Dimensions ak 74 made of wood. How it is done, how it works, how it works

Description of the presentation for individual slides:

1 slide

Slide Description:

Municipal Budgetary Educational Institution "Verkhovskaya Secondary School No. 1" Oryol Region, Verkhovye Village Production of a model - a copy of the AK-74 Kalashnikov assault rifle Performed by: student 9kl. Andriyanov Ivan Head: technology teacher Martynov Oleg Ivanovich Verkhovye 2015

2 slide

3 slide

Slide Description:

Choosing and justifying the idea of \u200b\u200bthe project I study in the 9th grade, I am fond of technology, the history of weapons, I love tinkering. I really like the technology lessons. I decided to prepare a creative project and take part in the technology Olympiad. The teacher advised me to take the development of a product suitable for making by students in technology lessons and in the “Skillful Hands” circle as the theme for the project. The product should be easy to manufacture, technologically advanced, made from available materials, and cheap to manufacture. When working on it, as many different operations as possible for processing wood and metal with hand tools and on machine tools should be used. In the lessons, we usually made pointers, mallets, boxes, benches. mops, but it was not very interesting. I thought that usually the guys like to play war, are interested in weapons, and decided to develop and make a model of some small arms. In addition, it will be useful for the school detachment of the youth army. 1

4 slide

Slide Description:

Aims and Objectives Purpose: To create an original, technological, cheap product, suitable for making by schoolchildren in technology lessons and in a circle, necessary for the school. Tasks: 1. To learn to mentally represent the subject and graphically express it in the form of a technical drawing and drawing, to work with design and technological documentation. 2. To know and correctly carry out various technological operations for the processing of wood and metals. 3. Realistically assess your knowledge and skills. 2

5 slide

Slide Description:

Choice of product options Having examined several models of the AK assault rifle, I opted for option No. 4 of the AK-74 model with a wooden butt, deciding that the model of this assault rifle, made of wood, would look more impressive. 1 2 3 4 3

6 slide

Slide Description:

A brief history of the creation of the machine "It is not a weapon that kills, it is a man who kills." MT Kalashnikov During the Great Patriotic War, it became necessary to transfer the main small arms of the Red Army to the 7.62 mm cartridge. The main advantage of such a cartridge is sufficient destructive power at medium distances in comparison with pistol ones, and the lower weight of an intermediate cartridge in comparison with a rifle cartridge allows a fighter to carry more ammunition. After the creation of an intermediate cartridge of 7.62 mm. in 1943, the active development of small arms began, in which the most famous designers of the USSR took part. Kalashnikov also took part in the competition. His development showed good results, which allowed him 4

7 slide

Slide Description:

go to the second stage of the competition. In 1947, Kalashnikov presented a modified version of the assault rifle he had developed, which was subsequently adopted in 1949. The first Kalashnikov assault rifles had two modifications: with a wooden non-folding stock (AK-47) and with a metal folding stock (AKS-47). Kalashnikov has created a practical and reliable weapon. The merit of the developer is the optimal arrangement of time-tested technologies into a single sample that meets all the requirements. Despite the fact that the Kalashnikov assault rifle entered the armament of the SA back in 1949, due to Soviet secrecy, the weapon was introduced only in 1956. In the 1950s, samples of medium-sized small arms began to be replaced by Kalashnikov assault rifles. Soon it became the main type of small arms in the allied countries of the USSR, as well as in Finland and in some other countries. Such a rapidly growing popularity of the machine was associated with the simplicity and reliability of the design. as well as low cost of weapons. In the early 70s, the USSR began to develop a new automatic cartridge of 5.45x39 caliber. In 1974, the new AK-74 assault rifle was adopted by the Soviet army under the 5.45 cartridge. More than 60 years have passed since the creation of the first version of the Kalashnikov assault rifle. The well-known developer managed to achieve his goal: “to develop a weapon that would be understandable to an ordinary soldier”. Indeed, the Kalashnikov assault rifle is very popular 5

8 slide

Slide Description:

on all continents. The Kalashnikov assault rifle is one of the most popular weapons in the world. It is in service with the armies of 106 countries of the world. Recognized as the invention of the century and listed in the Guinness Book of Records as the most widespread weapon in the world. For his Kalashnikov assault rifle he received the Stalin Prize of the first degree. 6

9 slide

Slide Description:

10 slide

Slide Description:

Choice of materials For the manufacture of my product, I used the most affordable and cheapest material - wood, metal trimmings, wire. For the receiver, store horn and handle, it is advisable to use birch, since its wood is dense, hard and does not have pronounced annual layers, but it is suitable and pine, spruce. Only birch should be used for turning the barrel and gas pipe. Birch tree. It has a very uniform structure, color, light, closer to white, sometimes with a yellowish tint. It is used for the manufacture of plywood, handles for tools, furniture, etc. Spruce. The wood is white with a yellowish tinge, knotty. It is used for the manufacture of musical instruments, in construction. Pine. The wood is reddish-yellow, has a small number of knots. It is used in the construction of bridges, wagons, flooring, etc. Tin. Galvanized sheet 0.2 mm thick, bends well, cut with scissors, processed with a file. Used for the manufacture of the trigger bracket, the lever of the translator, front sight. sighting bar. For finishing the finished product, I took black enamel, and for the butt, the texture for wood, the color "walnut". eight

11 slide

Slide Description:

Choice of tools and equipment In the manufacture of my product, I used the following tools and equipment: Pencil Ruler Scribe Caliper Square Joiner's workbench Locksmith's workbench Drilling machine Lathe STD-120 Lathe TV-6 Electric drill Hacksaw Locksmith scissors Rasp Planer Chisel Kiyerka Oobzik Obrazik Mill

12 slide

Slide Description:

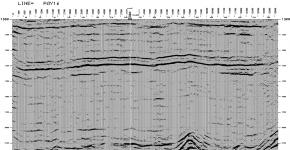

Preparation of technological documentation I thoroughly studied the design and types of the AK-74 Kalashnikov assault rifle. Having removed all sizes from a full-size metal model of an assault rifle available in the OBZh classroom, with the help of a teacher, I developed a technology and procedure for the production of individual parts, drew and cut out from cardboard templates for a case with a butt, a magazine, a handle. Completed drawings and flow charts for the manufacture of the main parts of the machine. The templates will later be used by other students to make a model of the machine. ten

13 slide

Slide Description:

14 slide

Slide Description:

Specification Receiver with stock. Gas pipe with trim. Fly. Sighting bar. Shutter lever. Translator checkbox. Barrel with compensator. Ramrod. Cleaning rod brackets. Score. Trigger brace. A pen. The trigger. 12

15 slide

Slide Description:

Flow charts for the manufacture of the main parts of the AK-74 Kalashnikov assault rifle 13

16 slide

Slide Description:

Technological map No. 1 Manufacturing receiver with buttstock 14 No. Name Quantity Scale Material 1 Receiver 1 1: 1 Birch

17 slide

Slide Description:

The sequence of technological operations Graphical representation Tools, equipment 1. Select a workpiece of the required dimensions. Ruler, pencil, hacksaw 2. Apply the contours of the future product to the workpiece according to the template. Template, pencil 3.Cut the part from the workpiece along the lines. Joiner's bench, jigsaw, clamp 4. Cut the ribs at the top of the receiver. Joiner's workbench, router, clamp 5. Process the stock according to the sample. Joiner's workbench, plane, rasp, knife 15

18 slide

Slide Description:

The sequence of technological operations Graphic representation Tools, equipment 6. Drill a hole with a diameter of 20 mm to install the barrel. Drill, drill 7. Drill holes with a diameter of 20 mm. Drill, drill 8.Collapse the slots for installing the magazine and the handle. Joiner's workbench, chisel, chisel, mallet 9. Finish the finished product Sandpaper 16

19 slide

Slide Description:

The sequence of technological operations Graphical representation Tools, equipment 1. Select a workpiece of the required dimensions. 2. Apply to the workpiece according to the template the contours of the future product. Ruler, hacksaw Template, pencil 3. Cut the shop horn along the lines from the blank. Jigsaw, carpenter's bench, clamp 4. Mill the edges of the leading edge of the part. Joiner's workbench, router, clamp 5. Apply with a burner the marks on the sides of the front edge of the store. Joiner's workbench, pencil, electric burner Technological map No. 2 Making the barrel of an assault rifle No. Name Quantity Scale Material 1 Barrel 1 1: 1 Birch 17

20 slide

Slide Description:

The sequence of technological operations Graphic representation Tools, equipment Select a workpiece of the required size. Ruler, hacksaw 2. Process the workpiece in the form of an octagon and glue the centers. Planer, center punch, hammer 3. Fasten the workpiece in a lathe and turn to a diameter of 26 mm Lathe STD-120, chisels, vernier caliper 4. Perform further turning according to the drawing Lathe STD-120, chisels, vernier caliper 5. Finish finished product. Lathe STD-120, sandpaper 18

21 slide

Slide Description:

Technological map No. 3 Production of a gas tube with a cover plate No. Name Quantity Scale Material 1 Gas tube 1 1: 1 Birch 19

22 slide

Slide Description:

The sequence of technological operations Graphical image Tools, equipment 1. Select the workpiece of the required dimensions Ruler, pencil, hacksaw 2. Process the workpiece in the form of an octagon and mark the centers. Joiner's workbench, planer, center punch, hammer 3.Fix the workpiece in the lathe and grind to a diameter of 39 mm. Lathe STD-120, chisels, vernier caliper 4. Make further turning of the part according to the drawing. Lathe STD-120, chisels, vernier caliper 5. Cut off the lower part of the part by 5 mm and finish. Joiner's bench, planer, sandpaper 20

23 slide

Slide Description:

Technological map No. 4 Making the handle of the machine No. Name Quantity Scale Material 1 Handle 1 1: 1 Birch 21

24 slide

Slide Description:

The sequence of technological operations Graphic representation Tools, equipment 1. Select the workpiece of the required dimensions. Pencil, ruler, hacksaw 2. Apply the contours of the future product to the workpiece according to the template. template, pencil 3. Cut out the part from the workpiece along the marking lines and round off the edges of the side faces. Joiner's workbench, clamp, jigsaw, rasp 4. Apply a pattern to the sides of the handle with a burner. Joiner's workbench, pencil, ruler, electric burner. 5. Make the final finishing of the part. Sandpaper 22

25 slide

Slide Description:

Technological map No. 5 Magazine horn manufacturing No. Name Quantity Scale Material 1 Magazine horn 1 1: 1 Birch 23

26 slide

Slide Description:

The sequence of technological operations Graphic representation Tools, equipment 1. Select the workpiece of the required dimensions Ruler, pencil, hacksaw 2. Apply the contours of the future product to the workpiece according to the template. Pencil, template 3. Cut the part out of the workpiece. Joiner's workbench, clamp, jigsaw 4. Cut the edges of the front edge of the part. Joiner's workbench, clamp, milling cutter 5. Apply notches to the leading edge with a burner and finish the part. electric burner, sandpaper 24

27 slide

Slide Description:

Safety precautions when working with tools and machine tools When manufacturing a product, it is necessary to know and strictly follow the rules of safe work of all technological operations performed, to use work clothes and protective equipment. 25

28 slide

Slide Description:

Stages of manufacturing a product The sequence and main stages of manufacturing the machine are shown in the figures. The following technological operations were carried out: Marking Sawing Planing Drilling Chiseling Sawing Cutting metal Cutting metal Sawing Bending metal Turning Brazing Wood burning Milling Finishing 26

29 slide

Slide Description:

30 slide

Children often ask their parents to make some kind of toy out of wood. The boys demand to make weapons for them, with which they could continue the endless courtyard "wars". The best option for a child will be a dummy 47 made of wood. How to make an AK-47 out of wood? Even a beginner can handle this task with the right tool. Information on how to make an AK-47 out of wood with your own hands is presented in the article.

Where to begin?

To everyone who is interested in how to make AK-47 from wood, craftsmen recommend, first of all, to acquire high-quality raw materials. The product will turn out to be reliable and strong if you use a pine board with a thickness of at least 50 mm for work. In addition, you need to have a corresponding drawing.

Manufacturing

All elements of the machine are made of wood. For those who do not know how to make an AK-47 out of wood, so that the dummy looks as believable as possible, experienced craftsmen recommend equipping the product with a removable store. The workpiece of the future product is cut out of the board using a jigsaw. For the side walls of the machine, you need two sheets of plywood. In the future, they will cover the store mount. It can be made from the same board as the dummy machine gun. The movement of the store in the fastening mechanism will be carried out without delay if all corners are carefully grinded with a file and then with a grinder. PVA is suitable for gluing the side walls. The process can be optimized using tools such as clamps. Connected parts that are securely attached should be left to dry for several hours.

About the trunk for dummy

For this element, you will need a cylindrical blank. You can make it yourself on a lathe or purchase a finished product in a store. The barrel must be equipped with a front sight. You will have to cut it out of the tree yourself. In addition, for the muzzle of the machine gun, the stock must be equipped with holes. They will turn out to be smooth if you work on a special drill stand. After the muzzle holes are ready, cylindrical blanks are inserted into them. Then, with the help of PVA, an already turned and carefully polished front sight is glued to the barrel.

About painting works

In addition to the question of how to make an AK-47 out of wood, many are still interested in what paint is best to cover the finished product. The dummy will look very realistic, experts advise, if you apply oak-colored paint to it.

It is water-based. The dummy painted black also looks good. On top of nitro paint, some craftsmen also varnish their products.

In the modern world, many children are practically indifferent to toys. Electronic gadgets are of much greater interest now. Of course, every parent is concerned about this and is trying to introduce the kid to play with real objects.

One of the best ways you can wean your child from virtual worlds is to make a toy with him. A hand-made machine will be a great toy with which you can have a lot of fun. And if you manage to save it, then it will be an excellent souvenir "from childhood", entailing a lot of pleasant memories.

There are several ways you can create an automaton. It all depends on how much time and effort you are willing to invest in the craft. Another important factor is the availability of all the necessary tools. Indeed, not everyone has in stock a whole set for the carpentry craft.

If the child for whom the product is intended is old enough, then you can additionally diversify the toy. Namely, add a shooting function.

Remember the main thing in order not to overshadow the process of creating a wooden machine, you should also not forget about basic safety rules. Protect your hands when working with cutting tools. Purchase a protective mask and respirator in advance, for working on a grinding machine or with sandpaper.

There are tons of fun activities that you can play with your children. Undoubtedly, these are outdoor games. At the same time, an integral advantage of a wooden toy is its durability. What can not be said about plastic counterparts.

How to make a simple machine out of wood

To diversify your child's games, you can make a simple wooden machine. It won't take long, but you need to prepare everything you need first.

Tools:

- Circular saw;

- Drill;

- Jigsaw;

- Sharpener 10 cm.

- Sandpaper;

For ease of use, print a drawing of the machine model. The drawing can be found without much difficulty on the Internet. Then follow the instructions below:

- Take a block of wood or a piece of thick board;

- Based on a drawing or photograph of the machine gun, carefully mark the boundaries of the future weapon on the tree with a marker;

If you print an image of the machine on paper, and then cut it out and use it as a stencil, the product will turn out to be very realistic. After all, all the proportions can be observed.

- Start cutting straight lines with a circular saw;

- Pay particular attention to cutting out the curved parts of the machine. To do this, you must use a jigsaw;

- Use a sharpener to process the weapon along the contour;

- To make the rifle more interesting, remember to drill holes such as the muzzle;

- Polish the resulting weapon by hand using sandpaper;

- Take a small piece of wire, preferably aluminum, to build the trigger;

- At the end, paint the machine or cover it with varnish;

Such a toy machine made of wood is quite simple to manufacture, and will bring a lot of joy to the child.

How to make a realistic Kalashnikov assault rifle

A realistic model of the machine can be made at home using the available tools. So, here's a list of things you'll need:

- Thick and wide board (the thickness must be at least 4 cm);

- Wood stalk (thin enough);

- Plywood sheet;

- PVA glue;

- Paint;

- Jigsaw;

- Milling machine;

- Sandpaper;

- Magnets;

- Marker;

First, choose the necessary material for work. Better to choose a pine board.

When choosing wood for the product, please note that there should be no branches or chips on it.

We sketch on the wood. Marker outline the outline of the future "Kalashnikov". It should be borne in mind that the store will be separately attached to the machine, so you need to draw it separately. When the image is ready, start carefully cutting the blank with a jigsaw.

In order for the magazine to be securely attached to the base of the weapon, you need to try it on and grind it several times. Nothing should catch on, only in this case the child will be comfortable during the game.

On a milling machine, add volume to the product. To do this, it is necessary to remove the chamfer from the handle, as well as from the butt. Subsequently, grind the workpieces as best as possible.

Take the prepared side pieces, cut from plywood, and glue them to the main part of the machine, greasing them liberally with glue. Particular attention should be paid to the contour of the workpiece. Then press down on all the parts, for a more secure adhesion, and leave for several hours until completely dry. As a result, it is worth sanding the product again so that the plywood parts do not stand out.

Start modeling the barrel of the future wooden machine gun. At this stage, you will need a thin shank (you can make it yourself, or purchase it from the construction department of the store). You also need to cut out the front sight and drill holes in the machine to fasten the barrel later. Lubricate all parts with glue at the bonding points. After the vending machine is completely assembled, give it time to dry.

At the final stage, paint the resulting machine model. You can use dark paint or varnish.

If you prefer paint, then use water-based paint. It is safer.

To make the magazine attached to the machine more reliably, you must use magnets. If the purchased magnets are in the form of a tablet, then before gluing them, it is worth drilling small holes in the store and the inside of the machine. The diameter of the holes must match the diameter of the magnets. If a roll-type magnet was purchased, then glue a piece of the magnet of the desired shape and size to the inside of the machine. And in this case, you need to glue a metal plate to the store. It is better to choose glue of quick drying, or superglue.

Now the wood machine is ready. This weapon model is very interesting and realistic, which means it will undoubtedly be in demand among children.

How to make a toy machine and wood

Before starting work on the future toy, carefully draw a sketch of the future machine and transfer it to the material from which the product will be made. In this case, each detail must be drawn separately.

Make sure you have all the tools you need for the job at your fingertips. For the initial finishing you need: hammer, chisel, hatchet, plane, hacksaw for wood, hacksaw for metal, drill, level.

For harvesting, you should choose coniferous wood. And leave at least 15% of the material on the “blank” as a reserve. This is required for subsequent adjustments to the shape of the product. All elements of the future machine are cut out separately.

After all the parts are cut out of wood, you need to proceed to the sanding stage. Use the following sequence to achieve the desired result. First, process each part with files. Then use coarse sandpaper, and then fine sandpaper, to bring the surface of the product to the required level of smoothness.

At the last stage, start designing your future toy. To do this, cover the surface of the wood with varnish, preferably in two layers. Prime the places where the paint will be applied.

Let the toy machine dry. And you can start playing.

How to make a Schmeiser machine

There are different ways to make a machine gun out of wood. It all depends on your craftsmanship and the materials at hand.

To make a model of the machine you will need:

- Wooden lath - 2 pcs.;

- Super glue;

- Nails;

- Espagnolette;

- Hacksaw;

- Sandpaper;

The boards or slats to be used must be at least 50 centimeters long. We cut the first rail along the middle, leaving only a third. While the bottom part needs to be removed. Divide the second rail into two unequal segments. The longer part will be the magazine, and the short one will be the handle of the future machine.

The prepared parts of the product must be sanded with sandpaper. Then fasten all the parts using glue.

Also, any weapon needs a front sight. Make it from a nail, gently driving it in the top of the barrel. Make the trigger in a similar way. Attach a latch on the side of the machine as a bolt.

At the final stage, sand the future toy again with sandpaper. Then cover the entire machine with a dark paint. And let the product dry.

Now you can play with such a slot machine with pleasure and win new victories.

How to make a simple Schmeiser

It often happens that there is not enough time to create a complex automaton model. But this is not a problem, because a simple Schmeiser can be made from scrap materials. You will need:

- Chisel;

- Nails;

- A pair of wide slats;

Divide one of the slats into two parts. It is desirable that one of the halves is longer than the other.

On the second rail, cut a few pieces in the area of \u200b\u200bthe future trunk. Also on the opposite side, saw off a piece of wood so that you get a sharp corner. It will be an impromptu butt, machine gun.

Finally, attach the magazine and the handle to the main body of the toy with nails.

How to make a dummy machine gun out of wood

Plain plywood is often an excellent material for creating a dummy. Using one of the methods, you can easily make a model of the machine yourself.

To work you need the following "basic" tools and accessories:

- Plywood.It is not necessary to use a whole sheet of material, in most cases, scraps are enough. However, it is important that the pieces are of the correct size and thickness. Sometimes it is worth choosing a thicker plywood, since the layout can be subjected to significant loads during use;

- Tools.This list includes both tools for grinding and cutting. To make various recesses and holes on the surface of the dummy, you must have a carpenter's knife or chisel at hand. While for sanding, a few sheets of sandpaper, varying in grain size, are enough;

- Protective covering.The future product, first, must be coated with a special compound that protects against moisture. And then cover the dummy with wear-resistant paint. Most often, black wood paint is used. But you can also use silver.

- Glue. In order for all the parts of the machine to be securely fastened, it is necessary to use epoxy resin as an adhesive. If it is not available, then you can get by with PVA glue. And in some cases, even superglue;

To create a real dummy, you need to find in advance a sketch of a real machine. It is desirable that all exact dimensions are indicated on the drawing.

When all the components of the future dummy have already been cut out of plywood, it is necessary to glue them together and securely fasten them until they are completely dry. Clamps are very helpful in this process. They will securely enough fix all the parts together.

In order for the "blank" to take the shape of the required machine, it is necessary to recreate all the holes and recesses. Use a jigsaw for this, first drilling the holes, and then shaping them.

A dummy must have a realistic look. So you will need to work hard. If you don't have a lot of experience with picks, it's best to start with the simpler parts. Otherwise, you can accidentally damage the product and work will have to start from scratch. However, the result should please with its similarity to the original.

Pay special attention to grinding. To give the necessary smoothness, carefully process the dummy with sandpaper. First, go over the entire surface with coarse sandpaper. For example, marked M - 100. And then use fine paper for finishing.

Of course, you need to paint the dummy. Please note that the colors must match the original of the given model of the machine. Choose the colors you want.

How to make a machine gun that shoots with rubber bands

Any model of the machine presented above can be modified if you add the ability to shoot.

The easiest way is to attach a small handle to one side of the machine. A thin strip may also work. You can install the "trigger" both from above and from the side. The main thing is to be comfortable for small children's hands.

You can attach the stalk with nails or super glue. The main thing is that the mount is reliable.

Another thing necessary for shooting is an elastic band. Better to use the so-called "bank" rubber bands. They cost very little and are also great in size. A couple of such rubber bands are possible, you can find them in your organizer. To charge the weapon, weave two rubber bands, to one of which attach a paper clip. If possible, it is better to do several charges. Gently grasp a paper clip to fire a shot. In this case, the elastic must be pulled to the very edge of the cutting. Then release the paperclip.

Try not to point the weapon at people and animals, because the shot can be very powerful and harm others.

How to modify the machine

In order for the wooden weapon to be fully equipped, in addition to the machine gun itself, you will need a bayonet, a knife and a belt for carrying. This will be especially true if the toy was made of dense wood.

The belt can be made of canvas tape. And to be attached to the machine on two rings of metal wire, or in pre-cut holes. Also, for more comfortable wearing, you should make a "double loop" from the tape. To do this, you will need a piece of the weapon strap twice the length of the standard length and a ring of thick wire. First, we attach the belt to the machine gun, so that one of the edges is fixed near the barrel, then we thread the belt into the prepared ring and draw it closer to the base of the barrel. We pass the middle of the tape through the mount near the butt. If everything is done correctly, there should be a long "tail" from the belt, to the edge of which, it is necessary to sew a ring made of strong metal, which remains hanging on the fixed section of the tape.

In the future, it is the elongated part of the belt that is put on the person, and the machine remains hanging on it. This option of carrying a wooden weapon will allow the child to play carefree, without having to hold the machine gun with his hand all the time. However, when calculating the length of the belt, it is worth considering that in the free position, the muzzle should not touch the ground.

Now the wooden dream machine is created and fully equipped!

How to make an AK-47 from a garden shovel aslan wrote in February 11th, 2017

There have always been craftsmen in Russia who amazed the world with their skills and inventions. We are especially good at making weapons. So the Izhevsk master Mikhail Kalashnikov created the legendary AK-47 assault rifle, which inspired another master to create a copy of it from a simple garden shovel and iron pipes.

And by the way, this is not at all a Russian craftsman.

On the left in the photo, by the way, is the same machine from a shovel, and on the right is a Dragunov sniper rifle (SVD).

But we are getting ahead of ourselves.

The master who made it hails from the USA. Once he was driving past a shop with garden tools, he saw a shovel there and decided to buy it. This was the best deal you could get for $ 2, he thought.

The handle from the shovel, by the way, later turned into a butt and is surprisingly quite comfortable.

I decided to try on the stock on an old Kalash. The cat looks in disbelief, is the owner drunk again?

I cut off the tray from the shovel, from which the body of the machine will be made.

Thoroughly calcined it on fire.

Now you need to align this iron sheet.

We fold the sheet, drill holes.

To the left is a detail from the present "Kalash", to the right of the future.

Specialists, of whom there are always many, will tell you in the comments what this detail is.

More details.

Weld

It was the turn of the barrel, you could buy the original for $ 200, but they preferred the economy version for $ 30.

Below in the photo is the upper barrel from a real "Kalash", in the middle there is a ready-made factory version of the barrel and the third, collective farm version - our choice.

We process the trunk.

Trying on.

Finishing the details.

We weld parts from a real machine.

There is very little left.

We drill a hole to vent the gases.

Trying on the store, and the butt from the shovel, everything seems to fit!

What is most surprising - he shoots, and at the same time bullets fall quite heap.

After 60 shots, the barrel warmed up slightly, but my homemade AK-47 performed pretty well.

In total, at minimal cost, we get a pretty good, combat-ready weapon. Thanks to Mikhail Kalashnikov for his great invention!

If you have anything to add, dear weapons experts, please comment.

Provoking srach about Russia, Ukraine and Putin in a ban without warning.

Click on the button to subscribe to "How It's Done"!

If you have a production or service that you want to tell our readers about, write to Aslan ( [email protected] ) and we will make the best report that not only the readers of the community, but also the site will see How is it done

Subscribe also to our groups in facebook, vkontakte, classmates and in google + pluswhere the most interesting from the community will be posted, plus materials that are not here and videos on how things work in our world.

Our channels on youtube

How it's done - https://goo.gl/fy5MFe

Kak eto sdelano - https://goo.gl/8YGIvl

Jean Peugeot - https://goo.gl/L88mip

Subscribe to our community in LiveJournal -