the same container can be used both for hard and fast heating and for the most gentle heating.

Minuses:

- Significantly increases distillation time, because you have to first warm up the steam generator system itself.

- Additional equipment is required - a second cube, a steam line, etc. This greatly complicates and increases the cost of the process.

That's all. I have listed the main heating methods. I hope today's article was interesting and useful for you.

Maybe I forgot something? If so, correct me in the comments.

All the best and see you soon.

An interesting solution is to equip the distiller with a tubular electric heater (TEN). The device is quite quickly distills mash And does not require installation on a stove or oven. True, electricity generates money, and the re-equipment itself will also force you to spend a little money.

Let's figure out what kind of heating element we need and how to properly install it into the distillation cube. Of course, you can purchase a ready-made one, but its price will be noticeably higher. In this case, you can try to do everything on your own.

A heating element with a BUILT-IN thermostat (from 300 to 2000 rubles) is best suited.

Best fit Heating element with stainless steel thermostat. Depending on the power, they cost from 300 rubles and more. Decent ones can be purchased for 2 thousand rubles, which will serve you faithfully for quite a long time.

Each volume of mash requires its own power:

The shape of the heater does not matter. The main thing is that it screws into the tank.

- Up to 10 liters – 1 kW.

- Up to 20 liters – 2 kW.

- Up to 30 liters – 3 kW.

- Up to 40 liters – 4 kW.

Roughly speaking, for every 10 liters of mash you need 1 kW of power. For large cubes, you can install two heaters at once.

Moreover, during heating both work, and after the temperature of the start of evaporation (63 degrees) we turn on only one.

A detailed video about the types of heating elements and their operation can be viewed on the Youtube channel Hootch Moonshine. Even though the guys advertise their products, they still tell a decent amount of information and share their experience with other moonshiners.

How to properly install a heating element in a moonshine still

With welding

This is the method most often used. It does not require the purchase of additional equipment, although welding skills are required. The method is considered not entirely reliable for the reason that due to welding, the seam near the bottom of the cube is broken, as a result of which it can burst and leak.

Therefore, at your own peril and risk take a welder and weld the clamp two inches into a similar hole, which must be cut in advance (a drill bit costs 250 rubles). Then the heating element will be quietly screwed in there, and after distillation it will be removed back.

This process is clearly shown in the video from the channel Steel Jet, where the author of the video shows the conversion of a Luxstal distillation cube.

No welding

An innovative solution was invented by the guys from the online store moonshine-i-vodka.ru, who identified the negative impact of welding on stills. It was decided to insert the heaters without welding. For this we only need special nut And sealing ring for heating element(native will not work).

The work looks like this:

Screwed-in heating element without welding.

- Using a drill with a crown, a hole is drilled for the heating element. This is usually two inches, but varies depending on the size and power of the heater.

- The original ring is removed from the heater and a special one is put on (Where can I get it? More on that later).

- A heating element is inserted into the hole, and a special nut is screwed onto it from the inside, which firmly attaches the heater to the container.

As a result, the ring follows the contours of the container, and the nut tightens everything. As a result, no welding and unnecessary work.

This set is sold in a specialized store, which I mentioned a little earlier. I didn't find a price for the nut, but the ring costs only 70 rubles. In any case, this matter will not be very expensive, because the nut, although unique, is quite simple. You can see all this in the video below.

Pros and cons of using heating elements

The main advantages are simplicity And speed distillation. There is no need to put the container on the fire, you can choose any room or even distill moonshine on the street. Heating occurs quickly.

However, not everything is so rosy. We are losing money, and the quality of distillation may be impaired if we do not buy a thermostat and a thermometer.

The heating element must always be immersed in water. Otherwise it will burn out.

- Heating element costs money. You won’t be able to do everything yourself for free, and a ready-made cube with a heater will cost even more.

- Electricity. All heating elements consume relatively a lot of energy, so this cost can be immediately included in the cost of one bottle of moonshine.

- Thermostat required. In villages they drink it without it, but sometimes the mash burns and the taste of the drink becomes clearly worse. In order not to take risks and adequately control the process, you will need to overpay for a temperature thermostat.

Is the game worth the candle? In our opinion, it's very worth it.

For all the re-equipment, we don’t pay so much money that we have to strain our backs and drag the cube onto the stove.