Rules for installing gas appliances in a private home. Where can I install a gas boiler in a private house? Rules and requirements for equipment

Independent installation of a gas boiler in an apartment or private house is complex both technologically and organizationally.

Important! We must not forget that gas is a highly dangerous fuel, and all work must be carried out by specialists. Otherwise, the risk of a fatal mistake is too great, the result of which will no longer be additional costs, but damage to the health and sometimes even lives of people.

About the types of gas equipment

Installation of gas boilersInstalling gas equipment in any case will require going through the authorities, obtaining the necessary permits and a whole heap of various documents. Both the devices and the room itself must meet the requirements and standards laid down in the regulatory documentation. Installation of units must be carried out according to the rules. However, before you start visiting regulatory organizations, it is worth understanding the types of gas equipment used for heating and hot water supply.

To create a complete heating and hot water supply system, you will need to install a double-circuit boiler. The unit must have all the necessary automation. Such devices are expensive, and their installation should only be carried out by specialists.

The budget option is to use gas equipment only to produce hot water. That is, we are talking about a gas water heater. Compared to electric heaters, it is more efficient and cheaper to operate. Even an expensive device will pay for itself in about a year and a half. Here you need to take into account that its installation is not permissible in all apartments. The advantage of water heaters is that you can easily install them yourself. You need to decide which option to choose based on specific conditions.

Boiler room at home

A full-fledged boiler room based on a gas boiler can be equipped in a country wooden house, in a cottage, or in an ordinary city apartment.

Its “heart” is a double-circuit boiler with automatic systems. Automation ensures not only security, but also the efficiency of operation of the entire network. It is on its operation that the provision of a comfortable temperature regime and the possibility of reducing gas consumption during operation of the device depend.

Despite all its advantages, installing a boiler with automation has one important nuance. In the event of a power outage, the unit will switch to minimal room heating mode.

About installation rules

There are a number of requirements for installing gas equipment:

- The vast majority of models need to be located in a separate room. The exception is wall-mounted units - they can be mounted in non-residential rooms, for example, in the kitchen or bathroom, if their size allows. Before installing the boiler, it is necessary to ensure the required ventilation in the boiler room.

- The volume of premises for the installation of gas equipment with a closed chamber is not regulated, but the area must comply with the standards. In addition, the unit must have an outlet to the flue. It is unacceptable to bring it near the ventilation ducts.

- Horizontally located parts of the gas duct cannot be more than 3 meters long and have more than three turns. The flue outlet must be raised above the roof level by at least a meter.

- Wall-mounted models are mounted at a distance of 800 mm or more from the floor surface. No objects should be placed under the boiler, and a metal sheet must be laid on the floor. An expansion tank and an air valve must be installed.

Gas equipment cannot be installed in the following types of premises:

- In the apartments of an apartment building without a main gas duct - these are the majority of old buildings.

- In rooms with false ceilings and capital mezzanines.

It is almost impossible to install a floor model in an apartment in a multi-storey building. After all, this will require serious redevelopment with all the ensuing problems and costs. There are no restrictions on the installation of such equipment in a private home. Here it is better to make a separate boiler room, for example, in an extension. This room must meet the following standards:

- Entrance doors are no longer 80 cm.

- There must be a chimney that goes either to the roof or through the wall to the outside.

- The height of the boiler room must be at least 2.2 m. The room is equipped with a ventilation system.

A double-circuit boiler with automation will require a separate branch of electrical wiring. An additional 20 A circuit breaker is installed on it. It is advisable to provide backup power to the automation, capable of maintaining its operation in normal mode at least for a day. To do this, you can purchase a diesel generator or a UPS - an uninterruptible power supply.

Severe demands are placed on the gas duct. Its minimum diameter is 110 mm, regardless of the power of the installed equipment. The optimal diameter of the flue is calculated based on the power characteristics of the unit - the higher the power, the larger the diameter.

Boiler connection

Gas heating boilers installation and configuration

Gas heating boilers installation and configuration The main parameter when choosing a gas boiler is its power. It should be sufficient to ensure the normal functioning of the heating network, but at the same time not excessive. With excess power, there is a high risk of cracking the heat exchanger. So-called acid condensate can also form when the return temperature drops below the gas dew point - 56 degrees. The high-power unit quickly warms up the system and goes into standby mode until the temperature drops to certain parameters. After cooling, the boiler turns on again, but powerful heat exchangers have high thermal inertia, so acidic condensate may form before it is reheated.

The optimal power should be determined on the basis of thermal calculations. The excess power must be within the permissible run-up. In a private house, you will have to do thermal calculations yourself or invite specialists. For apartment buildings, such data can be found in the technical inventory office.

Before installing the boiler, it is necessary not only to equip the room, but also to collect the necessary documentation:

- A gas supply agreement is not required when installing a water heater.

- Documents for the meter - without this device it is prohibited to connect gas heating and water heating equipment.

- Documents from the BTI on amendments to the technical passport of a house or apartment. The new plan must take into account the location of the boiler room.

- Technical passport for boiler equipment.

At this stage, you can submit an application to the gas service for the development of design documentation and specifications. You can install the device yourself before receiving the finished project, but provided that the room fully complies with the standards and is approved by regulatory services. Gas connections should only be made by gas service employees. A suitability statement must be obtained from a gas engineer before commissioning.

If you connected the boiler to the gas mains yourself, there is practically no chance of getting an engineer’s opinion. Such work should only be carried out by gas specialists. You can install the hydraulic and electrical connections of the boiler yourself. As a rule, all the necessary requirements and instructions can be found in the instructions for the device.

Project and specifications

Boiler check

Boiler check Design and technical specifications (technical conditions) are the most important documents for the installation of a gas autonomous heating network. Technical conditions are drawn up in the gas service. In essence, this document is an official permit to install equipment. For premises that fully comply with the requirements of regulatory documentation, registration of technical specifications takes about 14 days.

Project documentation is developed after receiving the specifications. In essence, it represents a diagram for installing the unit and laying the gas pipeline. For a private house, the project must include a highway route through the site. This documentation is also developed only by licensed design specialists.

Approvals

Even documents developed by specialists must be approved by regulatory gas services. All this can take up to three months, depending on the complexity of the developed project. Along with the project documentation, it is necessary to submit to the gas services:

- Heating device data sheet and operating instructions.

- Certificates for equipment.

- Conclusion of the examination.

Let's start installation

Installation diagram of a double-circuit gas boiler

Installation diagram of a double-circuit gas boiler Wall-mounted and floor-standing gas boilers must be installed by specialists licensed to perform such work. The work is carried out in a room with a temperature of at least +5 degrees and in several stages:

- Preparing the hole through which the coaxial pipe or flue will be discharged.

- Installation of the unit. Wall-mounted - on a bracket, floor-mounted - on a pre-prepared place.

- Connection in hydropiping.

- Installation of a gas tap, meter, if it was not installed previously, and sensors.

- Connecting the unit to the electrical wiring and grounding it.

- Exiting the coaxial pipe outside the house.

- Filling the system with coolant and pressure testing.

- Check for gas leaks.

Conclusion

Regardless of the type of equipment you purchase, only gas specialists should install a boiler in a house or apartment. Independent work is allowed only partially and provided that it does not require intervention in the gas main . All documentation on the basis of which the boiler is installed must be approved. Only the simplest water heaters, that is, geysers, can be installed independently.

Related PostsNowadays gas is one of the most common types of space heating. Therefore, many are interested in what is needed in order to install gas equipment in their house or apartment. What are the room requirements for installing a gas boiler? Requirements for equipment and places of its installation are clearly regulated by SanPin standards. Controlling organizations monitor their implementation, because the place equipped for a boiler room is explosive. Therefore, you should strictly follow the standards.

Gas boiler in a private house - main types

- Floor-standing. They are very common. Installation of such equipment should be carried out in specially equipped places with good ventilation. Suitable for heating large areas.

- Wall-mounted. Such units take up very little space and are used for heating small places.

Installation Requirements

First you need consent to install gas equipment. To do this, you need to contact GorGaz, write an application and provide the following documents:

- a project that includes a connection scheme to the central city highway;

- technical passport of the selected unit;

- instructions for use;

- conclusion of the expert commission on the suitability of the equipment.

NOTE! For an installation with a power of less than 30 kW, the boiler room area is at least 7 m2 . If the power is up to 60 kW, it is equal to 13 m2. Over 60 kW – 15 m2 and more.

Requirements for a gas boiler room in the basement

Previously, it was prohibited to install boiler rooms in basements. However, recently this has become possible thanks to the transition to propane, which is in a gaseous state. Now it is allowed to install a gas boiler in the basement. Only the power of the equipment is limited; it should not exceed 200 kW. You just need to comply with all the requirements assigned by Sanpin.

As a rule, equipping a boiler room in a private house does not cause difficulties. All the necessary requirements are quite easy to fulfill. You only need to build a boiler room that meets all prescribed standards.

Installation in an apartment poses a number of difficulties. The most suitable place for this is the kitchen. To install a gas boiler in it, you need to meet certain requirements. This:

Important! Independent connection is strictly prohibited, especially to central highways. The first setup should be carried out by a specialist.

Before you begin building and equipping a boiler room, you first need to purchase the right boiler. Then, based on its power, select the size of the room, while observing all the necessary requirements. To save money and time, it is recommended that you first familiarize yourself with all the rules and only then proceed to arranging the room that will serve as a boiler room.

Despite the growing popularity of solid fuel, mains gas remains the main energy carrier consumed for space heating. Accordingly, homeowners continue to purchase gas-using equipment. The next step is the installation of a gas boiler, carried out in an apartment or private house in accordance with regulatory and technical requirements. We suggest going through this procedure virtually, starting with choosing a heating unit.

Homeowner's procedure

The installation or replacement of gas heating in country cottages or premises of an apartment building is carried out with the permission of the relevant service. Moreover, you can install the boiler and make the piping yourself, subject to compliance with current building codes. Employees of the gas supply organization perform 3 types of work: project development (with approval), gas connection and start-up of the heat generator.

Reference. Design and installation are usually ordered by fuel supply companies, although the law does not prohibit hiring third-party companies. The question is the cost of services and the duration of the approval procedure.

How to proceed correctly to install a gas boiler in your home:

- Select a room for installation of a heat source.

- Buy a heat generator of the required power, compatible with the heating system.

- Submit an application to the gas supply organization, attaching a package of documents. Obtain technical specifications (TS) for connecting a gas-using installation.

- Based on the specifications, order the production of design documentation and have it approved by the relevant service of the gas supplier company.

- Following all the rules and requirements set out in the project, install and connect the boiler to the heating system.

- Call Gorgaz specialists who will connect to the fuel line and initial start-up of the heat source.

In general, the specified procedure for installing and connecting boilers is valid in all countries of the former USSR. In any case, the homeowner receives technical specifications that list the requirements of current state regulations. Let's look at each stage separately.

Installation room

According to the requirements of SNiP and other sets of rules, installation of gas-fired heaters is allowed in the following premises:

In most cases, gas heating boilers are installed in a separate combustion room. In apartments and small country houses, heating units are located in the kitchen, less often in the passage corridor (applies to wall-mounted versions of heat generators).

Placing the heat generator in a separate room

What are the requirements for the premises:

It is difficult for the average homeowner to calculate ventilation based on air flow in 1 hour. Hence the advice: organize an exhaust through a channel with a minimum cross-section of 14 x 14 cm, the optimal size is 28 x 14 cm. The exhaust shaft exits in the upper zone of the room, the inflow is organized through the entrance door, where a grille with a live (useful) cross-section of 0.025 m² is built in. The premises of the gas boiler room are described in detail in the video:

Selection of heating unit

The first criterion for choosing a gas boiler is the thermal power required for heating. Depending on the operating conditions, the performance of the heat generator is calculated as follows:

- In a temperate climate zone, the power is calculated by multiplying the heated area by 100 W. An increasing safety factor of 1.2 (+20%) is applied to the resulting figure.

- With a ceiling height of 3 m or more, the performance is calculated based on the volume of the building - the cubic capacity is multiplied by the average value of 40 W.

- In the southern regions, the area is multiplied by 80, in the northern regions - by 200 W. The safety factor is maintained.

- The design power of double-circuit versions and conventional boilers operating in conjunction with an indirect heating boiler is multiplied by a safety factor of 1.5 (+50%) instead of 1.2.

- If the heat generator is connected according to the scheme with a buffer tank - a heat accumulator, the power reserve is doubled (+100%).

The type of unit depends on. Non-volatile models of gas boilers - floor and parapet - are suitable for gravity open systems. Closed circuits operating under pressure are best connected to wall heaters equipped with their own circulation pump and expansion tank.

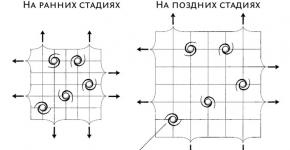

In apartments and private houses, where for various reasons it is impossible to remove flue gases in the traditional way, it is recommended to install a gas boiler with a closed combustion chamber and forced air injection. Such heat generators are equipped with a coaxial chimney laid out through the wall. The principle of operation is as follows: air is drawn in by a turbine through the external channel of a double-walled pipe, and combustion products are ejected through the internal passage.

Registration of permits

Let us clarify the sequence of actions a little: first you need to contact the gas specialists for permission to install the boiler, then buy a heating unit, then request technical specifications and order the project. To obtain specifications and contact designers, prepare a package of documents:

- ownership of housing - an apartment or a private house;

- current building layout;

- passport and operating instructions for the gas heat generator;

- product certificate.

Note. The certificate and documentation of the heater are provided by the equipment manufacturer.

Example of a boiler room project

Having received the technical specifications, pass them on to the design engineers, supported by drawings of the building and your own wishes regarding the installation location of the boiler. If there are no plans, you will have to pay extra for an on-site inspection - the technician will draw up a drawing after the fact.

Advice. Carefully discuss with the designers the main points - the exact location of the heating unit and the design of the chimney. This will save time and start installation work without waiting for project approval.

The finished project documentation (at least 3 copies) is endorsed by the responsible persons of the gas supply organization. At this stage, it is worth ordering the laying of external and internal gas pipelines. Contact the same office or another licensed company.

Requirements for the furnace room

Installation requirements

When installing a floor-standing boiler that burns natural gas, it is recommended to maintain the minimum distances to walls and other building structures:

- the width of the free area in front of the front part of the heater is 1250 mm;

- side passages for maintenance and troubleshooting – 700 mm;

- The minimum clearance at the rear of the unit is 50 cm.

For mounted gas boilers, the requirements are softer - at least 1 m of free space must be left in front, 20 cm on the sides, and 300 mm on the bottom. The structure hanging over the heat generator should be located no closer than 45 cm, as shown in the diagram.

Before installing a stationary boiler on wooden floors, be sure to place a fireproof gasket made of basalt cardboard and roofing steel, protruding 100 mm beyond the dimensions of the casing, 70 cm in front. If, for various reasons, the heater is located close to the walls of a wooden house, they should be cover with non-combustible materials:

Similar precautions are taken when installing a wall-mounted heat generator on a wooden wall. The simplest fire-prevention measure is to place galvanized metal under the body, protruding 10 cm (downwards - 70 cm), as shown in the photo.

Connection to chimney and heating

Gas heating units with an open combustion chamber require connection to a chimney pipe with good natural draft. Its head should not fall into the wind support zone, otherwise the traction force will decrease to zero. The minimum height of the chimney is 5 m (counting from the burner), the optimal one depends on the location and distance from the ridge of the pitched roof (indicated below in the diagram).

Important point. Connecting the gas boiler pipe to brick ventilation ducts made in the wall of an apartment or country house is strictly prohibited.

The general requirements for chimneys and connecting gas boilers are as follows:

- The diameter of the pipe is not less than the size of the unit’s nozzle designed to remove combustion products.

- The material of the chimney duct is galvanized steel, stainless steel, brick or ceramics. No aluminum corrugations.

- The total length of the horizontal section cutting into the vertical pipe is no more than 3 m; An inspection hatch is installed below the insertion point with a minimum offset of 25 cm.

- The distance from the metal smoke duct to wooden structures is 0.5 m. If you cover the flammable material with asbestos or roofing iron, the distance can be reduced to 100 mm.

- The maximum number of 90° turns of the chimney should not exceed 3. This does not include 30 and 45° bends used to bypass the roof overhang.

The requirements for the installation of coaxial pipes of turbocharged boilers are simpler: the channel is made with a slight slope towards the street, plus compliance with fire safety measures when passing through wooden walls. The structure of chimney pipes is described in detail.

The boiler piping is carried out according to the following recommendations:

- the wall-mounted heat generator is simply connected to the heating system through shut-off valves with American connections;

- Install mesh filters at the gas and coolant inlet;

- for a floor heater, you need to assemble a circuit corresponding to the heating system: install a circulation pump, expansion tank and safety group;

- connect the make-up from the water supply network to the return pipeline with the coolant;

- When working together with a wood-burning or electric boiler, consider installing check valves.

Under a turbocharged heater with high efficiency, equipped with a fan and automation, install an outlet with a supply voltage of 220 volts and a grounding wire. Make sure that in case of an accident it does not become flooded. When connecting via a stabilizer or uninterruptible power supply, organize a special shelf or cabinet for these devices.

Conclusion

Upon completion of the work, gas service personnel will check the correct installation and compliance with the project. If any critical comments arise, the shortcomings will have to be eliminated - without this, the company will not allow commissioning and gas supply to the facility. If there are no complaints, specialists will connect the gas pipe, configure and start up the equipment. All that remains is to take the last step - to conclude an agreement for the supply of fuel.

Design engineer with more than 8 years of experience in construction.

Graduated from the East Ukrainian National University. Vladimir Dal with a degree in Electronics Industry Equipment in 2011.

If you don’t dream of autonomous gas heating with hot water supply, then every householder has probably seriously thought about it, both in a city apartment and in a private house. Only today it can reliably provide a comfortable temperature in the house cheaper than the central one. However, installing a gas boiler with your own hands is a complex, responsible matter that requires a permit. Actually, taking on it yourself makes complete sense only if you have sufficient funds to purchase a double-circuit boiler with a boiler and a full set of automation, and your home according to the specifications is suitable for installing a boiler.

The second case when you need a gas boiler is if you are not rich, and there is no hot water in the house and is not expected. In this case, you need a simple budget single-circuit instantaneous hot water boiler that allows you to wash dishes and take a shower. A gas boiler is more expensive than an electric boiler, but taking into account the cost of installing a gas meter, at current rates it will pay for itself in a year and a half over the winter, depending on where you live. If, again, you can install it in your apartment, and you are not afraid of going through the authorities.

Two big differences

The boilers mentioned above are the extremes of a huge variety of models of gas water heating devices. They are available for self-installation. Any other gas heating boiler requires professional work for installation. However, every cloud has a silver lining - specialized companies also take on the preparation of the premises and the preparation of documents. But why can you install only the “tips of scissors” yourself?

Simple water heater

The simplest boiler is really very simple: a gas burner, a heat exchanger - that's all. It is enough to connect water and gas to it, vent the exhaust into the chimney - and you can use it. If the papers have already been completed; otherwise - an inevitable large fine.

Home boiler room

A double-circuit boiler with a boiler and full automation is so “smart” that installing it is as easy as the simplest one. Automation is important not only for simplicity: a complete system with a double thermostat and a microprocessor monitors the temperature in the house and outside, according to a given program, reduces heating to a minimum according to sanitary standards when no one is at home (for example, when everyone is at work). The gas consumption of such a boiler is 30-70% less than with manual or semi-automatic adjustment, and the savings are greater the more severe the weather.

But such a home boiler room has a serious drawback: if you find yourself in a natural disaster zone and the power supply is disrupted, the automation “stalls” and the boiler goes into the mode of minimal heating of the room. Therefore, such a boiler requires additional costs for guaranteed power supply. It is not difficult to provide it yourself, see below.

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

Note: 8 cubic meters free - with a boiler power of up to 30 kW. For power from 31 to 60 kW – 13.5 cubic meters; for power from 61 to 200 kW 15 cubic meters. For boilers with a closed combustion chamber, the volume of the combustion chamber is not standardized, but the dimensions must still be observed.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

Power supply

The automation of heating boilers consumes little electricity, but according to the rules, the boiler still requires a separate wiring branch with a 20 A automatic circuit breaker, just like a boiler. For backup power supply, any computer UPS is well suited. A kilowatt will “keep” the automation for half a day or a day. This is quite enough to take the necessary measures in case of an emergency.

About the gas duct

The cross-sectional area of the house flue for it depends on the required boiler power (see below). At any power, the diameter of the flue must be at least 110 mm and not less than the diameter of the exhaust pipe. The dependence of the flue diameter on the boiler power is as follows:

- up to 24 kW – 120 mm.

- 30 kW – 130 mm.

- 40 kW – 170 mm.

- 60 kW – 190 mm

- 80 kW – 220 mm.

- 100 kW – 230 mm.

Boiler selection

Power

It is obvious that the boiler power must be sufficient. But it should not be excessive, especially if the heat exchanger is cast iron. Drops of condensate from the flue cause hot cast iron to crack. There is another dangerous effect: the dew point temperature of the exhaust gases is approximately 56 degrees Celsius. If the water temperature in the heating return is lower, acidic condensate may form in the combustion chamber. What does this have to do with excess power? A boiler that is too powerful will quickly warm up the system and go into standby mode until it cools down. The thermal inertia of a powerful heat exchanger is high, and while it warms up again, acid dew may form.

With correctly selected boiler power, the temperature in the combustion chamber will be 80-90 degrees. The permissible difference in power is quite large, but if you install a 60 kW boiler in a medium-sized private house, then acid rain from the inside will quickly damage it.

The required boiler power for a specific room is determined by thermal engineering calculations. It’s easier for residents of high-rise buildings: the data is available in the DEZ, the technical inventory bureau or the owner. In any case, you can use approximate data by calculating an intermediate value for yourself. Maximum power values are given for cases of minimum outside temperature of –25/-40 degrees:

- One-room apartment on the middle floors – 8/14 kW.

- Corner apartment 60 sq.m. the total area on the top floor of the Khrushchev block is 20/28 kW.

- Private house 100 sq.m. common – 24/38 kW.

Boiler

The purpose of the boiler is to accumulate hot water for domestic needs. If you look at the instructions for the boiler, the power will be indicated there as a fraction, for example - 10/22 kW. The first number is the heating power for average conditions; it determines gas consumption by 80%. The second power, maximum, is for quickly heating domestic water.

If the boiler is emptied, the boiler temporarily stops heating the heating (it does not have time to cool down) and heats domestic water at maximum. Gas consumption is, of course, maximum. If you take a little water from the boiler, then it will be heated in operating mode, without force majeure. Based on this, the capabilities of the boiler can be judged by its capacity:

- 2-10 l – wash hands and wash dishes.

- 30-50 l – take a quick shower.

- 100 l – wash thoroughly in the shower.

- 150 liters or more - you can take a bath and connect a washing machine to the hot water supply.

Note: If you already have one, it is advisable to leave it by turning off its machine. It will make a good hot water accumulator, and if you have problems with a gas boiler, you can turn it on.

Video: expert opinion on choosing gas boilers

Documents for the boiler

Let's say you have equipped the furnace room in compliance with all requirements. Are we buying a boiler? It is too early. First of all, check if the previous gas papers have been lost, and bring them out into the light of day:

- Gas supply contract if the boiler is a heating boiler. Subconsumers can only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing you can do, you need to install it and arrange it, but that’s a different topic.

Now you can buy a boiler. But, having bought it, it’s too early to install:

- The BTI needs to make changes to the registration certificate of the house. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be shown, and clearly marked: “Furnace room” or “Boiler room”.

- Submit an application to the gas service for the project and specifications. The required documents also include a technical passport for the boiler, so it must already be purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas connection.

- Submit an application to gas workers for commissioning.

- Wait for the gas service engineer to arrive, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

Note: Gas workers are not supposed to give permission to private individuals to work on gas equipment. Therefore, to connect gas to the boiler, you will have to call a specialist or then “resolve the issue” with an inspector during commissioning. As a rule, the former is cheaper.

Boiler installation

It is unacceptable for the boiler body to be adjacent to any of the walls, so redo the fastenings of wall-mounted boilers, recess the boiler into a niche, etc. it is forbidden. After installing the boiler in place, its piping is done - connecting three systems: gas, hydraulic and electric. The gas connection should be done, as indicated, by a gas specialist, and last of all, when everything else is already connected.

You can do the electrical and hydraulic connections yourself. The main guiding document here is the instructions for the boiler. A typical boiler hydraulic circuit is shown in the figure. For any boiler, the following conditions must be strictly met:

- Water and hot gases in the boiler heat exchanger must flow countercurrently, otherwise it can simply explode with any automation. Therefore, it is extremely important not to confuse, either through negligence or for the sake of ease of installation, cold and hot pipes. After hydropiping, carefully inspect the entire system again, then rest for an hour and inspect it again.

- If antifreeze has been poured into the heating system, drain it completely and rinse the system twice with clean water. An admixture of antifreeze in the water entering the heat exchanger is also explosive.

- Do not neglect the “mud collectors” - coarse water filters. They should be located at the lowest points of the system. The accumulation of dirt between the thin fins of the heat exchanger also creates a dangerous situation, not to mention excessive gas consumption. At the beginning and end of the heating season, drain the sediment through the mud traps, check their condition and, if necessary, flush the system.

- If the boiler has a built-in expansion tank and a deaeration system, remove the old expansion tank and turn off the old air valve tightly, having first checked its condition: air leakage will also create a dangerous situation.

Video: example of installing a wall-mounted gas boiler

Bottom line

Installation of a gas boiler is technically and organizationally complex. You can independently install only the simplest hot water boilers or expensive, fully automated home boiler rooms. But connecting the boiler to the gas supply system (gas pipework) must still be carried out by a gas service specialist or a certified installation organization. Otherwise, it is prohibited by the rules for the installation and operation of household gas appliances.