Photos of a homemade airplane made of plywood and wood. Let's build our own plane! How to build a model airplane yourself

Every boy in childhood dreamed of being at the controls of an airplane. The sky, clouds, and travel have always attracted adventurers and brave men. But to feel closer to aviation, you don’t have to buy a plane ticket or enroll in a flight school. After reading this article, you will learn how to make an airplane out of wood with your own hands.

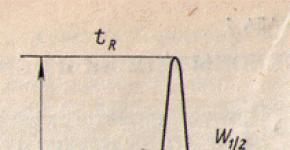

Required tools and materials

Before you search for a suitable aircraft model and its drawing, you need to provide yourself with the necessary materials. The best option would be. In its manufacture, three layers of birch veneer are glued together using phenolic glue.

In this case, the thickness of the material is important; it should be about 1 mm, but thicker sheets of plywood may be needed. If you don’t know how to make a flying airplane out of wood, then pay attention to this parameter. Moreover, this material is very light, flexible and durable.

When choosing plywood suitable for the job, you should pay attention to its appearance. Its thickness should be the same over the entire area. There must be no defects of any kind, delamination, chips or cracks. The material should be dry, so it is easier to process.

made of wood

Now that you have mastered the information on how to make an airplane out of wood in various ways, you can choose any of the options and modify it as you wish.

You can construct the structure yourself, but to do this you will need to study publications on the design of modern aircraft. Various virtual design programs may be useful.

If you are unable to find dry material, you can prepare plywood sheets yourself by keeping them in a room with low humidity and constant temperature for two to three weeks.

If you have never made and do not know exactly how to make an airplane out of wood, then take on the job only if you know what the future model will be like, or when its aerodynamic properties are not important (making a children's toy).

When making a decorative model or toy, you should get rid of sharp corners by chamfering.

If you are working on a model intended for flight, then special attention should be paid to the precise positioning of the tail and wings. After all, the aerodynamic properties depend on them.

Conclusion

Airplane models of varying levels of complexity are made by craftsmen all over the world. At the same time, the most complex controlled models can perform aerobatic maneuvers.

Having selected a suitable drawing, you can easily figure out how to make an airplane out of wood. However, such work will be uncomplicated only when making the simplest models. Novice builders will not be able to undertake more labor-intensive tasks; they should master the simplest technologies and schemes, as well as understand the process in more detail.

Since childhood, many boys have been fascinated by technology, various cars, trains, and airplanes. They are of great interest in all elements that are directly related to these subjects. To get your child interested in creativity, invite him to make toys together that look like an airplane.

Children's crafts in the shape of an airplane will be a great way to spend time together with your child. You can have fun in your free time. In addition, such crafts can be done together with the children at children's parties.

The photo of airplane-themed crafts demonstrates the variety of models that you can make with your own hands.

Airplane made of wood

When creating an airplane from wood, the question arises, what can you make an airplane out of? To create an airplane craft, you need to have a clothespin, wooden sticks, acrylic paints, brushes, Moment glue, scissors and sandpaper.

Algorithm for creating a toy airplane

Let's look at step-by-step instructions on how to make an airplane. This will allow you to create a craft without any problems if you strictly follow the instructions for creating a toy airplane.

We take blue paint and paint the wings of the future airplane. Then we take red paint and paint the clothespins, which will later become the basis of the airplane. To create the hind wings, you need to cut the stick into two parts. Scissors must be used to round the cut edge.

The tail of the plane consists of a piece of stick. Cut a piece of 10 millimeters from the stick. To do this we use a stationery knife. The edge should not be smooth.

Using sandpaper, sand the surface of the wooden sticks. We paint the resulting parts and glue them together.

Cardboard airplane

To create this version of the airplane you will need blue cardboard, matchboxes, scissors, Moment glue, and cork.

We take a stencil and cut out all the parts of the aircraft, from which we will then create it.

We take a matchbox and glue it to the base of the plane. You need to cut out one small strip from cardboard, which you then glue to the base of the plane. Blanks of the same size are then glued on top of the matchbox on the other side.

To create a tail, you need to cut a strip measuring 50 millimeters by 10 millimeters. The edges are rounded on both sides. The resulting strip must be divided into three equal parts. Each strip should be 15 millimeters. To do this, you need to use a utility knife.

You need to glue stars to the airplane. They will become a real decoration of the model.

We take a wine cork. Using a utility knife, cut off a small circle. Next, apply a little glue to the surface of the cut piece of cork and glue it to the plane. Then you need to create a propeller. Its creation is described as a wooden airplane.

We take a needle that needs to be used to pierce the cork. Then we attach all the parts to the base of the plane. We create small flowers from several sheets of colored paper. To do this, you need to take a decorative hole punch. These leaves must be glued to the entire surface of the airplane.

Note!

Airplane from a bottle

To create an airplane from a bottle, you need to take the bottle itself. Using a knife, you need to make several slits into which you will later need to insert cardboard. This cardboard should look like the wings and tail of an airplane.

From thick cardboard we cut out a part that looks like a propeller. In the center of this figure you need to cut out a place for a plastic plug. It is necessary to install a propeller over the neck of a plastic bottle, and then screw on the plastic cap. This will allow you to secure the propeller to the plastic bottle.

After this, you can invite the child to paint the plastic bottle in the color he wants. The child will be happy to color the base of the plane and its wings.

Thus, crafts from airplanes will be ready. The presented options for creating children's airplanes allow you to quickly make a craft.

You can conduct a master class on airplane-themed crafts. This will make the children's party more interesting and at the same time useful.

Note!

You can make your own choice of materials for crafts with your own hands. If your child is interested in wooden crafts, then it is best to make an airplane out of wood, but if your child is interested in crafts from cardboard, then it is recommended to create a flower airplane.

Photo crafts airplane

Note!

Modern toy stores are simply bursting with a large assortment of all kinds of cars, bears, construction sets and much more. But remember the old days, when there was no such abundance. Then, in clubs and craft classes, we were taught to make toys ourselves, and the main material for creativity was plywood for modeling. It is precisely these crafts that we will tell you about today.

Preparation of material and tools

Like any business, and making a toy for a child is a very important step, you must first prepare both the material and the tools that will be needed in constructing the model.

If you are missing something from the list above, buy these missing items urgently.

- Hand jigsaw for wood, an electric tool in our case is not our help; we do everything manually.

- Model plywood, usually the thickness of the material is three and seven millimeters, otherwise it is also called three-layer and seven-layer, respectively.

- Pencil, ruler.

- Sandpaper and square file for processing aircraft spare parts.

- PVA glue or any other, which is designed for gluing wood.

- Great patience and desire to bring joy to the child.

We need to start our design, of course, by marking out all the parts of the future airplane, namely: the fuselage, wings and stabilizer. You can first draw a drawing on paper, and then transfer it to the plywood itself, or you can immediately draw the details on the plywood, whichever is more convenient for you.

Since our model of an airplane made of plywood was invented on the fly, there are no exact dimensions and, accordingly, a template or drawing. But as an example, we will take a certain size of the wingspan, and we will build on it when assembling our aircraft.

Let's make the wingspan thirty centimeters long, this is perhaps the most optimal option; for those who find such an airplane small, they can increase the size of the wings and thereby make the airplane a little larger.

Cutting out blanks with a jigsaw

As you can see in the photo, all the components can be easily drawn by hand, there is nothing complicated here. Let's start with the fuselage, the length of which can be made ten millimeters larger than the wings. Just draw the body itself by hand as shown in the picture.

Immediately on the fuselage body, make tenon joints for attaching the wings. Due to such connections, prefabricated plywood models are quite strong and can be easily connected with glue, so be sure to use them.

Let's move on to the wings, as we have already decided, the wings will be thirty centimeters long, respectively eight to ten centimeters wide. Remember the main thing, the lower wing should be no more than ten millimeters shorter than the upper one.

All that remains is to draw the struts to support the wings, the rear flap, and the stabilizer. When everything is ready, you can start cutting out the parts with a jigsaw. Carefully cut out all the parts for the plane based on the outlines you drew. Don’t be discouraged if there are some unevenness somewhere, in any case, you try, and you will succeed.

Advice!

The cut parts must be sanded with sandpaper immediately before assembling the model.

Once you assemble the plane, it will be inconvenient to polish it, as the model can be damaged.

Assembling our plane

As a rule, modeling from plywood is an interesting and meticulous task, and if you have already prepared tenon joints on the fuselage, now you need to make grooves on the wings for fastening to the body and for the struts supporting the wings.

Feel free to use a file while working and adjust the connections as accurately as possible. Start assembly by installing the stabilizer, which you will glue to the tail of the toy.

At the next stage, our instructions recommend installing the wings in their place. To do this, apply glue to the joint and install the upper wing. Having turned the model over, we install racks to support the wings, and also pre-apply glue to the attachment points.

There is very little left and our homemade plane will be ready, we install the lower wing and our assembled structure. Also carefully coat all the butt joints on the assembled model with glue and place the plane on the shelf, allowing the glue to dry completely.

It’s not at all difficult to make such an airplane, of course it’s not an ideal option, and if you want, you can look for other drawings of prefabricated plywood models, because the flight of fancy and creative ideas don’t end there. Let's take a look at what other crafts can be made from wood.

We continue to make homemade products

Well, let's not stop halfway, but let's try to please the child some more, with some kind of plywood craft. If you focus on a boy, then it is possible that you want to know how to make a tank out of plywood? Quite a logical question, let's try to answer it.

As an example, we invite you to consider our small model of a plywood tank, which is easy to manufacture and, when assembled, looks no worse than tanks made from plastic construction sets.

Let's look at all the design stages in order, and start with the materials that are needed for modeling.

- Plywood is, of course, the basis of our model; in this case, the thickness of the plywood should be two to three millimeters. With such plywood it will be very convenient to cut out parts and then assemble them.

- Copy paper, with its help we will transfer the drawing to the workpiece.

- A set of needle files will help in processing tenon joints when assembling the model.

- A hand jigsaw and files for it, as for the files, prepare several of them, usually when cutting a model from plywood with your own hands, the files tend to break.

- Glue, preferably using PVA, it interacts well with wood and becomes discolored after drying.

- Sandpaper and clear varnish.

Advice!

It is recommended that before starting to outline the details of the tank, the prepared material, plywood, should be cleaned with emery cloth and the surface made smooth.

This approach will ensure more accurate copying of the drawing onto the plywood surface.

Copy the drawing and cut out the elements of the tank

The next step in constructing a tank model will be to transfer all the component parts of the model from paper to plywood. In the modeling process, namely answering the question of how to make a tank from plywood, model drawings play a very important role.

Tank model drawing. Part 1

Now that you have a ready-made template of parts in your hands, you need to transfer it to plywood using carbon paper. Outlining the details is best done with a simple pencil or using an empty ballpoint pen.

Do not forget about the numbering of parts; when copying, also transfer them to the material. In the future, when assembling, it will be easier for you to navigate the details. The rules of assembly are the joining of parts in sequence according to numbers: number one is connected to number one, number two is connected to number two, respectively.

When everything is ready and the drawing has been transferred to plywood, you can start cutting out the parts. We won’t teach you how to use a jigsaw, but we will give you a recommendation. After you cut out all the parts, be sure to sand them down, so you will smooth out all the corners left by the jigsaw and ultimately get a neat model.

Now, in order of numerical designation, we begin to assemble our model of the tank; after joining, we coat all connections with glue and let them dry a little. After assembling all the components, you should have a tank model that is almost ready.

As in any other matter, it remains to put an end to it, and our point is to treat the assembled model with colorless varnish. Believe me, the price of such a homemade toy is not comparable to the joy of your baby who will play with it, you can be sure that you did not waste your time making such a model.

What else can be made from plywood

In fact, modeling has enormous potential for creativity; plywood as a material is ideal for these purposes. Various plywood car models are very popular; as a rule, they are easy to manufacture and are in demand among children.

Here, for example, is a simple model of a truck; its manufacture will require very little material, and it will not take much time to assemble. If you take into account that you already have all the necessary tools, you can make such a craft without much effort.

In order to make such a truck, it is enough to transfer the template and all the spare parts of the car onto the material. Then collect all the parts and connect them together. These drawings of plywood car models have a common base and on this base you can assemble various versions of trucks.

If you get creative, you can make a closed van instead of a body, or cut out a fire escape, fantasize and bring your ideas to life together with your child.

Making a boomerang yourself

Another very interesting toy is the boomerang. In fact, this toy was considered a throwing weapon in the old days, but today both adults and children really enjoy the flight of this unique invention and return it to the place from which it was launched.

Let's figure out how to make a boomerang from plywood, while respecting all its aerodynamic properties. As a rule, first of all we need a material, in our case it will be plywood ten millimeters thick, and a template.

For the template, you will need a sheet of paper measuring fifty by sixty centimeters, and apply a grid with a mesh size of fifty millimeters on this sheet of paper. Then we draw the boomerang itself on the template, try to do this as shown in the figure below.

After the boomerang template is ready, we cut it along the contour and transfer it to our plywood blank and follow a simple procedure:

- We trace the contours of the template with a pencil on the workpiece.

- Using a hand jigsaw, cut out the boomerang according to the contours.

- The resulting boomerang must be further processed and given aerodynamic properties.

- We clamp the boomerang blank with a clamp and use a small plane from the center to the edges to remove the excess wooden covering.

- As a result of processing, we should get a uniform transition from the edge to the center. The central part should be ten millimeters thick, the edges of the boomerang six millimeters. Try to make the transition smooth and not jagged.

- The next step is to be thorough. The boomerang must be perfectly smooth, this directly affects the aerodynamics.

- Now the toy needs to be opened with varnish and, after drying, painted in a bright color. Typically, bright colors will make the toy easy to spot in flight or when searching after it lands.

Information!

The boomerang by its nature belongs to the category of dangerous toys, so be careful when launching it so as not to harm yourself and the people around you.

It is advisable to launch in the field, in places where there are not crowded people and no residential buildings.

Finally

Very often, lovers of fakes are interested in: how to make a balalaika from plywood and is it possible to do this in practice at home? We hasten to please you, although such a product is considered a complex musical instrument, it can still be made at home. But we will talk about this complex process another time.

In the video presented in this article you will find additional information on this topic.

An airplane made of plywood is a common type of fake that you can easily make with your own hands.

Important qualities of the material are considered:

- Environmental cleanliness;

- Durability;

- Strength.

Plywood is used in many industries: in the production of aircraft, ships, cars. This type of material always remains popular and indispensable in the creative processes of craftsmen and designers. Products obtained with its help can amaze the imagination.

Preparation of tools and material

To construct a model aircraft, you must first prepare suitable material and tools. It is recommended to stock up on:

- Using a hand jigsaw on wood, because electric tools will not help in this case, everything is done by hand.

- Model plywood, the thickness of which is chosen to be 3 mm or 7 mm, this type of material is called three-layer and seven-layer, respectively.

- Pencil, ruler.

- Sandpaper and a square file for processing spare parts of the structure.

- PVA glue or any other that is intended for gluing wood.

- Patience and the desire to bring joy to the child.

Begin design with markings of all elements of the future structure, namely from the following:

- Fuselage;

- Wings;

- Stabilizer.

Attention! You can initially draw drawings of airplanes from plywood on a sheet of paper, then transfer them to plywood fragments. It is also possible to draw elements directly on sheets of plywood.

Without having certain dimensions to create a design, if the model is invented on the fly without templates and drawings, they start from specific indicators of the wingspan when assembling the unit. The optimal parameters for this structure can be taken as 30 cm for the span length. As the wingspan increases, the size of the aircraft itself increases accordingly.

Creating blanks

If the question arises of how to make an airplane from plywood, you should start the process with creating preparatory elements:

- The constituent elements can be easily drawn by hand, because there is nothing complicated here. Usually they start with the fuselage, the length of which can be made 10 mm longer than the length of the wings. The body of the product is hand drawn, giving the desired shape to the airplane.

- On the fuselage body it is recommended to immediately make tenon joints for attaching the wings. Thanks to such connections, prefabricated models from this material are created quite strong and are simply connected with glue, so they must be used.

- When the parameters of the wings have already been calculated - length 30 cm and the corresponding width 8-10 cm, you need to take into account the correct proportion. Since the lower wings must be made a maximum of 10 mm shorter than the upper ones.

- All that remains is to draw the struts as wing support elements and make a sketch of the rear flap and stabilizer.

After completing the above procedures, it’s time to start cutting out spare parts using a jigsaw. All spare parts for the product are carefully cut out along the drawn contours. If you get some irregularities, you don’t need to be upset, they won’t be too noticeable.

Note! The parts obtained by cutting are sanded with emery cloth until the aircraft is assembled. After all, if the structure is already finished, it will be inconvenient to polish it, and there is also a high probability of damage to the airplane.

Assembly

It’s not difficult to make an airplane out of plywood with your own hands. If the fuselage has already been prepared with tenons, it is time to start creating the grooves on the wings, as well as for fasteners on the body and for the struts that support the wings. It is convenient to use a file during the assembly process and adjust the connections with greater accuracy.

Assembly begins with the installation of a stabilizer, which is glued to the tail of the product. Next, you should install the wings in their places using an adhesive solution, which is applied to the joints and install the upper wings. By turning the model over, racks are installed to support these elements, after applying glue to the connection points.

Next, the lower wings must be installed. In the same way, carefully coat the joints on the plane with an adhesive solution when it is already assembled. After this, you need to let the structure rest while the glue dries.

Elevator and rudder

The plywood model of the aircraft ensures that no difficulties arise during the manufacture of the rudder elements. They may appear during their installation. After all, you need to make a level installation so that there are no difficulties when flying the product. When creating the steering wheel, it should be taken into account that the connecting jumper of both halves is small in size and requires a strengthening process. Reinforcement can be done using a thin strip of ruler, placing it on glue. It is possible to increase the area of this site.

There is also the possibility of amplification using carbon tubes. Upon completion, the reinforcement is covered with tape, after which warming up is strictly prohibited. The adhesive tape holds the element quite well, and when you try to heat it, it becomes possible for the stabilizer to shift. For the rudder, the same recommendations are taken into account.

The elevator is leveled using struts, which are made of thin spokes. There should be no problems when gluing it into the fuselage, it is a simple process.

But problems may arise with the rudder - you need to work hard to install it evenly. For gluing into the fuselage, rod ends are used, which are glued to the spokes. It is also recommended to use supports made from rulers. So that the supports for strengthening the elevator are not conspicuous, they can be hidden under white tape.

Chassis

Aluminum rulers for creating the chassis turned out to be an ideal option when creating the product. Wheels can be taken from toy products.

It will be reliable to make a structure from one ruler, but you can use two rulers, each 15 cm long. Here the excess parts are cut off and folded according to the drawing. It is better at this stage to combine gluing and drilling holes for mounting screws.

Install the chassis after covering. Before the gluing process, I used the method of gluing the desired element, first wrapping it with thread turn to turn, after which it was lubricated with an adhesive solution.

Hood

It is recommended to make this element, as an option, from strip ceilings. Cut a rectangle 7 cm wide and about 30 cm long, apply it to the nose of the plane and wrap it. The bottom is glued with tape. An important point is to choose the correct direction of the bends of the ceiling. There are cases where the heating method is used to create suitable shapes for the part. A propeller from a processor cooler with a suitable size is used as the front of the motor. This helps solve problems with ventilation of engine compartments. You can limit yourself to stickers of blinds printed on a printer from a drawing diagram.

Features of the drawing

When they don’t know how to make an airplane out of plywood, ready-made drawings may be appropriate. Gluing is easy - there are marks on the sheets that can be combined to obtain the correct lines without displacement.

When transferring an image to the ceiling, the following two options can be used:

- The first involves fixing the sheet on the ceiling with pins and piercing along the contour with a thin awl. Then, for clarity, connect the holes made on the ceiling using a pencil, or you can cut them with a sharp knife. On a straight section it will be enough to make a few punctures, but on curves a transfer with a large number of punctures will be accurate.

- The second option is suitable if the drawing is printed on an inkjet printer. To transfer, moisten the tile, apply the drawing and iron it on a smooth surface with a warm iron. The picture will remain on the fragment of material.

When placing the drawing, take into account that the ceiling tiles have different bending strengths. I check this point by bending the sheet on different sides.

Here the top and bottom of the plane are shown as halves of different sizes. To draw the lines correctly, it is recommended to first draw one half, then make a mirror image of it. The upper part is divided into two segments - the front one runs from the nose of the car to the leading edge of the wing; rear from the end of the product to the trailing edge.

When creating a plane from plywood with your own hands, the drawings are simply irreplaceable for the work process.

Such a task, difficult at first glance, as building a wooden airplane on your own, can be done by any aviation enthusiast, even a schoolchild who regularly attends an aircraft modeling club. Do not think that this model of aircraft is intended to carry passengers on board. For all his efforts, the inventor will be rewarded with excellent flying characteristics of the aircraft and its high strength. The creators who launch their wooden gliders gain experience in controlling and adjusting free-flying aircraft models, and also receive unforgettable, incomparable impressions from the real flight of a wooden airplane constructed with their own hands.

Let's look at what you might need for this. Most likely, the materials and tools from the following list will be sufficient:

- pine slats;

- jigsaw;

- PVA glue;

- plane;

- aluminum wire;

- Styrofoam;

- lavsan film;

- household iron with thermostat.

Let's assume that you have prepared everything you need. This means that you are ready to go and can proceed directly to the design process.

This is the initial stage of work on modeling a wooden airplane. Take your slats (5x5 mm cross-section) and glue them together using PVA glue. When the glue is completely dry, you can reinforce the frame structure with internal corners, which can be made from foam plastic. This material is excellent for aircraft modeling, as it has sufficient strength with minimal weight. Therefore, you can also cut the upper end of the keel from a small piece of foam with a knife. You can use balsa. The front and rear edges of the frame must be rounded. Mylar film will be useful for the keel, which will look much more attractive if covered with such colored film. The steering wheel needs to be glued to the trailing edge. As a rule, it is cut out of cardboard with a thickness of about 0.5 mm.

Making a stabilizer

We also assemble this part from pine slats of the same cross-section as in the case of the frame of our model. Having rounded the edges, also reinforce it with foam elements. Bend the end parts of the future stabilizer from the prepared wire. You can also use an aluminum knitting needle, a piece of wire, or other suitable material. The ending must be tightly wound to the frame with threads treated with PVA glue or epoxy resin. When you have a finished stabilizer, just like the keel, cover it with a thin layer of lavsan film.

Collecting wings

Make a wing from pine wood. The front and rear edges of the wing must correspond to a section of 3.5x9 mm, and the spar - 3.5x7 mm. A pine blank or linden is suitable for constructing a rib. After completing the frame assembly, plan the edges along the wing profile, rounding them.

Fuselage design

You can also make it from pine slats, only with a larger cross-section - 10x15 mm. This rail should smoothly and evenly thin towards the tail along its entire length. Plane a spout from pine or linden and insert a balancing weight into the hole. You can take a piece of lead as a load, which will be easy to rivet.

Connecting elements

After you have glued and processed the fuselage, use PVA glue to glue the fin to it, and then the stabilizer. Be sure to maintain mutual perpendicularity for the tail elements, and also ensure that the stabilizer is evenly positioned relative to the fuselage beam. Cover the varnished fuselage with brightly colored nitro paint.

Pre-adjustment

Your wooden glider model is ready for adjustment. At the front and rear edges of the fuselage, you need to tie a pylon with a rubber band, and then begin to move the wing along the beam to determine the desired position. This can be determined by the relation of the center of gravity to the position of the wing.

Trial run

To carry out a test run, it is better to use the gym premises. If you don't have this option, choose a calm day. With a gentle throw along the horizon, launch the model airplane. Try to achieve the lowest descent speed, for which use adjusting wedges made of wood. They should be placed between the fuselage and the pylon. Gain experience in "piloting" techniques so you can confidently demonstrate your design skills on your own wooden airplane. Successful launches will bring a sea of positive emotions not only to you, but also to the curious public.

Aircraft modeling helps a person develop in many directions. By studying in a circle or on your own, you acquire knowledge and skills when working with accessible, environmentally friendly, familiar materials, such as wood, PVA glue, cardboard, plywood, polystyrene foam, and so on. Also, at the same time, you learn to analyze your actions and make competent decisions in the most unusual situations. A person who is interested in aircraft modeling develops needs for self-realization and self-knowledge. Interest in the design and modeling process is developing. In addition to practical skills, a culture of communication with colleagues in the circle is formed, as well as important moral and volitional qualities such as determination, will, self-discipline, a sense of mutual assistance and collectivism. Of particular importance in our time is the formation of healthy lifestyle skills and patriotism. During the classes you can learn a lot about significant personalities in the history of aircraft manufacturing and aviation in general.