What's the best grade for laminate flooring? How to choose a laminate, selection criteria - the pros and cons of different types. Interview with a master How laminate is classified

Among the many types of flooring, laminate is very popular with many developers. This material is manufactured using the most modern equipment and using innovative technologies and materials.

Laminate is an excellent substitute for expensive parquet and natural floors, looks good in rooms with different interiors. The coating consists of several layers.

- Upper protective. A transparent extra strong acrylic or melamine resin is used. The classification of a laminate is largely dependent on the physical characteristics of the sheeting.

- Decorative layer. For decoration, moisture-resistant paper is used, imitating various types of natural wood.

- Moisture resistant film. It is made of durable polymers and serves for additional protection of the bearing surfaces from the negative effects of moisture.

- Fiberboard panels or other foreign analogs. The panel perceives static and dynamic forces, the bearing indicators depend on its thickness. There are technological connecting locks at the ends of the panel.

- Bottom waterproof layer. Most often, moisture-resistant paper is used, but there are options with polymer films. The function of the film is to keep moisture out of concrete floor slabs.

Among the many advantages, the laminate has several significant disadvantages, they should be taken into account when choosing a class. Unfortunately, manufacturers are reluctant to disclose objective performance indicators, which has led some consumers to become frustrated when they start using laminate floors. What are the essential limitations has a laminate?

- Failure to withstand prolonged direct contact with water. Despite the fact that fiberboard is moisture resistant and additionally there are several layers of protective coating, the laminate is afraid of such contact. In the event of an emergency, the laminate swells and the flooring has to be changed.

- Impossibility of repair. If the wooden coatings after scraping and sanding completely restore their original characteristics, then the laminate cannot be repaired. In case of traces of critical wear or other mechanical damage, the floor must be dismantled and a new one should be laid.

To obtain permission to sell products, responsible manufacturers perform tests on the following indicators.

- Resistance to mechanical stress. Abrasion, ability to withstand static and multidirectional dynamic loads is tested. These parameters depend on the physical characteristics of the substrate, the thickness of the top cover and the dimensions of the sheet.

- Resistance to various chemical compounds. The reaction of the upper protective layer to the action of detergents is checked. In some cases, other chemical compounds, including aggressive ones, can be used for testing.

- Resistant to high temperatures. An important indicator that allows you to increase the fire safety of buildings and structures.

- Resistant to harsh UV and infrared rays. Most polymers react negatively to UV rays; under their influence, the interatomic bonds of complex molecules are weakened. The material loses its plasticity, becomes brittle, etc. To improve performance, modern innovative additives are used. At the same time, the stability of the color shades to infrared rays is checked.

- Slip indicators. The surface of the laminate should provide strong traction with different types of soles. According to this indicator, the laminate is inferior to traditional materials from natural wood, the surface is slippery, which requires increased attention of users.

- The amount of harmful chemical compounds released into the air. An ambiguous indicator, each country has its own norms. If in one material can be considered safe, then in another such indicators are unacceptable.

- Ease of maintenance... The indicators of the accumulation of static electricity, the coefficient of adhesion of various contaminants to surfaces are checked.

- Manufacturability. The laminate should be easy to assemble, while the reliability of fixing the locks should guarantee the required reliability for the entire period of use.

Only after the results of laboratory tests meet the current state standards and regulatory requirements, the products can be sold. But this rule applies only to certified products from well-known manufacturers. The rest can produce not only low-quality, but also unhealthy goods. The classification of the laminate is considered objective guidance when choosing a particular type of flooring.

According to the existing rules, there are six classes of laminate.

| Laminate class | Manufacturer's operating recommendations |

|---|---|

| The cheapest and low-quality products, the manufacturer's warranty is two years. Recommended for use in residential areas with minimal stress on the flooring (bedroom, closet, etc.) |

| Has a more durable topcoat, recommended for medium-traffic residential areas (living rooms, bathrooms, etc.) |

| The most resistant to various influences laminate for individual use. Has increased strength and wear resistance of the upper protective layer. Such a laminate can be used to lay floors in the corridor, kitchen, children's room and other rooms with a relatively high probability of mechanical damage. |

| Floor covering for common areas. The cheapest in terms of cost, the lowest in quality. Recommended for use in office premises and government organizations with low traffic. Professionals advise using a laminate of this class for flooring in apartments and cottages. In terms of cost, this class slightly exceeds the price of the 23rd laminate, and in terms of strength it significantly surpasses it. The investment pays off by increasing the operating time. |

| The most demanded class of laminate for flooring in rooms with medium mechanical stress. It can be used in shops, kindergartens, large offices, etc. The top coating has increased resistance to abrasion, due to the increase in the thickness of the chipboard, the resistance to static loads increases. |

| The most expensive class of laminate, used for installing floors in restaurants and bars, hospitals and schools. The locks have a special engineering design that completely eliminates the likelihood of noise while walking. |

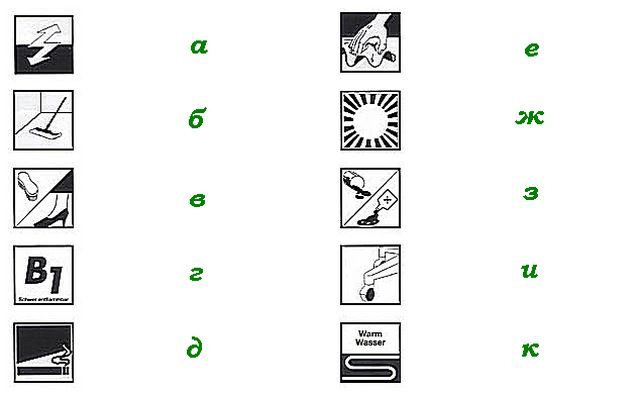

In addition to the designation of the class of wear resistance and physical strength, the packaging may contain other information in the form of special images:

- the surface does not attract dust, does not accumulate static electricity;

- easy care of the laminate, you can clean it with an ordinary damp brush;

- not afraid of exposure to solid objects, you can walk in upper shoes;

- does not support open fire;

- can resist the smoldering of a burning cigarette;

- hygienic, does not emit harmful chemical compounds into the air;

- resistant to the negative effects of ultraviolet radiation;

- during cleaning, you can use special surface active detergents;

- low resistance to point loads, low abrasion rates;

- it is allowed to use a warm floor as a topcoat.

By type of surface, the laminate can be glossy smooth, matte or structured. Glossy is the most slippery, the presence of a relief surface significantly reduces the likelihood of slipping.

There are a lot of color options, from almost black to almost white. According to the pattern, it can be one-, two- and three-strip, the decorative coating imitates block parquet or parquet boards, natural boards of various breeds. A specific choice in terms of appearance should be made taking into account the existing style of decoration, the size and purpose of the premises.

Laminate manufacturers

It is very difficult to independently check the quality of products; this can be done only by a few parameters. How exactly - we will describe a little below. You have to trust the designations on the packaging, but their manufacturers write with different reputations. What manufacturers can be found on the domestic building materials market?

Chinese companies

You should not immediately discard products from China, not all of them are low-grade. The country strictly monitors the quality of products exported. Deviation from the norms is considered a serious crime, and the heads of such state-owned enterprises are severely punished by criminal charges. But in China there are also clandestine enterprises that manufacture laminate flooring in basements using unknown equipment and from low-quality raw materials. Unfortunately, domestic businessmen buy very cheap and very low-quality products from them, it is not profitable for them to bring expensive high-quality laminate from China. How to recognize bad laminate flooring, we will explain in this article below.

The cost of a real Chinese laminate is no different from the European one, the low cost of labor has almost no effect on pricing. The fact is that the products are manufactured on modern high-performance equipment, the degree of influence of the human factor is minimized. The quality of the laminate depends only on the technical characteristics of the equipment and the parameters of the raw materials used. Conclusion - do not be afraid to buy laminate from China if it is made by licensed well-known companies. In terms of technical development, by the way, China has far outstripped our country, this should always be remembered.

| Company name | Short description |

|---|---|

| Austrian company, the products are very popular in America and Europe. The company is part of the organization of manufacturers of laminated coatings, the products fully comply with accepted standards. Laminate is produced from raw materials with environmental class E 0.5. This means that the level of emission of harmful substances from products is two times lower than that of parquet boards and other building materials made of synthetic resins. Another plus - the use of 3-D technology during the creation of decorative coatings gives them maximum realism, not only visually, but also in terms of tactile sensations. The available special fastening system allows you to install the laminate not only on the floor, but also on the walls. The warranty period is thirty years. |

| Produced in Belgium and at subsidiaries in Russia. Premium class products, one of the most famous in Europe. The company was the first to use a locking system of laying, which significantly increased the strength of the connection of individual lamellas. The products have significantly higher scratch resistance than their closest competitors. The effect is achieved through the use of an innovative protective top coat. The variety of colors and shades ensures maximum accuracy of the simulated materials. The disadvantage is sensitivity to high humidity. |

| Premium products from a Belgian manufacturer. The brand is the ancestor of laminate flooring, the first products appeared at its enterprises in 1977. Disadvantage - a plate made using the direct pressure method is used for production. Such plates do not fully meet the high modern requirements of buyers. |

| In terms of price and quality, it belongs to the category of elite, Belgian production. A feature of the brand is a waterproof laminate that is allowed to be used in bathrooms. Water resistance is achieved through patented locks that prevent water from entering the joint. The disadvantage of the brand is the restrained decor options. |

| Laminate from a German manufacturer, premium goods. The surface is mainly glossy, the products are manufactured using a patented technology of coating with acrylate resin. The choice in appearance is huge. The disadvantage is the same as with all glossy coatings - dust and dirt are very noticeable on them. |

| The leader among dark laminates, characterized by high performance and the same price. The manufacturer has created a standard of black color, it completely lacks light streaks. Disadvantages - on uneven ground, the floor quickly begins to creak. |

| German manufacturer, premium goods. The slats can be over 240 mm wide and 220 cm long. These dimensions make it easier to install the flooring in large rooms. It is affordable for many consumers, and meets stringent quality standards. |

| Made in Germany, comfort class products. Environmentally friendly materials are used for manufacturing. The disadvantage is the highest prices in the segment, sometimes they can exceed the cost of premium laminate. |

Prices for the laminate of the company "Tarkett"

laminate tarkett

We have already mentioned that the specified classification can only be trusted if the laminate is made by a reputable manufacturer. How do you know what kind of product you have to deal with? The advice applies not only to unknown Chinese manufacturers, but also to unscrupulous domestic ones.

- Pay attention to the smell. Almost all low-quality laminate has an unpleasant specific odor. It is emitted by synthetic coatings, which have an exceeded content of harmful substances. The odor is most easily detected on the long or short side of the locks, in these places it is concentrated and persists for a long time.

- Take a close look at the spike of the lock. On low-quality products, the locks have a large amount of wax. Do not believe the advertisers' claims that this is done specifically to increase moisture resistance. Any laminate cannot be in contact with water for more than four hours, then it swells, and the floor covering will have to be rebuilt. Wax is applied only to hide the use of low-quality fiberboard. Run a sharp metal object over the lock, large scratches indicate a low density of the material, you should not buy such a laminate, whatever the designations are on the packaging.

- Look at the end of the lamella, it should be clean, natural wood color. If there are traces of paint, this indicates a problem.

- Turn the board upside down... The red color indicates an unscrupulous Chinese manufacturer.

- All European manufacturers indicate a specific country of manufacture well-known domestic companies do the same. The absence of a country of production confirms the dubious origin of the goods and, accordingly, the same quality. In addition to the country, the board should contain batch number and production time.

- Lack on box barcode 100% indicates that the product was released in China by unlicensed enterprises.

The durability and ease of use of laminate coverings depends on several more factors, these data are not indicated on the packaging, only professional builders with extensive practical experience know about them. What are they paying attention to?

Chamfer classification

The cut along the edges of the laminate board gives it a unique look. Due to the chamfer, it is possible to hide minor imperfections of the boards and extend the life of the flooring. The chamfer can be only on two longitudinal sides or on all four. In shape, there are options for U-shaped and V-shaped, in cut depths up to 1 mm and up to 2 mm. Disadvantages of chamfering - dust and dirt accumulate in them, the process of cleaning rooms becomes more complicated. Professionals do not recommend buying beveled materials for installation in corridors, areas with a large number of people, etc.

Lock classification

There are several options that differ in the length of the slot and the depth of the groove, the height of the side, the presence of additional metal elements to strengthen the locks, with water-repellent impregnations. The same laminate in terms of physical strength and wear resistance according to the classification can have different types of tool joints. The recommendation for all cases is the same - the greater the load on the flooring, the more reliable the lock should be. Keep in mind that squeaks during walking appear in castles. It is impossible to eliminate these unpleasant sounds; you will need a complete re-flooring of the floor.

Classification by color and external surface

Color classification meets European standards and is indicated on the packaging. Light-colored flooring creates the illusion of more space and is used to create flooring in small spaces with insufficient natural light. Light floors allow to make a design accent on the interior details, which is often used by professionals. These tones make it possible to create various styles, from the always relevant classic to the most modern high-tech. Disadvantage - any dirt is very noticeable on light floors.

Dark colors are more practical from the point of view of cleaning, they are recommended for use in rooms with high traffic. The dark floor is perceived as more status, retains its attractiveness in any light.

By the appearance of the external surface, there are such material classes:

- natural. The surface accurately imitates wood of various species;

- textural. Almost does not differ from natural in texture, imitates fibers, knots and natural defects of wood;

- artificially aged. Lamellas resemble old worn boards, they are used to create exclusive interiors in country houses;

- waxed, glossy and silvery glossy surface. Each class has its own nuances, strengths and weaknesses. The decision is recommended to be made after consultation with a professional designer.

Each manufacturer has its own classification of the laminate, carefully study all the information provided to them.

Video - Classification of laminate

Laminate - has become a versatile floor covering, so it is used in completely different conditions. It is well suited for both domestic and commercial use. And all due to the fact that, although there are not a great many varieties of it, they have different characteristics. Therefore, this flooring has become universal.

It differs not only in the manufacturer, color and size of the board, but also in the classes in which the abrasion characteristics are enclosed, moisture resistance, impact resistance and others. Now let's find out how to choosethe class of wear resistance of the laminate and which one is better to use in which rooms.

Knowing the main features of these characteristics, you can easily select a floor covering that will meet your requirements and significantly save on unnecessary properties that are not essential for use in this type of premises. If all conditions are selected correctly, the floor covering will delight you with its gorgeous look for many years.

Why are they divided into classes?

Since then, as the laminate has firmly entered the sex life, the firms producing it and the people buying it began to grow exponentially. Therefore, a controlling organization was created, which prevented the flooding of the market with products of inadequate quality. And with the introduction of certain standards and norms, it became much easier for the consumer to navigate when choosing this product. Far away 1999 western laminate flooring manufacturers have formed an association (EPLF). In turn, this membership in this association is an indicator of the quality of a given firm. In our homeland, of course, quality control is not the same as in the West, and for this, the manufactured products of domestic manufacturers are classified according to abrasion tests.

Why choose laminate flooring?

Very easy to install. Planks are elementary connected to each other using lock joints: Click ( which snap), this type of connection is considered to be more reliable and Lock ( which are driven in).

Doesn't require special attention in cleaning. Basically, it is enough to use a vacuum cleaner once a week.

Very durable (depending on class). Hairpins from ladies 'heels, pets' claws, cigarette burns, furniture wheels - sneeze on all this laminate!

A wide range of styles and colors. You can easily choose exactly the pattern and size that suits your design decision.

Environmentally friendly (quality models only). Will never cause allergies or other skin and asthma diseases.

Not flammable. Easily tolerates high temperatures and does not support combustion.

Starts with a low price. Due to the low pricing policy (again, depending on the class and manufacturer), it is in good demand.

Therefore, after weighing all the advantages of laminate, some people use it not only as a floor covering, but also for walls and sometimes ceilings.

Testing

European classification laminate standard EN 13329 includes 18 different tasks. Laminate is marked at the exit, depending on the result of this test.

The results of studies of different types of the same class may differ, since each manufacturer tests the manufactured products himself.

We list the tests that are carried out:

- Abrasion resistance.

- Resistance to

- Shock resistance.

- High temperature tolerance.

- Delamination test.

- Fade resistant.

- Testing resistance to household chemicals.

- Slip resistance.

- Soaked Water Swell Test.

- Test n emitted substances.

In fact, there are a lot of tests, this is only a part of the most basic ones.

To test the manufactured products, the following actions are carried out in the laboratory: a special device is attached to the front side(Taber abrasimeter) with a grinding wheel, in the end, how many revolutions the protective coating will wear off will be the determining factorwear resistance class of laminate.

I would like to note that according to the new methodology, the measurement standards have changed. According to the old tradition of measuring, the abrasive paper of a special circle was changed every 500 circles, and according to the new technology it must be changed every 200 circles, this leads to more intense abrasion with each new block of the laminate. And due to these innovations, manufacturers often indicate both parameters at once, both according to the old scheme and according to the new one.

table of correspondence

| Designation symbols | Use load level | Application area | Abrasion coefficient | |

| According to EN 438 | According to EN 13329 | |||

| Living spaces | ||||

| 21 | easy | study, bedroom, closet | ≥2000 | ≥900 |

| 22 | average | nursery, living room | ≥2000 | ≥900 |

| 23 | high | kitchen, corridor, hallway | ≥6000 | ≥2500 |

| Public spaces | ||||

| 31 | easy | The meeting room | ≥6000 | ≥2500 |

| 32 | average | Office, boutique, reception | ≥10000 | ≥4000 |

| 33 | high | Gym, bar, cafe, shop | ≥15000 | ≥6500 |

Classification

An important criterion when choosing any floor finish is to understand what functions it will perform. After that, it will become clear which laminate is better for a particular room. It would seem yes? - take the most durable and mold it everywhere. But no, prices for different types of laminate differ significantly. And sometimes it makes no sense to overpay for the most wear-resistant laminate, laying it, for example, in the bedroom, where, in fact, there is no particular load.

All laminate flooring is divided into 6 wear resistance classes. Half is for residential and half for commercial.

Surely you are not going to live your whole life without repairs. If we take an average estimate, the replacement of the floor covering occurs every five years, for one reason or another. Someone gets bored with the color, someone wears out from not careful use. Yes, a lot of options. If you do not plan to use this coating for a long time, then the models will probably suit you 21, 22 or 23 grades. They endowed with average technical characteristics and are perfect for flooring both in the hallway and in the bedroom. On the other hand, if the design of the project envisages the use of laminate in the kitchen or in the bathroom, then you should pay attention to the laminate of at least class 31. Which will last longer in such conditions.

If you are purchasing a covering for use, for example, in an office or a small store, the laminate should also have increased characteristics. In this case, choosing which laminate is better directly depends on the class of wear resistance. The best solution would be a laminate with the number 33.

Due to the reorientation of potential buyers to high-strength laminated coatings, in the production of laminate, they began to increasingly use the coating of the 31st class or 33rd. Today, in the production of wood-based panels, a protective coating of class 31 or more is increasingly used. Therefore, the 32nd class has become the most common type of laminate wear resistance. With its correct operation, the service life reaches about 20 years.

For both commercial and household laminates, the box should always have a pictogram showing a drawing that defines the class of this laminate. (see picture below). Having memorized these drawings, you will easily understand.

Household laminate

Laminate with wear resistance classes 21, 22, 23 falls into this category. The price category is medium. TOWhich class of laminate is the best in this category is up to you, do not forget just todurability with proper care from two years.

Class 21

![]() Term wear resistance, subject to the rules of operation, fluctuates around 2 years old. The main reason for this was the lack of quality protective layer. Recommended for use in utility rooms or storage rooms.

Term wear resistance, subject to the rules of operation, fluctuates around 2 years old. The main reason for this was the lack of quality protective layer. Recommended for use in utility rooms or storage rooms.

Class 22

Has a slightly more reliable protective layer. Recommended for use in rooms with low traffic (bedroom, toilet). The service life, subject to the rules of operation, does not exceed 2-3 years.

Has a slightly more reliable protective layer. Recommended for use in rooms with low traffic (bedroom, toilet). The service life, subject to the rules of operation, does not exceed 2-3 years.

Cunning!

To extend the life of this class of laminate, you can go for a trick! Laying a carpet on top of it or an original carpet in the middle of the room.

23rd grade

It is a modernized version of the previous class. The wear resistance is slightly improved. Focused on average cross-country ability. The service life does not exceed 4 years. So it turns out that there are differentlaminate classes and which one is better to choose is up to you.

It is a modernized version of the previous class. The wear resistance is slightly improved. Focused on average cross-country ability. The service life does not exceed 4 years. So it turns out that there are differentlaminate classes and which one is better to choose is up to you.

Commercial laminate

Class 31

The cheapest in this category. Mainly applicable in commercial premises with low traffic. In commercial operation, it will last no more than 3–4 years, and if in domestic use, sometimes the service life reaches 10 years. The starting price per square meter of the 31st class of laminate is 200 rubles.

The cheapest in this category. Mainly applicable in commercial premises with low traffic. In commercial operation, it will last no more than 3–4 years, and if in domestic use, sometimes the service life reaches 10 years. The starting price per square meter of the 31st class of laminate is 200 rubles.

Class 32

The most popular class of laminate in Russia. Will go as the best solution in terms of price-quality ratio. In the office, this coating will stand in its original state, subject to the rules of operation, no more than 5 years, and when used in domestic conditions, the service life reaches 12-15 years. For this type of laminate, prices start at 700 rubles per square meter.

The most popular class of laminate in Russia. Will go as the best solution in terms of price-quality ratio. In the office, this coating will stand in its original state, subject to the rules of operation, no more than 5 years, and when used in domestic conditions, the service life reaches 12-15 years. For this type of laminate, prices start at 700 rubles per square meter.

Grade 33

Proven for superior durability. Unless, of course, you do not take into account class 34, which is not officially available. This coating is suitable for hotels, dance floors, or restaurants where traffic is very high.

Proven for superior durability. Unless, of course, you do not take into account class 34, which is not officially available. This coating is suitable for hotels, dance floors, or restaurants where traffic is very high.

It owes its durability to a thickened lamella (10-12mm), despite the fact that it is designed for commercial use, the service life of this coating will be more than 6 years. And if you decide to lay such a covering at home, then it will serve you for more than 20 years, and some manufacturers generally give a lifetime warranty. Accordingly, if you take care of him properly. The cost per square meter of such a laminate is around 1,500 rubles.

Cunning!

Class 33 laminate with parquet-like texture in appearance is sometimes confused with real parquet.

Class 34

![]() It is recognized in the world as the most durable and wear-resistant type of laminate. Able to take on the workload of a gym, car dealership or airport lounge. Home rarely gets this type, in view of its high cost, which starts from 1800 rubles. The most wear-resistant class. Withstands the loads typical of gyms, car dealerships, airport halls. Few people decide to buy a 34-class laminate for a home, since its price starts at 1,800 rubles per sq. m. But when used at home, the manufacturers Alloc and Pergo give a lifetime warranty. By the way, they are the manopolists in the market for the production of this class of laminated flooring.

It is recognized in the world as the most durable and wear-resistant type of laminate. Able to take on the workload of a gym, car dealership or airport lounge. Home rarely gets this type, in view of its high cost, which starts from 1800 rubles. The most wear-resistant class. Withstands the loads typical of gyms, car dealerships, airport halls. Few people decide to buy a 34-class laminate for a home, since its price starts at 1,800 rubles per sq. m. But when used at home, the manufacturers Alloc and Pergo give a lifetime warranty. By the way, they are the manopolists in the market for the production of this class of laminated flooring.

In laboratory tests, this 34-digit laminate performs better than even the EPLF, which is why it is considered an extra-class laminate.

So the answer to the questionwhich laminate is better to lay in the apartment will be class 33, again depending on how long you plan not to do the next renovation and what is the current budget.

Conclusion

It is not always necessary to purchase l aminate of the highest class. An important criterion for making such a decision will be taking into account the passability of the covered area. In an apartment, it is better to lay laminate flooring at numbers 31 and 32, due to the moderate load and low traffic, this will be enough. In this case, it is worth considering the parameters of moisture resistance (if you plan to cover the bathroom or kitchen). Laminated dies of the 33rd class perfect for both home and commercial use. And if the planned floor loads are very high, they recommend a laminate with the number 34.

Class 33 moisture resistant laminate

Video instruction

Laminate flooring in an apartment is becoming more and more popular every year, and many homeowners prefer it when carrying out repairs. With relatively low costs and ease of installation, which is feasible to do on your own, you can get a floor surface that is not much inferior to natural wood - both in decorative performance and in performance.

However, when going to the store to purchase the desired coating, inexperienced buyers often face a problem - which one will be optimal for flooring in a particular room? If everything is more or less clear with decorative qualities - each apartment owner their preferences and their own vision of the design of the future room, then it is quite possible to get confused in the operational classification of the material due to the abundance of icons and pictograms on the packaging. However, everything is not so difficult - the laminate class will tell you a lot about how to choose which one for specific conditions and will be described in this publication.

What is laminate flooring, its advantages and disadvantages

The term "laminate" is most often understood as prefabricated panels of a certain size based on wood composite for installation of flooring. They can be decorated in different ways - the vast majority of them are made with an imitation of a natural wood texture (floorboards, solid boards, parquet or cork), although there are collections in which the external design is made under natural stone or ceramic tiles or even under a more original texture eg rusty metal. The thickness of the laminated panels can vary from 4 to 12 mm.

The basic structure of a laminate is a four-layer structure, each layer of which performs its own specific functions:

1 – external protective coating (overlay) - in fact, this is the laminate layer of the panel. It is a transparent polymer high-strength film based on acrylic or melamine resins. The quality and thickness of this layer largely determines the wear resistance of the material, its ability to withstand abrasive and shock loads. It performs the most important function of protecting all underlying layers from moisture, dirt, aggressive chemical attack and ultraviolet rays. The quality of this coating determines the hygiene of the floor, ease of maintenance, environmental friendliness of the material.

2 – decorative layer. On a paper or foil base, a drawing is applied, which shines through the upper transparent overlay. In fact, these two top layers create an incomplete coverage of the necessary textured decorative effect.

3 – base layer, on which the overall strength of laminated panels depends. This is the thickest layer of the overall “pie”. It is made from a wood composite close to what we used to call fiberboard in everyday life. However, the differences from conventional fiberboard are quite significant.

If MDF sheets ( Medium Dеnsity Fibroboard- literally from English "medium density fiber board"), then the practice of using laminated flooring has shown that the strength of such a material is clearly insufficient for such operating conditions. Therefore, at present, all reputable companies have abandoned the use of MDF in favor of HDF (High Density Fiberboard - high density). The specific gravity of such a composite can reach 850 - 900 kg / m³. This material is distinguished by excellent rigidity, strength, perfectly keeps the given shape, low hygroscopicity.

- The adhesive laminate is equipped with conventional tongue-and-groove locks without latches. Installation is carried out with gluing the ends of the panels using a special glue.

With correct assembly, a solid monolithic surface is obtained, which, in principle, is very good for use in rooms with high levels of humidity (for example, in the kitchen). However, laying this requires advanced qualifications, and it is unlikely that you can do it yourself. In addition, the coating is obtained non-separable and cannot be dismantled or repaired.

At present, the production of this type of laminate is practically discontinued, and it is not easy to find it, even if desired.

- Laminated panels with locks of the "Lock" type are also found less and less nowadays - manufacturers refuse them due to low indicators of connection reliability.

Diagram of the device and operation of the lock type "Lock"

Diagram of the device and operation of the lock type "Lock" The assembly of such a laminate requires the obligatory application of a translational impact force so that the curly spike enters the groove and locks in it. This causes certain difficulties during installation, and during operation, when the temperature or humidity conditions change, the appearance of cracks at the joints is not excluded. Dismantling the coating without damaging it is also very problematic, since the spike most often breaks off at the same time.

- The most perfect is the system "Click" - locks. The complex figured design of grooves and tenons allows the connection to be made only at a certain angle. Then, when the panels are rotated in one plane, a complete reliable closing occurs, accompanied by a characteristic sound - a click, which, in essence, gave the name to the lock.

The most reliable are click-type locks.

The most reliable are click-type locks. The figure shows one of the configuration options for such a lock, but there are many different types of different levels of complexity. In high-quality laminates, the hinge part is treated with hot wax at the production stage, which gives it strength and the elasticity necessary for joining.

Such a lock provides a secure connection between the panels, without the risk of gaps. Another advantage is that such a coating, if necessary, can be disassembled in order, for example, to replace one of the boards.

Some high-end laminate models have a "Click" lock, additionally reinforced with a metal profile.

Video: types of interlocking laminated panels

A lot of information about the quality and performance of the laminate can be gleaned from the pictograms printed on its packaging. Some of them are shown in the diagram:

a) This symbol indicates that the coating has pronounced antistatic properties.

b) Laminate is easy to clean, does not require particularly careful leaving.

c) A pictogram indicating the resistance of the laminate to abrasion and point loads.

d) Degree of fire hazard. Class B 1 will be optimal for the house - such a laminate is a non-flammable material.

e) A lit cigarette falling on the floor should not cause damage to the surface of the laminate.

f) Laminate is highly hygienic.

g) Badge about the resistance of the coating to ultraviolet rays, in particular - to fading in the sun.

h) Spilled food and household chemicals will not stain the floor.

j) Such a laminate can be safely used for the system. This icon can vary slightly, for example, indicating the type of underfloor heating system - electric or water.

There is also an icon denoting the presence of a V-chamfer on laminated panels. This improvement has several advantages:

- The chamfer gives a special look to the floor covering, almost completely imitating a natural board.

- Possible connection defects at the joints are hidden, become invisible.

- A compensating gap is formed, which will smooth out the expansion of the material during temperature changes.

- Such a laminate has the highest moisture resistance. Even with a seemingly catastrophic flooding of the floor, it can be disassembled, dried and re-assembled without losing the quality of the coating.

When choosing a laminate for your own apartment, to waste time on trifles, to save on quality is by no means the most correct approach. A penny win may result in the need to replace the coating after a few years. A solid, high-quality laminate floor of the corresponding class should last at least 15 - 20 years. And some manufacturers are not afraid to even give their models a lifetime warranty.

But in order not to run into a fake, one should not show unnecessary modesty and hesitate to demand from the seller a certificate for the purchased laminate. According to federal law, this document must be presented at the first request of the consumer.

The main difficulty in buying laminated flooring is the choice of material according to the requirements of the consumer. The abundance of designation and markings confuses people who have no experience in finishing work. Classification of laminate flooring by classes and durability will help you decide which material to choose for a particular room.

Wear resistance class - what is it

Laminate flooring is a canvas or board, consisting of four technological layers: stabilizing, supporting, decorative, top. The bottom layer determines the rigidity of the laminate and protects the web from deformation.

The carrier layer is made from dense wood raw materials and determines the heat-insulating and sound-insulating properties of the material. A lock and a groove are located on the bearing layer, which are involved in connecting the panels to each other.

The decorative layer determines the pattern, texture and texture of the coating. The top layer provides durability, protection against damage and impact.

The protective melamine coating largely determines the wear resistance of the material

The wear resistance class of a laminate is a conventional concept that determines the wear resistance of the top melamine or acrylic coating. More broadly, the concept of a class can include the density of a material, its ability to withstand point and local loads, and its service life.

In Russia and the CIS countries, it is customary to use the concept of "class", while in Germany, Belgium and Austria such designation as "AC" with an index from 1-6 is introduced. When choosing a suitable coating, both indicators should be taken into account, since the Russian definition of “class” does not reveal and shows the technical qualities of the material.

For example, cheap laminate from Chinese manufacturers is often labeled as “Grade 33”, although it is actually a hard backing for commercial use, but with a weaker topcoat with an AC3 index.

That is, in the end we have that two different laminates of the same class can have completely different service life and have different characteristics.

Types of household laminate

Summary table of the main classes of laminated cladding

Currently, household laminate flooring is not produced due to low technical characteristics and unprofitability. Previously, this coating was used for flooring in apartments and private houses, where 1 to 3 residents live. The average service life of the material did not exceed 5-6 years.

Conventionally, this laminate can be classified into 3 groups:

- Class 21 (AC1) - a coating intended for laying in storerooms, utility rooms and areas with minimal traffic. The period of use is up to 2 years;

- 22 (AC2) class - a coating that is more resistant to abrasion and mechanical stress for installation in nurseries, bedrooms and rooms with medium traffic. The cover is intended for residential areas with 2 occupants. The period of use is up to 4 years;

- Grade 23 (AC3) is a popular type of laminate, widely used until 2001-2002. I fit in apartments where 3-4 people live. Designed for bedrooms, living rooms, children's rooms and hallways. The period of use is up to 6 years.

Classification of commercial laminate

Covering class 33 is the optimal cladding for use in apartments and houses

Commercial laminate flooring is a floor covering with a service life of 3 to 6 years, used in commercial premises: lounges, offices, cafes, restaurants, shops and gyms. /

The classification of the laminate for wear resistance is as follows:

- Class 31 (AC3) - used in rooms with light exercise and walking intensity. Service life - 2-3 years. With gentle use at home, it can last up to 8-10 years. It is considered the most affordable and common type of laminate;

- 32 (AC4) class - used in rooms with an average degree of stress. Service life - 3-5 years. At home, the service life increases to 10-15 years. The best choice for a limited budget;

- 33 (AC5-6) class - a covering for laying in premises with high traffic and high loads. Under constant load, it can last up to 5-6 years, with home use - 15-20 years. The best coating for flooring in urban environments, country buildings and houses.

More recently, class 34 laminate from several foreign manufacturers has gone on sale. In fact, this is the same class 33, only more durable, wear-resistant and expensive.

The material is distinguished by its exorbitant quality and reliability. For example, the top layer of class 34 laminate is 0.6 mm with a total thickness of 8 mm or 12 mm. This is a very large thickness capable of withstanding 1.5-2 higher loads than the closest analogue of the 32nd class.

Classification by moisture resistance

As such, the classification of the laminate by moisture resistance is not carried out. To indicate that, a special image on the packaging indicates: a drop, an umbrella and a drop, a drop and an upward arrow.

As a name or a postscript after the designation of the trade mark and the model range, there is a text with the use of the words “Aqua Resist”, “Water Protect” or “Hydro Plus”. That is, in the name of the laminate or on the back of the package there should be a corresponding icon and text explaining that this coating can be installed in rooms with high humidity.

The choice of flooring is an important part of any major renovation, but making a decision on the purchase is often more difficult than it seems at first glance. More and more people are abandoning linoleum, which was boring in the Soviet era, you cannot cover all the floors with carpeting, and noble parquet is too expensive.

And here a fashionable and democratic laminate comes to the rescue - comfortable, effective and quite durable. To understand all the intricacies of choosing the best laminate flooring, we invited an expert to answer our questions - a master with 12 years of experience, Alexander Eremeev.

This comfortable, beautiful and durable material is now available in a wide range.

- Alexander, tell us, first, what criteria should be followed when choosing a laminate flooring? What to look at: price, manufacturer, board thickness or design?

Buying a laminate is a responsible business, because floorboards are bought for more than one year or even five. To choose the best coating, be sure to consider several factors: brand and country of origin, price, wear resistance, moisture resistance and shock resistance, scratch resistance. And, of course, the design.

- Let's start with durability. Laminate has several classes, but how do you understand them?

Today, laminate flooring is usually divided into 7 main classes: 21, 22, 23, 31, 32, 33 and 34. The first number 2 in the marking indicates use in residential premises, number 3 - in public, commercial.

- class 21 boards are laid in rooms with the smallest traffic - bedrooms, living rooms,

- 22 is suitable for children, where there are constant games,

- 23 - for the kitchen and corridor.

However, these types of coatings are already unpopular, and the manufacturer gives them a minimum warranty of 6 years. Today the most popular types on the market are “30s”. They are used for both residential and non-residential premises:

- 31 - in conference rooms,

- 32 - in offices,

- 33 - in shops and sports clubs,

- 34 is a laminate "for ages", for places with the largest human flow.

The guarantee for high-grade laminate boards is from 10 to 20 years, and it can last much longer.

- And yet, what class of laminate to buy for an ordinary city apartment?

From my professional experience, I can say: the best choice in terms of price-quality ratio for apartments is 32nd class laminate, for the noisiest and most active families - 33rd. But here you need to take into account some subtleties.

Wear resistance is determined both by the rate at which the top layer of the board breaks down and by how easily the surface is scratched. To determine the class of the laminate, the following test is carried out in production: the board is fixed in a special device under the abrasive disc and it is considered how many revolutions it takes to destroy the top layer and leave noticeable scratches. Often, these figures differ significantly for different brands, but add up to the same indicator. For example, some boards may have scratches already at the 300th revolution, and the destruction of the protective layer - at 5000th, the average number is 2650 revolutions. In another laminate class, scratches are visible after the 1500th revolution, and the protection is damaged at the 3800th. The average indicator is the same as in the previous sample, but the scratch resistance is 5 times higher.

Therefore, it happens that a person buys an expensive class 33 product, but the coating quickly scratches and loses its shine, although the top layer is still intact. The same is with a good laminate of a lower class: it happens that the 32nd has practically no scratches, but the boards are noticeably worn out.

- Moisture resistance is also an important property of the laminate, especially in an apartment with children. How to choose a coating that practically does not allow water to pass through, is durable, and does not appear when laying?

First of all, you need to have a good idea of what the laminate board consists of. This is a stabilizing layer, then an HDF board, then a decorative layer (photograph) and a transparent protection. The most important part is the HDF board, the higher its density, the less the laminate is afraid of water and the stronger its locks.

The board of this modern flooring consists of several layers.

Moisture resistance also depends on the type of laminate - adhesive or lock. If the slabs are laid on glue, then there are no gaps between them, which means that moisture will not penetrate inside. But such a coating has a significant disadvantage - it will be impossible to replace 1-2 damaged tiles, unlike those boards on which the side locks simply snap into place when laying. There is a worthy alternative - water-resistant lock laminate on a standard basis.

For a good laminate, the moisture resistance indicator should be no more than 18%. To check this, you need to saw off a small piece of the slab and lower it into the water for 8 hours at home. The branded board will swell by 15-18%, while for a low-quality one this percentage can reach 40.

The thickness of the laminate board is also important - the more millimeters it contains, the stronger it is, and it is easier to lay. In addition, such a coating perfectly absorbs sounds, so in apartments where there are babies, I always recommend buying a laminate no thinner than 8-12 millimeters.

- What is a laminate backing?

The underlayment is a very important material for floor renovation, the material insulates the laminate boards from the floor and provides heat and sound insulation. In a high-quality laminate of the 32nd class and higher, the substrate usually already exists; when buying cheaper classes, you need to purchase it separately.

There are three types of substrate, the most affordable and popular is polyethylene foam. It is resistant to moisture, it is as easy as shelling pears to lay it, but over time, such a layer sags. Cork is a little more expensive - it keeps heat well, but it can release condensation. The solution is very simple - to buy a cork substrate with the addition of bitumen or rubber. There is also a so-called special substrate, it is the most expensive, but it perfectly absorbs sound, retains heat, and condensation never appears on it.

The substrate can be made on the basis of cork material

- What can you say about sustainability? How important is this quality for an apartment laminate?

The environmental friendliness of building materials has long been at the forefront, and in my work I definitely take this factor into account. Phenol-formaldehyde resin is used in the production of flooring boards, which reduces production costs and the price of the final product, but releases formaldehyde, which is hazardous to health. Therefore, when buying a laminate, you need to look at the degree of content of hazardous resins in the tiles.

So, in Europe, the formaldehyde content in laminate flooring is strictly regulated, and expensive parquet and standard laminate are equally harmless to health. Another thing is China, according to the laws of this country, the requirements for the content of phenol-formaldehyde resin in wood-like boards are much lower!

When choosing a laminate in a store, trust only yourself and your observation - an opened package should emit only a faint aroma of sawdust. Any foreign smell - glue, paint, etc. - should alert you. See also the price tag: too cheap laminate in almost 100% of cases is dangerous to health. And here it makes no difference where you buy building materials - even in a large hypermarket there may be a dangerous product. I know that large stores often write in contracts that the supplier bears full responsibility for the quality of the laminate, in addition, hypermarkets are not even legally obliged to check certificates for goods - this is the concern of special organizations.

- Let's talk about cover design. What colors are in vogue today, wood, stone or monochromatic? Can you choose a quality laminate by color?

The situation with the design of laminate tiles is quite interesting. Classic laminate flooring is an imitation of parquet flooring, and real wooden floor boards are unique - you will not find two identical ones. Therefore, the best laminate flooring boasts minimal pattern repeatability, knots and natural variegation of wood. The repetition of the image 1: 6 will tell about the European production - this means that 4 packs should have at least 6 variants of the color "under the tree". By the way, in the most expensive collections of premium manufacturers, for example, Quick Step, this ratio reaches 1:60.

The Quick Step material has beautiful and virtually non-repeating patterns

But the Russian consumer has his own quirks - we are accustomed to a solid color of floors, so we believe that the correct laminate should be either a solid color, reminiscent of floor paint, or an even shade "like a tree", the same, symmetrical and without any knots. Usually such coloring is found in inexpensive Chinese laminate - they use the simplest imitation pattern, and the repeatability is 1: 3.

And so it turns out that the whole world is chasing an exclusive parquet laminate, but give us what is simpler.

- Nowadays there is a lot of talk about beveled laminate. What is it and what are the advantages of these plates?

A chamfer is a V-shaped bevel of the end edge of a laminate board (1-2 mm deep), due to which small grooves appear at the joints of the boards when laid. Chamfers are found both along the entire perimeter of the board, and along 2 long sides, double-sided.

As we have already said, a sign of an expensive laminate is a complete resemblance to parquet, and the bevel only enhances this similarity, because there are almost always such grooves on a natural tree. In addition to aesthetics, the chamfer allows you to increase the life of the laminate by 2-3 times, and when exposed to moisture, it helps the coating not to lose its original shape.

Another plus - if you buy a beveled laminate flooring, you do not need to spend a lot of money and effort on the perfect leveling of the floor. Usually, a perfectly flat surface is needed so that cracks do not appear on the planks, which over time take the shape of the floor. The chamfer hides these cracks - provided that the difference on the floor is not more than 4 mm per 1 meter.

- You have repeatedly mentioned the high quality of European brands of laminate flooring. So which manufacturer should you choose? Only Europe, or China and Russia also produce high-quality laminate flooring?

I have been dealing with laminate flooring for many years and I can say with confidence: the best and most responsible manufacturers are Europeans. Manufacturing a laminate board is a high-tech process, it does not require cheap labor, as in China, but the most modern equipment and high responsibility of companies. Not a single European manufacturer with a worldwide reputation will place the production of laminate flooring in the Middle Kingdom - it will simply be a blow to the image.

In addition, there is another indicator of quality - a construction company must necessarily be a member of the Association of European Manufacturers of Laminate Flooring (EPFL), in this case it bears full responsibility for its product and for what is written on the label. Therefore, I always advise my clients - if you need a high-quality laminate, be sure to check if the manufacturer is a member of the Association - on the company's website on the Internet.

Russian and Chinese manufacturers, which are not part of the trade union, have every right to write anything on the label, therefore, a 32nd class badge can flaunt on a low-grade laminate. In fact, the quality can correspond to class 21.

- Tell us about the most famous manufacturers. Which laminate flooring is better to choose, taking into account the different purchasing power of consumers?

In terms of price-quality ratio, laminate has three classes: premium, comfort and economy.

In the premium segment, the most famous firms are Austrian Kaindl, Belgian Quick-Step and Pergo. These companies have excellent quality, interesting collections, but an expected high price. Interesting lines of glossy coatings from the German HDM, the Belgian company Balterio is famous for its unique black laminate.

Austrian brand Kaindl is a premium flooring material

From the comfort class I can definitely recommend the French Alsafloor - it is excellent quality, many different design lines, there are boards of the 33rd class with a thickness of 12 mm and high strength. The German manufacturer Kronotex works in comfort and economy class, but it does not have the widest color palette, minimum technical characteristics. Another well-known representative of the economical laminate option is the German Egger. The price of such a coating is quite affordable, but the design also suffers - the minimum number of colors, imitation wood, mainly from photographs.

- Let's summarize our conversation. Can you formulate a few rules for our readers, according to which it will be easy to distinguish branded Western laminate from cheap and low-quality ones?

I have already mentioned a few rules - this is a pleasant woody smell of a laminate board, a moisture resistance index of no more than 18%, a pattern repeatability of at least 1: 6.

Another indicator of a good floor covering is its high price: a real laminate cannot be cheaper than 400-500 rubles per square meter. Also, always look at the markings: Chinese laminate flooring often does not have identification marks or has, but with errors. In European, the information is always indicated in full, and the name of the country - without abbreviations. Another identifying feature is the color of the back of the laminate tiles - a pleasant beige color, while for Asian products it is brown. Recently, however, oriental manufacturers have also begun to supply laminate flooring with a beige backing.

A special size will tell about Chinese production with almost 100% probability - the length of the laminate board is 1215 mm, the thickness is 12.3 mm. For Asian manufacturers, these dimensions are very convenient, the manufacture of such plates is the least expensive, so such parameters should also alert.

High-quality material will serve you for a long time and will delight you with its appearance

There are a lot of rules, but remembering them is quite real. Take your time with the choice of flooring: go to several stores, look through the prices, check the manufacturers you like for the "quality mark" - and you can easily buy the best laminate for your apartment.