Warming the walls of the bath from the inside with your own hands. Proper insulation of the walls of the bath from the inside with your own hands What material is better to insulate the bath inside

Lining is a finishing material, it is attached to the walls when all other work is completed, including insulation. Therefore, the question of how to insulate the bath from the inside under the lining should be asked long before its installation begins.

However, it happens differently - the bath has long been finished, but it does not suit how it keeps warm. And then you need to think about how to properly insulate the bath under in order to eliminate the problem with thermal insulation. Of course, it will have to be dismantled for a while. And then - to act exactly as if you were just building.

Types of suitable heaters

In our opinion, it makes sense to divide the types of thermal insulation materials for a bath into sheet, roll and backfill. In addition, there are heaters that are applied to the walls in the form foam or moistened mass- These are polyurethane foam and ecowool, which are sprayed using special equipment.

Mineral wool can be purchased in rolls or sheets. It all depends on its density and the binders used.

BY THE WAY! We rarely name specific brands, but do you understand that under the names Rockwool or Izover there is one and the same mineral wool produced by different companies?

Basalt wool- This is a type of mineral wool, a literal indication of a similar mineral used. There is practically no difference.

Basalt wool for baths

But to confuse mineral wool and glass wool it’s not worth it - these are different heaters, from different materials and with different properties.

glass wool it is no longer worth using anywhere, because it is extremely unpleasant for a person - when it gets on the skin, it causes itching, it is dangerous to health if it gets into the eyes or respiratory organs. Yes, and fiberglass crumbles during operation, turns into dust, and it penetrates through the cracks, and you breathe it.

He does not like fiberglass insulation and the elevated temperatures inherent in the bath.

Styrofoam and extruded polystyrene foam- good heaters, especially the last one, but it is dangerous to use them in a bath. They are categorically not suitable for a steam room, but could (theoretically) be used in other rooms, but we will not recommend them, as they are fire hazardous.

ADVICE! In the bath, foam plastic and foam plastic can be used in floors under a concrete screed - there they pose no danger.

So, leafy heaters are mineral wool, foam glass (an excellent, but expensive insulation), calcium silicate and magnesium silicate sheets, non-recommended polystyrene foam and extruded polystyrene.

Foam glass

Rolled heaters are again mineral wool (lower density), glass wool. foamed polyethylene, with or without foil (penofol, isolon, etc.).

We have already spoken about fiberglass, now about foam polyethylene e. It is often used as an additional insulation in residential buildings, but polyethylene does not tolerate high temperatures, so you should not use it instead of foil to insulate the steam room.

Foil insulation Penofol

IMPORTANT! Polyethylene at a temperature of one hundred degrees already melts. By the way, it supports combustion.

In general, it is quite possible to insulate other rooms of the bath with them (as a second layer).

Bulk we will divide the heaters for the bath into those that can be moistened and “glued” to the wall, and those that cannot. Expanded clay and vermiculite belong to the second category, ecowool - to the first.

AND vermiculite can be used for floor insulation and, where they perfectly hold and keep heat indoors. In order to insulate the walls of the bath with them, it is necessary that there be a gap between the two layers of the main material of the wall, a cavity that can be filled with insulation.

Ecowool- this is waste paper (cellulose) shredded into dust, flame retardants so that it does not support combustion. And she really does not support him - this is a good material for warming baths where it is on sale. Ecowool is used in dry and wet form. In dry - for warming floors and ceilings, as well as for filling cavities. In wet - for application to the walls.

Also on our website you can read two articles that make a more complete overview of heaters that can be used in the bath:

Insulation for lining in baths built from different materials

How does the wall material affect the choice of thermal insulation? Let's sequentially consider the options for what a bathhouse can be built from, and compare the material and insulation technology.

Brick

Brick baths - cold and non-combustible. The first circumstance prevents them from becoming traditional, because a cold bath (practically made of stone) needs to be warmed up for a long time, which is not particularly welcome in our high-speed age.

But the fact that it does not burn out is a big plus, given that baths burn most often.

So, it is precisely in order to reduce the disadvantages that thermal insulation should be used - it is most effective in this kind of buildings.

IMPORTANT! The thermal insulation of a brick structure can be not only internal or external, but also located between two layers of brickwork.

The latter circumstance increases the possibility of choosing a heater. Backfill expanded clay or ecowool is a great solution. Ecowool, for example, is used in “double beam” constructions, and it has been working great for decades.

You can also fearlessly fill the gap polyurethane foam- it is expensive, it requires hiring a team with equipment, but it is reliable and safe, because polyurethane is combustible, and nothing threatens it in the gap between the layers of brick, including ultraviolet, which destroys it.

In other cases, the traditional mineral wool- most often, because, for all its shortcomings, it does not support combustion, and high-quality ones also do not emit volatile organics that are harmful to health.

You can learn more about the brick wall insulation technology from the article.

Blocks

Of course, a brick is also a block, but in practice we often call products made of slag concrete, foam concrete, aerated concrete. Of course, they are larger and more like blocks, but they still have more internal resemblance than bricks.

The fact is that high-quality brick does not crack, holds fasteners well, and does not pick up moisture. In essence, it is burnt clay, almost a stone. And concrete blocks either contain light (by density) impurities in the form of slag, or are foamed in one way or another, that is, they contain air bubbles.

You can find out more about the similarities and differences between various foam concrete and cinder concrete.

Both greatly affect a number of qualities. Significantly thermal conductivity decreases blocks, they themselves perfectly keep heat even without heaters. But most of them are afraid of water, all of them do not hold fasteners well (it is problematic to hammer a nail into such a wall, but what about fasteners, for example?). Breaking blocks is pretty easy.

But we are talking about thermal insulation. Do blocks need it? Yes, in the bath and living quarters it is needed, especially if the climate is harsh. But in addition to thermal insulation, it is worth taking good care of waterproofing wall material. To do this, it is closed with all sorts of films and membranes.

Mineral wool is also afraid of water, so it’s better to be afraid of blocks and mineral wool together, under a layer of vapor and waterproofing inside and out. You will find the device of the correct heat-insulating cake in the article.

frame

A frame structure, in essence, is a heater between the slats, closed on both sides with OSB shields, boards, and other sheet material.

In other words, insulation is the main of two or three materials, forming a wall. Therefore, there is no need to carry out any additional work on thermal insulation if the initial calculation was made correctly and you correctly selected the thickness of the insulation.

Frame wall pie. See more about the insulation of frame walls.

Standard "pie", that is, the layers that make up the wall of the frame structure are as follows:

- if you start from the inside, then the first layer will be finishing, for example, lining;

- lining is nailed to the crate, which is attached to the racks of the frame;

- under the crate there is an obligatory layer of vapor protection, that is, a material that is one hundred percent impervious to water vapor - it can be a plastic film or foil;

- vapor protection directly covers the insulation, which is most often mineral wool, but there can also be reed slabs, a mixture of sawdust and gypsum / cement / clay, ecowool;

- the insulation is located between the racks of the frame, equal to them in the thickness of the layer;

- next comes, for example, an OSB board, which covers the thermal insulator from the outside and stiffens the structure;

- a membrane or hydroprotection film is mounted on top of the wall panel, which is permeable to water vapor from the side of the insulation, and impervious to the opposite side;

- on top of the waterproofing, the outer wall decoration is attached.

More detailed information about frame insulation technologies is in the article.

Tree

Wooden baths are either log cabins, that is, they are placed from cylindrical logs, or from a bar- logs with a square or rectangular section.

By tradition, such baths do not need additional thermal insulation at all, if they are correctly laid and carried out. caulk gaps between crowns. As a material for caulking can be used tow, moss, linen. But for laying between the crowns at the construction stage, it is most often recommended to lay strips jute.

natural heaters in the bath are preferable, but in addition to this, you can use modern wood sealants, which have a certain elasticity, which allows them to change dimensions along with the one that “breathes” even after the building has given final shrinkage.

If, during the operation of the bath, it turned out that the thickness of the beam or frame does not correspond to the severity of the climate, then you have to do additional insulation. This is also a standard "pie", consisting of lining, crates, vapor protection and insulation, the latter being attached directly to a wooden wall.

About how a bath from a bar is insulated, it is said in the article.

How to properly insulate in a steam room

steam room- this is the main bathing room, from which visitors expect certain properties, in particular - long-term heat retention. To do this, it is insulated, but this must be done taking into account the preferences of certain traditions.

The point is that in Russian bath long-term heating and heat retention is carried out due to long-term heating by the same brick oven. Slowly heated wooden surfaces also give off heat for a long time. If the thickness of the walls is not small and there are no gaps in them, then additional insulation is not required.

In addition, the Russian bath is not chasing high temperatures. If you make a "thermos" in it, it can become an obstacle to maintaining fairly low temperatures(40-70 degrees), typical for this type of national bath. "Thermos" is made using foil.

For more information on using ceiling foil, see this

As for the Finnish bath - sauna, then the task is precisely to reach the set high temperature in the steam room in the shortest possible time and keep it until the end of the procedures, subject to intensive air exchange.

It is worth warming the steam room only if there are real problems with heat loss.

ADVICE! Focus on the material of the walls: in a brick bath, the thermal insulation of a steam room is mandatory, in a frame bath, the thickness of the walls is included in the project, in a block bath it can be moderate, with more emphasis on waterproofing, and in a wooden one it may not be needed at all.

About the "thermos" a little lower, but otherwise the insulation scheme looks standard - most use mineral wool, because in fact there are not so many options for insulation in the bath for lining the steam room. But even if it is mineral wool, you need to pay attention to the fact that it is intended strictly for saunas and baths - this means that in it reduced content of phenols and other harmful substances in a bunch for stone fibers.

Apart from mineral wool in the steam room baths can be used ecowool, and some other materials that are harmless to health.

You already know that the insulation is placed directly on the wooden walls of the bath, in other cases it separates steam protection one side and hydroprotection with another. This applies to heaters that are afraid of moisture and lose their insulating properties from its action.

You can read more about the materials and technologies for thermal insulation of the steam room in the article.

Basalt wool specially designed for baths and saunas

Foil

Foil always arouses fierce controversy. The disputes themselves are divided into two categories: is foil needed in a Russian bath and what is its effectiveness in reflecting heat.

Let's start with the fact that mirror surfaces have long been used for focusing and redirects different types of radiation, including infrared - remember the device of the same reflector. Lining in the bath is not a hindrance to infrared radiation.

IMPORTANT! But there is an essential condition for the operation of a mirror surface as a reflector - it is necessary that there be air in front of the foil. Adjacency of other material to the foil from the side of reflection is unacceptable. The ventilation gap from the foil to the lining is just right.

As for the use of foil in a Russian bath, there is no categorical prohibition, of course, but it is desirable that you have ways temperature control, for example, with the help of ventilation and the oven itself. In a steam room with an iron stove without brick or stone lining, with foil insulation, you will get a tough version of the sauna, the harm from which is more than good.

We have two articles in which we analyze the types of foil and the arguments for and against its use in the bath -,

A little about insulation inside and out

Buildings are isolated from the external temperature not only from the inside, but also from the outside, however, each type has its own specifics that you need to know in order to make the right choice.

Residential buildings often insulated from the outside. Have you wondered why? The main reason is to make sure that the insulation is the first to take the blow of frost, and the wall material under it freezes less. Consequently, the temperature difference between the room and the wall is reduced, along the way shifting the dew point.

BUT! All this works in a constantly heated room, that is, in residential buildings.

A bath is a place occasional use, in winter you warm it up for a long time, spending part of the heat released from the stove to raise the temperature of walls, ceilings and floors. So, if thermal insulation is done inside, then the time to warm up the bath is reduced, because the low thermal conductivity of the insulator allows you to heat almost only air.

If the bath is isolated outside, walls, floors and ceilings are inside the protection, and the furnace will have to work hard to heat this mass of wood or stone. That is why it is not recommended to insulate periodically used rooms from the outside. Or do it in parallel with internal insulation where the climate is especially harsh. in Telegram to keep abreast of all the news of the site! Vkontakte

The warmer the bath itself is, the less firewood will be consumed to heat it and the longer it will retain heat. In general, the warming of the bath is a complex process. And the rest room, steam room and dressing room can be insulated in completely different ways: due to their constant microclimate. So how to properly insulate the bath? Let's figure it out.

Insulation of the bath from the inside: photos, diagrams and videos

So, how to insulate a bath from the inside, depending on what material it was built from.

Features of the thermal insulation of the log house

Since ancient times, no one has ever insulated a log cabin - even the floors. Just from time to time the logs changed and the lower crowns were repaired. But today, when a good log house and a real Russian steam room are almost a rarity, the question of high-quality insulation is far from the last. After all, its longevity depends on how protected from moisture and cold the bath is.

In general, insulation in a wooden bath is necessary only when the dimensions of the timber are small, in all other cases caulking and good waterproofing are really enough. For internal insulation of a sauna steam room from a bar, a traditional “pie” with mineral wool is used - except that only the thickness of the working layer itself can be 2 times less than for a brick steam room.

Brick bath and its insulation

How to insulate a bath from foam, cinder blocks and concrete

Cinder blocks and foam blocks themselves have fairly good thermal insulation materials due to their porous structure. But they can still freeze in the winter, and therefore it is necessary to additionally insulate the block bath. Otherwise, all its walls will delight in frosts with unaesthetic dark wet spots.

Mineral wool and fiberglass are most suitable for such a bath. But in general, the whole cake must be provided with a reliable vapor barrier - any blocks extremely do not like high humidity in the air, and absorb water into themselves like sponges. In general, it can be used as a heater and foam.

The first task when insulating the aerated concrete walls of the bath is to remove the ice mass of concrete from the heating circuit. Why, inside the entire structure, the frame must be done with an indent from the walls. Moreover, the resulting space must be well ventilated - for this, at the top of the bath and at the bottom, special windows-vents must be made from the outside. During the bath procedures, they must be closed, and during the drying of the bath - open. And then the usual “pie” of warming is made in the steam room and washing room. The most standard one looks like this: aerated concrete or block wall - a frame for insulation with an indent from the wall - insulation - board - vapor barrier where the steam room is finished with aspen or cedar board. Thus, the ice walls do not have to be heated - that's all the tricks.

Rules for warming a frame bath

Option two: the warming of the frame bath occurs according to this scheme. A vapor barrier made of parchment (or roofing material, or roofing felts) is laid directly on the frame, which is fastened by wood cladding. Between the resulting inner and outer walls, you need to put foam, fiberboard or heat-insulating slabs of reeds. All this is covered from all sides with layers of asbestos cement, which makes the frame bath both stronger and warmer.

You can also insulate the frame bath with sawdust, gypsum and wood chips. All this is mixed with lime in a ratio of ten to one and a thick layer is laid between the outer and inner lining. The main thing is that the sawdust is well dried, and the layers are treated with iron sulphate.

Features of ceiling and floor insulation

Ceramic tiles are ideal for the pre-bath and washing room of the bath - but there must also be thermal insulation under it. Here is the most common scheme for warming the floor in the bath: a cranial bar is sewn to the beams, on which a draft floor of boards is laid. After that comes a layer of vapor barrier, and then the space between the beams must be filled with the selected heat-insulating material - polystyrene foam or expanded clay, for example.

On top of this, a reinforced metal mesh is placed and a concrete screed is poured. After the latter has dried, the floor is waterproofed with a waterproofing layer. Again, the screed is 3-5 cm thick and you can build in the underfloor heating system if desired. And finally, ceramic tiles are placed on the screed.

But in the steam room and the rest room, the floor is necessarily made of wood - so that the so-called "heat stroke" does not happen.

Making a "pie" when insulating the ceiling

The warming of the bath from the inside always starts from the ceiling - after all, the highest temperature is always at its level, and therefore special attention should be paid to this part of the steam room. The ceiling should be arranged as follows: vapor barrier - insulation - sheathing - beam beam - ceiling boards.

If the attic or the second floor in the bath is residential, then the insulation cake will look a little different: the ceiling boards need to be smeared with clay in a two-centimeter layer and covered with wood chips up to 20 cm, or expanded clay or use some kind of insulation. The main thing is that it should be the right thickness.

This is how the insulation of a bath from foam blocks, a log house and a brick happens. Each type of building has its own technology, and knowing at least its basics will help you always keep your steam room warm.

There are many materials for warming the bath, there are plenty to choose from. These are mineral wool, basalt, fiberglass and foil foam, as well as various wood seals. They are equally well suited for any work and are used for both walls and ceilings of steam rooms. When choosing the best way to insulate a bath, take into account a few tips:

- The packaging must contain information on the coefficient of thermal conductivity and the maximum thickness of the material. If instead of exact numbers the thermal range is indicated, then it is better to refuse it.

- Correctly you need to choose the density of the material. High performance is not always a positive side. Give preference to those with lower thermal conductivity.

- The fire safety class should be marked as follows - “GO” or “G1”. The insulation should not be toxic, so that when it is used in the steam room, volatile substances harmful to humans are not released.

An excellent option would be foil penoizol. It does not require additional vapor barrier, and installation is carried out by hand in a short time without a specialized tool.

Wall insulation from the outside - a "fur coat" for a bath

The wooden bath is insulated with tow. She lays all mezhventsovye connections. The structure of round logs does not require this, because during processing special cuts are made in the logs and they fit snugly together.

Wall insulation from the outside is carried out only in brick baths. This is done according to the principle of a ventilated facade. As a material for vapor and waterproofing, polyethylene film is used, and as a heater - mineral wool.

How brick walls are insulated - work plan:

- First, a frame made of a metal profile is mounted over the entire surface of the wall, the distance between the guides should be selected based on the size of the insulation so that it does not need to be cut.

- Mineral wool is laid between the frame elements.

- From above, the insulation is covered with a vapor barrier film to protect the wool from condensation.

- The joints of the vapor barrier material are glued with adhesive tape.

- The insulation through the vapor barrier is attached to the wall with special dowels, the cap of which looks like an umbrella.

- After that, the walls are sheathed with the selected finishing material.

There is nothing complicated and all the work on warming the walls of the bath from the outside can be easily done with your own hands. Thanks to the appearance on the market of modern materials such as foil pinotherm, you can do without additional hydrovapor barrier. It is laid on the wall and the whole structure is sewn up with a finishing material.

Wall insulation from the inside

Having dealt with outdoor work, you can proceed to the next step. How to insulate a bath from the inside? For this, an old, tried and tested method is used - a frame device with a gasket of heat-insulating material. The principle is similar to the installation of a ventilated facade during the insulation of the outer wall.

- First, a frame made of wooden bars or metal elements is mounted around the entire perimeter of the load-bearing walls. The distance between the guides of the frame should be equal to the width of the insulation.

- Then, a heater is laid in the finished structure, on top of which foil waterproofing must be overlapped. The joints are glued with construction tape.

- The final step will be the installation of a wooden lining.

This method is laborious, but proven over the years. It will not be difficult to insulate the walls of the bath with your own hands, but for clarity, you can watch the video.

Floor insulation

Let's describe the general principle. They are insulated with foam, and the scheme looks like this:

- We level the base as much as possible and lay the waterproofing material.

- We carefully place the insulation on a flat film, if necessary, filling the voids with cut-off pieces.

- On top of this "pie" we place a reinforcing mesh and fill everything with concrete.

- After hardening, finishing, laying tiles, etc.

Many may ask why foam? This is the most durable and rigid material of all roll or plate heaters. It withstands significant mechanical loads without changing its characteristics in a humid environment. Numerous air bubbles are hidden in the thickness of the foam, providing low thermal conductivity. It won't rot or get moldy over time. In fact, this is a universal material, it is also used to insulate the walls of the bath, both outside and inside.

Ceiling

This is a mandatory part because a lot of heat escapes through the roof. Some still use old-fashioned methods, filling the attic with soil, straw or sawdust. Today there are more modern options, but the essence of the work has not changed. you need from the outside, that is, from the side of the attic.

Expanded clay, polystyrene or mineral wool can be used. From the side of the steam room, if the chimney pipe exits through the top, it is lined with asbestos cloth and coated with fire-retardant mastic. Styrofoam or mineral wool should be laid no closer than 15–20 cm from the pipe. Expanded clay can be poured next to the pipe, since it is absolutely non-combustible material.

Do-it-yourself ceiling insulation sequence:

- First, we cover the entire surface with waterproofing material.

- Between the lags we lay the material. If it is polystyrene or mineral wool, we cut it according to size, fill up the expanded clay and level it over the entire area.

- We lay another layer of vapor barrier film on top of the insulation and sew up the structure with boards on top - if you want to make a floor in the attic or lay flooring for passage during maintenance of the attic space.

When considering the use of expanded clay, it must be taken into account that this material does not have very good thermal conductivity and for normal insulation a thick layer will be required. Do you think the cover will hold up? The best options would be rolled or slab heaters.

Entrance door

With complex insulation, you will need to think about this problem. Experts recommend making the doors narrow and low. This will greatly reduce heat loss. Well, if you still need their additional protection, then let's look at how to insulate the door to the bathhouse with your own hands. There are several ways, differing in complexity of execution.

The first is the laying of material into the inner cavity of the door. In this embodiment, a two-layer frame structure is required. The method is laborious and not everyone can do it. At the initial stage, you will have to assemble a door from two canvases, with a heat insulator laid inside.

In the second method, you can fix the material on top of the structure. Then close everything with a decorative coating. This option is easier. A foil insulation is stuffed onto the canvas, which is hidden under moisture-resistant plywood or other decorative material.

All measures for warming the bath inside and out are carried out at the construction stage. An integrated approach and the right choice of material will reduce the cost of heating the steam room and maintain a comfortable room temperature.

Each owner of the bath wants the heating process to be as short as possible, and the cooling period to be as long as possible. This can be achieved only if the internal or external insulation of the bath is carried out.

Expert opinion

Konstantin Alexandrovich

Ask an expertAs a result of ensuring good thermal insulation, it will be possible not only to solve the above problems, but also to significantly save the fuel used to heat the bath.

The need to insulate the steam room

Almost any steam room, even if it is equipped with materials with low thermal conductivity, requires additional insulation measures. It is desirable to pay special attention to the thermal insulation of the inner surfaces of the steam room, i.e. walls, ceilings and, of course, floors.

The steam room is a very specific design, for finishing which not all materials are suitable, as they may not be able to cope with the high humidity of the room. And such as glassine or the same roofing material are not afraid of moisture, but, because of their unpleasant smell, they will make staying in the steam room uncomfortable. Therefore, it is very important to choose the right heat-insulating means, always taking into account what materials the bath is built from.

Choosing a heater for a steam room

A steam room is a place that has its own characteristics and therefore requires a careful approach to the selection of materials that will insulate its room from the inside. Mandatory criteria in the selection of suitable materials should be their moisture resistance, non-toxicity and the ability to endure elevated temperature effects. Stone and basalt wool are most fully endowed with these qualities. These widely used varieties of mineral wool are produced in the form of slabs of various sizes and thicknesses. If necessary, the slabs can be easily cut by yourself using a regular construction or kitchen wavy knife.

Best of all, a special foil material will cope with the role of hydro and vapor barrier in the steam room. Manufacturers offer options for such an insulator on a foam basis and on kraft paper. Each of them is suitable for use for the indicated purposes, but it is preferable to opt for the second option for warming the steam room.

Independent thermal insulation of the bath

How to equip your steam room, the owners decide on their own, taking into account their tastes and preferences. Traditionally, the decoration of the walls and ceiling in the steam room is done with natural clapboard. The main thing when choosing it is that the wooden lining must be made of suitable wood. The best material will be linden, aspen or larch. It is advisable not to use lining made of resinous woods, since, when heated, it will fill the room with heavy fumes. It is also important that the lining is free from any structural defects (knots, cracks, etc.). Thus, in order for the steam room to have a beautiful internal appearance and be comfortable, first of all, good quality material must be taken for cladding.

The cladding of the bath room is carried out in the traditional way, observing the “golden rule” of any insulation technology: first we insulate the ceiling, then the walls. The process begins with the installation of the frame, placing the bars in increments of the planned layout of the wooden lining. Then an aluminum foil vapor barrier is fixed to the prepared walls. And only then do they begin to attach the slats themselves with the provided tongue and groove locks, as required by the technology.

Materials and tools for work

To begin with, it would be wise to purchase or prepare the tools and materials necessary for warming the steam room:

- screwdriver;

- saw;

- hammer;

- foil;

- lining made of linden or aspen;

- anti-corrosion composition;

- building level;

- material for thermal insulation;

- bars;

- foil;

- waterproofing material;

- polyethylene film;

- masking tape;

- nails, screws.

Arrangement of thermal insulation of the ceiling

When starting to insulate the ceiling in the steam room, it must be borne in mind that to complete this work you will need significantly more materials than when insulating a dressing room. This is due to the fact that the Russian bath, unlike the sauna, involves holding steam for as long as possible. And we can achieve such a result only by organizing high-quality thermal insulation of the room.  For this we need:

For this we need:

- We mount the frame, between the bars of which insulation material will be laid.

- From above, we close the frame with waxed roll paper or, if funds allow, with an overlapped foil vapor barrier membrane, closing all joints and gluing the joints with aluminum tape.

- Between the bars covered with paper or foil, we lay insulation boards. It is best to use mineral wool at least 15 cm thick as a heater.

- We cover the insulation with a new layer of foil or foil membrane, which will act as a heat insulator. We seal all edges and joints by fastening them with construction tape.

- We fix the lining on the ceiling on pre-attached counter rails.

For your information! It will be mandatory to use insulation for a frame or brick bath, but if the bath is built from timber or logs, then insulation is not needed. The ceiling of such a bath can only be lined with boards, at least 6 cm thick.

The process of wall insulation inside the steam room

After completing the insulation of the ceiling, we proceed to the insulation of the walls of the steam room. The technique of this process will be similar to the technique of thermal insulation of the ceiling, but still has its own characteristics, since when insulating the walls, it will be necessary to equip the ventilation inlets. The most suitable option in solving this problem would be to insulate the walls with such materials and in such a way that, if necessary, they can be repaired or replaced with new ones.

- Narrow strips or bars are mounted on the walls, pre-treated with means to protect against moisture. It is better to use slats, since, unlike bars, they are less susceptible to deformation under the influence of temperature fluctuations.

- Using a stapler, a foil or foil vapor barrier membrane is fixed on top of the rails, which are designed to protect them from high humidity. The strips of the insulator are overlapped, the joints are closed with a special tape or construction tape.

- Next, the finishing lining of the walls of the steam room is carried out - a lining is laid on top of the insulating layer, not forgetting to leave a gap of about 2 cm between the insulator and the lining.

The need for floor insulation in the bath

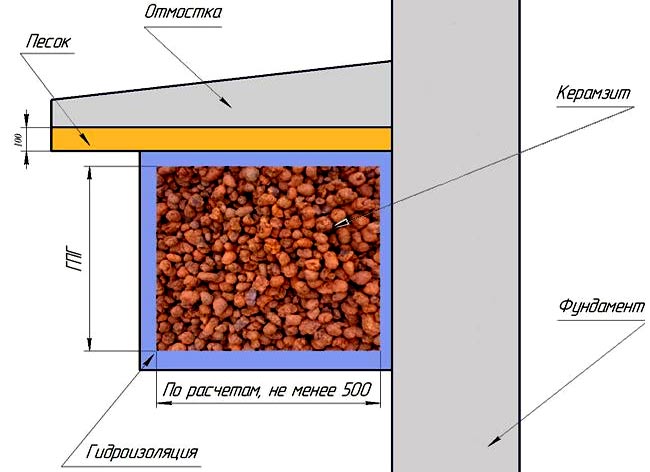

When the walls and ceiling of the steam room are insulated, you can begin to arrange the thermal insulation of the floor, because it is through the cold floor that warm air quickly leaves the room. And in the case of a couple, this is highly undesirable. Expanded clay suitable for quality and price will be the most acceptable for these purposes. This insulation is a reliable protection of the steam room from the negative effects of high humidity, which will not allow significant heat loss. In addition, expanded clay is distinguished by its environmental friendliness and low weight.

If the floor in the steam room is made of wood, then expanded clay is poured between the lags, when pouring the concrete floor, it is laid between the layers.

Work on the insulation of the concrete floor in the bath has the following order:

- Pour the initial layer and let it harden well.

- A layer of expanded clay is poured, at least 10 cm thick.

- A steel reinforcement grid is laid on expanded clay and a second layer of concrete is poured.

- After it hardens, the floors are leveled with a prepared cement-sand screed.

Important! When pouring the floor, do not forget to provide for laying pipes for draining water.

Additional insulation of the bath from the outside

To make the bath room even more heat-saving (especially if it is wooden), its additional insulation from the outside will not interfere. To do this, a frame is mounted on the outer walls, between the posts of which mineral wool slabs are placed and fixed with “umbrella” dowels. A vapor barrier membrane is fixed on top of the insulation, and only after that the finishing wall cladding is carried out.

The easiest and fastest way to do this is using facade panels, but it is also possible to use other finishing materials.

These are the main steps in the process of warming the steam room in the bath. Everyone understands that it is necessary to carry out a whole range of works in order to achieve the desired result. It will be necessary to qualitatively organize the insulation of all surfaces of the steam room, including the ceiling, and carry out external insulation of the walls. The step-by-step instructions presented above will allow you to do this work yourself.

It is only important not to forget that you will have to make a lot of efforts when working in a specific room that requires a careful approach to the implementation of insulation work. It is not recommended to try to save on materials or skip any technological steps, because this saving can first of all make your stay in the bath uncomfortable. And over time, it may become impossible, so the room will require urgent repairs.

It is also important, when carrying out thermal insulation measures, to take care of reducing heat loss through door and window openings, and to properly install and use ventilation systems.

Finally

Before starting work on the insulation of the bath room, you need to carefully study the theory of this issue in order to understand whether you can independently implement the entire range of thermal insulation work. And if in doubt, it will be possible to seek help from professionals who can select high-quality materials and guarantee their correct application.

But since the services of specialists are not cheap, it is still better, having prepared well and making every effort, to do this work with your own hands.

Video about the thermal insulation of the bath with your own hands

The main function of the Russian bath is to improve human health. In order to achieve this goal and in no case harm your body during a visit to the bath, it is necessary to correctly perform the warming of the bath. Subject to all the rules for warming this type of room, the heat in the bath is stored for a long time, which significantly saves money spent on heating it.

The process of wall insulation in the bath

The process of wall insulation in the bath In most cases, insulation must be done indoors. This allows you to quickly heat the bath and also quickly cool it if necessary. Baths are characterized by the following properties:

- Relatively low air temperature 50-60 degrees;

- High humidity. Sometimes it can reach up to 100%.

Step-by-step internal warming of the bath

Step-by-step internal warming of the bath

In order for these indicators to remain normal, it is necessary not only to properly insulate the bath, but also to use for this purpose proven over the years and well-proven.

Existing types of heaters for the bath

Existing types of heaters for the bath All of them, without exception, must meet the following safety requirements:

- Do not disturb, but only maintain a healthy atmosphere in the bath.

- Resistance to temperature changes in air.

- Absence of harmful impurities emitted into the atmosphere.

- Without smell.

- Fire resistance.

All these indicators should be taken into account in the process of general warming of the bath, especially when choosing a heater for the steam room.

The scheme of warming the steam room in the bath

The scheme of warming the steam room in the bath Nowadays, there are many completely different types of heaters on the market. Among them, the most popular and popular among buyers are the following types.

Mineral wool

Mineral wool is a natural material with a fibrous structure. It is obtained by processing a mineral stone, some of its rocks, for example, basalt rocks. Cotton wool has a number of useful properties. These include:

Mineral wool sheets for thermal insulation

Mineral wool sheets for thermal insulation Mineral wool comes in different densities and hardness. In specialized stores, it can be purchased in the form of soft rolls, semi-rigid mats or rigid plates. It all depends on what purpose it is intended for. In other words, with its help they will insulate the bath from the inside, or vice versa from the outside.

glass wool

Glass wool in terms of its technical indicators lags far behind mineral wool. It is made using glass, or rather, its waste remaining during its production.

The process of finishing the bath room with glass wool

The process of finishing the bath room with glass wool Glass is mixed with soda, sand and dolomite. The result is a quality insulation.

Glass wool is recommended to insulate the bath only from the outside, as it does not tolerate high temperatures. And over time, it begins to smell rather unpleasant. Basically, glass wool insulates the attic and the roof of the bath.

jute felt

It is also called an interventional type of insulation. Jute fiber felt is a natural material of natural origin. It is produced from the fibers of the jute plant.

It looks like a roll of jute felt

It looks like a roll of jute felt Basically, jute fiber is used for the production of ropes. It also produces fabric - burlap. Everywhere they insulate the bath, namely its walls.

Jute is able to retain heat well indoors, and also removes excess moisture from it. By itself, jute fiber is quite fragile and tough. That is why, in order to enhance its thermal insulation properties, flax fibers are added to it. The most famous brands of this insulation are flax jute, felt, linen.

All of them are collected in tape bobbins. It is characterized by such properties as resistance to settling and drying out, and also the felt practically does not rot.

Expanded clay

It is a material with thermal insulation properties. It is used mainly for warming the genitals and in the bath. Expanded clay in appearance looks like small balls. Their development is associated with such a process as the rapid firing of clay.

An example of floor insulation in a bath with expanded clay

An example of floor insulation in a bath with expanded clay

Thermal insulation of the chimney with expanded clay

Thermal insulation of the chimney with expanded clay

It is used as one of the types of backfill. The effect of thermal insulation is achieved when the backfill layer reaches a height of at least 25 centimeters.

Styrofoam

It is used for insulation of external walls. The whole is pasted over with the material, then it is plastered or covered with sheathing.

An example of finishing a bath with foam plastic

An example of finishing a bath with foam plastic

Styrofoam cannot be used for wall insulation inside the building itself. It releases phenol into the atmosphere. Styrofoam is unable to withstand elevated temperatures and it does not have sufficient fire resistance.

Watch the video review of heaters for the bath.

An example of fixing a heater in a frame bath

An example of fixing a heater in a frame bath

They are pre-coated with a protective film and only then the insulation is fixed - basalt wool.

The process of installing a vapor barrier in a frame bath

The process of installing a vapor barrier in a frame bath In the steam compartment, a vapor barrier film with foil is additionally used.

Insulation of a log bath

A bathhouse carved out of wood practically does not need to be insulated. The only places that are subject to this process are the intervention joints. For thermal insulation, jute fiber is used with the addition of flax elements to it.

Detailed scheme for warming a log bath

Detailed scheme for warming a log bath

The steam room of the bath is also subject to additional insulation. Mineral wool is suitable as a heater for it. Foil is used for vapor barrier of walls.

Block bath insulation

The insulation of a block-type bath is similar to the process of warming a brick bath. To begin with, the walls of the bath are insulated from the outside. This will keep the room at the optimum temperature. The walls from the inside are traditionally sheathed with aspen clapboard. It is the most suitable option, as it has low thermal conductivity.

Scheme and names of elements for warming a block bath

Scheme and names of elements for warming a block bath In addition to such insulation, the walls in the steam room are covered with the so-called warm puff. It consists of a layer of mineral wool surrounded on both sides with foil or vapor barrier film.

The process of mounting a wooden frame on blocks

The process of mounting a wooden frame on blocks

Having thus completed all the necessary steps to insulate a block bath, it is possible to achieve relative ease in warming up the room to certain temperature indicators and maintaining it for as long as necessary.

Proper insulation of individual bath blocks

Any bath needs good thermal protection. At the same time, each individual block of the bath must be insulated in its own way. Not only modern types of expensive heaters are suitable for this. Since the time of our grandfathers, simple and affordable materials have been known. So how and with what can you insulate the bath yourself?

The names of the elements and the principle of warming the bath room

The names of the elements and the principle of warming the bath room Insulation of the foundation of the bath

For its insulation, only those types of insulation that have such properties as:

- Resistant to high humidity.

- Biological resistance to various types of damage.

- Ability to withstand temperature extremes.

Styrofoam has such properties. With its help, they do it immediately after it hardens. In this case, sheets of cellular foam are fixed on the outside of the base of the bath.

Bath foundation insulation scheme

Bath foundation insulation scheme

The thickness of these layers should be 5 cm. It is best to use 2 layers of foam, arranged in a checkerboard pattern.

As additional insulation, the foundation is covered with warm plaster.

Read also

Construction of a sewer for a bath

Insulation in the bath floor

Traditionally, the floor in the bath is a wooden flooring. There are two types of flooring:

- Leaking floor. This name was given to a cold floor, between the boards of which there are small gaps. Through them, water leaves the bath room to the street.

- Non-leaking floor. This is the so-called blind floor. It differs from the previous floor in a way. This floor is made with a slight slope in one direction. In the basement of the bath, a special water collector is made.

The process of warming the floor in the bath

The process of warming the floor in the bath

Insulation in the bath is subject only to a non-leaking floor. At the same time, two types of insulation are suitable for such purposes: expanded clay and basalt wool. They fill all the gaps between the two floorings: rough and finish. At the same time, do not forget that both of these materials need protection from moisture. It is performed both from the outside and from the inside. If a concrete floor is provided in the bath, then foam plastic or mineral wool is used for its insulation, in the form of rigid mats.

The process of laying foil material on the floor

The process of laying foil material on the floor

In the steam room, the concrete floor is not insulated at all. To protect from the cold, you just need to put wooden lattices on top of it. In the washing department for the concrete floor, a so-called underfloor heating system is created.

Bath wall insulation

In the process of warming the walls of the bath, it is especially worth paying attention to them. To enhance the protection of walls from moisture, it is not at all a film specially designed for this purpose that is used, but a heater with a reflection effect or foil.

The scheme of wall insulation in the bath

The scheme of wall insulation in the bath

When installing such a heater, it is imperative to leave a small gap between it and the finish of the bath.

An example of laying mineral wool on the walls in the bath

An example of laying mineral wool on the walls in the bath

When installing the upholstery, it is advisable to use a crate. It is fixed over the mirror side of the insulation. The mirror film is fixed on the walls in a vertical position. In this case, stretching of the strips should be avoided.

The process of attaching foil to the walls in the bath room

The process of attaching foil to the walls in the bath room Since this material is quite thin, the foil on the wall is made two-layer. All joints between the strips are glued with special adhesive tape.

In stone baths, with additional wall insulation, basalt wool is used. On both sides it is protected by hydro-vapor barriers.

Insulation of the ceiling in the bath

The ceiling, like no other part of the bath, needs reliable thermal protection. The heated bath air comes out most of all through it. The ceiling of the bath can be insulated in two ways. These include:

Previously, in order to qualitatively insulate the ceiling of the bath, sawdust with foliage was used. Dry sand at least 5 cm thick was poured on top. Ceilings were covered with a layer of liquid clay. This method of ceiling insulation is quite popular, it is used today.

Bath roof insulation

The roof of the bath is insulated using the standard insulation scheme. Exactly in the same way. Insulation is chosen based on how the attic of the bath will be used in the future.

Scheme for installing insulation on the roof of the bath

Scheme for installing insulation on the roof of the bath

If planned, then in this case the roof is covered with mineral wool.

If the attic is planned to be used only for household needs, then mineral wool can be replaced with glass wool.

This will help to significantly save the money allocated for the purchase of insulation.

Example of foil thermal insulation on the ceiling

Example of foil thermal insulation on the ceiling