How to build a new bath. Stages of building a bath: from foundation to interior decoration

How beneficial the bath is, it doesn't take long to paint. And not only for physical and mental health. To have a bathhouse on the site is to gain prestige and respect from neighbors. And the opportunity to invite a useful person to take a steam bath will bring direct benefits. Let's be realistic, many important issues are being decided in the bathhouse, and a document is being signed at the conference table. There is no need to look for corruption schemes here: after the bathhouse, it brightens in the head, unnecessary husks fade away, and the essence of the matter comes out. Villains, by the way, do not appoint a "shooter" in the bathhouse, there the conscience awakens.

This article is devoted to the question of how to build a bath with your own hands. Who said that only the powerful of this world have the right to the complete blessing of the bath? But why, one wonders, build yourself? The structure seems to be unpretentious, in demand. Maybe it's better to order on a turnkey basis?

It's all about being in demand. Combined with a little circumstance: the bath is not an essential or vital object. Hence, the contractor's wrapping is limited only to the contents of the customer's pocket, as for luxury goods. What builders use - the market is the market, they also need to live, and they want better.

Take a look at fig. The bathhouse on the left will cost about $ 8000 on a turnkey basis, and the one on the right - at $ 23,000-25,000. Impressive? We will modestly keep silent about 2-3-storey saunas with pools, billiard rooms, banquet halls and massage rooms. And if you build yourself? Self-construction of a bathhouse for 2 compartments of 3x4 m from a bar (this is the one on the left) will cost about $ 1800, and a 4x6 m log cabin of 3 branches will cost about $ 4000-5000. It is impressive, however, the difference is not only at times, but also fundamental: if the turnkey sums do not fit into the average budget, then the squatter has already been able to do it without an overwhelming consumer credit. a mortgage with a lower rate for the bath will not be given now.

The purpose of this article is first of all to show: the devil is not so terrible as he is painted. The bathhouse is a serious building, it must meet certain requirements. And the emphasis in the following is made on how to satisfy them without mastering complex technologies and not spending excessively. If you know how to cut the board straight, drill a hole straight, drive a nail without bending, and after reading the rest, believe that building a bath is within your power and resources, we will consider our task completed. Therefore, the material is built for a more complete coverage of the key points, but due attention has been paid to the peculiarities of the technology of building baths from various materials.

Russian or sauna?

The Finns themselves, and the doctors too, admit that the Russian bath is superior to the Finnish one. In a Russian bath you can create perfectly dry steam, like in a sauna, but you won't be able to "burn" in the last vigorous steam. But the sauna has a valuable advantage - it is not very demanding on the design of a bath room with a heat source. A compact electric sauna the size of a wardrobe can be put in a city apartment, and nothing, normal steam there. But the Russian requires a separate bathhouse and a stove for it. Therefore, further we will talk about the Russian bath, and we will leave the saunas for another case.

Ancestor

The original Russian bath consists of 2 sections: a dressing room and a steam room, see fig. on right; sizes - from 2.3x4 to 5x6 m. The fashion for such baths is now reviving, they are called wild baths. Indispensable features of the "wild" Russian bath:

- The foundation is not buried from natural (also wild) boulders, without a basement.

- The structure is a blockhouse made of selectively chopped wild logs, i.e. which have not undergone any technical processing, except debarking and drying.

- Construction - without a single nail.

- Cauliflower - only with moss and tow.

- The ceiling is flat (see below).

- Floor and ceiling insulation - moss and peat.

- Waterproofing - resin or boot var.

- The roof is shingle or turf.

- The oven is brick.

It is not hard to guess what these archaisms are worth in our time. Turnkey wild bath for less than 1 million rubles. - a marvel. In addition, it is fire hazardous; peat, moss and wood not impregnated with fire retardants are combustible materials. But then we will see how to build a cheaper and simpler safe sauna on our own, not inferior to the original one. First, modern materials and technologies will help; besides the traditional tree, unexpected solutions are possible. Secondly, in the old days, bath stoves were built from bricks only in the absence of suitable metal ones. In fact, a stainless steel stove with an afterburner, an air convector and a properly arranged sauna heater is better in every way. So, to the point. The action plan is as follows:

- Reconnaissance with surveys - we see if it is possible to put a bathhouse on the site, where exactly, what size and layout;

- The choice of material for construction;

- Design and project approval;

- Construction and equipment, from foundation and drain to furnace installation.

Project

You should dwell on the project immediately. The procedure for its approval is the same as for other non-residential buildings. However, it is not recommended to start a squatter and legalize it later. The bathhouse is not an essential building. If, after its construction, harmful neighbors complained like: “And we have a stinking carrot from the garden like they built a bathhouse!”, Then it will be very problematic and expensive to prove your own. On the other hand, for the same reasons (uninhabited, not vital) the dreary walking through the authorities is simplified and facilitated. Based on this, 3 options are possible:- Order a turnkey project from local designers, i.e. already approved and tied to the place, it will cost up to 5,000 rubles for a small bath. + state duties and fees;

- Designing yourself is undesirable, without being a builder, you will get confused, and in the organs of arrogant amateurs are not favored;

- Download the finished sketch from the Internet, i.e. not tied to the locality, the project, and tie it to yourself.

The last option is optimal if you are not afraid to sit under the offices for 5,000 savings. He has, so to speak, a sub-option - to give the downloaded sketch to the designers for binding and design. In this case, the savings are cut in half or three times, but walking is on their soul, and she is there like a fish in water. You just have to choose a suitable building, estimate its location, make a copy from the home ownership plan and show the designer where the bathhouse will be. However, you should not download the first beautiful 3D picture you like with some schemes, you need to check that the bath project contains at least the following sheets:

- Floor plan with the necessary sections and explication (technical description) of the premises, like the one in Fig. below;

- A summary sheet of the required materials, and then keep the receipts on them, so that if something happens, show - not built from stolen;

- Recommended type of foundation and its plan.

An important point in a building permit is the consent of the neighbors. This is not an IOU, other laws apply here. A simple piece of paper with a signature as an argument will not work, but if there is a stamp “Approved” and a visa on it and other sheets, then the conversation with that neighbor is short: “Do you see the seal on your squiggle? Yes? So you went to your garden to pick carrots.

And yet such a mum-a-lazy remark. It is not necessary to count nails one by one and measure out according to the project, where to hit. Builders are well aware that deviation from the project is far from the same as squatter construction. Therefore, having an approved project, more or less experienced developers build, if only it looks like it, and then suddenly something will settle down. The number of storeys, the dimensions in the plan, the location of the load-bearing walls (in a small bath there are already 4 of them), the material from which it is built - wood, wood, brick, so brick - and the foundation, its type and material should coincide. The rest, if we are talking about a bath, will no longer be a violation, but a deviation from the project, which can be solved. Any foreman on this topic will tell such stories - you will marvel and laugh.

Note: the question may arise - what kind of liberalism to deviations? It's about mother earth, they are building on it, and it is still impossible to predict exactly how it will behave. Therefore, they give free rein to the grated builders, so that at their own risk they can decide on the spot according to the circumstances - how to build, so that it will stand.

Location, size, layout

The requirements for the location of the bath on the site are shown in Fig. on right. Of these, when approving, they look especially strictly at the distances to the water supply source, home, and drain from the borders with neighbors. They should be followed with a margin, with the priority of water supply being the highest. If, for example, according to local conditions, it is necessary to take the distance from a well or a well from 30 m to the nearest sources of pollution (and the bath is one of those), then we take this or another large value. The same applies to the distance to neighbors, carrots can really smell from the bath runoff.

Other requirements are flexible enough based on local conditions. For example, the distance to the house is taken so that seepage from the bath drain does not undermine the foundation. If the bathhouse is lower down the slope, and the underground drain is directed from the house to it, then it is possible to keep within 5-7 m, then only according to the results of on-site surveys.

A lot of "creak" when approving bath projects is caused by the orientation of the entrance not to the south. There is already a medical reason: suddenly, the steamed one will come out into the cutting north wind, not long before pneumonia. But, say, in the Ciscaucasia, the worst wind in winter is just the southern one, the so-called. similar to the mountains, but in the wind rose in the north there is a dip, so in this case the orientation of the entrance to the bath can be opposite to the typical one. Well, it doesn't matter where the window is looking. If you want to admire the sewer hatch while washing, it's up to you.

On an ordinary personal plot, the very possibility of building a bath can be solved by a meter and a half of its size. In such a case, we give informal norms of the area for 1 washable: 1.5 sq. m of dressing room and 1 sq. m washing (shower). That is, a fairly comfortable home bath is possible in sizes from 3x4 m.Examples of layouts of such baths are shown in Fig. below, with a separate steam room combined with a washing room. Their peculiarity is that the front door can be on any of the walls of the dressing room, which facilitates the location of the bath on the site.

You should stay in the steam room especially. The fact is that the general state of health of modern citizens often simply does not allow them to take a steam bath. In this case, a 3-section sauna with a separate steam room is required. In 3x4 m, such a layout can be laid, on the right in Fig. with plans, but then there is a problem of heating the shower in cold weather. It is irrational to let the shower warm up, wasting hot water in vain, there is so little of it in the hot water heater, and there is no place for a separate stove in the shower.

A way out can be found by deviating from the bath-planning traditions, especially if the area available for construction allows to increase its size. For example, in fig. - bath layout from 3x5 to 4x6 m with a small dressing room, in fact, a dressing room.

A large washing room is heated either by a separate stove (indicated by?; A simple home-made stove or something like that will do here), or by a stream of air from part of the convector of a modern sauna stove in a steam room. In the latter case, 2 solutions are possible: either non-combustible partitions and part of the air convector goes into the washing room, as in the figure, or the intake of cold air above the floor of the washing room and supplying it heated under the ceiling using tin boxes or metal corrugations. Due to the presence of the vestibule, the general entrance can be oriented as you like, and for those who like to bite into a fresh snowball or a pool in the steam room there is a separate exit.

Note: about the second sign? in fig. and drain with drain see below.

Materials

The choice of material for building a bath is primarily due to the physical processes in it. More precisely, our ancestors, based on the availability and medical and hygienic requirements, understood at that time intuitively, but rightly, came up with the design of the bath building. Therefore, it turned out to be quite conservative and tightly tied to the tree. Wooden buildings require very high craftsmanship and long technological breaks for shrinkage and their own shrinkage, if inexpensive timber is used. It is possible to find a replacement for wood with a bath, for example. the foam blocks considered below or wood concrete, or sawdust concrete. Therefore, before choosing a material, let's see what kind of physics works in the bath.

Bath physics

First, the bath is not constantly heated, the heated one gets very hot, and when washed it damp. Second - during heating, the sauna stove must first give a powerful stream of thermal (IR, infrared) radiation, which will heat the walls and be absorbed by them, and a little later - a strong stream of heated air, which gives a uniform temperature in the steam room. At the time of washing, the furnace firebox is weakened so that the washable ones do not burn its directional IR. People in the IR bath from the heated walls and the warmth of the air should gently and evenly envelop; this, in addition to air far from being saturated with moisture, is an indispensable condition for light steam.

First, the bath is not constantly heated, the heated one gets very hot, and when washed it damp. Second - during heating, the sauna stove must first give a powerful stream of thermal (IR, infrared) radiation, which will heat the walls and be absorbed by them, and a little later - a strong stream of heated air, which gives a uniform temperature in the steam room. At the time of washing, the furnace firebox is weakened so that the washable ones do not burn its directional IR. People in the IR bath from the heated walls and the warmth of the air should gently and evenly envelop; this, in addition to air far from being saturated with moisture, is an indispensable condition for light steam.

The lightness or severity of the bath is not so strongly associated with temperature. Steam at 45 degrees can be heavy and at 70 degrees light. The tolerance and benefits of the bath for people of different, as they say, the constitution is expressed by a parameter that can be called the intensity of exposure to steam; among the people it has long been known as the "vigor" of the bath. Also, the classification of baths on this basis has long been developed:

- Lightweight, for women and children - from a linden forest, the heat capacity of the walls is small, the IR from them quickly "exhales" and the washable ones are warmed with more air.

- Plain, or condo - traditionally from a coniferous forest. Heating the IK from the walls and with air approximately equally, depending on the mode of the furnace, is suitable for almost everyone. It can be built from any materials suitable for a bath.

- Vigorous - from thick oak logs. Thanks to the long and powerful IR from the walls with a high heat capacity of only 50 in the steam room, one sweep with a broom penetrates, as they say, the bones are playing. But it is possible to withstand vigorous steam only with iron health. In general, a vigorous bath is a heroic one, after which, figuratively speaking, it is just right to throw trucks around, grabbing the car by the hitch.

Light baths were built by the rich more for wives, daughters and other women dear to them: a light bath has a beneficial effect on women's health and allows you to preserve beauty for a long time; both sexes add sexual activity. Dear Russian cocottes of the past certainly, before accepting, let their visitors through a light bathhouse, long before the Russian word for their profession became indecent.

However, linden timber was expensive in the old days. Nowadays, all the age-old lime-trees are under protection, and there is no harvesting of lime-based commercial timber. Nevertheless, the properties are close to a light lime bath made of foam blocks and a frame, which will be described in more detail below. They are the cheapest and easiest to build. But it is categorically contraindicated to ride after a light bath in the snow or to dangle in an ice-hole. Even before leaving it on the street, you need to cool down in a warm dressing room, and then, having dressed warmly, quickly sneak into the house.

A vigorous bath, on the contrary, is very expensive and difficult, because it can only be built from logs of the highest quality. Longitudinal hollows between the crown of the log house act as catchers of the initial IR furnace, driving heat into the walls; timber walls absorb IR not so greedily. The same applies to any log baths, so the "almost vigorous" bath can be built from pine logs with a diameter of 200 mm. We will further focus on "normal" kondova baths, as the most versatile and affordable.

Selection and rejection

The best material for a bath is wood, because it was created for him. We will talk about foam blocks and other suitable materials further when describing baths from them, because they go into action immediately without rejection. This cannot be said about wood: the one that is quite suitable for the house may not last for a long time in the bath due to the specific conditions described above.

Note: a brick bath is inferior to a wooden one in all respects, except for one - a large one, from 70-100 sq. m in plan, a brick bath building will be cheaper than a wooden one, and its bathing qualities with such a large building volume will become acceptable. Therefore, brick baths have been and are being built mainly by large public ones.

The best tree for a bath is larch, and for a vigorous one is bog oak, but both are expensive. Most often, baths are built from pine or spruce wood after preliminary screening of lumber. The first thing you should pay attention to is the complete absence of cracks (pos. 1 in the figure), then wormholes, pos. 2 and blue, blackness, etc. signs of decay, pp. 2 and 3. Blue usually accompanies wormholes (pos. 2), but it can also appear as separate spots, pos. 3. The third sign of unconditional rejection of this piece is knots falling out. If the forest is conditioned, the selection criteria come into force.

Tar and dry chip

Coniferous timber, especially pine, has 2 varieties - tar and dried wood. The second is an ordinary timber cut in blocks. The first one is saturated with resin, it smells strongly of it, if you run your finger along the saw cut, it sticks and gets dirty. Smolka is expensive because trees on it are chopped selectively during sap flow, which is by no means useful for the forest as a whole. Nevertheless, building a bathhouse from logs or timber, it is worth spending money on tar for 2-3 lower crowns: it does not rot at all, but under the influence of moisture it turns to stone, turning into a kind of bog oak. For a frame bath, it is also advisable to take a bar of the lower strapping (bearing belt) with resin. And one more thing: on the rough floor of any bath, it is very, very desirable to buy much less expensive semi-finished products and waste sawing tar with wane, first of all - the cheapest croaker, see fig. You will have to sweat more, debarking and adjusting, but the floor will come out forever and inexpensively.

Note: Predatory felling is still practiced in some places, when trees are cut quarterly all year round. Neighboring bathhouse builders benefit from this - tar can be taken directly from the timber yard cheaper than then a dry chip from the distributor's warehouse. But for nature, such an approach is nowhere worse, and you need to be able to assess raw wood by eye for warpage during drying, see below, about the timber.

Impregnation

All lumber for building a bath must be impregnated with antiseptics, biocides and fire retardants. In addition to tar, it doesn’t rot anyway, it won’t accept any impregnation, and once it is petrified, it will become very badly combustible. Impregnations for wood are sold separately, i.e., if it is cheaper that way, then you can buy inexpensive untreated wood and process it yourself.

Impregnating materials for timber are made on the basis of refined mineral oils and / or silicone. You can find recommendations to replace them with working off or fresh engine oil, but it is not necessary. Machine oils contain additives that are useful for machinery, not people. In the bath, they will inevitably get into the air and soak you through your steamed skin.

Logs

Raw, i.e. wild logs are rarely sold now - it is more profitable to dissolve them into measured material, and the waste will go to business, for cellulose, etc. There are companies that trade in wild wood, but the choice is my respect. Therefore, suddenly, after reading the rest, you intend to build a log bath, then you will have to buy rounded logs.

The first selection criterion - the log should be solid chamber drying; this is a very expensive material. Glued imitation, pos. 1 in the figure, will be great for a residential building, but not for a bath, because due to different warping of the lamellas (fragments from which the log is glued) in the bathing conditions, they will soon split and rot with any impregnation.

The second point is cracks. T. called. healthy radial cracks, pos. 2, in the log cabins of residential buildings are quite acceptable, but in the bath they will become condensate collectors with everything that comes with it; naturally air-dried logs cannot exist without them, therefore, as mentioned above, only chamber ones are suitable. For the same reason, the profile of the log should not have upward-facing recesses, pos. 3. From logs of the Finnish profile and any of its modifications excellent houses are obtained, but baths are not built from them.

The log for the bath should be with the usual so-called. lunar groove, pos. 4 facing down. To do this, during construction, you need to choose a suitable cut-out scheme, see below. The best standard sizes for a bath are 190 or 210, marked in Fig. If a bathhouse is being built "more vigorously" from pine logs, then, in addition to the increased diameter, it is necessary to choose logs with a dark core and light sapwood, on the right in Fig. Logs with dark and light belts of growth rings will be scattered into a regular bath.

Note: if the "vigor" of the bath does not matter much, then logs can be taken of a slightly different diameter. When cutting into a block (this is the best way for a small bath, see below), a completely suitable frame is obtained from different-sized logs, see Fig. left.

Bar

A log bath will cost much less than a log bath and, in appearance, fits well into a suburban residential development, see Fig. The cheapest and easiest way is to build it from a conventional clean-cut timber (rectangular in cross section). The criteria for its rejection are the same as for logs, but a check for evenness is added.

It seems that now there is no simple bar of chamber drying at all - it is unprofitable. And the air-dried bar is all warped to one degree or another. In general, this is not scary, in the construction of a log house they always provide for a technological break for shrinkage and the tree's own shrinkage. During it, the bars will lie against each other and become cemented, as they say, they will live with caulking from an almost solid mass.

However, the shrinkage of the tree is not unlimited and if the timber was dried incorrectly, it may turn out to be excessively warped, and the frame from it will remain with cracks. There are 2 options for purchasing: either from a trusted supplier according to the live recommendations of reliable people, or with an inspection of the stack in the warehouse by an invited specialist - a carpenter, furniture maker, forestry technician, etc. unfortunately not possible.

A beam for the construction of a bath "under a log"

It is very attractive, but requires a particularly careful rejection of the tree, the construction of a timber bath from a three-edged bar with wane (pos. 1 in the figure on the right) or a 2-edged, also semi-edged sleeper, pos. 2.

These are semi-finished products, i.e. are inexpensive. Cutting them is not much more complicated than a simple bar and may well be done by a non-carpenter. But it is possible to build a bathhouse from such a bar that looks very similar to a "steep" log one, and in terms of properties - with an intensive firebox close to vigorous.

As for the profiled timber, it is, firstly, expensive. Then, glued beams should not be allowed into the bath, for the same reasons as imitation of a log, pos. 2 in Fig. A one-piece chamber beam is even more expensive, and only one selected entirely from the kernel (pos. 1) or sapwood will go to the bath. If you can see both at once on the saw cut of the bar, it will split in the bathhouse structure. Finally, in the profile of the beam, as in the logs for the bath, there should be no notches facing up, pos. 4. All this turns the choice into a living hell, especially since the sellers, knowing that their product is quite good at home, do not understand such fastidiousness.

More about brick

Suddenly you want to build a brick bath, keep in mind that the brick for it is also subject to rejection. For the bath, you need a heavy and dark, low-porous, or moderately, without warping and swelling, burnt iron ore, or clinker. A beautiful face brick of dry or semi-dry molding is definitely not suitable.

Building

Well, we will assume that we have passed the difficult and crucial stage of selection and rejection of material. In the end, the cost of it only needs time, knowledge and attention. Now - we are building a bath! There is a lot to look out for here, besides the usual construction work steps. In general, the sequence for building a bath is as follows:

- Foundation;

- Underfloor insulation and drainage equipment;

- For frame baths - frame;

- For them - a technological break for 2-6 months. to shrink the frame;

- Walls;

- For log and log baths - log caulking;

- For them, made of air-dried materials (non-profiled timber, wild and debarked non-cylindrical logs) - technical break for 6-18 months. for shrinkage / shrinkage of the log house;

- Openings, doors, windows;

- Ceiling;

- Roof;

- Interior arrangement and, mainly, installation of the stove.

Foundation

In the old days, the baths were placed on an unburied foundation made of boulders (item 1 in the figure), this made it possible to reduce the processing of the lower crown logs to a minimum. For this, something like a lodgement or centers was collected from wild stones, in which round logs did not roll. At the corners, large boulders with crisscrossing natural hollows were especially prized; these are the very cornerstones. The original meaning of this term is now forgotten. The boulder foundation under the bath can be laid even today, but, alas, the wild stone is now far from waste material.

Note: don't be surprised at the mention of cornerstones in the Bible and the Gospel. The now almost treeless Levant was then rich in excellent cedar wood. It was enough for both buildings and fleets. What was King Solomon's palace built of? "Thanks" to the high value of the Lebanese cedar, now it is almost gone.

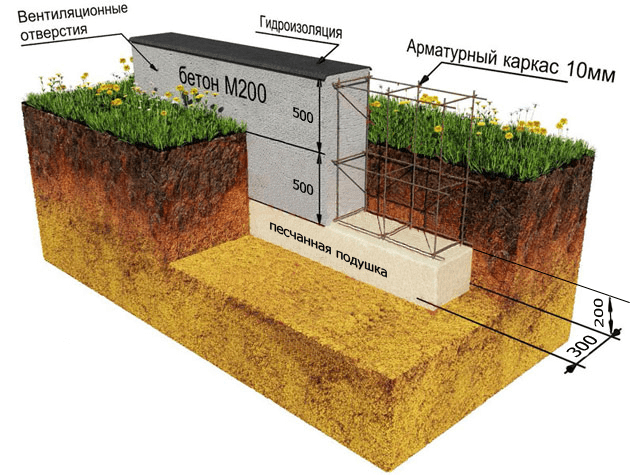

A full replacement for boulder - shallow or shallow, pos. 2. The first one is suitable for any wooden bath, and the second - for a foam block. In terms of complexity and laboriousness, the establishment of both is available to novice builders, and at a price - for a family budget below average. There is only one drawback: not suitable on unreliable soils. These include:

- Medium loamy is closer to strongly loamy and strongly loamy (heaving is over 6-7% by volume) - small silty sandy loam, dense loam, plump clays, etc.

- Subsidence category II, over 5% by volume - loose loess-like and clayey.

- Weak, with a bearing capacity of less than 1.7 kg / sq. cm - humus, silty, peaty, loose sandy loam.

In places with a stable positive winter and a low probability of freezing of the runoff, an excellent, simple and cheap option for the foundation for a wooden bath is a columnar, not buried, from ready-made blocks 200x200x400, pos. 3. A conscientious and attentive office city dweller, undertaking to build, can lay it down over the weekend.

On a slope, which is very good for a drainage device, and on unreliable soils, a bath can be placed on a columnar foundation made of asbestos-cement pipes, pos. 4. For a wooden structure, it is approximately equal to the belt one in terms of cost and labor intensity. Insulation of the subfloor in places with frosty winters increases both only slightly. Under a bath made of foam blocks or bricks, the heads of the posts will have to be tied with round beams or grillage, pos. 5, this is already a rather complicated and expensive process, especially the imposition of the grillage. However, for baths, you can most often do with randbalk.

Finally, the pile-grillage foundation, pos. 6. It can be welded metal, both in the figure, and concrete on bored piles. Both are quite difficult and expensive, and a high-quality metal pile foundation also requires special equipment.

Pile foundations are laid under buildings on soils, as they say, none: silty, peaty, weak, heavily watered; in general, "in the swamp". A bathhouse is not placed on rotten wet soil, but the laying of a pile foundation under it is justified in special cases.

For example, the author had a chance to take a steam bath in a vigorous sauna on a steep river above the river. A platform protruded above the whirlpool, and a ladder went straight into the water from it. Springs gushed from the bottom there - in summer the water was icy, and in winter there was a hole. Feelings - unspeakable, if they are soaring in paradise, then it is exactly this and not otherwise. But it is possible to build in such a place only on piles, otherwise in a year or two the earth will creep, and the bathhouse will only gurgle or float, swaying. It is for such exclusives that the pile foundation for the bathhouse is intended.

Insulation and lathing for walls

Before building any bath, on any foundation, except for boulder, you need to apply double waterproofing made of bitumen and roofing material, see Fig. It is applied after the foundation has gained strength, except for metal welded.

If a wooden bath is being built on a strip foundation, then before laying the 1st crown of a log house or the lower belt of the frame on the tape, 30x30 mm or 40x40 mm slats are laid out on the insulation, as shown in Fig. left; with high-quality lumber, you can get by with thick, from 10 mm, shit. The purpose of this lathing is to prevent wood from rotting from underneath due to capillary locking. The remaining gap is then caulked along with the walls.

Note: no anchor bolts or the like in any case. no need to attach the walls to the foundation. With thermal shocks that the structure of the bath experiences, there will be no benefit from them, except harm.

Floor and drain

The floor and drain of the bath are inextricably linked and therefore considered together. Together they make up the most complex and critical structural unit of the bath, which largely determines its operational and sanitary and hygienic qualities.

In the old baths, the runoff went directly to the ground through the crevice floor. Nowadays it is forbidden to dump any wastewater onto the surface of the ground, but the crevice floor of the steam room / washing room is quite appropriate, see below.

The drain from the bath can be arranged scattered, across the entire surface of the floor, or point (concentrated) through the grate (ladder) in the floor. The first, as we will see below, is more complicated, but much more hygienic. A point drain is most often done if the drain pit is under the floor. This saves space and the amount of earthwork, but sanitation and hygiene - by 3 minus. In addition, there are no drain pits that do not require cleaning and pumping at all, and in this case, you will need to break the floor for plumbing. An additional minus - due to the infiltration of wastewater directly under the building, the bathhouse will sooner or later "lead".

As an argument in favor of a hole under the floor, they often say that it will not freeze. And, sorry, are you heating your bath all winter? If you can afford it, then why the squatter? Order a turnkey sauna and take a steam bath. Unfortunately, there is no reason to add "health", since the hole is under the floor. The way to protect any sewage pit from freezing has been known for a long time: it is a wooden cover 30-40 cm under the inspection hatch. The drain from the bath is warm and, under a double lid, will have time to soak into the soil before the most severe frost reaches it.

Note: sometimes they also say, they say, you need to put a gas-tight cover on the pit under the bath. Pure curiosity in the spirit of black humor - any sealed sewer once explodes like a poorly sterilized jar with home preservation. In the bathhouse - mainly during washing, because a thermal shock during heating will play the role of an initiator.

The device of the diffused drain from the bath, it is clear from pos. 1 fig. It is highly desirable to equip the concrete drain with a homemade water seal, pos. 2, this will ensure that the bath meets the most stringent sanitary requirements. The concrete on the screed is taken waterproof; with self-mixing, a water-polymer emulsion is added to the water at the rate of 200 ml per 10 l, and the hardened and gaining strength screed is treated with bitumen mastic. This should be done in the warm season, and before laying the floor, give a technical break for 5-7 days.

The bathhouse must have a separate drainage pit. Bath runoff is large for domestic sewage and salvo, but much cleaner than kitchen gray, not to mention fecal from, and contains a little fat. If you run the bath drain into the general, correctly calculated and constructed, then it will choke, and the active bacteria in it will die. If you build a large and expensive septic tank based on a salvo discharge, then the usual runoff for bacteria will not be enough for food, the activated sludge will acidify, and the sewage system will stop working again. A drain hole is dug at the rate of 50-100 liters per 1 washable one to a depth of at least 30 cm below the calculated (standard) freezing depth, provided that it is buried in the mainland (under the fertile layer) soil by at least 1.2 m. In most regions RF, these conditions are maintained when the drain is deepened by 1.6-1.8 m.

The simplest and cheapest drain pit is obtained from car tires in a clay castle, pos. 3. But sewage water will inevitably stagnate in its side pockets, and you will have to disinfect such a pit much more often. Bearing in mind the future costs of antiseptics, cleaning and pumping, it turns out to be more profitable to buy a pair of (60-70) cm concrete or plastic rings for wells. These are the smallest and cheapest well rings. Their height is standard - 90 cm; 2 pieces are just enough. With a diameter of 0.7 m inside, the volume of the pit is sufficient for 5-6 washable.

Suddenly, the pit is still under the floor (maybe there is simply no room for the outside on the site), then the bath can be used no more than once a week. In this case, point drainage will be cheaper, and its complex and expensive concrete catcher under the floor can be replaced with an overturned low wooden tent. Then, around the mouth of the pit, it is necessary to apply high-quality waterproofing with a removal of at least 0.5 m beyond the contour of the drain grate, pos. 4. However, this is also a bad way out: water will leak under the insulation anyway, and what kind of biocenosis will develop there, it is better not to think about it. At least before eating.

Floor

The floor of the bath must, firstly, provide a quick and complete drain of water, without decaying itself. Secondly, to provide sufficient insulation and guarantee from drafts from below, provided that it is impossible to clog the subfloor with thermal insulation, you will have to limit yourself to backfilling with expanded clay. For this, the floor of the bath is made floating, pos. 1 in the figure, i.e. not rigidly connected with the building structure. Lay the floor on the joists; their ends in the log wall are inserted into the cutouts of the lower crown, pos. 2. In a log bath, the ends of the logs are tied with crossbars to form a solid lattice, and in a frame house, as in a frame house, the floor logs together in the lower belt form the main supporting frame.

The step of the lag is 40-60 cm. Their height is 100-120 mm for a span of up to 4 m and 150 mm for a span of 4-5 m. With a larger span, intermediate posts or inner sections of the tape must be provided in the foundation. The thickness of the lag is taken approximately 1/50 of the span length, i.e. 60 mm for 3 m, 80 mm for 4 m, etc.

In the intervals between the lags, the croaker is laid with the convex side up. Because slab boards taper to one end, they are laid alternately with a narrow end in one direction or the other. Gaps of 5 mm are left between the boards, the same pos. 2 in Fig. This design does not impede drainage, to some extent improves thermal insulation, and together with the finished floor boards laid across the humpbacks, it protects against drafts.

On the logs and rough flooring from the slab, it is very, very desirable to take tar pine. To reduce the cost of the floor, the logs can be made from a 3-edged bar or a half-edged sleeper opened in two, see above. But then they will have to be trimmed from the side of the wane, so that the base for the final floor is even and horizontal.

A finishing floor with a diffused drain is laid from an ordinary planed clean-edged board, preferably tar, with a thickness of 40 mm. Reducing the cost, again, will cost extra work: you can take an uncut and unedged tar board, "bring to mind" yourself on a circular and a planer (the old Soviet desktop UBDS-1 and the like are very convenient for this), and put it on the flooring wane remains down. A clean floor is laid with gaps between the boards of about 5 mm, for water drainage.

To lay a floor with a point drain, first a board made of larch or tar with a drain grate is placed between the logs above the pit or water seal. Lay the floor without gaps, with a cutout above the grate, pos. 3 and 4. The board must be taken not grooved, but with a locking quarter, pos. 5. After a technical break for the shrinkage of the structure, the joints of the boards are poured with liquid nails or rubbed with a waterproof putty on wood.

With all the high cost, complexity and labor intensity, this is far from the best option. On pos. 4 it can be seen that, judging by the general condition of the floor and the grill, the bath is still new, but the floor under the bench has already slipped. Apparently, the dislike of the builders to the scattered runoff through the crevice floor is explained by prejudices and incomplete knowledge of the history of the Russian bath.

Walls and frame

The log sauna looks, of course, gorgeous, see fig. But we will not dwell on them for a long time: these buildings are generally not for beginners. In any case, in order to build the simplest bathhouse, you will need to master 2 difficult technologies - cutting logs with a burr with the rest, pos. And in the figure, and with a paw without a remainder, pos. B-D. The latter, by the way, is technologically simpler, but requires calibrated logs, since the proportions of the marking template (pos. D) are tied to the side of the square inscribed in the diameter of the log, pos. D. In any case, the bottom of the logs of the first crown must be very precisely and evenly hanged, because a boulder foundation that can be adjusted to fit logs is now unrealistic.

Note: cutting into a flash and into a simple bowl (see fig. on the right) is often considered the same working operation, because the configuration of the logs ready for laying in the blockhouse is the same. In fact, when cutting into the bowl, the recesses and grooves turn upward, which is unacceptable for a bath. When cutting into a block, fitted logs are transferred to a frame with a turnover, this complicates and slows down the assembly of a frame on the foundation.

From a bar

It is already quite possible for a beginner to build a bathhouse from a bar: you do not need to choose curved grooves and holes in a tree. It is enough to know how to handle a saw, hammer, chisel and ax. To build a small, up to 4x5 m, bath, you need to master only 3, or only one, simple operation: cutting into half a tree or into ochr with the remainder, or cutting without residue into the paw (at the end); are marked in Fig. "!"

A beam from 100x100 to 250x250 mm will go to the bath. The thicker, the naturally better and more expensive. In general, "hundred parts" will be enough south of Voronezh, 150x150 for the Moscow region, and 200x200 - north of St. Pereburg. For 1-3 lower rims, you need to take a bar one size larger, and again, it is highly desirable, tar.

Actually, the process of assembling a log house without a remainder from a non-profile clean-cut bar (the simplest and cheapest) with a cut into the butt is shown on the trail. fig. First, the ends of the cut-to-size bars are prepared according to the template, pos. 1. If, instead of a timber, there is a semi-edged sleeper (pos. 1a) that is conditioned for a bath (see above), then you can get an almost complete imitation of a log frame.

When assembling the frame, it is necessary to prevent lateral displacement of the beams. The lunar grooves hold a blockhouse of logs, but connections at the corners are not enough for smooth beams. There are 2 possible options. First, pos. 2 is simple, but not the best. nails in a log house will rust. The blockhouse is immediately knocked down tightly, and the caulk tape (see below) is applied immediately. The location and length of the nails are the same as the nails in the trail. option. Nails are needed secret, with a completely recessed head, or a special tool for the hammer - a doboinik; it looks like a center punch with a milled end.

In the 2nd way, pos. 3, the bars are fastened with round blind dowels - pins. Calibrated pins are on sale, it's better to take oak ones. The connection of the crowns with dowels is done as follows:

- The next one is laid on the previous crown.

- Holes are drilled exactly according to the diameter of the dowels through the upper beam to half the height of the lower one.

- Remove the upper crown.

- Lay the caulk tape.

- Insert the pins, piercing the caulk over the nests under them.

- Again, now for good, the upper crown is laid, putting it on the pins.

- The procedure is repeated until the complete assembly of the log house; the pins are staggered, see again pos. 3.

Note: with a span of up to 6 m, it is enough to fasten the beams at the corners, as shown in Fig.

And if the timber is profiled?

One of the reasons why the profile bar was invented is the desire to get rid of the rather laborious and costly fastening with dowels. However, this consideration is not applicable to the bath: profiles that hold each other "ironically" are not suitable for a bath. And for those who will not "catch" condensate, bath temperature deformations will soon break the ridges. Therefore, the blockhouse of a bath from a profiled bar still needs to be fastened.

Cauliflower

Log and squared logs for assembly caulk. The log will require a thorough caulking skill and a complete caulking tool set, see fig.

It is easier to caulk a bar: you will need a curved steel caulk - a lebeza, a narrow wooden straight and a mallet, see fig. below. The sauna blockhouse is caulked in both of the ways shown there: when assembling the log house, a heel is placed between the crowns for caulking, and at the end of the caulking it is finally caulked into a set.

Note: the swan is designed to push the hemp between the logs. From its name comes "fawning" in the sense of rubbing into trust, groveling with thoughts in mind, in general, to crawl under the skin. If you heal jute (see below), and the log house is lumber, you do not need a swan.

It is impossible to do without caulking with waterproofing, even the most modern one: caulking does not just seal the seams, but "coalesces" with the tree into a single array and finally holds the frame. There is no synthetics that can replace it yet.

In the old days, they were caulked with moss in a stretch, and in a set - with an oiled or resinous tow of linen tow. Nowadays, most of all caulk is made with jute fiber, it is almost wood in composition and lignin content. It is better to take jute hemp in the form of a set of tape and cord, see fig. The tape is loose, it is easy to pierce it with a finger under the dowel. They lay the tape when assembling the log house, and then you do not need to fiddle it, after assembling the log house they immediately finish digging it with a cord into the set.

So that the blockhouse does not lead, caulk is strictly in the following sequence: the dull long side of the lower crown inside, then outside, then the same opposite to it. Then - the short sides of the lower crown, starting with the one where there are no openings, also first from the inside, then from the outside. In the same sequence, the remaining crowns are caulked strictly in turn from bottom to top.

Total for cant and log

Rounded logs of chamber drying can be considered a type of profiled timber. A bath made of it and a profiled beam also of chamber drying can be used immediately after construction, because shrinkage and shrinkage of these materials passed during processing; This is the undoubted advantage of "chamber" wood. The cost of 1 sq. m of bath space made of these materials in most regions of the Russian Federation exceeds the cost of a square of living space in new buildings of the middle class.

The most expensive, complex and laborious, but also the most prestigious, will be a log bath. Its bathing qualities are exactly the same as those of a traditional Russian bath. In terms of "steepness" and cost, it is almost equivalent to a log sauna, but technologically it is much simpler and can be supplied by an amateur builder of average skill. In terms of steam quality, a log bath can be made almost indistinguishable from a log bath.

The use of a chamber profiled beam for the construction of a bath can be justified if it is not possible to reject air-dried or raw material individually, for example, in regions where there is no logging of their own and traders flatly refuse to sell ordinary sawn timber selectively. Otherwise, it is possible, using semi-finished products of industrial wood, to put a log bath, and seemingly almost indistinguishable from a log bath.

In general a log or log bath can be recommended for those who are sufficiently wealthy, monitors his health, keeps physical shape, and has already built at least a country house or a barn. If you are not sure that a condo and even more vigorous steam room will benefit you, then it is better to build some of the light baths described below. The same option is shown with a lack of funds and building experience: light baths are simple and inexpensive, and their steam will not harm anyone.

Technical break

After assembling and caulking the log house, it is temporarily sewn up from above with boards, plywood, cardboard, etc., and covered with foil. The film is fixed in any way so as not to be blown off by the wind. The log house is left to dry and sit down for at least six months; best from spring or early summer until next fall. During this time, the tree will not only shrink and shrink, but will also live with caulk.

Openings, doors, windows

The ways of arranging door and window openings in timber baths are mainly used 2. 1st, pos. 1 and 2 in the figure, "for the lazy and uneconomical": only 1 upper beam is selected in size along the width of the opening, and after a technical break, the opening is simply cut out. However, this method is not so wasteful: trimmings can go to the panel ceiling (see below) and certainly - to the internal equipment of the bath, bed, etc. And it will not work out too lazy with this method: in order to avoid a sudden "game" when cutting out a tense after the shrinkage of the log house, the edges of the future opening must be reinforced with dowels when assembling the log house, like corners.

In the 2nd way, pos. 3, the beams are cut to size in advance, and a spike is selected at the ends protruding into the opening. The disadvantage of this method is that special door and window boxes are needed, while in the first method simple frames from boards will go to them. In general, it is better to make openings "in the first place" when the appearance of the bath does not matter much, and "in the second way" - when you want "more abruptly".

Note: from the baths of the mid-budget class, the bar ones are certainly the best. Therefore, we give in addition a video about the details of arranging a bar bath:

Video: building a bath from a bar, the correct device

Wireframe

A frame bath is built as well. Immediately after assembling the frame, rafter beams are placed, and the frame dries / shrinks under its own roof, in the center in Fig. Since the openwork structure is blown by all winds, a minimum technical break for drying / shrinkage is needed. Usually the frame is assembled in the spring, in the same autumn the bath is completed and even before the cold weather they are already steamed.

The second feature is that the finishing floor is laid together with the wall cladding outside, on the right in the figure, in the usual sequence from bottom to top, i.e. starting from the floor. It is not necessary to insulate the walls from the outside, as is sometimes advised. For decorative purposes, something like siding is enough, without laying foam in the crate cells. So it is necessary that the walls are better ventilated. But it is necessary to insulate from the inside thoroughly, as in the foam block bath described below, excluding the underlying plaster.

A frame bath turns out to be the simplest and cheapest, even cheaper than a foam block bath. By the "vigor" of the steam, this bath is only and only light. However, steaming in it in the winter north of Moscow is very problematic: it gives off heat well, and the insulation measures used in frame houses make the steam heavy. In general frame bath - a typical summer weekend bath; especially well serves as a country bath, combined with a utility block.

Note: there are no restrictions on the outer cladding of the frame bath, therefore imitations under a bar, log, etc. are possible.

Foam block

A foam block bath is the only type of bath structure in our time that allows you to put a light bath in any climate due to the high heat-insulating properties of the wall material. Aerated concrete baths can also be considered the cheapest and simplest technologically: their cost is lower than that of a bar-shaped one, by 25-30%, and even up to 50%, see below. The number of operations of measurement and precise adjustment during construction in a foam block bath is several times less than in a frame bath, and it is not at all required to form curved surfaces in the material.

It is also important that, with a generally significant expenditure of working time, little physical effort is required when building a bath from foam blocks. There is no need to wave a saw and an ax all the time; in general, the construction technique is set, attached, nailed. For townspeople who are not used to physical labor, this circumstance can be decisive. And for summer residents - the fact that the technical break during construction is needed is minimal, for the curing of mortars. In a typical summer, a week is enough for this, and next weekend you can continue construction. Which, working on weekends together or three, can, starting in April, be completed by July and still have a good time before winter.

The foam concrete from which the foam blocks are made is a light material, it floats in water. Therefore, on stable and well-bearing soils, the construction of a foam block bath can be further simplified and made cheaper. In general, a strip foundation is recommended for a foam block bath, pos. 1 in fig. But on reliable soils, it can be replaced with an unburied columnar made of ready-made concrete blocks, as for a frame bath, and the walls can be erected on a frame made of a bar from 200x200 to 300x300, impregnated with an antiseptic, a water repellent and covered with waterproofing, like a concrete tape.

However, the lightness and, especially, the porosity of aerated concrete set the same labor during construction; true, not difficult and uncomplicated. It is especially necessary to protect the walls from locking from the inside and outside: it dampens the aerated concrete not only easily, but downright pleasure, but it dries very hard and for a long time. Therefore, looking ahead, we will immediately say that, having covered the roof, the bath must be surrounded by a ventilated facade with a gap of about 5 cm.With any other method of external insulation / insulation, the dew point entering the porous wall greedily absorbing moisture is inevitable.

Further, when erecting walls, pos. 2, only the first 2-3 rows are placed on a regular cement-sand mortar, and then they switch to a special glue for aerated concrete, it looks like a regular masonry mortar. Here the lightness of the material already plays a role: the cement masonry joint, being weakly loaded, does not resist shear loads very well, and the wind can simply fill up the structure.

The most features relate to internal insulation. It is produced in the following order:

- Walls with waterproof plaster (lime; water-polymer emulsion is added to the solution water);

- On completely dried plaster, paint with water-repellent paint, preferably polymer facade paint, in extreme cases - iron red lead, zinc or titanium white;

- On the dried paint, waterproofing is laid with an overlap of 15 cm, securing it with horizontal slats;

- Mats of long-fiber mineral wool are placed between the slats, pos. 3;

- Mineral insulation is sheathed with rolled foil on 2 sides with glass wool, also long-fiber, pos. 4 and 4a, with an overlap of 25 cm;

- Vertical slats are stuffed on foil insulation and the inner lining is already led along them;

- Upon completion of finishing and installation of doors / windows, all cracks are carefully foamed, pos. 5: foam concrete doesn't care where to block it, moisture spreads in it instantly. A cloud escaping from the steam room into the dressing room can destroy the bath.

And again, looking ahead, but not by much: due to the peculiarities of the building, visible in pos. 1, the ceiling in a foam block bath is made only hemmed.

Ceiling

The ceiling of the bath is made flat, hemmed or panel board. The first is the original ceiling of a small Russian bath. For its construction, an established log house is sewn up from above with boards, the cracks are caulked with moss into a set from the attic side and poured with resin. Then the rafter beams are applied (see below, about the roof) and the gaps between them are covered with peat; sometimes the entire ceiling is tarred before backfilling. The floor of the attic is either being laid or not. Now, of course, it is better to caulk it with jute, cover the flooring with waterproofing before installing the beams, and insulate it with long-fiber mineral wool.

The false ceiling, see fig., Is suitable for any bath, because it is stronger - the ceiling beams are at the same time the rafters, moreover, they are mechanically connected to the frame / structure. The panel ceiling is a combination of a floor ceiling with a hemmed ceiling: a shield with insulation and insulation is assembled on the ground, and then, using a crowd, or a crane, or a mini-excavator manipulator, they put it on the frame. The panel ceiling is good because it can be "blind" from scraps, but it is only suitable for a timber bath up to 4x5 m in size.

Roof

A gable roof is suitable for any of the described baths. Roof trusses are simple triangles with one gusset bar, in the center in the figure:

The gables are sewn up with boards; be sure to need dormer windows that can be opened for the summer and for the duration of use + an hour and a half after it in winter. Hanging rafters are suitable for a log bath, on the left in the figure, for the rest - a complete truss with a screed beam, on the right in the same place. The lathing for the roof deck is sparse, with slots from 30 mm, for ventilation. The flooring itself is any, except for iron, it does not hold heat well and quickly rusts in the bath.

Arrangement

The requirements for finishing materials for the bath, except for decorative ones, are moisture resistance, hygiene, complete chemical neutrality. By their combination, they often take a wooden lining from an array. MDF and laminate are not suitable, they will swell and become limp! The profile of the lining for any orientation of the boards must meet the requirements described above: no pockets facing up, for example, as in Fig. on right.

In the steam room, of course, you need a bed. They are made 2-3 tiered, with a vertical step of 50-60 cm, even if only one person is steaming all the time. The reason is that you need to be able to choose the height of the location when soaring, depending on the general condition, so that the bathhouse does not come out sideways.

The width of the beds is 60-80 cm; flooring - necessarily with slots of 10-20 mm, on the left in fig. The clean floor under the floors is not laid, it will slip! The length of the beds is 180-200 cm for soaring in a prone position or 80-100 cm for soaring while sitting. "Economical" 150 cm for vaping with knees raised is not the best option. Sometimes you want and need to raise your knees while soaring in prone position, but if you soar like this all the time, your health will not be beneficial due to the constant outflow of blood from the legs to the heart and head.

It is better to finish the shower / sink from the boards upright, on the right in the figure, so there is less chance of decay - it is easier for water to drain from the grooves. Also in the washing room, whether they eat there or roll out of the gang, benches are needed - to sit, steamed, to do their feet, without risking slipping, for children.

About partitions

Capital partitions in the bath are not needed. On the contrary, they need to be made lighter so that the heat of the stove quickly dissipates throughout the bath. Partitions are placed in front of internal insulation, insulation and decoration. Material - boards or wooden lining on a wooden frame; total thickness - 50-70 mm. Moisture resistant plasterboard, plywood, etc. are not suitable, they will not last long in the bath.

Oven

A requirement common to all sauna stoves is an elongated firebox channel so that the furnace door can be brought into the dressing room. Tradition is a tradition, but in the old days it was most often consumed in the baths: a person's susceptibility to carbon monoxide increases sharply with an increase in air temperature.

For a bath with a common steam-washing room, an inexpensive bath stove without an air convector, like "Heat" and its home-made copies, is most suitable. A stove stove for a bath with a water heater will also go - in the smallest steam room, you can provide the length of the horizontal part of the chimney from 2 m, which will make the stove quite economical.

It is unrealistic to maintain in a small bath the distance of the stove from the walls of 60 cm required by the PB, and special fireproof ones, as in the steam room on the previous one. fig. are very expensive. Therefore, the nook for the oven in the bath must, firstly, be covered with a mat of vermiculite or mineral cardboard, pos. 1 in fig. on right. Ordinary refractory bedding made of asbestos and steel sheet is not suitable for a bath - iron heated to 60-70 degrees can be badly burned by stepping on your foot, because the severity of the burn depends on the amount of heat energy transferred to the body, and the metal gives off heat well and quickly. Therefore, by the way, steam burns are so dangerous - in this case, a very large latent heat of water condensation is released.

Secondly, the walls near the furnace must be covered with refractory sheathing. In the same pos. 1 builders did not skimp on fireclay bricks for her. Physically - excellent, but constantly moistened, the chamotte will soon crumble, and the skin will have to be changed. The same high-burnt (dark) ceramic working brick that went to the top of the cladding would have worked right down to the bottom.

A little more about the shape of the sauna stove. In a collective steam room, it is best to put a round oven, pos. 2 in the same fig., Or a basket stove with a combustion part hidden in the heater. Then all soaring people will receive equal shares of health.

Unusual differences

The nucleus of the Russian baths is the dugout bath, see fig. For its construction, a dry sandy (better), sandy or loamy hillock is required. Walls, stove, chimney - from boulders or large rubble; the roof is covered with turf. On the earthen floor, a wooden lattice is placed, which is then thrown back against the wall so as not to rot. Runoff into the ground, which in our time is possible only furtively, but steam - Ilya Muromets would only groan and hoot.

And here's something else - a hiking mini-bath, see next. fig.

The design on the same principle is repeated by many, both in mobile and stationary versions, see at least the video:

Video: mini-bath

But let's take a closer look at fig. Doesn't this structure look like ...? If you take a milky, not translucent on the skin? Unless the owners are prone to exhibitionism, and even then the neighbors will complain. In general, it is worth trying in the country.

Not everyone has the desire and opportunity to invest a lot in the construction of a bath. And in most of our country, sometimes it is simply necessary to warm up. The only way out is to build a bathhouse inexpensively, with your own hands. There are a sufficient number of building materials and technologies that can be called budgetary.

If we talk about the construction of full-fledged, albeit small, but separate baths, then the most budgetary technologies are frame and monolithic ones. Cheap baths are often made on a wooden frame, sheathed with plywood, OSB, boards - whoever has what. Insulation is laid inside, between the two skins.

One of the options for the frame structure - with board cladding

In monolithic construction, the most popular for the construction of baths is arbolite - a mixture of cement with sawdust. Sawdust can be generally free or cost very little. Little cement is required in wood concrete, so this type of construction is unlikely to hit hard. A removable formwork is placed along the perimeter of the building, the mixture is loaded into it, and rammed. The next batch is mixed. It's that simple. The disadvantage of this material is considered flammability, but after all, wooden and frame baths are also flammable. So this is not an argument.

Sawdust concrete or wood concrete is a warm, natural material that consists of sawdust, sand, cement and water

Sawdust concrete or wood concrete is a warm, natural material that consists of sawdust, sand, cement and water Polystyrene concrete (granular foam mixed with cement and water) is not much more expensive, but not everyone likes the use of "chemistry" - foam - in the construction of a bath. However, by itself, this material allows you to get a cheap and light construction, which, if properly finished, will only delight the owners.

All three technologies provide a combination of low prices and good thermal performance, that is, heating such buildings requires a little fuel, which is the main indicator of efficiency in baths.

There are regions where timber is still the cheapest material. It may be the cheapest place to put a chopped bath in them. From round timber or from a bar - this is optional. The plus of such a solution is a natural material (although it must be impregnated with chemistry in order to maintain its appearance and protect it from diseases and insects). But chopped baths have their drawbacks - you can start steaming no earlier than a year after the walls have been erected and the roof installed. It is necessary to wait until the main shrinkage passes and only then begin insulation and finishing work. The second disadvantage is that it is necessary to regularly update the protective coating, otherwise the building will become gray and unsightly. But the wooden baths themselves are very good for their special atmosphere.

Inexpensive foundations

Inexpensive wall technology is not all. Sometimes, almost half of the funds required for the construction of a building as a whole are spent on building a foundation. The technologies listed above are good in that lightweight foundations can be made for them. Somewhere it is enough columnar, somewhere pile or pile-grillage. Any of the walls listed above can coexist quite normally with them, leveling their shortcomings (possible uneven shrinkage of different support points).

The foundations listed above may not be implemented on all soils. Sometimes a shallow or normal strip foundation may be required, and a monolithic slab may be needed on particularly heaving or unstable soils. On such grounds, to the above technologies for the construction of walls, you can add more building blocks - foam concrete, cinder block, expanded clay concrete. All of them have their own characteristics (basically, careful protection from high humidity is required), but the construction technology is also inexpensive, although more solid foundations are required.

Compact or temporary

If at the dacha you want to build a mini-bath, a very small booth, then you need to take a closer look at the construction technology or. If desired, even an ordinary construction trailer, shed or shed can be turned into a more or less normal steam room. It is only important to insulate well and put the correct stove. Everything else is not so important.

Cheap frame bath in stages - photo report

The initial data are as follows: a bath in terms of no more than 4 * 5 meters, the budget is small - no more than $ 200-300 per month. From the initial data - heaving clay soil, 4 meters from the fence - a cliff. Bringing all this together, it was decided to build a frame bath on a columnar foundation.

The bath itself turned out to be 5 * 3 m, plus a 1 meter wide terrace on the long side. It was decided to make the pillars under the bath from asbestos-cement pipes 34 cm in diameter, under the terrace of 15 cm. In the center of the plan, 4 additional pillars are marked - this is the foundation for a brick oven.

We bury ourselves below the freezing depth - 140 cm for this region. By the way, we cut the pipes by 20 cm more - the total length is 160 cm, so that the bath is 20 cm above the ground.

A frame made of reinforcement 12 mm in diameter is installed inside each pillar. 4 rods are connected, the release from the post is 10-15 cm, so that you can then easily weld the strapping.

Ready-made concrete was ordered, grade M250. A formwork was placed along the perimeter between the posts and a boat was immediately poured in, which will close the gap between the bathhouse floor and the ground.

A week later, the concrete gained enough strength, continued work. A harness was welded from a 70 * 70 mm corner with a wall thickness of 6 mm (the corner was on the farm). To connect the posts and the metal, we weld the reinforcement outlets to the corner shelves.

I must say right away that this foundation is redundant in terms of bearing capacity. On it, you can build a two-story heavy building, and not a light one-story frame. But, since they did it "for themselves," and there is also a clay cliff nearby, it was decided to play it safe.

In the washing room and the rest room, it was decided to make warm floors - sometimes you just need to wash, without steaming, and doing this on a warm floor is much more pleasant.

Therefore, insulation (expanded polystyrene) is laid on the subfloor, waterproofing, reinforcing mesh on top, pipes are tied to it, and the whole economy is filled with concrete. Naturally, the warm floor was not poured under the stove.

A week later, when the concrete gained enough strength (it was not covered, but watered regularly), work began on the construction of the frame. For the racks, a beam of 150 * 150 mm was used, spacers - a board of 50 * 150 mm (again, a solid margin of safety, but this is out of a desire to build a good bath).

The bathhouse was built mostly alone, therefore, a sequential installation method was chosen - the racks are placed first in the corners, then in those places where door-windows will be installed or adjacent walls. If as a result, somewhere there are gaps of more than 1 meter, additional racks are placed. But in this case, since all the racks were made of a very powerful bar, intermediate ones were not set, and the rigidity of the structure was given by slopes.

Further, so that when the floor was laid, it would not drip on the head, they began to manufacture the roof of the bath. It is made the most budgetary - single-slope, with a minimum rise of 15 °. To ensure this slope, the racks were made in different lengths in advance.

A board of the upper strapping is nailed to the racks at one level, the ceiling beams are attached to it. Rafters with the required slope are attached to the same racks. A solid lathing under the roofing material is stuffed on top.

The shed roof rafter system is very easy to manufacture

The shed roof rafter system is very easy to manufacture After the roof was ready, the walls of the OSB were sheathed, and then the floor was laid on the rest of the bath.

The next stage is laying the stove. This is a long-term business - it took a whole month. The stove is folded with a closed stove. A cast-iron box is built in the chimney formation zone, in which stones are laid. A door leads into the heater, which leads to the steam room.

The stove also has a built-in register that heats water for the warm floor (outlets on the side of the stove). It is not always necessary to heat the floor, therefore there are two modes of operation - summer without floor heating, and winter, with "turning on" register heating. Transfer from one mode to another - by means of a latch.

This is followed by finishing work, and they will be different in different cases. The only thing that will be more or less general is insulation. Mineral wool was used to insulate the walls and ceiling. The thickness of the layer on the walls in "cold rooms" is 100 mm, in the steam room and on the ceiling - 150 mm. The steam room on top of the insulation is sheathed with foil on kraft paper.

After the insulation, a vapor barrier is attached. In the rest room, the walls are sheathed with OSB, a cork is glued on top. In the shower room, tiles are glued to OSB, the "dry" part is upholstered with clapboard (horizontally).

Washing room - dry area and shower

Washing room - dry area and shower In the steam room, first the lathing is filled with lining, then a wide lining. The steam room turned out to be quite small, and the stove also takes up a lot of space. Two are accommodated comfortably, three are more difficult, but also quite convenient. To regulate the number of seats in the steam room, the shelves were made retractable.

The whole construction process took two years, the work was carried out mainly "in one hand". The assistants were only at the stage of pouring the foundation, and then at the stage of installing the frame - to set the racks (they must be 100% vertical).

Video example of the construction of a bath from monolithic arbolite

Inexpensive bath 3 * 6 with your own hands - step by step photos

The log for the future bath was prepared and sanded in advance; it was covered from rains and dried for about 5 months. The building will consist of two halves: a steam room and a sink made of logs, and a relaxation room on a wooden frame. It turns out two rooms 3 * 3 m.Construction began with a layout: in the plan 6 * 3.

The soil is sandy, so we make it shallow. We dig a trench 60 cm deep, set the formwork. The width of the tape is taken with a good margin - 35 cm.

We make doors - from a frame, on which OSB is stuffed on one side, and lining on the other. How to do

We leave it in this form for the winter - the blockhouse should "sit down". In the spring, we insulate the frame part of the building, we cover the insulation with a vapor barrier membrane.

We start finishing the ceiling. It was decided to make a budget filing of the ceiling - to fill short boards between the rafters. They can be bought very inexpensively. We process, cut into the desired length. We stuff support bars onto the rafters, to which we knock boards cut to size from below.

Outside, the yuan was sheathed with siding - both the frame part and the log house. It was far from perfect. And there is a ventilation gap between the siding and the wall, so there are no problems with moisture removal.

Do-it-yourself budget bath - another inexpensive solution - siding

Do-it-yourself budget bath - another inexpensive solution - siding We started to cover the interior. We fill the crate, lining on it.

Inside the rest room was lined with clapboard

Inside the rest room was lined with clapboard Moving on to finishing the steam room. First, they punched everything with foil. The room itself will consist of a steam room area, separated by a glass door, and a "washing" area. In the washing wall we will surround with moisture-resistant plasterboard, on which we will then glue the tiles, and in the steam room - with clapboard.

We cover the steam room area with clapboard and

We cover the steam room area with clapboard and We cut an opening in the wall for the installation of the stove. She will be heated from the rest room, and her "body" will be in the steam room. We lay a brick base under the stove, install it. We cover the fuel removal with fireclay bricks.

We decorate the sink with tiles.

For the main work, that's all, the decor and all sorts of things remained - buckets, ladles, thermometers and the rest of the "filling.

For a Russian person, a bath is not a luxury, but a vital necessity. Even historians are convinced that love for a bath broom and good heat is literally in our blood, and even in the poorest villages nearby, new steam rooms were regularly built every five years (the old ones burned down). And Peter I, during a trip to France, could not stand two days without his own steam, urgently ordering to build a Russian bathhouse right on the bank of a foreign river, which shocked the natives a lot. But what if building is so expensive today, and public steam rooms are not to everyone's liking? And if relaxation in the steam room is not just useful procedures, but also valuable communication with friends, barbecue and the opportunity to breathe fresh air? Then we will learn the cunning tricks of modern Russian craftsmen who manage to build their steam rooms literally for vacation pay.

So, let's look at the most successful projects for the construction of baths and their implementation, where the main task was to save as much as possible, but at the same time not to lose in the comfort of bath procedures. After all, as they say, the most budgetary bath is the vestibule of a summer commuter train.

What can and cannot be saved on when building a bath?

Agree, no savings are worth the loss of health, property or life. But the most sad situations occur when the question of cheapness is approached thoughtlessly: such baths first slowly poison their owners by releasing hazardous substances, and then either burn or deteriorate quickly. But this does not mean that it is better to give up and give all the hard-earned money to the conscience of the construction team - it is better to just give up dangerous use during construction from the very beginning:

- Non-certified materials and counterfeits, for which unscrupulous sellers ask for several times less. And at the same time they convince the buyer that "there is no difference with the expensive material, there is simply no markup for the brand, my brother / matchmaker / son-in-law has had a bath with this for half a century, and nothing."

- Materials that are strictly not intended for the construction and decoration of baths. So, if it is impossible to insulate the walls in a sauna with foam plastic, then it is impossible, and this is not a whim of the manufacturer. Again, a neighbor who, at his own peril and risk, insulated in this way and now boasts is not an example.

- Unsuitable accessories for conducting electricity in the bath (wires, sockets), unprotected lamps or cheap Chinese products.

- Homemade stoves and water heaters that no one has tested for fire safety.

- Combustible materials and those that do not indicate that they can be used in conditions of high humidity and heat.