Insulation of a finished roof from the inside. Roof insulation from the inside: materials, features, tips, methods

Without high-quality thermal insulation at home, it will not be possible to save on heating in winter. Walls and floors are not the only ways through which heat leaves a living space. In addition to them, it is also necessary to insulate the roof.

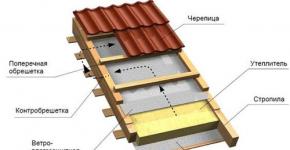

Internal insulation scheme

A kind of pie is a high-quality insulation of the roof from the inside, consisting in almost all cases of three main layers:

- Waterproofing

- Thermal insulation

- Vapor barrier

However, the basis of the entire structure is the rafter system, which will act as a base link. The easiest way is to lay a thermal insulation layer inside it.

Properly selected materials for each layer of the pie are the basis for high-quality insulation. The market is rich in various products, but you should not pay attention only to cheap options, giving preference to the golden mean.

The main purpose of the waterproofing layer is to protect the insulation from moisture from outside. It accumulates inside it, destroys the structure of the material and renders it unusable. The task of the vapor barrier layer is to prevent rising vapors from passing through.

To protect against wet environments, special membrane or film materials are used. The permeability indicators of the former are better, but their market value is more expensive. Since it will not be possible to ensure complete sealing of the insulation, it is necessary to provide ventilation gaps and seams.

Introductory video on insulating a pitched roof in a house

Choosing thermal insulation material

Many manufacturers offer consumers a variety of thermal insulators, each of which has positive and negative sides. Among all operational characteristics, special attention is paid to the following:

- Level of moisture absorption - the lower this ability of the materials in question, the longer their service life can be counted on

- Thermal conductivity – it should be as low as possible. However, this indicator is relative, since an increase in porosity and importance can significantly worsen it

- Low-density insulation materials have much better thermal insulation properties

Video on material selection

You should also pay attention to such characteristics as environmental friendliness, chemical resistance, flammability and frost resistance.

The most widely used materials for insulating roofs from the inside are mineral wool and glass wool. They have all the necessary characteristics and are relatively easy to use.

Expanded polystyrene is no less popular. In addition to high thermal insulation properties, it practically does not absorb moisture, is durable and rigid, resistant to high temperatures and open fire. A significant disadvantage is the susceptibility to rodent infestation. That is why it has not become widespread.

Other, less common methods of internal insulation are also possible:

- The use of spraying is one of the most expensive methods, which is recommended to be entrusted to a professional craftsman. If you need to insulate a conventional attic, you should choose this method. Material costs will be paid off by performance characteristics

- Insulation with liquid compounds (polyurethane foam or foam concrete) is not very popular, as it requires the use of specialized equipment to carry out the work

If thermal insulation of a classic attic space is required, additional insulation is provided above the ceiling (expanded clay, sawdust, sand, etc.).

Let's start insulating the roof with our own hands

The most common case is the insulation of pitched roofs using rolled materials. First of all, you need to draw up instructions for yourself, following which you can count on high quality results. Let's consider the case when the roof has not yet been laid.

First, you need to go through the attic again and make sure that all the components are in perfect order. If defects are found (rotting, cracks, etc.), they should be eliminated immediately.

Sometimes various communication systems are laid on the roof: electrical wiring, heating, water supply, etc. They are also subject to thorough inspection and elimination of defects. Only after order has been established can further work begin.

The first step will be to apply a waterproofing film to the outer surface. In order for it to fulfill its purpose, several rules must be taken into account:

- It is necessary to lay the film across, and at the joints, stripes of about a meter are applied, which are glued with tape.

- It is necessary to select a material for waterproofing only after purchasing insulation so that they match each other’s characteristics

- Under no circumstances should you pull it tightly over the surface. At sub-zero temperatures it will begin to shrink and, as a result, may burst.

Having completed the work with waterproofing, it is necessary to begin arranging the sheathing. For it, beams treated with antiseptic materials with a size of no more than 25 mm are recommended. Corrosion-resistant self-tapping screws are used for fixation

Roofing materials can be attached directly to the sheathing. Things will be a little different with a soft roof. It is recommended to place moisture-resistant plasterboard or chipboard between it and the wood.

The next stage is laying thermal insulation material into the gaps between the rafters. It is recommended to adjust the slabs to the width between the rafter opening; the mats are cut into pieces equal to each other.

The material is laid in such a way that there are no gaps between the elements. It should also not be pressed very tightly against the roof so that there is a ventilation gap.

Another feature is the laying of thermal insulation material not in one, but in two layers. At the same time, they are positioned relative to each other with an offset so that the through joints are closed.

Having finished laying the insulation, you can proceed to the next stage - tensioning and fastening the vapor barrier film or membrane. It is recommended to nail it to the rafters with staples. It, unlike waterproofing, is stretched much tighter.

Next, you can proceed to the final stage of insulating the roof from the inside - interior finishing. A wooden frame is placed on top of the vapor barrier film, to which the desired finishing material will be attached.

Video on thermal insulation using polyurethane foam

Some useful tips

When insulating a roof from the inside, not everything can go as smoothly as it seems at first. In addition, any rafter system has its own characteristics.

We list a number of rules that may be useful when performing roof insulation work:

- Particular attention to waterproofing and vapor barrier must be paid when working with mineral insulation. They are most susceptible to the accumulation of moisture inside, causing destructive effects.

- Sometimes, for a light roof, the roof truss system is constructed from timber of a small cross-section. In this case, you will have to use a combined method of thermal insulation, placing the material not only between the beams, but also under them

- When the pitch of the rafter system is too large, the insulation is additionally fixed with wire, which is pulled between the screws screwed into the rafters

- To ensure that the insulation is not tightly located between the rafters, its width must be greater than the similar characteristic of the openings

- You should not make too many layers of insulation. For example, for thermal insulation with a thickness of 20 cm, two layers of 10 cm each would be better than four layers of 5 cm each.

- The insulation can be placed close to the super diffusion membrane. In all other cases it is necessary to leave a ventilation gap

- It is necessary to monitor ventilation gaps, which should not be blocked by thermal insulation material

In custody

Absolutely everyone can make high-quality insulation of the roof from the inside, which will serve for decades, reliably retaining heat and keeping out the cold. However, for those who do not want to waste their time and energy, professionals offer their services. The cost of work can vary between 5-25 USD. e. per square.

Insulating the roof from the inside is the best option for work for several reasons.

Roof insulation is done only for residential attic spaces; due to this, heat losses are significantly reduced and living comfort is increased. Today, companies produce a wide range of insulation materials, all of which have both positive and negative sides. When choosing a specific insulation, it is important to know its features and take into account the characteristics of the building’s rafter system.

There are many names of materials for insulation, but they are all divided into two large groups.

Table. Roof insulation groups.

| Name of insulation | Operational and physical characteristics |

|---|---|

| This group includes mineral wool from basalt, glass wool from recycled glass and ecowool from waste paper. Cotton wool insulation can be pressed in the form of mats of standard sizes or rolled. There are options for spraying liquid ecowool. In terms of thermal conductivity and weight, the listed types are almost the same from each other. Mineral wool is the most expensive. |

| Polystyrene foam, polystyrene foam, polyurethane foam, etc. All these insulation materials are made on the basis of the same polymer and differ in production technology and some additives. Most often they take the form of slabs of various thicknesses and sizes; they can differ significantly in terms of physical strength. Thermal conductivity is almost the same; minor fluctuations in practice have no effect. The price range is wide. Can be used in liquid form (sprayed) or as slabs. |

As an example, we will look at the two most common options for insulating a roof from the inside. The examples are not only budget-friendly, but also effective. The process is divided into several stages, and the final quality of the work depends on the correct execution of each of them.

Inspection of the rafter system and roof covering

A very important stage of preparation for insulation. Inspect all elements of the roofing system, check the condition of the roof covering. If problems are discovered, they must be corrected immediately.

Measure the distance between the rafter legs, this will help you navigate the choice of insulation. The fact is that all insulation has standard width dimensions. This simplifies and speeds up installation work and reduces waste. The width of the insulation is 60 cm, but, unfortunately, some manufacturers allow fluctuations in one direction or another by several centimeters. The distance between the rafter legs should be within 56–57 cm. In practice, it is rare to find such correct roofs.

See if a wind barrier is installed between the roof and the attic, and if it has vents for natural ventilation. This is very important in cases where insulation is planned to be done with mineral wool.

Selection and purchase of materials

The most commonly used materials for roof insulation are mineral wool and polystyrene foam; we will dwell on them in detail. If you have a simple gable roof, then insulating it is not very difficult technologically. The situation is completely different with a sloping or hipped roof. These structures have many different stops, purlins, ties and other elements that strengthen the rafter system. During insulation, you have to cut the mineral wool or foam plastic, make various folds and bends. As a result, the complexity of the work increases and the amount of waste increases.

But this is not all the problems. Complex roofs will never be able to be hermetically sealed with a vapor barrier layer; there will always be places through which moist air gets into the insulation. For mineral wool this is a very unpleasant phenomenon. Experienced builders recommend insulating complex roofs with foam plastic rather than taking risks with mineral wool. Wet cotton wool not only almost completely loses its heat-saving abilities, but also accelerates the putrefactive processes of wooden structures of the rafter system.

Roof insulation work

The technology of work largely depends on the chosen material, but for all cases there are general tips.

If you have the opportunity to work with an assistant, great, the insulation process will go much faster. There is no such possibility - no problem, all the work can be done independently.

A fully insulated house must have a roof that is thermally insulated from the inside. Roof insulation may also be needed if you would like to convert the attic into a separate floor and/or replace the roofing. Some coatings, such as metal tiles and corrugated sheets, can become covered with condensation and ice due to temperature changes, which over time leads to damage to the decking. Before insulating the roof of a house from the inside, it is necessary to protect it from moisture on both sides - install a waterproofing layer under the slate and a vapor barrier under the insulation. Some types of insulation do not require waterproofing, but they either cost more or are inferior in quality to classic insulation.

General form

How to properly insulate a roof so as not to damage your home and so that the roof lasts a long time? A simplified roof insulation scheme has three main layers:

- Wind and water repellent. It prevents moisture from getting on the insulation from outside and protects against adverse weather conditions.

- Thermal insulation. This is the insulation itself. It prevents heat from escaping from the room and protects against temperature changes.

- Vapor repellent. Prevents the collection or penetration of condensation that may form due to temperature differences under the insulation. Basically, a special film is used for this.

Before installation, it is recommended to erect a rafter system. This is the “skeleton” of the roof, on top of which a waterproofing layer and roofing are laid, and insulation and vapor barrier material are placed inside. Transverse and counter battens protect the structure from mechanical damage, and thanks to the presence of rafters, it becomes easier to install insulation.

Attention! If there is no need to insulate the attic itself, then only the attic floors can be insulated. This will be enough to prevent heat from the lower room from escaping through the ceiling. In this case, there is no need to disassemble the roof and purchase expensive insulation.

Materials

Proper selection of materials specifically for your case can not only extend the life of the attic space, but also significantly facilitate the installation process. On the market you can find materials of different quality and price categories. But you shouldn’t buy the cheapest or the most expensive - it’s better to proceed from price-quality considerations, and also look for options to suit your case. It is important that the selected material has low thermal conductivity, can withstand environmental changes, is environmentally friendly and durable.

A membrane or film coating is ideal for creating a waterproofing layer. In the first case, not only the most complete moisture insulation is ensured, but also ventilation through special membranes. However, their price is higher, so if you decide to use a regular film coating, it is recommended to think about creating small ventilation gaps and seams.

At the moment, manufacturers provide a large selection of roof insulation materials, which have different characteristics, pros and cons. When choosing, pay attention first of all to these characteristics:

- Degree of moisture absorption. It is advisable to choose the one with the lowest indicator. However, if you are confident in the quality of your moisture-repellent layer, then you can choose one with an average rating. The higher the indicator, the lower the price and the shorter the service life.

- Thermal conductivity level. It should also be as low as possible. Porous materials have the lowest level, but they have a higher degree of moisture absorption.

- Density. It should also be lower.

It is also advisable to pay attention to flammability, environmental friendliness, chemical and frost resistance.

There are two types of materials most common on the market.

Mineral and glass wool

They have low density, thermal conductivity and price, but they also absorb moisture better, last less and are more susceptible to fire and pests. Most suitable for insulating the roof from the inside with your own hands, because it is easier to install.

Expanded polystyrene

The characteristics may vary significantly depending on the brand. Basically, they are resistant to moisture, fire, many pests, and have an acceptable level of thermal conductivity. However, due to their high density, they are more easily susceptible to mechanical damage, which makes them more difficult to install. The cheapest options are also susceptible to rodent infestation.

Preparatory stage

How to properly insulate a roof so that it lasts longer? The preparation and installation process may vary depending on the type of roof. Let's look at the preparation using the example of insulating pitched roofs using rolled materials. It is advisable to remove the roof, because... it will interfere with installation.

Check the attic for defects (cracks, mold, rot, inconsistencies, etc.) and eliminate them. If everything is “too neglected”, then it is recommended to completely rebuild the attic space, because... Even with good repair of defects, they will make themselves felt over time. Also, if any communications are laid through the roof, then they also need to be checked for damage and repaired.

Then install the support rails, on top of which the waterproofing layer and sheathing will be attached. They serve as support for the entire structure, so they must be strong enough. Because in most cases, the supports are made of wood; they also need to be treated with special materials to prevent moisture, fire and pests.

Waterproofing and sheathing

A moisture-proof film/membrane is stretched onto the outer part of the finished cornice, which should completely cover the roof area. In order for the film and insulation to serve for a long time, be sure to apply these tips:

- Lay the film only across.

- At the joints between the strips, you need to make an overlap of about one meter and tape it with tape so that moisture does not get through the micro-openings at the joints.

- Check the characteristics of the material for waterproofing and insulation with each other. They should match as closely as possible. It is best to select a waterproofing layer only after purchasing insulation.

- Try not to stretch the film too much, because... it may be damaged in the future due to temperature changes.

Next, a sheathing is erected from beams measuring 15 - 25 mm. The beams also need to be treated with moisture, fire, and pest repellents. It is best to fasten them using stainless steel screws. The roof is laid on top of the sheathing.

Installation of insulation and vapor barrier layers

We insulate the roof by installing insulation in the gaps between the support slats. Regardless of the type of insulation, the installation process is approximately the same. The material is measured and cut, after which it is attached. Basically, mounting foam, construction adhesive, screws or profiles are used for fastening (depending on the type). During installation, it is important that there are no gaps between the insulation and the supports; however, there should be a small space (no more than 30mm) between the roof and the insulation for ventilation.

After the roof has been insulated, a vapor barrier layer is stretched, which should lie almost flush against the insulation. Attached to construction boards using special brackets. In this case, the film can be pulled tighter, because It is not in danger of severe temperature changes if you have selected high-quality insulation.

As a final step, a wooden frame is applied to the film, on top of which finishing material can be mounted. The requirements for the frame depend on the characteristics of the finishing material.

Conclusion

To properly insulate your roof from the inside with your own hands, use these tips:

- If you work with mineral insulation, pay special attention to protection from moisture.

- If there is a large distance between the beams in the rafter system, the insulation is additionally secured with wire.

- There is no need to apply several layers of insulation (1-2 are enough).

- Some ventilation gaps should not be blocked by insulation, but they need to be monitored.

It is quite possible to insulate the roof yourself, but if you are not sure that you can do it, then it is better to outsource the work to a professional team of builders. They will select high-quality insulation and waterproofing layers for the roof based on your wishes and carry out installation.

When building or renovating a private house, roof installation is one of the most important stages. If it is not designed correctly, precipitation will accumulate on it, which will create an extra load and contribute to the deterioration of the roofing material. If you lay the roof incorrectly, then moisture will get into the seams and over time it will leak into the house, and if you do not insulate the roof from the inside, then cold air will very quickly enter the room and will not allow it to be fully warmed up by any means, that is, living in such conditions all the time year will be impossible.

Physical factors: impact

Any house that is used for housing must meet certain requirements to make living in it cozy and comfortable. It is important to lay the foundation correctly so that the house does not shrink or crack, insulate it and build a roof. The choice of covering is very important because it determines the weight that is applied to the house, the time it takes to complete the covering work and the cost. In addition to all this, it is necessary to take care of insulating the inside of the roof so that the structure of the house remains as reliable as possible and the residents feel comfortable at any time of the year.

In different climatic conditions, buildings are affected by various factors.

Our latitudes will be characterized by:

- precipitation in the form of rain;

- snow, cereals and similar phenomena;

- hail;

- roof icing;

- active sun;

- strong wind.

To withstand all these negative factors, the roof must be covered with sufficiently dense materials that can reliably protect the house for many years.

A private house is a structure that consists of a main floor and an attic. If the roof is not insulated, then up to 15% of the heat from the room escapes through the ceiling in cold weather, which makes it necessary to intensively heat the rooms. In addition, having an insulated attic, this space can, if desired, be made residential and used as rooms for a specific purpose. For a large family this is an ideal option.

Processes inside

In order to properly insulate a private house and make the roof a full-fledged protective mechanism for both the main room and the attic, you need to be able to choose the right material for insulation. Usually the selection is based on the physical processes occurring inside, under the roof.

There are several of the most important ones.

- Heat exchange, which occurs due to different temperatures in and outside the house. If the roof is not insulated, then some of the heat escapes through the roof, and the insulation prevents this process and maintains optimal temperature in the room.

- Moisture exchange, which arises from the person himself, his breath, fumes from body temperature to cooking processes, when vapors rise to the ceiling, carrying particles of moisture that are removed through the roof. If the roof is insulated, the humidity level remains optimal, and unnecessary odors can be removed using ventilation.

When insulating the roof, you can protect yourself from temperature changes inside the room, because the insulation has its own temperature, which is often slightly higher than that on the street, and does not allow the heat of the building to escape outside, which will eliminate the need for additional heating, which requires reserve funds.

Insulating layer helps prevent condensation, which is formed by the contact of hot and cold air, therefore laying it together with insulation will help preserve its appearance and performance. Properly performed work increases the service life of the building by almost two times and minimizes the need for repair work every year.

Necessity or whim?

A private home often has a pitched roof that creates an attic space on top of the main living floor. If there is no insulation, then living in such conditions will be very uncomfortable due to the lack of heat during the cold season. If the attic is designed as a residential floor - the same attic, then the insulation process must be mandatory.

Any roofing material cannot protect as much as polystyrene foam, mineral wool or another type of coating. In addition to the insulation itself, it is important to use a vapor barrier film that can cope with various types of fumes.

If you ignore the installation of an insulating coating, then in addition to the cold in the house, very soon problems will begin with the roof rafter system, which will rot and there will be a risk of collapse. The same effect can be observed with incorrect installation technology or inaccurate choice of insulation. If you choose the wrong thickness of the insulation, then instead of protection it will have the opposite effect. Under normal conditions, when there is a difference in temperature, protection is provided against condensation and heat loss, which makes it possible to feel comfortable in any weather.

If the thickness is compromised and thin insulation is selected, then an excessively large amount of condensation will form on it, which will contribute to the rapid rotting of the rafters and disruption of the microclimate of the room.

Failure to comply with standards is dangerous for both health and safety, as the roof structure may collapse. The choice of material that needs to be insulated depends on a wide variety of factors that are important to consider in order to be able to independently install what is needed. If difficulties arise with the choice of insulation or its installation, it is better to contact professionals and receive comprehensive advice and assistance in installation.

Roof “pie”: what is it like?

A properly constructed roof involves a large number of layers of different materials that are layered on top of each other, resembling a pie - hence the name. The basis of the construction “pie” is the rafters, on which all other layers are already being laid.

To correctly lay out all the layers, it is important to know their correct sequence, which looks like this:

- Roof.

- The lathing on which the finishing materials will be installed. It can be laid completely or with gaps.

- A counter-lattice in the form of bars, which serves to ventilate the space under the roof itself.

- Film for waterproofing.

- Materials for thermal insulation.

- A layer of vapor barrier material.

- Creating a sheathing where insulating materials and internal lining are mounted.

- Material for internal lining.

If you lay the “pie” correctly, you can avoid heat loss from the living space during the cold season, and it will also help prevent the space from overheating in extreme heat. The waterproofing layer will help protect the insulation from moisture coming from outside, and the vapor barrier layer will protect against various types of fumes.

Pitched roof is a fairly common type, so it will not be difficult for her to select all the necessary materials. The positive aspect of high attics is the convenience of insulating them and the ability to create a full-fledged living space.

Without additional work, it will be extremely unpleasant to be in it - it is very cold in winter, and too hot in summer.

Requirements for materials and their functions

To carry out quality work, it is necessary to choose the right materials. It will depend on them how accurately it will be possible to create comfortable living conditions and secure the roof supports. The choice will depend on the region where the building is located, its size, purpose, as well as the funds available to purchase materials.

There are four main methods of insulation.

- Use of mineral wool, which is the most commonly used material due to its properties. It is best to purchase the basalt variety. It is advisable to obtain a quality certificate from the store in order to know for sure that the products are safe and meet all norms and standards. There are varieties that are lighter in weight; they are suitable for working in conditions of independent insulation of the room. The positive qualities of cotton wool can be considered non-flammable composition and moisture repellence, which corresponds to the main task of this layer. In addition, rodents do not like it, which means you don’t have to worry about someone getting in the house, especially on the roof.

Among the disadvantages, one can note the rather high cost, but it is fully compensated by the positive aspects.

- Use of glass wool. Some time ago, this material was considered the main one for roof insulation, but due to some dangerous properties, safer analogues were soon found. The thermal insulation of glass wool is quite good, and the efficiency is very high. When working with such material, it is very important to follow all safety rules, namely, use a protective suit, gloves, and goggles. It is important to close your nasopharynx and eyes to prevent pieces of glass dust from getting into them.

People with allergies will not be able to live in such a house, so you need to be able to choose the right type of internal insulation coating.

- Polymer roof insulation– these are special tiles made of polystyrene foam and expanded polystyrene. They have both advantages and disadvantages. This is an inexpensive option, so anyone can afford it, but if you look at the disadvantages, you should think carefully about purchasing such insulation. These materials are very flammable, and when burned they produce a large amount of smoke, which is very dangerous to humans.

Usually this type is used when other options cannot be used.

- Insulation with expanded clay. This material is very often used for floor insulation and has good thermal insulation properties, but it is very difficult to use for roofs due to heavy installation. Usually only experienced workers can handle it to make internal insulation of the ceiling in the house.

If we consider alternative options, among them are polyurethane foam, which can be used in two states - in the form of slabs and foam. It is advisable not to take slabs for arranging the ceiling, because working with them is inconvenient and they are very expensive. At the same time, liquid or foamed polyurethane is easy to apply and has a number of advantages. With its help, you can fill voids of any shape and size; cracks and opening lines are very well clogged. If other materials need to be cut and achieved maximum fit, then in this case the foam will fall on its own, the main thing is to distribute it correctly and evenly.

It is very convenient to use foam for roofing made of slate or broken structures when there are many differences on the roof and the frame has significant differences. Another significant advantage is the independence from hydro- and thermal insulation, which are not needed for polyurethane foam. In addition, the material has excellent flammability resistance, which ensures home safety.

How to choose?

When choosing a material for insulation, it is important to understand what exactly you should pay attention to, what indicators will play a decisive role in the selection of one type or another.

The main criteria are:

- Mass of material. Heavy insulation will serve as additional weight on the house itself, which will affect both the roof rafters and the building as a whole. If the house is built from high-quality bricks or foam blocks, then enhanced insulation can be allowed, but in this case the rafters need to be made more powerful so that they can withstand a lot of weight.

- Thermal conductivity index. The lower the numbers, the better for the roofing material. If the indicator is approximately 0.04 W/m*s, then this will be the best option.

- An indicator of resistance to adverse environmental factors.

- The density of the material, which affects the heat transfer of the material. If the density is low, the porosity of the insulation increases, which reduces thermal conductivity and leads to an increase in thermal insulation properties.

- Ability to absorb moisture. In order to repel moisture, any insulation can be treated with a hydrophobic substance. Some materials are already sold with such impregnation.

- Flammability indicators, which is the most important factor for arranging a roof.

- Ability to resist low temperature levels.

- Resistant to chemical elements.

- Environmental friendliness of the material.

Having considered all these indicators, the best option would be to use mineral and glass wool. Glass and mineral wool are sold in the form of rolls or slabs. It is safer to insulate with mineral wool, because it is more resistant to fire.

If we consider modern insulation materials, the most advanced technology would be roof sheathing with foam flex. This is a durable and lightweight unit that can be easily installed on any surface, be it a wall or ceiling. You can cut the desired piece with a regular knife.

In addition, the storage conditions for penoflex are also distinctive; they can be kept outside at any temperature, but it is better to have packaging on it.

It is convenient to use polystyrene foam, which is also called penoplex, in rooms with unfavorable conditions, because it is not afraid of them, and various microorganisms will not begin to develop in it. A very important feature is the environmental friendliness of this insulation. It does not emit any harmful odors or fumes and is completely harmless to both adults and children.

Preparation

To carry out insulation procedures, it is important to clearly understand what type of roof you will be working with. By correctly determining the order of work, you can quickly and efficiently insulate the roof. It is also worth considering the materials that will be at hand during work. It is important to clearly understand for yourself what exactly you have to work with and what to do.

If the insulation process has become completely clear, then you can cope with absolutely any roof, be it a rural house or a large villa by the sea. In order to carry out insulation work, it is important to prepare the roof itself for this.

There is a specific procedure for this, which includes:

- inspection of the rafter system so that damaged boards can be identified in time and replaced;

- treating wooden structures with an antiseptic;

- checking communications if they are located under the roof. This applies to piping and wiring.

As soon as the roof is ready, you need to check the availability of all the materials that will be used for insulation, prepare the tools, and only after that you can get to work. The work process has its own rules and patterns that you need to know in order not to make mistakes and get a good and high-quality result.

The process step by step: how to do it?

In order for the work to proceed quickly and efficiently, it is important to prepare well, read articles on the topic, watch videos in order to clearly see what is done and why during the work on internal roof insulation.

The algorithm for carrying out the work comes down to four points.

- Installation of the waterproofing layer. This task should be performed at the time of covering with roofing material. The waterproofing is installed along the rafters so that there is slight sagging. A slate house involves laying this material directly on top of the insulation. It is important to lay the waterproofing correctly - its smooth side should be on top. The strips of material must be sealed with tape to prevent cracks from forming over time. Only after this are the counter-battens placed on the rafters, to which the sheathing will be installed. The roofing material must be laid on the finished boards.

- Installation of thermal insulation. It is important to choose a thermal insulation mat with the required thickness and lay it between the rafters. The material is placed in a spacer or on a rough backing, which is made from small-width slats, fishing line and rope, which are attached to the rafters with nails. Thermal insulation mats take up free space, and excess pieces are cut out.

If you need to insulate a room as efficiently as possible, the mats are laid, moving to the side with each row.

- Placement of a vapor barrier layer. This material consists of a smooth side, which is placed towards the insulation, and a rougher one, which is directed towards the building itself and collects vapor emissions from the room. Laying such a film is an important point for its full operation. The installation process takes place using a stapler. In this case, you can do without a counter-lattice, but it is important to glue all joints with tape.

- The process of installing profiles and guide bars. These materials serve as the basis for the installation of decorative elements and ventilation, which is necessary for the proper operation of insulation.

The technology of work will be similar, be it a dacha, where the house has a flat ceiling, or a large country house, where a gable roof is built. The correct choice of materials and installation in the right sequence will give the desired result.

A house built and furnished with one’s own hands is the real pride of any owner. An integral stage in the arrangement of any residential building is the internal insulation of the roof. And if in most cases no problems arise with the thermal insulation of walls, then the insulation of the roof structure can confuse an untrained craftsman. Therefore, before starting the practical part, study all the theoretical recommendations proposed below.

After installing the insulation and all related elements, the roofing system will look like a layer cake. The design is based on a rafter system. All other elements are laid and secured onto it.

Modern roofing “pie”

In the classic version, the layers of the pie, starting from the finishing roofing, are placed as follows:

- roofing;

- lathing for installation of finishing material. Can be solid or sparse;

- counter-lattice bars. Needed to create a ventilation gap under the roofing material;

- waterproofing film;

- thermal insulation material;

- vapor barrier material;

- lathing for installation of insulating materials and internal cladding;

- inner lining material.

A properly installed roofing pie will significantly reduce heat loss in cold weather and prevent overheating of the space under the roof in hot weather. Waterproofing will protect the insulation from atmospheric moisture, and the vapor barrier material will prevent the formation of condensation and the occurrence of all related problems.

How to insulate?

The modern market offers a huge range of materials that can be successfully used for internal roof insulation. Try to avoid excessive savings - materials must be of high quality.

Insulation parameters

When choosing a suitable insulation, you need to pay attention to a number of basic characteristics of the material, namely:

- weight. The heavier the insulation, the more significant load it will place on the roof. This imposes a number of additional requirements on the rafters and sheathing - their configuration and strength must correspond to the characteristics of thermal insulation;

- thermal conductivity. It is better for this parameter to be as low as possible, if possible no more than 0.04 W/m*C;

- resistance to adverse external influences.

Preferred insulation materials

Not many materials meet the above requirements. Among all the existing insulation options, professionals recommend giving preference to mineral wool insulators and foam panels. All other things being equal, mineral wool is more preferable.

Additional insulation materials

In combination with insulation, the roof will need to be additionally insulated using vapor and moisture insulation materials. For roof waterproofing, polyethylene and roofing felt are usually used. These materials are highly resistant to moisture.

The vapor barrier layer is best equipped using special membranes, glassine or modern foil materials.

Regardless of the chosen insulation (installation is still carried out in the same sequence), during the work process you must adhere to a number of basic recommendations, without which you cannot count on high-quality internal insulation of the roof.

All the rules can be combined into one brief summary of tips, namely:

Thus, even before starting thermal insulation work, the master needs to study a fairly large amount of information and remember a number of important requirements. The work must be done to the highest possible quality. Properly equipped insulation will make living in the house as comfortable as possible and will significantly reduce the cost of heating the premises.

Use the recommendations received and remember: insulation must be done with the obligatory installation of vapor barrier and moisture barrier layers. Only such a complex will make it possible to obtain a reliable, durable roofing system that is resistant to any adverse external influences. It’s better to immediately do everything according to the rules and live peacefully in a safe home than to patch holes in the roofing pie after every heavy rain.

Preparing for roof insulation

The insulation procedure remains almost the same regardless of the type of roof, materials used and other points. Having understood the main points of thermal insulation work, you will be able to successfully apply them in practice.

First of all, carefully prepare the roof for the upcoming internal insulation.

First step. Inspect the rafter system. If you find rotted or damaged elements, replace them with new parts.

Second step. Treat all wooden elements with an antiseptic.

Third step. Check the condition of pipelines and electrical wiring if these communications are laid under the roof.

Guide to internal roof insulation

Start working on the internal insulation of the roof. The event is held in several stages. Go through each of them sequentially, not forgetting the recommendations received earlier.

It is assumed that the rafters, sheathing and other necessary elements have already been installed and all you have to do is install the insulating materials and then lay the final roofing covering.

The first step is vapor barrier

Lay the film with a 10-centimeter overlap. To attach the vapor barrier to the bars, it is convenient to use a construction stapler with staples. Double-seal all joints with duct tape. Be especially careful and thorough when sealing various difficult areas, such as the junction of the film with pipes, walls and other structural elements.

The second step is insulation

EKOTEPLIN - roof insulation

Place the selected insulation in the cells of the sheathing. Usually the sheathing is assembled so that the step between its bars is a couple of centimeters less than the width of the insulation, so you can place the insulating boards as tightly as possible. The sheathing bars themselves must be nailed to the rafters perpendicular to them.

If you really want, you can do without lathing - you hammer nails along the edges of the rafter legs and stretch the wire between them. It will hold the insulation boards. However, it is better not to give up the sheathing - it is safer with it.

The insulation itself is usually laid in 2 layers. In this case, the top layer must be laid with a certain offset in relation to the bottom one - it is impossible for the joints of the insulation boards of both layers to coincide.

Third step - waterproofing

Place the waterproofing film so that it completely covers the insulation, sheathing and rafters. To fix the film, it is most convenient to use a construction stapler with staples.

Place waterproofing under the roof overhang - this will create the conditions necessary for effective water drainage in the future.

At the end, all you have to do is lay the selected roofing material on the roof.

Thus, although independent internal insulation of the roof is a very important and responsible undertaking, there is nothing overly complicated in its implementation. Do everything in accordance with the instructions, and very soon your home will become truly cozy and warm, and heating costs during the cold season will significantly decrease.

Good luck!

Video - Do-it-yourself roof insulation from the inside