Make a recliner. Do-it-yourself sun lounger - schemes and best ideas on how to create a comfortable and stylish lounger

The word "chaise lounge" is immediately associated with a comfortable outdoor recreation. In addition, a comfortable portable chair will emphasize the style and individuality of a summer cottage or garden plot. A store-bought chaise lounge can be quite expensive, but you can easily assemble it yourself from improvised materials.

Chaise lounge - the general principle of design, varieties

Any deck chair is a folding chair on a frame, often with an adjustable backrest. The word "chaise lounge" comes from the French expression Chaise-longue - "loafer".

Variety by purpose

Depending on the purpose, sun loungers have a different configuration.

- For cottages and home gardens.

- For beach.

- Baby chair.

Variety by design

By design, sun loungers can be seated and recumbent.

- Standing folding chaise longue made of wood with a hard seat. It is often made from wooden slats, rather than plywood or sheet plastic, to facilitate construction.

- Standing folding made of wood with fabric.

Fabric seat can be easily removed for washing or transport

- Stand-up folding aluminum tube with fabric seat.

- Lying folding with a wooden seat.

- Recumbent chaise lounge made of aluminum tubes with a fabric seat. In fact, it is very close to the cot so familiar to all of us.

- Hanging deckchair.

Photo gallery: the variety of sun loungers has no limits

Eco-friendly products are popular with summer residents

Eco-friendly products are popular with summer residents  Chaise lounge with a plastic seat in a classic crate is suitable for the beach

Chaise lounge with a plastic seat in a classic crate is suitable for the beach  Chaise lounge can be a kind of upholstered furniture

Chaise lounge can be a kind of upholstered furniture  Chaise lounge "Leonardo" is equipped with a mattress

Chaise lounge "Leonardo" is equipped with a mattress  The fabric for the seat should be strong and dense, not subject to stretching.

The fabric for the seat should be strong and dense, not subject to stretching.  The simplest folding garden chaise lounge "Valdai" - the most budget option

The simplest folding garden chaise lounge "Valdai" - the most budget option  Non-folding sun loungers are best used permanently

Non-folding sun loungers are best used permanently  Chaise longue Cosatto - minimalistic plastic and metal

Chaise longue Cosatto - minimalistic plastic and metal  Chaise lounge CHAISE LONGUE is made of thick plywood

Chaise lounge CHAISE LONGUE is made of thick plywood

The choice of design and material for construction

You need to clearly understand what you would like to receive and what opportunities you have. If you need a solid construction, and weight does not matter much, then you need to focus on a metal or wooden deck chair with a wooden seat. The easiest way is to make such a seat from pallets - there is a ready-made assembly of boards on the frame, but the boards themselves are of poor quality and will require long processing after assembly - sanding, painting. Making a deck chair from bent steel pipes requires skills in handling a welding machine. The finished structure will be very strong, but heavy. If, on the contrary, you need an extremely lightweight and space-saving design, then think about a deck chair from the frame of an old folding bed.

But the easiest option to make is the usual wooden deck chair with a fabric seat.

Future deck chair - drawing and description

We settled on a simple wooden structure: bars connected with bolts, nuts and washers. The strength of this deck chair is given by three slats in the back, they also allow the chair to transform. The seat made of durable tent fabric is fixed on two round bars.

Tools and materials

We need tools:

- saw;

- drill;

- wood file and sandpaper.

Metal fittings and other little things:

- bolts and nuts - 4 pieces;

- washers (under the bolt head and nut) - 8 pieces;

- joiner's glue;

- screws;

- reinforced thread for a sewing machine.

Ingredients for wood preparation:

- impregnation against decay and moisture;

- primer (linseed oil or other);

- paint or stain.

Table: necessary parts for a sun lounger

It is necessary to carefully approach the choice of fabric for sitting, it should be hard and comfortable, should not wear out quickly. The best option is awning fabric; but any other dense fabric is also suitable - tarpaulin, denim, canvas. Well, if it is bright and not light. It's smarter and more practical.

Preparation for work

All bars must be sanded, starting with coarse-grained skins, ending with the smallest. It is advisable to impregnate them with a special anti-rotting impregnation or water-repellent impregnation, then prime and paint or stain. Then the deck chair will serve you for many years in any conditions.

Chaise lounge assembly

- You can start with the frame of the back of the deck chair. A beam with a section of 2 × 6 × 61 centimeters will be the main bearing link, so we fasten it very carefully. In the back of the seat we mount the crossbars. With the help of a stop that changes its position, the backrest tilt changes. At the same time, these crossbars work as stiffeners. You can not attach the planks, then in their place it is necessary to make cutouts 20, 25, 30 and 35 centimeters from the rear edge of the structure. Be sure to leave a centimeter gap between the two bars to secure the fabric seat.

- According to the drawing, we drill the necessary holes: on the back - two, from the edges - 41 centimeters each; on the seat from the top edge - 43 centimeters; on the bar to support the back - in the center.

- Then we combine the back and seat. We check the alignment of the holes. We connect them with bolts and nuts. Be sure to put washers between the wooden parts.

- We connect the elements of the frame. We mount the back support. A round bar is inserted into a hole drilled for it with glue.

- We fold the pre-cut rectangular piece of fabric in half and sew it with a reinforced thread with an indent of one and a half centimeters from the edge. We turn the stitched part inside out, make a drawstring for a round bar with a line. We do the same on the other side. We put it between the planks and fix it with a wooden rod. With this decision, it will be easy to remove the fabric seat and wash it, along with this there is no risk of falling out of the deck chair - the seat is firmly fixed.

Fabric can be removed without much effort

Nuts have the ability to unwind, but they cannot be tightened tightly - otherwise the deck chair will not be able to easily unfold and fold. To avoid untwisting, you can add one more locknut; or you can put nuts on glue or paint, only then do not touch the structure for some time so that the glue or paint dries. But at the same time, it is first necessary to adjust the tightening of the nut so that the parts move freely relative to each other.

Here is another approximate drawing of a slightly different design - all parts, dimensions and connections are clearly visible here.

Further care

If you carefully approached the preparation of wooden parts, then special care is not required. But over time, all sanding, impregnation, priming and painting should be repeated by removing the fabric seat. The removable seat can be removed when it rains and can be easily washed when dirty. You can also make it from washable fabric. For the winter, it is better to clean the sun lounger indoors.

The simple process of making a deck chair with your own hands will please any craftsman with a wonderful end result. A variety of materials and fabrics will allow you to be creative and create an original thing. And with proper care, your chaise longue will serve you for years to come.

Camping in nature is a great way to unwind. Some go to the village, others go to the country, where they are waiting for comfortable sun loungers, allowing them to forget about the environment and take a nap. Such attributes relieve tension from the spine and almost all muscles, you just have to choose the most comfortable option for yourself: a rocking chair, a regular folding chair or a sunbed.

The easiest way is to buy a ready-made deck chair, choosing it for the interior of the cottage or for your individual needs. But not everyone has the financial means to do so. A model made by oneself is more appreciated and fully corresponds to the taste of its owner.

Kinds

Creating homemade deck chairs is not difficult. Before starting work, you need to choose the type of this furniture that you want to bring to life. There are several of them:

- Armchair. As a basis, you can take elements from a crib or folding bed. Armrests are custom made.

- Sunbed. The creation process takes about four hours. The product can be made of plastic or wood, which is ideally sanded and varnished.

- Rocking chair. Its back is at an angle, so it is possible to lie down, relax, take a nap. At the same time, it is important to make the bottom of the attribute strong so that it does not loosen when swinging.

In addition to the distribution of products in appearance, there are variations in the types of structures:

- Monolithic. When it is created, all elements are fastened together, so disassembly is impossible. Such a deck chair is strong and durable, but the back is not adjustable here and the product as a whole does not add up. As a result, transportation problems may arise.

- Portable. Reliable and compact folding attribute has a special mechanism that allows you to easily adjust its position.

- Soldered with inserts. A practical product will decorate any interior due to its attractive appearance. But inserts from other materials do not guarantee durability.

If the chaise lounge is made of durable materials, it can be supplemented with a blanket, pillows and other items for a comfortable stay.

Possible materials

When choosing a deck chair material, you need to consider its location. It can be a summer cottage, a beach, a special place by the pool, or even at home. There are the following options:

- Wooden. This design is durable, comfortable, environmentally friendly, different in shape and appearance. The only drawback is a lot of weight. To facilitate the transfer of the deck chair, wheels are attached to the legs.

- Plastic. Products are lightweight, inexpensive, easy to care for. Of the negative sides - fragility.

- Fabric. Attributes are convenient and compact. The frame can be made of boards, metal, profile pipes.

- From rattan. Against the backdrop of nature, these sun loungers look incomparable. They are environmentally friendly but expensive. If you have skills in weaving, making such an attribute for relaxation is easy.

- From PVC. The same lounger with a fabric base, however, the base of the frame is PVC pipes.

Making a deck chair yourself is not difficult, you need to correctly determine the dimensions of all the elements and spend several hours assembling them.

Scheme of manufacturing various options

Before you start making an attribute for relaxation, you need to draw a diagram of it. It plays an important role, because it determines the dimensions of the elements for the product, their shape, quantity and other details. You can make such a scheme yourself, but not everyone can do it. Therefore, we give an example of such a scheme. A high-quality deck chair (fabric) will turn out according to such a drawing with dimensions.

It remains only to find materials to create a sunbed. There are also other options for drawing different types of sun loungers.

From a wooden lattice

Such a deck chair is quite durable, reliable, and its back can be adjusted. For such a model, you should take wooden slabs from coniferous species, as they are resistant to climatic changes. Here is a diagram with the indicated dimensions:

All work is carried out in stages:

- A frame is created from the bars, it is fastened with the help of metal corners.

- Boards are attached to the outside, and legs are attached to them.

- The plate is sawn with a jigsaw and a wooden grate is made.

- The adjustable backrest is separated from the main part of the attribute and fastened to it with a door hinge.

- A fastening bar is attached in the area of \u200b\u200bthe headboard, and a stand is attached to it with screws.

- The finished product is polished and varnished.

If the sunbed will often move from one place to another in the future, it is better to attach wheels to its legs, because the weight of the attribute itself will be considerable.

Fabric on the frame

The work on the frame occurs in this order:

- Ready base is taken from a folding bed or baby cot. In the absence of such, rails of the desired length are taken or cut and polished.

- Holes are drilled in the main frame, the other is supplied with cutouts (4 pieces) for adjusting the backrest.

- Holes are made at both ends of the rails to install the seat.

- Round crossbars lubricated with glue and installed in the holes.

Now you should prepare the seat itself. To do this, you need to fold the base of the product and measure the length of the canvas. It should sag to comfortably accommodate the wearer. All edges are processed on a sewing machine. Then the transverse round bar is wrapped with a cloth and nailed on both sides with small carnations. The attribute is ready and you can enjoy your vacation.

from pallets

This is the easiest way to create a sunbed. Such a product is lightweight (it is easy to move it to different places) and practical (you can put a mattress on it for more comfort). The work takes place in the following order:

- Pallets are dismantled, all nails are pulled out.

- A frame is made from two even boards. They are placed edgewise and parallel to each other, and the rest are sawn in half and attached to the base. The result is a seat with two support legs at the back.

- To create the front legs, a board from a pallet is sawn into two equal parts.. Then, with the help of bolts, they are screwed to the seat base and tightened with nuts through washers. The cross bar is necessary to strengthen the legs.

- The back is made from two boards, which are connected to the seat frame with bolts, nuts, washers. This should be done at an equal angle. After that, boards for the back are attached to the support boards with screws. Behind it, a bar is attached to the rear legs - this is necessary for the strength of the structure.

The final step is grinding the attribute with an emery sheet.

To prevent rotting of the boards, the product is varnished.

From polypropylene pipes

The drawing of such a deck chair is identical to the fabric one, only the wooden frame is replaced here with polypropylene pipes. To create a product, you need 2-inch pipes, fittings in the form of the letters "g" and "t" 8 and 6 pieces, respectively. The assembly process has several stages:

- First, a vertical bar is made. A t-shaped connector is taken and pipes of 30 and 45 cm are fastened with it. L-shaped fittings are put on the ends. The lower vertical is also fastened and the two sides are connected.

- An important point: the horizontal bar must be solid and have a length of 66 cm. O on is mounted closer to the connection with the letter "t", which must be directed to the inside of the structure. The other side is two 30 cm pipes, fastened with a T-fitting. This tee must be rotated from the oblong side by 45 degrees. The end result is a rectangle.

- For a rotating seat, a 5 cm pipe is inserted into the triple connecting element, which is fixed with the same part. This will be the base of the horizontal frame.

- The long sides of the horizontal frame are made in the same way as the vertical ones. For the cross bars, a tube 30 cm long is taken and another, consisting of 2 x 20 cm with a tee fitting. The result is a rectangular figure in the same figure.

- The seat will be located between the short section of the horizontal section and the elongated vertical. After adjusting the level of inclination, a support is inserted at the back.

The frame is ready, which means that now a fabric base is needed. To do this, take a dense canvas and fix it on the base.

"Kentucky"

Such an attribute for recreation has a number of advantages: compact, convenient, easy to fold, light in weight, durable and reliable, takes up little space when folded. It looks like a chair with a high back. The unusual assembly method looks original. To do this, you will need bars, galvanized wire (diameter 4 mm) and the same brackets for fixing the wire (16 pieces), wire cutters, a hammer. The process goes like this:

- A protective coating is applied to the bars. But the parts must be ready for assembly.

- Holes are made. However, they should be larger than the wire by a couple of millimeters.

- The bars are assembled in an interesting way, which makes the whole structure look creative. Here is the diagram:

At the end of the whole process, the chair gently rises and unfolds. This folding product looks stylish and modern.

original ideas

People with creative thinking do not always want to see simple sun loungers on their territory, so there are several original ideas for creating models for relaxation.

From birch chocks

This design has an unusual appearance, so you have to work hard. For such a lounger, birch logs with a diameter of 75-120 mm are needed. But you need to consider, the larger the diameter of the chocks, the more the product will weigh. Before starting work, stock up on the following tools:

- electric saw;

- drill;

- set of drills;

- self-tapping screws;

- staples.

Surely the word "chaise longue" in your imagination appears a pleasant picture of relaxing in the sun. But, sometimes, we overpay in stores for a “comfortable” seat. In this article we will tell you how to make a deck chair with your own hands. Take a look at this photo of a sun lounger and you won’t say that this is homework, not factory work. Making a deck chair is not as difficult as it might seem at first glance.

Types of sun loungers

Before you get started, you need to understand what kind of deck chair you need. Depending on the type of seat device, frame, we can say that there are several types of homemade sun loungers.

Chaise lounge with a monolithic frame

All parts are connected to each other and are inseparable. This type is very reliable and can withstand even heavy weights. However, there are also disadvantages: you can’t change the angle of the backrest, and you won’t be able to compactly fold such a deck chair.

Monolithic chairs with special inserts can fit perfectly into any interior. However, inserts make the design less reliable.

If you want the chaise lounge to change its position freely, then you need a portable design. It's also ideal for travel as it can easily be folded into the trunk of a car.

Blueprints

One of the most important components of the successful creation of this seat is the drawings for the manufacture of a deck chair. You should select competent drawings, where all the small details are written. If you are new to this business, it is recommended to choose not very complex designs so that the deck chair lasts as long as possible, and you do not damage your health.

wooden deck chair

What is needed to make such a deck chair? What materials do we need?

- Glued wooden plate 20 mm wide

- For the base, we need some boards and beams

- Tools needed for making:

- Drills, preferably different sizes

- four rollers

- Sheets for grinding our parts

- Components to further prevent breakage:

- Varnish for wood

- Dye

Detailed instructions for a sun lounger with your own hands

First, determine the size of your sun lounger. As a rule, the standard size is 60 * 190 centimeters. However, you can choose any other option that will fit your dimensions.

After determining the dimensions, you can safely proceed to the manufacture of the seat. We will assemble the base from the prepared wooden beams. Between themselves, the bars must be connected by means of metal corners to assemble the bed.

Depending on the size you choose, you should prepare the legs for the deck chair. As a rule, their size varies from five to ten centimeters in height. At a short distance from the edge of the base, you need to attach the legs. Use longer screws to secure.

In the center of all legs, with the help of screws measuring 3-5 centimeters, it is attached along the roller. Then prepare the planks. Cut out planks with a jigsaw with a format of 8 * 60 centimeters. Next, screw these strips to the base with a distance of 1-2 centimeters between them.

After you have assembled the frame, treat the chaise longue with special products to keep your item of manufacture for years to come. Once the products are dry, cover the deck chair with varnish or paint.

Chaise longue with fabric

In addition to the usual wooden deck chair, you can make a seat with fabric. For its production, we will also need wood blocks, durable fabric, fastening materials, an air drill, glue and sandpaper.

The best fabric option in this case is denim or canvas, as they do not fade in the sun, and they are also not afraid of wet weather. When choosing such fabrics, your deck chair will retain a presentable look for many years.

Durability

In order for your deck chair to remain in working condition longer, you should treat it with antiseptics and impregnations intended for wood during and after its manufacture. This protects your deck chair from various bugs, moisture and rapid destruction.

Photo of sun loungers with your own hands

A deck chair in a garden plot is an important furniture attribute that is suitable for a useful and comfortable pastime, and also brings a special originality to the design of the local area. Made from natural materials, the product can be placed both in a sunny area and in the shade, but in any case it will harmoniously fit into the backyard interior.

Do-it-yourself wooden deck chairs for summer cottages have a number of distinctive characteristics and advantages, thanks to which this piece of furniture has gained popularity. Among the main advantages of its use are the following:

- the design features of the deck chair, the structure of its back, armrests and seat allow a person to comfortably be in a reclining or semi-sitting state, which contributes to greater relaxation;

- the possibility of using for sunbathing;

- due to the lightness of the material and the simplicity of the design, the deck chair is quite portable and can be moved from place to place;

- do-it-yourself folding deck chair can be used as a bench for relaxing;

- has small dimensions when folded, which facilitates the process of its storage;

- wooden deck chairs are famous for their durability and endurance in operation;

- has a high aesthetic appeal.

Varieties of a country chaise lounge

Depending on the design features, the chaise lounge chair is conventionally divided into several types:

- Monolithic products- these are chairs in which all components are interconnected during manufacture and it cannot be disassembled. Such sun loungers have good indicators of strength, endurance and can withstand heavy loads. However, during the operation of such a piece of furniture, certain inconveniences may arise. For example, in such a product it is impossible to change the angle of the backrest, it cannot be folded, due to which, moving from place to place will be problematic.

- Monolithic armchair with inserts. This type of do-it-yourself deck chair made of wood is distinguished by decorative appeal. The presence of additional fragments made of various materials will reduce the strength and reliability indicators, but this will make the chair more aesthetic and neat.

- Portable sun lounger. The design of such a product provides for the presence of a mechanism through which you can quickly and easily change the position and overall configuration of the chair. You can change the angle of the footrest, headrest or backrest. In addition, a folding deck chair can be transformed into a compact cargo and taken with you when leaving the city.

- Armchair on a metal base. It is somewhat more difficult to make such a deck chair with your own hands from the photo and often get a finished product. It is distinguished by the presence of an aluminum or steel frame on which the fabric is attached. The advantage of the chair is its light weight, compactness, resistance to dirt and mobility.

Standard chaise lounge: manufacturing guide

Putting multifunctional and decorative furniture in your summer cottage is quite simple. To make a deck chair with your own hands, you will need a drawing. You need to put a little diligence and physical labor, and as a result, get a reliable design for leisure activities.

Making tools

- saw;

- self-tapping screws;

- wood putty;

- roulette;

- sandpaper;

- marker;

- paint of the desired color;

- drill;

- square.

Materials for product processing

- wooden boards 400x2.5 × 8 cm - 4 pcs.;

- wooden bars 400x5x10 cm - 3 pcs.;

- studs for fixing - 2 pcs.

Instructions for making a sun lounger

1. The primary task is to build a reliable framework. To do this, you need to make 4 parts from a wooden beam: 2 longitudinal 215 cm and 2 transverse 50 cm long.

2. Let's start making the seat. To do this, you need to take a board and cut it into uniform bars 60 cm long. For the design you will need 13 such fragments.

3. We fix these segments to the deck chair frame with self-tapping screws so that there is a distance of 1 cm between them.

4. We make legs for the future design. To give greater stability, in the seating area you need to make double supports 35 cm long. We make them from a bar. On the side of the headboard, it is enough to attach single legs with the same length.

5. We build the back of the product. For the manufacture of the frame, we prepare 2 parts 88 cm each, 3 parts 39 cm long. Such dimensions must be observed so that the frame can enter the main structure. In this case, small gaps should remain on all sides.

6. In the direction of the length of the product, you need to fix the boards on the back frame. To make the appearance more aesthetic, the upper edge of the planks needs to be rounded off.

7. We fix the back to the base of the deck chair so that it can easily change the raised and lowered position. To do this, make holes at a distance of 9 cm from the edge of the seat. The grooves must be through and pass freely through both structures.

8. On both sides of the product, we fix the structure with studs.

9. We make two grooves in the base of the deck chair, where the support bars will be placed. This will allow you to hold the back of the product in various positions. One recess 5x10 cm should be done at a distance of 9 cm from the hairpin. The second groove is made 20 cm from the first, but with a slot size of 5x5 cm.

10. In the first groove, you need to horizontally put a support beam 60 cm long. This will allow the backrest to lean on it and maintain a half-sitting position.

11. To change the angle of inclination and make a reclining position, you need to remove the first beam and put a board in the second groove, only vertically.

12. Making a deck chair with your own hands is almost complete. It remains to carry out the final finishing of the structure by sanding and opening with paint.

A guide to making a garden lounger with your own hands on the video can be seen here:

Original country chaise longue: a step by step guide

An extraordinary deck chair for a garden plot is not only a beautiful piece of furniture, but also a suitable way to recycle wood. Its advantage lies in the fact that it is environmentally friendly, harmonizes with the country exterior and does not require additional decorative processing. And for the comfort of the location of the body, you can lay a warm blanket or pillows.

Tools and materials for processing

- Round logs with a diameter of 75-120 mm.

- Chainsaw 18 V.

- Cordless drill.

- Impact wrench18 V.

- Screws.

- Deck screws and brackets.

- Drill.

Important! Such sizes of logs are considered optimal, since they are easy to drill and the deck chair will be lightweight.

Manufacturing instructions

- Initially, you need to prepare fragments from a log, each 45 cm long.

- Then you should form a layout for the future deck chair. To do this, use electrical tape, which can be applied to the floor contour.

3. Make holes in the cut logs with a drill. These slots will allow you to use short screws in the future.

4. Fasten together all the pieces of wood one by one. To do this, you can use a socket wrench and a cordless drill. 4 screws must be screwed into each log.

5. Turn the structure over and do the first test: sit, lie down on it to see where it swings. In these places, you can add another fragment for stability.

6. Fix the deck screws and steel braces on the back side of the deckchair to make the structure more rigid and durable.

Ready! Construction work has been completed. Despite some difficulties and troublesome process, as a result you get an original deck chair, which will become a useful and beautiful attribute of a summer cottage.

Examples of extraordinary ideas for making a deck chair can be seen in the video:

How nice after a hard day's work to retire in the garden or sit on the lawn by the pond in order to relax, unwind and enjoy the sounds of nature. And what piece of garden furniture do most people associate with a comfortable stay? Yes, garden chair! A comfortable portable elongated chair, in addition to its direct functional value, will act as a spectacular exterior element that emphasizes the style of a summer cottage. There is nothing difficult in making a garden deck chair with your own hands. We have selected for you several options for easy-to-make sun loungers. Among them, it will not be difficult to choose a suitable model, which anyone can build.

Such a deck chair can be safely used instead of a bed: a flat surface, an adjustable backrest. What else do you need for an afternoon break?! The only drawback of this design is that it is very problematic to move around the site yourself.

Chaise lounges of this design are very popular, both among vacationers on the sea coast and among the owners of suburban areas.

But there is a way out! We suggest considering the option of a deck chair equipped with rollers. To make a sun lounger, you need to prepare:

- 18 mm thick laminated spruce boards;

- Wooden bars 45x45 mm (for the frame);

- Boards 25 mm thick for sidewall sheathing;

- Electric jigsaw and screwdriver;

- Drills with a diameter of 40 mm for woodworking;

- 4 fixing corners for beds;

- Countersunk head screws;

- 4 rollers 100 mm high;

- Sanding sheet grit 120-240;

- Varnish or paint for woodworking.

Slabs of the required size can be purchased at a carpentry workshop or at the construction market. When choosing plates, it is better to give preference to coniferous products, since they are more resistant to precipitation.

The size of the deck chair depends on the desire of its owner. In most cases, the design is made in the size of 60x190 cm. Having decided on the dimensions of the deck chair, we make two long and two short sidewalls from wooden bars. From them we assemble the frame of the structure, fixing it together with the help of mounting corners. We cover the outer side of the frame with boards.

On long slats at a distance of 5-8 cm from the corner, we fasten the legs of a deck chair, the material for the manufacture of which was bars 5-10 cm long

We fix the legs to the boards using screws 60 mm long.

We mount the wheels: we install rollers in the center of the short legs of the deck chair, fixing them with screws 30 mm long, equipped with a semicircular head with a diameter of 4 mm

To make a wooden grate, using an electric jigsaw, we cut boards 60x8 cm in size from plates.

We attach the planks to the lounger on self-tapping screws, leaving a gap of 1-2 cm. To maintain the gap, it is most convenient to use special spacers

When planning to make a deck chair with an adjustable back, the lattice should be divided into two parts: a sunbed and a headboard. We put both parts on connecting boards and fasten them together with a door hinge.

To equip the mounting plate between the long bars of the deck chair frame, we fix the transverse rail. On the mounting plate we fix the support post, fixing it on both sides with screws

The finished deck chair can only be processed by walking with a grinder, and opened with varnish or paint.

We invite you to watch a video that shows how such a deck chair model is assembled:

Option # 2 - fabric chaise lounge on the frame

Another no less popular model of a deck chair that can be folded, giving an almost flat shape.

It is convenient to move a light chair around the site, choosing open sunny glades for relaxation, or, on the contrary, shaded and hidden corners in the garden from prying eyes

To make a folding deck chair, you need to prepare:

- Rectangular slats 25x60 mm thick (2 parts 120 cm long, two 110 cm each and two 62 cm each);

- Reiki of circular cross section with a diameter of 2 cm (one piece 65 cm long, two - 60 cm each, two - 50 cm each);

- A piece of durable fabric measuring 200x50 cm;

- Nuts and furniture bolts D8 mm;

- Fine-grained sandpaper and a round file;

- PVA glue.

Reiki is best made from hardwood species, which include birch, beech or oak. For the manufacture of a deck chair, it is better to use fabrics that are characterized by increased strength and resistance to abrasion. For example: canvas, tarpaulin, jeans, mattress teak, camouflage.

We cut the slats of the required length. Using sandpaper, carefully sand the surface.

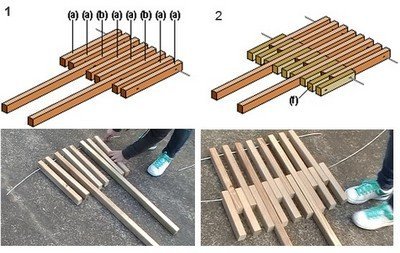

According to the scheme, where A and B denote the main frames, C represents the stop-regulator, we assemble the main structural elements

In the long rails of the main frames at a distance of 40 and 70 cm from the corners of the structure, we drill holes with a diameter of 8 mm, and then grind them with a round file.

To make it possible to change the position of the back in the deck chair, in frame B we make 3-4 cutouts at a distance of 7-10 cm. To equip the seat, we drill holes with a diameter of 2 cm, stepping back from the two ends of the rails. We install crossbars in the holes - round slats, the ends of which were previously lubricated with PVA glue.

Let's start assembling the deck chair: we connect parts A and B with the help of screws inserted through the upper holes. By the same principle, we connect parts A and B, only through the lower holes

The frame is assembled. It remains only to cut and sew the seat. The length of the cut is determined by the possibility of folding. Too short a cut will not allow the deck chair to fold, and an excessively long one will sag in the disassembled position. To determine the optimal length, you need to fold the deck chair and measure the fabric: it should be slightly stretched, but without effort.

We nail a piece of fabric with finished edges to round slats located on parts A and B. To do this, we wrap the crossbars with the edge of the cut, and then fix them with small carnations with thick caps. A variant is possible in which “loops” are made at the edges of the cut and put on the crossbars.

Option #3 - Kentucky Folding Chair

The original chair is assembled entirely from bars. If necessary, the chair can always be folded and put away for storage.

The advantage of such a garden chair is that, when disassembled, it does not take up much space, while the design is designed in such a way that it allows you to completely relax your muscles.

To make a chair, we need:

- Wooden bars measuring 45x30 mm;

- Galvanized wire D 4 mm;

- 16 pieces of galvanized wire clamps;

- Fine-grained sandpaper;

- Hammer and cutters.

For the manufacture of a chair, bars of 50x33 mm in size are also quite suitable, which can be obtained by sawing a 50x100 mm board into three equal parts. The total length of the bars should be 13 meters.

Instead of galvanized wire and staples, galvanized studs can be used, the edges of which are fixed with eight nuts and washers.

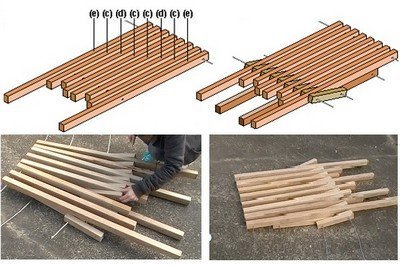

To determine the required number and length of wooden bars, it is convenient to use the pivot table. According to the drawing, we make through holes

The diameter of the holes should be 1.5-2 mm larger than the thickness of the wire used. Having prepared the required number of bars, you should carefully process all the edges, sanding the surface with fine-grained sandpaper.

Let's start building the structure.

For clarity, we use the assembly diagram of the seat with dividers, as well as the back of the chair. The dotted lines indicate the places of through holes with a wire threaded through them.

On a flat surface, according to the scheme, we lay out the bars for arranging the seat. Passing wire through through holes

By the same principle, we assemble seats with separators, connecting wooden bars with pieces of galvanized wire

The main structural elements are assembled. We take the ends of the wire, holding the sides of the structure, and carefully raise the chair.

It remains only to cut off the excess wire with wire cutters, and then bend and secure the ends with galvanized staples

Chaise lounge for a summer residence: 8 do-it-yourself models

The garden chair is ready. If desired, it can be coated with a semi-matt varnish for woodworking. This will significantly extend the life of such a popular element of garden furniture.