Environmental security measures at the enterprise. Ecological safety at the enterprise

State bodies of environmental protection Minatom of Russia Ministry of Health of Russia Ministry of Internal Affairs of Russia Integrated state bodies Ministry of Natural Resources of the Russian Federation Sanitary inspection of the Russian Federation Roshydromet of the Ministry of Emergency Situations of Russia Functional state bodies Roskomzem Rosselkhoz Goskomrybolovstvo Ministry of Agriculture of the Russian Federation Sectoral state organs

The main directions of the state environmental policy Decree of the President of the Russian Federation on "On the state strategy of the Russian Federation on environmental protection and sustainable development" 1. Ensuring environmentally safe sustainable development in the context of market relations. 2. Protection of the human environment. 3. Improvement (restoration) of disturbed ecosystems in ecologically unfavorable regions of Russia. 4. Participation in solving global environmental problems.

Two directions of the state environmental policy Order of the Government of the Russian Federation on the Ecological Doctrine of the Russian Federation 1. Ecology Reduction of pollution of the environment and resource-saving health care Ensuring sustainable environmental management Preserving and restoring the natural environment after-effects

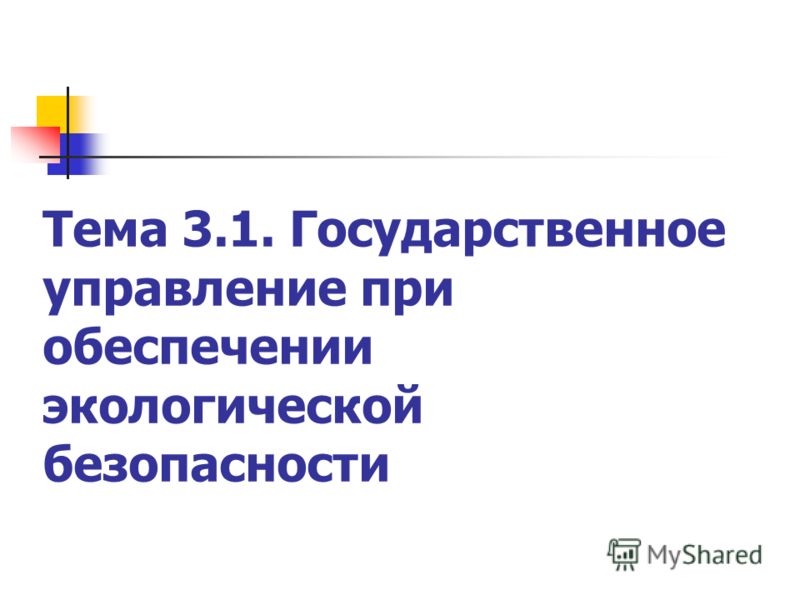

Two directions of the state environmental policy Order of the Government of the Russian Federation on the Environmental Doctrine of the Russian Federation 2. Environmental safety Environmental health priorities Ensuring safety in the implementation of potentially hazardous activities and during emergencies Prevention of terrorism that creates a danger to OS Prevention and reduction of environmental consequences Emergency Control use and distribution of alien species and genetically modified organisms

Ecological Expertise Ecological Expertise Ecological Expertise Establishment of compliance of documents justifying the planned economic and other activities with the environmental requirements established by technical regulations and legislation in the field of environmental protection in order to prevent the negative impact of such activities on the environment. Types: - State environmental impact assessment (Rostekhnadzor, Rosprirodnadzor, Ministry of Natural Resources); - public environmental review.

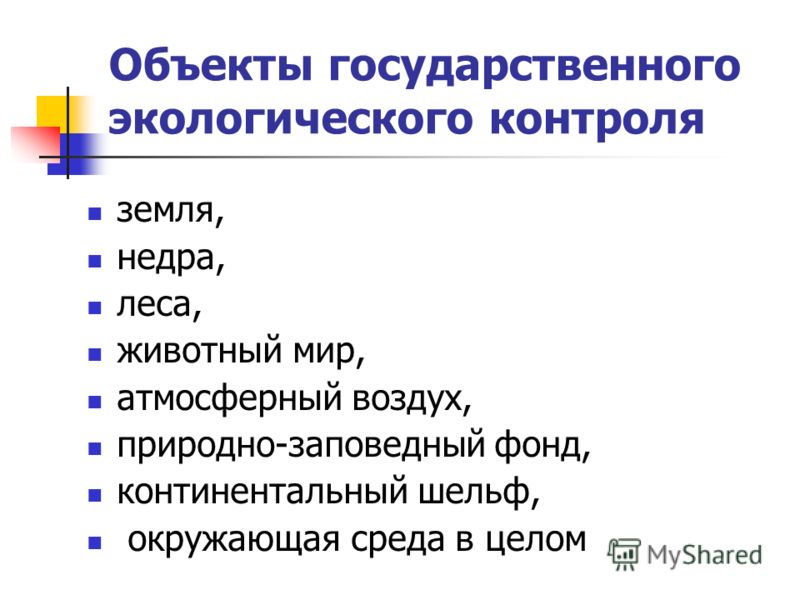

Objects of state environmental review Any project and pre-project documents; New equipment and technology, products, raw materials and materials; Draft standards and regulations. The task of the state environmental review is to assess the compliance of the planned economic or other activity with the requirements of environmental safety.

The procedure for obtaining land for use for the implementation of the planned activity Development of a Declaration of a specific activity: Socio-economic significance of the planned activity Impact on the OS Volume of natural resources involved in the turnover Positive conclusion GEE Development of materials justifying the choice of a land plot Development of a feasibility study, including . EIA: Positive conclusion of the GEE Financing of design and survey works Quantitative and qualitative indicators of environmental change (component) Possible social and environmental consequences as a result of changes Fulfillment of preconditions for environmental management Compliance with the rules and requirements of environmental safety Positive conclusion of the SER for use of the land plot

Environmental Impact Assessment (EIA) EIA EIA is a type of activity to identify, analyze and record the direct, indirect and other effects on the environment of a planned economic or other activity in order to decide whether it is possible or impossible to carry it out. The EIA procedure precedes the SER.

Standard content of materials on the EIA of the planned activity in investment design 5. Description of possible types of environmental impact of the planned economic and other activity on alternative options. 6. Description of the asset that may be affected by the planned economic and other activities as a result of its implementation. 7. EIA of the planned economic and other activity on alternative options, including an assessment of the reliability of the projected consequences of the planned investment activity. 8. Measures to prevent and / or reduce the possible negative impact of the planned economic and other activities. 9. Identified during the assessment of uncertainty in determining the effects of the planned economic and other activities on the OS.

Environmental Monitoring OS Monitoring (Environmental Monitoring) OS Monitoring (Environmental Monitoring) is a comprehensive system of monitoring the state of the environment, assessing and forecasting changes in the state of the environment under the influence of natural and anthropogenic factors. Environmental monitoring is an important part of environmental monitoring.

Environmental monitoring includes monitoring of the atmosphere of the surface layer and the upper atmosphere, monitoring of precipitation; monitoring of the hydrosphere, i.e. surface waters (rivers, lakes and reservoirs), oceans and seas, groundwater; monitoring of the lithosphere (primarily soil)

![]()

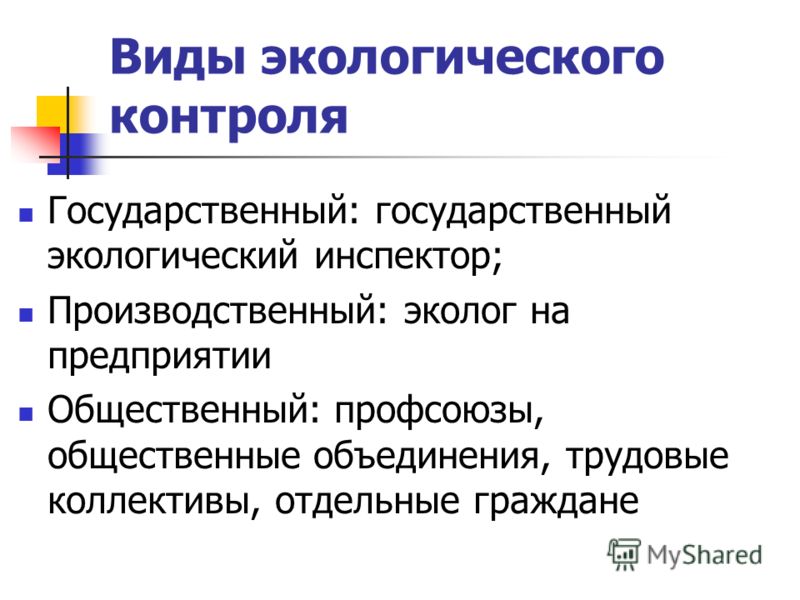

Ecological control Ecological control Ecological control is a system of measures aimed at preventing, detecting and preventing violations of legislation in the field of environmental protection, ensuring that business and other entities comply with the requirements, including standards and regulations, in environmental protection.

![]()

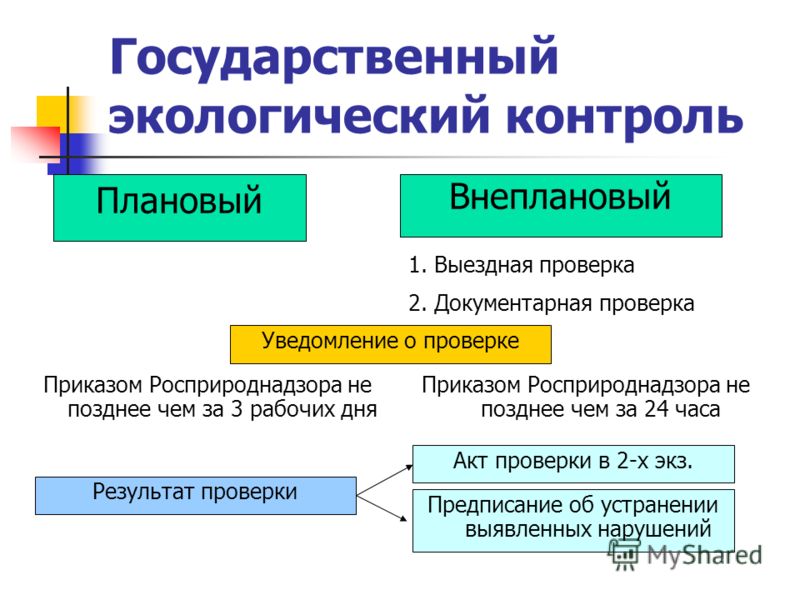

State environmental control Planned unscheduled 2. Documentary check 1. On-site check Notification of check by Order of Rosprirodnadzor not later than 3 working days by Order of Rosprirodnadzor not later than 24 hours Check result Check act Inspection in 2 copies. Prescription on the elimination of violations

Grounds for carrying out an unscheduled inspection 1) the expiration of the period for the discharge by the enterprise of a previously issued order for the elimination of the identified violation of mandatory requirements; 2) admission to the state body of complaints, the emergence of the threat of causing harm to life, health of citizens, harm to animals, plants, the environment, as well as threats of emergency situations of natural and man-made character; 3) the order of the head (deputy head) of the state environmental control (supervision) body issued in accordance with the instructions of the President of the Russian Federation, the Government of the Russian Federation.

Environmental certification Purpose: ensuring regulatory, technical and legal regulation of environmental safety of the Federal Law "On Consumer Protection" (1992) National standards GOST R ISO series (since 1998)

The tasks of environmental certification are the prevention of adverse effects on human living conditions and the state of environmental factors associated with the production and use of products, waste management and the use of natural resources; ensuring the rational use, protection and reproduction of the natural resource potential; protection of consumers against the purchase of goods that are hazardous to life, health and property, or have a harmful effect on the environment during their use; increase the competitiveness of domestic products, export promotion.

Objects of environmental certification objects of the environment; production and consumption waste; technological processes; services aimed at ensuring environmental safety and the prevention of environmental damage, commercial products.

Send your good work in the knowledge base is simple. Use the form below.

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted at http://www.allbest.ru/

Introduction

Pollution of the environment with gaseous, liquid and solid substances and industrial waste, causing habitat degradation and detrimental to the health of the population, remains the most acute environmental problem of priority social and economic importance.

The relevance of the work “Ecological safety at an enterprise” is due, on the one hand, to a great interest in modern science, and on the other hand to its insufficient elaboration. The ecological situation in which the modern economy has to function, necessitates a comprehensive consideration of economic problems from the point of view of environmental requirements and, conversely, the environment from the point of view of economic development requirements. This explains the practical and theoretical relevance of the topic of work.

Today, more than ever, F. Engels’s warning that “one should not be deceived by victories over nature, is actual, because for every such victory nature takes revenge on man, that each of such victories has, besides the immediate consequences that man expects, also completely different , unintended consequences that often destroy the value of the first. "

The deterioration of the natural environment is due to the following reasons:

Lack of knowledge about ecological systems and the limits of their sustainable functioning (ability to withstand stress);

Inability to predict changes in the biosphere and their impact on human health;

Departmental and narrow professional limitations in dealing with economic and engineering issues, underestimation of measures to prevent degradation and protect the biosphere;

Insignificant developments or lack of scientific both technological schemes and economic research aimed at developing production criteria in order to preserve the balance of the environment;

Unpreparedness of production - not all enterprises are equipped with sewage treatment plants, the existing ones are often weak, etc .;

Low qualification of personnel working at the treatment plant;

A certain staff mentality and inertia of thinking.

The selected topic “Environmental safety at the enterprise” on the example of the Smolensk lamp factory is relevant, theoretically and practically significant.

The purpose of the work is to study environmental safety.

To achieve this goal, the following tasks are solved:

Examine the concept of "environmental safety of the enterprise";

Investigate the legal regulation of environmental safety of the enterprise;

Object of study - Smolensky lamp factory.

The subject of the study is environmental safety at the Smolensk Lamp Plant.

The statistical and reporting data of the Smolensk lamp factory were used as an information base.

1. Theoretical foundations of environmental safety

1.1 The essence of environmental safety

environmental risk safety plant

Ecological safety is a set of states, processes and actions that ensure the ecological balance in the environment and does not lead to vital damage to the natural environment and man. It is also the process of ensuring the protection of the vital interests of an individual, society, nature, the state, production and all of humanity from real or potential threats posed by anthropogenic or natural environmental impact. The objects of the DL are the rights, material and spiritual needs of the individual, natural resources and the natural environment or the material basis of state and social development.

In our time, civilization has enormous pressure on nature. Industrial emissions are harmful to the human and animal world, the density of the atmosphere decreases, the number of days with fog increases, visibility deteriorates, and corrosion of metal products occurs.

Relations that arise in the field of environmental protection are governed by legislation on the sanitary and epidemiological welfare of the population and legislation on health protection, as well as other legislation aimed at providing a favorable environment for humans.

This is an independent type of activity in the field of economic regulation and government, which is closely connected with other types of economic relations. The most significant problems are: pollution of land, forests and water, pollution of the atmosphere in cities, disposal and disposal of toxic industrial waste, storage and destruction of chemical weapons.

The concept of environmental safety includes a system of regulation and management, allowing to predict, prevent, and in case of occurrence - eliminate the development of emergency situations. The problems of environmental safety and rational nature management are inextricably linked with the socio-economic development of society. The main sources of environmental hazards are pollution of all environments: air, water, soil, food, exposure to electromagnetic radiation and noise. The system of environmental safety has a multi-level nature - from a source of environmental impact to a national one, from an enterprise, a municipality, a subject of the Federation to a country in a planetary aspect.

Ecological safety ensures compliance of the organization’s environmental activities with regulatory requirements by means of developed organizational technical measures constituting the whole structure. It should be noted that the competitiveness of enterprises is largely determined in terms of the environmental activities of this organization. Thus, the introduction of environmental technologies helps to save energy and other resources, which in turn affects the profitability of production, productivity, attractiveness for foreign investment.

Ecological safety is achieved by a system of measures (forecasting, planning, early preparation and implementation of a set of preventive measures), providing for a minimum level of adverse effects of nature and technological processes of its development on livelihoods and human health, while maintaining sufficient economic development rates. Ecological safety is carried out within the limits of all forms of sectoral environmental management, including direct and indirect human exposure at all levels - global, regional and local. At all stages of its existence, humanity was constantly subjected to numerous dangerous influences by external forces.

The solution to the problem of security must be sought in the ways of agreement between political, environmental, economic and social requirements. The state plays a decisive role in ensuring environmental safety. The leading role of the state as the main subject of environmental safety in the creation and organization of the effective functioning of the national system of environmental safety is due to the following circumstances. First of all , national security in general and environmental security in particular, are closely related to the fundamental human rights to life, health and a favorable environment. The main guarantor of ensuring these rights is the state as a political institution with the highest level of differentiation and specialization of internal structures. Secondly, it is the state that possesses the most significant and powerful “resource arsenal” necessary to effectively counter environmental hazards, threats and risks. Thirdly, the most serious environmental hazards and threats, as a rule, are large-scale in their parameters, territory, time, consequences.

Accordingly, effective and complex counteraction is possible to ensure only under the influence of the state. In modern times, in the context of globalization, it would be absurd to argue that the concept of environmental security is limited to the security of only one state. Recently, environmental security is understood as a complex of states, phenomena, and actions that provide ecological balance throughout the Earth. From the standpoint of the concept of national security, the essence of environmental security is revealed through the category of interests of an individual and society.

Environmental problems today, due to the global deterioration of the state of nature, have moved to a completely different level and have ceased to be the subject of research only for such a science as “Ecology”. This is explained by a number of factors. Firstly, in the course of its development, the links between various regions of the world were invariably strengthened, as a result of which humankind naturally came to a situation where serious problems arising in a certain region of the earth inevitably affect the state of the entire planet. This effect is observed in all areas, including environmental. Secondly, the development of scientific and technological progress was an equally important reason, the consequences of which manifested themselves in literally all spheres of human activity.

Ecological safety at an enterprise is a whole complex of measures aimed at identifying negative factors at the first stage that may affect the health or even the life of the employees.

The main goal of environmental safety is to achieve sustainable development with the creation of a favorable habitat and comfortable conditions for life and reproduction of the population, ensuring the protection of natural resources and biodiversity, and the prevention of man-made accidents and disasters.

Thus, not only actions that ensure the ecological balance in the environment, but also the protection of vital interests can be attributed to environmental safety.

1.2 Legal regulation of environmental safety

Environmental security is governed by the norms of environmental law - an integral part of the legal system of the state at the present stage of development. At the same time, environmental law is a natural resource law and environmental law taken in interrelation and interdependence. Environmental law, like other branches of law, is a regulator and a way to solve the complex problems that have arisen in society, which need to be streamlined, sometimes with the help of a forceful, coercive (often encouraging) mechanism. Environmental law is an important tool used by the state in the interests of conservation and rational use of the environment. Due to the sharp exacerbation of environmental problems at the present stage of development of society, the role of environmental law and in general the administrative-right direction is constantly growing. The general rules of conduct provided for by environmental law are not personalized, not exhausted by execution, i.e. calculated for an indefinite number of cases, are mandatory. All this proves that these rules of behavior of people in the environment and relations with the environment belong to the legal system.

The core of regulated social relations are human, social relations in the field of interaction between society and the environment. They certainly have their own specifics - they arise, change and cease with regard to environmental protection and the rational use of natural resources. This kind of relationship is not regulated by any other branch of law. Like other social relations regulated by law, environmental relations are industrial, social in nature, since the greatest polluter of the environment is the production sphere of human activity, when in the process of labor a person is the main participant in anthropogenic pollution. The right of citizens of the Russian Federation to a favorable environment is based on the Constitution of the Russian Federation and is detailed by the RSFSR Law "On the Protection of the Environment". Environmental aspects of environmental management in the framework of natural resource relations are considered in the laws governing the nature of environmental management in the system of land, water, forest, subsoil use, etc. In the Russian context, the main source of environmental law is secondary legislation. They include decrees of the President of the Russian Federation, decrees of the Government of the Russian Federation, departmental acts, normative acts of the constituent entities of the Russian Federation, organizations and other acts.

The main bylaws are decrees of the President of Russia: they are considered to be under-law because, according to Art. 90 of the Constitution of the Russian Federation, must not contradict the Constitution of the Russian Federation and federal laws; in addition, according to Art. 80 of the Constitution of the Russian Federation, the President of Russia determines the main directions of domestic and foreign policy and the state in accordance with the Constitution of the Russian Federation and federal laws. Bylaws include orders of the Government of the Russian Federation. Among those provided for in Art. 114 of the Constitution of the Russian Federation, the powers of the Government of the Russian Federation are such as are related to the regulation and implementation of environmental relations, namely: development and presentation of the federal budget, and ensuring its implementation; ensuring the implementation in the Russian Federation of a unified state policy in the field of ecology; management of federal property; implementation of measures to ensure the legality of the rights and freedoms of citizens, the protection of property and public order. Next in the hierarchy of bylaws are departmental acts - orders, instructions, rules, instructions. Accepted by the central executive authorities, which, according to the Law of the Russian Federation on the Government of the Russian Federation, include ministries, state committees and departments. The sources of environmental law include regulations, i.e. acts are accepted in organizations and institutions. Normative acts of the organization, although they are in the hierarchy of normative acts at the lowest level, because must comply with all higher regulatory acts, however, are important sources of environmental law. Currently, the legislation of the Russian Federation provides for property disciplinary, administrative and criminal liability for environmental pollution. Disputes in this area are resolved in court. Citizens and officials who have committed offenses that have caused environmental pollution are subject to all of these types of liability. Enterprises, institutions and organizations bear administrative and civil liability.

The basic documents include:

Constitution of the Russian Federation

Federal Law "On Security"

National Security Strategy of the Russian Federation

Message of the President of the Russian Federation to the Federal Assembly of the Russian Federation on December 3, 2015

The documents of economic security include:

Environmental Doctrine of the Russian Federation

Fundamentals of the state policy of the Russian Federation in the Arctic for the period up to 2020 and beyond

Doctrine of food security of the Russian Federation

Russian water strategy for the period up to 2020

Climate Doctrine of the Russian Federation

Energy strategy of the Russian Federation for the period up to 2030

Transport Strategy of the Russian Federation until 2030

Environmental doctrine is a concentrated expression of the system of official views and regulations that are developed by the political leadership of the state and proclaim the main goals, principles, directions and forms of its activities to ensure rational interaction between society and nature, and to preserve the proper quality of the environment of living substances, including humans.

An analysis of the practice of applying environmental legislation shows that the most frequently used measure is an administrative penalty. It involves the imposition of a fine and compensation for harm. The most severe measure of administrative pressure on enterprises is the suspension or complete cessation of production activities. Administrative responsibility for environmental offenses is provided for by many laws and by-laws issued by public authorities. Bringing persons to administrative responsibility does not exempt them from civil liability, which provides, inter alia, compensation for the harm (damage) caused. So, in art. 77 of the Law of the Russian Federation "On Environmental Protection" states: "Legal and physical persons who have caused environmental damage as a result of its pollution, depletion, damage, destruction, inefficient use of natural resources, degradation and destruction of natural ecological systems, natural complexes and natural landscapes and other violations of the legislation in the field of environmental protection shall be obliged to compensate it in full in accordance with the legislation. ” The damage caused to the environment is determined in accordance with the approved rates and methodologies approved by the established procedure. In their absence, the amount to be reimbursed is determined on the basis of the actual costs of restoring the disturbed state of the environment and the losses incurred, including lost profits. According to Art. 78 of this Law, compensation for environmental damage caused by violation of environmental protection legislation is carried out voluntarily, by decision of a court or arbitration court.

1.3 Environmental risks of the enterprise

Environmental risk may occur during the operation of the facility and equipment operation, and be an integral part of industrial risk. Environmental damage is expressed in the form of pollution or destruction of forests, water, air, land resources, damage to the biosphere and agricultural land. Damage to third parties is expressed as an increase in disease and mortality. At the same time, civil liability arises for inflicting harm to third parties in the production process, which can be legal entities (organizations) or individuals (population).

The most likely cases are accidents, excessive emissions and leakage of harmful substances at a production facility, the impact of which will affect the surrounding areas.

In our case, we are dealing with a fluorescent energy-saving lamp. Energy-saving lamps consist of a flask filled with pores of mercury and argon, and a control gear (starter). A special substance, called a phosphor, is applied to the inner surface of the flask. A phosphor is a substance that, when exposed to ultraviolet radiation, begins to emit visible light. When we turn on the energy-saving light bulb, under the action of electromagnetic radiation, the pores of mercury contained in the lamp begin to produce ultraviolet radiation, and the ultraviolet radiation, in turn, passing through the phosphor deposited on the surface of the lamp, is converted into visible light. The phosphor can have different shades, and as a result, it can create different colors of the light flux. The designs of existing energy-saving lamps are made under the existing standard sizes of traditional incandescent lamps.

Saving electricity. The efficiency of the energy-saving lamp is very high and the light output is about 5 times greater than that of a traditional incandescent bulb. For example, a 20-watt energy-saving light bulb creates a luminous flux equal to the luminous flux of an ordinary incandescent lamp 100 watts. Due to this ratio, energy-saving lamps can save 80% savings while at the same time without loss of illumination of the room you are used to. Moreover, in the process of long-term operation from an ordinary incandescent bulb, the luminous flux decreases with time due to the burning of a tungsten filament, and it illuminates the room worse, and energy-saving lamps do not have this disadvantage.

Long service life. Compared to traditional incandescent bulbs, energy-saving bulbs last several times longer. Conventional incandescent bulbs fail due to burnout tungsten filament. Energy-saving lamps, having a different design and a fundamentally different principle of operation, serve much longer than incandescent bulbs on average 5-15 times. This is approximately from 5 to 12 thousand hours of lamp operation (usually the lamp life is determined by the manufacturer and indicated on the package). Due to the fact that energy-saving lamps last for a long time and do not require frequent replacement, they are very convenient to use in those places where the process of replacing light bulbs is difficult, for example, in rooms with high ceilings or in chandeliers with complex structures, where you have to disassemble the light bulb .

Low heat emission. Due to the high efficiency of energy-saving lamps, all the electricity consumed is converted into luminous flux, while energy-saving lamps emit very little heat. In some chandeliers and lamps it is dangerous to use ordinary incandescent bulbs, because they emit large amounts of heat can melt the plastic part of the cartridge, the adjacent wires or the body itself, which in turn can cause a fire. Therefore, energy-saving lamps just need to be used in lamps, chandeliers and sconces with temperature limitation.

Great light output. In an ordinary incandescent light comes only from the tungsten spiral. Energy-saving lamp glows throughout its area. Due to this, the light from the energy-saving lamp is soft and uniform, it is more pleasing to the eyes and spreads better around the room.

The only and significant drawback of energy-saving lamps compared with traditional incandescent lamps is their high price. The price of an energy-saving light bulb is 10-20 times more than a conventional incandescent bulb. But an energy-saving light bulb is not without reason called an energy-saving light. Considering the savings on electricity when using these lamps and with their service life, in total, the use of energy-saving lamps will become more profitable for you and your budget.

The energy saving lamp is filled inside with mercury vapor. Mercury is considered a dangerous poison. Therefore, it is very dangerous to break such lamps in an apartment and a room. You should be very careful when handling them. For the same reason, energy-saving lamps can be classified as environmentally harmful, and therefore they require special disposal, and throwing out such lamps is, in fact, prohibited. But for some reason, when selling energy-saving lamps in the store, sellers do not explain where to put them then.

Among the numerous group of toxic substances, mercury occupies a special place, possessing (from the ecological and hygienic point of view) unique properties due to its increased ability to be distributed in the environment, a variety of forms of location and the specificity of their transformation under natural conditions, as well as a diverse spectrum of negative effects on living organisms even with relatively small doses of exposure. One of the possible sources of its entry into the habitat are mercury discharge lamps.

In general, two main types of mercury lamps should be distinguished - lamps into which metallic (liquid) mercury is introduced, and lamps in which liquid mercury is replaced by amalgam (due to lower pressure of mercury vapor above the amalgam lamp becomes more acceptable in production and operation). At the Russian electric lamp factories in the process of vacuum treatment of lamps, liquid (metallic) mercury is injected in the overwhelming number of them. This is inevitably accompanied by its technological losses and pollution of the working environment, which leads to a negative impact on workers, metal emission into the habitat and the formation of mercury contamination zones in the vicinity of enterprises. In turn, failed mercury lamps are a potential source of toxic mercury and other harmful substances in the environment, which determines the need for their selective collection and processing.

Used lamps as a potential source of habitat pollution.

Mercury, which is part of the lamps, is a hazardous pollutant and occupies one of the first places in the lists of environmental pollutants subject to mandatory environmental and hygienic control. For example, already in the well-known List of the EU Council Directive on Toxic and Hazardous Waste (78/319 / EEC of March 10, 1978), mercury and its compounds were given the second position. In essence, this is why in many countries of the world special attention is paid to creating a special system for disposing of mercury-containing waste and, in particular, used mercury lamps, in which the latter are removed from the general waste stream and then disposed of. For example, in the USA, used fluorescent lamps are included in the list of hazardous waste by a special decision of the Environmental Protection Agency. Now in most European countries, failed mercury lamps are subject to mandatory recycling.

If we assume that 50 mg of mercury contained in a spent and discarded lamp will eventually enter (evaporate) into the atmosphere, then this amount is enough to pollute the air with toxic mercury to its level of maximum permissible concentration (maximum permissible concentration) in a room of 160 thousand m3

It should be noted that the selective utilization of used lamps and other types of mercury-containing waste products (thermometers, galvanic cells, etc.) not only helps to reduce the level of pollution of the environment by mercury and other pollutants, but also increases the environmental safety and economic efficiency of the known methods of disposal masses of waste generated in cities.

Thus, environmental risk may arise not only during the operation of the enterprise and the operation of equipment, but it is covered at all levels - from local to global.

2. Analysis of environmental safety of JSC "OSRAM»

2.1 Characteristicenterprises as a source of environmental pollution

In the early 2000s, the leadership of the international corporation OSRAM estimated the prospects for the development of the Russian market and concluded that a high growth rate expects it. The company studied a number of production facilities and made a choice in favor of the Smolensk plant “Svet” due to its strategically advantageous geographical position in the central part of Russia and experienced staff of the enterprise. The plant was built in the 60s, and immediately after the transaction was completed in 2003, OSRAM began to modernize the enterprise.

OSRAM did not make a bad choice - in these 10 years the plant in Smolensk became the largest manufacturer of T8 fluorescent lamps in Europe and the second largest enterprise of the corporation in the world after the main production in German Augsburg. Today, the plant in Smolensk employs about 1,000 employees, the company produces more than 88 million lamps per year, which are sold not only in Russia, but also exported to Eastern and Western Europe. In 2012/13, the turnover of OSRAM in the CIS countries amounted to more than 3.5 billion rubles, and about 270 million rubles from the company were brought by the export of goods.

Due to the sharp and continuous increase in the volume of various emissions from anthropogenic sources, the problem of controlling environmental management and environmental protection has become very topical, not only at the planetary level, but also at each enterprise specifically.

Industrial enterprises are among the main users of natural resources and environmental pollutants. Therefore, the improvement of environmental activities in the enterprise is key to solving environmental problems. Their solution is possible only with closer examination. The analysis of the ecological situation in our city can serve as an urgent problem to study, and one of the important links is environmental management at one of the largest electric-lamp factories in Russia - the Smolensk Lamp Factory.

The plant in Smolensk is a unique combination of two well-established labor systems: on the one hand, this is more than a century of history and the German principles of OSRAM, and on the other, the 50-year-old Svet factory with its trade unions, collective agreement and honor roll. The company’s management is trying to preserve the positive traditions of Smolensk-made manufacturing and introduce OSRAM methods with a democratic style of relations between all employees, respect for each employee and strict adherence to local legislation. Among the basic principles of OSRAM work is the employee motivation system, according to which each member of the team knows the goals of the company and understands that their personal well-being depends on the result of the work of the whole team. The plant encourages talented and ambitious employees, many employees are paid for teaching foreign languages and are given the opportunity to build a career at the international level.

Environmental management at an enterprise, organization can be motivated not only by external pressure of environmental legislation, GOST, instructions, etc., but also by internal informal opinions and beliefs of decision-makers. On the contrary, the decision and activities of environmental managers are not always internally motivated solely by the principles of eco-efficiency and eco-justice. Any one of them, one way or another, is imposed by the restrictions and requirements of legislation, official and internal instructions, no matter how they are personally interested in the effectiveness of their work. The main purpose of the plant is to make a profit.

The main types of economic activity are:

Light source production;

Production of various types of consumer goods;

Rendering various kinds of services to enterprises, organizations and people;

The development of subsidiary agricultural production;

Implementation of construction, repair and construction and installation and construction works;

Conducting supply and sales, trading and intermediary operations;

Foreign economic activity.

At the same time, the main tasks of the plant include: maintaining a high level of its brand, due to good product quality, continuous improvement of the technical level of production, product renewal, training and involvement of young people in the labor process and constant interested work with consumers of the plant’s products, as well as constant striving to the maximum satisfaction of requirements for quality, supply and payments for products.

Among the main elements of the organization of economic activities of the Plant, its organizational structure (structure) is dominant, i.e. the design on the basis of which the management of production activities takes place, as well as stable links between the links of the plant.

The organizational structure of the OJSC consists of 5 main units, each of which includes departments, bureaus, other units. The activity of each link is coordinated by the director or the chief reporting to the general director. The work of individual structural divisions is headed by the head of this division, which is subordinate only to the sole superior head.

The emergence of environmental management systems in the enterprise is largely due to the increasing complexity of the human condition in the modern world, the emergence of difficulties, problems, opinions and beliefs encountered in everyday life, both individuals, companies, and entire communities.

These problems include: emergency waste situations; transport clot; air and water pollution; the aggravation of the environmental consciousness of people; the emergence of new markets for environmental technologies.

A sensible attitude of people to the environmental consequences of economic activity arouses the need to create new firms with an environmental orientation and to appropriate restructuring of traditionally functioning enterprises, which:

Produce environmentally friendly products;

Use environmentally friendly technologies, including recycling materials and raw materials;

Apply ecological clean technologies or equip obsolete equipment;

Environmental auditing and environmental management systems are introduced.

Modern practice shows that this approach provides a competitive advantage in the medium and long term. Today, public consciousness forms new instruments of environmental policy.

2.2 Environmental policy of the enterprise

The environmental policy of the enterprise is the statement of the enterprise about its intentions and principles related to its overall environmental performance, which serves as a basis for action and for setting targets and targets. It determines the environmental policy of the enterprise by its top management. Top management may consist of an individual or a group of persons bearing administrative responsibility for the organization.

At each enterprise, an environmental policy should be formulated that would fully correspond to its production activities, services or products. And for this very purpose, the enterprise develops a system for managing the environmental situation, which is part of the overall management system.

The environmental policy of almost any enterprise determines the principles of activity and the general direction, the required level of responsibility of officials for the state of the environmental situation of the environment, and also determines the characteristics on the basis of which an assessment of further actions is carried out. It is developed only with the permission of the top management; it is also responsible for its determination. But, along with this, even ordinary employees of an enterprise should fully realize their responsibility and obligations for the preservation and protection of a favorable environmental situation. For the development, implementation, modification and formulation of changes are the responsibility of managers at all levels and departments of the enterprise.

Each employee of the company performs certain duties in terms of continuous improvement of the environmental situation and the prevention of environmental pollution. The company's management must strictly comply with all requirements for all environmental aspects. Thus, environmental policy is the basis for the definition and analysis of objectives and goals for improving the environment. It is mandatory for all employees and moreover, is available to the public.

The environmental policy of the company is based on the following principles:

The protection and protection of nature is the basis for achieving effective development of the enterprise in the future.

Ensuring the environmental safety of technological processes of production, as well as itself, is based on the requirements of international and domestic standards.

Attitude to the issues of environmental protection should be a permanent component of the management system of the enterprise.

Careful classification and consideration of the causes of the negative impact on nature, the resources involved, the volume and composition of liquid and solid wastes.

The environmental management system includes such tools as organization, experience, responsibility, methodologies, resources and processes for the formation, implementation, relevance and analysis of environmental policy, including the distribution of responsibilities and documentation.

The protection and preservation of the environment by all industrial enterprises is the basis for the formation of sustainable development with respect for the interests of both present and future generations. Ensuring the environmental safety of products, as well as production processes, is built in accordance with domestic standards and laws, international requirements and regulations, as well as its own regulations and standards of the enterprise and the requirements of end users.

The mechanism of environmental management is a set of means of influence both on the formation of the actual environmental situation and on the possible environmental consequences of human activity. And the functions of environmental management - a set of various activities that are necessary for the management of environmental processes.

Regardless of the type of production and the nature of the activity, the enterprise acts as an indirect element, defining a kind of connection between itself and its environment, and various types of information are exchanged at all stages of economic activity. The company is the main element influencing environmental pollution as a result of human activities.

Environmental management in an enterprise is also the art of making effective management decisions in order to improve the environmental performance of an enterprise.

The development of environmental policy is aimed at solving the main task - ensuring the sustainability of the parameters of the state of the environment under various types of impacts on it. Consider the environmental activities of the enterprise as a user of natural resources and a source of environmental pollution. (Picture)

The main directions of the environmental strategy of the enterprise

An enterprise should be considered as an autonomous ecological system based on its economic activity that has an impact on the environment, in accordance with the terminology of international environmental standards. The development strategy of the enterprise’s environmental activities is determined by its environmental policy, which is aimed at ensuring a steady state of the environment when an enterprise carries out certain economic activities. The implementation of the environmental policy of the enterprise is carried out with the help of a special organizational structure for the management of environmental activities - the environmental management of the enterprise. In addition to the main types of environmental activities of all types of ecosystems - environmental management and environmental activities at the enterprise level - it is necessary to develop new areas of environmental activities that have a direct impact on improving the results of its financial and socio-economic status, the implementation of economic activities. These new directions are connected with ensuring competitiveness, quality and environmental safety of products and social development of an enterprise, as well as with the inclusion of its environmental activities in an automated management system.

2.3 Maindirections environmental strategyenterprises

Environmental strategy is one of the central elements of environmental management at a strategic level. The company's basic strategies today are mainly aimed at reducing costs, improving product quality, leadership in speed of supply and speed of response to market demands. However, with increasing importance for the business of environmental and social factors, the range of traditional parameters that determine the potential for success of the company is expanding at the expense of environmental and social parameters. Environmental and social factors must be considered when developing an enterprise strategy: either by incorporating environmental components into strategies, or by developing an independent environmental strategy. In both cases, there should be a constant optimization of the relationship between the active and the passive approach. (Table 2.2.)

The problem area of the enterprise was revealed, which tells us that when disposing of production wastes and used lamps at the old installation for de-mercuration of lamps, mercury vapor in the air is contaminated.

Comparative characteristics of the active and passive approach to the environmental strategy of the enterprise

|

Passive company: OOS as a threat to the company |

A company with an active environmental policy |

||

|

Products |

High consumption of energy, resources (including rare and non-renewable) and environmentally hazardous materials, low level of recycling |

Focusing on renewable resources, recyclable, environmentally friendly materials, low energy intensity |

|

|

Processes |

Environmentally hazardous, with the formation of large volumes of waste, including toxic, energy-intensive, with a high risk to the health of personnel |

Environmentally friendly, with low waste and energy intensity, resource-saving, safe for the health of personnel |

|

|

Environmental "concern" of consumers |

Consumers are indifferent to the environmental side of the enterprise |

Consumer interested in the environmental activities of the enterprise |

|

|

Attitude of the company to environmental standards |

Low standards orientation, non-compliance with strict standards |

Follow strict standards |

|

|

Obligation of managers and staff to environmental protection |

There is no obligation |

Managers and staff are required in the field of ecology. |

|

|

Professional level of staff |

Low, staff narrowly specialized in traditional technologies. |

High, widespread education and qualifications |

|

|

Opportunities in research and development |

Low profiling |

Possession of a creative team with a short "promotional" cycle |

|

|

Capital equipment |

Lack of capital environmental equipment |

Owning environmentally responsible financial institutions |

The known method of thermal demercurization of mercury-contaminated materials includes the destruction of lamps, heating of materials in a sealed chamber, vacuum distillation of mercury vapor, trapping mercury vapor in a low-temperature trap. In this method, metallic mercury is collected in a low-temperature trap and can be returned to production after cleaning. Such a cycle of mercury turnover looks most appropriate. The method is implemented in the installation of URL-2M. However, in the implementation of this method there are drawbacks that prevent to fully use the advantages of the method:

1. The vacuum technology is not adapted for the processing of dirty, broken lamps, for the processing of wet waste, for the processing of waste containing plastics, as the vacuum system fails both from water and when heated plastics, and from other substances whose components litter vacuum system.

2. The vacuum technology recommends heating to temperatures not exceeding 170 ° C, above which the components of the PCB and compounds clog up the vacuum system, and the most stable mercury compounds, in particular cinnabar, calomel, sublimate, etc., do not decompose and mercury does not evaporate entirely from demercurized materials. In addition, the performance of such technology and equipment is limited, the technology is energy-intensive, requires a large amount of electricity for the implementation, the use of expensive liquid nitrogen. This method has significant unit disposal costs.

A method for utilization of mercury-containing fluorescent lamps is proposed. It consists in their destruction, separation into cullet, bases, mercury-containing phosphor in air flow using vibration, characterized in that air flow is generated by underpressure 100-10000 Pa, using vibration in the range of 1 ... 10000 Hz, mercury-containing the material crushed to a size of not more than 1 mm is heated in a hermetic volume to temperatures in the range of 600–900 ° C, keeping at a temperature of 600–700 ° C for at least 30 minutes, mercury vapor is condensed in a cooled trap, etc. carrying out all the processes provide a double seal.

The essence of the invention lies in the fact that the proposed technical solution allows for the complete utilization of mercury-containing waste, instruments, mainly fluorescent lamps for metallic mercury, nonferrous metal, glass raw materials and neutral building material. The proposed technology has the best technical and economic parameters.

Carrying out the separation of components in air flow with a pressure difference of 100-10000 pascals ensures the separation of the volatile dust fraction from the solid components of fluorescent lamps, glass and metal bases. When the pressure drop is less than 1 mm Hg, the air flow will not carry away the mercury-containing phosphor, and the creation of a vacuum of more than 1/10 of the atmosphere is impractical due to the increased power of the ventilation and dust removal systems and air purification. In the case of a vacuum of more than 0.1 atm. (10,000 Pa) together with the mercury-containing phosphor will be carried away a large amount of glass that does not contain mercury. The result is achieved within the specified pressure drops and differs in technical characteristics of the dust entrainment. In principle, the technology will work even with large pressure drops, but the power consumption will increase and more glass waste that does not contain mercury by itself will get into the filters. The ratio of mercury-containing phosphor ablation and cullet in the composition depends on the material carried by the air flow. (Table.)

The ratio of mercury content of mercury-containing phosphor and cullet in the composition of the material entrained by the air flow

In the end, the main strategy of the enterprise is to provide production with competent technologies for the demercurization of mercury-containing waste.

Conclusion

Currently, ecology and economics are increasingly intertwined with each other, forming a complex complex of causes and effects. The main elements of greening production are: the use of renewable reserves of raw materials and energy, the development and use of production processes, recycling and recycling of various raw materials and the prevention of pollution. Preserving the environment and conserving its resources are currently high-priority objectives for each enterprise. International environmental management strictly enforces laws and sets high standards. Thus, already in the process of developing our products, the main goal should be: an environmentally friendly design of fluorescent lamps, technical safety and health protection of workers. Smolensk Lamp Factory is thinking about ecology and is responsible for it. The company is making great efforts for the economical use of material and energy resources and is trying to reduce the amount of waste arising in the production process.

Our company in its activities takes into account the long-term guarantee of the natural foundations of people's lives. Three essential factors are put in the forefront, such as economics, environmental protection and social responsibility. The administration develops a conscious attitude of workers to environmental, health and safety issues, and takes all necessary preventive measures to minimize the risks for customers, employees and the environment. The company spreads knowledge in the fields of management and technology in order to avoid the harmful effects of products on the environment and for the economical use of energy and other resources. Already during the development of product samples and technological processes, possible questions regarding the ecology and safety are taken into account.

The impact of economic activity on the environment is characterized by the production of large quantities of pollutants, waste and other factors that lead to changes in natural landscapes, pollution of the atmosphere and natural water bodies.

In this regard, the problem of control of environmental management and environmental protection in each enterprise has become very relevant.

A sensible attitude of people to the environmental consequences of economic activity awakens the need to create new enterprises with an environmental orientation or to appropriate restructuring of existing enterprises that: produce environmentally friendly products; they use environmentally friendly technologies, including recycling acceptable materials and raw materials, etc.

In the first chapter of the course work was considered the environmental safety of the enterprise. For this purpose, the main elements of the environmental management system in Russia, such as: licensing, certification, limitation and certification, carried out in accordance with the requirements of regulatory documentation, are considered, and the legislation of the Russian Federation in the field of environmental safety has been reviewed.

The second chapter analyzes the management of environmental policy and environmental protection at a state-owned enterprise, in particular at the Smolensk Lamp Plant. Next, consider the environmental policy of the enterprise. Also considered the main environmental strategies in the enterprise.

For this purpose, a general description of the enterprise is given, its mission is defined: to meet the needs of customers with modern lighting products in order to fully meet the interests of the management and employees in obtaining stable and growing profits.

Further, the problem area of the enterprise was revealed, which consists in the following: when disposing of production wastes and used lamps at the old installation for lamp demercurization, pollution of atmospheric air, surface and internal wastewater with mercury vapor occurs. In addition, there remains a large amount of waste to be disposed of at a special landfill due to the impossibility of their reuse in production due to high toxicity. All this has a negative impact not only on the health of staff, the environmental situation in the area of the enterprise, but also significantly reduces economic performance due to high environmental charges and the cost of waste disposal (11,694,000 rubles a year).

The resulting waste will have an insignificant effect on the state of the environment and human health if the existing environmental, sanitary and epidemiological standards and rules are observed during their collection, temporary storage and transportation, eliminating the release of the waste and its components to the atmosphere and internal soil horizons, water bodies. All waste must be transported to the place of their organized storage or disposal under separate contracts.

...Similar documents

The concept of environmental safety. Scheme showing the level of environmental safety, depending on the intensity of the impact of a particular environmental factor. The concept of environmental risk, its types. The content of environmental auditing.

abstract, added 10/06/2014

The concept of global environmental safety. Theoretical aspects of environmental safety, the causes of threats threatening it. The main environmental problems of Russia: flora and fauna, the use of mineral resources, the rationale for measures to address them.

examination, added 01/12/2010

The concept and levels of environmental safety. The problem of preserving the resources of the planet. The unbalanced development of nature and society on the planet is the main cause of global environmental problems. The Constitution of Russia as a source of environmental law.

examination, added on 07/29/2010

Characteristic conditions for the occurrence of environmental disasters and accidents. Concepts of absolute security and acceptable risk. Principles for ensuring environmental safety of production. The stability of industrial facilities in emergency situations.

term paper added 07.08.2009

The activities of the state, organizations, legal entities and individuals to ensure environmental safety. Activities aimed at maintaining a balance between the biosphere and anthropogenic pressures. The influence of the environment on the human body.

presentation added on 1/19/2011

Problems of ensuring the environmental safety of vehicles. Analysis of a set of environmental measures aimed at improving the environmental performance of rolling stock and transport infrastructure. Methods to reduce exhaust emissions.

abstract, added 05.08.2013

The organization of low-waste production. Modern methods of preparation and disposal of electroplating wastewater. Methods and apparatus for wastewater treatment. Analysis of environmental safety in the enterprise. The water system of the plant.

term paper, added 11/29/2009

Criteria of environmental safety, its legal support and regulatory levels. Environmental risks: basic concepts, price, management terms and hazard assessment. Global, regional and local levels of implementation of environmental safety.

examination, added 03/18/2010

The legislation of the Russian Federation on environmental impact assessment, its principles and types; powers, rights and obligations of state bodies. Justification of safety equipment and technology. The order of the state environmental review.

training manual added 12/24/2009

Characteristics of the main means of ensuring environmental safety. Conformity assessment of the processes of production, storage, transportation and disposal of products and waste to safety requirements. The main tasks of the state environmental review.

Introduction

1 Theoretical aspects of environmental safety

1.1 the state of the organization of low-waste production

2 Analysis of environmental safety in the company OOO “Specstal design”

Conclusion

References

Electroplating is one of the industries that seriously affect environmental pollution, in particular with heavy metal ions, which are the most dangerous for the biosphere. The main supplier of toxicants in electroplating (at the same time, the main consumer of water and the main source of wastewater) are wash water. The volume of wastewater is very large due to the imperfect method of washing parts, which requires a large flow of water (up to 2 m3 or more per 1 m2 of the surface of the parts).

At wastewater treatment plants, the most common method of neutralizing electroplating is the reagent method, in particular, the precipitation of metals with calcium hydroxide, which does not ensure that the content of heavy metal ions in the effluent is up to modern MPC. The main disadvantage of this method is the large amount of sludge containing toxic heavy metal compounds. The disposal and processing of the sludge produced is a very complicated and expensive production, and in some cases the sludge cannot be recycled. In such cases, the return of chemicals and metals in the production cycle is practically excluded. The main method of neutralization of such wastes is to bury them at special sites, if any. However, most often these sludges are either stored on the territory of the enterprise, or uncontrolledly dumped into ravines, reservoirs, forests, and, at best, at city dumps. Only a part of galvanostriches is used in construction in the production of building materials.

A similar problem is inherent in the production of the plant LLC "ZhBI 1". This company is taking certain measures to change the technology of electroplating (reduction of cyanic pollution). However, implementation is delayed indefinitely due to the need for large capital investments. Therefore, the problem of wastewater treatment remains relevant for the enterprise. This paper addresses the issues of chromium-containing wastewater purification and extraction of valuable components, since chrome plating operations are also planned to be carried out when introducing promising technologies.

The Department of Chemical Technology of the Oak Ridge National Laboratory (Tennessee) proposed a biological method for the isolation of chromium, where pinhead-sized balls obtained from seaweed, which contain about 1 million microorganisms each, are used as a sorbent. Extraction is carried out on the principle of fluidized bed in columns. After saturation, the sorbent is filtered, dried and burned to obtain a concentrate of sorbed impurities. Http://www.masters.donntu.edu.ua/2006/fizmet/klutkina/diss/zac.htm

In the US, a method is proposed for incomplete biological treatment of wastewater containing heavy metal ions and sulfation with their reduction to water-insoluble compounds. The method consists in passing sewage (periodically or continuously) through a porous matrix with microflora, including Desulfovibrio and Desulfotomaculum species. Bacteria of these species in anaerobic conditions convert sulfation into hydrogen sulfide. Hydrogen sulfide forms insoluble compounds with heavy metal ions, which are deposited on the matrix and can be removed. The process should be carried out at a pH from 6 to 11 (preferably in the range from 7 to 10), at a temperature from 0 to 600 (preferably in the range from 12 to 350) and the flow rate of waste water is 820 l / day per 1 m2 of the matrix surface (preferably the range from 86 to 270 l / (day * m2)).

British scientists conducted a study on the behavior of heavy metals in short-term experiments of wastewater treatment in a hydroponic system with a gravel base. Studies have been conducted to remove cadmium, chromium, nickel, copper, and zinc from previously treated wastewater. It was determined that the degree of removal of these metals depends on the exposure time, from 6 to 8 hours, simulating overflow or volley load. The concentrations of metals in the sediment, as well as in the leaves, stems and roots were measured. Greater removal efficiency was observed for chromium, copper, nickel and zinc (up to 70% after 6–8 hours). Chromium was removed from the mixture of all 5 metals by more than 95%. The applied hydroponic system was 12 m long. The addition of heavy metals to wastewater led to a distinct weakening of the culture only in the first 2 to 3 meters. Plants growing farther were healthy and well developed.

1.2 Modern methods of preparation and disposal of electroplating wastewater

The most common method is to convert soluble substances to insoluble by adding various reagents, followed by their separation as precipitates. Calcium and sodium hydroxides, sodium sulfides, ferrochromic slag, iron (II) sulfate, pyrite are used as reagents. In the USA, a method is proposed for obtaining non-hazardous sewage sludge containing heavy metals. The method consists in the deposition of heavy metals with phosphoric acid or its salt. The advantage of this method is that phosphates are much less soluble than the hydroxides and sulfates of the same metals. In addition, phosphates are not amphoteric. The process of deposition of metals includes the following stages:

1. Adding phosphoric acid or its acidic salt to an aqueous solution at the rate of mol of phosphate per mol of heavy metal;

2. Lowering the pH to 3 by adding sulfuric acid;

3. Adding coagulant FeCl3 at a concentration of 0.75-1.5

4. Increasing the pH of the solution to 8.5 by adding calcium hydroxide and obtaining a precipitate comprising coagulated metal phosphates;

5. Sludge dehydration.

The precipitate obtained is little leached. If the aqueous solution contains cyanidions, they are oxidized to stage 1 by adding sodium hypochlorite and sodium hydroxide. Cr (VI) in wastewater is reduced to Cr (III) with sodium metabisulphite between the 2nd and 4th steps. An ionic polymer is used as a flocculant. Also in the USA, a method has been proposed for removing heavy metal ions from industrial wastewater by adding a 1-2% aqueous suspension of FeS2. As a result of the exchange reaction, heavy metals in the form of sulfides are precipitated. Another way to remove heavy metal ions from wastewater, also developed in the United States, involves precipitating them in the form of an alkali or alkaline earth metal tritium carbonate (Na2CS). Preference is given to tritiocarbonate Na, K, Ca; The pH of the solution is adjusted to between 6 and 9. For complete precipitation, tritiocarbonate will be added in a slight excess with respect to the heavy metal content of the wastewater. Pretreatment of wastewater with an oxidizing agent or reducing agent is often required, for example, chromium (VI) is reduced to chromium (III) using hydrazine or sodium metabisulfite. Precipitated heavy metal sulfides are easily separated from water. From the precipitation obtained by known methods, metals are obtained that are reused in production.

In world practice, the effect of high concentrations of heavy metal ions on the efficiency of their extraction by the biochemical method was investigated. Thus, the rate of change in the concentration of hexavalent chromium was determined in glass reactors, strictly maintaining the anaerobic conditions of the process. For the development of sulphate-reducing bacteria, Postgate B nutrient medium was introduced into the reactors. In addition, separate series of experiments were carried out on a pilot plant of continuous action, consisting of a flow type biotank and a settling tank.

Currently, electrochemical methods for the separation of heavy non-ferrous metals from electroplating wastewater are becoming more widely used. These include the processes of anodic oxidation and cathodic reduction, electrocoagulation, electro-flocculation and electrodialysis. All these processes occur on the electrodes while passing a direct electric current through the solution. Studies on wastewater treatment of galvanic production under electrochemical non-equilibrium conditions have established that reduction processes in wastewater occur during the interaction of solvated electrons with hydrated and bound in complex compounds metal ions.

It is shown that the content of Zn, Cu, Cd, Mo, Co in the wastewater after treatment in the conditions of electrochemical irregularity does not exceed, and in some cases significantly lower than the MPC.

Electrocoagulators are introduced in a number of enterprises. Developers: electrocoagulation unit (CSTI, Petropavlovsk-Kamchatsky); installation “Lost” (SRC “Potential”, Rivne); pressure electrocoagulator “Eco” (Trust “Color Water Purification”, Ekaterinburg); electrocoagulator (SRI “Strela”, Tula); electrocoagulator (TsNIIST, Sevastopol), Diode OJSC (Vladimir), etc.

The electrocoagulation unit at Diode OJSC consists of a three-section electroplating bath, a VAKR-1600-12U4 rectifier and an intermediate tank with two pumps for pumping neutralized wastewater to a sump. As the direct current passes through the wastewater in the electrolysis bath in the iron electrodes, anodic dissolution of the electrodes occurs, and the ions of the 2-valent iron that are formed reduce the hexavalent to trivalent chromium ions. At the same time, hydrolysis of iron ions and secondary compounds occurs with the formation of insoluble hydroxides Fe (OH) 2, Fe (OH) 3, Cr (OH) 3, etc. The process is continuous, under a voltage of 12V and a current density of 0.5 - 1 A / dm2. Filtration of waste water is produced on a vacuum filter.

A laboratory setup for purifying water from heavy metals and organic impurities using electrocoagulation using alternating asymmetric current is described.

In Armenia, the Avtogenmash plant has studied the possibility of cleaning the drains of a galvanic plant of precision machines using electrocoagulation using iron shavings. Currently, both industrial plants operate in Kirovokan factories.

Electroflotation methods developed relatively recently allow recycled waste water to be returned to production and recovered valuable components. In this process, wastewater is removed from suspended particles using gas bubbles formed during the electrolysis of water and the use of soluble electrodes. Oxygen bubbles appear at the anode, and hydrogen at the cathode. Rising in waste water, bubbles float suspended particles.

The method provides treatment of galvanic wastewater from heavy metal ions to the maximum permissible concentration, and also removes fats and oils. Experiments are being carried out to extract heavy metal ions from galvanic wastewater using insoluble anodes. The method is implemented in a number of enterprises.

Developers and manufacturers: RHTU them. Mendeleev, JSC "Impulse" (Moscow).

Electrolyzers of the type E-UEK, E-91A, EPU (VPTIEMP), the module MOPV (NITIAP, Nizhny Novgorod), regenerators (TsMI “Kontakt”, Perm) were developed.

In the processes of electrochemical oxidation takes place at the positive electrode - the anode, to which ions give up electrons. Substances in sewage disintegrate completely to form more simple and non-toxic substances that can be removed by other methods. Various electrically insoluble substances are used as anodes: graphite, magnetite, lead, manganese, and ruthenium dioxides, which are applied to the titanium base. The cathodes are made of molybdenum, an alloy of iron with tungsten, an alloy of tungsten with nickel, graphite, stainless steel and other metals coated with molybdenum, tungsten or their alloys. The method is used in many enterprises.

The use of electrolysis until recently has been hindered by the low productivity of devices with flat electrodes. Prospects for solving this problem opened with the development and implementation in practice of fairly simple and reliable electrolyzers with flow-volume-porous fiber electrodes. They allow you to speed up the process of extracting metals by more than 100 times due to the high specific surface area and increased mass transfer coefficient (up to 0.05 - 0.1 m3 / s).

In the USA, a design of an electrolyzer has been developed for the extraction of heavy metals, in which a uniform stream of tiny air bubbles, directed perpendicular to the surface of the cathode, destroys the diffuse electrolyte layer adjacent to the cathode. This dramatically improves the mass transfer in the electrolyte and increases the current efficiency. Also in the USA, an electrolyzer equipped with bipolar carbon steel electrodes is widely used. Electricity consumption is 10 kW per 1 kg of heavy metals. When the content of heavy metals is more than 50 mg / l, the electrochemical treatment is carried out in several stages. The concentration of harmful impurities of heavy metals after cleaning does not exceed for each of them 0.05 mg / l.

There are also electrolytic methods, which include the method of galvanocoagulation.

The methods of membrane separation used in the technology of extraction of non-ferrous metals from the wastewater of electroplating are conventionally divided into microfiltration, ultrafiltration, reverse osmosis, evaporation through membranes, dialysis, electrodialysis. The greatest success in terms of efficiency and manufacturability of non-ferrous metal extraction was achieved using reverse osmosis, ultrafiltration and electrodialysis.

Reverse osmosis and ultrafiltration are the processes for filtering solutions through semipermeable membranes under pressure exceeding osmotic pressure. Membranes pass solvent molecules, retaining solutes. In reverse osmosis, particles (molecules, hydrated ions) are released, the size of which does not exceed the size of the solvent molecules. With ultrafiltration, the size of individual particles is an order of magnitude larger.

Manufactured installations such as UGOS, URZh (NIITOP, Nizhny Novgorod); USOVO-2.5-001 (PO "Tochradiomash", Maikop); DRKI (SBNPO-Biotechmash, Moscow); UMG (Membrany JSC, Vladimir) are difficult to use, are used in rare cases.

Electrodialysis is a method based on the selective transfer of ions through partitions made of ion exchangers (membranes) under the action of an electric current. Usually use packages of alternating anion - and cation-exchange membranes. Ion exchange membranes are permeable only for ions having a charge of the same sign as that of mobile ions.

Despite the obvious theoretical advantages, these methods are not yet widespread in domestic electroplating. The main reason for this is high capital intensity, as well as the fact that mass-produced electrodialyzers have a large inter-membrane distance (2 mm), which leads to an increase in their size, an increase in ohmic losses, as well as a decrease in the unit productivity of the apparatus. Manufactured installations such as EDU, ECHO and others are designed for the desalination of natural waters. Electroplating cases are rare. Developers: TSNTI, VNIIHT, NTTB “Impulse”, etc.

Sorption methods are the most common for the isolation of chromium from electroplating wastewater. They can be divided into three types:

Sorption on activated carbon (adsorption exchange);

Sorption on ion exchangers (ion exchange);

Combined method.

The adsorption method is one of the effective methods for extracting non-ferrous metals from electroplating wastewater. As sorbents, activated carbons, synthetic sorbents, waste products (ash, slag, sawdust, etc.) are used.

1.3 Methods and apparatus for wastewater treatment

There is still no universal method for the treatment of polluted industrial wastewater, which would meet all modern requirements. All known methods of wastewater treatment are divided into the following groups: mechanical, chemical, physico-chemical, thermal, biological (biochemical). Mechanical methods are mainly used as preliminary. They are designed to separate insoluble impurities of various size from water. For these purposes, the following equipment is used: gratings, drum screens, filters, sand traps, sumps, oil traps, oil filters, and traps (Figure 1-2).

Figure 1 - Septic tank :) multi-tiered; b) disc

The sedimentation tanks are the main structures for the mechanical treatment of wastewater used to remove settling or pop-up coarse dispersed impurities. Sludge ponds are also used to remove the above impurities.

Figure 2 - A clarifier clarifier: a flocculation chamber, a settling zone, a tray for collecting clarified water, a central pipe, a tray for draining floating substances, a pipeline to remove sludge

If the impurity is lighter than water, it is removed from the surface of the water, and the septic tanks are called traps.

At present, hydrocyclones are used for mechanical wastewater treatment, requiring significantly smaller areas. Wastewater after mechanical treatment, depending on the composition and requirements imposed on them, is sent to chemical, physicochemical or biological treatment.

Chemical cleaning is used in cases where the release of contamination is possible only as a result of a chemical reaction between the impurity and the reagent with the formation of new substances that are easily removed from the waste water. For such purification, the reactions of oxidation, neutralization, transfer of harmful impurities into harmless ones, neutralization by the method of chlorination, etc. are used. Chemical methods require a large consumption of reagents. In addition, the resulting substances of the reaction must be removed from the wastewater and processed. Neutralization of wastewater has been widely used to remove acids, alkalis, and metal salts from them.

Physico-chemical purification methods are divided into reagent and non-reagent. Reagents include methods in which special substances are used to precipitate and isolate compounds from effluents - coagulants (aluminum and iron salts, ammonia water, etc.) and flocculants (polyacrylamide, synthetic polymers, natural polymers, inorganic substances, for example, active silicic acid) .

Wastewater treatment by the reagent method includes several stages: preparation and dispensing of reagents, mixing them with water, flocculation, separation of flocculent impurities from water.