Ttk on the device for coating waterproofing. TTK

TYPICAL TECHNOLOGICAL CARD (TTK)

PERFORMANCE OF WATERPROOFING WORKS USING MATERIALS OF THE PENETRON SYSTEM

1. SCOPE OF THE "PENETRON" SYSTEM MATERIALS

The materials are used for the construction and restoration of waterproofing of existing and in the stage of construction of monolithic and prefabricated concrete and reinforced concrete structures of all categories of crack resistance grade not lower than M100.

Some examples of structures where materials of the PENETRON system are used:

Hydraulic structures:

Tanks (open, bunded, etc.)

Pools (indoor and outdoor)

Elevator shafts

Vegetable pits, etc.

Industrial and agro-industrial facilities:

Industrial premises

Cooling tower pools

Vaults

Chimneys

Concrete structures exposed to corrosive effects, etc.

Civil Defense and Emergency Situations:

Fire tanks, etc.

Energy complex facilities:

SNF spent fuel pools

Pumping stations

SNF storage facilities

Fuel trestles

Cable tunnels

Concrete structures exposed to radiation, etc.

Transport infrastructure facilities:

Tunnels (road, rail, pedestrian, etc.)

Subways

Elements of bridges and roads, etc.

General information

PENETRON material system

Typical nodes

1. Existing monolithic construction.

2. Waterproofing of communication entry points, hollow-core slab ceilings.

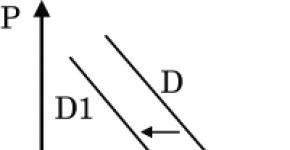

3. Device for horizontal waterproofing.

4. Waterproofing of concrete block structures.

5. Waterproofing on a brick wall (from the inside).

6. Monolithic construction made of concrete with the addition of "Pentron Admix".

7. Waterproofing on a brick wall (outside).

8. Cutting off capillary suction in case of damaged waterproofing.

2. ORGANIZATION AND TECHNOLOGY OF WORK PERFORMANCE

2.1. Preparation of the concrete surface before using the materials of the "PENETRON" system

Clean the surface of concrete from dust, dirt, oil products, cement laitance, efflorescence, shotcrete, plaster layer, tiles, paint and other materials that prevent the penetration of active chemical components of the PENETRON system materials. Clean concrete surfaces with a high pressure water jet or other suitable mechanical method (for example, a metal bristle brush). Treat smooth and sanded surfaces with a weak acid solution and rinse with water for an hour. Remove excess water formed on a horizontal surface after working with a high-pressure water jet system with a special vacuum cleaner.

Along the entire length of cracks, seams, joints, junctions, abutments and around the input of communications, make the punches "P" -shaped configuration. Clean the slabs with a metal bristle brush. Remove loose concrete layer (if any).

Cut cavities of pressure leaks with a jackhammer to a width of at least 25 mm and a depth of at least 50 mm with an inward expansion (if possible in the form of a "dovetail"). Clean the inner cavity of the leak from loose, exfoliated concrete.

Attention! Before applying the materials of the PENETRON system, it is necessary to thoroughly moisten the concrete until the concrete structure is completely saturated with water.

2.2. "PENETRON": preparation of the composition

Mix the dry mixture with water in the following proportion: 400 grams of water per 1 kg of PENETRON material, or 1 part of water per 2 parts of PENETRON material by volume. Pour water into the dry mixture (not vice versa). Mix for 1-2 minutes by hand or with a low speed drill. The type of prepared mixture is a liquid creamy solution. Prepare an amount of solution that can be used within 30 minutes. Stir the solution regularly during use to maintain its original consistency. Re-adding water to the solution is not allowed.

TECHNOLOGY OF WATERPROOFING WORKS USING PENETRON SYSTEM MATERIALS

Before applying the materials of the "PENETRON" system, it is necessary to prepare the concrete surface in accordance with clause 2.1.

2.3. Waterproofing of concrete structural elements

Attention! Before applying the PENETRON system materials, the concrete must be thoroughly moistened.

Vertical and horizontal (including ceiling) concrete surfaces in order to eliminate and prevent capillary filtration of water must be treated with a solution of "PENETRON" material.

After surface preparation (p.2.1) apply a solution of PENETRON (2.2) in two layers with a synthetic fiber brush or using a mortar pump with a spray nozzle. Apply the first layer of PENETRON to damp concrete. Apply the second layer on a fresh, but already set first layer. Moisten the surface before applying the second layer.

Attention! The application of the PENETRON solution should be carried out evenly over the entire surface, without gaps.

Internal waterproofing on a brick wall

Overlapping of hollow core slabs

External waterproofing on a brick wall

Monolithic construction

(existing)

Monolithic construction

(under construction)

Construction under construction ":

When concreting, use concrete of design strength with the addition of "PENETRON Admix" 1% by weight of cement.

Concrete block construction

Waterproofing of the underground part of the structure

Construction under construction

Waterproofing of technological openings after removing the formwork

Existing design

3. REQUIREMENTS FOR THE QUALITY OF PERFORMANCE OF WORKS

Methods and means of quality control of work performed

Work on the installation or restoration of waterproofing of concrete and reinforced concrete structures using materials of the penetrating action of the Penetron system must be carried out in strict accordance with the "Technological Regulations for the Design and Execution of Waterproofing and Anticorrosion Protection of Monolithic and Precast Concrete and Reinforced Concrete Structures".

The main method of quality control of the work performed on the installation or restoration of waterproofing of concrete and reinforced concrete structures is to measure the increase in water tightness by an accelerated method of non-destructive testing with a device such as "AGAMA" in accordance with GOST 12730.5-84 "Concrete. Methods for determining water resistance". Measurements must be carried out before the start of waterproofing works and after their completion (but not earlier than 28 days after the application of Penetron materials).

An additional method of quality control of the work performed can be the determination of the increase in compressive strength by the accelerated method of non-destructive testing by the OMSh-1 shock pulse device in accordance with GOST 22690-88 "Concrete. Determination of strength by mechanical methods of non-destructive testing".

4. MATERIAL AND TECHNICAL RESOURCES

1. Equipment:

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> high pressure water jet apparatus (voltage - 380 V; power - 8400 W; pressure - 20-230 bar);

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> puncher (voltage - 220 V; power - 1000 W; frequency - 900-2000 bpm);

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> cutter (voltage - 220 V; power - 2200 W; frequency - 6000-10000 rpm);

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> industrial vacuum cleaner (voltage - 220 V; power - 1100 W);

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> drain pump (voltage - 380 V; power - 6000-8000 W);

Concrete mixer "href =" / text / category / betonomeshalka / "rel =" bookmark "> concrete mixer (voltage - 220 V (380 V); power - 1100 W - 2200 W);

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> compressor (voltage - 380 V; power - 2200 W; productivity 250 l / min ).

2. Tools:

maklovitsa ";

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> metal spatula;

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 height = 15 "height =" 15 "> hammer;

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> diamond disc for reinforced concrete;

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> chemical resistant rubber gloves;

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 height = 15 "height =" 15 "> respirator;

https://pandia.ru/text/80/218/images/image013_32.gif "width =" 15 "height =" 15 src = "> thick fabric workwear;

Labor safety in construction ", Part 2.

When cleaning surfaces with acid, wear protective goggles, rubber gloves and heavy-duty clothing.

Work on mixing and applying solutions in rubber gloves and goggles, avoid contact of materials with eyes and skin, in case of contact, rinse with water.

When performing waterproofing work, it is necessary to provide for measures to prevent the exposure of workers to the following hazardous and harmful production factors associated with the nature of the work:

Increased dust and gas content in the air in the working area;

Increased or decreased temperature of surfaces of equipment, materials and air of the working area;

Location of the workplace near a height difference of 1.3 m and more;

Sharp edges, burrs and roughness on the surfaces of equipment, materials.

In the presence of hazardous and harmful production factors mentioned above, the safety of waterproofing works must be ensured on the basis of the implementation of the following labor protection solutions contained in the organizational and technological documentation:

Organization of workplaces with an indication of methods and means for providing ventilation, fire extinguishing, protection from thermal and chemical burns, lighting, performing work at height;

Special safety measures when working in closed rooms, apparatus and containers.

Workplaces for performing waterproofing work at a height must be equipped with paving equipment with fences and ladders for climbing on them, in accordance with the requirements of SNiP 12-03-2001 "Labor safety in construction", Part 1.

6. TECHNICAL AND ECONOMIC INDICATORS

Consumption of "PENETRON" material in terms of dry mixture when applied in two layers is from 0.8 kg / m to 1.1 kg / m. PENETRON "from 0.8 kg / m https://pandia.ru/text/80/ 218 / images / image014_35.gif "width =" 13 "height =" 28 "> possibly on uneven surfaces with significant cavities or dents.

BIBLIOGRAPHY

SNiP 3.03.01-87. Bearing and enclosing structures.

SNiP 3.04.01-87. Insulation works and finishing coatings.

SNiP 12-03-2001. Labor safety in construction. Part 1. General requirements.

SNiP 12-04-2002. Labor safety in construction. Part 2. Construction production.

SNiP 12-01-2004. Organization of construction.

SNiP 23-02-2003. Thermal protection of buildings.

Technical conditions "Mixes dry waterproofing dispersed systems" PENETRON "TU 5745-001-77921756-2006.

Specifications "Waterproofing pad" Penebar "TU 5772-001-77919831-2006".

SNiP 2.03.01-84. Concrete and reinforced concrete structures.

SNiP 2.03.11-85. Corrosion protection of building structures. NIIZhB.

SNiP 2.06.01-86. Hydraulic structures. The main provisions of the design.

GOST 310.3-76. Cements. Methods for determining normal density, setting time and uniformity of volume change.

GOST 7473-94. Concrete mixes.

GOST 8735-88. Sand for construction work. Test methods.

GOST 10060.0-95. Concrete. Methods for determining frost resistance. General requirements.

GOST 10180-90. Concrete. Methods for determining the strength of control samples.

GOST 12730.0-78. Concrete. General Requirements for Methods for Determining Density, Moisture, Water Absorption, Porosity and Water Impermeability.

GOST 12730.3-78. Concrete. Method for determining water absorption.

GOST 12730.5-84. Concrete. Methods for determining water resistance.

GOST 28570-90. Concrete. Methods for determining strength by samples taken from structures.

GOST 28574-90 (ST SEV 6319-88). Corrosion protection in construction. Concrete and reinforced concrete structures. Test methods for protective coatings.

GOST 22690-88. Concrete. Determination of strength by mechanical methods of non-destructive testing.

GOST 31189-2003. Dry building mixes. Classification.

Technical information of SCS "Stroytekhnolog".

Documents of the database "Techexpert".

The electronic text of the document was prepared by Kodeks CJSC

and verified against the author's material.

Installation of a soft roof made of rolled waterproofing roofing material

(Stekloizol, Technoelast, Bikrost)

1 area of use

The technological map is developed for the device of a soft roof made of welded roll materials Stekloizol, Technoelast, Bikrost and their analogues.

The roll material consists of a cardboard, fiberglass or polyester base, covered on the outside with a layer of bitumen-polymer binder, and on the inside with a fused layer of bitumen mastic, which makes it possible to use it for installing one-, two- and three-layer roofs without adhesive mastics. The bases for the overlaid roof can be the surfaces of reinforced concrete slabs or thermal insulation, as well as prefabricated or monolithic screeds. For the device of the lower and upper layers, roll materials of various modifications are provided. The type of roll material must correspond to the project.

The composition of the work considered by the technological map includes:

- surface preparation;

- vapor barrier device;

- device of a heat-insulating layer;

- screed device;

- device of a weld-on roof made of a weld-on roll material;

- the device of water intake funnels and abutments.

The device of a soft roof made of welded roll materials is performed in accordance with the requirements of federal and departmental regulations, including:

- SanPiN 2.2.3.1384-2003. Ministry of Health of the Russian Federation. Hygiene requirements

to the organization of construction production and construction work.

The materials are fed to the roof using a "Pioneer" jib crane or a KOR crane.

Works are performed in one shift in summer conditions during daylight hours.

2. Organization and technology of work

Before the start of the robot for the construction of the base and roof covering from the welded roll waterproofing material, the following organizational and preparatory measures and works must be performed:

- completed and accepted work on the installation of supporting structures, parapets

roofs, grouting joints between precast concrete

structures;

- details of expansion joints are made;

- embedded parts installed;

- holes were made for the passage of communications;

- areas of stone structures are plastered to the height of gluing

roofing carpet;

- a work permit for high-risk work has been issued;

- prepared tools, devices, inventory;

- materials and products were delivered to the workplace;

- to acquaint performers with the technology and organization of work.

The front of work in the plan is divided into seizures, and seizures into plots. The work on the plot is carried out within one day.

The device of the base and covering of the roof from the deposited roll material is performed in the following order:

- installation of drainage funnels;

- leveling screed device;

- vapor barrier device;

- laying of a heat-insulating layer;

- the roofing is carried out layer by layer with the help of the deposited

waterproofing roofing material.

The device of a cement-sand screed is performed with a thickness of at least 30 mm in the following order: install guides from pipes with a step of 1.5 ... 2.0 m; the mortar mixture is laid in strips with leveling and smoothing according to the rule along the guides in 2 stages: first, odd stripes, and after the solution hardens in them, even ones.

The mortar mixture is fed by means of mortar pumps through pipes or by means of trolleys on pneumatic wheels.

Expansion joints are arranged in the screed with a step of 4 meters. In the places where the rolled carpet adjoins walls, parapets, shafts and risers, fillets with a radius of at least 100 mm are arranged.

After gaining strength, the cement-sand screed is primed with a cold bitumen primer. The primer is applied with brushes, a roller, and with a roof area of more than 200 sq. - using a spray gun.

When installing a leveling screed made of asphalt concrete, it is laid in strips up to 2 m wide and compacted with a roller with a mass of at least 50 kg.

By the beginning of the roofing device, it is necessary to control the quality of the base and comply with the slopes, check the completeness of other construction and installation work on the roof, check the availability and completeness of materials for the roofing, prepare machinery and equipment for transport and roofing work, prepare the construction site and workers places for labor protection and fire safety, check the availability and readiness of tools and devices.

When installing a vapor barrier, the following processes and operations are possible: cutting off mounting loops; removal of construction waste; alignment of defective areas on supporting structures; dedusting the surface; drying wet areas; supply of vapor barrier materials to the work site.

Mounting loops protruding from the plane of the plates are cut off with an electric grinder or a gas cutter.

Dedusting the surface is carried out with brushes, brooms, an industrial vacuum cleaner or a jet of compressed air.

Leveling the surface of the slabs, as well as sealing joints, chips, potholes and cavities larger than 5 mm in size, is performed with cement-sand mortar of grade 50.

Drying of wet areas of the base occurs naturally (solar radiation).

The surface is primed with a primer.

The vapor barrier is laid dry (the moisture content of cement-sand screeds should not exceed 4% by weight, and asphalt concrete screeds - 2.5%). The joints are glued with tape to seal the joints. The panels are laid out starting from the lowered sections and gutters.

The device of bulk thermal insulation from expanded clay is performed in the following order: mark the top of the thermal insulation on the parapets and lighthouse posts; install lighthouse rails with a step of 3 ... 4 m and verify their position; prepare and submit materials; distribute bulk material into strips with compaction.

1 - parapet; 2 - rail; 3 - expanded clay; 4 - lighthouse rail; 5 - solution or column.

Installation of a soft welded roll waterproofing roofing on corrugated board

The laying of the corrugated board is carried out in such a way that both transverse and longitudinal slopes to the gutters are created at the same time.

Before installing the vapor barrier layer, you must:

- complete all types of construction work on the pavement;

- install shaped elements made of steel at the junction of the corrugated board

to parapets and lantern walls;

- install metal expansion joints in the places of the device

expansion joints.

On all vertical surfaces, the vapor barrier material must be glued, leading it above the thermal insulation layer by 30-50 mm.

When laying the vapor barrier material on the profiled sheet, the material is rolled along the edges of the profiled sheet. The side overlaps of the vapor barrier material should be 80-100 mm and always be located on the edges of the profiled sheet.

Laying of thermal insulation along the corrugated board under the roofing waterproofing roll

deposited material

Laying of heat-insulating plates on a profiled sheet is to be done by placing the long side of the insulation boards perpendicular to the direction of the corrugated board ribs.

When installing thermal insulation from two or more layers of slab insulation, the seams between the slabs should be positioned "apart", ensuring a tight fit of the slabs to each other. Seams between insulation plates over 5 mm must be filled with heat-insulating material.

Filling the voids of the corrugated board ribs with bulk insulation on the roof is not allowed.

The easiest way to start laying insulation is from the corner of the roof. When laying, the thermal insulation boards are additionally cut so that the joints of the boards of the 1st and 2nd layers do not coincide. Such a cut of the insulation is suitable for insulation with a size of 500x1000 mm or 600x1200 mm.

Roofers on the finished layer of vapor barrier first lay the lower layer of mineral wool slabs of increased rigidity, and then the upper layer of solid mineral wool slabs. Next, using an electric screwdriver, plastic anchor buttons are installed. The roofer puts a button on the working tip, pushes it into the thermal insulation layer with a light blow, and at the same time turns on the screwdriver, with which the self-tapping screw is wrapped.

When fixing Technoruf mineral wool slabs to a profiled sheet, the slab or part of the slab must be fastened to the base with at least one fastening element. To fix the mineral wool insulation to the base through the first layer of the roofing carpet, use a plastic glass with a diameter of 50 mm with spikes (Fig. 2), to attach only the insulation to the profiled sheet, use a glass with a diameter of 75 mm (Fig. 2).

Insulation plates can be glued together with TechnoNIKOL No. 41 hot roofing mastic. Bonding should be uniform and make up at least 30% of the area of the bonded surfaces.

Mineralized insulation Technoruf soaked during installation must be removed or replaced with a dry one.

An insulating roofer uses a trolley to bring them to the workplace and then manually spreads the slabs across the area, starting from the top point. First, on a plot of 10 - 20 m², slabs are laid in the lower layer, and then in the upper one.

The creation of longitudinal slopes to the gutters in the gutters is carried out using Technoruf B60 slope (with a two-layer thermal insulation system, laying is carried out on the first (top) layer of the material), Technoruf B60 fillet (designed to ensure a smooth transition of the waterproofing material from the horizontal plane of the roof to the vertical plane of the parapet) , Technoruf N30 wedge (to create a slope on the roof 1.7% and 4.2%,)

If the project provides for the creation of slopes to the water intake funnels, then before laying the slabs, a loose material is sent with a layer of variable thickness. The installation of an insulating layer of mineral wool slabs is performed after leveling the expanded clay. Plates are laid close to each other in the direction from bottom to top. A layer of insulation is laid in such a way as to ensure reliable drainage and exclude stagnant water. Hydrophobized aerated concrete slabs are laid dry on the vapor barrier.

Cloths of rolled roofing overlaid waterproofing material are fused by thinning the covering layer onto a screed, concrete surface, insulation or other underlying layer.

When installing roll roofing, the processes and operations are performed in the following sequence:

- preparation of roofing materials, mastics, compositions and details;

- the device of eaves overhangs;

- supply of roofing waterproofing surfacing materials, mastics;

- priming the base;

- gluing additional layers of rolled roofing

waterproofing material in the places of installation of drainage funnels,

gutters;

- gluing rolled waterproofing material at the junction points

waterproofing roofing layer to walls, shafts, parapets, pipes;

quality control of the processes performed.

The device of the rolled roof on the grippers is performed from lowered sections to raised ones. Rolling and gluing of panels of roofing waterproofing materials is performed in the direction opposite to the water flow.

Gluing panels of roofing waterproofing deposited material is carried out as follows

After preparing the base and marking the position of the first panel, roll out the roll along the marking line, then roll it up from one end by 1.5 ... 2 m, ignite the gas burner and direct the flame to the mastic layer of the rolled roofing waterproofing material. The roofer holds the burner cup at a distance of 100… 200 mm from the roll and melts the mastic layer by pendulum movements of the burner along the roll. After the formation of a bead of the layer of mastic that has dripped from the bottom side of the roll, the roofer rolls out the roll, smoothes and presses the panel to the base. The work is carried out cyclically: melting of the mastic in the area of the panel, rolling. The roll gluing speed is determined visually as the sculptor bead is formed during fusion.

Laying scheme for rolled roofing waterproofing material

1,2 - the position of the first panel;

2 - axis of the groove; 3-gas burner; 4 - rolled up part of the panel; 6 - cloth; 7 - a stack of rolls; 9 - balloon.

The procedure for arranging a rolled carpet made of deposited materials is as follows. Mark the position of the first strip of material

The device of a rolled roofing waterproofing carpet in the places where the water intake funnels are installed is performed in the following order. Before gluing the layers of the main roofing, check the marks of the completed screed or laid rigid insulation. Under the collar of the water intake funnel, two layers of the underlying roll waterproofing deposited material are additionally glued.

Requirements for quality and acceptance of works

When installing a roof made of welded roll material, production quality control is carried out, which includes: incoming control of materials and products; operational control of the performance of roofing works, as well as acceptance control of the work performed. At all stages of work, inspection control is carried out by representatives of the customer's technical supervision.

The manufacturer must accompany each batch of products with a quality document, which must indicate: - the name and address of the manufacturer; number and date of issue of the document; batch number; designation and brands of structures; date of manufacture of structures; designation of technical conditions.

The document on the quality of the products supplied to the consumer must be signed by the employee responsible for the technical control of the manufacturer.

Incoming quality control of materials consists in checking by external examination their compliance with GOST, TU, project requirements, passports, certificates confirming the quality of their manufacture, completeness and compliance with their working drawings. Incoming control is performed by line personnel when materials and products arrive at the construction site. The shape and main dimensions of the products must correspond to those indicated in the project.

All products are subject to external inspection in order to detect obvious deviations of geometric dimensions from the project. Dimensions and geometric shape are checked selectively by one-stage control.

The installation of a roof made of welded roll materials is allowed only after acceptance of the base elements. The operational quality control scheme is shown in the table.

Scheme of operational quality control of roofing

waterproofing works (example)

| Controlled operations | Requirements, tolerances | Methods and means of control | Who and when controlled | Documentation |

| Screed device | ||||

| Visually | Foreman | Quality document, draft | ||

| Layer thickness | Not less than 30 mm | Measuring | Master | General work log |

| Compliance with specified planes, elevations and slopes | Measuring | Master | General work log | |

| Potholes, cracks | Not allowed | Visually | Master | |

| Screed strength | According to the project | Measuring | Construction laboratory | |

| Ready for roofing | According to the project | Measuring | Foreman | Certificate of Survey of Hidden Works |

| Vapor barrier device | ||||

| Properties of the materials used | Compliance with regulations and design | Visually | Foreman | Quality document, draft |

| Foundation readiness | Compliance with the project | Visually | Foreman | Acceptance certificate |

| Application or styling quality | Compliance with the project | Visually | Foreman | General work log |

|

||||

| Thermal insulation device | ||||

| Properties of the materials used | Compliance with regulations and design | Visually | Foreman | Quality document, draft |

| Deviation of the thickness of the thermal insulation layer | + 10% of the design thickness, but not more than 20 mm | Measuring, 3 meas. for every 70-100 m² of coverage | Foreman in the process of work | General work log |

| Deviation of the thermal insulation plane from the specified slope | horizontal + 5mm vertical + 10mm deflected. from a given slope no more than 0.2% | Measurement for every 50-100m² | Master in the process of work | General work log |

| The size of the ledge between adjacent insulation elements | No more than 5 mm | Measurement for every 50-100m² | Master in the process of work | General work log |

| Roofing device made of roll material | ||||

| Properties of the materials used | Compliance with regulations and design | Visually | Foreman | Quality document, draft |

| Substrate priming quality (primer application) | According to the project | Visually | Foreman | Certificate of Survey of Hidden Works |

| Direction of adhesive roofing roll waterproofing material | Direction of sticker | From low to high areas | Visually | Master in the process of work |

| The amount of overlap of adjacent roofing panels | Not less than 70 mm in the lower layers, 100 mm in the upper layer | Measuring, 2-meter rail | Master in the process of work | General work log |

| Compliance with the specified thicknesses of planes, elevations and slopes | According to the project | 5 measured. 70-100m² visually | Master in the process of work | General work log |

| Strength of adhesion of layers of roll material | The tearing off of the web occurs along the material. Adhesion strength 0.5 MPa | Measure at least 4 times per shift | Master in the process of work | General work log |

| The quality of adhesion of additional layers of material at the points of abutment to vertical structures | According to the project | Visually | Master in the process of work | General work log |

|

||||

| Acceptance of works | ||||

| Coating surface quality | According to the project | Visually | General journal of work, act of acceptance of work performed | |

| Quality of abutments and gutters | According to the project | Visually | The foreman, after the end of the work | |

| Overlap values of panels | not less than 70 mm in the lower layers, 100 mm - in the upper layer | Visually | The foreman, after the end of the work | |

| Cross-over labeling | Not allowed | Visually | Foreman | |

| Bubbles, blisters, air sacs, tears, punctures, spongy structure, sagging and sagging | Not allowed | Visually | Foreman | |

| Water resistance | Water drainage from the entire roof surface without leaks | Visually | The foreman, after the end of the work | |

The device of each element of the roof should be performed after checking the correctness of the implementation of the corresponding underlying element with the drawing up of an act of survey of hidden works. Acts for the repair and installation of a roll waterproofing welded roof are drawn up for the following work: preparation of the base, priming of surfaces, laying of each layer of roll material, arrangement of abutments.

Acceptance of the roof should be accompanied by a thorough examination of its surface, especially at funnels, drainage trays, in gutters and in places of abutment to protruding structures above the roof.

The completed roll roofing must meet the following requirements: have the specified slopes; not have local reverse slopes where water can be trapped; the roofing carpet must be firmly glued to the base, not flaking, free from bubbles, depressions.

Manufacturing defects found during inspection of the roof must be corrected before the buildings or structures are put into operation.

General safety requirements for overhaul of a soft roof or repair of an old roll deposited waterproofing material

APPROVED

General Director, Ph.D.

___________ S.Yu. Jedlichka

ROUTING

ON PAINTING DEVICE

WATERPROOFING OF FOUNDATIONS

COLD BITUMEN

MASTICS

The map contains organizational, technological and technical solutions for the installation of paint waterproofing of foundations with cold bitumen and bitumen-polymer mastics, the use of which should speed up work, reduce labor costs and improve the quality of foundation waterproofing.

The technological map contains: scope, organization and technological sequence of work, requirements for quality and acceptance of work, calculation of labor costs, schedule of work, the need for material and technical resources, decisions on safety and labor protection and technical and economic indicators.

The initial data and design solutions, in relation to which the map was developed, were taken taking into account the requirements of the current building codes and regulations, as well as the conditions and features typical for construction in Moscow.

The technological map serves as a technological document in monolithic housing construction and is intended for engineering and technical workers of construction and design organizations, work managers, foremen and foremen associated with the production of waterproofing works of monolithic reinforced concrete structures, as well as technical services of the customer.

Employees of JSC PKTIpromstroy participated in the development of the technological map:

Savina O.A. - development of a technological map, computer processing and graphics;

Chernykh V.V. - general technological support;

V. N. Kholopov - check of the technological map;

Bychkovsky B.I. - development of a technological map, technical guidance, proofreading and regulatory control;

Kolobov A.V. - general technical guidance for the development of technological maps;

Ph.D. Edlichka S.Yu. - general management of the development of technological documentation.

1 AREA OF USE

APPROVED

General Director, Ph.D.

___________ S.Yu. Jedlichka

«_ 10 _» __ December __ 2003

ROUTING

ON PAINTING DEVICE

WATERPROOFING OF FOUNDATIONS

COLD BITUMEN

MASTICS

57-03 TC

Chief Engineer

____________ A.V. Kolobov

Department head

____________ B.I. Bychkovsky

2003

The map contains organizational, technological and technical solutions for the installation of paint waterproofing of foundations with cold bitumen and bitumen-polymer mastics, the use of which should speed up work, reduce labor costs and improve the quality of foundation waterproofing.

The technological map contains: scope, organization and technological sequence of work, requirements for quality and acceptance of work, calculation of labor costs, schedule of work, the need for material and technical resources, decisions on safety and labor protection and technical and economic indicators.

The initial data and design solutions, in relation to which the map was developed, were taken taking into account the requirements of the current building codes and regulations, as well as the conditions and features typical for construction in Moscow.

The technological map serves as a technological document in monolithic housing construction and is intended for engineering and technical workers of construction and design organizations, work managers, foremen and foremen associated with the production of waterproofing works of monolithic reinforced concrete structures, as well as technical services of the customer.

Employees of JSC PKTIpromstroy participated in the development of the technological map:

Savina O.A. - development of a technological map, computer processing and graphics;

Chernykh V.V. - general technological support;

V. N. Kholopov - check of the technological map;

Bychkovsky B.I. - development of a technological map, technical guidance, proofreading and regulatory control;

Kolobov A.V. - general technical guidance for the development of technological maps;

Ph.D. Edlichka S.Yu. - general management of the development of technological documentation.

1 AREA OF USE

1.1 The technological map was developed for the installation of painting waterproofing of 1000 m2 of the surface of foundations with cold bitumen mastics in housing, civil and industrial construction.

1.2 The technological map is developed for the production of works at positive temperatures. General instructions for the performance of work in the winter are given in p. ,,.

1.3 When linking the technological map to a specific object and construction conditions, the scope of work, the calculation of labor costs, the brand of mastic, the application methods and the means of mechanization are specified.

1.4 The form of using the card provides for its circulation in the field of information technology with the inclusion in the database on the technology and organization of construction production of an automated workstation for a construction production technician (AWP TSP), a contractor and a customer.

2 ORGANIZATION AND TECHNOLOGY OF WORK PERFORMANCE

2.1 Materials for the waterproofing device are selected according to the characteristics that are most important for operation, taking into account the peculiarities of the construction and installation work and the possibilities of caring for the waterproofing during operation.

The most commonly used are:

Petroleum construction bitumens;

Roofing petroleum bitumen;

Oil insulating bitumens.

The technical characteristics of petroleum bitumen are presented in the table.

Table 1- Technical characteristics of petroleum bitumen

|

Softening point, ° С |

Elongation, cm, at temperature, ° С |

Depth of needle penetration, degree of penetration, at temperature, ° С |

|||||

|

Construction (for construction work in various sectors of the national economy) |

Not standardized |

||||||

|

Insulating (for insulating pipelines from soil corrosion) |

|||||||

|

Roofing (for the production of roofing materials) |

|||||||

2.2 For the manufacture of cold bitumen mastics, organic solvents, fibrous and pulverized fillers are used. Their composition is named in the project and is determined in a laboratory way for each batch.

2.3 Prior to the commencement of waterproofing works, the facility must be prepared for waterproofing works:

The pits were drained (construction dewatering was carried out) in the presence of a high level of groundwater;

Foundations completed;

Scaffolds or scaffolding (if necessary) have been prepared along the work front;

Entrances for vehicles and other equipment are provided;

Electricity supply and temporary electric lighting were completed;

The equipment was delivered and tested with a mechanized method of applying paint layers.

2.4 Cold bitumen mastics for painting waterproofing, as a rule, are prepared in the factory and only for small amounts of work is it allowed to prepare the mastic on site.

2.5 The device of painting waterproofing is started only after preparation of the foundation surface, schematically shown in the figure, for waterproofing. Surface preparation for painting waterproofing is as follows:

Sealing shells and cracks;

Shearing off protruding reinforcing bars and wires;

Cutting down concrete and mortar inflows;

Removing rust, if any;

Rounding with a radius of 30 - 50 mm or beveling on a chamfer of corners;

Drying of surfaces;

Immediately before painting - in cleaning surfaces from dirt and dust and wiping the cleaned surface with a rag.

Requirements for surface preparation are set out in Table 2 of SNiP 3.04.01-87.

Picture 1- Schematic foundation plan

2.6 The scope of work considered by the map includes:

Surface preparation;

Primer application;

Waterproofing horizontal and vertical surfaces mechanically or manually with cold bitumen mastics;

Coating formation (drying, curing).

2.7 Before applying the paint composition, the insulated surfaces should be primed with a thinned paint composition according to the data in the table without gaps and breaks, and the corners and edges should be pasted over with strips of fiberglass or waterproofing with a width of at least 200 mm. The primer must have a strong adhesion to the substrate, and there must be no traces of the binder on the tampon attached to it.

table 2- Compositions of cold bituminous primers,% mass

2.8 The moisture content of concrete when waterproofing from compositions containing organic solvents should not be more than 4%.

2.9 The application of paint layers is carried out only after the primer layer has completely dried, as a rule, by a mechanized method with units with screw pumps, and in case of small volumes of work, as an exception, by hand (with paint brushes or brushes). The paint waterproofing is applied in the form of a thin waterproof coating on the insulated surface from the wetted side in 2 - 4 layers with a total thickness of 3 - 6 mm with overlapping adjacent strips.

2.10 The insulating bitumen composition should be applied in continuous and even layers or in one layer without gaps and sagging. Each subsequent layer must be arranged on the hardened surface of the previous layer.

1 - insulated structure; 2 - waterproofing; 3 - filling with mastic; 4 - pipe (anchor); 5 - protective metal diaphragm

Figure 2- Coupling of embedded parts with waterproofing

Table 3- Physicochemical indicators of BNK bituminous mastics

|

Norm for the brand |

Test Method |

|||

|

OKP 02 5622 0202 |

OKP 02 5622 0201 |

OKP 02 5623 0201 |

||

|

1. Depth of penetration of the needle at 25 ° C, 0.1 mm |

||||

|

2. Softening temperature along the ring and ball, ° С |

||||

|

3. Brittleness temperature, ° С, not higher |

||||

|

4. Solubility in toluene or chloroform,%, not less |

||||

|

5. Change in mass after heating,%, no more |

||||

|

6. The depth of penetration of the needle at 25 ° C in the residue after heating,% of the initial value, not less |

||||

|

7. Flash point, ° С, not lower |

||||

|

8. Mass fraction of water, no more |

||||

|

9. Mass fraction of paraffin,%, no more |

||||

|

1.0 to 2.5 |

||||

|

Note - For bitumen from a mixture of oils containing more than 50% of West Siberian oils, the penetration index should be from 0 to 2.5. |

||||

3.6.3 Each batch of bitumen mastic is supplied with instructions for use and a document, which must indicate:

The name of the manufacturer or its trademark;

The name of the mastic, the index of the component or composition (for multi-component mastics);

Designation of a regulatory document for a specific type of mastic;

Batch number and date of manufacture;

Net weight of a container;

Brief instructions for use.

3.6.4 Packaging should ensure the safety of the mastic during transportation and storage. Features of the packaging indicate in the regulatory document for a specific type of mastic.

3.6.5 During the production, storage, transportation and use of mastics, it is necessary to comply with the safety requirements established by the sanitary and epidemiological supervision authorities, which must be indicated in the regulatory document for a specific type of mastic, and GOST 1510-84 *.

Delivery of mastics to the object should be carried out by specialized vehicles (auto-aspirator) or in a special container with a lid.

3.6.6 The normative document for a specific type of mastic should contain indicators of the fire hazard of a mastic coating: flammability and flammability groups - for waterproofing mastics.

3.6.7 During loading and unloading operations, safety requirements in accordance with GOST 12.3.009-76 * must be observed.

3.6.8 The mastic at the facility should be protected from the action of sunlight, stored in a tightly closed container in warehouses or under a canopy in places far from open flames and flammable objects.

3.7 The results of incoming control should be recorded in the “Log of incoming accounting and quality control of the received parts, materials, structures and equipment”.

3.8 During operational control, check all operations for the installation of paint waterproofing in accordance with the requirements of SNiP 3.04.01-87.

The adhesion strength of the applied compositions to the base must be at least 0.4 MPa.

3.9 During acceptance control, the quality of the foundation waterproofing device is checked.

3.10 The composition of production quality control is shown in the table. The results of production quality control of work should be recorded in the work production log.

Table 4- Composition of production quality control of works

|

Foreman or foreman |

||||||||

|

Operations subject to control |

Operations at the entrance control |

Operations under operational control |

Acceptance control operations |

|||||

|

Preparation of the surface to be insulated |

Preparation of painting material |

|||||||

|

Control composition |

Cleanliness and dryness of the surface. Smoothness of the horizontal surface. Surface defects, protruding rods and wires. Bevels and rounding of corners |

The quality of the primer, reinforcement of waterproofing at the corners, drying of primed surfaces |

Compliance of the mastic with passport data. The temperature of the molten bitumen and the correctness of the liquefaction of bitumen |

The consistency of the composition and temperature of the mastic |

Correct application of primer and paint waterproofing |

Layer uniformity |

Mastic temperature when waterproofing |

Compliance of the finished waterproofing coating with the project requirements |

|

Control method |

Visually, 2 meter rail |

Visually, with a moisture meter |

Visually, with a thermometer |

Sampling |

Visually |

Visually |

Thermometer |

Visually |

|

Control time |

Before sealing |

After finishing work |

||||||

|

Who is involved in control |

Laboratory |

Laboratory |

Laboratory |

Technical supervision |

||||

|

The presence of an act for hidden works (+) |

||||||||

3.11 Requirements for the quality of work:

The painting material is applied evenly without gaps over the entire insulated surface in at least two layers;

The paint waterproofing must be continuous;

Swelling, delamination, spongy structure of the waterproofing layer, drips, sagging are not allowed.

3.12 When installing paint waterproofing, acts for hidden work are drawn up:

Insulated surface condition;

Installation of embedded parts, including seals;

Surface priming and gluing of waterproofing reinforcement strips;

Painting waterproofing device.

3.13 Requirements for finished insulating coatings are given in Table 7 of SNiP 3.04.01-87.

3.14 Acceptance of all works related to the installation of paint waterproofing of foundations with cold bitumen mastics should be carried out in accordance with the requirements of Chapter 7 of SNiP 3.01.01-85 * "Organization of construction production", SNiP 3.04.01-87 "Insulation and finishing coatings" and SNiP 3.04 .03-85 "Protection of building structures and structures from corrosion".

4 REQUIREMENTS FOR HEALTH AND SAFETY, ENVIRONMENTAL AND FIRE SAFETY

4.1 When performing work on waterproofing of foundations with cold bitumen mastics, the following hazardous and harmful production factors associated with the nature of the work may occur:

Increased dust and gas content in the air in the working area;

Increased or decreased temperature of materials, surfaces and air in the working area;

Location of the workplace near a height difference of 1.3 m and more;

Sharp edges, burrs and roughness on surfaces and materials;

Increased contamination of the air, skin, overalls with chemical compounds, aerosol, dust;

Increased severity of work;

Increased level of noise, vibration;

High or low temperature, humidity and air mobility;

Increased level of static electricity;

Fire and explosion hazard;

Unprotected (unshielded) moving parts of painting equipment;

Insufficient illumination at workplaces.

4.2 To prevent exposure of workers to hazardous and harmful production factors, the safety of insulation work must be ensured by observing the following measures:

Organization of workplaces with an indication of methods and means for providing ventilation, fire extinguishing, protection from thermal burns, lighting, performing work at height;

Special security measures when performing waterproofing works in closed basements;

Safety measures during the preparation, transportation and application of mastics to the surface.

4.3 All new workers entering the construction site must undergo both introductory briefing and initial instruction at the workplace on safety and labor protection in working with mechanisms, tools and materials. Instruction at the workplace is carried out by the work supervisor or foreman with the recording of the results of the instruction in the “Journal of the instruction in the workplace”. Those who have passed the induction briefing are recorded in the "Register of introductory briefing on labor protection".

4.4 Persons admitted to work on waterproofing foundations must have professional training (including work safety), corresponding to the nature of the work, a qualification group for electrical safety not lower than II for persons allowed to operate equipment with an electric drive, and persons allowed to operate hand-held electric machines.

4.5 Working with oil bitumen must be provided with personal protective equipment in accordance with the standard industry standards for the issuance of overalls, footwear and other personal protective equipment: filtering gas masks in accordance with GOST 12.4.034-2001, suits in accordance with GOST 12.4.111-82 * and GOST 12.4.112- 82 *, footwear in accordance with GOST 12.4.032-77 *, mittens in accordance with GOST 12.4.010-75 * and goggles. There are no special requirements for personal hygiene.

4.6 Workers and engineers and technicians are required to undergo training, testing of knowledge of the rules of safe work performance, ensuring fire safety, using primary fire extinguishing equipment, providing first aid to victims, etc.

4.7 When performing insulation work using bitumen, workers should use special suits with trousers over boots and gloves.

4.8 In order to prevent and timely detect occupational diseases or poisoning, all hired and permanently employed workers must undergo preliminary and periodic medical examinations and receive a certificate of suitability for performing waterproofing work.

4.9 Waterproofers should:

Be trained in safe and progressive techniques for performing the relevant operations of the technological cycle;

Have a work permit for the production of these works, and before they begin to be instructed on occupational safety at the workplace;

Allowed to work with sealants and mastics containing toxic and easily volatile flammable substances, only after special training, and also instructions on the properties of materials and fire safety measures.

4.10 Requirements for materials, their storage and transportation.

The materials used for waterproofing works must be accompanied by passports certifying their quality indicators and instructions for the use of the supplied materials.

Storage and transportation of waterproofing and auxiliary materials is organized in accordance with the requirements set out in the technical conditions and standards for finished products.

4.11 In the areas of work in rooms where insulation work is carried out with the release of harmful and fire hazardous substances, it is not allowed to perform other work and find unauthorized persons.

4.13 The room in which the bitumen is handled must be equipped with supply and exhaust ventilation. If the supply and exhaust ventilation suddenly stops working, waterproofing work with materials containing organic solvents should be suspended, and workers should be removed to a safe distance.

4.14 The levels of noise and vibration in workplaces generated by machines and mechanisms should not exceed the standards established by GOST 12.1.003-83 and GOST 12.1.012-90.

4.15 Equipment for painting waterproofing of foundations must comply with GOST 12.2.003-91. When moving bitumen at workplaces manually, use metal tanks in the shape of a truncated cone, facing down with the wide part, with tightly closing lids and locking devices.

4.16 To prevent fires, it is necessary to strictly observe the fire safety requirements in accordance with PPB 01-03 "Fire safety rules in the Russian Federation" and regularly instruct workers.

4.17 When installing waterproofing using organic solvents, it is necessary to organize a fire station, which should include a blanket of 2 × 3 m in size. at work.

4.18 When igniting small amounts of bitumen, extinguish with sand, felt mat or foam fire extinguisher. Extinguish developed fires with a foam jet from fire monitors.

4.19 For smoking, special places should be allocated, equipped with urns, barrels of water, boxes with sand.

4.20 Waste from bitumen production is neutralized by incineration in an afterburner.

4.21 All electrical installations at the end of work must be turned off, and cables and wires must be de-energized.

4.22 When working in basements, sufficient natural or forced ventilation and illumination of workplaces should be provided. The voltage of the power supply when working in closed rooms should not exceed 12 V with explosion-proof fittings.

4.23 Workplaces for performing waterproofing work at a height should be equipped with paving equipment with fences and ladders for climbing them, in accordance with the requirements of SNiP 12-03-2001.

4.24 Places where waterproofing works should be equipped with primary fire extinguishing equipment - fire extinguishers, barrels of water, boxes of sand, crowbars, axes, shovels, hooks, buckets.

4.25 Each worker should know his responsibilities in the event of a fire and extinguish it, be able to use fire extinguishing equipment, quickly notify the fire brigade using communication means, disconnect electrical appliances and de-energize the wiring.

4.26 To comply with environmental standards, it is necessary to provide a water tank designed for washing tools and mechanisms.

4.27 After use, cleaning material must be collected in a special container for subsequent release to the surface and disposal. Do not burn used cleaning material.

4.28 When installing paint waterproofing of foundations with cold bitumen mastics, it is necessary to be guided by the requirements:

Table 5- List of requirements for basic materials for 1000 m

5.2 The need for machines, equipment; tools and inventory are given in the table.

Table 6 - Statement of the need for machines, equipment, tools and inventory

|

Name |

Type, brand, GOST |

Technical specifications |

|||

|

Installation for applying cold mastics |

Productivity, m2 / h |

||||

|

Power, kWt |

|||||

|

Weight, kg |

|||||

|

Thermos for cold mastics |

Design of SKB Mosstroy |

Capacity, m3 |

|||

|

power, kWt |

|||||

|

Electric brush |

|||||

|

Roofing brush |

Beam length, mm |

||||

|

Beam diameter, mm |

|||||

|

Weight, kg |

|||||

|

Hair brush |

|||||

|

Weight, kg |

|||||

|

Roller roll-on |

Length, mm |

||||

|

Scraper spatula |

Web width, mm |

||||

|

End pliers |

|||||

|

Rebar shears |

r.h. PRP-8-00 |

Weight, kg |

|||

|

Trust Orgtekhstroy Glavzapaduralstroy |

|||||

|

Mastic tank |

Drawings 3956СБ |

Capacity, l |

|||

|

SKB Mosstroy |

|||||

6 TECHNICAL AND ECONOMIC INDICATORS

6.1 As a unit of measurement for calculating the cost of labor and machine time, the schedule for the production of work, 1000 m2 of paint waterproofing of the foundation is taken.

6.2 The costs of labor and machine time for the installation of paint waterproofing of the foundation and underground structures are calculated according to the "Uniform norms and prices for construction, installation and repair and construction work", put into effect in 1987, and are presented in the table.

6.3 The duration of work on the installation of paint waterproofing of foundations is determined by the work schedule presented in the table.

Table 7 - Calculation of labor costs for the installation of paint waterproofing of the foundation

The unit of measurement of the final product - 1000 m2

|

Justification (ENiR and other norms) |

Name of technological processes |

Scope of work |

Time rate |

Labor costs |

|||||

|

workers, man-h |

workers, man-h |

drivers, man-hours (work of machines, machine-hours) |

|||||||

|

Cleaning the surface from dust, dirt, sludges of solution with electric brushes |

|||||||||

|

Priming of insulated surfaces with a ready-made cold bitumen primer in a mechanized way |

|||||||||

|

Painting waterproofing in two layers with cold bitumen mastic in a mechanized way |

|||||||||

|

Total Protection of building structures and structures from corrosion; SSBT. General sanitary and hygienic requirements for the air in the working area; 23 TR 94.08-99.2000 Technical regulations for operational quality control of construction and installation and special works during the construction of buildings and structures. Waterproofing the underground part of the building. | |||||||||

"TECHNOLOGICAL CARD for the device of waterproofing foundations by fusion with the use of rolled bitumen-polymer ..."

ROUTING

for the device of waterproofing foundations by fusion using a rolled bitumen-polymer material Technoelast EPP

Moscow 2012

Terms and Definitions

General Provisions

Materials used

Organization and technology of work

Requirements for the quality of work

Occupational health and safety

The need for material and technical resources

10. Technical and economic indicators

Appendices Appendix 1. The composition of the operational control when performing work on the construction of a waterproofing membrane

Appendix 2. List of technological equipment, tools, inventory and fixtures

Appendix 3. Rates of consumption of materials

Appendix 4. Rates of labor input

Appendix 5. Collection of knots

Application area.

1.1. This Technological Map has been developed for the construction of a waterproofing membrane of foundations made of monolithic reinforced concrete by the fusion method using a rolled bitumen-polymer material Technoelast EPP.

1.2. In this technological map, only the construction of a two-layer waterproofing membrane made of Technoelast EPP material is considered.

1.3. This Technological Map can be used in the development of design documentation for the construction of industrial and civil construction projects.

2.1. When developing this Technological Map, references to the following regulatory documents were used *:

GOST 12.1.

004-91 SSBT. Fire safety. General requirements GOST 12.4.

011-89 SSBT. Protective equipment for workers. General requirements and classification MDS 12-29.2006 Guidelines for the development and execution of the technological map PPB 01-03 Fire safety rules in the Russian Federation SP 20.13330.2011 Loads and impacts SNiP 12-03-2001 Labor safety in construction. Part 1. General requirements SNiP 12-04-2002 Labor safety in construction. Part 2. Construction production

2.2. The following references were used in the development of this document:

Guidelines for the design and construction of waterproofing foundations. Corporation "TechnoNICOL". Moscow. 2012.

Typical technological map for the device of gluing with welded materials on monolithic reinforced concrete walls. TTK-100029434.094-2010. 92 / 6t-2010 TT-49.

GPO "Minskstroy" OJSC "ORGSTROY", Minsk. 2010 * When using the Technological Map, it is advisable to check the status of the normative document to which the link is given. If the reference standard is replaced (changed), then the replaced (changed) document should be followed.

Terms and Definitions.

A waterproofing membrane is an element of a waterproofing system that protects foundation structures from the effects of water.

The base for the waterproofing membrane is the surface on which the waterproofing materials are laid.

Reinforcement layer - a part of the waterproofing membrane, performed at the points of abutment to protruding parts and foundation structures to increase the reliability and tightness of the waterproofing coating.

General Provisions.

4.1. Work on the construction of a waterproofing membrane made of Technoelast EPP material should be carried out in dry weather at a temperature not lower than minus 25 ° С.

4.2. Constructive solutions for the construction of a two-layer waterproofing membrane for waterproofing foundations using Technoelast EPP material are shown in Fig. 1 and fig. 2.

1 - foundation slab; 2 - protective screed; 3 - the second layer of the waterproofing membrane made of Technoelast EPP material; 4 - the first layer of a waterproofing membrane made of Technoelast EPP material; 5 - bituminous primer TechnoNICOL; 6 - concrete preparation; 7 - foundation wall

- & nbsp– & nbsp–

4.3. The basis for the waterproofing carpet is:

concrete preparation - when installing horizontal waterproofing (Fig. 1);

flat surfaces of structures made of precast and monolithic concrete or reinforced concrete - when installing vertical waterproofing (Fig. 2).

4.4. Requirements for the quality of the base for laying the waterproofing membrane, as well as the controlled parameters are given in Table 1.

4.5. To protect the waterproofing membrane from mechanical damage, XPS CARBON extruded polystyrene foam is used, which is also thermal insulation, or special profiled PLANTER membranes.

- & nbsp– & nbsp–

Materials used.

5.1. For the installation of a waterproofing membrane, a rolled bitumen-polymer material Technoelast (TU 5774-003-00287852-99) is used. The main physical and mechanical characteristics of the material are shown in Table 1.

- & nbsp– & nbsp–

* Indicator for reference. The manufacturer reserves the right to change this indicator ** Test method according to GOST 2678-94 5.2. To seal the unevenness of the base for laying the waterproofing material, use a repair compound on a polymer-cement basis.

5.3. To prepare the base surface in order to increase the adhesion of the waterproofing material, the following can be used:

Bituminous primer TECHNONICOL No. 01 (TU 5775-010-17925162-2003);

Bitumen-polymer primer TECHNONICOL No. 03 (TU 5775-042-17925162-2006);

Bitumen emulsion primer TECHNONICOL No. 04 (TU 5775-006-72746455-2007).

5.4. To increase the reliability and tightness of assemblies and junctions of the waterproofing membrane to various building structures, the following are used:

Polyurethane sealant TECHNONICOL No. 70;

TECHNONICOL bitumen-polymer sealant No. 42 (TU 5772-009-72746455-2007);

TechnoNICOL adhesive mastic No. 27 (TU 5775-039-72746455-2010);

Nikobend tape;

Bentonite cord;

Sealant (cord like "Vilatherm");

PVC waterstop.

5.5. To protect the waterproofing membrane from mechanical damage, the following is used:

Extruded polystyrene foam XPS CARBON (TU 2244-047-17925162-2006);

Profiled PLANTER membranes (TU 5774-041-72746455-2010).

Acceptance and storage of building materials 5.6.

5.6.1. When accepting the building materials used, it is necessary:

check the condition of the packaging (containers), the presence of tags (labels, packing lists), allowing to identify the received material;

check the absence of external damage to the material;

check the completeness of the batch of building materials;

if necessary, ask the manufacturer for a quality certificate (copy thereof) for a given batch of material.

5.6.2. The packing list indicating the name of the material, the physical and mechanical characteristics of the material, the manufacturer's plant, the date of production, the batch number must be kept until the end of the waterproofing work.

Storage Technoelast EPP.

5.7.1. Rolled bitumen-polymer materials should be stored in a vertical position in one row in height on pallets or without them at a distance of at least 1 m from heating devices.

5.7.2. It is allowed to store pallets with Technoelast EPP in two rows in height, while the weight of the upper pallets should be evenly distributed on all rolls of the lower row using wooden panels or pallets.

5.7.3. Rolled bitumen-polymer materials should be stored indoors, under a canopy or otherwise protected from direct exposure to sunlight.

5.7.4. Short-term (no more than 14 days) storage of pallets with Technoelast EPP in an open area is allowed.

5.7.5. By agreement with the manufacturer, other storage conditions for roll materials are allowed, providing protection from moisture and sun exposure.

Storage of mastics, primers, sealants.

5.8.1. Storage of pallets with mastics should be carried out in one row in height:

Bitumen primer TECHNONICOL No. 01, bitumen-polymer primer TECHNONICOL No. 03 and bitumen-polymer sealant TECHNONICOL No. 42 should be stored in a dry, dark place at temperatures from -20 ° C to + 30 ° C. Shelf life - 12 months;

Store the bitumen emulsion primer TECHNONICOL No. 04 in a dry, dark place at a temperature not lower than + 5 ° C. The guaranteed shelf life is 6 months.

Organization and technology of work.

Organization of work production.

6.1.1. Before starting work, you must:

appoint persons responsible for the safe performance of work;

the responsible performer of work to receive an admission certificate and an admission order for the production of work of increased danger;

the responsible executor to conduct targeted briefing of employees on labor protection, electrical, fire safety and environmental protection against signature in the training log;

to familiarize the working personnel with the technology of work production, project documentation, POS, PPR and this technological map;

allocate areas for storage and storage of materials;

deliver to the object and carry out in the prescribed manner the incoming quality control of building materials;

bring the necessary tools, fixtures, inventory, etc. to the object.

provide all workers with the necessary tools, inventory, fixtures, rigging, overalls and other personal protective equipment;

check the serviceability of mechanisms, equipment and tools;

accept the scope of work on the acceptance certificate of the work performed.

6.1.2. Works on the construction of a waterproofing membrane of foundations by fusion using a rolled bitumen-polymer material Technoelast EPP is performed by a link consisting of:

insulator of the 3rd category (I1) - 1 person;

insulator of the 4th category (I2) - 1 person.

6.1.3. Schemes of the organization of workplaces in the production of work on the device of a horizontal and vertical waterproofing membrane are shown, respectively, in Fig. 3 and fig. 4 real technological cards.

I1 I2 I1 I2 1 - pallet with roll materials; 2 - hand cart; 3 - a bucket of water; 4 - fire extinguishers; 5 - gas cylinder; 6 - rolls of waterproofing materials; 7 - foundation wall; I1, I2 - insulators Fig. 3. Scheme of the organization of the workplace at Fig. 4. Workplace organization scheme for horizontal waterproofing device; vertical waterproofing device. Work technology.

Works on the construction of a waterproofing membrane include:

Preparatory work:

checking the base for laying waterproofing materials;

signing an act for hidden works;

organization of the workplace.

Main works:

preparation of the base for laying waterproofing materials;

laying waterproofing materials on a horizontal surface;

laying waterproofing materials on a vertical surface;

device of nodes.

Preparatory work.

6.2.1. Check the quality indicators of the base for laying the waterproofing membrane in accordance with the requirements of Table 1 of this document.

6.2.2. If the indicators deviate from the standard values, take measures to improve the quality of the foundation to the required values.

6.2.3. The installation of a waterproofing carpet is started after drawing up and signing an act for hidden work.

Basic work.

Preparation of the base for laying waterproofing materials.

6.2.4. If there is cement laitance, rust and other substances of non-fatty origin on the surface of the base, remove them hydraulically, mechanically or in combination, then rinse and dry the base.

6.2.5. Remove grease from the surface of the substrate. With an insignificant depth of contamination, they are treated with surfactants (surfactants) and washed, at a greater depth, the oily place is removed and replaced with a new concrete mixture or repaired with a polymer-cement-based repair compound.

6.2.6. Fill up irregularities, cavities, cracks existing on the base with a polymer-cement-based repair compound.

6.2.7. In the places where the foundation slab adjoins the walls of the foundation, make inclined sides at an angle of 45 ° and a height of 100 mm from a cement-sand mortar.

6.2.8. Clean the base from dust, dirt and debris.

6.2.9. Check the moisture content of the substrate.

6.2.10. To ensure the necessary adhesion of the rolled materials to be welded to the base, treat the entire surface of the base with cold priming compounds (primers). As a primer applied to dry surfaces, use:

Primer TECHNONICOL No. 01 or No. 2 with a moisture content of not more than 4% by weight;

Bitumen emulsion primer TECHNONICOL No. 04 at base moisture up to 8% by weight (use is possible at temperatures not lower than +5 ° С).

6.2.11. Apply the primer in one layer using brushes, brushes or rollers.

6.2.12. Technoelast EPP is deposited after the primed surface has completely dried (no traces of the primer should remain on the tampon applied to the surface).

6.2.13. It is not allowed to perform work on the application of the primer composition simultaneously with the work on the fusion of the waterproofing material and other work using an open flame.

Laying waterproofing materials on a horizontal surface 6.2.14. Before laying waterproofing materials, mark the surface of the base to ensure smooth gluing of the rolls, in order to avoid displacement of the rolls in the end seams.

6.2.15. In the cold season, before starting the work, keep the roll waterproofing materials in a warm room at a temperature not lower than "plus" 15 ° C for at least 24 hours.

6.2.16. If it is necessary to suspend the laying of Technoelast EPP for a period of more than 14 days, take measures to protect the laid material from exposure to UV rays.

This can be done using sheets of flat slate or DSP, geotextiles weighing 300 g / m2 and other materials that provide reliable protection from solar radiation and do not lead to the destruction of the bitumen-polymer material.

6.2.17. Before direct installation, roll out the rolls of waterproofing materials on a horizontal surface so that the panel is leveled and flattened.

6.2.18. Roll out the rolls during stacking in one direction.

6.2.19. Glue the roll material to be welded in the process of melting the bottom side of the panel with the flame of the burner while simultaneously heating the surface of the base or previously laid layer, unrolling the roll and pressing it to the base.

6.2.20. Perform heating with smooth movements of the burner for uniform heating of the laid material and the surface of the base (previously laid layer). This will ensure continuous adhesion of the material and avoid non-melted spots.

6.2.21. The deformation of the indicator pattern on the film applied on the underside of the material sheet when it is melted by the burner flame indicates the degree of heating of the bitumen-polymer binder and the readiness of the material for gluing.

6.2.22. For high-quality adhesion of the material to the base or to a previously laid layer, it is necessary to achieve the formation of a small bead of bitumen-polymer binder at the point of contact of the material with the surface (Fig. 5).

- & nbsp– & nbsp–

6.2.23. A sign of sufficient heating of the material is the leakage of the bitumen-polymer binder from under the side edge of the material by 5-10 mm, which is a guarantee of the tightness of the overlap.

- & nbsp– & nbsp–

6.2.26. After laying the bottom layer of the waterproofing membrane on the horizontal surface, lay the top layer of the waterproofing membrane on the horizontal surface.

6.2.27. The technology for laying the top layer of a waterproofing membrane is similar to the technology for laying its bottom layer.

6.2.28. Roll out the rolls of the upper layer of the waterproofing membrane in the same direction as was chosen for the lower layer. Cross-sticking of the panels of the rolls of the upper and lower layers is not allowed.

6.2.29. The distance between the side joints of Technoelast EPP panels in adjacent layers must be at least 300 mm. End overlaps of adjacent panels of material should be offset relative to each other by at least 500 mm (Fig. 7).

- & nbsp– & nbsp–

Laying waterproofing materials on a vertical surface 6.2.30. The rules for laying the deposited materials on a vertical surface are the same as for laying the deposited materials on a horizontal surface. The main difference lies in the technique of fusing roll materials.

6.2.31. When installing a vertical waterproofing membrane, rolls are fed in two ways: manual and mechanical (Fig. 8, 9). For the convenience of working with the manual method of feeding rolls, use cut material blanks with a length of no more than 2 m. The mechanical feed of the roll is carried out using a winch or a truck crane, which makes it possible to lay rolls to the entire height of the foundation wall without cutting.

Rice. 8. Manual roll feed with the device ver- Fig. 9. Feeding the roll with the help of a winch with tikal waterproofing device of vertical waterproofing 6.2.32. Roll out the rolls during stacking in one direction, from bottom to top.

6.2.33. Laying the roll materials to be welded on vertical surfaces is to be carried out in the process of melting the bottom side of the panel with the flame of the burner while simultaneously heating the surface of the base or previously laid layer, unrolling the roll and pressing it to the base.

6.2.34. For high-quality adhesion of the material to the base or to a previously laid layer, it is necessary to achieve the formation of a small bead of bitumen-polymer binder at the point of contact of the material with the surface (Fig. 5).

6.2.35. In the process of performing work on the installation of a vertical waterproofing membrane, ensure the overlap of adjacent panels of at least 100 mm (lateral overlap). The end overlap of the rolls should be 150 mm (fig. 6).

6.2.36. To increase the reliability and tightness of the end overlap, trim the corner of the material that is in the overlap from below (Fig. 6).

6.2.37. After laying the bottom layer of the waterproofing membrane on the vertical surface, lay the top layer of the waterproofing membrane on the vertical surface.

6.2.38. The technology for laying the top layer of a waterproofing membrane is similar to the technology for laying its bottom layer.

6.2.39. Roll out the rolls of the upper layer of the waterproofing membrane in the same direction as was chosen for the lower layer. Cross-sticking of the panels of the rolls of the upper and lower layers is not allowed.

6.2.40. The distance between the side joints of Technoelast EPP panels in adjacent layers must be at least 300 mm. End overlaps of adjacent panels of material should be offset relative to each other by at least 500 mm (Fig. 7).

The device of the nodes.

Foundation sole assembly (Fig. 10).

In the places of abutment of horizontal and vertical surfaces, make inclined sides at an angle of 45 ° and a height of 100 mm from a cement-sand mortar and lay a reinforcement layer from Technoelast EPP roll material.