Oil pipeline security zone snip. Regulations

BUILDING REGULATIONS

MAIN PIPELINES

SNiP 2.05.06-85*

Moscow 1997

DEVELOPED BY VNIIST Ministry of Oil and Gas Construction (candidate of technical sciences) - topic leader, candidates technical. Sciences , engineer . L.A.Solovyova, candidates of technical Sciences , A.S. Bolotov, N.P. Glazov,) with participation of YuzhNIIGiprogaz ( And ), State Gas Supervision of the USSR R.G. Toropova), VNIIGaz Mingazprom (candidate of technical sciences) And 3. I. Nefedova), Hydraulic pipelines of the Ministry of Oil Industry (B. A. Alimov) and MINHIGP im. Ministry of Higher Education of the USSR (Doctor of Technical Sciences, Prof. L.G. Telegin).

INTRODUCED by the Ministry of Oil and Gas Construction.

PREPARED FOR APPROVAL BY Glavtekhnormirovanie Gosstroy USSR ().

PREPARED FOR REPUBLICATION by the Department of Technical Standardization of the Ministry of Construction of Russia ( )

SNiP 2.05.06-85* is a reissue of SNiP 2.05.06-85 with amendments No. 1, No. 2, approved by resolutions of the USSR State Construction Committee dated January 8, 1987 No. 1, dated 01.01.01 No. 61, and amendment No. 3, approved by the resolution of the Ministry of Construction of Russia dated 01.01.01 No. 18-78.

Items and tables to which changes have been made are marked in these building codes and regulations with an asterisk.

When using a regulatory document, you should take into account the approved changes to building codes and regulations and state standards published in the journal “Bulletin of Construction Equipment” of the USSR State Construction Committee and the information index “State Standards of the USSR” of the State Standard.

1. General Provisions

2. Classification and categories of main pipelines

3. Basic requirements for the pipeline route

4. Design requirements for pipelines

Placement of shut-off and other valves on pipelines

5. Underground pipeline laying

Laying pipelines in mountain conditions

Laying pipelines in mining areas

Laying pipelines in seismic areas

Laying pipelines in permafrost areas

6. Pipeline crossings through natural and artificial obstacles

Underwater pipeline crossings through water barriers

Underground passages of pipelines across railways and roads

7. Overhead laying of pipelines

8. Calculation of pipelines for strength and stability

Design characteristics of materials

Loads and impacts

Determination of pipeline wall thickness

Checking the strength and stability of underground and above-ground (embankment) pipelines

Checking the strength and stability of overhead pipelines

Compensators

Features of the calculation of pipelines laid in seismic areas

Pipeline connecting parts

9. Environmental protection

10. Protection of pipelines from corrosion

Protection of pipelines from underground corrosion with protective coatings

Protection of above-ground pipelines from atmospheric corrosion

Electrochemical protection of pipelines from underground corrosion

Electrochemical protection of pipelines in areas of permafrost soils

11. Pipeline technological communication lines

12. Design of liquefied hydrocarbon gas pipelines

13. Materials and products

General provisions

Pipes and connecting parts

Welding materials

Products for securing pipelines against floating

Materials used for anti-corrosion coatings of pipelines

These standards apply to the design of new and reconstructed main pipelines and branches from them with a nominal diameter of up to 1400 mm inclusive. with excess pressure of the environment over 1.2 MPa (12 kgf/cm2) up to 10 MPa (100 kgf/cm2) (for single installation and installation in technical corridors) for transportation:

a) oil, petroleum products (including stable condensate and stable gasoline), natural, petroleum and artificial hydrocarbon gases from areas of their production (from fields), production or storage to places of consumption (oil depots, transshipment bases, loading points, gas distribution stations, individual industrial and agricultural enterprises and ports);

b) liquefied hydrocarbon gases of fractions C3 and C4 and their mixtures, unstable gasoline and petroleum gas condensate and other liquefied hydrocarbons with a saturated vapor pressure at a temperature of plus 40 ° C not exceeding 1.6 MPa (16 kgf/cm2) from the areas of their production ( fields) or production (from the main pumping stations) to the point of consumption;

c) commercial products within compressor (CS) and oil pumping stations (OPS), underground gas storage stations (UGS), booster compressor stations (BCS), gas distribution stations (GDS) and gas flow metering units (UZRG);

d) pulse, fuel and starting gas for CS, UGS, BCS, GDS, UZRG and gas reduction points (GRP).

The main pipelines include:

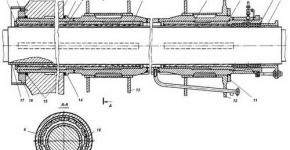

pipeline (from the point of exit from the field of commercial products prepared for long-distance transport) with branches and loopings, shut-off valves, transitions through natural and artificial obstacles, connection points for oil pumping station, compressor station, UZRG, PRG, nodes for starting and receiving treatment devices, condensate collectors and devices for methanol input;

installations of electrochemical protection of pipelines from corrosion, lines and structures of technological communication, means of telemechanics of pipelines;

power lines intended for servicing pipelines and power supply devices and remote control of shut-off valves and electrochemical protection installations for pipelines;

fire-fighting means, anti-erosion and pipeline protection structures;

tanks for storing and degassing condensate, earthen pits for emergency release of oil, petroleum products, condensate and liquefied hydrocarbons;

buildings and structures of the linear pipeline operation service;

Approved

resolution

Gosstroy USSR

dated 01.01.01 No. 30

Term

introduction

into action

January 1, 1986

The design of gas pipelines with a pressure of 1.2 MPa (12 kgf/cm2) or less, oil pipelines and oil product pipelines with a pressure of up to 2.5 MPa (25 kgf/cm2), intended for laying in the territory of populated areas or individual enterprises, should be carried out in accordance with the requirements of SNiP 2.04.08-87*, SNiP 2.11.03-93 and SNiP 2.05.13-83.

1. GENERAL PROVISIONS

1.1. Main pipelines (gas pipelines, oil pipelines and oil product pipelines)1 should be laid underground (underground installation).

The laying of pipelines on the surface of the earth in an embankment (ground laying) or on supports (above-ground laying) is allowed only as an exception with appropriate justification in the cases given in clause 7.1. In this case, special measures must be taken to ensure reliable and safe operation of pipelines.

1 In the text of the standards, with the exception of specially specified cases, instead of the words: “main pipeline(s)” the word “pipeline(s)” will be used.

1.2. The laying of pipelines can be carried out singly or in parallel with other existing or projected main pipelines - in a technical corridor.

1.3. The technical corridor of main pipelines should be understood as a system of parallel pipelines along one route intended for transporting oil (petroleum products, including liquefied hydrocarbon gases) or gas (gas condensate).

In some cases, subject to a feasibility study and ensuring the reliability of pipeline operation, joint laying of oil pipelines (oil product pipelines) and gas pipelines in one technical corridor is allowed.

1.4. The maximum permissible (total) volumes of transportation of products within one technical corridor and the distances between these corridors are determined in accordance with building codes and regulations approved in the prescribed manner.

1.5. It is not permitted to lay main pipelines through the territories of populated areas, industrial and agricultural enterprises, airfields, railway stations, sea and river ports, marinas and other similar objects.

1.6. To ensure normal operating conditions and eliminate the possibility of damage to main pipelines and their facilities, security zones are established around them, the size of which and the procedure for carrying out agricultural and other work in these zones are regulated by the Rules for the Protection of Main Pipelines.

1.7. The temperature of gas, oil (petroleum products) entering the pipeline must be set based on the possibility of transporting the product and the requirements for the safety of insulating coatings, strength, stability and reliability of the pipeline.

The need and degree of cooling of the transported product is decided during the design.

1.8. Pipelines and their structures should be designed taking into account the maximum industrialization of construction and installation work through the use, as a rule, of pipes with factory insulation and prefabricated structures in a block-complete design from standard and standard elements and parts manufactured in factories or in stationary conditions, ensuring their high-quality production. At the same time, the decisions made in the project must ensure uninterrupted and safe operation of pipelines.

2. CLASSIFICATION AND CATEGORIES OF MAIN PIPELINES

2.1 . Main gas pipelines, depending on the operating pressure in the pipeline, are divided into two classes:

I - at operating pressure over 2.5 to 10.0 MPa (over 25 to 100 kgf/cm2) inclusive;

II - at operating pressure over 1.2 to 2.5 MPa (over 12 to 25 kgf/cm2) inclusive.

2.2. Main oil pipelines and oil product pipelines, depending on the diameter of the pipeline, are divided into four classes, mm:

I - with a nominal diameter of over 1000 to 1200 inclusive;

II - the same, over 500 to 1000 inclusive;

III - the same, over 300 to 500 inclusive;

IV - 300 or less.

2.3. Main pipelines and their sections are divided into categories, the requirements for which, depending on operating conditions, the scope of non-destructive testing of welded joints and the value of test pressure, are given in Table. 1.

Table 1

|

Coefficient of pipeline operating conditions when calculating its strength, stability and deformabilitym |

Number of assembly welded joints subject to physical control, % of the total number |

Test pressure and duration of pipeline testing |

|

|

Accepted |

|||

|

SNiP III-42-80* |

|||

|

Note. When testing a pipeline for its linear part, it is allowed to increase the pressure to a value that causes stress in the pipe metal to the yield point, taking into account the minus tolerance for wall thickness. |

table 2

2.5 . Categories of sections of main pipelines should be taken according to table. 3*.

Table 3*

|

Purpose of pipeline sections | ||||||

|

gas pipelines when laying |

oil pipelines and oil product pipelines |

|||||

|

underground |

ground |

elevated |

underground |

ground |

elevated |

|

|

1. Crossing water barriers: | ||||||

|

a) navigable - in the riverbed and coastal sections with a length of at least 25 m each (from the average low water horizon) with a pipeline diameter, mm: | ||||||

|

1000 or more | ||||||

|

b) non-navigable water mirrors with a width of 25 m or more during low-water periods - in the channel part and coastal sections with a length of at least 5 m each (from the average low-water horizon) with a pipeline diameter, mm: | ||||||

|

1000 or more | ||||||

|

c) non-navigable water mirrors with a width of up to 25 m during low-water periods - in the channel part, irrigation and diversion canals | ||||||

|

d) mountain streams (rivers) | ||||||

|

e) river floodplains along the high water horizon of 10% probability with pipeline diameter, mm: | ||||||

|

700 and more | ||||||

|

f) sections with a length of 1000 m from the boundaries of the high water horizon of 10% probability | ||||||

|

2. Crossings through swamps like: | ||||||

|

1 II - for diameters of 700 mm and more, III - for diameters up to 700 mm. |

||||||

|

3. Crossings through railways and highways (on stretches): | ||||||

|

a) railways of the general network, including sections 40 m long each on both sides of the road from the axes of the outer tracks, but not less than 25 m from the base of the embankment of the roadbed | ||||||

|

b) access railways of industrial enterprises, including sections 25 m long each on both sides of the road from the axes of the outer tracks | ||||||

|

c) motor roads of categories I and II, including sections 25 m long each on both sides of the road from the base of the embankment or the edge of the roadbed excavation | ||||||

|

d) motor roads of II, III-p, IV, IV-p categories, including sections 25 m long each on both sides of the road from the base of the embankment or the edge of the roadbed excavation | ||||||

|

e) motor roads of category V, including sections 15 m long on both sides of the road from the base of the embankment or the edge of the roadbed excavation | ||||||

|

f) sections of pipelines within the distances specified in table. 4, adjacent to transitions: | ||||||

|

through all railways and highways of categories I and II | ||||||

|

through highways of III, IV, III-p, IV-p and V categories | ||||||

|

4. Pipelines in mountainous areas during installation: | ||||||

|

a) on the shelves | ||||||

|

b) in the tunnels | ||||||

|

5. Pipelines laid in loosely bound sand dunes in desert conditions | ||||||

|

6. Pipelines laid across irrigated and irrigated lands: | ||||||

|

a) cotton and rice plantations | ||||||

|

b) other agricultural crops | ||||||

|

7. Pipelines laid across the territory of permafrost soils having a relative settlement of more than 0.1 during thawing | ||||||

|

8. Transitions through mudflows, alluvial fans and saline soils | ||||||

|

9.* Linear fittings installation units (except for sections of categories B and I) | ||||||

|

10. Gas pipelines at a length of 250 m from linear shut-off valves and underwater crossing combs (except for sections of categories B and I) | ||||||

|

11. Pipelines at a length of 100 m from the boundaries of adjacent sections of category II, shown in pos. 3e | ||||||

|

12. Pipelines adjacent to the territories of UGS storage facilities, gas purification and drying installations, head structures from the collectors and pipelines within the distances specified in pos. 5 tab. 4 | ||||||

|

13.Interfield collectors | ||||||

|

14. Starting and receiving units for cleaning devices, as well as sections of pipelines 100 m long adjacent to them | ||||||

|

15. Pipelines within the territories of the PRG of the linear part of gas pipelines | ||||||

|

16.* Pipelines located inside buildings and within the territories of CS, PRG, UGS, BCS, GDS, PS, UZRG, including fuel and starting gas pipelines | ||||||

|

17.* Connection nodes to the gas pipeline, sections between security valves, suction and injection gas pipelines of CS, UGS, UKPG, UPPG, booster compressor stations (loops) and head structures, as well as gas pipelines for own needs from the connection point to the fencing of the territories of these structures | ||||||

|

18. Gas pipelines adjacent to the gas distribution station within the distances specified in pos. 8 tab. 4, as well as areas behind security cranes 250 m long | ||||||

|

19. Pipelines adjacent to the secant crane UZRG and PRG, 250 m long in both directions | ||||||

|

20. Intersections with underground utilities (sewers, oil pipelines, oil product pipelines, gas pipelines, power and communication cables, underground, above-ground and above-ground irrigation systems, etc.) within 20 m on both sides of the crossed utility | ||||||

|

21. Intersections with communications shown in pos. 20, and among themselves multi-line main gas pipelines with a diameter of over 1000 mm and a pressure of 7.5 MPa (75 kgf/cm2) or more and oil pipelines with a diameter of over 700 mm within 100 m on both sides of the intersecting communication | ||||||

|

22. Intersections (in both directions) within the distances specified in pos. 12 tables 4*, with overhead power lines voltage, kV: | ||||||

|

a) 500 or more | ||||||

|

b) from 330 to 500 | ||||||

|

23. Pipelines laid through mined areas and areas prone to karst phenomena | ||||||

|

24. Crossings through ravines, beams, ditches and drying up streams | ||||||

|

25. Oil pipelines and oil product pipelines laid along rivers with a water surface width of 25 m or more during low-water periods, canals, lakes and other reservoirs of fishing importance, at a distance above populated areas and industrial enterprises. distance from them to 300 m with a pipe diameter of 700 mm or less; up to 500 m with pipe diameters up to 1000 mm inclusive; up to 1000 m with pipe diameters over 1000 mm | ||||||

|

(without preliminary hydraulic testing on the highway) |

||||||

|

26*. Gas pipelines, oil and petroleum product pipelines laid in one technical corridor, at the locations of UZRG, PRG, units for installing linear shut-off valves, launching and receiving treatment devices, units for connecting CS, CGTU, UPPG, UGS, BCS, GS to the pipeline within distances indicated in pos. 9, 10, 14 and 15, 17 and 19, and from the CS connection points into the pipeline within 250 m on both sides of them | ||||||

|

(if they do not belong to a higher category based on the type of gasket and other parameters) |

||||||

|

Notes: 1. Categories of individual sections of pipelines, emergency damage of which can cause interruptions in the supply of gas, oil and petroleum products to cities and other large consumers of great economic importance, as well as environmental pollution, with appropriate justification, may be increased by one category. 2. Types of swamps should be accepted in accordance with the requirements of SNiP III -42-80*. 3. When a pipeline crosses an array of swamps of various types, with appropriate justification, it is allowed to accept the category of the entire section as for the highest category in a given swamp area. 4. Testing of pipeline sections laid through water barriers with a low-water surface of less than 10 m should be carried out as part of the installed pipeline in one stage. 5*. Existing pipelines that are in satisfactory technical condition (according to the conclusion of representatives of the customer of the structure under construction, the operating organization and the relevant government supervision body), when they are crossed by the designed pipelines, power lines, as well as underground communications specified in pos. 20 and 21, and with parallel installation in accordance with pos. 26*, cannot be replaced by pipelines of a higher category. 6. Existing pipelines crossed by railways and roads under construction are subject to reconstruction in accordance with pos. 3. 7. The category of pipeline sections laid in floodplains of rivers subject to flooding under a reservoir should be accepted as for crossings through navigable water barriers. 8. If the duration of flooding by flood waters is short (less than 20 days) and the depth of this flooding is insignificant, allowing prompt implementation of emergency restoration work on pipelines in the area in case of damage, compliance with the requirements of pos. 1d is not necessary for gas pipelines. for shipping - according to pos. 1a; for non-navigable - according to pos. 1b and 1c. |

3. BASIC REQUIREMENTS FOR THE PIPELINE ROUTE

3.1. The choice of pipeline route should be made according to optimality criteria. As optimality criteria, one should take the given costs for the construction, maintenance and repair of the pipeline during operation, including the costs of measures to ensure environmental safety, as well as metal consumption, design layouts, safety, specified construction time, availability of roads, etc.

3.2. Land plots for pipeline construction should be selected in accordance with the requirements stipulated by the current legislation of the Russian Federation.

When choosing a route, construction conditions should be taken into account in order to ensure the use of the most efficient, economical and high-performance methods of construction and installation work.

3.3. The choice of route between the start and end points must be made within the search area defined by the ellipse, the foci of which are the start and end points.

Minor axis of ellipse b , km, determined by the formula

Where l- distance between the starting and ending points along the geodetic line, km;

K p - pipeline line development coefficient.

Pipeline line development coefficient K p should be determined from the condition

Where W Wed o - reduced costs for 1 km of pipeline along a geodetic straight line between the starting and ending points, taking into account transitions over obstacles;

W Wed n - reduced costs for 1 km of pipeline along a geodetic straight line between the starting and ending points without the costs of crossing natural and artificial obstacles.

3.4. Compensation for losses to land users and losses of agricultural production during land acquisition for pipeline construction and damage to fisheries should be determined in accordance with the established procedure.

3.5. To reach the pipelines, existing roads of the general network should be used as much as possible.

The construction of new roads and road structures should be envisaged only if there is sufficient justification and it is impossible to avoid obstacles on existing public roads.

3.6. When choosing a pipeline route, it is necessary to take into account the long-term development of cities and other settlements, industrial and agricultural enterprises, railways, roads and other facilities and the projected pipeline for the next 20 years, as well as the conditions for the construction and maintenance of the pipeline during its operation (existing, under construction, designed and reconstructed buildings and structures, reclamation of wetlands, irrigation of desert and steppe areas, use of water bodies, etc.), predict changes in natural conditions during the construction and operation of main pipelines.

3.7. It is not allowed to provide for the laying of main pipelines in railway and highway tunnels, as well as in tunnels together with electrical and communication cables and pipelines for other purposes belonging to other ministries and departments.

3.8.* It is not allowed to lay pipelines on bridges of railways and highways of all categories and in the same trench with electrical cables, communication cables and other pipelines, except for the cases of laying:

technological communication cables of this pipeline at underwater crossings (in one trench) and at crossings through railways and roads (in one case);

gas pipelines with a diameter of up to 1000 mm at a pressure of up to 2.5 MPa (25 kgf/cm2) and oil pipelines and oil product pipelines with a diameter of 500 mm or less on fireproof bridges of highways of III, III-p, IV-p, IV and V categories. In this case, sections of pipelines laid along the bridge and on the approaches to it at the distances indicated in Table. 4, should be classified as category I.

3.9. The laying of pipelines over bridges (in the cases given in clause 3.8), through which long-distance communication cables are laid, may only be carried out in agreement with the Ministry of Communications of the USSR.

3.10. The laying of the pipeline in landslide areas should be provided below the sliding surface or above ground on supports buried below the sliding surface to a depth that excludes the possibility of displacement of the supports.

3.11. The route of pipelines crossing mudflows should be chosen outside the dynamic impact zone of the flow.

3.12. When choosing a route for underground pipelines on permafrost soils, you should, if possible, avoid areas with underground ice, aufeis and heaving mounds, manifestations of thermokarst, slopes with ice-saturated, clayey and waterlogged silty soils. Heaving mounds should be bypassed from the downstream side.

3.13. The basic principle of using permafrost soils as a foundation for pipelines and their structures is principle I, according to SNiP 2.02.04-88, in which permafrost foundation soils should be used in a frozen state, maintained during the construction process and throughout the entire specified period of operation of the pipeline.

BUILDING REGULATIONS

MAIN PIPELINES

SNiP 2.05.06-85*

DEVELOPED BY VNIIST Ministry of Oil and Gas Construction (candidate of technical sciences) I. D. Krasulin - topic leader, candidates technical. Sciences V. V. Rozhdestvensky, A. B. Ainbinder, engineer . L.A. Solovyova, candidates of technical Sciences V. F. Khramikhina, A. S. Bolotov, N. P. Glazov, S. I. Levin, V. V. Spiridonov, A. S. Gekhman, V. V. Pritula, V. D. Tarlinsky, A. D. Yablokov) with participation of YuzhNIIGiprogaz (I. I. Pankov And N. N. Zheludkov), State Gas Supervision of the USSR R.G. Toropova). VNIIGaz Mingazprom (candidate of technical sciences) S. V. Karpov and 3. I. Nefedova), Hydraulic pipelines of the Ministry of Oil Industry (B. A. Alimov) and the Ministry of Economy and State Enterprise named after I.M. Gubkin of the USSR Ministry of Higher Education (Doctor of Technical Sciences, prof. L. G. Telegin).

INTRODUCED by the Ministry of Oil and Gas Construction.

PREPARED FOR APPROVAL BY Glavtekhnormirovanie Gosstroy USSR (I.V. Sessin).

PREPARED FOR REPUBLICATION by the Technical Standardization Department of the Gosstroy of Russia (N.A. Shishov).

SNiP 2.05.06-85* is a reissue of SNiP 2.05.06-85 with amendments No. 1, No. 2, approved by resolutions of the USSR State Construction Committee dated January 8, 1987 No. 1, dated July 13, 1990 No. 61, and amendment No. 3, approved by Resolution of the Ministry of Construction of Russia dated November 10, 1996 No. 18-78.

Items and tables to which changes have been made are marked in these building codes and regulations with an asterisk.

When using a regulatory document, you should take into account the approved changes to building codes and regulations and state standards published in the journal “Bulletin of Construction Technology” and the information index “State Standards”.

These standards apply to the design of new and reconstructed main pipelines and branches from them with a nominal diameter of up to 1400 mm inclusive. with excess pressure of the environment over 1.2 MPa (12 kgf/cm 2) up to 10 MPa (100 kgf/cm 2) (for single installation and installation in technical corridors) for transportation:

a) oil, petroleum products (including stable condensate and stable gasoline), natural, petroleum and artificial hydrocarbon gases from areas of their production (from fields), production or storage to places of consumption (oil depots, transshipment bases, loading points, gas distribution stations, individual industrial and agricultural enterprises and ports);

b) liquefied hydrocarbon gases of fractions C 3 and C 4 and their mixtures, unstable gasoline and petroleum gas condensate and other liquefied hydrocarbons with a saturated vapor pressure at a temperature of plus 40 ° C not exceeding 1.6 MPa (16 kgf/cm 2) from areas their extraction (fields) or production (from the main pumping stations) to the place of consumption;

c) commercial products within compressor stations (CS) and oil pumping stations (OPS), underground gas storage stations (UGS), booster compressor stations (BCS), gas distribution stations (GDS) and gas flow metering units (UZRG);

d) pulse, fuel and starting gas for CS, UGS, BCS, GDS, UZRG and gas reduction points (GRP).

The main pipelines include:

pipeline (from the point of exit from the field of commercial products prepared for long-distance transport) with branches and loopings, shut-off valves, transitions through natural and artificial obstacles, connection points for oil pumping station, compressor station, UZRG, PRG, nodes for starting and receiving treatment devices, condensate collectors and devices for methanol input;

installations of electrochemical protection of pipelines from corrosion, lines and structures of technological communication, means of telemechanics of pipelines;

power lines intended for servicing pipelines and power supply devices and remote control of shut-off valves and electrochemical protection installations for pipelines;

fire-fighting means, anti-erosion and pipeline protection structures;

tanks for storing and degassing condensate, earthen pits for emergency release of oil, petroleum products, condensate and liquefied hydrocarbons;

buildings and structures of the linear pipeline operation service;

permanent roads and helipads located along the pipeline route, and approaches to them, identification and signal signs for the location of pipelines;

head and intermediate pumping and loading pumping stations, tank farms, compressor stations and gas distribution stations;

heating points for oil and petroleum products; pointers and warning signs.

These standards do not apply to the design of pipelines laid in cities and other populated areas, in offshore areas and fields, as well as pipelines intended for transporting gas, oil, petroleum products and liquefied hydrocarbon gases that have a corrosive effect on the metal of pipes or cooled to a temperature below minus 40 °C.

The design of pipelines intended for transporting stable condensate and stable gasoline should be carried out in accordance with the requirements of these standards for oil pipelines.

Stable condensate and gasoline include hydrocarbons and their mixtures that have a saturated vapor pressure of less than 0.2 MPa (2 kgf/cm2) (abs) at a temperature of plus 20 °C.

The design of pipelines for liquefied hydrocarbons with a saturated vapor elasticity at a temperature of plus 20 °C above 0.2 MPa (2 kgf/cm 2) - liquefied hydrocarbon gases, unstable gasoline and unstable condensate and other liquefied hydrocarbons - should be carried out in accordance with the requirements set out in section 12.

Design of buildings and structures, including utilities, located at CS sites. NPS, GRS. UGS and BCS should be carried out in accordance with the requirements of regulatory documents for the design of relevant buildings and structures, approved by the USSR State Construction Committee, taking into account the requirements of these standards.

The design of gas pipelines with a pressure of 1.2 MPa (12 kgf/cm2) or less, oil pipelines and oil product pipelines with a pressure of up to 2.5 MPa (25 kgf/cm2), intended for laying in the territory of populated areas or individual enterprises, should be carried out in accordance with requirements of SNiP 2.04.08-87*, SNiP 2.11.03-93 and SNiP 2.05.13-90.

1. GENERAL PROVISIONS

1.1. Main pipelines (gas pipelines, oil pipelines and oil product pipelines) 1 should be laid underground (underground laying).

The laying of pipelines on the surface of the earth in an embankment (ground laying) or on supports (above-ground laying) is allowed only as an exception with appropriate justification in the cases given in clause 7.1. In this case, special measures must be taken to ensure reliable and safe operation of pipelines.

1 In the text of the standards, with the exception of specially stated cases, instead of the words: “main pipeline(s)” the word “pipeline(s)” will be used.

1.2. The laying of pipelines can be carried out singly or in parallel with other existing or projected main pipelines - in a technical corridor.

1.3. The technical corridor of main pipelines should be understood as a system of parallel pipelines along one route intended for transporting oil (petroleum products, including liquefied hydrocarbon gases) or gas (gas condensate).

In some cases, subject to a feasibility study and ensuring the reliability of pipeline operation, joint laying of oil pipelines (oil product pipelines) and gas pipelines in one technical corridor is allowed.

1.4. The maximum permissible (total) volumes of transportation of products within one technical corridor and the distances between these corridors are determined in accordance with building codes and regulations approved in the prescribed manner.

1.5. It is not permitted to lay main pipelines through the territories of populated areas, industrial and agricultural enterprises, airfields, railway stations, sea and river ports, marinas and other similar objects.

1.6. To ensure normal operating conditions and eliminate the possibility of damage to main pipelines and their facilities, security zones are established around them, the size of which and the procedure for carrying out agricultural and other work in these zones are regulated by the Rules for the Protection of Main Pipelines.

1.7. The temperature of gas, oil (petroleum products) entering the pipeline must be set based on the possibility of transporting the product and the requirements for the safety of insulating coatings, strength, stability and reliability of the pipeline.

The need and degree of cooling of the transported product is decided during the design.

1.8. Pipelines and their structures should be designed taking into account the maximum industrialization of construction and installation work through the use, as a rule, of pipes with factory insulation and prefabricated structures in a block-complete design from standard and standard elements and parts manufactured in factories or in stationary conditions, ensuring their high-quality production. At the same time, the decisions made in the project must ensure uninterrupted and safe operation of pipelines.

2. CLASSIFICATION AND CATEGORIES OF MAIN

PIPELINES

2.1. Main gas pipelines, depending on the operating pressure in the pipeline, are divided into two classes:

I - at operating pressure over 2.5 to 10.0 MPa (over 25 to 100 kgf/cm 2) inclusive;

II - at operating pressure above 1 , 2 to 2.5 MPa (over 12 to 25 kgf/cm2) incl.

2.2. Main oil pipelines and oil product pipelines, depending on the diameter of the pipeline, are divided into four classes, mm:

I - with a nominal diameter of over 1000 to 1200 inclusive;

II - the same, over 500 to 1000 inclusive;

III - the same. over 300 to 500 inclusive;

IV - 300 or less.

2.3. Main pipelines and their sections are divided into categories, the requirements for which, depending on operating conditions, the scope of non-destructive testing of welded joints and the value of test pressure, are given in Table. 1.

Table 1

|

Coefficient of pipeline operating conditions when calculating its strength, stability and deformability m |

Number of assembly welded joints subject to physical control, % of the total number |

Test pressure and duration of pipeline testing |

|

|

Accepted |

|||

|

SNiP III-42-80* |

|||

|

Note. When testing a pipeline for its linear part, it is allowed to increase the pressure to a value that causes stress in the pipe metal to the yield point, taking into account the minus tolerance for wall thickness. |

|||

table 2

|

Purpose of the pipeline |

||

|

underground |

ground and above ground |

|

|

For transportation of natural gas: |

||

|

a) with a diameter less than 1200 mm |

||

|

b) with a diameter of 1200 mm or more |

||

|

c) in the northern construction-climatic zone |

||

|

For transportation of oil and petroleum products: |

||

|

a) diameter less than 700 mm |

||

|

b) with a diameter of 700 mm or more |

||

|

c) in the northern construction-climatic zone |

||

Table 3*

|

Purpose of pipeline sections |

gas pipelines |

oil pipelines and oil product pipelines |

|||||

|

underground |

ground |

elevated |

underground |

ground |

elevated |

||

|

1. Crossing water barriers: a) navigable - in the riverbed and coastal sections with a length of at least 25 m each (from the average low water horizon) with the diameter of the pipeline. mm: |

|||||||

|

1000 or more |

|||||||

|

less than 1000 |

|||||||

|

b) non-navigable water mirrors with a width of 25 m or more during low-water periods - in the channel part and coastal sections with a length of at least 25 m each (from the average low-water horizon) with a pipeline diameter, mm: |

|||||||

|

1000 or more |

|||||||

|

less than 1000 |

|||||||

|

c) non-navigable water mirrors with a width of up to 25 m during low-water periods—in the channel part, irrigation and diversion canals |

|||||||

|

d) mountain streams (rivers) |

|||||||

|

e) river floodplains along the high water horizon of 10% probability with pipeline diameter, mm: |

|||||||

|

700 and more |

|||||||

|

f) sections with a length of 1000 m from the boundaries of the high water horizon 10% security |

|||||||

|

2. Crossings through swamps like: |

|||||||

|

3. Crossings through railways and highways (on stretches): |

|||||||

|

a) railways of the general network, including sections 40 m long each on both sides of the road from the axes of the outer tracks, but not less than 25 m from the base of the embankment of the roadbed |

|||||||

|

b) access railways of industrial enterprises, including sections 25 m long each on both sides of the road from the axes of the outer tracks |

|||||||

|

c) highways of categories I and II, including sections 25 m long each on both sides of the road from the base of the embankment or the edge of the roadbed excavation |

|||||||

|

d) highways of II, III-p, IV, IV-p categories, including sections 25 m long each on both sides of the road from the base of the embankment or the edge of the roadbed excavation |

|||||||

|

e) motor roads of category V, including sections 15 m long on both sides of the road from the base of the embankment or the edge of the roadbed excavation |

|||||||

|

f) sections of pipelines within the distances specified in table. 4, adjacent to transitions: |

|||||||

|

through all railways and highways of categories I and II |

|||||||

|

through motor roads of III, III-p, IV, IV-p and V categories |

|||||||

|

4. Pipelines in mountainous areas during installation: a) on the shelves |

|||||||

|

b) in the tunnels |

|||||||

|

5. Pipelines laid in loosely bound sand dunes in desert conditions |

|||||||

|

6. Pipelines laid across irrigated and irrigated lands: |

|||||||

|

a) cotton and rice plantations |

|||||||

|

b) other agricultural crops |

|||||||

|

7. Pipelines laid across the territory of permafrost soils having a relative settlement of more than 0.1 during thawing |

|||||||

|

8. Transitions through mudflows, alluvial fans and saline soils |

|||||||

|

9*. Linear fittings installation units (except for sections of categories B and I) |

|||||||

|

10. Gas pipelines at a length of 250 m from linear shut-off valves and underwater crossing combs (except for sections of categories B and I) |

|||||||

|

11. Pipelines at a length of 100 m from the boundaries of adjacent sections of category II, shown in pos. 3 e |

|||||||

|

12. Pipelines adjacent to the territories of UGS storage facilities, gas purification and drying installations, head structures from the side of collectors and pipelines within the distances specified in item 5 of table. 4 |

|||||||

|

13.Interfield collectors |

|||||||

|

14. Starting and receiving units for cleaning devices, as well as sections of pipelines 100 m long adjacent to them |

|||||||

|

15. Pipelines within the territories of the PRG of the linear part of gas pipelines |

|||||||

|

16*. Pipelines located inside buildings and within the territories of CS, PRG, UGS, BCS, GDS. NPS. UZRG, including fuel and starting gas pipelines |

|||||||

|

17*. Connection nodes to the gas pipeline, sections between security valves, suction and injection gas pipelines of the CS, UGS, UKPG, UPPG, booster compressor station (loops) and head structures, as well as gas pipelines for auxiliary needs from the connection point to the fencing of the territory of these structures |

|||||||

|

18. Gas pipelines adjacent to the gas distribution station within the distances specified in pos. 8 tables 4, as well as areas behind security cranes 250 m long |

|||||||

|

19. Pipelines adjacent to the cutting valve UZRG and PRG, 250 m long in both directions |

|||||||

|

20. Intersections with underground utilities (sewers, oil pipelines, oil product pipelines, gas pipelines, power and communication cables, underground, above-ground and above-ground irrigation systems, etc.) within 20 m on both sides of the crossed utility |

|||||||

|

21. Intersections with communications shown in pos. 20, and among themselves multi-line main gas pipelines with a diameter of over 1000 mm and a pressure of 7.5 MPa (75 kgf/cm 2) and more oil pipelines with a diameter of over 700 mm within 100 m on both sides of the intersecting communication |

|||||||

|

22. Intersections (in both directions) within the distances specified in pos. 12 tables 4*, with overhead power lines voltage, kV: |

|||||||

|

a) 500 or more |

|||||||

|

b) from 330 to 500 |

|||||||

|

23. Pipelines laid through mined areas and areas prone to karst phenomena |

|||||||

|

24. Crossings through ravines, beams, ditches and drying up streams |

|||||||

|

25. Oil pipelines and |

|||||||

|

oil product pipelines laid along rivers with a water surface width of 25 m or more during low-water periods, canals, lakes and other reservoirs of fishing importance, above populated areas and industrial enterprises at a distance of up to 300 m from them with a pipe diameter of 700 mm or less; up to 500 m with pipe diameters up to 1000 mm inclusive; up to 1000 m with pipe diameters over 1000 mm |

(without preliminary hydraulic testing on the highway) |

||||||

|

26*. Gas pipelines, oil and |

|||||||

|

oil product pipelines laid in one technical corridor, at the locations of UZRG, PRG, units for installing linear shut-off valves, starting and receiving treatment devices, units for connecting CS, CGTU, UPPG, UGS, BCS, GS into the pipeline within the distances specified in pos. 9, 10, 14, 15, 17 and 19, and from the CS connection points into the pipeline within 250 m on both sides of them |

(if they do not belong to a higher category based on the type of gasket and other parameters) |

||||||

|

Notes: 1. The categories of individual sections of pipelines, emergency damage of which can cause interruptions in the supply of gas, oil and petroleum products to cities and other large consumers of great economic importance, as well as environmental pollution, may be increased by one category with appropriate justification. 2. Types of swamps should be accepted in accordance with the requirements of SNiP III-42-80*. 3. When a pipeline crosses an array of swamps of various types, with appropriate justification, it is allowed to accept the category of the entire section as for the highest category in a given swamp area. 4. Testing of pipeline sections laid through water barriers with a low-water surface of less than 10 m should be carried out as part of the installed pipeline in one stage. |

|||||||

|

5*. Existing pipelines that are in satisfactory technical condition (according to the conclusion of representatives of the customer of the structure under construction, the operating organization and the relevant government supervision body), when they are crossed by the designed pipelines, power lines, as well as underground communications specified in pos. 20 and 21, and with parallel installation in accordance with pos. 26*, cannot be replaced by pipelines of a higher category. 6. Existing pipelines crossed by railways and roads under construction are subject to reconstruction in accordance with pos. 3. 8. If the duration of flooding by flood waters is short (less than 20 days) and the depth of this flooding is insignificant, allowing prompt implementation of emergency restoration work on pipelines in the area in case of damage, compliance with the requirements of pos. 1d is not necessary for gas pipelines. for shipping - according to pos. 1a; for non-navigable - according to pos. 1b and 1c. |

|||||||

1 II - for diameter 700 mm and more, III - for diameter up to 700 mm

BUILDING REGULATIONS

MAIN PIPELINES

OFFICIAL PUBLICATION

DEVELOPED BY VNIIST Ministry of Oil and Gas Construction (candidate of technical sciences I. D. Krasulin - topic leader, candidates of technical sciences V. V. Rozhdestvensky, A. B. Ainbinder, engineer L. A. Solovyova, candidates of technical sciences V. F. Khramikhina, A. S. Bolotov, N. P. Glazov, S. I. Levin, V. V. Spiridonov, A. S. Gekhman, V. V. Pritula, V. D. Tarlinsky, A. D. Yablokov) with the participation of YuzhNIIGiprogaz (I. I. Pankov and N. N. Zheludkov), State Gas Supervision of the USSR R. G. Toropov). VNIIGaz of Mingazprom (candidates of technical sciences S.V. Karpov and Z. I. Nefedova), Hydraulic Pipeline of the Ministry of Oil Industry (B.A. Alimov] and MINHIGP named after I.M. Gubkin of the Ministry of Higher Education of the USSR (Doctor of Technical Sciences, Prof. L G. Telegin).

INTRODUCED by the Ministry of Oil and Gas Construction.

PREPARED FOR APPROVAL BY Glavtekhnormirovanie Gosstroy USSR (I.V. Sessin).

Main pipelines

Instead of SNiP

These standards apply to the design of new and reconstructed main pipelines and branches from them with a nominal diameter of up to 1400 mm inclusive. with excess pressure of the environment over 1.2 MPa (12 kgf/cm2) up to 10 MPa (100 kgf/cm2) (for single installation and installation in technical corridors) for transportation:

a) oil, petroleum products (including stable condensate and stable gasoline), natural, petroleum and artificial hydrocarbon gases from areas of their production (from fields), production or storage to places of consumption (oil depots, transshipment bases, loading points, gas distribution stations, individual industrial and agricultural enterprises and ports);

b) liquefied hydrocarbon gases of fractions C3 and C4 and their mixtures, unstable gasoline and petroleum gas condensate and other liquefied hydrocarbons with a saturated vapor pressure at a temperature of plus 40?? C not exceeding 1.6 MPa (16 kgf/cm2) from the areas of their extraction (fields) or production (from the main pumping stations) to the place of consumption;

c) commercial products within compressor stations (CS) and oil pumping stations (OPS), underground gas storage stations (UGS), booster compressor stations (BCS), gas distribution stations (GDS) and gas flow metering units (UZRG);

d) pulse, fuel and starting gas for CS, UGS, BCS, GDS, UZRG and gas reduction points (GRP).

The main pipelines include:

pipeline (from the point of exit from the field of commercial products prepared for long-distance transport) with branches and loopings, shut-off valves, transitions through natural and artificial obstacles, connection points for oil pumping station, compressor station, UZRG, PRG, nodes for starting and receiving treatment devices, condensate collectors and devices for methanol input;

installations of electrochemical protection of pipelines from corrosion, lines and structures of technological communication, means of telemechanics of pipelines;

power lines intended for servicing pipelines and power supply devices and remote control of shut-off valves and electrochemical protection installations for pipelines;

fire-fighting means, anti-erosion and pipeline protection structures;

tanks for storing and degassing condensate, earthen pits for emergency release of oil, petroleum products, condensate and liquefied hydrocarbons;

buildings and structures of the linear pipeline operation service;

permanent roads and helipads located along the pipeline route, and approaches to them, identification and signal signs for the location of pipelines;

head and intermediate pumping and loading pumping stations, tank farms, compressor stations and gas distribution stations;

heating points for oil and petroleum products; pointers and warning signs.

These standards do not apply to the design of pipelines laid in cities and other populated areas, in offshore areas and fields, as well as pipelines intended for transporting gas, oil, petroleum products and liquefied hydrocarbon gases that have a corrosive effect on the metal of pipes or cooled to a temperature below minus 40 °C.

The design of pipelines intended for the transportation of stable condensate and stable gasoline should be carried out in accordance with the requirements of these standards for oil pipelines.

Stable condensate and gasoline should include hydrocarbons and mixtures thereof, which at a temperature of plus 20 ° C have a saturated vapor pressure of less than 0.2 MPa (2 kgf/cm2) (abs).

The design of pipelines for liquefied hydrocarbons with saturated vapor pressure at a temperature of plus 20 ° C above 0.2 MPa (2 kgf / cm2) - liquefied hydrocarbon gases, unstable gasoline and unstable condensate and other liquefied hydrocarbons - should be carried out in accordance with the requirements set forth in Section . 12.

Design of buildings and structures, including engineering communications located at the CS sites. NPS, GRS. SPHG and DKS.should be carried out in accordance with the requirements of the standard

tive documents for the design of the relevant buildings and structures approved by the USSR State Construction Committee, taking into account the requirements of these standards.

The design of gas pipelines with a pressure of 1.2 MPa (12 kgf/cm2) and less, oil pipelines and oil product pipelines with a pressure of up to 2.5 MPa (25 kgf/cm2) intended for laying on the territory of settlements or individual enterprises should be carried out in accordance with the requirements of SNiP ????-37-76, SNiP????-106-79 and SNiP 2.05.13-83.

1. GENERAL PROVISIONS

1.1. Main pipelines (gas pipelines, oil pipelines and oil product pipelines)1 should be laid underground (underground installation).

The laying of pipelines on the surface of the earth in an embankment (ground laying) or on supports (above-ground laying) is allowed only as an exception with appropriate justification in the cases given in clause 7.1. In this case, special measures must be taken to ensure reliable and safe operation of pipelines.

1.2. The laying of pipelines can be carried out singly or in parallel with other existing or projected main pipelines - in a technical corridor.

1.3. The technical corridor of main pipelines should be understood as a system of parallel pipelines along one route, designed to transport oil (oil products, including liquefied hydrocarbon gases) or gas (gas condensate).

In some cases, subject to a feasibility study and ensuring the reliability of pipeline operation, joint laying of oil pipelines (oil product pipelines) and gas pipelines in one technical corridor is allowed.

1.4. The maximum allowable (total) volumes of transportation of products within one technical corridor and the distance between these corridors are established in accordance with SNiP????-10-74.

1.5. It is not permitted to lay main pipelines through the territories of populated areas, industrial and agricultural enterprises, airfields, railway stations, sea and river ports, marinas and other similar objects.

1.6. To ensure normal operating conditions and eliminate the possibility of damage to main pipelines and their facilities, security zones are established around them, the size of which and the procedure for carrying out agricultural and other work in these zones are regulated by the Rules for the Protection of Main Pipelines.

1 In the text of the standards, with the exception of specially stated cases, instead of the words: “main pipeline(s)” the word “pipeline(s)” will be used.

1.7. The temperature of gas, oil (petroleum products) entering the pipeline must be set based on the possibility of transporting the product and the requirements for the safety of insulating coatings, strength, stability and reliability of the pipeline.

The need and degree of cooling of the transported product is decided during the design.

1.8. Pipelines and their structures should be designed taking into account the maximum industrialization of construction and installation work through the use, as a rule, of pipes with factory insulation and prefabricated structures in a block-complete design from standard and standard elements and parts manufactured in factories or in stationary conditions, ensuring their high-quality production. At the same time, the decisions made in the project must ensure uninterrupted and safe operation of pipelines.

- CLASSIFICATION AND CATEGORIES OF MAIN TRAINS

PIPELINES

2.1. Main gas pipelines, depending on the operating pressure in the pipeline, are divided into two classes:

Class - at operating pressure over 2.5 to 10.0 MPa (over 25 to 100 kgf/cm2) inclusive;

Class II - at operating pressure over 1.2 to 2.5 MPa (over 12 to 25 kgf/cm2) inclusive.

2.2. Main oil pipelines and oil product pipelines, depending on the diameter of the pipeline, are divided into four classes, mm:

Class - with a nominal diameter of over 1000 to 1200 inclusive;

Class II - the same, over 500 to 1000 inclusive;

III class - the same. over 300 to 500 inclusive;

IV class - 300 or less.

2.3. Main pipelines and their sections are divided into categories, the requirements for which, depending on operating conditions, the scope of non-destructive testing of welded joints and the value of test pressure, are given in Table. 1.

Table 1

|

Coefficient of pipeline operating conditions when calculating its strength, stability and deformability m |

Number of assembly welded joints subject to physical control, % of the total number |

Test pressure and duration of pipeline testing |

|

|

Accepted |

|||

|

SNiP??????-42-80 |

|||

|

Note. When testing a pipeline for its linear part, it is allowed to increase the pressure to a value that causes stress in the pipe metal to the yield point, taking into account the minus tolerance for wall thickness. |

table 2

Table 3

|

Purpose of pipeline sections |

||||||

|

gas pipelines when laying |

oil pipelines and oil product pipelines during installation |

|||||

|

underground |

ground |

elevated |

underground |

ground |

elevated |

|

|

1. Crossing water barriers: a) navigable - in the riverbed and coastal sections with a length of at least 25 m each (from average water horizon) with the diameter of the pipeline. mm: |

||||||

|

1000 or more |

||||||

|

b) non-navigable water mirrors with a width of 25 m or more during low water - in the channel part and coastal sections no less than 25 m each (from the average low water horizon) with pipeline diameter, mm: |

||||||

|

1000 or more |

||||||

|

c) non-navigable water mirror width during low-water periods up to 25 m in the channel part, irrigation and diversion canals |

||||||

|

d) mountain streams (rivers) |

||||||

|

e) river floodplains along the high water horizon of 10% probability with pipeline diameter, mm: |

||||||

|

700 and more |

||||||

|

f) sections with a length of 1000 m from the boundaries of the high water horizon of 10% probability |

||||||

|

2. Crossings through swamps like: |

||||||

|

3. Crossings through railways and highways (on stretches): |

||||||

|

a) railways of the general network, including sections 40 m long each on both sides of the road from the axes of the outer tracks, but at least 25 m from the base of the embankment of the roadbed |

||||||

|

b) access railways of industrial enterprises, including sections 25 m long each on both sides of the road from the axes of the outer tracks |

||||||

|

c) highways?? And???? categories, including sections 25 m long each on both sides of the road from the base of the embankment or the edge of the excavation of the subgrade |

||||||

|

d) highways of ??????, ??????-p, IV, ????-p categories, including sections of 25 m each on both sides of the road from the bottom of an embankment or the edge of a road excavation |

||||||

|

e) motor roads of category V, including sections 15 m long on both sides of the road from the base of the embankment or the edge of the roadbed excavation |

||||||

|

f) sections of pipelines within the distances specified in table. 4, adjacent to transitions: |

||||||

|

across all railways and car roads?? And???? categories |

||||||

|

through highways??????, IV, ??????-p, ????-p and V categories |

||||||

|

4. Pipelines in mountainous areas during installation: a) on the shelves |

||||||

|

b) in the tunnels |

||||||

|

5. Pipelines laid in loosely bound sand dunes in desert conditions |

||||||

|

6. Pipelines laid through fallow and irrigated lands: |

||||||

|

a) cotton and rice plantations |

||||||

|

b) other agricultural crops |

||||||

|

7. Pipelines laid across the territory of permafrost soils having a relative settlement of more than 0.1 during thawing |

||||||

|

8. Transitions through mudflows, alluvial fans and saline soils |

||||||

|

9. Units for installing linear fittings (with the exception of sections of categories B and ??) and adjacent sections 15 m long in each direction from the boundaries of the installation unit of the linear part of the pipeline |

||||||

|

10. Gas pipelines at a length of 250 m from linear shut-off valves and underwater crossing combs (except for sections of category B and??) |

||||||

|

11.Pipelines at a length of 100 m from the boundaries of adjacent areas???? categories given in pos. 3 e |

||||||

|

12. Pipelines adjacent to the territories of UGS storage facilities, gas purification and drying installations, head structures from the side of collectors and pipelines within the distances specified in item 5 of table. 4 |

||||||

|

13.Interfield collectors |

||||||

|

14. Start-up and receiving units for cleaning devices, as well as sections of pipelines of length 100 m adjacent to them |

||||||

|

15. Pipelines within territories PRG of the linear part of gas pipelines |

||||||

|

1b. Pipelines located inside buildings and within the territories of CS, PRG, UGS, BCS, GDS. NPS. UZRG, including fuel and starting gas pipelines |

||||||

|

17. Connection nodes to the gas pipeline, sections between security valves, suction and injection gas pipelines of compressor stations, gas processing facilities, storage gas storage facilities, gas processing facilities, booster compressor stations (loop loops) and head structures, and also gas pipelines for own needs from the connection point to the fencing of the territories of the specified structures |

||||||

|

18. Gas pipelines adjacent to the gas distribution station within the distances specified in pos. 8 tab. 4, as well as areas behind security cranes 250 m long |

||||||

|

19. Pipelines adjacent to the secant crane UZRG and PRG, 250 m long in both directions |

||||||

|

20. Intersections with underground communications (sewers, oil pipelines, oil product pipelines, gas pipelines) mi, power cables and cables communications, underground, above-ground and above-ground irrigation systems and etc.) within 20 m on both sides of the crossed utility line |

||||||

|

21. Intersections with communications shown in pos. 20, and among themselves multi-line main gas pipelines with a diameter of over 1000 mm and a pressure of 7.5 MPa (75 kgf/cm2) or more and oil pipelines with a diameter of over 700 mm within 100 m on both sides of the intersecting communication |

||||||

|

22. Intersections (in both directions) within the limits lah of the distances indicated in pos. 12 tables 4, with overhead power lines voltage, kV: |

||||||

|

a) 500 or more |

||||||

|

b) from 330 to 500 |

||||||

|

23. Pipelines laid through mined areas and areas prone to karst phenomena |

||||||

|

24. Crossings through ravines, beams, ditches and drying up streams |

||||||

|

25. Oil pipelines and oil product pipelines waters laid along rivers with a water surface width of 25 m or more during low-water periods, canals, lakes and other reservoirs that have of fishery importance, higher than settlements and industrial enterprises at a distance. from them to 300 m with pipe diameter 700 mm or less; up to 500 m with pipe diameters up to 1000 mm inclusive; up to 1000 m with pipe diameters over 1000 mm |

(without preliminary hydraulic testing on the highway) |

|||||

|

26. Gas pipelines, oil and petroleum product pipelines laid in one technical corridor, at the locations of UZRG, PRG, installation units ki of linear shut-off valves, start-up and acceptance of treatment devices, connection points of CS, CGTU, UPPG, SFGS, BCS, GS into the pipeline within the distances specified in pos. 9, 10, 14 and 15, and from the CS connection points into the pipeline within 250 m on both sides of them |

||||||

|

(unless they belong to a higher category by type gaskets and other parameters) |

||||||

|

cause interruptions in the supply of gas, oil and petroleum products to cities and other large consumers of great national economic importance, as well as environmental pollution, with appropriate justification, it is allowed to increase by one category. 2. Types of swamps should be accepted in accordance with the requirements of SNiP??????-42-80. 3. When a pipeline crosses an array of swamps of various types, with appropriate justification, it is allowed to accept the category of the entire section as for the highest category in this area 4. Testing of pipeline sections laid through water barriers with a water surface in Low water less than 10 m should be provided as part of the installed pipeline in one stage. |

||||||

|

5. Operating pipelines that are in a satisfactory technical condition (according to the conclusion of the representatives of the customer of the structure under construction, the operating organization and the relevant state supervision authority), when they are crossed by the projected pipelines, power lines, as well as underground utilities indicated in pos. 20 and 21, and at parallel to the laying in accordance with pos. 26, cannot be replaced by pipelines of a higher 6. Existing pipelines crossed by railways and roads under construction are subject to reconstruction in accordance with pos. 3. 8. With a short duration of flooding by flood waters (less than 20 days) and the insignificant depth of this flooding, which allows the rapid conduct in the area emergency recovery work on pipelines in case of damage, fulfillment of the requirements of pos. 1d is not necessary for gas pipelines. for shipping - according to pos. 1a; „ non-navigable - according to pos. 1b and 1c. |

1 area of use

1.1 This set of rules applies to the design of new and reconstructed main pipelines and branches from them with a nominal diameter up to DN 1400 inclusive, with an overpressure of the medium in excess of 1.2 to 10 MPa inclusive (with a single laying and laying in technical corridors) for transportation:

a) oil, petroleum products (including stable condensate and stable gasoline), natural, petroleum and artificial hydrocarbon gases from areas of their production (from fields), production or storage to places of consumption (oil depots, transshipment bases, loading points, gas distribution stations, individual industrial and agricultural enterprises and ports);

b) liquefied hydrocarbon gases of fractions C3 and C4 and their mixtures, unstable gasoline and petroleum gas condensate and other liquefied hydrocarbons with a saturated vapor pressure at a temperature of plus 40 ° C not more than 1.6 MPa from the areas of their extraction (fields) or production (from head pumping stations) to the point of consumption;

c) marketable products within the compressor station, oil pumping station, pumping station, underground gas storage stations, booster compressor station, gas distribution station and gas flow metering unit;

d) pulse, fuel and starting gas for CS, UGS, BCS, GDS, UZRG and gas reduction point (hereinafter - PRG).

This set of rules does not apply to the design of pipelines laid in cities and other populated areas, with the exception of main oil pipelines laid to connect them to oil processing, transshipment and storage enterprises, in offshore areas and fields, as well as pipelines intended for gas transportation , oil, petroleum products and liquefied hydrocarbon gases that have a corrosive effect on the metal of pipes or cooled to a temperature below minus 40 ° C.

The design of pipelines intended for the transportation of stable condensate and stable gasoline should be carried out in accordance with the requirements of this set of rules for oil pipelines. Stable condensate and gasoline should include hydrocarbons and their mixtures having a saturated vapor pressure of less than 0.2 MPa (abs) at a temperature of plus 20 °C.

1.2 Design of pipelines for liquefied hydrocarbons with saturated vapor pressure at a temperature of plus 20 °C above 0.2 MPa - liquefied hydrocarbon gases, unstable gasoline and unstable condensate and other liquefied hydrocarbons - should be carried out in accordance with the requirements of section 16. Design of buildings and structures, in including engineering communications located at the sites of compressor stations, pump stations, substations, GDS, UGS facilities and BCS, should be carried out in accordance with the requirements of technical regulations, standards, other regulatory documents in the field of technical regulation that apply to the design of relevant buildings and structures, taking into account the requirements this set of rules. The design of gas pipelines with a pressure of 1.2 MPa or less and oil product pipelines with a pressure of up to 2.5 MPa, intended for laying in the territory of settlements or individual organizations, should be carried out in accordance with the requirements of SP 62.13330, SP 110.13330 and SP 125.13330, technical regulations, standards and others normative documents in the field of technical regulation.

This set of rules uses references to the following regulatory documents: GOST R 51164-98 Main steel pipelines. General requirements for corrosion protection GOST R 52568-2006 Steel pipes with protective external coatings for main gas and oil pipelines. Technical specifications GOST 9.602-2005 Unified system of protection against corrosion and aging. Underground structures. General requirements for corrosion protection GOST 2246-70 Steel welding wire. Technical specifications GOST 3845-75 Metal pipes. Hydraulic pressure test method GOST 5457-75 Dissolved and gaseous technical acetylene. Technical specifications GOST 5494-95 Aluminum powder. Technical specifications GOST 5583-78 Oxygen gas, technical and medical. Technical specifications GOST 6996-66 Welded joints. Methods for determining mechanical properties GOST 8050-85 Carbon dioxide, gaseous and liquid. Technical specifications GOST 9087-81* Fused welding fluxes. Technical specifications GOST 9238-83 Approximation dimensions of buildings and rolling stock of 1520 (1524) mm gauge railways GOST 9454-78 Metals. Test method for impact bending at low, room and elevated temperatures GOST 9466-75 Coated metal electrodes for manual arc welding of steels and surfacing. Classification and general technical conditions GOST 9467-75 Coated metal electrodes for manual arc welding of structural and heat-resistant steels. Types GOST 9544-2005 Pipeline shut-off valves. Classes and standards of tightness of valves GOST 10157-79 Argon gaseous and liquid. Technical specifications GOST 12821-80 Steel butt welded flanges on Ru from 0.1 to 20 MPa (from 1 to 200 kgf/cm2). Design and dimensions GOST 13109-97 Electrical energy. Electromagnetic compatibility of technical equipment. Standards for the quality of electrical energy in general-purpose power supply systems GOST 20448-90 Hydrocarbon liquefied fuel gases for municipal and domestic consumption. Technical specifications GOST 25100-2011 Soils. Classification GOST 30456-97 Metal products. Rolled sheet metal and steel pipes. Impact bending test methods SP 14.13330.2011 “SNiP II-7-81* Construction in seismic areas” SP 16.13330.2011 “SNiP II-23-81* Steel structures” SP 18.13330.2011 “SNiP II-89-80* General plans for industrial enterprises" SP 20.13330.2011 "SNiP 2.01.07-85* Loads and impacts" SP 21.13330.2012 "SNiP 2.01.09-91 Buildings and structures in mined areas and subsidence soils" SP 22. SP 28 .13330.2012 “SNiP 2.03.11-85 Protection of building structures from corrosion” SP 47.13330.2012 “SNiP 11-02-96 Engineering surveys for construction. Basic provisions" SP 62.13330.2011 "SNiP 42-01-2002 Gas distribution systems" SP 86.13330.2012 "SNiP III-42-80* Main pipelines" SP 110.13330.2011 "SNiP 2.11.03-93 Oil and petroleum products warehouses. Fire safety standards" SP 125.13330.2012 "SNiP 2.05.13-90 Oil product pipelines laid in cities and other populated areas" SNiP 2.01.51-90 "Engineering and technical measures of civil defense"

Note- When using this set of rules, it is advisable to check the effect of reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annually published information index "National Standards", which was published as of January 1 of the current year , and according to the corresponding monthly published information signs published in the current year. If the reference standard is replaced (modified), then when using this set of rules, one should be guided by the replacing (modified) document. If the reference document is canceled without replacement, then the provision in which a reference to it is given applies to the part that does not affect this reference.

3 Terms and definitions

In this set of rules the following terms with corresponding definitions are used:

3.1 shut-off valves: Industrial shut-off valves designed to shut off the flow of a working medium with a certain tightness.

3.2 bypass: A pipeline with shut-off and control valves connecting the inlet and outlet of a technological installation (structure), and designed to direct all or part of the flow of the pumped product bypassing this installation, including to exclude it from operation during maintenance or in case of failure.

3.3 edge of the trench (ditch, excavation): The line of intersection of the wall of the trench (ditch, excavation) with the surface of the earth.

3.4 connecting parts: Pipeline elements designed to change the direction of its axis, branch from it, change its diameter.

3.5 working pressure: The highest overpressure of the pipeline section for all stationary pumping modes provided for in the design documentation.

3.6 pipeline test pressure: The maximum pressure to which a pipeline section is subjected during pre-start strength tests for the required time.

3.7 pipeline depth: Distance from the top of the pipe to the ground surface; in the presence of ballast - the distance from the surface of the earth to the top of the ballasting structure.

3.8 anodic grounding: A device that ensures the protective current of cathodic protection flows into the ground and consists of one or more anode grounding conductors.

3.9 cathodic protection: Slowing down the rate of the corrosion process by shifting the potential of exposed sections of the pipeline towards more negative values than the free corrosion potential of these sections.

3.10 elastic pipeline bending: Changing the direction of the pipeline axis (in vertical or horizontal planes) without using bends.

3.11 drain cable: A conductor connecting the negative terminal of the DC source to the pipeline (cathode drain line) and the positive terminal to anode grounding (anode drain line).

3.13 compensator: A special structure or section of a pipeline of a given curvature, designed to accommodate temperature movements.

3.14 looping: A pipeline laid parallel to the main pipeline and connected to it to increase its capacity.

3.15 protection zone of the main pipeline: Territory or water area with special conditions of use, established along the main pipeline to ensure its safety.

3.16 underwater pipeline crossing: A section of a pipeline laid through a river or reservoir with a low-water width of more than 10 m and a depth of more than 1.5 m, or a low-water width of 25 m or more, regardless of depth.

3.17 protective coating: A material and (or) structure that isolates the outer or inner surface of the pipeline from the external or internal environment.

3.18 protective potential: cathodic potential providing the required inhibition of the corrosion process.

3.19 passage along the main pipeline: The facility of the main pipeline, intended for the transportation of goods and personnel along the route of the main pipeline during its construction and operation.

3.20 protector: an electrode made of a metal or alloy having a more negative potential than the protected pipeline.

3.21 technological redundancy: the presence of mutually redundant technological units designed to put one of them into operation in the event of being taken out of operation due to a malfunction of the other.

3.22 pressure wave smoothing system: A structure equipped with a set of technical devices that provides protection for main pipelines and intermediate oil pumping (pumping) stations from pressure overload in case of an emergency stop of one or more pumping units.

3.23 insulating connection: an insert between two sections of a pipeline that disrupts its electrical continuity.

3.24 cathode station: A complex of electrical equipment designed to create a direct electric current between the anode ground electrode and an underground structure (pipeline, tank, etc.) with cathodic protection of the latter from corrosion. Note - There are networked cathode stations (the most common), the source of electricity for which is power lines, and autonomous ones, which include autonomous power supplies.

3.25 compressor station: a main gas pipeline facility that includes a complex of buildings, structures and devices for receiving and pumping gas through the main gas pipeline.

3.26 pumping station: an object of a main oil product pipeline, which includes a complex of buildings, structures and devices for receiving, accumulating, accounting and pumping oil products through a main oil product pipeline.

3.27 pumping station: an object of the main pipeline of liquefied hydrocarbon gases, which includes a complex of buildings, structures and devices for receiving, accumulating, accounting and pumping liquefied hydrocarbon gases through the main pipeline.

3.28 oil pumping station: a main oil pipeline facility that includes a complex of buildings, structures and devices for receiving, accumulating, accounting and pumping oil through the main oil pipeline.

3.29 stray currents: currents in the ground, flowing outside the circuits intended for them and arising from the operation of external sources of direct or alternating voltage (electrified vehicles, welding machines, electrochemical protection devices for foreign structures, etc.).

3.30 pipeline route: the position of the pipeline axis, determined on the ground by its projection on the horizontal and vertical planes.

3.31 main pipeline: A single production and technological complex, including buildings, structures, its linear part, including facilities used to ensure the transportation, storage and (or) transshipment of liquid or gaseous hydrocarbons to road, rail and water transport, measurements of liquid (oil, oil products, liquefied hydrocarbon gases, gas condensate, a wide fraction of light hydrocarbons, their mixtures) or gaseous (gas) hydrocarbons that meet the requirements of the legislation of the Russian Federation.

The site contains up-to-date documentation (SNiP, GOST, STO, etc.) for sewer systems and water supply. By following the link you can read, download or print any document. All documents are in PDF format. All regulatory documents presented on this page are for informational purposes only.

SNiPs