Melting point of sand into glass. Original roofing and designer roofs: How to make glass yourself at home

Glass production began at least as early as the third millennium BC, as evidenced by glass particles found in Mesopotamia. Glassmaking, once a rare art, has become a mainstream industry, with products made from glass being used in both commercial and domestic applications, as glass containers, insulating material, reinforcing fibers, lenses, and arts and crafts. Although the materials used to make glass may vary, the basic process of how glass is made remains the same and is described below.

Get enough silica sand. Also called silica sand, siliceous sand is the main ingredient in glass making. Iron-free glass is used to make clear glass, since iron, when present, makes the glass greenish. If you cannot find sand without iron impurities, then the tint effect can be eliminated by adding a small amount of manganese dioxide.

Add sodium carbonate and calcium oxide to the sand. Sodium carbonate (or soda) lowers the temperature required for commercial glass production. However, it allows water to penetrate the glass, so sodium carbonate or calcium hydroxide is added to neutralize this property. Magnesium and/or aluminum oxide may also be added to make the glass stronger. As a rule, these additives form no more than 26-30 percent of the glass mixture.

To improve the quality of glass, add other chemical elements according to the purpose of its use. The most common additive for the production of decorative glass is lead oxide, which gives luster to transparent glass products, as well as ductility, which makes the glass cutting process easier, and, in addition, lowers the melting point. Spectacle lenses may contain lanthanum oxide, due to its refractive properties, while iron helps the glass absorb heat.

Crystal can contain up to 33 percent lead oxide; however, the more lead oxide, the more skill is required to shape the molten glass, so many crystal makers opt for less lead in the glass.

If you need to make glass of a certain color, add chemicals to it. As mentioned above, iron impurities in quartz sand give the glass a greenish tint, so iron oxide, like copper oxide, is added to increase the green tint. Sulfur compounds impart a yellowish, amber, brownish, or even blackish tint to glass, depending on how much carbon or iron is added to the mixture.

Place the mixture in a good heat-resistant crucible or container.

Melt the mixture until liquid. For the manufacture of industrial quartz glass, melting is carried out in a gas furnace, while special glass can be produced using an electric melting furnace, a kettle furnace, or a roasting furnace.

Quartz sand without additives turns into glass at a temperature of 2,300 degrees Celsius (4,174 degrees Fahrenheit). When sodium carbonate (soda) is added, the temperature is reduced to the required level for making glass, up to 1,500 degrees Celsius (2,732 degrees Fahrenheit).

Remove bubbles and ensure homogeneity of the molten glass mass. This means stirring the mixture until it becomes thick and adding chemicals such as sodium sulfate, sodium chloride or antimony trioxide.

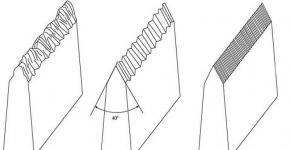

Molten glass shape. Glass shaping can be done in one of several ways: molten glass is poured into a mold and cooled in it. This method was used by the Egyptians and is now used to make lenses.

Much of the molten glass may accumulate at the end of a hollow tube, which is then blown into with air while simultaneously rotating the tube. The glass is shaped by the air that enters through the tube, gravity pulls the molten glass towards itself, and the glassblower uses various tools to work with the molten glass.

Molten glass can be poured into a bath of molten tin as a base and pressurized with nitrogen to give the glass its shape and gloss. The glass made using this method is called float glass and it is the same method that has been used to make window panes since the 1950s.

Leave the glass to cool.

To increase the strength of the glass, you need to resort to heat treatment. This process is called firing, and it removes the damage that was formed during the glass cooling process. When this process is completed, the glass can be coated, laminated, or otherwise treated to improve its strength and durability.

Annealing is the next manufacturing process in which polished, shaped glass is placed in an oven heated to at least 600 degrees Celsius (1,112 degrees Fahrenheit) and then quickly cooled (“tempered”) using a strong stream of high-pressure air. . Annealed glass breaks into small pieces at 6,000 psi, while tempered glass breaks into small pieces at no less than 10,000 psi and typically around 24,000 psi. psi

The crushed pieces of old glass can be added to the glass mix before the glass is melted in order to be recycled into new glass. Old glass or "cullet" must first be checked for impurities that can weaken the properties of new glass when they enter it.

Components you will need:

- quartz sand (silicon dioxide);

- sodium carbonate (soda);

- calcium oxide (calcium hydroxide);

- other oxides and salts: (for example, magnesium oxide, alumina, iron oxide, magnesium or sodium oxide, or calcium salts as desired);

- lead oxide (optional)

- heat-resistant crucible, shaped or hollow tube;

- kiln or oven for glass This completes the production of glass.

Today we will talk about how to make glass with your own hands at home. We will also consider methods and technologies for self-manufacturing of glass and glass products, namely furnaces, devices and tools for melting glass.

At factories and in chemical laboratories, glasses are obtained from a mixture - a thoroughly mixed dry mixture of powdered salts, oxides and other compounds. When heated in furnaces to very high temperatures, often above 1500°C, salts decompose to oxides, which, interacting with each other, form silicates, borates, phosphates, and other compounds that are stable at high temperatures. Together they make glass.

We will prepare the so-called fusible glasses, for which a laboratory electric furnace with a heating temperature of up to 1000°C is sufficient. You will also need crucibles, crucible tongs (so as not to burn yourself) and a small flat plate, steel or cast iron. First we will weld the glass, and then we will find a use for it.

Mix with a spatula on a sheet of paper 10 g of sodium tetraborate (borax), 20 g of lead oxide and 1.5 g of cobalt oxide, sifted through a sieve. This is our burden. Pour it into a small crucible and compact with a spatula so that you get a cone with a top in the center of the crucible. The compacted mixture should occupy no more than three-quarters of the volume in the crucible, then the glass will not spill.

Place the crucible with tongs in an electric furnace (crucible or muffle), heated to 800–900 °C, and wait until the mixture has melted. This is judged by the release of bubbles: as soon as it has stopped, the glass is ready. Remove the crucible from the oven with tongs and immediately pour the melted glass onto a clean steel or cast iron plate. Cooling on the stove, the glass forms a blue-violet ingot.

To obtain glasses of other colors, replace the cobalt oxide with other coloring oxides. Iron(III) oxide (1-1.5 g) will color the glass brown, copper(II) oxide (0.5-1 g) green, a mixture of 0.3 g of copper oxide with 1 g of cobalt oxide and 1 g iron oxide (III) - black. If you take only boric acid and lead oxide, then the glass will remain colorless and transparent. Experiment yourself with other oxides, such as chromium, manganese, nickel, tin.

Crush the glass with a pestle in a porcelain mortar. In order not to injure yourself with fragments, be sure to wrap your hand with a towel, and cover the mortar with a pestle with a clean rag.

Pour fine glass powder onto thick glass, add a little water and grind to a creamy state with a chime - a glass or porcelain disc with a handle. Instead of a chime, you can take a small flat-bottomed mortar or a polished piece of granite - this is what the old masters did when they rubbed paint. The resulting mass is called slip. We will apply it to the aluminum surface in much the same way as they do when making jewelry.

Clean the aluminum surface with sandpaper and degrease by boiling in a soda solution. On a clean surface, trace the outline of the pattern with a scalpel or needle. Cover the surface with a slip with an ordinary brush, dry it over a flame, and then heat it in the same flame until the glass melts onto the metal. You will get enamel.

If the badge is small, it can be covered with a layer of glass and heated in a flame in its entirety. If the product is larger (say, a plate with an inscription), then it is necessary to break it into sections and apply glass to them one by one. To make the color of the enamel more intense, apply the glass again. In this way, it is possible to obtain not only decorations, but also reliable enamel coatings to protect aluminum parts in various devices and models. Since in this case the enamel carries an additional load, it is desirable to cover the metal surface after degreasing and washing with a dense oxide film; to do this, it is enough to hold the part for 5-10 minutes in an oven with a temperature slightly below 600 ° C.

Of course, it is more convenient to apply slip on a large part not with a brush, but from a spray gun or simply by watering (but the layer should be thin). Dry the part in an oven at 50–60°C, and then transfer it to an electric furnace heated to 700–800°C.

And from low-melting glass, you can prepare painted plates for mosaic work. Pieces of broken porcelain dishes (they will always be given to you in a china shop) pour a thin layer of slip over them, dry them at room temperature or in an oven and melt the glass onto the plates, keeping them in an electric furnace at a temperature of at least 700 ° C.

Having mastered the work with glass, you can help your colleagues from the biological circle: they often make stuffed animals there, and stuffed animals need multi-colored eyes ...

In a steel plate about 1.5 cm thick, drill several recesses of different sizes with a conical or spherical bottom. In the same way as before, fuse the multi-colored glasses. Gamma, perhaps, is enough, and to change the intensity, slightly increase or decrease the content of the coloring additive.

Place a small drop of bright molten glass into the recess of the steel plate, then pour in the iris-colored glass. The drop will enter the main mass, but will not mix with it - this is how both the pupil and the iris will be reproduced. Cool products slowly, avoiding sudden temperature changes. To do this, remove the hardened, but still hot “eyes” from the mold with heated tweezers, put them in loose asbestos and cool it to room temperature already in it. .

Of course, fusible glasses can be found in other applications. But wouldn't it be better if you look for them yourself?

And at the end of the experiments with glass, using the same electric furnace, we will try to turn ordinary glass into colored glass. The natural question is: is it possible to make sunglasses in this way? It is possible, but it is unlikely that you will succeed the first time, because the process is capricious and requires some skills. Therefore, take the glasses only after you have practiced on the pieces of glass and make sure that the result is as expected.

The basis of paint for glass will be rosin. From resinates, acid salts that make up rosin, you previously prepared driers for oil paints. Let us turn again to resinates, because they are able to form a thin, even film on glass and serve as carriers of the coloring matter,

In a solution of caustic soda with a concentration of about 20%, dissolve with stirring and remembering, of course, caution, pieces of rosin until the liquid becomes dark yellow. After filtering, add a little solution of ferric chloride FeCl3 or other ferric salt. Keep in mind that the concentration of the solution should be small, salt should not be taken in excess - the precipitate of iron hydroxide, which in this case forms, will interfere with us. If the salt concentration is low, then a red precipitate of iron resinate is formed - it is there that is needed.

Filter off the red precipitate and dry it in air, and then dissolve to saturation in pure gasoline (not automobile, but solvent gasoline), it would be even better to use hexane or petroleum ether. Paint the glass surface with a thin layer with a brush or spray gun, let it dry and place it in an oven heated to about 600 ° C for 5-10 minutes.

But rosin belongs to organic substances, and they cannot withstand such a temperature! That's right, but that's exactly what you need - let the organic base burn out. Then the thinnest film of iron oxide will remain on the glass, well adhered to the surface. And although the oxide is generally opaque, in such a thin layer it transmits part of the light rays, that is, it can serve as a light filter.

Perhaps the light protection layer will seem too dark or, on the contrary, too light. In this case, vary the conditions of the experiment - slightly increase or decrease the concentration of the rosin solution, change the firing time and temperature. If you are not satisfied with the color in which the glass is painted, replace the iron chloride with another metal chloride, but certainly one whose oxide is brightly colored, such as copper or cobalt chloride.

And when the technology is carefully worked out on pieces of glass, it is possible to make the transformation of ordinary glasses into sunglasses without much risk. Just remember to remove the glass from the frame - the plastic frame will not withstand the heat in the oven in the same way as the rosin base ...

.

To get glass, sand must be melted. You must have walked on hot sand on a sunny day, so you can guess that for this it needs to be heated to very high temperatures. An ice cube melts at a temperature of about 0 C. Sand begins to melt at a temperature of at least 1710 C, which is almost seven times the maximum temperature of our usual oven.

Heating any substance to such a temperature requires a lot of energy and, consequently, money. For this reason, in the production of glass for everyday use, glassmakers add a substance to the sand that helps the sand melt at lower temperatures - about 815 C. Usually this substance is soda ash.

However, if only a mixture of sand and soda ash is used in the melt, an amazing type of glass can be obtained - glass that dissolves in water (frankly, not the best choice for glasses).

To prevent the glass from dissolving, a third substance must be added. Glass makers add crushed limestone to sand and soda (you must have seen this beautiful white stone).

The glass commonly used to make windows, mirrors, glasses, bottles, and light bulbs is called soda-lime silicate. Such glass is very durable, and in molten form it is easy to give it the desired shape. In addition to sand, soda ash and limestone, this mixture (experts say "mixture") includes a little magnesium oxide, aluminum oxide, boric acid, as well as substances that prevent the formation of air bubbles in this mixture.

All these ingredients are combined and the mixture (the mixture is placed in a giant furnace (the largest of these furnaces can hold almost 1,110,000 kg of liquid glass). .

The strong fire of the furnace heats the mixture until it begins to melt and turns from a solid to a viscous liquid. Liquid glass continues to be heated at high temperatures until all bubbles and veins disappear from it, since the thing made from it must be absolutely transparent. When the mass of glass becomes homogeneous and clean, the fire is reduced and the glass is waited until the glass turns into a viscous viscous mass - like a hot toffee. The glass is then poured from the furnace into a casting machine where it is poured into molds and shaped.

However, in the production of hollow things, such as bottles, the glass has to be blown like a balloon. Previously, glass blowing could be seen during fairs and carnivals, now this process is often shown on TV. You've probably seen glassblowers blowing a piece of hot glass hanging from the end of a tube to create amazing figurines. But you can also blow glass with the help of machines. The basic principle of glassblowers is to blow into a glass drop until an air bubble forms in the middle, which becomes a cavity in the finished thing.

After the glass has been given the necessary shape, a new danger lies in wait for it - it can crack when cooled to room temperature. To avoid this, craftsmen try to control the cooling process by subjecting the hardening glass to heat treatment. The last stage of processing is removing excess glass droplets from the handles of cups or polishing plates with special chemicals that make them perfectly smooth.

Scientists are still arguing whether glass should be considered a solid or a very viscous (syrup-like) liquid. Since the windows of old houses are thicker at the bottom and thinner at the top, some claim that the glass runs down over time. However, one can object to this that earlier window panes were not made perfectly even and people simply inserted them into the frames with a thicker edge down. Even glassware from ancient Roman times shows no signs of "fluidity". Thus, the old window glass example does not help resolve the question of whether glass is in fact a highly viscous liquid.

Composition (raw materials) for glass production at home:

Quartz sand;

soda ash;

Talamit;

Limestone;

Nepheline syenite;

Sodium sulfate.

How glass is made at home (production process)

Usually scrap glass (broken glass) plus the above components are used as ingredients.

1) The constituent elements of the future glass enter the furnace, where it all melts at a temperature of 1500 degrees, forming a homogeneous liquid mass.

2) Liquid glass enters the homogenizer (an apparatus for creating stable mixtures), where it is mixed to a mass with a uniform temperature.

3) The hot mass is allowed to settle for several hours.

This is how glass is made!

- It takes millions of years for glass to decompose.

- Glass is recycled without loss of quality.

- The thickest glass in the world is the 26 cm screen of the Sydney Aquarium.

What is glass made from?

To make glass, craftsmen take: quartz sand (the main component); lime; soda;

First, quartz sand, soda and lime are heated in a special furnace to a temperature of 1700 degrees above zero. The grains of sand are interconnected, after they are homogenized (turns into a homogeneous substance), the gas is removed. The mass is "dipped" into molten tin with a temperature above 1000 degrees, which floats on the surface due to its lower density. The smaller the mass that enters the tin bath, the thinner the glass will be at the exit.

Interesting Facts:

- The most expensive glass in the world is Murano glass. Products from it cost millions of dollars. Since ancient times, Venice has been famous for the production of high-quality glass. It is authentically known that in the 13th century the government of the state transferred production to the large island of Murano, and the craftsmen were strictly forbidden to leave it. Punishment is a death sentence. In addition, for tourists or other residents of Venice, the entrance to the island was also closed. Such strict measures made it possible to keep the secret of production.

- One of the most interesting mental illnesses of the Middle Ages is the glass disease. A person with such a disorder thought that he was made of glass, and was afraid to break. The French king Charles VI suffered from such an ailment. The monarch always wore several layers of clothing and forbade anyone to touch himself.

What functions do soda and lime perform in the production process?

Soda helps to reduce the melting point by 2 times. If it is not added, the sand will be very difficult to melt, and, accordingly, to connect individual grains of sand to each other. Lime is needed so that the mass endures water. If it were not in the composition, the window, for example, would dissolve immediately after the first rain, and the glass would burst after contact with water.

Related materials:

How and from what is chewing gum made?

Interesting Facts:

- China did not produce glass for over 500 years, from the 14th to the 19th centuries. Now the state is one of the leaders in production, and controls a third of the world glass market.

- 1994 was a very busy year for glass recycling in the US. If you put all the glass products processed during that year in one line, you get a kind of “road” to the moon.

How is colored glass made?

Glass is produced not only colorless. To obtain a colored product, in addition to the main components, chemical compounds are added to the melting furnace:

- Iron oxides give the glass a rich red tint.

- Nickel oxides - brown, violet (depending on the amount).

- To get a bright yellow tint, add uranium oxides to sand, soda and lime.

- Chrome makes glass green.

What are the characteristics and properties of glass?

The proportions of components for the manufacture of glass goods are selected depending on their purpose. Allocate: household glass - something from which they make dishes, glasses, jewelry; building - showcases, windows, stained-glass windows;