Small electric machine. The principle of operation and features of the use of electroerosive machines

To change the shape of the dimensions of a metal workpiece, you can use the electroerosive processing method. It has been used for many years in various industries, it is characterized by high accuracy but low productivity. To apply this processing method, you should use a special electric spark machine, which can be purchased or made by yourself. Homemade version can be used in everyday life in small-scale production. Its cost of making it yourself will be lower than buying an industrial version. Therefore, let us consider in more detail how you can make the electric spark machine in question with your own hands, what is needed for this and in what cases it can be used.

Homemade electric spark machine

The principle of the considered processing method

A feature of processing with an electric spark installation can be called the fact that the evaporation of the metal occurs due to the effect of a certain charge on the surface of the workpiece. An example of such an impact can be called the closure of a capacitor on a metal plate - a hole of a certain size is formed. EDM creates a high temperature that simply vaporizes the metal from the surface. It is worth noting that a machine from this group has already been used over the past 50 years in various industries. The main condition for using such an electric spark machine is that the workpiece must be made of a certain metal. In this case, it is not the degree of machinability that is taken into account, but the electrically conductive properties.

Main structural element

The EDM has a spark generator that acts as a capacitor. For processing, a large capacity storage element should be used. The principle of processing is to accumulate energy for a long time, and then release it over a short period of time. The device of the laser installation also works according to this principle: a decrease in the time interval for the release of energy leads to an increase in the current density, which means that the temperature rises significantly.

Electrical diagram of the electrospark installation

The principle of operation of the generator, which is installed on the EDM machine, is as follows:

- the diode bridge conducts rectification of industrial current with a voltage of 220 or 380 volts;

- the installed lamp limits the short circuit current and protects the diode bridge;

- the higher the load indicator, the faster the charging of the electric spark machine;

- after charging is completed, the lamp will turn off;

- having charged the installed accumulator, it is possible to bring the electrode to the workpiece being processed;

- after the circuit is opened, the capacitor starts charging again;

- The charging time of the installed storage element depends on its capacity. As a rule, the time interval is from 0.5 to 1 second;

- at the moment of discharge, the current strength reaches several thousand amperes;

- the wire from the capacitor to the electrode must have a large cross section, about 10 square millimeters. In this case, the wire must be made exclusively of copper.

The frequency of generation when the electrode of the electric spark machine is applied is 1 Hz.

The design of the electric spark machine

There are schemes that are quite difficult to implement. The scheme under consideration can be implemented with your own hands. Parts for the installed generator are not in short supply, they can be purchased at a specialized store. Capacitors are also very common, as is the diode bridge. At the same time, when creating a home-made electric spark machine, the following points should be taken into account:

- on the capacitor, the indicated voltage should not be less than 320 volts;

- the number of energy storage devices and their capacity are selected taking into account the fact that the total capacity should be 1000 microfarads. All capacitors must be connected in parallel. It should be borne in mind that the power of a home-made version increases if it is necessary to obtain a stronger spark strike;

- the lamp is installed in a porcelain cartridge. It is necessary to protect the lamp from falling, a circuit breaker is installed with a current strength of 2 to 6 Amperes;

- the machine is used to turn on the circuit;

- electrodes must have strong clamps;

- a screw clamp is used for the negative wire;

- The positive wire has a clamp with a copper electrode and a tripod for guiding.

Homemade wire version has a relatively small overall dimensions.

Homemade electric spark machine

The main elements of the scheme of electrospark equipment

The scheme is represented by the following elements:

- electrode;

- clamp screw used to fix the positive wire and electrode;

- sleeve for direction;

- housing made of fluoroplast;

- hole used to supply oil;

- tripod.

The body, which is used to connect all the elements, is machined from fluoroplastic. A grounding pin is used as a bushing, in which a threaded hole is machined along the axis for attaching the electrode. All structural elements are mounted on a tripod, which is made with the possibility of changing the height. A hole is also created through which oil is supplied.

Diagram of an electric spark machine

Often, cutting is carried out using a device that is powered by a starter with a coil connected to 220V. The starter rod can have a stroke of 10 millimeters. The starter winding is connected in parallel with the lamp. That is why at the time of charging the capacitors, the lamp is on, and after this process is completed, it goes out. After the stem has been lowered, a spark charge occurs.

If you find an error, please select a piece of text and press Ctrl+Enter.

stankiexpert.ru

Do-it-yourself machine for electroerosive processing of metals

The electroerosive machine is designed for cutting metal parts of complex shape. Modern piercing equipment makes it possible to process conductive material along four axes at once, to produce products of any shape, even from hard alloys that are difficult to machine.

Possibilities of EDM machines

EDM wire machine

EDM wire machine The EDM machine copes with complex technological tasks:

- making recesses and holes of complex configuration, including blind openings;

- processing of titanium, tool and alloy steels, hard alloys and hardened steel of the highest hardness;

- execution of recesses of various configurations on the internal surfaces of the part;

- threaded holes in hard metal blanks;

- production of parts that is impossible or difficult on CNC turning and milling machines.

Types of processing

There are several types of electroerosive machining:

- combined - performed simultaneously with other types of processing;

- electroerosive-abrasive - the material is destroyed by electricity and polished with abrasive particles;

- electrochemical - the metal dissolves in the electrolyte under the influence of current;

- anode-mechanical - the metal dissolves with the appearance of an oxide film, combined with the electroerosive method;

- hardening;

- bulk copying - a processing method that allows you to get a projection of the tool on a blank;

- marking;

- grinding - metal grinding occurs under the influence of electricity;

- flashing - the tool cuts into the blank and forms a hole;

- cutting - the tool-electrode performs feed movements and is constantly rewound, removes the upper layers of the workpiece, creating the necessary shape;

- cut - the division of the blank into separate pieces;

- fine-tuning.

The principle of the machine

The primary processing of the blank and the removal of the main volumes of material takes place on a CNC lathe or milling machine. The principle of operation of electroerosive equipment is that the metal is processed by current discharges that appear between the workpiece and the tool. A stretched wire is used as a cutter.

The generator releases current in pulses without changing the properties of the working environment. When the tension between the electrodes is higher than the critical one, a plasma channel is formed that destroys the surface of the workpiece. A small notch appears. The polarity of the current is selected in such a way that the part is destroyed more strongly.

In order to reduce cutter wear, unipolar electric pulses are created. Depending on the length of the pulse, the polarity is selected, since with a short duration the negative electrode wears out faster, with an increased one, the cathode wears out. In fact, both principles of creating unipolar electrical impulses are applied during processing: a variable positive charge and a negative charge are applied to the blank. Water reduces the temperature of the tool (wire) and carries away the destruction products.

Under the influence of high-frequency pulses, erosion passes evenly along the length of the gap, gradually expanding the narrowest point. Gradually, the tool (wire) or part is advanced in the required direction, increasing the area of impact. It is possible to process according to this principle a part from any material that transmits electricity.

The processing time depends on the physical properties of the material (electrical conductivity, thermal conductivity, melting point). The faster the work is done, the more roughness remains on the surface. The best effect is achieved by multi-pass processing with decreasing pulse power.

Machine design

The main elements of the EDM machine:

- frame - made of special high-strength cast iron, which gives strength and stability to the structure.

- desktop - rectangular shape made of stainless steel;

- working stainless steel bath;

- the wire feeder consists of drive spools (ceramic), wire guides and drive system;

- automatic wire installation device (installed at the request of the customer);

- the dielectric block consists of cardboard or paper filters, a dielectric tank and a tank for ion-exchange mass, a pump for running water;

- the generator is used anti-electrolysis, which prevents the destruction of the workpiece;

- numerical control system with display.

We make a machine with our own hands

spark generator circuitThe main difficulty in making a machine with your own hands is the assembly of a spark generator. For some time, he must accumulate a sufficient amount of electricity and throw it away in one gulp. It is necessary to achieve the shortest period of current surge so that its density is as high as possible. You can pull out the components for it with your own hands from an old TV or buy it.

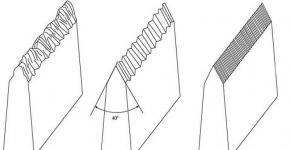

diagram of a homemade machine: 1 - electrode; 2 - electrode clamp screw; 3 - positive contact clamp screw; 4 - direction sleeve; 5 - body made of fluoroplast; 6 - opening for oil inflow; 7 - tripod

diagram of a homemade machine: 1 - electrode; 2 - electrode clamp screw; 3 - positive contact clamp screw; 4 - direction sleeve; 5 - body made of fluoroplast; 6 - opening for oil inflow; 7 - tripod The capacitor must withstand from 320 V, with a total capacity of 1 thousand microfarads. All parts are assembled in an insulated PTFE box. From the grounding pin of the euro socket, you can make a guide sleeve for the electrode. It is moved forward as it evaporates, for which the clamp screw is loosened. The tripod for mounting the entire device must be height-adjustable. A tube is inserted into the hole for the oil inflow, and the directional sleeve drips oil along the longitudinal line of the electrode.

A drive is connected to the electrode (starter with a 230V coil). The stroke of the stem fixes the depth of the hole. While the capacitors are charging, the lamp turns on, and the starter rod is held inside. As soon as the capacitors are sufficiently charged, the lamp goes out, the stem moves down. He touches the workpiece and a discharge occurs in the form of a spark, the cycle repeats. The repetition rate depends on the power of the lamp.

The oil may ignite during operation. It is important to observe safety measures! After all these actions, we will get a do-it-yourself erosion machine.

The video demonstrates the capabilities of the EDM machine:

stanokgid.ru

How to do. - Erosion machine.

HOW TO MAKE AN ELECTRIC SPARK MACHINE

(garage)

I bought it at the price of scrap, such a tripod. And for a long time my head hurt what to do with it. As they say, the time has come. All this is done so that, in garage conditions, small molds can be made. But in order to achieve good results, you need to work hard and try hard.

The tripod itself. Started making the head. The head consists of coils, yoke and damper device.

The lower part of the head, with two screws, for fixing the soft insert and the electrode. The upper part of the head consists of a U-shaped bracket with a bolt for adjusting the springs. The yoke up to the middle of the coil consists of iron and the continuation of textolite. At the end of the washer and between the washer are two springs.

Head assembled. A groove is made along the yoke in the iron part, into which we screw the stopper.

At the bottom of the bed I made a bath for kerosene. Collected according to this scheme. But the capacitor that stands between the working electrodes is selected during operation. Its capacity depends on many factors.

I assembled the electrical circuit in such a case. But just in case, I put everything in the left side of the locker. Left half of the empty space for an electronic generator for the future.

To check the bronze machine made such an electrode. finished electrode.

Left trace. Far from perfect, but we will work on it.

This should work only with an electronic generator.

See work.

www.ucoz.com

Small electric spark machine

A simple electric spark setup (Fig. 1) makes it possible to easily and quickly process small parts made of electrically conductive materials of any hardness. With its help, you can get through holes of any shape, remove a broken threaded tool, cut thin slots, engrave, sharpen tools, and much more.

The essence of the process of electrospark processing is the destruction of the workpiece material under the action of a pulsed electric discharge. Due to the small area of the working surface of the tool, a large amount of heat is released at the discharge site, which melts the substance of the workpiece. The processing process is most effective in a liquid (for example, in kerosene), which washes the place of contact between the vibrating tool and the workpiece and carries away the erosion products with it. The tool is brass rods (electrodes), repeating the shape of the intended hole.

Rice. 1. Small-sized electric spark installation: 1 - workpiece; 2 - tool; 3 - electromagnetic vibrator; 4 - clamping device; 5 - bath.

The circuit diagram of the installation is shown in fig. 2. The installation works as follows. The discharge capacitor C1 is connected with its positive terminal to the workpiece 1. Its minus is connected to the tool 2. The electromagnetic vibrator 3 informs the tool of continuous oscillations. This ensures a constant spark at the point of contact and prevents the tool from welding to the workpiece. The workpiece 1 is fixed in the clamping device 4, which has reliable electrical contact with the bath 5.

The power transformer is assembled on a Sh32 core made of ordinary transformer steel. The thickness of the set is 40 mm. The primary winding contains 1100 turns of PEV 0.41 wire with a tap from the 650th turn. The secondary winding has 200 turns of PEV-2 wire with a diameter of 1.25 mm. A shielding winding III is placed between the primary and secondary windings, consisting of one layer wound with a PEV 0.18 wire. The capacity of the discharge capacitor is 400 μF (two capacitors of the KE-2 type 200 x 50 V). Rheostat R1 is designed for a current of 3-5 A. This rheostat is wound with a nichrome wire with a diameter of 0.5-0.6 mm on the resistance BC-2.

Rice. 2. Schematic diagram of the electric spark installation.

Diodes D1-D4 type D304, other types of diodes can be used. At the output of the rectifier, the voltage is about 24-30 V. You can use power supplies with a lower voltage, but with a large current, so that the power consumed by the charge circuit is at least 50-60 watts.

During the operation of the installation, continuous sparking occurs. To reduce the interference generated by the installation, it is necessary to include a simple radio interference filter in its power circuit.

Photo instructions included.

Erosion machine.pdf (542 kB)

To obtain elements with a complex profile from hard-to-cut metals, an electroerosive machine is used. Its work is based on the impact of electric current discharges, which create a high temperature in the processing zone, due to which the metal evaporates. This effect is called electrical erosion. Industry has been using machines based on this principle for more than 50 years.

Types of equipment and processing methods

The operation of an EDM machine can be described as follows:: take a charged capacitor and bring it with electrodes to a metal plate. During a short circuit, the capacitor discharges. A bright flash is accompanied by the release of energy (high temperature). A recess is formed at the closure site due to the evaporation of a certain amount of metal from high temperature.

Various types of electrical discharges are implemented on technological equipment . The main schemes are:

- electrospark;

- electrocontact;

- electropulse;

- anode-mechanical.

Implementing one of the schemes in practice, machines are manufactured. On the principle of electrical erosion, the following machines were produced in various modifications:

- cut;

- wire;

- firmware.

To obtain accurate dimensions and automate the process, the equipment is equipped with numerical control (CNC).

The electric spark machine is powered by a spark generator. A generator is an energy storage device that gives an electrical impulse. For a constant supply of pulses, a capacitor bank is organized.

To organize an electrical circuit, the cathode is connected to the executive tool, and the anode to the workpiece. The constant distance between the electrode and the workpiece guarantees a uniform process. When the electrode is lowered vertically onto the part, the metal is pierced and a hole is formed, the shape of which is determined by the shape of the electrode. This is how the EDM machine works.

For the manufacture of parts from carbide and hard-to-cut parts, an electroerosive wire machine is used. A thin wire acts as an electrode in it. When the metal evaporates, oxides with a high melting point are formed on the surface of the workpiece. To protect against them, the process is carried out in a liquid medium or oil. During sparking, the liquid begins to burn, taking oxygen and other gases from the working area.

Machines of this type are sometimes the only possible way to manufacture a structural element. But buying EDM equipment for infrequent jobs is a waste of money. Therefore, if the need arose, then you can make an electroerosive machine with your own hands.

Features of a homemade device

Before you start making a homemade EDM machine, you need to understand its device. The main structural elements include:

Making a spark generator

For the manufacture of a spark generator, parts can be found everywhere (in old TVs, power supply monitors, etc.). The principle of its work is:

Work Safety Measures

Since organized do-it-yourself electroerosion is associated with the possibility of electric shock, safety must be approached with all responsibility. The workpiece must not be grounded. Otherwise, a state of emergency will occur - a short circuit in the supply network. Capacitors rated at 400V can be lethal at only 1000uF.

Since organized do-it-yourself electroerosion is associated with the possibility of electric shock, safety must be approached with all responsibility. The workpiece must not be grounded. Otherwise, a state of emergency will occur - a short circuit in the supply network. Capacitors rated at 400V can be lethal at only 1000uF.

Connecting devices excludes contact with the body. To connect the capacitor to the electrode, a copper wire with a cross section of 6–10 square meters is required. mm. A large volume of oil used to prevent the formation of oxides may ignite and cause a fire.

Machining metals of various hardness levels with high precision is possible using non-traditional methods. These include cutting, grinding and strengthening the surface with electroerosive effects. The electroerosive machine was invented a long time ago, but has become widespread only in recent decades.

The first industrial level machine was created by CHARMILLES TECHNOLOGIES in 1952, and the CNC EDM appeared in 1969. Compared with traditional methods of metal processing - forging, casting, grinding, milling, the electrospark method can be considered innovative. The first mention of forged and cast products is several thousand years old.

All metals are electrically conductive, so EDM is applicable to all types of alloys. With its help, you can perform a wide range of work, ranging from simple cutting and drilling to:

- fine grinding;

- surface build-up and configuration restoration;

- hardening;

- copying;

- firmware;

- engraving;

- spraying.

EDM equipment is based on the principle of a short-term electric arc, which leads to the loss of material by the cathode and anode. With a short pulse, the substance is removed from the anode, with a longer pulse, from the cathode. Modern EDM machines use both types of pulses in their work. Both the working tool and the workpiece can be connected to the positive or negative pole.

The only condition that is observed in all types of machines is that only direct current is used. The voltage level and current strength depend solely on the parameters of the metal being processed. The frequency of occurrence of pulses is determined by the mechanical approach and separation of the electrode and the working surface - a breakdown occurs only at a certain distance between the contact surfaces.

Electropulse processing of metals aimed at the destruction of the workpiece (cutting or drilling) is carried out in a dielectric medium, which is a special liquid. Oil, kerosene or distilled water are most commonly used. Surface building, hardening or spraying operations are carried out in air or vacuum.

EDM cutting of metal

This type of processing is used in cases where it is necessary to manufacture small parts with complex contours with high edge accuracy, the manufacture of parts from especially hard alloys, and in jewelry. Restrictions on the size of workpieces and the thickness of the material being processed are determined only by the design of a particular machine. In most cases, EDM cutting is used in industrial enterprises focused on large-scale production of high-precision parts that do not require further processing.

But without much difficulty, you can build an EDM machine with your own hands, if you have some locksmith skills and certain knowledge of electronics and electrical engineering. The scheme of a home-made EDM cutting machine is simple and can be implemented even at home, not to mention a metalworking workshop or a workshop of a small enterprise.

But it should be noted that in home-made machines it is very difficult to realize the main advantages of electrical discharge machining - high accuracy and versatility. Refractory metals and alloys are cut very slowly and require a lot of electricity.

When cutting metal, the workpiece is connected to the positive pole of the current source, the working electrode - to the negative. The loss of matter at the anode is nothing more than erosion, a cut whose thickness depends on the geometry of the cathode. An important role is also played by the type of dielectric with which a certain type of EDM machines works.

For industrial production, two main types of equipment are used - an electroerosive wire machine (cut-out) and an electroerosive piercing machine. The first type is used when processing large parts made of thick-walled metal, the second type is used for more precise work on copying parts made of high-strength materials or strict requirements for their shape.

Wire cutting machines

An electroerosive industrial wire-cutting machine operates on the non-contact principle of interaction between a conductive wire (molybdenum, tungsten or other refractory metal) with a diameter of 0.1-0.2 mm and the workpiece. It is possible to process metal of any level of refractoriness in various thicknesses of the part. A positive pole is connected to a wire wound on rotating drums, which moves in two directions - vertically and towards the workpiece, and a negative pole is connected to the workpiece.

As the wire line moves, a discharge occurs, which burns the line of the required configuration into the part. In fact, EDM on a wire machine performs milling operations, but on metals of particular strength and with an accuracy unattainable in machining. This includes:

- ultra-small angles;

- rounding of microdiameters;

- maintaining parallel lines throughout the depth;

- high edge surface accuracy.

The processing accuracy reaches 0.110-0.012 mm.

Electroerosive piercing machines

Electrocontact piercing processing of metals consists in the action of a point electrode with a given cross-sectional shape, on which the shape of the erosion depression in the workpiece depends. They are used to process:

- stainless steels;

- tool alloys;

- titanium;

- hardened steel.

But they can work with all types of conductive materials when it is required to make holes or recesses of great depth with a minimum diameter and precise cross-sectional geometry.

One of the most difficult operations of a broaching machine is the production of threaded holes in high-strength refractory materials. In this case, only CNC machines are used. The thin wire electrode is inserted into the hole and moves in the longitudinal and transverse directions (along the X, Y axes, with simultaneous movement along the Z axis). It turns out a hole with a complex configuration of the wall, threaded or other profile.

Electrocontact processing allows you to get high-precision impressions of stamps, molds or other small parts. In this case, the electrode is a miniature copy of the required product, made of copper or graphite. Depending on the polarity of the connection, clear depressions or no less distinct protrusions are obtained on the workpiece. Such EDM machines are produced both in stationary and desktop versions (for example, G11 ARAMIS (Czech Republic)).

Homemade EDM machines

It is advisable to assemble a home-made EDM machine if high-precision work with metal is performed frequently and in relatively large volumes. This is a difficult to manufacture equipment that is rarely used in everyday life. It is justified in metalworking shops and workshops as a finishing tool for processing workpieces after milling or turning machines or manufacturing small parts of complex configuration.

The principle of operation of the EDM machine requires the manufacture of both an electronic circuit that generates a high-power pulsed current, and a complex mechanical part that ensures the movement of the electrode (wire or piece). The main difficulty is to make a generator that can accumulate enough charge for a breakdown in a short time, throw it away in a split second and restore it in an equally short period. With insufficient current density, EDM is not possible even on thin parts made of soft metals.

The main parts of a homemade wire EDM machine:

- bed - cast iron or steel;

- desktop - durable plastic or stainless steel;

- dielectric bath serving as a working area;

- wire feed system (two coils, electric motor, drive, guides);

- electrode control system (for piercing);

- start and stop system;

- dielectric pumping unit - pump, filters, pipelines;

- generator;

- control system.

The last point is one of the most difficult, it is necessary to synchronize the wire feed in speed and direction, the pulse frequency and the feed of the dielectric liquid. It should be taken into account that during operation the liquid is ionized, and its properties change significantly.

Depending on the generator circuit of the machine, it uses very dangerous currents of 1-30A at a voltage of 220 V. The insulation of all conductive parts must be extremely reliable. How a homemade machine works can be seen on the video, or here.

After analyzing various information from the Internet, we can conclude that only industrial machines are truly efficient. Homemade products are suitable for engraving, inscriptions, sawing thin sheets of metal, which a high-quality professional jigsaw can handle.

A simple electric spark setup (Fig. 1) makes it possible to easily and quickly process small parts made of electrically conductive materials of any hardness. With its help, you can get through holes of any shape, remove a broken threaded tool, cut thin slots, engrave, sharpen tools, and much more.

The essence of the process of electrospark processing is the destruction of the workpiece material under the action of a pulsed electric discharge. Due to the small area of the working surface of the tool, a large amount of heat is released at the discharge site, which melts the substance of the workpiece. The processing process is most effective in a liquid (for example, in kerosene), which washes the place of contact between the vibrating tool and the workpiece and carries away the erosion products with it. The tool is brass rods (electrodes), repeating the shape of the intended hole.

Rice. 1. Small-sized electric spark installation:

1 - workpiece; 2 - tool; 3 - electromagnetic vibrator; 4 - clamping device; 5 - bath.

The circuit diagram of the installation is shown in fig. 2. The installation works as follows. The discharge capacitor C1 is connected with its positive terminal to the workpiece 1. Its minus is connected to the tool 2. The electromagnetic vibrator 3 informs the tool of continuous oscillations. This ensures a constant spark at the point of contact and prevents the tool from welding to the workpiece. The workpiece 1 is fixed in the clamping device 4, which has reliable electrical contact with the bath 5.

The power transformer is assembled on a Sh32 core made of ordinary transformer steel. The thickness of the set is 40 mm. The primary winding contains 1100 turns of PEV 0.41 wire with a tap from the 650th turn. The secondary winding has 200 turns of PEV-2 wire with a diameter of 1.25 mm. A shielding winding III is placed between the primary and secondary windings, consisting of one layer wound with a PEV 0.18 wire. The capacity of the discharge capacitor is 400 μF (two capacitors of the KE-2 type 200 x 50 V). Rheostat R1 is designed for a current of 3-5 A. This rheostat is wound with a nichrome wire with a diameter of 0.5-0.6 mm on the resistance BC-2.

Rice. 2. Schematic diagram of the electric spark installation.

Diodes D1-D4 type D304, other types of diodes can be used. At the output of the rectifier, the voltage is about 24-30 V. You can use power supplies with a lower voltage, but with a large current, so that the power consumed by the charge circuit is at least 50-60 watts.

During the operation of the installation, continuous sparking occurs. To reduce the interference generated by the installation, it is necessary to include a simple radio interference filter in its power circuit.

Industrial processing of metals includes dozens of methods and methods for changing the shape, volume, and even the molecular structure of a material. Electrospark processing of metals is one of the widespread technologies for working with metal, characterized by high precision and productivity. With the help of electric spark machines you can:

- cut metal;

- drill holes of microscopic diameter;

- build up defective areas of parts;

- to carry out jewelry work with precious metals;

- harden the surface of products;

- grinding products of the most complex shape;

- remove stuck broken drills and cutters.

Many machine tools for industrial use have been created on the basis of the electrospark method of metal processing. This is a high-precision and expensive equipment that only large enterprises specializing in metalworking can afford to buy.

But sometimes electric spark machines are also required in workshops or workshops, where their services are required from time to time. To do this, you can buy an industrial device with somewhat limited capabilities (functionality within the most popular operations), or build a home-made electric spark machine. This is quite possible even at home, not to mention enterprises that include turning and electromechanical workshops or sections.

The processing of metals by the electrospark method is based on the property of an electric current to transfer a substance during a breakdown. At high voltage and direct current (1-60 A), the anode (positively charged electrode) heats up to a high temperature in the range of 10-15 thousand degrees Celsius, melts, ionizes and rushes to the cathode. There, due to electrical interactions, it settles.

So that a full-fledged electric arc does not occur during operation, the electrodes approach each other only for short moments, lasting a fraction of a second. During this time, a spark occurs that destroys the anode and builds up the cathode. The treated area is subjected to heating and electric current for milliseconds, while the neighboring areas and the underlying layer do not have time to warm up and their structure is not disturbed. The problem of boundary conditions does not arise in principle.

If cutting or drilling is required, the working tool serves as the cathode, and the workpiece is the anode. When building up, strengthening the surface or restoring the shape of the part, they change places. For these types of processing, special machines have been created, each of which performs its own operations.

Brass or copper-graphite electrodes, which conduct current well and are inexpensive to manufacture, serve as tools in electroerosion installations. With their help, you can cut and drill the hardest alloys. So that the cathode metal does not settle on the electrode and does not increase its size, the process takes place in a liquid medium - the liquid cools the melt drops, and it cannot settle on the electrode, even if it reaches it. The viscosity of the liquid determines the speed of movement of material particles, and they do not keep up with the current. The metal settles in the bath in the form of a precipitate and does not interfere with the further passage of current.

When building up the surface of parts or strengthening, the metal from the anode is transferred to the cathode. In this case, a positive electrode, which serves as a metal donor, is fixed on the vibration unit, and the part is connected to the negative pole. No water or oil is used in this process, everything happens in the air.

Technological indicators

The electric spark installation, depending on the operating mode, can provide the accuracy of the result over a wide range. If high performance is required with relatively low requirements for the surface condition (I and II class), then currents of 10-60 A at voltages up to 220V are used. In this case, electrospark erosion can remove metal from the cutting or drilling zone in a volume up to 300 mm 3 /min. At higher accuracy classes - VI and VII, the performance is reduced to 20-30 mm 3 / min, but the currents are also required less, no more than 1 A at voltages up to 40 V.

Such a wide range of adjustments shows that electrospark metal processing can be used in various areas, both for the production of large series of parts, and for one-time work, including jewelry.

A feature of the use of electric spark installations can be considered the possibility of strengthening parts of various configurations. The thinnest layer of a more durable alloy or metal is applied to the surface of the workpiece without heating the base to a great depth. This allows you to save the metal structure of the base product and significantly change the properties of its surface. In some cases, a tough base and a high surface hardness are required, or vice versa. Only an electric spark machine can solve this problem.

Diagram of an electric spark machine

The processing of metals by the electrospark method is very common, so it is very difficult to consider all types of equipment and models of specific installations. They are all united by common structural elements:

- direct current source;

- capacitor;

- vibrator;

- mode switch.

A design operating in the electrospark mode may differ in a number of characteristics that allow working with one material or another, but the general principles for constructing a working circuit are the same.

The capacitor bank is coordinated with the mechanical movement of the electrode, the discharge occurs at the moment of maximum convergence of the working surfaces. Relaxation pulse generators determine the maximum charge of the capacitor at the maximum amplitude of deviation from the approach point. After a spark discharge, the capacitor has time to fully charge.

The difference between spark erosion and arc welding and cutting

The use of pulsed electric current is different from the effect of an arc. The impulse works in a very limited space, not having time to warm up the neighboring areas. Even on the most complex alloys in terms of thermal oxidation, an inert atmosphere is not required - the interaction occurs on areas of no more than 0.05-1 mm 2 at an impact depth of 0.05-0.3 mm. Even in the most aggressive atmosphere, conditions for active oxidation do not have time to arise.

Do-it-yourself electric spark machine

One of the main details of the electric spark installation, which can be implemented by one's own hands, of course, subject to all safety regulations, is given below. It should be noted that this is only one of many schemes that can be used in the design of the machine.

The working table of the machine must be equipped with an oxide removal system (continuous supply of oil or kerosene). They reduce the likelihood of oxide film deposition on the surface of the part and, as a result, the termination of sparking. Breakdown requires reliable electrical contact. As the main option, you can use a bath filled with liquid.

The electrode is a brass or copper wire of the required diameter, which is fixed in a clamp. The clamp, in turn, is a part of the vertical rod of the crank mechanism, which is driven by an electric motor. The frequency of the reciprocating movement of the electrode is selected depending on the characteristics of the material being processed.

All conductive parts and cables must be insulated with high quality and reliably, the installation itself must be grounded. You can see how household home-made installations work on the video:

It should be noted that home-made machines will never be equal in capabilities to industrial ones, for example, the ARTA series. For the production of handicrafts or use as one of the types of hobbies, they may be suitable, but they do not “hold out” for work in a workshop or locksmith shop. Not to mention that the complexity of the electrical circuit and the need to precisely match the kinematics and discharge of the capacitor make them very difficult to adjust.