The sequence of installation of interior doors. How to properly install an interior door

The ability to handle carpentry and measuring tools is already a reason to try to solve such a difficult task as installing interior doors with your own hands. The work is simple, but tricky in its own way. It will take scrupulousness, and even tediousness in marking and adjustment, otherwise it will not work to install the interior door with the box correctly.

Features of installing interior doors

At first glance, nothing complicated, but this is only a superficial impression. We are talking about not just installing the frame and the door leaf in the interior opening, but doing it beautifully, without distortions, scratches and sagging hinges. If this is the first experience, then it is best to make detailed step-by-step instructions for installing interior doors with your own hands before starting work. It's not embarrassing for newbies. Even experienced craftsmen often make notes with their own hands - what not to forget and what to look for when installing a door frame on a specific interior partition.

During the installation process, you will need to solve the two most difficult tasks with your own hands:

- Correctly assemble and install the frame of interior doors, align and fix it so that the frame does not sag under the weight of the door leaf;

- With your own hands, mark and cut out the mounting grooves on the vertical rack of the box and on the end of the interior door leaf.

An experienced craftsman takes 2-3 hours to install an interior door, a beginner will need at least a day to fully install the frame and hang the door leaf.

Advice! It is not necessary to stupidly follow the instructions for installing interior doors, which recommend consistently inserting lock fittings, attaching hinges, and only at the very end to solve problems with hanging interior doors. The main thing is to install the box and the door leaf with a fresh head with your own hands, and the platbands, locks and handles with platbands can be postponed for the next day.

You will have to measure and cut a lot. All cuts are made by hand with a hand saw, therefore, in addition to fresh forces, you will need to stock up on high-quality tools.

Tools for installing interior doors

A day or two before the start of work, it will be necessary to assemble a working arsenal for working with lumber. It can be collected from friends or rented. Why two days before installation? Because ahead of time before the start of work, you will need to check with your own hands the serviceability and performance of each tool:

- Building levels - small, 70-100 cm, and large, 150 - 200 cm, with a working bubble indicator. Usually, they do not pay attention to the condition of the camera and the beacon, considering them to be in good condition, but at the box office, it happens that there are bent and even broken specimens, this is the most important tool in installing interior doors;

- Marking tool - a carpentry corner with a ruler, a tape measure and a meter metal ruler. We check the presence of marks of angles of 90 o and 45 o;

- Screwdriver or electric drill with a bit nozzle for cross heads of self-tapping screws. We check with our own hands how the cartridge holds, and the serviceability of the wiring - batteries;

- A cutting tool, you can cut the timber of interior doors with an electric jigsaw, but it is best to stock up on a pair of hacksaws - carpentry and metal. The first is used for cutting the details of the box, the second is used for thin cutting of the platbands.

In addition to the tool, you will need a hammer, a clamp, a carpenter's chisel, mounting foam in a can, adhesive tape and gloves. There is little dust and waste when installing interior doors, but you still have to periodically clean it with your own hands so as not to spread it throughout the apartment.

In addition, it would be right to have a puncher with a spatula-bayonet in stock, because when installing the interior door frame, there may be problems with the doorway in the wall. Ideally, the gap between the racks of the box and the ends of the opening should remain 10-20 mm, for normal alignment and foaming of the slots. In reality, the opening may be uneven, and you will need to use your own hands, a puncher or a hammer with a chisel, to knock down part of the concrete or stone.

How to assemble an interior door frame

The best option would be to buy a ready-made door kit, which usually includes:

In this case, the entire process of mounting the interior frame box comes down to transferring the second parts of the hinges to the frame parts with your own hands, assembling the loot with self-tapping screws and installing it in the opening.

The entire job will take less than two hours. One of the options for installing interior doors with your own hands on video

The only drawback of the above scheme is that not all manufacturers of modern models of interior doors produce their products in kits designed for do-it-yourself installation. Most often, the customer buys a door leaf, and platbands and frame parts are purchased in order to install an interior door with a frame on their own.

How to install an interior door with your own hands

First of all, it is necessary to lay out the door leaf on a flat area. Next, the selected pair of beams is laid to the left and right ends of the sash. With a tape measure, we measure the width and estimated height of the future carrier frame. Then, with the help of a building level and a tape measure, the dimensions of the interior passage are checked.

Important! This is done in order to determine whether the platbands will close the edges of the gap in the wall, and how thick the additional elements should be used.

If you “miss” with the height or width of the frame, you will have to redo the trim with your own hands or, even worse, you will need to raise the interior door in height.

We assemble the frame of the door frame of arbitrary size

In order for the installation of the interior door to turn out without distortions, it is important to choose the right distance between the left and right pillars so that the door leaf enters the frame with a small gap, no more than 2 mm per side. In this case, the door will open freely without wedging in the loot.

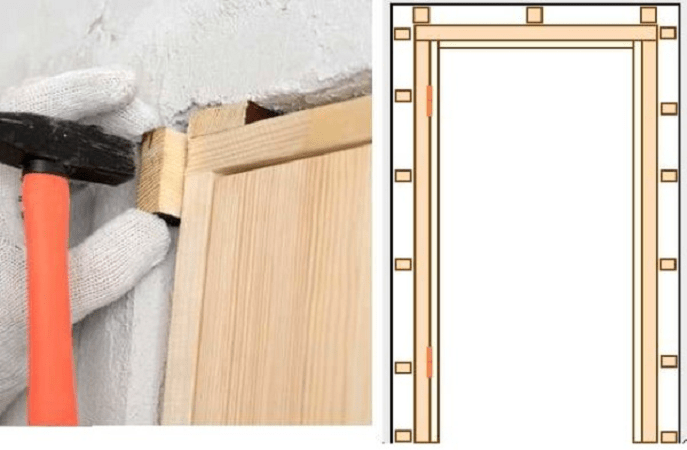

The easiest way is to assemble the frame with your own hands using a clamp, a saw and two blanks. Vertical racks, as in the case of preparation, are attached to the ends, aligned and fixed with clamps.

From the side of the upper and lower edges of the web, an allowance equal to the thickness of the beam is left on the blanks. At the same time, a cut line is applied to the left allowance with their own hands at an angle of 45 ° for further docking with the horizontal crossbars of the frame. Without disassembling the structure, they apply markings for cutting grooves for awnings, locks and handles.

If the interior door is too wide or of a complex shape, then usually at this stage the conformity of the frame configuration with the door to the shape of the interior opening is checked. To do this, a pair of nails is hammered onto a wooden plank at a distance from each other equal to the outer width of the frame. The bar must be fixed above the opening, and a couple of construction plumb lines are hung on the nails. If the gap between the frame and the wall is 10-15 mm, then the calculation is correct.

Installing hinges on an interior door

After all the checks have been completed, it is necessary to cut mounting grooves for the canopies in the canvas with a chisel or a carpenter's knife and a hammer. The easiest way is to mill a niche with a manual router, but, as practice shows, you can do the work yourself and without expensive power tools.

If this operation is difficult, then overhead hinges or models for drilling can be used for interior doors. For installation, you only need to drill holes for screwing fasteners.

Fasten the frame in the doorway

- We mark with a marker on the steppe the level of the upper horizontal cross member of the frame, this will help to perform the correct installation horizontally and vertically;

- With the help of wedges and a building level, we align the frame vertically and horizontally with our own hands. We fix the position of the frame in the opening with wooden plugs and wedges.

Advice! If the frame and door leaf are light, then the frame can be fixed with mounting perforated petals to the wall of the interior partition.

Next, it is necessary to blow out the space between the frame and the wall with mounting foam, while installation on the PPU is being carried out, it is necessary to check again and, if necessary, finally align it vertically using a long building level. We apply a small building level to the upper mark and, if necessary, knock the frame to the desired height.

Door leaf installation

After the loot is firmly fixed with hardened foam, it is necessary to install the mating parts of the canopies. To do this, initially the door leaf is lifted with wedges so that a gap of 1-2 mm is obtained between the threshold and the lower edge.

It remains only to install the sash on the awnings, and you can proceed to the decorative trim of interior doors.

Installation of platbands on the interior door

Facing the frame with platbands is not particularly difficult. First of all, install the vertical strips of the platbands. The height of the bar is measured according to the mark made earlier, after which the casing is applied to the frame and the line is washed down at an angle of 45 °.

Advice! It is best to make an undercut with your own hands using a thin hacksaw blade for metal. Preliminarily, adhesive tape is glued to the cut line. The bar is nailed with wallpaper nails or put on glue.

In a similar way, install the second vertical platband. After the vertical parts have been installed, you can mark the cut line on the horizontal bar, and install it on the door frame in the same way.

What are the sizes of extensions for interior doors

Additional strips are used as an additional element to increase the width or thickness of the door frame. Most often, the installation of extensions on interior doors is required in a situation where the wall is much thicker than the canvas, and there is a gap between them that needs to be closed.

The width of the additional rails ranges from 10 mm to 200 mm, for interior structures, the most common size is 10-20 mm, and often, due to the non-standard profile of the slot, the extensions have to be ordered or cut out with your own hands from the trim strips.

How to install extensions on an interior door

If, after installing the box, the unpleasant fact is revealed that the vertical plane of the frame is recessed into the space of the interior opening relative to the wall surface, then the only way to correct the situation is to use additional strips.

First you need to determine the size of the extension, for this the building level is applied to the wall and the distance to the front edge of the box is measured with a ruler. Thin planks are nailed with wallpaper nails, wide extensions are glued to the frame.

Professional advice on how to install interior doors

Among the features of installing home doors, the following problem areas can be noted.

Before mounting the platbands, you need to make sure that the frame or additional plank is located in the same plane with the surface of the interior wall. Otherwise, even if you make the edges washed down with your own hands perfectly, a gap will definitely appear between the platbands.

The second problem that one has to face is the sagging of the doors when installed incorrectly. To correct the situation, it is necessary to remove the canvas, put washers, or cut the edge and install the door in place.

Conclusion

Do-it-yourself installation of interior doors will require a little practice in installing canopies and extensions, but in general the work is simple, and with proper skill, the canvas can be hung in a few hours. Masters claim that with each installation, the quality of work with their own hands doubles.

The functionality of the design and aesthetic appeal depend on the quality of installation of interior doors: in any home or office, inspection of the premises begins with doorways. Experienced specialists will promptly take measurements, offer the most optimal options, and install in accordance with the design features.

It is also important to eliminate gaps by foaming with high-quality sealants, leveling the walls at the initial stage of installation and choosing a suitable model of domestic or foreign production.

Mounting Features

Installation of door frames is carried out at the final stage of repair. After wallpapering, work is carried out to install the door frame in accordance with the technical rules and safety requirements. Installing a door in a large opening without anchors and additional elements requires a professional approach: experts recommend not to do this work yourself. Once upon a time, dampers were used as door structures to prevent cold air and moisture from entering the room.

Nowadays, doors serve not only as an entrance and exit zone, but also as a spectacular addition to interior design that can last for decades with proper operation.

Knowledge of technology allows you to organize installation at a high technological level.

To install the structure you will need:

- form a block and equip the canvas;

- prepare material for use in conjunction with fittings;

- pick up hinges (with a regular handle or with an automatic latch).

A block is mounted in the opening, on which the canvas is arranged. Experts recommend pre-adjusting the mechanism. Platband trim is a great way to give the structure stylistic completeness and constructive unity, while it is advisable to use modern materials and the latest technologies. Activities are carried out in a strict sequence: during installation, actions are coordinated in accordance with building codes.

Plastic and metal-plastic installations are implemented in a complementary form, prepared for the fastening process. The box is a collection of wooden blocks of different parameters, door panels and special parts (slats) for platbands.

Assembling the box is a process that requires a professional approach:

- compliance of the measures taken with the requirements of operation;

- use of proven material and technologies;

- using a P-base with a threshold.

For this purpose, bars are used (rack, hinged timber). The base with a threshold requires the installation of a bottom material of a certain thickness, while the assembled block must have a strictly geometric configuration. Masters determine the dimensions of the doors, fix the format of the racks and lintels, taking into account the voids, cut out and design special bars.

Kinds

The dimensions of the box material must differ from the dimensions of the web. Measurements are made with simple tools, most often with a ruler. The web is measured along the perimeter: you should not count on an external effect, since distortions are observed during shrinkage. Deviations play a big role in measurements.

The sequence of work is as follows.

- The parameters of the outer sides of the looped material are analyzed;

- The operating parameters of the ceiling, feigned material are measured;

- The state of the surfaces in contact with the opening planes is diagnosed;

- Provides space for gaps (within 0.2-0.4 cm).

When installing glass structures, measurements of decor parameters are additionally carried out, drawing is carried out using modern methods, if provided. Installation of retractable and double door installations is carried out in accordance with the technical requirements fixed in GOSTs. Roller doors will require additional measures related to the selection of a suitable model, the installation of a structure that meets the standards and design requirements.

Swing and sliding options are a great option for those who are used to saving space and relying on modern design. Specialists will carry out preliminary measurements, select the most effective models and promptly carry out all stages of installation. At the request of the customer, non-standard door structures and classic double doors are installed.

With the help of these models, you can create an original interior design, equip any type of room (office, residential, warehouse). Subject to the installation parameters in an apartment, room or office, you can place overall furniture that always looks fashionable and stylish.

Boxes with a threshold acquire slotted holes along the perimeter in the plane of the door block without a threshold. The craftsmen will calculate the points for eliminating vertical posts, provide sufficient parameters for the opening.

When arranging the box, pay attention to the following points.

- Correspondence of the size ranges of the “P” configuration;

- The quality of drywall materials;

- Competent holding washed down the beam.

The miter machine is effective in creating cuts, often using a hand saw or self-tapping screws. When installing doors, innovative technologies are used: the method of washing down vertical racks involves adjusting the parameters of parts and lintels, while strict rules are observed, the design is adjusted to an angle of 45 degrees.

Competently carried out docking of parts gives the installation the necessary external format. The holes must be through, perpendicular to the cut.

Dimensions

When installing interior blocks, the question often arises of how to calculate swing doors for a niche. With small-sized piers, similar to the parameters of the door frame, finishing work is carried out using platbands. The formed set is installed on the sides of the box. This setting is designed to mask the foamed seam. Wooden or laminated platbands, if they are not processed, are installed using hardware, after which they resort to painting. The platbands may differ in shade from the bar, because contrasting options are always in trend.

The door frame made of wood is made in accordance with the requirements in the field of construction using cement-sand plaster. A wood canvas is not recommended to be installed together with fiberboard boxes: different levels of moisture resistance can lead to deformation and cracking.

Structural blanks for screws in an MDF installation are made at the preparatory stage, drilling is carried out with a tool with an optimal diameter. The size of the internal vertical bar level is calculated as the sum of the dimensional indicators of the canvas (usually 3 * 3 mm), if the design is with a threshold. The ceiling part is installed to special devices.

The use of self-tapping screws ensures high work efficiency. The parameters are determined by indicators such as sham and loop materials, the distance is determined as the sum of the parameters used for the side voids.

The beam is made in accordance with the technical parameters at a right angle, as this is required by the arrangement of the threshold. The block is formed on a straight base (for example, on the floor).

Arrangement of door fittings must be carried out in such a way as to ensure evacuation measures. You can choose universal door hinges with right or left mounting. Devices with a laminated surface are manufactured taking into account the parameters of the loop. Usually, 20 cm from the top and bottom edges are left as an indent. The area for installing the hinge to the box structure is determined taking into account technological voids.

What material is better to put

Door products are represented by an extensive model range. Modern interior doors are made using MDF panels, progressive materials (WPC, eco-veneer, natural wood).

- fiberboard- a great option for creating an inexpensive and spectacular door. The wood frame is covered with laminated fiberboard sheets. These economical designs, easy to install and compact, are popular in the construction market. Experienced specialists will help to increase the resistance of the structure to high temperatures and humidity, using special compounds.

- MDF allows you to make inexpensive and durable door blocks with optimal sound insulation performance.

- Wood differs in high durability and resistance to influence of hostile environment and mechanical influence. The porous structure of the material ensures the creation of an optimal microclimate. Such designs are great for author's design, perfectly complement the classic interior, while the parameters of interior doors must correspond to the specifics of the opening.

All-glass doors, metal-plastic structures, steel parts are non-standard products that require an individual project.

Reference door installations are placed in a durable box, the quality of which determines the durability and reliability of the entire structure.

- fiberboard box represents the strong installation capable to be deformed under the influence of mechanical influences.

- wood box, not subjected to processing - structures made of profiled timber. Differ in superstrength and reliability. When performing the installation, it will be necessary to use additional materials for the final finishing measures.

- Box made of laminated materials. This installation does not require final finishing. The defining moment is the nature of the lamination. The use of thin paper is not recommended, since in this case scuffs and cracks may appear that affect the external parameters of the product.

The doorway may be pretreated. This determines the specifics of the opening, its parameters, and the features of the interior of the room. Processing can be done at the expense of additional parts and platbands.

What tool do you need

Door installation requires the use of certain knowledge and technology: a vacuum cleaner and a miter saw are considered indispensable attributes of the kit. Experts recommend at the initial stage to think over an action plan: you will need to organize marking, inserting hinges, arranging door slopes.

Manual equipment and electrical equipment are used at the main stages of work. The question of how to use the router will be answered by experienced craftsmen with many years of experience, under whose guidance all major activities will be carried out.

With the help of a perforator, work surfaces are leveled and the opening expands. This tool allows you to make special recesses for the dowel. The drill helps to drill recesses of the required parameters for fasteners. The start of work is accompanied by a check of the equipment. The tightness of fixing the drill is very important, because the part can fly out during the work and damage the working surfaces of the doors.

The screwdriver allows you to securely fix the hardware in the hinges. The electric jigsaw handles complex surfaces that are difficult to access for sawing. A handheld electric router helps install the locking mechanism and build in the hinges. The pencil allows you to make special marks in places that require processing. For the same purpose, a marker is used (provided that it does not leave marks on the surfaces).

A three- and five-meter tape measure or a steel ruler, together with a calibration square, ensures accurate measurements. With the help of a caliper, the depth of the insert is measured, which is performed using a chisel.

The slope of the surfaces must be measured using a bubble level with parameters within 50 cm. Using a set of screwdrivers, hinges and canopies are attached, locks are equipped.

A miter saw is an excellent tool for sawing structural parts - bars and trim at an angle of 45-90 degrees. The circular saw helps to format the dimensions of the door leaf. The gun can be loaded with high quality caulk to close gaps.

What is included?

Self-tapping screws allow you to fix the elements of the device (mounting strips, hinges, trim, locking mechanism). The kit also includes liquid and finishing nails and micro-studs, which are fixed with an air gun. With the help of these devices, the mount acquires super strength and reliability. The mounting microstud is a compact hardware element without rivets, which provides a solid surface. You can measure the length and width using a tape measure or a metal ruler.

Interior doors are sold without fittings, which are known in domestic and foreign production.

Specialists will help you choose high-quality systems (hinges and locks) that are not subject to mechanical stress and corrosive deformations. By adjusting the hinges with the help of fasteners and a screwdriver while working with slopes, it ensures a high tightness of the web to the box, while using special devices that allow you to measure parts, insert structural elements at a high professional level.

The bath for the solution is made of a special material that provides an optimal format for mixing building mixtures and ease of cleaning after work. The kit includes brushes and rollers for finishing work. The grout set provides a reference view of the surface of the door unit.

How to install: step by step instructions

Interior structures are installed from scratch using step-by-step recommendations posted on Internet portals. Experts recommend not doing DIY activities if you do not have sufficient knowledge and experience.

Experienced craftsmen will tell you at what stage the preparatory measures should be carried out, and at what stage the structure is being installed.

- Determine the specifics of the means and quality of consumables for installing the structure.

- Outline the installation scheme for the blocks of a double-leaf interior door with extensions.

- Carry out constructive measures to install the door frame without self-tapping screws. Hinges are attached to the door block, a cutout is organized in the structure, a durable box is assembled, after which all the elements are assembled together. Metal bases must be structurally sound. The strap is fastened using self-tapping screws. The U-shaped design is the key to well-performed work.

- Mount the structure in the opening. The box is inserted into the doorway, alignment is performed. The end decorating detail is drilled on both sides.

- Install door structures on hinges. Lightweight fiberboard door allows you to hold events on your own.

- Foam the seams, thereby eliminating the voids between the wall surface and the box. Complete solidification is carried out within a day at room temperature.

- Carry out finishing work. Determining the type of finish will help create the optimal design.

Visually see the installation process in the following video.

How to install accessories?

Experts do not recommend independently carrying out work on installing a door structure, replacing a lock and arranging thresholds, since these activities require high professionalism. Experienced craftsmen will help you purchase a set of high-strength materials, determine the order of work, install the structure correctly, and insert the door frame into the opening. You can assemble the structure, ensuring high build quality, using special tools.

It is necessary to insert fittings using modern technologies and installation methods during preliminary measurements using a tape measure or ruler. High-quality hardware is used as fasteners. At the initial stage, a scheme of work is formed, a set of necessary tools is made, the box is inserted into the opening, and hidden hinges are installed.

Successful examples and options

Before you start installing the door, you need to familiarize yourself with successful examples and design options. On the websites of companies engaged in licensed activities, samples of doors in Khrushchev, a modern apartment, and an equipped kitchen are presented. At the same time, it is important to pay attention to high-quality installation, made in accordance with technical requirements: holes are carefully made in the wall, structural parts are inserted at the required angle.

Today, do-it-yourself installation of interior doors is done in most cases. Manufacturers strive to simplify the installation of their products as much as possible, so almost anyone can handle this. Next, we will consider this procedure in detail.

Before you install an interior door yourself, you will need to choose the right model. According to the method of opening, they are divided into the following categories:

- Folding. Such models consist of several wings at once, which move along the guide. They are divided into two subgroups: books (they consist of 2 sections and are durable) and accordions (an alternative to screens).

- Coupe (sliding). They have the largest number of modifications: 1 and 2 wing, opening inwards or along the wall, left- and right-handed, etc. The main advantage of such structures is space saving. When installed correctly, they also provide a high level of sound insulation.

- Swing. The last variety is the most popular. Installation of this type of door is much easier, and people without carpentry skills can handle it (which cannot be said about other categories). In addition, their cost is much lower. The main disadvantage of such structures is that they take up a lot of usable space.

Installation of the first two varieties is carried out according to various methods, which have significant differences. At the same time, the skills of a carpenter will be required from the master, otherwise it will not be possible to achieve a positive result. Therefore, our step-by-step instructions will consider the installation of swing doors.

A few words about the choice of canvas and calculations

Technical characteristics must be selected based on the conditions of the room. First, we determine the dimensions of the canvas, so we measure the opening. Don't forget to leave a gap. Between the uprights and the original surface 10-12 mm, between the canvas and the timber 3-5 mm. This is necessary in order to avoid jamming the door. It may appear due to the swelling of the canvas (from temperature fluctuations and high humidity). The standard width ranges from 60-100 cm, height 180-220 cm.

Remember: the finished canvas cannot be corrected, and expanding (narrowing) the opening is a labor-intensive business. Therefore, select the dimensions as accurately as possible - the complexity of installation will depend on this.

Technical gaps (12-15mm), the width of the box are subtracted from the size of the opening and multiplied by 2. The resulting number is subtracted from the width of the opening. Calculation example:

- We have an opening 78.5 cm wide.

- 78,5 - (1,2 + 2,5 + 0,3) *2 = 70,5.

- So, a model with a width of 70 cm is suitable for us.

The standard door length is 200 cm, so you have to adjust the opening for it. To calculate the required height, to two meters (or another figure, if we are dealing with a non-standard model), we add the thickness of the box, the size of the technical gap and 1 cm (the distance between the canvas and the floor). If a threshold is to be set, then add its thickness.

In addition to size, it is necessary to take into account the characteristics of the material from which the canvas is made. This is not so important, but you should not ignore this aspect. Remember a few simple guidelines:

- In rooms with high humidity, it is not recommended to use models made of materials that are unstable to moisture (chipboard, pressed sawdust, etc.). In a few years they will swell and lose their original appearance. In such cases, the installation of laminated doors is recommended.

Tip: if it became necessary to install such a variety, leave a technological gap 2 times larger, because such a canvas will swell much faster and stronger.

- If there are small children or large animals in the house, it is better to refuse models with glass inserts.

Another important point - for newly built wooden houses, when installing the box, it is recommended not to completely screw in the screws. This will allow her to easily survive the shrinkage.

Where to start - preparatory manipulations

First, you will need to perform several laborious and important operations.

What we need - we study the toolkit

Tools for installing interior doors do not differ in high cost and complexity. To perform all the manipulations you will need the following:

- A hacksaw with a miter box (it must be of the right size - so that the box fits completely into its grooves, otherwise it will be very inconvenient to cut). You can use a circular saw.

- Building level. Ideally, laser - it bestows maximum accuracy. However, for a one-time job, it makes no sense to purchase it - it is quite expensive.

- Drill with cutter.

- Pencil (or marker), tape measure.

- Hammer.

- Screwdriver or furniture screwdriver.

- Mounting foam with a gun.

- Fastening materials: finishing nails (usually they are included in the kit), self-tapping screws, dowels, screws (80 × 5), wedges.

- Two spirit levels (180 and 50 cm).

The first procedure - dismantling

This is the most difficult, and most importantly, the dirty stage of work. Self-installation of interior doors begins with the dismantling of the old ones. Let's consider everything in stages:

- During operations, an unthinkable amount of dirt and dust will appear. Therefore, immediately remove all furniture, carpets and other items from the room. What cannot be moved is covered with something. Do not forget about PPE (goggles, gloves, respirator).

- Take the old door off its hinges. To do this, unscrew the screws that hold them. If the hinges are of the “father-mother” type (that is, when one part is inserted into the other), then we simply open the door and pull it up at a right angle. If the loops were not lubricated, you will have to make a lot of effort, so we do the work with a partner.

Tip: If you no longer plan to use the old canvas, you can simply tear it off with sufficient force. This is the most radical and fastest way.

- Next, you need to dismantle the box. First of all, remove the solution that holds the frame.

- Then cuts are made in the upper parts of both racks. This will facilitate the extraction process: insert the mount into the holes made and simply pull strongly in different directions.

- As a result, they loosen up, and they can be easily removed from the opening.

Preparing the original surface

The next step is to bring the opening into proper shape. The work is done in the following sequence:

- We dismantle the insulation (if any). We do this with gloves, because this group of materials irritates the skin.

- We remove construction debris, after which we conduct a thorough audit.

- If there are materials that peel off easily, remove them. We also remove all fasteners (hinges, nails, etc.).

- As a result, we should get bare concrete (brick, timber - depending on what the walls are made of).

After such procedures, most likely the evenness and integrity of the surface will be violated. Therefore, it will need to be aligned. There are several ways, but the simplest is plastering.

If, after cleaning manipulations, the width of the opening has increased (for example, the surface layer of plaster has opal), then the installation of extensions will help. These are wooden (in most cases) planks 6-30 mm wide. They are installed in the case when you need to "increase" the size of the opening. A more durable option is cement mortar.

Main front of work

The installation procedure for interior doors must be strictly observed, so all further manipulations are presented in the correct sequence.

We collect the box correctly

Once again, making sure that the original surface is even, we proceed to collect the box. It is sold in the form of bars of various lengths. Of these, it is necessary to make a U-shaped structure (if a threshold is to be installed, then a rectangular one). The second option is used mainly for toilets and bathrooms.

If you ordered a box along with a door, then most likely it will be ready - you only need to assemble it (using long screws or nails). When purchased separately, it will have to be adjusted in size. This is the most complex process that will require maximum accuracy, because in the event of the slightest inaccuracy, the door will receive a slope, which will affect its performance.

Consider the assembly of the U-shaped structure:

- We lay two vertical racks on the floor, it is necessary that it be perfectly flat.

- We mark on them the height of the opening from the inside.

- From these points down we make a cut at an angle of 45 degrees, a miter box will help you with this.

- On the third rack (horizontal) we mark the width of the opening on the inside. From these points we make a cut of 45 degrees in different directions. Do not confuse the direction, these three elements must be assembled into a single structure, so do a fitting with each new cut.

- Then we mark the places for the hinges and the lock. This can be done later.

- We assemble the resulting structure and connect it with large self-tapping screws. For each joint we use at least 3 fasteners.

Attention! Watch for the vertical position of the self-tapping screw during twisting, because at the slightest deviation it will pierce the rack.

For a rectangular design, the assembly will be identical, only with the addition of a second horizontal post.

How to set the hinges correctly

The canopies will determine how comfortable the closing and opening will be, so perfect accuracy is required. Most people think that two loops are enough for normal use. We recommend using three (one is placed exactly in the middle). In this case, even with prolonged use, you will avoid distortions. So, you need to do the following:

- We apply loops to the applied markup and circle them with a pencil (marker).

- We make two grooves along the drawn lines (on the door and on the canopy) - to the depth of the canopy. A chisel will help us with this. The hinge should be "flush" with the main surface.

- Having made the adjustment, we fasten the canopies on self-tapping screws of medium length (at least 3.5 cm) first to the canvas, and then to the racks.

- If necessary, we make an adjustment: we put the structure on the floor and begin to open (close) - if the movement is not smooth, we tighten the screws.

Insert the box into the opening

The next step is to install the door frame. We do everything in the following sequence:

- If the hinges are of the “father-mother” type, then we take out the door - this will facilitate the work. Otherwise, leave it as is.

- We level all three racks with a level. We achieve perfect verticality!

- We burst the upper crossbar with wooden wedges.

- We level again and, if necessary, use linings.

- We drill through the side racks with a drill.

- We insert dowels into the holes in the wall.

- We fix the box with the help of long self-tapping screws.

- We carry out the final revision and alignment.

Final chords - handles, platbands

After making sure of the perfect evenness, we make the final manipulations. First, the handle is installed on the door. To do this, a through hole of the appropriate diameter is drilled in the canvas (If you purchased a complete set, then this will not be necessary). Then the two parts of the handle are connected. In most cases, this is not difficult.

At the end, platbands are exposed - decorative elements that hide all the irregularities and form the integrity of the structure. They are glued around the entire perimeter on special liquid nails. Joints are also made using a miter box.

We will tell you how to properly install an interior door. You will learn about the intricacies of choosing components and how you can understand the professionalism of the master. Interior doors must stand in their original packaging for at least 5 days in the room in which they will be installed.

Preparing boards for the door frame

To begin with, we will check the height and width of the opening and make sure that the doors with the frame will easily enter them.

Using a laser level, we estimate the difference in floor height on each side of the doorway. In our case, it was 2 mm, and we need to take this distance into account when making the door frame. Let's say a few words about the wizard's tool:

For a quality installation, we can not do with one hammer and chisel. We need a circular saw with a turntable. Now with its help we will trim the door frame blanks. It would be very difficult to cut a beautifully veneered blank with a conventional hacksaw. Let's start marking the door frame. With a sharp knife, mark the places for trimming the upper part.

The plate allows you to immediately take into account the gap of the door in the box. Usually it is 2-3 mm. In the arsenal of a real master, there should be such a device that allows you to keep the door in a vertical position:

We make a serif of places for loops. Usually it is 20-25 cm from the edge.

We put one of the boards of the door frame on the door and set the bottom gap. Usually it is 8-10 mm. As a rule, interior doors are assembled without thresholds. With a sharp knife, we make notches for the hinges on the board of the door frame. Mark the top edge of the board. We lay the left and right boards of the door frame together, set a slight shift of a few millimeters to compensate for the difference in floor height marked by the level.

In the places of subsequent cutting of the door frame boards, we need to carefully remove the wrapped veneer with a chisel. If this is not done, then when cutting on the machine, the board will stand up skewed and we will not be able to perform a perfect gash at 45 °. We install the board on the saw machine, and turn the saw itself for sawing at 45 °.

The chipped veneer board fits snugly against the machine at the rear. Carefully cut at 45°. Three parts of the door frame are ready:

We mark the loops. This process has one feature - the loop is installed with the logo up.

Marks for hinges on the board of the door frame are best done with a sharp knife. If you are not confident, do it with a pencil, but remember that it has a certain thickness, which can give an error. When using a knife, notches are applied at an angle towards the future sample. This will allow you to tightly and beautifully install the hinges in the future.

Another necessary tool for the master is a manual milling machine. We set the sample width to the width of the loop. The sampling depth is adjusted according to the thickness of the loop. With the help of a manual milling machine, work on making samples in the door frame board is completed in a minute.

A properly adjusted cutter will not remove anything superfluous:

During work, the master must pay attention to his extreme notches and not go beyond them. The same work done with a chisel and a hammer will not always be neat, and it will also take more time.

Since the loops have rectangular edges, we need to remove the roundness at the corners with a chisel. To do this, we will make two or three notches in the corners. So we are guaranteed to remove the excess and not touch the wood behind the sample. This work must be done carefully and slowly. It depends on it how beautiful the hinges in the door frame will look.

An important point - the loop must enter the sample with effort. It is recommended that before screwing the hinge, drill holes of a smaller diameter compared to the screws. In order not to drill through the floor, place a stop under the door frame board.

We drill holes for the second loop.

Door frame installation

Now we need to make holes for the screws with which we will fasten the door frame from the hinge side.

There is a rule here: the holes are made in the middle of the longitudinal and transverse axis, that is, for the upper loop they should be made a little lower, and for the lower loop a little higher. By this we achieve uniform fastening of the box to the doorway. The recess should be deep enough so that the twisted screw does not interfere with the installation of the hinges.

We will make potai in places where we will fasten the elements of the door frame to each other. Depending on the thickness of the bar of the box, we will make a sweat either higher or lower.

The main rule is that the sweat is performed at an angle of 90 ° with respect to the cut. In the upper element of the door frame, we sew in the center. Thus, the fastening of the door frame will be carried out on each side in three places.

We twist the wood screws into the elements of the box. Here it is important to accurately combine the parts and prevent their mutual displacement. If everything is done correctly, we will get the perfect angle. On the other hand, we will perform the same operations.

We will install the assembled box in the doorway, and so that the box does not fall, we will put a few pieces of cardboard. Set the laser level and check the verticality of the door frame from the side of the hinges.

Now we need wedges with which we will adjust the door gap and level the box. They can be made from scraps of box bars using a circular saw. First of all, we need to install wedges in places where we will fasten the door frame to the walls.

Additionally, we hammer one wedge into each of the upper corners of the box. We check the verticality of the installation with a laser level. If necessary, knock out or change the wedges.

Expose the door frame should be flush with the outer wall of the room. We carry out the fastening of the box through the made sweat in the loops.

Be sure to install wedges in places where we fasten the box. They should stay there forever. The door frame on the hinged side is fixed in two places and has three wedges. But the feigned side of the box has only one wedge on top. We will exhibit it after hanging the door. Do not forget to use the level to check the horizontal installation of the box. Since we took into account the unevenness of the floor when trimming the box bars, our level now shows the horizon.

While we are working on the door leaf, the pre-installed door frame must be partially foamed.

It takes some time for the foam to set a little before we hang the doors. First, the foam is applied in small portions from the inside of the room. The feigned part of the door frame is partially foamed, in a dashed way. This is necessary so that we have the opportunity to move the feigned part of the door frame, aligning it with the door leaf. Too much mounting foam should not be laid.

Installation of door hardware

Now the door is again placed on a special stand. We will be installing door hardware.

And again we mark the hinges, but already on the door leaf. We make marks with a sharp knife at an angle with respect to the loops. Using a milling machine, we carry out sampling under the hinges on the door leaf.

We also align the corners with a chisel. We get the perfect selection for the hinges in the door leaf. It is ideal because our loop is inserted inside with force, which means that there will be no gaps.

Consider how to properly drill holes for screws.

Drilling begins at an angle, leaning on the edge of the loop, then the drill is set vertically, and we drill exactly in the center. This simple technique makes it easy to drill holes in the center of the hinges. We apply the markup for installing the door latch. Usually it falls in the middle of the door.

When drilling a hole for the latch, be careful not to damage the excess veneer. To do this, set the rotation of the drill counterclockwise and apply a central marking with a drill. So the drill will not jump off and tear the adjacent veneer. Then we set the drill to normal drilling mode and drill the required hole. The depth of drilling can be adjusted by a special marker that you put on the drill. The marker in this case is the usual electrical tape.

The hole is ready, and we insert the latch into it.

Please note that the diameter of the hole must exceed the internal thickness of the latch. Mark with a knife.

And again we will use the milling machine, then with a wide chisel we will sample the corners.

As usual, we will make a few notches, and then clean up the corners. Now insert the latch and fasten it with screws.

Door leaf installation

Our foam has partially set. Now it will provide us with the elastic state of the box. We install a stop under the door and twist the upper loop.

A lever may be required to set the bottom hinge well. Don't forget to put a stop under it.

When the loop has exactly entered the groove, you can screw it onto two screws. In a suspended state, the vertical installation of the doors is checked.

Let's check the operation of the door frame seal. If it squeaks, coat it with a small amount of VD-40. We proceed to the alignment of the feigned side of the door frame. When the door is hung, we can appreciate how perfect the door leaf is. And right now we have the opportunity to align the feigned part of the box with the door. As in the previous case, we align this part of the box with wedges.

Slightly hardened polyurethane foam allows you to smoothly shift the feigned part of the box in one direction or another. After finishing the alignment, mark the center of the latch on the feigned bar of the box. When choosing door latches, give preference to those that have a ledge on the counterpart. With it, you can adjust the strength of the adjoining doors.

Having made a mark, we use the milling machine again.

This time we are making a recess for the door latch.

If necessary, the rounded edges can be corrected with a chisel. We drill the attachment points of the mating part of the latch and fasten it with screws.

Now we will drill a hole in this cavity for the third fixing screw. Regardless of whether an anchor bolt or self-tapping screw is used, it will be hidden inside this cavity. It is also necessary to install an additional wedge in this place.

We twist the self-tapping screw, which will fix the feigned part of the box through the drywall to the inner bar of the load-bearing wall.

Installation of door handles

Now you can collect door handles. Tighten the inner pin on one of the handles with a hexagon.

After inserting the handle, fix it with three self-tapping screws.

Insert the handle on the other side and do the same. Let's check the operation of the handle.

Finishing the assembly of the handle, we fix the second handle with a hexagon. We put on decorative caps on each side.

Now is the time to apply the foam between the wall and the door frame on the outside of the door. Do not forget to tighten the remaining screws into the door hinges.

Installation of extensions

The foam on the inside of the doors has already dried, this will allow us to move on to the next stage of installing the doors.

We need to install extensions from the inside of the room.

We determine the distance by choosing the most protruding part of the wall. Having made measurements from above and below, we will choose the largest. If there is a rounding in the inner groove of the box, it must be carefully cut with a knife. This will allow you to put the extension in this groove quite tightly without gaps.

We perform this operation on the other side. If the foam sticks out, it must be slightly cut off.

Now a circular saw with a top table is very useful to us. Having set the emphasis to a given width, we ideally cut the extension boards. Trim off the bottom edge.

We place the dobor board, resting it on the upper groove of the door frame.

We'll do the same on the other side. And again, we cut the extension boards to the final dimensions.

The groove of the door frame, into which we insert the extensions, is cleaned of foam with a small piece of board. We will do this around the entire perimeter of the door frame.

Install the dobor boards in the freed groove. To fix the extension, it is necessary to wedge it in the upper corners of the door frame.

Using a level or a straight board, it is necessary to ensure that the extension is either flush with the wall, or, if the wall is uneven, protrudes slightly.

The extension will hold perfectly if it is fixed with mounting foam. In this case, there is no need to make holes and fix it with screws to the wall. As the foam expands and hardens, it can be cut flush with the wall.

So, we installed the extensions and foamed them with mounting foam to fix them. If you do everything according to this technology, then the door can be used in 20 minutes. We just have to wait for the foam to completely harden, cut it off, plaster and level the sections of the wall adjacent to the door, glue the wallpaper or paint the walls, and only then nail the casing. When plastering a doorway, wet plaster should not be allowed to come into contact with the door frame. Use masking tape here, remove the plaster immediately. To make the door fit more tightly, bend the protrusion on the mating part of the latch.

All rights to the video belong to: DoHow

Installing interior doors is not as difficult as it might seem at first glance. If the master has at least a little experience working with doors, then this is a big plus. The only thing that is better to entrust to a specialist is fitting fittings. Incorrectly installed fittings can spoil the entire result of the work.

Stages

Installation of interior doors takes place in several stages:

- Box installation.

- Canvas installation.

- Installation of additional elements.

preliminary stage

The technology for installing interior doors is quite simple. However, before starting work, there is one crucial stage that cannot be missed. This is the stage of choosing a door.

The final result largely depends on how responsibly you approach the choice.

- The first thing to do is to go around the shops. Do not take the first available option. If we are talking about online stores, then here you need to carefully compare the characteristics of the designs.

- The door leaf should ideally fit the box in size. All characteristics of the door must be known in advance. Measurements are indispensable here.

- Sometimes very cheap options appear in stores. After purchase, the owner may find that the box or accessories are not included. You have to spend time and select the rest of the parts. It's not always possible to do it right. Therefore, do not look at too cheap door designs. In extreme cases, it is necessary to first clarify the presence of certain parts in the kit.

Materials and tools

Materials and tools for installation must be prepared in advance. From the tools you will need:

- wood saw;

- screwdriver;

- level.

From the materials you need to purchase:

- mounting foam (balloon);

- self-tapping screws;

- wedges.

Assembly and installation of the box

When the door is bought, you can get to work. The first step is to assemble the box.

Assembling the box is a simple process. The only thing to remember is that it is necessary to trim the standing boxes in order to set the gap between the door leaf and the floor. For ordinary apartments, the gap is set to about 10 mm.

After the gap is set, the racks are connected using self-tapping screws. After assembly, the stage of installing the box in the opening begins.

It is desirable that the opening was pre-treated. To do this, check the verticality of the walls, as well as the height and width of the opening.

The box is installed using a level and wedges. The level checks the position of the structure in the opening. The procedure is as follows:

- The box is fixed in the opening with wedges at the top and bottom.

- First, the door must be fixed with wedges from below, before that, having checked the position of the structure in two dimensions with a level.

- The average gap between the box and the opening on all sides should be about 10 mm.

The door leaf is hung on hinges. The box at this time is fixed only with spacers and wedges.

Foaming the door frame before hanging the canvas should not be. The fact is that you also need to make sure that the door will not open itself in this position.

After the canvas is hung, you can foam the gap between the box and the opening.

Care must be taken to ensure that foam does not get on the surface of the door. The composition of the mounting foam can easily damage the surface, so you should work carefully.

Now you need to install an additional element.

- The additional plank is measured to the size of the distance from the edge of the box to the edge of the wall.

- With a hacksaw, it is cut along the edge.

- The additional element is mounted in a groove and foamed. Foaming is done at several points.

platbands

After the additional element is installed, you must wait for the foam to dry. When working with mounting foam, you need to remember about its expansion property. The substance should always be dosed.

The next step after installing the additional strip is the trim.

- To install platbands, you need to determine their size.

- After that, the platbands are sawn with a hacksaw.

- Holes for nails are drilled.

- The platband is fixed.

If the platband is "with a beak", then it is attached to liquid nails. You don't need to sip it.

Types of interior doors

Today in stores you can find doors made of natural wood, glass, plastic, metal and composites. There are also mixed designs.

Usually the choice is made taking into account the design of the room and this is the right approach. However, it is necessary to consider all the main varieties of these structures in order to know their advantages and disadvantages, as well as the subtleties of care.

- Paneled hardwood. Such designs are very durable and prestigious. In addition, they are very expensive. The most common panel doors are made of oak and walnut. Designs are made either with or without glue. The last type is the most durable. Care for such a door is necessary, as well as for any natural surfaces. The door must be protected from moisture and high temperatures. It is recommended to wipe them with a tissue. The use of abrasives is prohibited.

- Paneled softwood. Ideal for summer cottages and cottages. In ordinary apartments, such doors do not look very appropriate. They are more suitable for country style. Care for such structures is the same as for hardwood doors.

- Paneled combined doors. These designs are made of veneer. They contain few valuable species of wood. Therefore, these doors are quite inexpensive. Their service life, however, is less than that of solid wood structures. However, they can stand for about 50 years, which is also very good. Special care for veneer doors is not required, this is their advantage.

- Shield structures. The advantage of panel doors is that they are inexpensive, do not require special care, are easily replaceable, and have a presentable appearance. In addition, they are well decorated and suitable for any interior. About 85–90% of all doors are panel doors. Such a design can be glazed, decorated with natural veneer or artificial materials. Shield doors - the best option for most apartments and offices.

Video: instructions for installing interior doors

Photo

Scheme