How to build a new bath. Stages of construction Baths: from the foundation to interior decoration

How much beneficial sauna, not yet to paint. And not only for the health of bodily and spiritual. Have a bathhouse on the plot - to purchase prestige and respect for neighbors. And the opportunity to invite the useful person will bring direct benefit. We will be realistic, many important issues are solved in the bath, and at the table of meetings, the document is signed. It is not necessary to look for corruption schemes here: after the bathhouse in the head brightened, the husk is unnecessary, and the essence of the case goes to the eyes. Villains, by the way, the "arrows" are not prescribed in the bath, there the conscience wakes up.

This article is devoted to the issue, how to build a bath with your own hands. Who said that only the strengths of this world have the right to a complete bunny benefit? But why, ask, build yourself? The construction seems to be unpaired, in demand. Maybe it's better to order a turnkey?

In demand, all and business. In combination with ma-a-linen circumstance: the bath is not an object of essential or vital. Hence, the cheating of the contractor is limited only by the contents of the customer's pocket, as well as for luxury items. Than builders and use - the market is the market, they also need to live, and want better.

Take a look at fig. Balke on the left will cost a turnkey somewhere at $ 8,000, and that on the right is $ 23,000-25,000. Impressive? About 2-3 storey baths with pools, billiards, banquet rooms and massage rooms modestly default. And if you build yourself? Independent construction of a bath on 2 compartments of 3x4 m from a bar (this is the one that the left) will cost about $ 1800, and a 4x6 m log of 3 separates somewhere in $ 4000-5000. Impressive, however, the difference is not only many times, but also fundamental: if the "turnkey" amounts in the average budget do not fit in any way, then samostroy has already been raised without ceiling consuming, because Mortgage with a smaller bet on the bath now will not be given.

The purpose of this article is primarily to show: not so terrible, how is his little. Bath - the building is serious, it must meet certain requirements. And the focus in the following is made on how to satisfy them, without mastering complex technologies and without spending excessively. If you can smoothly cut the board, directly drill a hole, drive the nail without beating and, after reading further, believe that the construction of the baths forces and means, we will consider our task made. Therefore, the material is built for a more complete lighting of key moments, but also the features of the construction of the baths from various materials paid due attention.

Russian or sauna?

The Finns themselves, and doctors, too, recognize that the Russian bath exceeds Finnish. In the Russian bath, you can create perfectly dry steam, as in the sauna, but it will not be possible to "cling" in the last poorer pair. But the sauna has valuable dignity - it is little demanding of the construction of a bathroom with a heat source. Compact electrosaun in the size of a wardrobe can be put in a city apartment, and nothing, there is a normal pairs there. But Russian requires necessarily a separate bath building and an oven for her. Therefore, it will be part of the Ban of Russian, and the saunas will leave for another case.

Rhodonachalnitsa

The original Russian bath consists of 2 branches: pre-bankers and steam room, see fig. on right; Dimensions - from 2.3x4 to 5x6 m. Fashion for such baths is now being revived, from called wild grounds. The indispensable features of the "wild" Russian bath:

- The foundation is unlightened from natural (also wild) boulders, without base.

- The structure is a log house from selectively chopped wild logs, i.e. Non-technical processing, except for chasing and drying.

- Construction - without a single nail.

- Canopate - only moss and packles.

- The ceiling is the flooring (see below).

- Floor insulation and ceiling - moss and peat.

- Waterproofing - resin or shoe var.

- Roof - Shot or Cherry.

- The oven is brick.

What are these archaisms in our time, guess it is not difficult. Wild key turnkey less than 1 million rubles. - Divo. To all, it is fire hazard; Peat, moss and non-impregnated wood wood - combustible materials. But then we will see how to build an independently safe bathhouse and easier, not inferior to the original. Help, firstly, modern materials and technologies; In addition to traditional wood, there are unexpected solutions here. Secondly, in the old days, the bath ovens were built of bricks only for the absence of suitable metal. Actually, a stainless metal stove with a long-standing, air convector and a properly arranged Kamenka for the bath is better in all respects. So, to business. The action plan is:

- Recognition with research - see if it is possible to put a bath on a plot, where exactly what size and layout;

- Selection of material for construction;

- Design and approval of the project;

- Building and equipment, from the foundation and runoff before installing the furnace.

Project

The project should be lined immediately. The order of its statement is the same as for other non-residential buildings. However, it is not recommended to climb samostroy and legalize it. Bath is the structure of not the essential. If, in its construction, harmful neighbors were pressed like: "And here I have become a carrot from the garden, it was built as they built!", I will prove your very problematic and expensive. On the other hand, for the same reasons (non-residential, not vital), the mutual walking on instances is simplified and facilitated. Based on this, 3 options are possible:- Order a turnkey project "turnkey" from local designers, i.e. Already approved and attached to the place will cost this for a small bath to 5,000 rubles. + state duty and fees;

- Designed by himself - undesirable, not being a builder, confused, and in the organs of arrogant amateurs do not complain;

- Download from the Internet Ready thumbnail, i.e. Not attached to the terrain, project, and bind it to themselves.

The last option is optimal if you are not afraid for 5,000 savings sit under the offices. He has, so to speak, the breeder - give the downloaded sketch to the designers for binding and design. In this case, the savings are twice as wide, but walking - on their soul, and she is there like fish in the water. You will also need to choose a suitable structure, estimate its location, make a copy from the planning scheme and show the projector where the bath will be. However, to download the first closing a beautiful 3D picture with some schemes should not be needed to check the Bani project to contain at least the following sheets:

- Floor plan with the necessary cuts and explication (technical specifications) of premises, like the fact that in Fig. below;

- The consolidated statement of the required materials, and keep checks on them, so that in the case of which to show - not from the stolen built;

- Recommended type of foundation and its plan.

An important point in building resolution is the consent of the neighbors. This is not a debt receipt, there are other laws. Simple paper with a signature as an argument will not pass, but if on it and other sheets, the stamp "approved" and a visa, then with that shorter the conversation is short: "You see the seal on your snapshot? Yes? So you went to my garden to break the carrot. "

And such a ma'a-lox remark. Consider the nails can and measure the project where to beat, not necessarily. The builders know perfectly well that the deviation from the project is far from the same that Samostroy. Therefore, having an approved project, the developers are more or less experienced build, if only it seems to be, and there suddenly, it is stupid. Flooding, dimensions in the plan, the location of the bearing walls must match (in a small bath there are already 4), the material from which the tree is built is so a tree, the brick is so brick - and the foundation, its type and material. Other, if it comes to a bath, will not be disruption, but by deflection from the project, which is solved. Any foreman on this topic of such stories will paint - winning and getting up.

Note: a question may arise - what is this liberalism to deviations? The point in the land of Mother, build something on it, and predict exactly how it will behave, while it is impossible. Therefore, grated builders give will, so that the risk to their fear can decide on the spot in circumstances - how to build up to stand.

Location, sizes, layout

Requirements for the location of the bath on the site shows Fig. on right. Of these, it is especially strict when approving, look at the distance to the source of water supply, at home, and draining from borders with neighbors. They should be followed with a margin, and the priority of the water supply is the highest. If, for example, on local conditions you need to take the distance from the well or well from 30 m to the nearest sources of pollution (and the bath is related to that), then we take this or other greater value. The same refers to distances to neighbors, carrots and really can get drone from the bath drain.

Other requirements are plastic based on local conditions. For example, the distance to the house is taken to leakage from the bath runoff not torture the foundation. If the sauna is below the slope, and the underground flow is directed from the house to it, then you can meet in 5-7 m, then only according to the results of the research in place.

A lot of "screens", when approving projects, the bath causes the entry orientation not to the south. There is already a cause of medical: suddenly the breakdown will be released on the seducing northern wind, long and before the inflammation of the lungs. But, let's say, in the predfaccise, the most evil wind is just southern, t. Naz. Slit from the mountains, and in the rose of winds in the north, the failure, so in this case the orientation of the entrance to the bath can be the opposite type. Well, and where it looks at the window, and it does not matter at all. Want when washing to admire the neutrition of a waste pit - your business.

On the usual household site the possibility of building a bath can solve the meter-one and a half of its size. At such a case we give informal standards of the area for 1 washing: 1.5 square meters. M of the pre-banner and 1 square meters. m washer (shower). Those., A sufficiently convenient domestic bath is possible by sizes from 3x4 m. Examples of layouts of such baths are shown in Fig. Below, with a parillery of a separate and combined with a washing. Their feature is that the entrance door can be on any of the pre-banner walls, which facilitates the location of the bath on the site.

On the pair you should linger especially. The fact is that the overall health of modern citizens often simply does not allow them to steam. In this case, a bath is needed from 3 separates with a separate steam room. In 3x4 m, such a layout can be laid on the right in Fig. With plans, but then the problem of heating the shower in the cold time. To start a shower for heating, spending in vain hot water is irrational, in the watering of the stove of it and so little, and there is no longer for a separate oven in the shower.

The output can be found by retreating from bath-planning traditions, especially if the area is available for building allows you to increase its size. For example, in fig. - Bath diagram from 3x5 to 4x6 m with a small pre-banner, actually changing.

A big washing is heated either a separate stove (designated?; There is a simple homemade bourgeitarian or something like), or the flow of air from the part of the convector of a modern bath in steam room. In the latter case, 2 solutions are possible: or non-combustible partitions and a part of the air convector goes into the washing, as in Fig., Or the fence of cold air over the floor of the washer and the feed is heated under the ceiling under the ceiling using tin boxes or metal. Thanks to the presence of a tambura, a common entrance can be focused as you like, but for lovers leaning, climbing in a fresh snowball or a pool in a steam room there is a separate output.

Note: about the second sign? In fig. And see the drain with the drain below.

Materials

The choice of material for the construction of the bath is due primarily to physical processes in it. More precisely, our ancestors based on the available and medical and hygienic requirements, understood at that time intuitively, but probably invented and the construction of a bath building. It turned out therefore quite conservative and tightly tied to the tree. Wooden buildings require very high skills and long technological breaks on the dermistem and their own shrinkage, if used inexpensive terrain forest. Replace the wood on the bath is possible, for example. The following foam blocks or arbolit, or opilk concrete. Therefore, before choosing the material, let's see what physics is valid in the bath.

Bath physics

The first - the bath is not heated constantly, the sweating strongly warms up, and when you wash it off. The second - during the protest, the bath furnace must first give a powerful flow of thermal (IR, infrared) radiation, which will warm the walls and absorb them, and slightly weather - a strong stream of heated air, which gives a uniform temperature in a steam room. At the time of the wash, the furnace furnace relaxes so that the washes did not burn her directional IR. People in the Ban of IR from the heated walls and heat of air should be gently and evenly envelop; This, in addition to the saturation of air intake, the indispensable condition of the lung pair.

The first - the bath is not heated constantly, the sweating strongly warms up, and when you wash it off. The second - during the protest, the bath furnace must first give a powerful flow of thermal (IR, infrared) radiation, which will warm the walls and absorb them, and slightly weather - a strong stream of heated air, which gives a uniform temperature in a steam room. At the time of the wash, the furnace furnace relaxes so that the washes did not burn her directional IR. People in the Ban of IR from the heated walls and heat of air should be gently and evenly envelop; This, in addition to the saturation of air intake, the indispensable condition of the lung pair.

With the temperature, the lightness or severity of the bath is not tied so much. Couples at 45 degrees can be heavy, and at 70 - easy. The tolerability and benefits of the bath for people are different, as they say, the Constitution is expressed by the parameter that can be called the intensity of the effect of steam; In the people, he has long been known as "poorerity" of the bath. Also for a long time there is a classification of baths on this basis:

- Easy, for women and children - From the lime forest, the heat capacity of the walls of Mala, IR from them quickly "exhaled" and washable warm with more air.

- Normal, or Condim - Traditionally from the coniferous forest. Heating IR from the walls and air is approximately equally, depending on the fire mode is suitable for almost everyone. It can be built of any material suitable for the bath.

- Easy - From thick oak logs. Thanks to a long and powerful IR from the walls with a large heat capacity of everything at 50 in the pair, one single-haired broom is pierced, as they say, there is also a bone. But you can withstand the diverse pairs you can only having iron health. In general, the poorest bath is the Bogatyr, after it, figuratively speaking, fit the trucks, grabbing the car for the hinge.

Light baths built rich more for wives, daughters and other women's expensive: Easy bath has a beneficial effect on women's health and allows you to save beauty for a long time; Both sexes adds sexual activity. Dear Russian Cockobots of the past certainly before accepting, missed their visitors through a light bath, long before the Russian word denoting their profession became indecent.

However, the lime trunk forest and in the old days there was roads. Now all age-old lipnyaks under the protection, the billets of the lime businesswood are not conducted. However, approached by properties to the lightweight linden bath of foam blocks and the frame, which will be described in more detail. They are the cheapest and simple in the construction. But to ride after a light bath in the snow or poke into the hole is categorically contraindicated. Even before getting out of it to the street, you need to cool in a warm pre-tribades, and then, it's warmly dressed, quickly scatter into the house.

A poorest bath, on the contrary, very road and complicated, because It is possible to build it only from the logs of the highest condition. Longitudinal hollows between the crowns of the cut act as the captors of the initial IR furnace, driving heat into the walls; Bruce walls absorb IR not so greedily. The same applies to any log baths, so the bath "Almost the pointed" can be built out of a pine log with a diameter of 200 mm. We will further take advantage of the "normal" conders, as the most versatile and affordable.

Selection and rejection

The best material for the bath is a tree, because For him, she was created. On foam blocks and other suitable materials, let's talk later when describing the baths of them, because They go to date immediately without rejection. It is impossible to say about the wood: that that is quite suitable for the house, in the bath can not last long as the specific conditions described above.

Note: The brick sauna is inferior to wooden in all indicators, except for one - large, from 70-100 square meters. m In terms, the bath structure of the brick will be cheaper than wooden, and its bath qualities with such a large volume of the building will become acceptable. Therefore, brick baths built and build predominantly large public.

The best tree on the bath is a larch, and on the poorest - the moon oak, but the other is expensive. Most often, the baths are built of pine or spruce wood after pre-rejection of sawn timber. The first thing to pay attention is the complete absence of cracks (pos. 1 in Fig.), Then Chervotochin, pos. 2 and blue, blacks, etc. Signs of rotting, PP. 2 and 3. Syneva as a rule, it is accompanied by wormworms (pos. 2), but may manifest itself with separate spots, pos. 3. The third feature of the unconditional selection of this thing is drop-down swirls. If the forest is conditioned, the selection criteria come into force.

ROOM AND SURFACE

The coniferous string forest, especially pine, has 2 varieties - a grill and a dryness. The second is the usual build forest, chopped in quarters. The first impregnated with the resin, it smells like it, if you spend my finger on the heap, it will stick and dumps. Resolve Road. The trees are chopped by selectively during the Software that for the forest is generally not useful. Nevertheless, building a bath from a log or a bar, it is worth spending on the tar for 2-3 lower crowns: it does not rot, but under the influence of moisture, turning into the likeness of the moraine oak. For the frame bath bar of the lower strapping (carrier belt), it is also desirable to take a resin. And yet: on the draft floor of any bath, it is quite highly desirable to purchase a much less expensive semi-finished products and sawing resilts with a surveillance, first of all - the cheapest hill, see fig. We will have to sweat more, raking and configuring, but the floor will come out eternal and inexpensive.

Note: So far, someone else is still practiced predatory forest, when the trees of the sem are quarterly all year round. The surrounding builders of the bath is on the hand - the grinding can be taken directly from the leathering cheaper than then the dryness from the distributor's warehouse. But for nature, this approach is no place for nature, and you need to be able to evaluate crude wood on the item during drying, see further, about the bar.

Impregnation

All lumber for the construction of the baths must be impregnated with antiseptics, biocides and antipirens. In addition to the fruit, she does not rot, no impregnation will accept, and ordering, it will become very badly fuel. The impregnations for wood are sold and separately, i.e., if so cheaper it comes out, then you can buy an inexpensive impropy forest and process yourself.

Impregnation materials for armored wood are based on purified mineral oils and / or silicone. You can meet the recommendations to replace them with working out or fresh engine oil, but not necessary. Machine oils contain additives, useful mechanisms, not people. In the bath, they will inevitably enter the air and are impregnated with you through the steaming skin.

Breed

Raw, i.e. Wild logs are now sold rarely - it is more profitable to dissolve them on the measuring material, and waste will go into the case, on cellulose, etc. There are firms selling wild forest, but selected and prices - my respect. Therefore, suddenly you, after reading further, removed to build a log bath, then buying logs will be purchased.

The first choice criterion - the log must be a solid chamber drying; This is a very expensive material. Glued imitation, pos. 1 in fig., Perfectly go on a residential building, but not on the bath, because Due to the different labeling of lamellae (fragments, from which the log glued in the bath conditions, the operating conditions will soon be excreted and reinforced with any impregnation.

The second moment is cracked. T. Name. Healthy radial cracks, pos. 2, in the cuts of residential buildings are quite admissible, but in the bath will be collections of condensate with all arising; There are no logs of natural air drying without them, therefore, as above, only chamber is suitable. For the same reason, the log profile should not have reversed recesses, pos. 3. From the log of the Finnish profile and any of its modifications, excellent homes are obtained, but the baths are not built.

The brood log on the bath should be with the usual T. Naz. Lunar groove, pos. 4 addressed down. To do this, when building, you need to choose a suitable wagon scheme, see below. The best sizes for the bath - 190 or 210, noted in Fig. If the sauna is built from pine logs, then, besides the enlarged diameter, you need to choose a log with a dark core and a bright zabol, to the right in Fig. The logs with dark and bright belts of the annual rings, the groza will go to the usual bath.

Note: If the "rode" of the baths of great importance does not have, then the logs can be taken a few different diameter. When writing in the region (this is the optimal method for a small bath, see below) from the solid-caliber logs, it turns out quite suitable log house, see fig. left.

Bar.

The timber saucer will cost much cheaper than the log cabin and the look fits into the country nozzles, see fig. Cheaper and easiest to build it from a conventional pure-bruised timber (rectangular in cross section). The criteria for its rejection are the same as for the logs, but the check is added to the evenness.

A simple chamber of chamber drying now seems to be on sale at all - unprofitable. And the air drying is all in one degree or another. In general, this is not scary, in the construction of a log house always provide for a technological break on the dermisk and its own shrinkage of the tree. During him, the bars will stick together to each other and seternally, as they say, will be convicted with a pantry with a practically a whole array.

However, the shrinkage of the tree is not limitless and if the timber was dried incorrectly, it could be excessively vigorous, and the log house from it will remain with the slits. There are 2 procurement options: either from a proven supplier for live recommendations of reliable people, or with a stack inspection in a warehouse invited specialist - a carpenter, a furniture-friendly, forestry engineering, etc. To learn to evaluate the degree of blocking of sawn timber and their further shrinkage in designs on descriptions with instructions, Unfortunately, it is impossible.

Bathing Bathing Bathing

It is very attractive, but it requires particularly thorough rejection of the tree, the construction of a brusade bath from a triplicate timber with a reflection (pos. 1 in Fig. Right) or a 2-kanta, he is a half-circuit sleeper, pos. 2.

These are semi-finished products, i.e. It is inexpensive. There is not much more difficult for them than a simple timber and can be done not a carpenter. But the bathhouse from such a bar can be built on the species very similar to the "cool" log, and according to the properties - with intensive firebox close to the poorer.

As to the profiled bar, then he, first, roads. Then, the glued bar cannot be allowed on the bath, for the same reasons that the imitation of the log, pos. 2 in fig. A one-piece chamber broom is even more expensive, and only the chosen from the kernel will go to the bathhouse (pos. 1) or Collus. If the bell can be seen on the heap immediately, both, in the building it will be split. Finally, in the bar profile, as in the logs on the bath, there should be no recess facing, pos. 4. All this turns the choice in the daytime hell, especially since the sellers, knowing that their goods are quite good at home, such advocacy do not understand.

More about brick

Suddenly you want to build a brick bath, keep in mind that the brick is also subject to rejection. The bath is needed heavy and dark tiny, or moderately, without warming up and running, checked ironing, or clinker. Beautiful facial brick dry or semi-drying is not suitable unequivocal.

Building

Well, we will assume that the complex and responsible stage of the choice and rejection of the material by us passed. In the end, the cost of it is needed only time, knowledge and attention. Now - we build a bath! Here, too, there is nothing to pay attention to the usual construction workers. In general, the sequence of the construction of the bath is as follows:

- Foundation;

- Warming of the sample and drain equipment with drain;

- For frame bath - frame;

- For them, the technological break by 2-6 months. for shrinkage frame;

- Walls;

- For log and bar baths - cutting cut;

- For them, from air drying materials (non-philicated timber, wild and dyeing non-cylindered log) - technical operability for 6-18 months. for drying / shrinkage sruba;

- Opening, door, windows;

- Ceiling;

- Roof;

- Interior arrangement and, mainly - installation of the furnace.

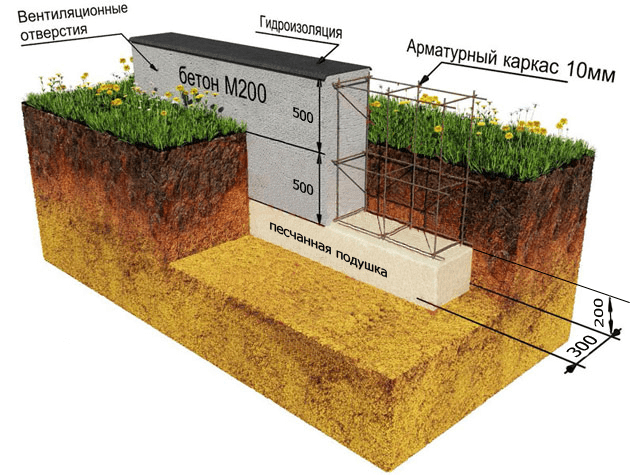

Foundation

In old days, the baths were put on an undelated foundation from boulders (pos. 1 in Fig.), It made it possible to reduce the processing of the logist's logs to a minimum. For this, something like a lounge or centers, in which round logs did not ride, were gained from wild stones. The corners were especially valued by large boulders with crossed natural hopes; These are the most cornerstones. The initial meaning of this term is now forgotten. The currency foundation under the bath can also be laid in our days, but, alas, the wild stone is now far from throwing material.

Note: Do not be surprised to mention the cornerstone in the Bible and the Gospel. Now, almost brass lender was then rich in an excellent cedar tree. He was enough for construction, and fleets. The palace of King Solomon from what was built? "Thanks" the high value of the Lebanese cedar, it is now almost left.

The full replacement of the wound - undelated or low-profile, pos. 2. The first is suitable for any wooden bath, and the second is under foam block. By complexity and complexity, the commissioning of the newcomers is available, and at the price - the family budget below average. The lack of one: not suitable on unreliable soils. These include:

- Medium-digitally closer to the rapid and highly fucked (hearing over 6-7% by volume) - small dustless squeeses, dense loams, chubby clay, etc.

- Celebrating categories of category, over 5% by volume - loose lesid and clay.

- Weak, with a carrying capacity of less than 1.7 kg / kV. CM - humus, or color, peat, loose sandy.

In places with a consistently positive winter and low probability of flock freezing, a great, simple and cheapest, option of the foundation under a wooden bath - the columns undelated from the finished blocks of 200x200x400, pos. 3. A conscientious and attentive office citizen, holding to build, can lay it out for the weekend.

At the slope, which is very good for the drain device, and on unreliable soils, it is possible to put a bath on a column foundation from asbetic pipes, pos. 4. Under the wooden structure, it is approximately equal to the ribbon under cost and complexity. The insulation of the sample in places with frosty winter increases the other slightly. Under the box of foam blocks or bricks, the pillars headcils will have to be tied by randbalkas or painters, pos. 5, this is a rather complicated and expensive process, especially the overlay of the Turks. However, for the bath, most often you can doly do the randbalkas.

Finally, pile-painted foundation, pos. 6. It can be both metal welded, both in Fig. And concrete on boronobiling piles. It is quite difficult and expensive, and special equipment requires a high-quality metal pile foundation.

Pile foundations are laying under the buildings on the soils, as they say, no: or flowing, peat, weak strongly flooded; In general, "on the swamp." The bath on rotten wets do not put, but the clarification of the pile foundation is justified in special cases.

For example, the author had a chance to shake in a poorest bath on the Rutaire over the river. A staircase was played over the pool, a staircase was right into the water. From the bottom there they beat the keys - in summer, the water is ice, and in the winter she held a hollow. Feelings - unspeakable, if the paradise crashes, it is not different. But it is possible to build in such a place only on the piles, otherwise in a year or two, the earth will crawl, and the bath only bouffrencies or float, shaking. Here for such exclusive and the pile foundation under the bath is designed.

Insulation and label under the walls

Before the construction of any bath for any foundation, except for the boulder, you need to apply double waterproofing from bitumen and runnerdoor, see fig. It is superimposed after a set of the foundation of strength, except for metal welds.

If a wooden bath on a ribbon foundation is built, then before laying the 1st crown of the cut or the lower belt of the frame on the tape on isolation, the rails of 30x30 mm or 40x40 mm are laid out, as shown in Fig. left; With high-quality sawn timber, you can do the tolstoy, from 10 mm, gaze. The appointment of this crate is to prevent the tree dropping from under the bottom due to the capillary winding. The remaining gap then canopate together with the walls.

Note: In any case, no anchor bolts, etc. It is not necessary to attach walls to the foundation. With thermal shoe, which is experiencing the structure of the bath, the benefits of them, besides harm, will not.

Paul and Stock

The floor and the ball are inextricably linked and therefore are considered together. Together they constitute the most complex and responsible constructive node of the bath, in many respects defining its operational and sanitary and hygienic qualities.

In the old baths, the stock was right on the soil through a slit floor. Now dropping any designers on the surface of the soil is prohibited, but the shielding floor of the steam / washer is quite appropriate, see below.

The flow from the bath can be organized scattered through the entire surface of the floor, or point (concentrated) through the grille (ladder) in the floor. The first, as we will see below, more difficult, but much more hygienic. The point stock makes most often if the drain pit is under the floor. This saves the place and volume of earthworks, but sanitation with hygiene - by 3 with a minus. In addition, the drain holes that do not require cleaning and pumping, does not happen, and in this case it will take the floor for the plumbrend. Additional minus - due to the infiltration of wastewater directly under the building, the bath is sooner or later "will behave."

As an argument in favor of the pit under the floor often lead - they say, will not freeze. A, sorry, what are you hanging off your bath all winter? If you are on your pocket, then what then samostroy? Order a turnkey bath and worry. Unfortunately, add "on health" there is no reason, once a pit under the floor. The way to protect any waste hole from freezing is known for a long time: it is a wooden cover at 30-40 cm under the revision hatch. The flow from the bath is warm and under the double lid will have time to absorb soil before it will get the most bodied frost.

Note: Sometimes they say, they say, on the pit under the bath you need to put a gas cover. Clean water curiously in the spirit of black humor - any sealished waste pit sometimes be exploded as a poorly sterilized bank with home preservation. In the bath - mainly during the wash, because The thermal impetus for the protrusion will play the role of the initiator.

The device of multiple flow from the bath is clear from the pos. 1 Fig. Extremely desirable concrete drain to equip homemade hydraulic, pos. 2, this will ensure the compliance of the bath with the most stringent sanitation. Concrete on the screed take waterproof; When independently, a water-polymeric emulsion is added to the water at the rate of 200 ml per 10 liter, and the freckled and the durability of the screed is treated with bitumen mastics. It is necessary to do it in the warm season, and in front of the flooring of the floor to give technical versions for 5-7 days.

The bath must have a separate drain pit. The flow from the bath is large for the house sewage and volley, but much cleaner of the kitchen gray, not to mention the fecal out, and contains a bit of fat. If you run the bathing stock into the general correctly calculated and constructed, it will choose, and the active bacteria will die in it. If you build a big and expensive septic tank in the calculation of the volley reset, then the usual flow of bacteria is not enough for food, active Il will scatter, and the sewage will stop working again. The drain pit is digging at the rate of 50-100 l per washing at least 30 cm. Below is the estimated (regulatory) depth of freezing, subject to the maintenance in the mainland (under the fertile layer) the soil is not less than 1.2 m. In most regions RF These Conditions are maintained with drainage by 1.6-1.8 m.

The simplest and cheap drain pit is obtained from automotive tires in the clay castle, pos. 3. But in its side pockets will inevitably be seeded, and to disinfect such a pit will have much more often. Having in mind future expenses for antiseptics, cleaning and pumping, it is more profitable to buy a pair (60-70) -cm concrete or plastic rings for wells. These are the smallest and cheapest well rings. Their height is standard - 90 cm; 2 pieces just enough. When the diameter of the on 0.7 m, the volume of the pits turns out to be sufficient for 5-6 washes.

Suddenly, the pit is still under the floor (maybe on the site just there is no place for external), then the bath can be used no more than once a week. In this case, the drain is cheaper. There will be a spot, and its complex and expensive concrete catcher under the floor can be replaced with a tipped low wooden tent. Then around the mouth of the pit it is necessary to impose high-quality waterproofing with a removal of a waste grille of at least 0.5 m, pos. 4. However, this is also a bad way out: water under insulation will still be leaving, and what the biocenosis will work out there, it is better not to think about it. At least before meals.

Floor

The floor of the bath should provide, firstly, the fast and full flow of water, without posting. Secondly, give sufficient insulation and guarantee from drafts from below, provided that it is impossible to score with thermal insulation, it will have to be limited to a refining with a clay. For this floor baths make floating, pos. 1 in fig., I.e. Not connected hard with the building structure. Floor Paul by lags; Their ends in the log wall are injected into the cutouts of the lower crown, pos. 2. In the brusade bath, the ends of the lag are associated with the cross, so that it is a solid lattice, and in the frame, as in the frame house, lagows of the floor together in the lower belt form the main carrier frame.

Step Lag - 40-60 cm. Their height is 100-120 mm for span up to 4 m and 150 mm for a span of 4-5 m. With a larger span, it is necessary to provide intermediate pillars in the foundation or internal parts of the tape. Lag thickness take approximately 1/50 from the length of the span, i.e. 60 mm for 3 m, 80 mm for 4 m, etc.

In the gaps between the lags are stacked with a slop with a convex side. Because The boards of the hill are narrowed to one end, they are placed alternately with a narrow end, then in the other side. Between the boards leave the gaps from 5 mm, the same pos. 2 in fig. Such a design does not interfere with the drain, to some extent improves the thermal insulation, and together with the hubbles laid by hrybille, it protects against drafts.

On the lags and draft flooring from the porridge is very and very desirable to take a pine-fruit. To reduce the cost of Paul Lagi, it is possible to make their 3-kantic timber or a seashed sleeper spreading along the sun. But then they will have to be submitted from the side of the ozol so that the basis for the purity floor was even and horizontal.

The finishing floor with a scattered drain is laid out of the usual puzzle of the pure-cutting board, preferably - grinding, thickness from 40 mm. Substitution, again, will cost more difficulty: you can take a plank-resin unstored and unedged, "bring to mind" on the cironary and fugoval machine (very convenient for this old Soviet Desktop UDDS-1 and the like), and put in the flooring Opel residues down. Pure floor flooring with gaps between boards about 5 mm, for water drain.

To send the floor with a point drain, first between the lags above the pit or the hydraulic, they put the board from larch or resin with a waste grille. Fill the floor without cracks, with a neckline above the grille, pos. 3 and 4. The board should be taken not tipped, but with a castle quarter, pos. 5. After a gear shrink, the joints of the boards are poured with liquid nails or rub the waterproof wood with a waterproof.

With all the high costs, difficulties and labor intensity, this is far from the optimal option. On pos. 4 It can be seen that, judging by the general state of the floor and the lattice, the bath is still new, but the floor under the bench is already clarified. Apparently, the hostility of the builders to the scattered drain through the shavy floor is explained by prejudice and incomplete knowledge of the history of the Russian bath.

Walls and logs

The log cabin looks, is definitely chic, see fig. But we will not linger on them for a long time: these buildings are actually not for beginners. In any case, to build the simplest bathhouse, you will need to master 2 difficult technologies - a womb of logs with an oiled with the residue, pos. And in fig., And with a paw without a residue, pos. Bd The latter, by the way, is technologically simpler, but requires calibrated logs, because The proportions of the marking template (pos. d) are tied to the side of the square, inscribed in the log diameter, pos. G. In any case, the bottom logs of the first crown must be very accurate and smoothly pose, because Current foundation that can be adjusted under the logs is now unreal.

Note: Wide in the oiled and in a simple bowl (see Fig. Right) often consider the same operating operation because Configuration ready for laying in log cabin is the same. In fact, when writing in the bowl of the batch and the grooves turn out to be drawn up, which is unacceptable for the bath. When writing in the region, the fitted logs are transferred to a coup with a coup, it complicates and slows down a log assembly on the foundation.

From Bruus

Build a bath from a bar newcomer is already quite possible: curvilinear grooves and wells in the tree do not need to choose. It is enough to be able to handle the saw, hammer, bits and ax. For the construction of a small, up to 4x5 m, the bath, you need to master only 3, or only one, an easy operation: Wide in Poledev or in the hid with the residue or a wrist without a residue in the paw (in the end); Marked in Fig. "!".

A bar will go to the bath from 100x100 to 250x250 mm. The thicker, naturally, better and more expensive. In general, the "weaving" is enough south of Voronezh, 150x150 for the Moscow region, and the 200x200 - north of St. Pesleburg. At 1-3 lower crowns, you need to take a bar for size more, and again, it is extremely desirable, a fruit.

Actually, the process of assembling the brusade cut without a residue from a non-core pure-cut bar (the simplest and cheaper) wrist in the end is shown on the trail. Fig. First, on the template prepare the ends of the closed in the size of Bruusyev, pos. 1. If instead of the bar there is a conditioned for a bath (see above) a semi-rubber sleeper (pos. 1a), then you can get almost complete imitation of the log cabin.

When assembling a log, you need to prevent lateral displacement of the BRUSEV. The log house holds the lunar grooves, but for smooth bars in the corners not enough. Here are 2 options. First, pos. 2 - simple, but not the best, because Nails in Siruba are powered. The log house is brought immediately tightly, and a caul-ribbon tape (see below) impose immediately. The location and length of nails are the same as brazed in the next. variant. Nails are needed secret, with a fully blended cap, or a special tool - Dobochnik to the hammer; It looks like a locksmith cerner with a wedding end.

In the 2nd way, pos. 3, the bars fasten with round deaf ducts - brazen. Calibrated brazening is on sale, take better oak. The conjunction of the crowns by nakedness is done like this:

- The next crown is stacked next.

- The drill holes exactly along the diameter of the brazers through the upper bar on the floor height of the lower.

- Remove the upper crown.

- Putting a caul-ribbon.

- Insert brazening, sticking to puncture over the nests for them.

- Again, now we are again, put the upper crown, putting it on begging.

- The procedure is repeated until complete grazing assembly; Begroen are located in a checker order, see again pos. 3.

Note: When spanging up to 6 m, the bars fasten enough in the corners, as shown in Fig.

And if the bar is profiled?

One of the reasons why the profile timber was invented is the desire to get rid of a rather time consuming and requiring additional costs of fastening. However, to the bath, this consideration is not applicable: the profiles that hold one of the "iron" friend, do not fit for the bath. And those who will not "catch" condensate, bath temperature deformations will soon break the ridges. Therefore, the log house from the profiled bar is still needed to fasten.

Konopka

Log and brusade log cabins are caught. For the logs, there will be thorough skills of hobble work and a complete set of boil tools, see Fig.

Bar canopate easier: need a steel cavity curve - leboz, wooden straight narrow and molding, see fig. below. The bathhouse canopate with both ways shown there: when assembling a log, they lay the rotor to puncture a cornea for a cavropka, and at its end it is finally in the set.

Note: The Lebes is designed to pushing caracks between the logs. From her name there is a "timber" in the sense to rub in trust, rebel with the rear thoughts on the mind, in general, under the skin to climb. If you can drink jut (see below), and the log cabin, the Lebes is not needed.

It is impossible to do without cacopata with waterproofing, at least the most modern one, it is impossible: it is impossible to pungent just compacts the seams, but "comes out" with a tree into a single array and finally fastens a log house. Synthetics capable of replacing it until not.

In the old days, it was caught in a stretching moss, and in a set - washed or mounted linen pacular harness. Now most of all canopate with jute fiber, it is almost wood in the composition and content of lignin. Jutene can be better taken in the form of a set of ribbon and cord, see fig. Ribbon ribbon, under the arrogant it is easy to pierce your finger. Put the tape when assembling a log cabin, and it is not necessary to warm it, on the assembly of the log house immediately finished the cord in the set.

So that the log house did not believe, cavalidate strictly in the following sequence: the deaf long side of the lower crown inside, then outside, then the same opposite. Then - the short sides of the lower crown starting with the one where there are no openings, also first from the inside, then outside. In the same sequence, the rest of the wands are strictly in turn from the bottom up.

Outcome on Brus and Brevel

The rolling chamber of chamber drying can be considered a type of profiled timber. Bath of it and profarboys also can also use the chamber drying at once in the construction, because Solution and shrinkage these materials were under the processing process; This is the undoubted dignity of the "chamber" wood. The cost of 1 square. A bathroom of these materials in most regions of the Russian Federation exceeds the cost of the square of the living space in the new buildings of the middle class.

The most expensive, complex and time-consuming, but also the most prestigious, will be a bathhouse. Its bath qualities correspond to such a traditional Russian bath. According to the "steepness" and the cost is almost equivalent to the timber bath, but it is technologically easier for it and can be delivered by the builder-lover of secondary qualifications. By the quality of the pair, the brusal bath can be made almost indistinguishable from the log.

The use of the chamber profar for the construction of a bath can be justified if there is no possibility to reject the air drying material or raw pieces, for example, in the regions where there are no own logging and sales traders refuse to sell ordinary sawn timber selectively. Otherwise, it is possible that applying semi-finished products of business wood, put the bar of the bath, and on the view almost indistinguishable from the log.

In general, log or timber bath can be recommended to put those who are sufficient enough Watching his health, keeps the physical form, and has already built at least a country house or a barn. If you are not sure that the condual and the more important steam room will benefit you, it is better to build some of the lung baths described below. The same option is shown in case of lack of means and construction experience: light baths are easy and inexpensive, and their steam will not hurt anyone.

Techniques

After the assembly and cavinc canopate, it is temporarily sewn with boards, plywood, cardboard, etc., and covered with a film. Film is fixed in any way so as not to the wind. Cube leaves to dry and sit down at least six months; Best of all - from spring or early summer until the fall of next year. During this time, the tree will not only die and swell, but also will be convicted with the pantry.

Operactions, doors, windows

The methods of the device of door and window openings in the bars are used mainly 2. 1st, pos. 1 and 2 in Fig., "For lazy and uneconomic": In the size of the width of the opening, only 1 top of its timber is selected, and after processer, the opening is simply peaked. However, this method is not so wasteful: trimming can go on a shield ceiling (see below) and certainly - on the interior equipment of the baths, pollutes, etc. and lazy in this way it will not be particularly not possible: to avoid a sudden "game" when drinking intense After the shrinkage of the cut, the edge of the future opening is needed when assembling a log, backing the corners.

In the 2nd way, pos. 3, the bars in the size are cut in advance, and in the emerging in the opening their ends is chosen. The disadvantage of this method is needed special boxes of doors and windows, whereas in the first way they will go simple frames from the boards. In general, the "first" opening is better to do when the appearance of a big value does not have a lot, and "secondly" - when you want to "more abruptly".

Note: From the Brochi-Budget Class Bat, definitely the best. Therefore, we give in addition to the video about the details of the arrangement of the Bruce Bath:

Video: Bath construction from timber, proper device

Frame

The frame of the bath is built as. Immediately after assembling the frame, there are rafting beams, and the frame of its own roof will dry, in the center in Fig. Since the openwork is purged by all winds, drying equipment / shrink needed minimal. Typically, the frame is collected in the spring, the same autumn will be completing the bath and still so far soaring.

The second feature - the finishing floor is filling along with the walls of the walls outside, on the right in fig., In the usual sequence from the bottom up, i.e. Starting from the floor. Warming the walls outside, as they sometimes advise, do not need. In decorative purposes, there is enough of something like a siding covering, without laying foam in the cell of the crate. It is necessary that the walls are better to ventilate. But it is necessary to warm from the inside, it is thoroughly as in the foam block described below, excluding the underlying plaster.

A frame bath turns out to be the simplest and cheapest, even cheaper foam blocks. According to the "dustness" couple, this bath is only easy. However, it is very problematic in it in winter, north of Moscow is very problematic: well gives warmth, and warming measures used in skew houses make steam heavy. In general, skeleton bath - Typical summer day of the day off; Especially well serves as a country bath combined with Hozblock.

Note: There are no restrictions on the outer covering of the frame bath, therefore imitation under the bar, log and others are possible.

Foam block

Bath of foam blocks is the only view of a bath structure in our time, which allows you to put a light bath in any climate due to the high thermal insulating properties of the wall material. Baths from aerated concrete can also be considered the cheapest and simple technologically: their cost is lower than that of the brusade, by 25-30%, and even up to 50%, see below. The number of measurement and accurate fit operations during the construction of a foam unit is several times less than that of the frame, and the curvilinear surfaces are not required in the material.

It is also important that, with generally considerable costs of working time, physical effort when building a bath from foam blocks requires a little. You don't need to wave a saw and an ax, as a whole, the construction technique - I put it, put it, pinned. For unusual physical work, citizens this circumstance can be decisive. And for Dachnikov - the fact that the construction of the construction is needed minimal to curing the building solutions. The usual in the summer of the week is enough for this, and during the next weekend you can continue the construction site. Which, working on the weekends together, it is possible, starting in April, to complete by July and until the winter will still get across.

Foam concrete, from which foam blocks are made - the material is lightweight, it floats water. Therefore, on stable and well-bearing soils, the construction of a foam block can still be easier and reduced. In general, a belt foundation is recommended for a bath from foam blocks, pos. 1 in fig. But on reliable soils, it can be replaced by unlightened columnar from the finished concrete blocks, as for a frame bath, and the walls are erected on a frame from a bar from 200x200 to 300x300, impregnated with an antiseptic, a hydrophobizer and waterproofing, as a concrete tape.

However, the ease and, especially, the porosity of the aerated concrete is set to work when building; True, not heavy and simple. It is especially necessary to protect the walls from the winding from the inside and outside: reuses aerated concrete not something that is easy, but even with pleasure, but dried very hard and long. Therefore, running forward, immediately say that, covering the roof, the bath must be pulled by a ventilated facade with a gap of about 5 cm. For any other method of outer insulation / isolation, the drop point in the porous greedily absorbing moisture wall is inevitable.

Next, when erecting walls, pos. 2, on the usual cement-sandy solution only the first 2-3 rows, and then go to a special adhesive for aerated concrete, it looks like a conventional masonry solution. Here the ease of material is already playing a role: cement masonry seam, being weakly loaded, badly resist shift loads, and the wind can simply fill the structure.

The most features relate to internal isolation. It is made with this order:

- Waterproof plaster walls (lime; water-polymer emulsion is added to the water for the solution);

- According to the fully dried plaster, paint water-repellent paint, better than polymer facade, as a last resort - iron umbrellas, zinc or titanium herbs;

- In the dried paint, waterproofing with an allen from 15 cm, fastening it with horizontal slats;

- Between the rails, mats are placed from long-fiber minvati, pos. 3;

- The mineral insulation is coated with a rolled follicate with a glass of 2 sides, also long-fiber, pos. 4 and 4a, with an overlap from 25 cm;

- On foil isolation, vertical rails are stuffed and an internal trim is already conducted;

- Upon completion of the finishes and installation of doors / windows, all the cracks are carefully fought, pos. 5: Foam concrete all the same, where to clutch, moisture in it spreads instantly. Breakdown from the steam room in the pre-banner cloud can destroy the bath.

And once again, running forward, but already slightly: due to the features of the construction visible to pos. 1, the ceiling in the bath from foam blocks make only the tail.

Ceiling

The ceiling of the bath is made of flooring, inner or shield. The first is an inequate ceiling of the Russian bathhouse of a small size. For its device, the established log houses are used on top of the boards, it canopate the slits moss into a set of the attic and poured with a resin. Then impose terropyl beams (see below, about the roof) and the gaps between them fall asleep peat; Sometimes the entire ceiling will be shown before falling down. Paul attic that whether they fill, or not. Now, of course, it is better to hide the jute, before installing the beams, coat the coat of waterproofing, and insulate the long-fiber mining.

Figure ceiling, see fig., Suitable for any bath, because It is stronger - ceiling beams at the same time and rafter, besides, they are mechanically connected with a firebone / structure. The shield ceiling is a combination of a fastener with stitched: on the ground they collect shield with insulation and insulation, and then the whole gurb is pushing, or a crane, or a mini-excavator manipulator, laid it on a log house. The shield ceiling is good because it can be "blind" from cropping, but is suitable for a brusade bath with a size of up to 4x5 m.

Roof

The roof for any of the bands described is suitable. Stropil farms are simple triangles with one rigle-golk, in the center in Fig.:

Fronttones are sewn by boards; Be sure to need auditory windows opened for the summer and at the time of use + hour and a half after it in winter. For the brusade bath, hanging rafters are suitable, on the left in fig. For the rest - a full farm with a beam-tie, right there. The lattice under the roof flooring is sparse, with slits from 30 mm, for ventilation. The most flooring is any except iron, it does not keep warm and quickly rust at the bath.

Arrangement

To finishing materials for the bath requirements, except decorative - moisture resistance, hygienicity, complete chemical neutrality. According to their aggregate, wooden lining from the array is often taken. MDF and laminate are not suitable, will be swollen and risked! The profile of the lining at any orientation of the boards must comply with the requirements described above: no pockets facing up, for example, as in Fig. on right.

In the pair, naturally, we need polluts. They are made by 2-3 tousing, with a vertical step 50-60 cm, even if only one person is batted all the time. Cause - You need the ability to choose the height of the location when carefully looking at a general state so that the bathhouse does not come out.

Poland width - 60-80 cm; The flooring is necessarily with the slits of 10-20 mm, on the left in Fig. Clean floor under the reservation do not fit, will eat! The length of the climb takes 180-200 cm for a sacking in a lying or 80-100 cm for a guy sitting. "Economical" cavities in 150 cm for a walker, crouching the knees - the option is not from the best. Raise the knees when sailing in the bed sometimes you want and need, but if all the time so steam, health will not benefit due to the constant outflow of blood from the legs to the heart and head.

The decoration of the shower / washer is better made from the boards, on the right in fig. So less likely to drop - water from the grooves it is easier to flock. Also in the washing, there are or peeled out of the gang, you need benches - sit, sprinkling, go to go, do not risk slipping, for children.

About partitions

Capital partitions are not needed in the bath. On the contrary, they need to be easier to be taken to make the heat of the furnace soon dispelled throughout the bath. Partitions put in front insulation, insulation and trim. Material - boards or wooden lining on the wooden frame; The total thickness is 50-70 mm. Moisture-resistant plasterboard, plywood, etc. Do not go, in the bath for a long time will not last.

Bake

The requirement is common to all bath furnaces - the elongated channel of the furnace so that the flue door can be derived to the pre-banner. Tradition tradition, but in the old days, they are most often as in the baths: the susceptibility of a person to the carbon monoxide grows sharply with an increase in air temperature.

For a bath with a common steam-washer, an inexpensive bath oven without a air convector, like "heat" and its homemade copies. A bourgeitarian for a bath with a water was also going - in the smallest pair you can provide the length of the horizontal part of the chimney from 2 m, which will make the burzhuyk economical.

To withstand in a small bath required by PB the distance of the furnace from the walls of 60 cm is unrealistic, and special fireproof, as in a steam room at before. Fig., It is very expensive. Therefore, the furnace for an oven in the bath is needed, first, to stroke a vermiculite or mineral cardboard, pos. 1 in fig. on right. An ordinary refractory litter from asbestos and a steel sheet for a bath is not suitable - about heated to 60-70 degrees of iron can be strongly burning, stepped up, because The severity of the burn depends on the amount of thermal energy that passed into the body, and the metal is good and quickly gives heat. Therefore, by the way, the ferry burns are so dangerous - there is a very large hidden heat of condensation of water.

Secondly, the walls in the furnace need to be covered with refractory trim. On the same pos. 1 Builders did not shake on a chammed brick for her. In physics - excellent, but, constantly moisturized, the shaft will soon turn around, and the trim will have to change. The same high-hearted (dark) ceramic worker brick, which went to the top of the trim, would be used to the Niza himself.

A little more about the form of a bath furnace. In the collective pair, it is best to put the oven round, pos. 2 on the same rice, or a stove-basket with a fiber part, hidden in Kamenka. Then all soaming will receive equal stakes of health.

Unusual difference

The root of the Russian baths - the dust bath, see fig. For its construction, dry sandy (better), sandy or loamy cloth needed. Walls, oven, chimney - from boulders or large boot; The roof lies with the turf. On the earthen floor they put a wooden lattice-slan, which then leans to the wall so as not to start. Stoke in the ground that in our time it is possible only by the sneaking, but Par - Ilya Muromets only woven and woven.

But even something else - a hiking mini-bath, see the next. Fig.

The design on the same principle repeat many, and in mobile, and in a stationary version, see at least a video:

Video: Mini Bath

But we take a look at Fig. Is there a construction on ...? If you take a milk, not translucent? Is that the owners are inclined to exhibitionism, and then the neighbors are pressed. In general, at the cottage to try.

Not everyone has a desire and the ability to invest a lot of money in the construction of a bath. And for the most part of our country, it is sometimes necessary to warm up, just necessary. The only way out is to build a bathhouse inexpensively, with your own hands. There is a sufficient number of building materials and technologies that can be called budget.

If we talk about the erection of full, though small, but separate baths, then the budget technologies are considered frame and monolithic. Cheap baths are more often on a wooden frame, we are plywood, osp, boards - who has something. Inside, a heater is laid between two trimbs.

One of the framework options - with a plaster

When monolithic construction, the arbolit is the most popular to build a mixture of cement with sawdust. Sawdust can be generally a gift or cost very little. The cement in the arbolit requires little, so this type of construction in the pocket is unlikely to hit greatly. A removable formwork is installed around the perimeter, the mixture is loaded into it, tram. The next game is mixed. That's so simple. The disadvantage of this material is to be combustible, but the wooden and skew baths are also combustible. So this is not an argument.

Opolk concrete or arbolit - warm, natural material, which consists of sawdust, sand, cement and water

Opolk concrete or arbolit - warm, natural material, which consists of sawdust, sand, cement and water The polystyrene polybetone is most expensive (granulated foam in a mixture with cement and water), but not everyone likes the use of "chemistry" - foam - when building a bath. However, this material itself allows you to get cheap and easy building, which, with the right finish, will only please the owners.

All three technologies give a combination of low prices and good heat engineering characteristics, that is, for heating such buildings, some fuel needed, which in the baths - the main performance indicator.

There are regions in which the forest is still the cheapest material. They may be cheaper than all will put a chopped bath. From the roundabout or from the bar is already at will. Plus this solution is a natural material (although it should be soaked in chemistry to preserve the appearance and protect against disease and insects). But the chopped baths have their own minuses - you can start steaming no earlier than a year after the construction of the walls and installation of the roof. We must wait until the main shrinkage goes and only then begin insulation and finishing work. The second minus - it is necessary to regularly update the protective coating, otherwise the construction will become gray and unsightly. But the wooden baths themselves are very good with a special atmosphere.

Inexpensive foundations

Inexpensive technology of the construction of walls is not all. Sometimes the construction of the foundation is almost half of the funds required for the construction of the building as a whole. The technology listed above is good because they can do lightweight foundations. Somewhere quite columnar, somewhere pile or pile-screened. Any of the above walls can well coexist with them, leveling their disadvantages (the possible uneven shrinkage of different points of support).

The foundations listed above can be implemented not on all soils. Sometimes there may be a ribbon foundation of small or normal downstream, and a monolithic plate may need to be needed on particularly bunched or unstable soils. On such grounds, it is possible to add more construction blocks on the above technologies of the walls - foam concrete, slagoblock, ceramzite concrete. All of them have their own characteristics (mainly a thorough protection against high humidity is required), but the construction technology is also inexpensive, although the foundations are already required more solid.

Compact or temporary

If you want to build a mini-bath at the cottage, a cabinet is completely small, then you need to look at the construction technology or. If there is a desire, even the usual construction trailer, barn or cabins can be turned into a more or less normal steam room. It is only important to inspire and put the right oven. Everything else is not so important.

Cheap skeleton bath stages - photo report

The initial data are as follows: the bath is not more than 4 * 5 meters, a small budget - no more than $ 200-300 per month. From the source data - clay pumped ground, 4 meters from the fence - a break. Without all this, it was decided to build a skeleton bath on a column foundation.

The bath itself turned out 5 * 3 m, plus along the long side of the terrace of 1 meter width. Under the pool of the poles, it was decided to make 34 cm from asbestos-cement pipes in diameter, under the terrace of 15 cm. In the center of the plan, another 4 additional pillar was marked - this is a foundation for a brick furnace.

Crave below the drainage depth - for a given region 140 cm. Pipes, by the way, cut more by 20 cm - the total length is 160 cm so that 20 cm the bath was above the ground.

Inside each pillar, a frame of 12 mm reinforcement is installed in diameter. 4 rods are connected, release from the pillar - by 10-15 cm so that you can quietly welcome the strapping.

Concrete was ordered ready, Mark M250. On the perimeter between the colums, the formwork was put up and the boot was immediately poured, which will close the gap between the floor of the bath and the ground.

After a week, concrete scored quite strength, continued work. From the corner of 70 * 70 mm with a wall thickness of 6 mm, the blockage was welded (the corner was in the economy). To tie pillars and metal, weld the reinforcement of reinforcement to the corner shelves.

Immediately I must say that this foundation is excessive on the bearing ability. You can build a two-story heavy building, and not a light one-storey skeleton. But, since they did "for themselves", and there is also a clay breakdown nearby, it was decided to reinstate.

In the washing and rest room, it was decided to make warm floors - sometimes you just need to wash, without a guy, and it is much more pleasant to do it on the warm floor.

Therefore, the insulation (polystyrene foam) is laid on the draft floor, the waterproofing, the reinforcing grid, the pipes are tied to it and all this household is filled with concrete. Under the furnace, naturally, the warm floor was not poured.

A week later, when concrete scored enough strength (not sheltered, but regularly irrigated), work began on the construction of a carcass. For the racks used the ram 150 * 150 mm, the struts - a board 50 * 150 mm (again a solid stock for strength, but this is from the desire to build a good bath).

A bath was built mostly alone, therefore a sequential installation method was selected - the racks are installed first at the corners, then - in those places where the door window will be installed or adjust the simpleness. If as a result of somewhere there are more spaces than 1 meter, additional racks are put. But in this case, since all the racks were made of a very powerful timber, the intermediates were not put, and the stiffness of the design was given by hide.

Next, so that when flooring the floor, it is not drowned, started making the roof of the bath. It is made the fastest - single-sided, with a minimum lift - 15 °. To ensure this slope, the rack for racks was made in advance of different lengths.

On one level, the board of the upper strapping is nailed, the ceiling beams are attached to it. The same racks are attached rafters with the required slope. From above, a solid doomle under roofing material is stuffed.

Single Single Roof System is very easy to manufacture

Single Single Roof System is very easy to manufacture After the roof is ready, the walls were shed, and then the floor was used on the rest of the bath.

The next step is the masonry of the furnace. This business is long - left a whole month. The furnace is composed with a closed heater. In the formation zone of the chimney, a cast-iron box is built into which stones are stacked. The door leads the door, which goes to the steam room.

Also in the furnace there is a built-in register, which warms the water for a warm floor (exits on the side of the furnace). It is not always necessary to warm the floor, therefore there are two modes of operation - summer without heating of the floor, and winter, with the "inclusion" of the register heating. Translation from one mode to another - with the assignment.

Then follow the finishing works, and they will be different in various cases. The only thing that will be more general is insulation. With the insulation of the walls and the ceiling used mineral wool. The thickness of the layer on the walls in the "cold rooms" is 100 mm, in the steam room and the ceiling - 150 mm. The steamer over the insulation is still covered with a foil on kraft paper.

After insulation, vaporizolation is attached. In the living room, the walls are covered with an OSP, a plug is pasted on top. In the shower on the osp, the tile is pasted, the "dry" part is crumpled by clapboard (horizontally).

Washing - dry zone and shower

Washing - dry zone and shower In the steam room, first the lamp under the trunk trim, then wide lining. The steamer turned out quite small, also the stove takes a lot of space. Two are placed with comfort, three is already more complicated, but it is also quite convenient. To regulate the number of! Sexual places in the steam room, the shelves made the retractable.

The whole construction process took two years, the work was carried out mainly "in one hands." The assistants were only at the stage of fillings of the foundation, and then at the stage of installation of the frame - to set the racks (should stand 100% vertically).

Video example of construction Baths from monolithic arbolit

Inexpensive bath 3 * 6 do it yourself - step-by-step photos

The log for the future bath is harvested and the skyrin in advance, covered from the rains it was dried about 5 months. The structure will consist of two halves: the steam room and the car wash is composed of a log, and a rest room on a wooden frame. It turns out two rooms 3 * 3 m. Construction began with markup: in terms of 6 * 3.

Sandy soil, therefore we make a small breed. ROOM trench depth of 60 cm, exhibit a formwork. The ribbon width is taken with a good stock - 35 cm.

We make the doors - from the frame, on which, on the one hand, OSP is packed, on the other - the lining. About how to make

In this form, we leave to winter - the log house should "sit down". In the spring, we warm the framework of the construction, we are tightening the insulation of a vaporizolation membrane.

We proceed to the ceiling finish. It was decided to make the bidder of the ceiling - to fill short boards between the rafters. You can buy them quite inexpensively. We proceed, cut the desired length. Rock up the supporting bars, which are cut into the size of the board below.

Outside, Yuan was sidding - and a frame side, and a log house. It turned out far from perfect. And between siding and wall there is a ventzor, so there is no problems with the elimination of moisture.

Budget Bath with your own hands - one more inexpensive solution - siding

Budget Bath with your own hands - one more inexpensive solution - siding We started the trimming of interior. Put the crate, on it lining.

Inside the rest room was chosen by clapboard

Inside the rest room was chosen by clapboard Go to the finish of the steam. At first, overtook all the foil. The room itself will consist of a zone of the steam room separated by a glass door, and the "washing" zone. In the washing wall, we share moisture-resistant plasterboard, which then glue the tile, and in the steam room.

Zone Parling We are wearing lining and

Zone Parling We are wearing lining and In the wall cut out the opening of the furnace. It will be treated from the rest room, and the "body" will be in the steam room. Under the furnace put the brick base, install it. Fuel removal we look with chamoten brick.

Separate a tile washing.

According to the main works, everything remained decor and all sorts of things - buckets, buckets, thermometers and the rest of the "filling.

For a Russian man, a bath is not a luxury, but a vital necessity. Even historians are convinced that the love for a bath broom and good heat we have literally in the blood, and even in the poorest villages near the smoked dilapidations, new pairs (old burned) were regularly built every five years. And Peter I, during a trip to France, could not stand without a native couple and two days, urgently ordered to build a Russian bath right on the shore of a foreign river than a very shocked natives. But what to do if it is so expensive today, and public pairs are not all soul? And if rest in the steam room is not just useful procedures, but also valuable communication with friends, kebabs and the opportunity to breathe fresh air? Then we will learn the cunning tricks of modern Russian masters who manage to build their pairs literally for vacation.

So let's consider the most successful projects of building a bath and their embodiment, where the main task was to save as much as possible, but at the same time not to lose the comfort of bath procedures. After all, as they say, the budgetary bath is a vestibule of a summer suburban train.

What can and cannot be saved when building a bath?

Agree, no savings are worth losing health, property or life. But the saddest situations occur when the question is suitable for cheapness, it is immenticated: such baths first slowly etch their owners the release of hazardous substances, and then either burn, or quickly deteriorate. But this does not mean that it is better to lower your hands to give all the blood on the conscience of a construction team - it is better to refuse to refuse dangerous use from the very beginning:

- Unattended materials and fakes for which unscrupulous sellers are assessed at times less. And at the same time, they convince the buyer that "there is no difference with expensive material, there is simply no cheating for the brand, my brother / matchmaker / son-in-law is already half a century worth it, and nothing."

- Materials are categorically not intended for construction and trim. So, if it is impossible to insulate the walls in the sauna, it is impossible, and this is not a whim of the manufacturer. Again, a neighbor, which at his own fear and risk insulated in this way and now boasts - not an example.

- Unsuitable components for electricity in a bath (wires, sockets), unprotected lamps or cheap Chinese products.

- Homemade furnaces and water heaters, which no one checked for fire safety.

- Combustible materials and those that are not indicated that they can be used in conditions of high humidity and heat.

If you build a bath with your own hands and are forced to save the materials as much as much as possible, try well every step, advise with experts and leave nothing without attention "seems to work." And finally, save with a limited budget better on the cubic meters of steam room, but not on the materials of its finishes. Such a board.

Let's figure out a little with affordable insulation. So, basalt cotton wool makes stone (basalt). Its main advantage is that the fibers inside the insulation are not connected by a chemical method, and another technology, and therefore, hazardous substances will not be released to the steam in the steam room. This insulation is not a fuel and well isolates the furnace. For a bath - the best option. If you want to save, then on the ceiling, put one layer of basalt wool and a couple of the layers of another, cheaper material.

Used as an economical version also foam-porous propylene with polyethylene film and foil spraying. You can buy it in a roller form, and secure immediately on a bare wall. This material is a good bridge of heat between the wall itself and insulation.

- The furnace is purchased without remote furnaces - so on the heating of the wage will leave much less than firewood, and there is such an assembly inexpensive.

- For sure to install the water tank is the fastest and most economical way.

- Foundation for a bath Make a cheap removable: it is much cheaper and easier to carry out repair work and change to another.

- Pay a maximum of attention to the insulation of the bath - the less you will "warm the street", the more economically the heating itself will be.

- On the window in the living room in the winter, cover the packaging film with bubbles - this is at least 50% will retain heat.

- Instead of an ordinary soul or shower, put the traditional Russian ears. And it is more useful for health, by the way. And it is not necessary to pour only icy water at all.

- By purchasing the lining, take the brushes of short sizes - they are cheaper and look no way worse.

- The roof at the bathhouse build a low, no more ratio of width and height 1: 3. There will be much less materials on such a design, and the chimney will not need to be high too.

Project # 1 - Compact Bath at a minimum cost

So, step-by-step process: