How to sew a padding mattress. Homemade mattress - sewing, use of natural materials

Any sleeping place requires a mattress. Indeed, for normal rest and proper sleep, the surface must be sufficiently elastic and even. There is a huge selection of such beddings on the world market, but their cost is pretty high and there is not always an opportunity to purchase. A more affordable alternative is a homemade mattress made from a variety of materials. Next, we will consider in more detail how you can quickly and easily sew a mattress at home with your own hands.

Choosing a filler for the inside of the product

It is quite easy to make a mattress for any bed, especially if you have certain cutting and sewing skills. In this case, the main question remains: "Which filler to choose?"

The choice is relatively small. One of the main and relevant options is foam rubber... It is more accessible and has a comfortable texture. Elastic polyurethane foam, popularly foam rubber, is also used in the manufacture of orthopedic mattresses.

Products made from this material can often be found in cots or strollers. Since the main advantages are:

- hypoallergenicity is one of the important criteria for use, especially when it comes to children's health;

- hygroscopicity, foam rubber is able to absorb moisture and does not create condensation. Perhaps this is the main advantage of the material;

- antibacterial - prevents the development, reproduction of various bacteria and mites. It is because of this property that products made of this material are so relevant in medical institutions;

- good ventilation: the structure of the foam rubber has a high porosity, this contributes to the rapid removal of moisture from the product and prevents its accumulation;

- polyurethane has good orthopedic properties, it is sufficiently elastic and provides the necessary fixation of the body on the surface.

However, this material is short-lived and tends to break and deteriorate. But with due regard and manufacture of high-quality materials, the product can serve for a long time, fulfilling its functions.

Another filler that is less popular today is cotton wool.

It used to be more relevant to use, especially as fillers for mattresses, blankets and other textile accessories. However, it is not a very good option for these purposes. Cotton wool has a fairly good primary porosity, but it is almost impossible to keep it in this form. Cotton fibers quickly lose their elasticity, and it becomes knocked down and hard.

How to sew any mattress with your own hands quickly and easily

Foam rubber can be purchased at any construction or textile stores. They are sold in rolls or sheets. You can also choose a certain thickness, which greatly simplifies the work. For example, to make children's mattresses for a crib or a stroller, foam rubber is used 2-4 or 5-6 cm thick. An adult body needs at least 13 cm thick.

Manufacturing technology. Before you start making a mattress, you should decide on the required size. Measure all sides accurately.

Then cut the desired size from the foam rubber.

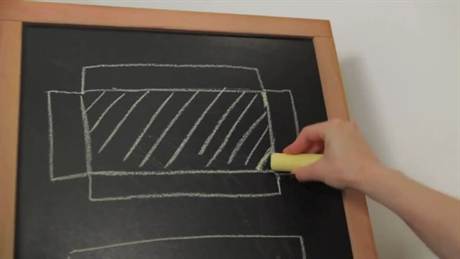

Now you can start sewing a mattress cover - a cover. Most often they use satin or calico. You need to cut two rectangles of the same size.

You should add up the width and length of the foam rubber and add a few centimeters to the allowances, then just cut out the material.

At the next stage, it is necessary to connect the material, this can be done using a sewing machine, it is difficult to do it manually, and it takes a long time. After stitching the cover on three sides, pull it over the foam, then just sew the remaining hole. Or sew in a small zipper in advance so that later it will not be difficult to wash the mattress topper.

If the mattress is small, it is better to zigzag along with the base. Wash the same together, the material dries quickly.

If a sufficiently massive mattress is made for an adult sofa, then you should take a solid base, and not trim. To obtain the required height, several sheets should be glued together.

In this case, it is very convenient to combine several layers with each other. You will get an orthopedic mattress by adding coconut bark to the layers.

The mattress is a soft bed, which can be with or without a frame. It can be of several types, but in everyday life only two are most often used - spring and stuffed. In our article, we will talk specifically about spring types, which, in turn, are divided into two types.

- With continuous weaving of springs called Bonnel

- With independent blocks of springs that are considered orthopedic

The first type is more common. It is inexpensive, therefore it is very popular. The second type has great capabilities, but it also costs more. In any case, this subject of discussion consists of a spring block or shock-absorbing parts, a rigid layer, a cover and a filler. The latter can be both soft and hard. As for the upholstery, it is better that it be made of natural fabric.

Products of this design can be found in any house or apartment. Many consider them obsolete, but this does not diminish their popularity in the least. And all because of the low cost. Mattress cushioning parts are made from materials such as hardened high carbon steel. They are connected to each other using a wire. The main drawback of this type of bed elements lies in the fact that they have extremely low orthopedic properties. This is because when you lie down on the bed, not one spring responds, but all at once.

Mattress with independent springs

This type is distinguished by higher levels of comfort. Springs for them are made of the same steel, but their diameter is smaller and the number of turns is larger. These elements often resemble a cylinder in shape. Sometimes their edges can be narrowed. The advantage of this type is that the springs are not fixed to each other. This improves the orthopedic effect. After all, each spring reacts to pressure independently of the others.

When a mattress needs repair

The quickest thing is that the outer covering of spring mattresses becomes unusable. But the fillers for them are made of high quality materials that have a long service life. The average service life of a spring product is fifteen years. When it loses its functional parameters, then you should not immediately throw it away. It is not so difficult to bring the product into proper form. There are several reasons why the mattress is in need of urgent restoration methods.

- Damage to the skin

- Deformation of flexible elements

- Filler wear

- Violation of construction

But this list can be expanded with a more scrupulous examination of this item. To repair a spring mattress with your own hands, there is no need for special knowledge and skills. You only need to carefully follow the advice of more experienced professionals.

Stages of the recovery process

The work of bringing an old mattress back to life can be divided into several main stages.

1) Disassembly

2) Cleaning

4) Bringing damaged parts into the correct position

5) Reliable strapping of shock-absorbing parts

6) Checking parts that have been repaired

7) Product casing

Materials and tools

To return a worn product to its proper appearance, you must use the following materials and tools.

1) New decorative cladding

2) Lining fabric

3) Padding material

4) Hammer

6) Furniture stapler

7) Wooden lath

8) Strong yet flexible lace

Stage 1. We clean and inspect the subject of repair

In the process of active use of the product, quite a lot of small debris, that is, dust, collects inside it. That is why experts recommend disassembling on the street. If this possibility is not considered, then you will need a vacuum cleaner. With its help, all surfaces of the spring product must be thoroughly cleaned. It is advisable to remove all furniture and carpets from the room in which the repair process will take place. As a last resort, cover everything in the room with oilcloth or similar material. Place the product on four sturdy benches with the decorative paneling at the bottom. This will allow you to approach the subject of repair from all sides. Pull all fasteners out of the mattress very carefully. After that, you need to remove the upholstery and seal. The fabric that covers the springs must also be removed. Clean all elements with the utmost care.

Stage 2. Inspecting the details

You must free the springs from the straps. After that, you can start pulling out the nails from the base. It is them that the manufacturers use to secure the straps. Now you need to bring all the spring elements to a vertical position. Be careful! All springs must be of the same height. All parts that are loose or come off altogether must be securely attached to the slats with nails. Note that if the mattress springs are attached with straps, then these straps must be removed. And the spring parts are fixed using nails.

In general, all straps in our facility must be disposed of. It will be better if you use regular slats instead. The latter should have a length equal to the width of the mattress. To fix them, you need to make preliminary markings on the body.

Stage 3. We fix the slats

Before you get rid of the frame fastening tape, mark the places where the tape was placed on its surface. After that, you need to carefully remove the nails and remove the old straps. Now you need to prepare the slats of the desired size. Then, according to the markings made, you must carefully cut out the grooves for them. After that, the slats are very carefully nailed from both sides to the base. Then you can set the spring elements to their previous position. Fix them with studs if necessary. The latter are folded on both sides to ensure high fastening reliability.

Stage 4. We tie the springs

When the springs are securely fixed to the frame, you can start strapping them. You need to drive nails against each row of springs. You need to fold them into hooks. At this stage it was the turn of the laces. It is with their help that the strapping will be carried out. First, start with a cross row. First, you must tie the outermost springs to the hooks. After that, tie the entire longitudinal row in the same way. In the process, the lace is also attached to the transverse laces. Finishing the process, you must sew diagonally. When the tying process is completely finished, you should bend the studs all the way to the base.

Stage 5. We proceed to the cladding

Before starting the process of covering the mattress with lining, you must make sure that all important parts are installed correctly. When everything is checked, you can take up the sheathing. To do this, use a furniture stapler. Place a gusset in the corners to provide additional protection. Then fasten the rollers to the backing base. They can be made from the material used for the seal. Ensuring reliability, the seal must be attached to the lining in several places at once. On top of all this, decorative fabric is stretched, which is firmly fixed with the same stapler. Remember to gently pull up the edges of the fabric to avoid holes or creases.

As for the orthopedic spring mattress, resting on it is not only comfortable, but also useful. But such a product also does not last forever and can wear out. But don't rush to buy a new mattress. It is possible that the old one can still be renovated. The repair of the orthopedic product is carried out in the same way as the usual one.

That's all. A product updated and repaired in this way will serve you for many more years. The mattress repair process does not require a lot of money from you. But the acquisition of a new one can cost you a pretty penny.

How to extend mattress life

It is clear that one mattress will hardly be enough for you for a lifetime. Over time, he will still need repairs. But we note that the moment when there will be nowhere to go, you can postpone a very decent period. To do this, you need to use this piece of furniture with maximum care. Try to avoid situations that could damage it.

- You need to buy a mattress according to your weight

- Don't let kids jump on the bed \\

- Never eat or drink while lying on bed

- Be sure to let the item dry and ventilate in the fresh air at least once a year

- The mattress should only lie in the places designated for it

- To prevent the decorative upholstery of the mattress from getting dirty, use additional removable covers

If you carefully follow all these simple rules of operation, then your mattress will serve you for many years, and it will take a long time to repair it. This ensures that your sleep will be healthy and sound.

The article was prepared with the help of specialists from the "Sleep Laboratory".

Website: http://sleep-lab.ru/ - Online store of mattresses.

Video. Repair of a spring mattress

Video. DIY mattress repair and hauling

To increase efficiency, general well-being, the body needs quality rest. The most important aspect of a good rest is good sleep. What can help improve sleep quality? First of all, a comfortable sleeping place.

A comfortable mattress gives you sound sleep and well-being. Therefore, you should pay special attention to your mattress.

The right mattress will help you sleep well. Manufacturers offer an extensive selection of all kinds of materials with various fillers. Models range from budget to premium. To take into account all individual needs, you will have to pay a large sum.

Finding a comfortable, quality mattress at a low price can be tricky. Sometimes it's easier to make your own mattress.

If the amount is too large for you, there is a way out - to make a mattress with your own hands. Such a solution will allow you to save money, create an ideal sleeping place for yourself, thereby ensuring a healthy, sound sleep.

A self-made mattress can be no worse than an analog from the manufacturer.

There are several types of mattresses that you can actually make yourself. These include:

- foam rubber;

- orthopedic;

- from the pillows.

With your own hands, you can create any mattress to your taste: even from ordinary foam rubber, even from pillows.

If you have an old worn-out mattress - just renovate it, it's even cheaper!

An old mattress can be easily turned into a new one - you just have to properly repair it and replace the cover!

Foam rubber (polyurethane foam, polyurethane foam) is perfect as a filler, it is cheap and durable. There are many varieties of foam rubber. They differ in their quality characteristics: density, elasticity, rigidity.

The easiest way to make a mattress is from foam rubber. Any suitable material thickness can be selected.

As a filler, a soft, elastic foam rubber is ideal, capable of quickly recovering its original shape after use. The quality of PU foam is determined by its density. The filler should have a density in the range of 25 to 40 kg / m3. For the manufacture of the frame, foam rubber with a higher density is required.

Foam mattress is the easiest and most convenient to manufacture. You don't need special knowledge to do it.

When choosing foam rubber, it is imperative to take into account the product labeling, choose a product with the designations EL (high rigidity, load up to 100 kg inclusive, low price; service life 5 years), HR or VE (have high air permeability, elasticity, soft enough, service life from 10 years old).

It is important to choose the right thickness and density of the foam rubber for the future mattress, as well as pay attention to the marking.

Before you start working directly, please note that for permanent mattresses you will also need spring blocks, for portable ones - only PU foam.

In order to make a foam mattress with your own hands, you will need:

- glue - you will need a special one for gluing foam rubber (it is not recommended to save on glue composition, cheap brands can be harmful to health);

- dense foam rubber - the basis of the frame, inside which soft PU foam (EL, HR or VE) will be located;

- fabric for sewing the cover.

To make it, a standard set of tools will do: tape measure, ruler (for measurements), knife, scissors. The quickest way to make a cover is on a sewing machine, but you can get by with a thread and a needle if there is none.

Prepare the necessary tools to make a foam mattress with your own hands.

To understand how to make a mattress with your own hands, use the step-by-step instructions.

- Decide on the size.

- Assemble the frame. Its purpose is to give the product the desired shape. Use high density polyurethane foam (average width 7-8 cm). Cut the bars of the required size, place them on a flat surface, generously grease with special glue at the joints.

- Place the filler in the finished frame (use a solid sheet of foam rubber up to 15 cm thick), having previously cut a piece of a suitable size. If you cannot find thick polyurethane foam, take thin sheets (<5 см) и склейте их между собой.

How to make a mattress with orthopedic properties

To maintain the tone of the musculoskeletal system, an orthopedic mattress is required. The decision to make a regular orthopedic foam adds a few extra steps to the filling process.

You can also make an orthopedic mattress with your own hands. This will require different layers of filler.

In the inner part of the finished frame, foam rubber and other materials are placed alternately in layers, it is better to use struttofiber or coconut coir (they control the rigidity of the product, the smaller the layer, the softer), the layers must be carefully connected using an adhesive composition, distributing it over the surface.

Another way is to use spring blocks instead of foam rubber to increase strength, but this is more laborious and expensive.

A more difficult option is to make a mattress with spring blocks with your own hands. It will take more time and cost.

The fastest, easiest and most affordable way to create a sleeping place is a pillow mattress. Ideal for children to play, mobile, compact, can be laid on the floor, used as a chair or as a comfortable bedding.

A pillow mattress is a great option for decorating a child's room. Making these mattresses is easy.

Necessary materials:

- Several pillows (quantity, size are chosen at your discretion);

- Linen or pillowcases;

- Scissors;

- Needles and thread (sewing machine).

It takes very little time to create a mattress from pillows. You just need to choose the right material and prepare several pillows of the same size.

The product is created in two ways:

- Arrange the required number of pillows in a row, measure the total length. Multiply the resulting number by 2.2 (the pillows will completely fit into the fabric). Fold the cut in half and sew (sew) the pillow sections. Place the pillows in the finished sections, then sew the edges (so that the pillows do not fall out), cut off the excess fabric.

- Take the pillowcases, position them so that the holes are on one side, sew together, then place them inside the pillow (if desired, the holes in the pillowcases can be sewn up).

Pillow mattresses not only fit perfectly into the interior, but are also suitable for compact storage in a closet.

How to remodel a stationary mattress with your own hands

Over time, any thing loses its original properties, wears out. Dents appear in mattresses, springs burst, cover breaks.

What to do with a worn-out mattress if it is a pity to throw it away? You can give it to specialists or repair it yourself.

You can get rid of these problems by buying a new one (which is quite expensive), or reconstructing the old one.

Even a sprung mattress can be refurbished without assistance, although this can be quite laborious.

You will need:

- Filler.

- The cloth.

- Thread, needle.

- Scissors, knife.

- If necessary: \u200b\u200bslats, springs, twine.

- Hammer, large nails, stapler, staples.

Prepare the necessary tools for the reconstruction of the mattress and follow the instructions.

Further actions depend on the degree of wear.

- Lightweight. Open the upholstery and assess the integrity of the springs. Replace some of them, pull the other with twine. Change filler (cover if desired).

- Labour intensive. You will need independent spring blocks of the correct size. Lay the blocks vertically, paying attention to the level of the springs (should be the same). Attach the lower part to the slats of the same size. Drive in nails from the end side of the berth (adhere to the level of the spring rows).

You will have to tinker with a spring mattress much longer. But these mattresses can also be repaired by yourself.

When finished, tie the springs with strong twine. Start with a cross row, continue along and finish with a diagonal stitching. Cover the top with a thick cloth, on it - the desired filler (synthetic winterizer, foam rubber, etc.). The last step is upholstery, fix the material with a furniture stapler.

Follow the simple instructions and you can easily repair your mattress without specialists!

Cover sewing

An obligatory attribute of any mattress is a cover. Sewing the mattress topper will not take much time, the technology is simple and straightforward.

Sewing a mattress topper with your own hands is not as difficult as it might seem at first glance. Find the right material and just follow the instructions.

Materials for work:

- Any thick fabric.

- Rubber.

- Safety pin (English).

- Measuring tape, pencil, ruler.

- Sewing machine.

Measure the length, width of the mattress, the height of the side. You can draw a pattern on a piece of paper. The cover material must completely cover the top and side edges. Remember to set aside 15 cm on each side.

Measure the mattress carefully, keeping in mind the required spacing and mattress height. This will determine how correctly the cover will sit on the mattress.

Place the fabric on the mattress, carefully folding the corners, secure with a pin. Carefully remove the canvas, sew the corners on a typewriter. On the wrong side, fold the fabric that has been set aside and sew a hem (just wide enough to thread in the elastic). Thread the elastic through the seam. The cover is ready.

Sewing a mattress cover takes a little time, and such a mattress topper looks no worse than a store one!

How to shrink your mattress at home

In some cases, it may be necessary to redo the mattress, for example, its size may not fit the bed, it may be too high.

When the old foam mattress does not fit the new bed, the easiest way is to trim it

If there are no springs in the product, the task is extremely simple - cut the seams and remove unnecessary filler material. Carry out the work as carefully as possible. After removing the excess, sew the seams.

You can easily reduce the size of the mattress yourself. The main thing is then to carefully sew up the product.

If springs are present, the extra spring block will have to be removed to reduce the height.

Conclusion

Making a mattress with your own hands is a very simple task, it is suitable for lovers of manual labor. All the necessary materials are widely available, inexpensive, and the manufacturing technology is straightforward.

With step-by-step instructions at hand, you can sew on your own a mattress of any complexity and for any budget.

As a result, you get an “ideal” sleeping place that fully meets your requirements and wishes, save money, and provide yourself with a healthy, sound sleep.

Video: DIY mattress - do it yourself mattress FOR SO

The prices for orthopedic mattresses may seem quite high - people want to sleep on good-quality and comfortable mattresses, but not everyone is ready to pay big money for this.

What to do in such a difficult situation? There are three ways out:

- Purchase a similar mattress from a little-known manufacturer;

- Buy inflatable orthopedic mattress;

- Make an orthopedic mattress with your own hands.

Is it really that beneficial?

By purchasing a mattress from a little-known manufacturer, we get at our disposal a product that is not much different from the products of famous brands. Large manufacturers spend a lot of money on advertising and promoting their product, incorporating advertising costs into the price of mattresses. Little-known companies work, as a rule, in local markets and do not aggressively promote their products - therefore, prices for mattresses are lower.

The disadvantage of this method is that some little-known companies produce extremely low-quality mattresses that cannot compete even with the cheapest models from well-known brands.

Having made an orthopedic mattress with our own hands, we will get a certain benefit. The raw materials are cheaper than the finished mattress, and we will hardly have any additional costs. Depending on the cost of materials, we we can save up to half the cost of the finished mattress... Let's figure out what we need to make an orthopedic mattress with our own hands.

In order to make an orthopedic mattress on our own, we will need raw materials - the main budget will be spent on their purchase. We will make a springless mattress, since it will be quite problematic to purchase blocks of independent springs, and classic spring blocks will not add orthopedic properties to our mattress.

To make a mattress we need:

- Thick polyurethane foam for lateral support;

- Main filler;

- Dense material for making a cover.

Dense polyurethane foam, laid along the edge of the mattress, will act as a retaining box. Thanks to him, the mattress will keep its shape well. And in the middle of the mattress there will be a filler.

As a filler, we can choose all the same polyurethane foam. It is advisable to get a single piece, suitable both in thickness and in dimensions of the sides. If there is a desire and opportunity, you can try to look for coconut fiber, laying it in turn with polyurethane foam. The result is a mattress of increased rigidity that is useful for the spine. We can also design a mattress with different firmness of the sides - on one side there will be coconut coir, and on the other - polyurethane foam.

Together with polyurethane foam, we can use dense struttofiber material. It has an interesting structure with vertical fibers and provides decent support for the spine. This material should be placed on top and bottom, and in the middle we can lay polyurethane foam or a mixture of polyurethane foam with coconut boards.

As for the cover, here you should give preference to dense natural fabrics. For example, it can be coarse calico or natural linen.

Filling materials are the hardest to obtain - this will be the hardest part of the mattress manufacturing process.

We start making a mattress

Making an orthopedic mattress with our own hands, we need to prepare the tools:

- Sewing machine;

- Roulette;

- Scissors and a sharp knife;

- Glue.

We need a sewing machine for sewing a cover, a tape measure is needed to measure materials, and we will cut our fillers with scissors and a sharp knife. As for the glue, it is necessary for gluing the individual layers of fillers - here we need some kind of glue that is safe for health and does not emit harmful toxins and odors. Consult a furniture repair shop for advice on this matter.

Before starting work, you need to measure the dimensions of your berth - they will be equal to the size of our future mattress. After that, we proceed to assembling the frame made of dense polyurethane foam, which will provide support for the filler from the sides and help the mattress to keep its rectangular shape. For this we use dense polyurethane foam with a thickness of 50 to 100 mm. The approximate thickness of the mattress should be 14-15 cm - less thickness will not add convenience.

The next step is to lay the filler. If you are lucky enough to get a solid piece of polyurethane foam of a suitable thickness, measure the dimensions of the free space in the resulting frame, and then cut out the corresponding piece of polyurethane foam - here you will need a sharp knife, for example, a clerical or boot knife.

If you decide to use a combined filler, then separate sheets of stuffing will need to be glued together so that the finished mattress is dense and does not "walk" under the weight of the person lying on top. For this we use safe, odorless glue, otherwise it will be simply impossible to sleep on the mattress.

Did you get only thin polyurethane foam? It doesn't matter - glue the individual layers into a single structure using glue. But do not try to use scraps and small pieces of polyurethane foam for stuffing - the base of the mattress should be closer to the monolith, and not consist of miniature elements like a cheap foam model.

After the stuffing is ready, we place it in our frame and start sewing the cover. To do this, we take measurements of the resulting mattress and measure two pieces of fabric - do not forget to leave a margin for the seams and the thickness of the side parts (approximately 3 cm is allocated for the seams on each side). The cover should turn out to be quite tight - it should be put on the filler with a frame with some difficulty so that the mattress turns out to be strong and resilient. The seams of the cover must remain inside.

Only natural fabrics and thick threads are used to sew the cover. Natural fabrics will ensure the absence of allergies and irritations, and strong threads will ensure the durability of the produced cover. It is possible that you will need someone's help to stretch the cover. After stretching, the cover needs to be sewn up (if necessary, we sew a zipper on one side).

By the way, this will be a permanent, non-removable cover. Therefore, it is recommended to sew a removable cover over it, equipped with zippers along the perimeter or on two adjacent sides - at any time this cover can be removed and sent to the wash. If you are too lazy to bother with another cover, buy a mattress topper, but in this case you need to be prepared for additional costs - the cheapest way is to sew the cover yourself.

After the mattress is ready, you need to give it a little air out in the open air - for this you can take it to the balcony or loggia, where unpleasant odors will disappear from it.

In conclusion, here are some tips:

- Accurately measure the dimensions of the components and the dimensions of the berth - the mattress should be tight, not falling apart. Yes and in its place, it should lie tightly, without moving to the sides;

- Do not make mattresses from foam rubber and batting - these materials will not allow you to create a mattress with orthopedic properties and anatomical effect;

- Do not use synthetic fabrics for sewing covers - they can cause allergic reactions and irritation;

- Do not use Bonnel spring blocks for self-production of orthopedic mattresses - it is almost impossible to create normal mattresses with orthopedic properties on their basis.

None of us can imagine how one can indulge in sleep and rest on bare ground or on a hard wooden bed. Modern man is accustomed to the fact that his body should lie on a soft base of one kind or another.

Most of the time, we sleep on a mattress. Today we will reveal the secret of how you can make a mattress using various natural or artificial materials with your own hands.

If back in the last century the basis of this product was mainly made up of various fillers of plant or animal origin, then in a modern mattress the main component is a spring. It is she who provides comfort and convenience.

All kinds of this wire element can not be found in modern beds. Each manufacturer is constantly striving to prove that it is his development that most fully takes into account the peculiarities of human forms and allows the body to take the most advantageous position in terms of rest.

And there are more and more enterprises producing these products for the modern market. The most responsible of them really spend a lot of money on studying the peculiarities of the operation of springs of various shapes, select their optimal ratio per unit area, experiment with various artificial and natural fillers.

Making a mattress using natural materials

At the same time, one of the main negative aspects associated with limiting the consumption of new generation mattresses is their rather high price. We bring to your attention a budget version of the product, which can be made by hand for a private house or summer cottage, using both traditional and not quite traditional, or materials forgotten over time.

We start the process of making a mattress with a fabric base - a cover of a certain size, which we will fill in the future. A sufficiently strong fabric must be prepared for sewing the casing. Moreover, it can be either traditional white or any other color, since the operation of the mattress is often carried out using bed linen.

From the prepared fabric, make a pattern for the details of the future homemade product. It will consist of two completely identical rectangular parts, the dimensions of which will depend both on the size of the people who will use the product and on the type of bed. Recall that modern stocks are divided in width into single, one and a half and double. Based on this, cut out the upper and lower half of the mattress. In addition to them, prepare one or more narrow strips, the width of which will determine the height of the product, and the total length should not be less than the perimeter (the sum of the lengths of the sides) of rectangular parts.

The cut parts must be connected together. To do this, first grind them with pins,

sweep and sew with high strength threads. It is best to first perform this operation manually, securely fixing the parts to each other in order to avoid their mutual displacement.

This is necessary to achieve high quality work. A strong thread will help to achieve maximum wear resistance of the joints of the fabric and the entire product as a whole. Of the most commonly used, it is possible to recommend using an underwear seam for these purposes.

Don't try to put all the pieces together. Remember to leave one short side unstitched. You will need it to fill the mattress. It is best to make a neckline in this part, which can be locked with a zipper or buttons.

Traditionally, the mattress assumes the most lush shape possible. To achieve this goal, a large list of different materials can be recommended for use. Remembering the fairy tale about the princess and the pea, try filling our product with down or feather. Taking into account its required quantity and the price of such materials, the cost of such a product will many times exceed the cost of the most expensive factory product. Instead of poultry products, you can use another natural material - a livestock product - sheep wool. It is also capable of retaining volume and has very high heat-retaining properties. Such a product can be made only for the winter cold period and in the presence of a sufficient amount of wool.

We suggest paying attention to one, perhaps the cheapest, but not the worst material for stuffing a homemade mattress - hay. It is a quality dried young herbs with an unforgettable natural aroma. And if you add 5-10% of dried mint, hop cones and other soothing plants to its composition, sleeping on such a product will bring you an unforgettable rest.

The choice of filler for the mattress

For stuffing the cover, we recommend using a large piece of clean plastic wrap, on which we lay the future mattress and gradually tamp the dried herbs into it. Using straw or mature grass for these purposes is not advisable, as tough stems can ruin the whole experience of rest.

It is better to carry out work on padding the mattress in work gloves and clothes with long, buttoned sleeves. Otherwise, small scratches cannot be avoided, many of which have appeared on your hands.

If there are agricultural processing enterprises in the immediate vicinity of your location, you can fill the mattress with, for example, buckwheat husks or other similar material.

Instead of a natural filler, you can also use chemical products in the form of a recently appeared substitute for wool - synthetic winterizer. It is lightweight, soft and non-allergenic.

After completing the above steps, you will become the owner of a unique product that will give you an unforgettable vacation and arouse the interest of your friends and acquaintances.

Dear readers, comment on the article, ask questions, subscribe to new publications - we are interested in your opinion :)