Door frame: materials of manufacture, parameters, design features. How to choose the right door frame or make it yourself Decorative door frame

The telescopic box got its name due to the principle of operation: the movement of a number of parts along special grooves. The opinion that the name is formed based on the appearance of the structure is erroneous. It has no resemblance to a telescope or a telescope.

Often, in the process of installing interior doors, one has to face difficulties caused by the incompatibility of the doorway and the box itself. Even the smallest discrepancy in dimensions can lead to undesirable defects, curvature of the shape of the web and frame. Be sure to take into account that the installation of a conventional door frame entails additional time and cost of work.

A telescopic frame for an interior door is a reliable construction, which consists of a set of special strips that are connected to each other by means of grooves. Thanks to this principle of assembly, the installation process is quick and easy.

Benefits for interior doors

With the advent of the telescopic design, all stages of interior door installation have been simplified. The assembly resembles the sequential connection of the parts of the designer on the principle of laying a parquet board or laminate. Each part is fixed by means of special grooves. Assembly requires the use of fasteners, there is no need for glue and nails.

The design is suitable for wall thicknesses greater than the standard width - for this, pull-out elements are provided. Suitable for installing interior doors in old houses. Here, the feature of the openings has its own specifics, and for them there is a need for adjustment. With a telescopic design, you don't have to worry that the dimensions of the opening and the width of the door frame will not match.

What is it made of

Each door system has its own materials. This could be:

- array;

- metal.

The choice of materials will depend on functionality, room requirements, pricing policy, interior aspect.

The most popular material for making telescopic door frames is MDF. This material is practical for the manufacture of such structures and is available for its price criteria.

The array has much greater durability, but it also costs an order of magnitude higher. Metal, such as aluminum, is less commonly used and is not suitable for all types of premises.

Correct installation

The entire installation process is simple and fast. The presence of a special tool will allow you to set the required size of the box, even for those who have no experience in carrying out construction work. It is important to understand the design feature and follow a clear sequence in the implementation of its assembly. It is necessary to select the size and shape of the frame in advance.

Initial parts for installation:

- box with grooves;

- additional strip with grooves;

- door leaf;

- corner platbands;

- accessories.

List of special material and tools:

- puncher;

- drill screwdriver;

- a hammer;

- roulette;

- pencil;

- level (preferably laser);

- liquid Nails;

- polyurethane foam.

The assembly process will depend on the type of trim used and the width of the box. For example, for openings of non-standard width, platbands are used that contain an additional strip - it can be hidden.

- Adjustment (trimming) of the additional strip is performed. Dobors are attached to the selected quarter from the back of the box.

- Then the bar is fixed with wedges (pieces of lath). It is important to make sure that the wedges that are installed do not go beyond the plane of the walls.

- The gaps between the frame and the wall are reliably bridged and filled with polyurethane foam.

- The telescopic platbands are fastened, after which they are cut - it is better to use a hacksaw. To avoid the formation of gaps between parts, the trimming process must be performed with increased accuracy.

The process of installing platbands is that they are pushed into the corresponding grooves. They need to be strengthened as accurately as possible. They are fixed firmly, but in some cases the craftsmen additionally use liquid nails. It should be noted that such an addition makes the structure one-piece. The result of the work - each side of the box should be one plane with good trims and trims.

The strength of the entire structure, as well as the duration of its operation, depends on the quality of the bow. Usually, the door frame and the door leaf are made from the same material. The main load of the opening sash falls on the frame, and you cannot save on purchasing a cheap flat, otherwise the structure will be short-lived.

The frame is part of the door block. It is used in models of the type, a sash is suspended from it on the hinges. Install the entrance door or interior door in the opening on the wall. Most popular material for the manufacture of boxes is considered array. Cheaper option - MDF and other combinations of wood waste. Bows can have grooved grooves at the end intended for fixing and.

The hidden door frame is hidden during installation in the wall, it is made of aluminum. Even the hinges remain invisible.

The door frame device involves the use of three or four elements. U-shaped bows without a threshold consist of two racks connected at the top by a crossbar. In a full-fledged ludka, the threshold is the fourth element. Such frames are required when installing a door block in a bathroom or at the entrance to a room.

Boxes are usually sold in a set with and. Additional elements help to refine the doorway. Device ludki differs in the following ways:

- with or without additions;

- with telescopic platbands or strips without grooves;

- with or without a seal;

- with invoice or mortise fittings.

Convenient in installation and use is a box with telescopic, as well as complete with a seal.

Box sizes

The consumer is offered different sizes of door frames, which is due to the place of their installation. Dimensions are in accordance with the standard. It is different for manufacturers from different countries. The most common standard size of the door frame for interior doors of a domestic manufacturer coincides with products from Finland, Italy and a number of other European countries.

By standard size is:

- sash width - 55, 60, 70, 80 and 90 cm;

- sash height - 190, 200 and 210 cm;

- the thickness of the box is from 2 to 7.5 cm.

This thickness of the door frame of the interior door has been determined for a reason. The run-up in size is due to different parameters of the walls.

It is considered optimal depth the door frame of the interior door - 7.5 cm. The ludka is suitable for walls made of gypsum plasterboard or brick. For thick partitions from a different material, boxes 10 cm wide are produced.There are imported bowls with a depth of up to 20.5 cm.

The total height and width of the door frame of the interior door is determined, taking into account the size of the sash. The thickness of the bow is added to the dimensions. An example will make it clearer. Take a canvas 60 * 200 cm and a box with a thickness of 7.5 cm.As a result of calculations, the total width of the door with the frame is 67.5 cm, and the height is 207.5 cm.

The size table will help to determine the dimensions of the box of interior doors.

Types of boxes

The types of door frames differ in design, material and other parameters. A ludka, consisting of three or four elements, has the following connection methods racks with a cross member:

- Spike. Docking of the door frame beams takes place with a thorn-groove lock. The method is complex but reliable.

- Baguette. The edges of the timber are cut at an angle of 45º. The connection of the elements is carried out with hardware.

- Right angle. Before joining at an angle of 90o, grooves are cut out at the end of the timber, removing part of the quarter.

Of all the options, the design of the door frame with a right angle is considered simple.

The device is different by the type of fastening of extensions and platbands:

- Simple comes without grooves. Dobors and platbands are fixed with glue, nails or self-tapping screws.

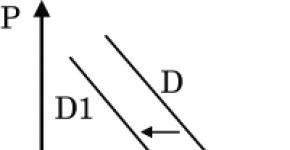

- Telescopic the frame for the door is equipped with special grooves, into which extensions and platbands are attached.

- Monoblock. Innovative design. The box and platbands are one piece.

The advantage of the monoblock telescopic box is its complete set. You don't have to buy extras and trims separately.

By design There are three types of ludka:

- Embracing. The structure consists of a frame, add-ons and platbands. The door frame is supplied with a seal. In cheap options, addons may not be available. You will have to buy the trims separately.

- End. The bow is designed to be mounted on a special metal frame. It is used when arranging openings of thin drywall walls.

- Corner. Ludka is considered universal. The frame with the casing is connected into a single structure. During installation, the installation of a seal is required.

Separately, it is worth considering the hidden door frame, completely hidden along with the hinges in the wall during installation. The entire block is made of aluminum and comes in two types:

- Finished box... The sash has a laminated, enameled or other coating. Mounting of mirrors is allowed.

- Bowl for finishing... The canvas is covered with a layer of primer. After installing the block, it is subjected to further wallpapering, painting or cladding with other materials.

The handles on the sash are also hidden. Usually this is a slit in the canvas or a magnetic device.

Materials (edit)

The bows differ according to the material of manufacture:

- The most common, inexpensive and durable are considered wooden door frames... Products from untreated timber during installation are impregnated with an antiseptic, opened with varnish or paint. For a budget option, boxes are used solid pine... Manufacturing technology from spliced timber allows you to get rid of wood defects. Frame elements are glued from small pieces.

- Door frames are made by pressing wood waste MDF, fiberboard and HDF... The frames are covered with laminate, veneer and other materials that protect the product from moisture, and also make it attractive. Laminated composites have excellent characteristics. The material alternates between layers of wood waste and plastic.

- Special aluminum box for glass door supplied with a seal and a set of corners. The well is installed in the glass openings of offices and other organizations. Fixation takes place with pressure plates on the tugs.

Metal door blocks usually come with a seal, platbands and fittings. Install products at the entrance to the building or individual offices of the organization.

How many accessories are needed for the opening?

When installing the door block, you will definitely need accessories. The aluminum door frame comes on sale with mounting plates, a seal, a set of corners.

When buying a door for an interior door, a design is selected taking into account the installation location. Frames with a threshold are placed in the bathroom, at the entrance or, if the height of the opening is required (for one door, 3 blanks are required). A U-shaped bow is mounted in ordinary interior partitions (2.5 blanks are needed for one door).

If the door frame is narrow, the protrusions of the thick wall are hidden with extras. The number of boards is calculated by the size of the protrusion.

Hinges will be needed from the fittings. For a light sash, 2 elements are enough, and for a heavy one, you can put 3 pieces. Overhead or hidden hinges are placed on the door frame at a quarter. By design, they are one-piece.

A lock and a peephole are installed on the front door. The last element is optional, though. Any sash is equipped with two handles, and a latch is attached to the interior door leaf.

Today, on the building materials market, interior doors are offered in a very large assortment. Door frames are made of wood, stone, steel, and in some cases, they are brickwork. Most of the models are manufactured to specific standards. But it should be remembered that there are no strictly established dimensions of door frames for interior doors. Therefore, you need to choose models in accordance with the dimensions of a particular doorway.

Standard sizes of door frames for interior doors

When choosing interior doors for your home or office, you should take into account not only their functional, decorative and design features. It is very important to accurately determine the correct size of door frames, standard for correct installation in the opening, without any complications and additional financial costs.

All doors, as a rule, come complete with a door frame, which is a very important installation element. It is a design similar to the letter "P". The size of the door frames differs from model to model. They are installed along the perimeter of the opening and serve to fix the canvas on the hinges.

The size of the door frames of the interior doors should be such that it allows the structure to fit harmoniously into the opening. The width of the box is a very important parameter; it is usually 25-35 millimeters.

Thus, the door structure is matched to the size of the opening. For proper installation, it is recommended that the height and width of the kit be slightly less than the opening (by about 3 cm).

The size of door frames does not have clear standards, but a conditional range can be distinguished:

- the width is from 500 to 900 mm;

- the height ranges from 1950 to 2070 mm.

Interior doors

The standard width of the doors, as a rule, depends on the purpose of the given room and its size. Most often, the most popular door kit is installed in the opening between the living rooms, having a standard size of 880x2050 mm. The width of the door leaf is 800 mm. Very often just such models are used in offices.

For the living room

The exception is the doors to the living room, which are considered a kind of hallmark of the room. In apartments with a modern layout, wide openings of 1220 mm are used for the installation of interior doors, in which stylish double-leaf doors are usually installed, the dimensions of which are 1190x1935 mm. In this case, the width of each leaf is 550 mm. In small apartments, doors are most often single-leaf, their width is 800-900 mm. It is not advisable to install less, since furniture should freely pass through the opening.

Kitchen

Canvases with certain parameters are installed in the opening in the kitchen. In this case, the size of the door frames is standard and is:

Before installing the door, you should calculate whether it will be possible to bring the necessary furniture into the kitchen. If it turns out that the standard model is narrow, then it will need to be abandoned. We'll have to expand the opening to install an oversized door.

For bathroom

Many people think that the size of the bathroom doors does not really matter. But this is a rather erroneous opinion. There are also many nuances here that are important to consider. Of course, if a qualified specialist is engaged in this business, you can not delve into the essence of the process. But when you decide to cope with the installation on your own, first you should familiarize yourself with the following information: bathrooms have the narrowest doorway.

Sizes of door frames for bathroom:

The most popular is considered to be a door set, the width of which is 550 mm. It should be noted that such doors are made by almost all manufacturers. In the modern layout of apartments, wide openings are often provided in the bathrooms. But even in this case, house owners prefer to install narrow door leaves, using special additional elements during work.

Maximum dimensions

The maximum standard door width is 900 mm. However, not all manufacturers produce models in this range. And this is due, first of all, to the fact that in multi-storey buildings, when planning modern apartments, such openings are quite rare. The design of the door set looks aesthetically rather cumbersome and does not match the interior of the room. Most often, interior doors, the width of which is 900 mm, are used:

Today, doors made of MDF have become very popular. These models are distinguished by rather low mechanical characteristics, therefore, the junction of the box with the wall should be strengthened with special wooden plates.

It must be remembered that interior doors from foreign manufacturers are made according to completely different standards. In this regard, before purchasing them, you should very accurately and carefully measure the main dimensions of the doorway.

Interior doors are constantly in sight. Therefore, they should not only very harmoniously fit into the interior, but also be correctly installed. Only in this case, the door set can give the room a complete and stylish look.

Wooden door frames

Traditional wooden doors have not lost their relevance over the years. They continue to rank high in today's home furnishings market. In addition, wooden structures with a box are becoming more and more popular due to a huge variety of design solutions, among which you can find your own suitable and unsurpassed option. Each product from an array of valuable species has a certain set of advantages and unique properties.

Advantages and disadvantages of wooden door structures

The main advantage of all wooden door structures is their environmental safety, which is very important for those houses where little children live. In addition, the essential oils found in conifers and many other types of wood have unique healing properties and create an extremely beneficial microclimate in the room. And yet, wooden door frames have a pleasant surface texture, an excellent level of heat and sound insulation, are durable and do not need special care during operation.

The only drawback of such structures is that they require coating with a waterproof protective compound.

The main characteristics and size of wood door frames mainly depend on the material used. The maximum accuracy of compliance with all the presented parameters is a guarantor of a quick and high-quality installation of the entire unit.

Most often, boards or bars are used for the door structure, the thickness of which is 50-60 cm, and the width is 100 mm. But the best option is when the thickness of the timber ideally matches the thickness of the wall. Wooden door frames, the dimensions of which do not have standards, must be selected carefully and according to certain rules. The structure should be 30 mm less than the opening, both in height and in width.

The door frame for interior doors is a link between the doorway and the door itself. It is needed as a supporting part of the structure, on which the entire power load is concentrated. It is fixed rigidly to the doorway, and door hinges, extensions, platband and related accessories are already mounted on it. It also fulfills an aesthetic role and can be either a separate element of the assembly or an extension of a homogeneous structure.

Door frame materials

The door frame, as a rule, matches the material of the selected door leaf. Between the rooms, you can put an iron door, for example, an armored one, and then the box will be steel. In public places, offices, shops, plastic and aluminum doors are now being installed, and the box in this case will be made of the same material. For swing, sliding and glass doors, the trap (frame) can be made of MDF or aluminum.

For the manufacture of an interior door frame, the following materials are used:

- Solid bar with the selected bosom, that is, the porch. The timber must be of good quality, dried, without cracks and knots, because the internal tension of the wood between the fibers over time and under the influence of external factors can lead to deformation of the canvas.

- Wooden array. Elite types of wood are oak, beech and ash. Doors made of mahogany are very beautiful: cherry, alder, walnut and eucalyptus. Of the cheaper species, spruce, linden, birch, maple are used, pine is most suitable.

This material requires final processing: grinding, putty, firing, painting, stain, varnishing or mastic at the request of the customer.

- Spliced timber along the entire length of the product using the "mini-thorn" technology or glued beams from small pieces of wood using the same technology. Retail sizes - 35x70x2100 mm. This material also needs finishing.

- Bars from MDF and HDF. Wood-shaving material impregnated with adhesives of medium and high density, pasted over with natural veneer. The thickness of the beams ranges from 30 to 60 mm, depending on the weight of the door leaf.

- Fiberboard strips Is a compressed laminated composite material with the required strength. Lined with artificial veneer.

Types of door frames

There are several types of door frames.

Corner

A versatile box that fits all types of walls. It is a construction of a decorative platband attached to the frame. The corner frame requires additional sealing of the gaps between the frame and the door leaf.

This will increase sound insulation and eliminate drafts.

End

It is used most often in an opening with thin partitions, for example, from plasterboard. This type of door frame is mounted in a metal frame to increase the reinforcement of the structure. Otherwise, the unreinforced structure will lead to loosening of the door mechanism as a whole.

Encompassing

View of the box, consisting of a frame and an extension with a platband. The best option, which allows you not to worry about the preparation, revision and subsequent finishing of the doorway. As a rule, this type of box is already provided with sealing elements.

Telescopic

Represents a set of planks that are connected to each other in the manner of a designer or laminate locks. Simplifies the process of adjusting the door frame to the features of the opening.

It does not need gluing elements, as it fits together with grooves.

Profile configuration

The door frame for interior doors is usually a rectangular bar with a selected quarter for the rebate.

The standard sizes are as follows:

- Thickness - 35 mm;

- Width - 60, 70, 80 and 100 mm;

- Length - 2100 mm;

- The width of the vestibule is 30 mm and the depth is 10 mm.

The porch can be made in a semicircle or with ribs. For wide doorways in the timber on the back side, opposite the vestibule, a quarter is made for an additional 10/10 mm. In recent years, profiled telescopic boxes are increasingly being produced, into the side grooves of which the extensions and platbands that come with the kit are inserted. In the area of the vestibule, a groove is made for fastening the seal. If there is no such groove, then a self-adhesive seal is attached.

It enhances sound insulation and prevents the door from banging loudly when closed.

Box assembly methods

When buying a door block, the box can be attached to the door already assembled, but most often the door is completed with special bars made of the same material as the door itself. Sometimes the box has to be purchased separately. The assembled interior box has a U-shape, consisting of two vertical beams and an upper horizontal one. To the O-shaped form, another threshold is added in the form of a lower horizontal bar.

Large and thick boxes are assembled using a spike connection. To do this, grooves are cut out at the edges of one sheet, and grooves are made on the other sheet, corresponding to the size of the grooves. The assembled spike joint is drilled through, and a key made of a denser wood is driven into the hole, or the joint is pulled together with self-tapping screws. Nails can also be used. When assembling, joiner's glue is used.

For the rest of the wooden boxes, it is enough to wash down the bars at 90 or 45 degrees and pull them together with self-tapping screws. All elements of the box with decorative features are cut strictly at 45 degrees. This job requires a miter saw or miter box with a fixed hacksaw. A hacksaw should have a blade with a fine tooth, for example, for metal. It is very difficult to prepare blanks reinforced with artificial veneer in another way, because it is simply impossible to putty or hide inaccuracies with any other method. These types include telescopic boxes.

Mounting

The door frame can be installed in different ways.

- Internal way. It is based on fixing the box in several places: in the hinges, under the lock plate and in the wall. In these places, the box is fastened with self-tapping screws, after which spacers are installed, and the resulting space is filled with mounting foam. This method provides a strong and durable fastening, however, it requires the utmost accuracy in the calculations and fitting the door, because after the foam hardens, it will no longer be possible to adjust the door.

- Bolt-on. Reliable and time-tested mounting option.

- Holes are drilled in the box.

- The box is applied to the opening, they indicate the places where it is necessary to make holes in the wall.

- The box is attached to the opening.

- The bolts are decorated with plugs.

- Suspension mounting. Hangers are plates attached to the box. After fixing them, the box is placed in the doorway, leveled and fixed with bolts in the hangers. This method is applicable only before finishing the room, since the suspensions on the wall must be hidden with plaster.

Casing box for a wooden house

Houses made of natural wood have the properties of "breathing" or "walking". This is manifested when the wood dries out and the house itself subsides. So that the doorway does not lead along with the house, and the rigid door structure does not interfere with the "walk" of the wall, a casing (jig) is placed in the place of the opening. There are three main ways to install it.

They differ in the different location of the thorn:

- The thorn is a monolith. When the box canvases have a monolithic T-shape with a spike in the middle, and the groove for it is made in the wall opening.

- Into the deck. The box canvases have a monolithic U-shape with a groove in the middle, and the spike is made on the wall opening.

With a sliding block bar. This is the easiest way. It should be considered in more detail.

To work, you need the following tools:

- fifty board;

- self-tapping screws.

- sealant;

- roulette;

- level;

- construction stapler;

- screwdriver;

- chainsaw;

- bar 50/50 mm;

- With a chainsaw, cut out the doorway of the required size. In the middle of its vertical sides, a groove is chosen for the bar. The same chainsaw cut off a bar less than the length of the groove by 50 mm. You can use not a solid block, but collect it from pieces. They hammer it into the groove so that it fits freely, but does not dangle. There is no need to fasten it, it is sliding.

- The board must be of the correct width. Cut it in length 50 mm less than the height of the doorway. In the upper part, cut a quarter 50 mm wide and 20 mm deep for the horizontal part. On the sides of the opening, strips of jute are shot with a stapler, leaving the bar free so that it does not screw on the screws. Planks are inserted into the opening and leveled. They are screwed with self-tapping screws 65-75 mm in length through to the bar, sinking in the canvas, while making sure not to stitch the bar through and through. The attachment points are putty.

- A horizontal board is cut to length. At the top, a quarter, apply a sealant and drive it into place. Fasten the box together with self-tapping screws from the back of the horizontal board. The distance left free above it is by no means foamed, but filled with tow.

Telescopic box advantages

In wooden houses, especially old buildings, one often has to deal with the problem of fitting the door frame to the deformed opening or the width of the walls. Before the advent of telescopic doorframes, these tasks were solved by using extensions and masking them with platbands. For the door to function properly, the doorway must represent a single plane on both sides. The telescopic device of the box solves the problem of fitting: the retractable fragments allow the box to be adjusted to any thickness of the opening.

It is known that furniture comes in standard and custom sizes. In the first case, it is easy to find suitable items and easy to repair. And their price is more affordable, since production does not require setting up equipment. In the second case, it is much more difficult to select a product with suitable parameters, and customization will cost more.

The thickness of the door frame of the interior door refers precisely to such parameters.

The emergence of the standard

The emergence of a standard for any product is associated with several factors. For kitchen furniture, this is, for example, the ergonomics and dimensions of kitchen appliances, for a bookcase - the size of books, which are quite standardized. Doorways are also made based on certain rules:

- the width of the opening cannot be less than 60 cm. Otherwise, it will be practically impossible to use it;

- the same parameter for a single-leaf structure cannot be more than 120 cm, since in this case the canvas will have an excessive weight;

- the height, as a rule, is limited to 2100 cm, and it is also found lower, since houses with very low ceilings were built in the USSR;

- the wall material practically does not affect the thickness of the box, but the thickness of the canvas matters;

- the material of the canvas is taken into account when developing the frame. As a rule, the frame and the canvas are made of the same material, so that the weight correspondence is observed here. But when replacing a product, this feature must be taken into account.

Dimensional parameters

In the store or in custom made, as a rule, the model is offered along with the box. Moreover, when choosing dimensions, attention is paid precisely to the overall dimensions. They measure the dimensions of the entire block, add 1.5 cm each and get those opening parameters that are needed to install the door.

If we are not talking about a capital wall with a very large thickness, then adjusting the dimensions of the opening to the dimensions of the canvas in the frame is easier and, ultimately, cheaper than ordering a product for the opening.

On average, the box adds 70 mm to the canvas around the perimeter. The standard dimensions of the box correlate with the parameters of the sash itself as follows.

Dimensions of interior door boxes: width, height and thickness.

| Interior door | Door frame | ||

| Height, mm | Width, mm | Height, mm | Width, mm |

| 2000 | 600 | 2071 | 671 |

| 2000 | 700 | 2071 | 770 |

| 2000 | 800 | 2071 | 870 |

| 2000 | 900 | 2071 | 970 |

| 2000 | 1202 | 2071 | 1272 |

| 2300 | 900 | 2371 | 970 |

| 2300 | 1402 | 2371 | 1472 |

| 2300 | 1802 | 2371 | 1872 |

The last 2 variants suggest the presence of 2 valves, at least a narrow inactive and a wide active one.

- What thickness of the interior door frame is suitable depends on the size of the wall. The wall thickness of the opening in most buildings is 75 mm. Accordingly, the standard thickness of the interior door frame is 75 mm. It is very rare to find a value of 95 mm, and even less often - 65 mm.

If the wall differs in very atypical dimensions, then they resort to special techniques. For example, with a large size, the opening is blocked with the help of an expander - a slope or a slope. And if the wall is too narrow, then it is even allowed to cut the frame, if only it could hold the canvas. In the photo - the design of the opening with slopes.

It is much more convenient to consider the parameters of the kit, and not the canvas, due to the fact that in the finished block there are gaps for free opening of the sash and for installing fittings. If the frame is selected separately, the gaps must be taken into account independently, and their value depends on the material of the canvas.

Materials (edit)

It is best if the entire door block is made of the same material. First, the same material reacts to changes in temperature and moisture in the same way. Secondly, the material wears out about the same, which does not cause aesthetic dissonance.

This parameter does not affect the dimensions of the box of interior doors in terms of thickness, however, if it is necessary to use expanders, it acquires a value.

- Solid wood is an expensive and beautiful material that is always popular. However, the massif reacts noticeably to dampness.

- MDF is the most popular material. The consistency of size compares favorably with wood: under the influence of temperature or dampness, the canvas does not change. MDF can have a different coating, which both increases the cost and reduces the cost of the product:

- veneer - a cut of natural wood. This option cannot be distinguished from the massif, and its resistance to dampness is higher;

- eco-veneer is a multilayer plastic that exactly reproduces the color and texture of wood. Eco-veneer has a very high wear resistance, which makes it recommended for use in public places;

- melamine film is a common material coating that reproduces the color, but not the structure of wood.